ENGINEERING TOMORROW

Design Guide

VLT® Integrated Servo Drive ISD® 510 System

vlt-drives.danfoss.com

Contents Design Guide

Contents

1 Introduction

1.1 Purpose of the Design Guide

1.2 Additional Resources

1.3 Abbreviations and Conventions

1.3.1 Abbreviations 7

1.3.2 Conventions 7

1.4 Copyright

1.5 Approvals and Certications

1.5.1 Low Voltage Directive 8

1.5.2 EMC Directive 8

1.5.3 Machinery Directive 8

1.6 Safety

1.7 Terminology

2 System Overview

2.1 General Description of the Servo System

2.2 VLT® Integrated Servo Drive ISD® 510

2.3 System Wiring

7

7

7

7

7

7

9

10

11

11

11

12

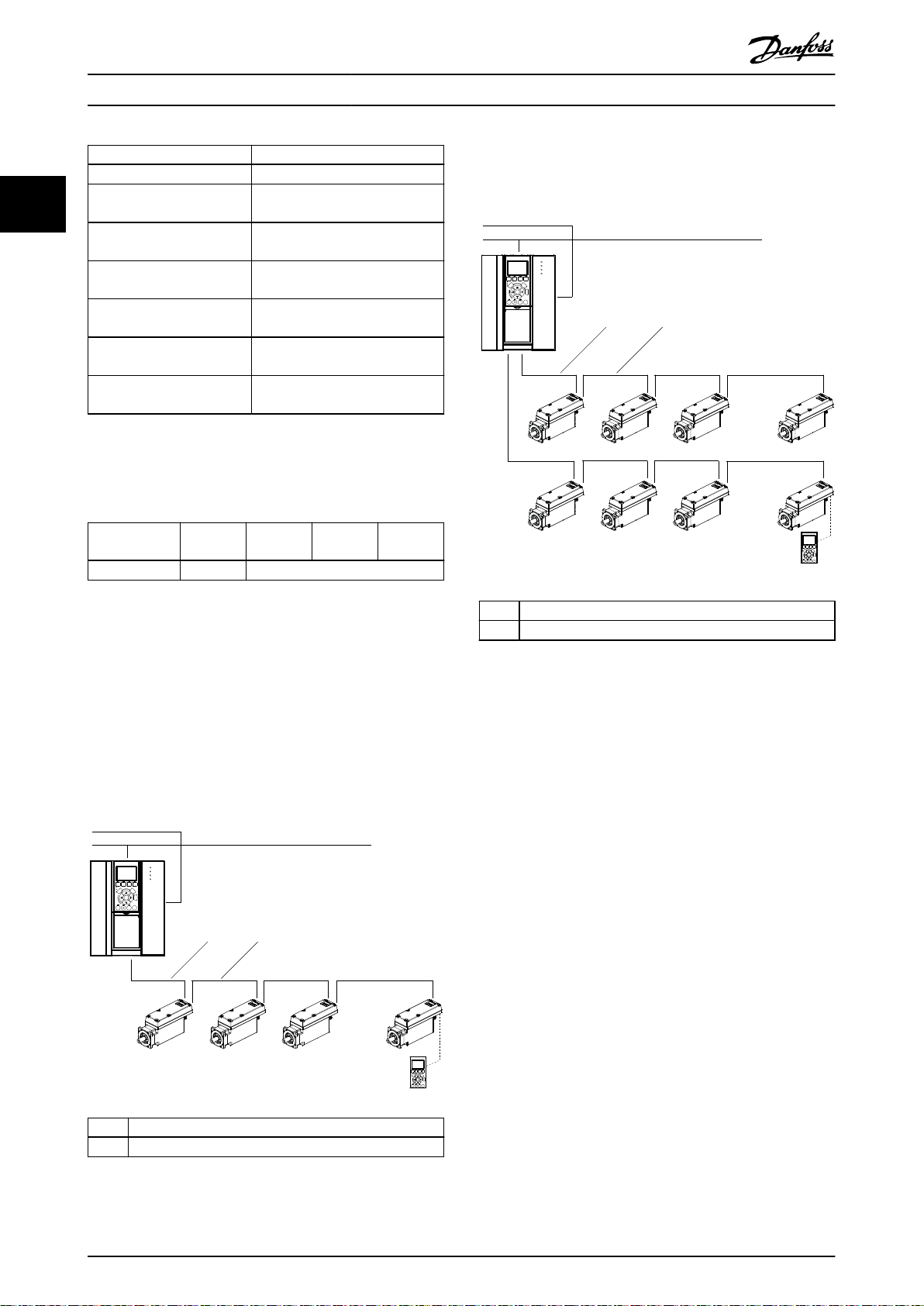

2.3.1 Ethernet POWERLINK® without Redundancy 12

2.3.1.1 Standard Cabling Concept for 1 Line 12

2.3.1.2 Standard Cabling Concept for 2 Lines 12

2.3.2 Ethernet POWERLINK® with Redundancy 13

2.3.3 Wiring with more than 1 SAB 13

2.3.3.1 Ethernet POWERLINK

2.3.3.2 EtherCAT

®

®

2.4 EtherCAT® with Redundancy

2.5 Description of Operation

2.6 Sequence of Operation

2.6.1 VLT® Servo Access Box (SAB) 15

2.6.2 VLT® Integrated Servo Drive ISD 510 15

2.6.3 Switching on the VLT® Integrated Servo Drive ISD 510 System 15

2.7 Functional Safety Concept

2.7.1 Notes 16

2.7.2 Abbreviations and Conventions 16

2.7.3 Functional Description 16

13

14

14

14

15

16

2.7.4 Installation 17

2.7.5 Commissioning Test 17

2.7.6 Application Example 20

2.7.7 Safety Function Characteristic Data 21

MG36C102 Danfoss A/S © 08/2017 All rights reserved. 1

Contents

VLT® Integrated Servo Drive ISD® 510 System

2.8 Communication

2.8.1 Fieldbus 21

2.8.1.1 EtherCAT

2.8.1.2 Ethernet POWERLINK

2.8.2 PC-Software 22

2.8.2.1 System Requirements 22

®

®

2.9 Operating Modes

2.10 Automated Operational Functions

2.10.1 Short Circuit Protection 24

2.10.1.1 Servo Access Box Features 24

2.10.1.2 ISD 510 Servo Drive Features 24

2.10.2 Ground Fault Protection 24

2.10.3 Temperature-controlled Fans 24

2.10.4 Thermal Protection 24

2.10.5 Additional Protection Features 24

2.10.5.1 Servo Access Box 24

2.10.5.2 VLT® Integrated Servo Drive ISD 510 25

21

21

22

23

24

2.11 Custom Application Functions

2.11.1 Brake Resistor 26

2.11.1.1 Mechanical Installation 26

2.11.1.2 Electrical Installation 26

2.11.1.3 Brake Resistor Calculation 26

2.11.2 External Encoder and Sensors 28

2.11.2.1 External Encoder 28

2.11.2.2 Sensor 28

2.11.3 Relays 29

2.12 Faults, Warnings, and Alarm Functions

2.12.1 Overview 29

2.12.2 Operating LEDs on the VLT® Integrated Servo Drive ISD 510 29

2.12.3 Operating LEDs on the VLT® Servo Access Box 30

2.13 User Interfaces

2.13.1 Overview 31

2.13.2 DDS Toolbox Software 31

2.13.3 Overview 31

26

29

31

2.13.4 TwinCAT® NC Axis 31

3 Application Examples

3.1 Intended Applications

4 System Integration

4.1 Operating Environment: VLT® Integrated Servo Drive ISD 510

2 Danfoss A/S © 08/2017 All rights reserved. MG36C102

32

32

33

33

Contents Design Guide

4.1.1 Humidity 33

4.1.2 Ambient Temperature 33

4.1.3 Cooling 33

4.1.4 Motor-generated Overvoltage 33

4.1.5 Acoustic Noise 34

4.1.6 Vibration and Shock 34

4.2 Operating Environment: SAB

4.2.1 Humidity 34

4.2.2 Ambient Temperature 34

4.2.3 Cooling 34

4.2.3.1 Cooling Fans 34

4.2.3.2 Calculation of Airow Required for Cooling the SAB 35

4.2.4 Acoustic Noise 35

4.2.5 Vibration and Shock 35

4.3 Operating Environment: General

4.3.1 Aggressive Atmospheres 35

4.3.1.1 Gases 35

4.3.1.2 Exposure to Dust 36

4.3.2 Electromagnetic Compatibility 36

4.3.2.1 Emission Requirements 36

4.3.2.2 Immunity Requirements 37

4.3.2.3 Grounding for Electrical Safety 38

4.3.2.4 EMC Grounding 39

34

35

4.3.2.5 Motor Bearing Currents 39

4.3.2.6 Earth Leakage Current 39

4.3.2.7 Touch Current 40

4.3.3 IP Ratings 41

4.3.3.1 Denitions 41

4.3.3.2 IP Ratings for SAB and Servo Drive 41

4.3.4 Radio Frequency Interference 41

4.3.5 PELV and Galvanic Isolation Compliance 41

4.3.5.1 Discharge Time 42

4.3.6 Maintenance 42

4.3.7 Storage 42

4.4 Mains Input

4.4.1 General Requirements 43

4.4.2 Harmonics 43

4.4.2.1 Mains Conguration and EMC eects 43

4.4.2.2 Mains Transients 43

4.5 System Concepts

43

44

MG36C102 Danfoss A/S © 08/2017 All rights reserved. 3

Contents

VLT® Integrated Servo Drive ISD® 510 System

4.5.1 Auxiliary Power Supply Selection 44

4.5.1.1 Shell Diagram 44

4.5.1.2 Auxiliary Power 45

4.5.1.3 24 V Supply 45

4.5.1.4 48 V Supply 46

4.5.2 Communication Topology 47

4.6 VLT® Integrated Servo Drive ISD 510

4.6.1 Motor Selection Considerations 47

4.6.2 Motor Grounding 47

4.6.3 Thermal Protection 48

4.7 VLT® Servo Access Box

4.7.1 Grounding 48

4.7.2 Eciency 48

4.8 Cables

4.9 Peripheral Components

4.9.1 AUX Power Supply 48

4.9.2 Sensors 49

4.9.3 Safety Supply Requirements 49

5 Typecode and Selection

5.1 Drive Congurator for VLT® Integrated Servo Drive ISD 510

5.2 VLT® Integrated Servo Drive ISD 510

5.2.1 Typecode and Denitions 50

47

48

48

48

50

50

50

5.3 Servo Access Box

5.4 Options

5.4.1 Mechanical Holding Brake 51

5.4.2 Feedback 51

5.4.2.1 Built-in Feedback Devices 51

5.4.3 Customized Flange 51

5.4.4 Shaft Seal 51

5.5 Accessories

5.5.1 Flexible Hybrid Cable 51

5.5.1.1 Feed-In Cable 51

5.5.1.2 Loop Cable 52

5.5.2 Fieldbus Cables 52

5.5.3 LCP Cable 52

5.5.4 LCP Mounting Kit 52

5.5.5 Blind Caps 52

5.5.6 Sensor Cable 52

6 Specications

51

51

51

53

4 Danfoss A/S © 08/2017 All rights reserved. MG36C102

Contents Design Guide

6.1 Servo Drive

6.1.1 Dimensions 53

6.1.2 Terminal Locations 55

6.1.2.1 Connectors on the Servo Drives 55

6.1.3 Characteristic Data 57

6.1.4 General Specications and Environmental Conditions 58

6.1.5 Motor Output and Data 58

6.1.5.1 Speed-Torque Characteristics: Size 1, 1.5 Nm at 25 °C Ambient Temperature

6.1.5.2 Speed-Torque Characteristics: Size 1, 1.5 Nm at 40 °C Ambient Temperature

6.1.5.3 Speed-Torque Characteristics: Size 2, 2.1 Nm at 25 °C Ambient Temperature

6.1.5.4 Speed-Torque Characteristics: Size 2, 2.1 Nm at 40 °C Ambient Temperature

6.1.5.5 Speed-Torque Characteristics: Size 2, 2.9 Nm at 25 °C Ambient Temperature

6.1.5.6 Speed-Torque Characteristics: Size 2, 2.9 Nm at 40 °C Ambient Temperature

6.1.5.7 Speed-Torque Characteristics: Size 2, 3.8 Nm at 25 °C Ambient Temperature

6.1.5.8 Speed-Torque Characteristics: Size 2, 3.8 Nm at 40 °C Ambient Temperature

6.1.6 Derating 61

6.1.6.1 Derating at High Altitude 61

53

59

59

59

59

60

60

60

60

6.1.6.2 Derating at High Ambient Temperature 61

6.1.6.3 Derating using Servo Drives with Shaft Seals 61

6.1.6.4 Derating using Servo Drives with Mechanical Holding Brake 61

6.1.7 Connection Tightening Torques 61

6.1.8 Installation 62

6.1.8.1 Allowed Forces 62

6.1.8.2 Bearing Load Curves 62

6.1.8.3 Installation Safety and Warnings 64

6.2 SAB

6.2.1 Dimensions 65

6.2.2 Clearance 68

6.2.3 Terminal Locations 68

6.2.3.1 STO Connectors 70

6.2.3.2 Mains Connectors 70

6.2.3.3 Brake Connector 71

6.2.3.4 Relay Connectors 71

6.2.3.5 Encoder Connectors 71

65

6.2.3.6 Ethernet Connectors 72

6.2.3.7 AUX Connectors 72

6.2.3.8 24/48 V IN Connector 72

6.2.3.9 UDC Connectors 72

6.2.3.10 Hybrid Cable PE 72

6.2.4 Characteristic Data 73

MG36C102 Danfoss A/S © 08/2017 All rights reserved. 5

Contents

VLT® Integrated Servo Drive ISD® 510 System

6.2.5 General Specications and Environmental Considerations 73

6.2.6 Mains Supply 73

6.2.7 Derating 73

6.2.8 Connection Tightening Torques 73

6.3 Cable

6.3.1 Feed-In Cable 74

6.3.1.1 Clearances 74

6.3.2 Loop Cable 75

6.3.3 Fieldbus Extension Cable 75

6.3.4 LCP Cable 76

6.3.5 Sensor and Encoder Cable 76

6.3.6 Ethernet Cable 76

7 Appendix

7.1 Glossary

Index

74

77

77

79

6 Danfoss A/S © 08/2017 All rights reserved. MG36C102

Introduction Design Guide

1 Introduction

1.1 Purpose of the Design Guide

This design guide for Danfoss VLT® Integrated Servo Drive

ISD® 510 System is intended for:

Project and systems engineers.

•

Design consultants.

•

Application and product specialists.

•

The design guide provides technical information to

understand the capabilities of the VLT® Integrated Servo

Drive ISD® 510 System, and to provide design consider-

ations and planning data for integration of the system into

an application.

Also included are:

Safety features.

•

Fault condition monitoring.

•

Operational status reporting.

•

Serial communication capabilities.

•

Programmable options and features.

•

Design details, such as site requirements, cables, fuses,

control wiring, the size and weight of units, and other

important information necessary to plan for system

integration are also provided.

Technical literature for Danfoss drives is also available

online at drives.danfoss.com/knowledge-center/technical-

documentation/.

1.3 Abbreviations and Conventions

1.3.1 Abbreviations

All abbreviations can be found in chapter 7.1 Glossary.

1.3.2 Conventions

Numbered lists indicate procedures.

Bullet lists indicate other information and descriptions of

gures.

Italicized text indicates:

Cross-reference.

•

Link.

•

Footnote.

•

Parameter name, parameter group name,

•

parameter option.

All dimensions in drawings are in mm (inch).

Copyright

1.4

VLT®, ISD®, and SAB® are Danfoss registered trademarks.

1 1

The design guide caters for the selection of ISD 510 servo

system components and options for a diversity of

applications and installations. Reviewing the detailed

product information in the design stage enables the

development of a well-conceived system with optimal

functionality and

Additional Resources

1.2

Available manuals for the VLT® Integrated Servo Drive

ISD® 510 System:

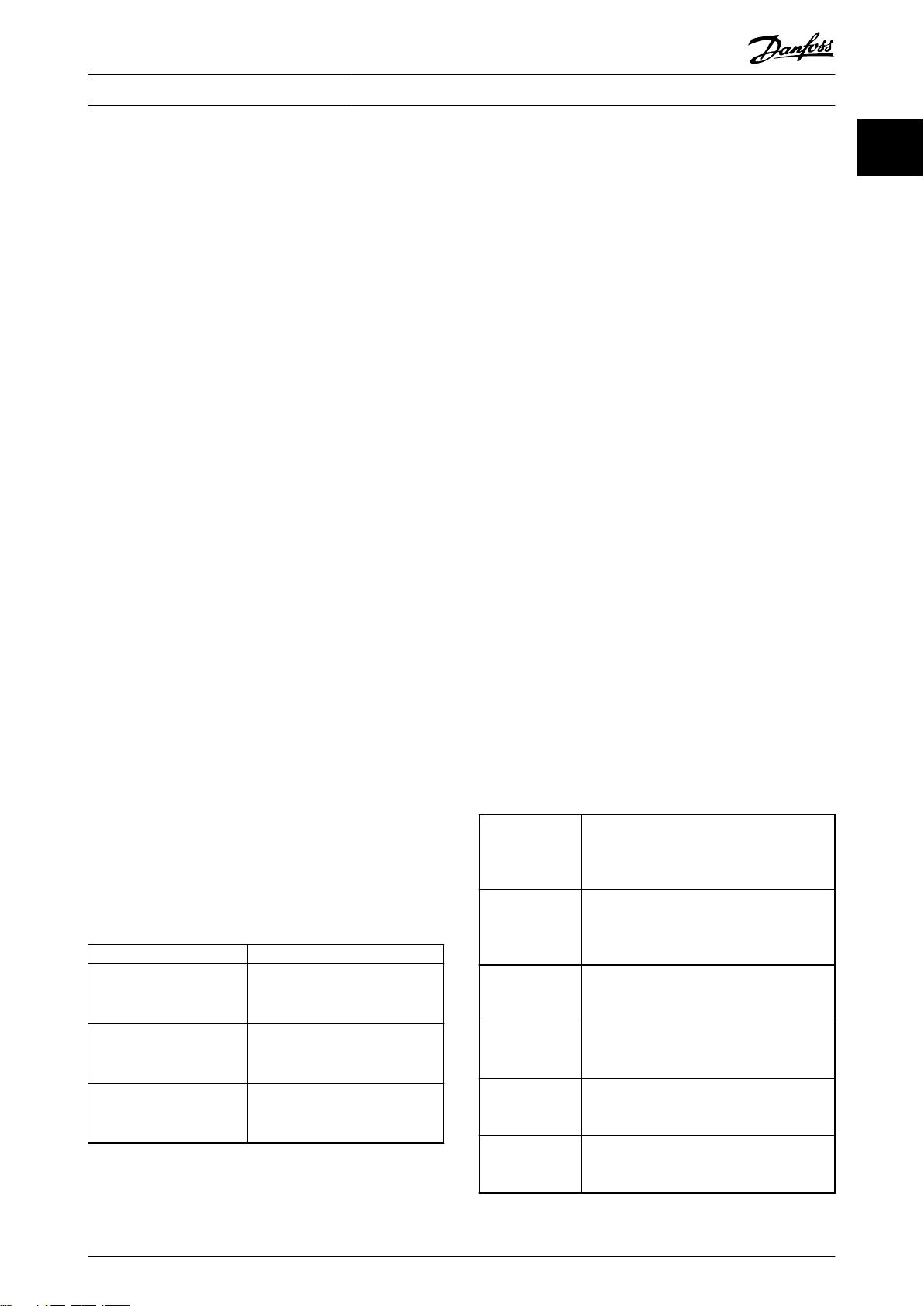

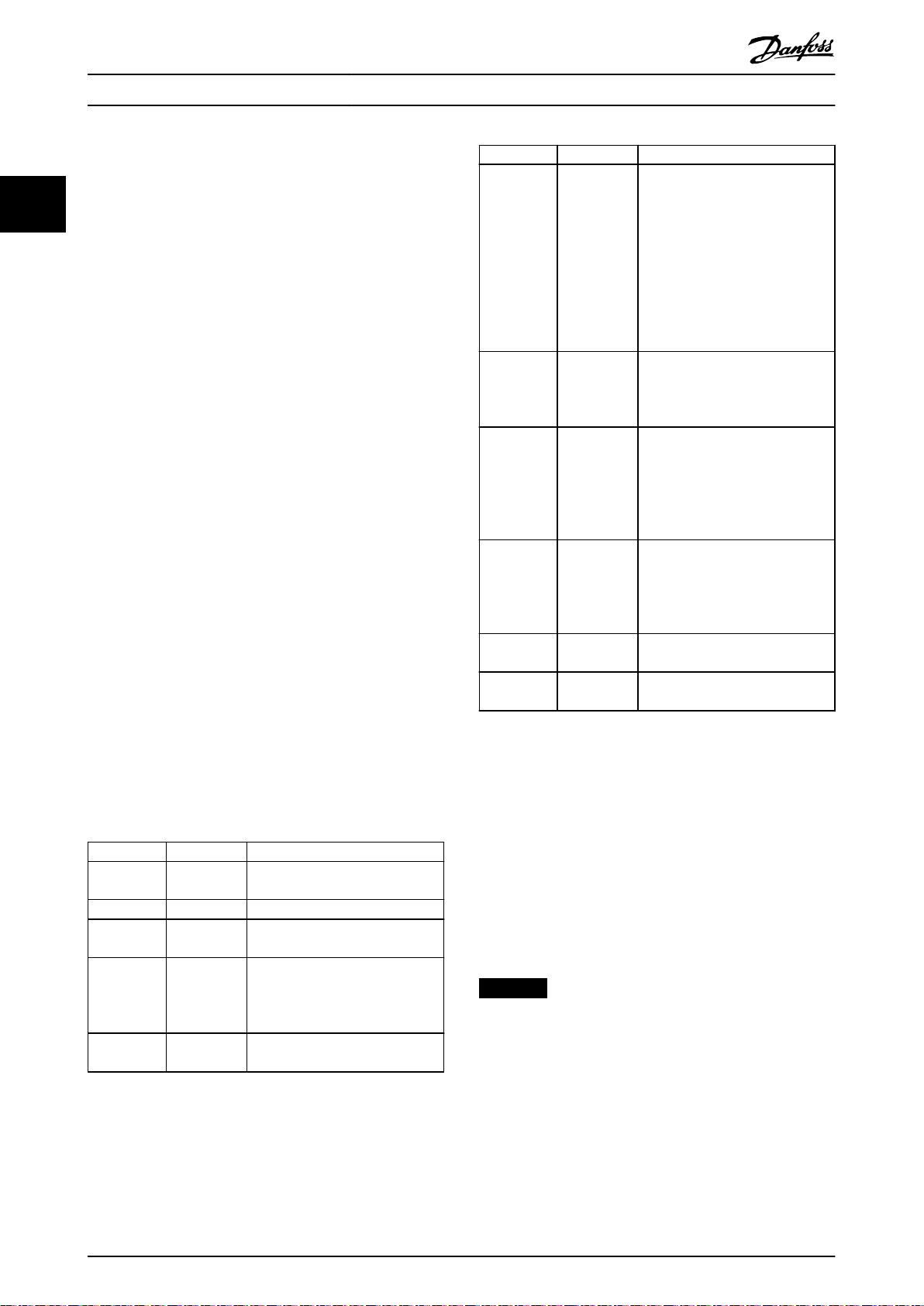

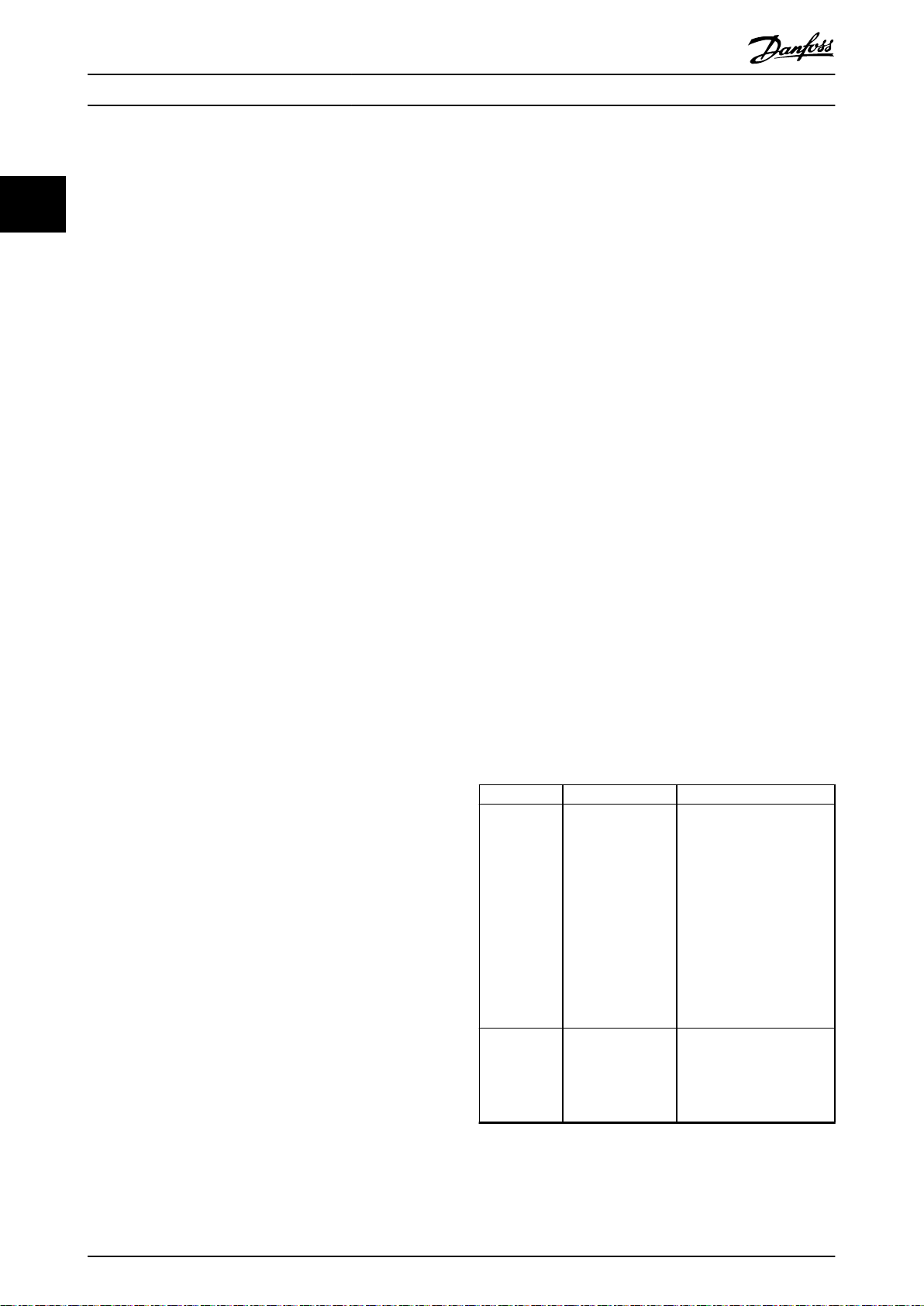

Manual Contents

VLT® Integrated Servo Drive

ISD® 510 System Operating

Instructions

VLT® Integrated Servo Drive

ISD® 510 System Design

Guide

VLT® Integrated Servo Drive

ISD® 510 System

Programming Guide

Table 1.1 Available Manuals for the ISD 510 Servo System

eciency.

Information about the installation,

commissioning, and operation of

the ISD 510 servo system.

Information about the set-up of

the ISD 510 servo system and

detailed technical data.

Information about the

programming of the ISD 510 servo

system.

Approvals and Certications

1.5

The VLT® Integrated Servo Drive ISD® 510 System fullls

the standards listed in Table 1.2.

IEC/EN 61800-3 Adjustable speed electrical power drive

systems.

Part 3: EMC requirements and specic test

methods.

IEC/EN 61800-5-1 Adjustable speed electrical power drive

systems.

Part 5-1: Safety requirements – Electrical,

thermal, and energy.

IEC/EN 61800-5-2 Adjustable speed electrical power drive

systems.

Part 5-2: Safety requirements – Functional.

IEC/EN 61508 Functional safety of electrical/electronical/

programmable electronic safety-related

systems.

EN ISO 13849-1 Safety of machinery – Safety-related parts of

control systems.

Part 1: General principles for design.

EN ISO 13849-2 Safety of machinery – Safety-related parts of

control systems.

Part 2: Validation.

MG36C102 Danfoss A/S © 08/2017 All rights reserved. 7

Introduction

VLT® Integrated Servo Drive ISD® 510 System

11

IEC/EN 60204-1 Safety of machinery – Electrical equipment of

machines.

Part 1: General requirements.

IEC/EN 62061 Safety of machinery – Functional safety of

safety-related electrical, electronic, and

programmable electronic control systems.

IEC/EN 61326-3-1 Electrical equipment for measurement,

control, and laboratory use – EMC

requirements.

Part 3-1: Immunity requirements for safetyrelated systems and for equipment intended

to perform safety-related functions (functional

safety) – General industrial applications.

UL 508C UL Standard for Safety for Power Conversion

Equipment.

1.5.2 EMC Directive

Electromagnetic compatibility (EMC) means that electromagnetic interference between apparatus does not hinder

their performance. The basic protection requirement of the

EMC Directive 2014/30/EU states that devices that generate

electromagnetic interference (EMI), or whose operation

could be aected by EMI, must be designed to limit the

generation of electromagnetic interference and must have

a suitable degree of immunity to EMI when properly

installed, maintained, and used as intended.

Devices used as standalone or as part of a system must

bear the CE mark. Systems must not be CE marked but

must comply with the basic protection requirements of the

EMC directive.

2006/42/EC Machinery Directive

CE

2014/30/EU EMC Directive

2014/35/EU Low Voltage Directive

RoHS

(2011/65/EU)

EtherCAT

Ethernet

POWERLINK

PLCopen

®

®

Restriction of hazardous substances.

Ethernet for Control Automation Technology.

Ethernet-based eldbus system.

Ethernet-based eldbus system.

®

Technical specication.

Function blocks for motion control (formerly

Part 1 and Part 2) Version 2.0 March 17, 2011.

1.5.3 Machinery Directive

The VLT® Integrated Servo Drive ISD® 510 System

components are

subject to the Low Voltage Directive, however components

or systems with an integrated safety function must comply

with the machinery directive 2006/42/EC. Components or

systems without a safety function do not fall under the

machinery directive. If components are integrated into a

machinery system, Danfoss provides information on safety

aspects relating to them.

Machinery Directive 2006/42/EC covers a machine

classied as electronic components

consisting of an aggregate of interconnected components

Table 1.2 Approvals and Certications

or devices, of which at least 1 is capable of mechanical

movement. The directive mandates that the equipment

1.5.1 Low Voltage Directive

design must ensure the safety and health of people and

livestock are not endangered and the preservation of

The VLT® Integrated Servo Drive ISD® 510 System

components are classied as electronic components and

material worth so long as the equipment is properly

installed, maintained, and used as intended.

must be CE labeled in accordance with the Low Voltage

Directive. The directive applies to all electrical equipment

in the 50–1000 V AC and the 75–1600 V DC voltage

ranges.

When servo system components are used in machines with

at least 1 moving part, the machine manufacturer must

provide a declaration stating compliance with all relevant

statutes and safety measures. Danfoss CE-labels comply

The directive mandates that the equipment design must

ensure the safety and health of people and livestock are

not endangered and the preservation of material worth so

with the machinery directive for drives with an integrated

safety function. Danfoss provides a declaration of

conformity on request.

long as the equipment is properly installed, maintained,

and used as intended. Danfoss CE-labels comply with the

Low Voltage Directive. Danfoss provides a declaration of

conformity on request.

8 Danfoss A/S © 08/2017 All rights reserved. MG36C102

Introduction Design Guide

1.6 Safety

The following symbols are used in this guide:

WARNING

Indicates a potentially hazardous situation that could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that could

result in minor or moderate injury. It can also be used to

alert against unsafe practices.

NOTICE

Indicates important information, including situations that

can result in damage to equipment or property.

The following safety instructions and precautions relate to

the VLT® Integrated Servo Drive ISD® 510 System.

Read the safety instructions carefully before starting to

work in any way with the ISD 510 servo system or its

components.

Pay particular attention to the safety instructions in the

relevant sections of this manual.

WARNING

HAZARDOUS SITUATION

If the servo drive, SAB, or the bus lines are incorrectly

connected, there is a risk of death, serious injury, or

damage to the unit.

Always comply with the instructions in this

•

manual and national and local safety

regulations.

WARNING

GROUNDING HAZARD

The ground leakage current is >3.5 mA. Improper

grounding of the ISD 510 servo system components may

result in death or serious injury.

For reasons of operator safety, ground the

•

components of the ISD 510 servo system

correctly in accordance with national or local

electrical regulations and the information in this

manual.

WARNING

HIGH VOLTAGE

The ISD 510 servo system contains components that

operate at high voltage when connected to the electrical

supply network.

A hazardous voltage is present on the servo drives and

the SAB whenever they are connected to the mains

network.

There are no indicators on the servo drive or SAB that

indicate the presence of mains supply.

Incorrect installation, commissioning, or maintenance can

lead to death or serious injury.

Installation, commissioning, and maintenance

•

must only be performed by qualied personnel.

WARNING

UNINTENDED START

The ISD 510 servo system contains servo drives and the

SAB that are connected to the electrical supply network

and can start running at any time. This may be caused

by a eldbus command, a reference signal, or clearing a

fault condition. Servo drives and all connected devices

must be in good operating condition. A decient

operating condition may lead to death, serious injury,

damage to equipment, or other material damage when

the unit is connected to the electrical supply network.

Take suitable measures to prevent unintended

•

starts.

WARNING

UNINTENDED MOVEMENT

Unintended movement may occur when parameter

changes are carried out immediately, which may result in

death, serious injury, or damage to equipment.

When changing parameters, take suitable

•

measures to ensure that unintended movement

cannot pose any danger.

1 1

MG36C102 Danfoss A/S © 08/2017 All rights reserved. 9

Introduction

VLT® Integrated Servo Drive ISD® 510 System

11

WARNING

DISCHARGE TIME

The servo drives and the SAB contain DC-link capacitors

that remain charged for some time after the mains

supply is switched o at the SAB. Failure to wait the

specied time after power has been removed before

performing service or repair work could result in death

or serious injury.

To avoid electrical shock, fully disconnect the

•

SAB from the mains and wait for at least the

time listed in Table 1.3 for the capacitors to fully

discharge before carrying out any maintenance

or repair work on the ISD 510 servo system or

its components.

Number Minimum waiting time (minutes)

0–64 servo drives 10

Table 1.3 Discharge Time

NOTICE

Never connect or disconnect the hybrid cable to or from

the servo drive when the ISD 510 servo system is

connected to mains or auxiliary supply, or when voltage

is still present. Doing so damages the electronic circuitry.

Ensure that the mains supply is disconnected and the

required discharge time for the DC-link capacitors has

elapsed before disconnecting or connecting the hybrid

cables or disconnecting cables from the SAB.

NOTICE

Full safety warnings and instructions are detailed in the

VLT® Integrated Servo Drive ISD 510 System Operating

Instructions.

1.7 Terminology

VLT® Integrated

Servo Drive ISD

510

VLT® Servo Access

®

Box SAB

PLC

Loop cable Hybrid cable for connecting servo drives in

Feed-in cable Hybrid cable for connection from the SAB to

Table 1.4 Terminology

An explanation of all terminology and abbreviations can be

found in chapter 7.1 Glossary.

Integrated servo drive

Unit that generates the DC-link voltage and

passes the U

and STO signals to the servo drives via a

hybrid cable.

External device for controlling the VLT

Integrated Servo Drive ISD® 510 System.

daisy-chain format.

the 1st servo drive.

, Real-Time Ethernet, UDC,

AUX

®

10 Danfoss A/S © 08/2017 All rights reserved. MG36C102

1

2

130BE385.10

System Overview Design Guide

2 System Overview

2.1 General Description of the Servo System

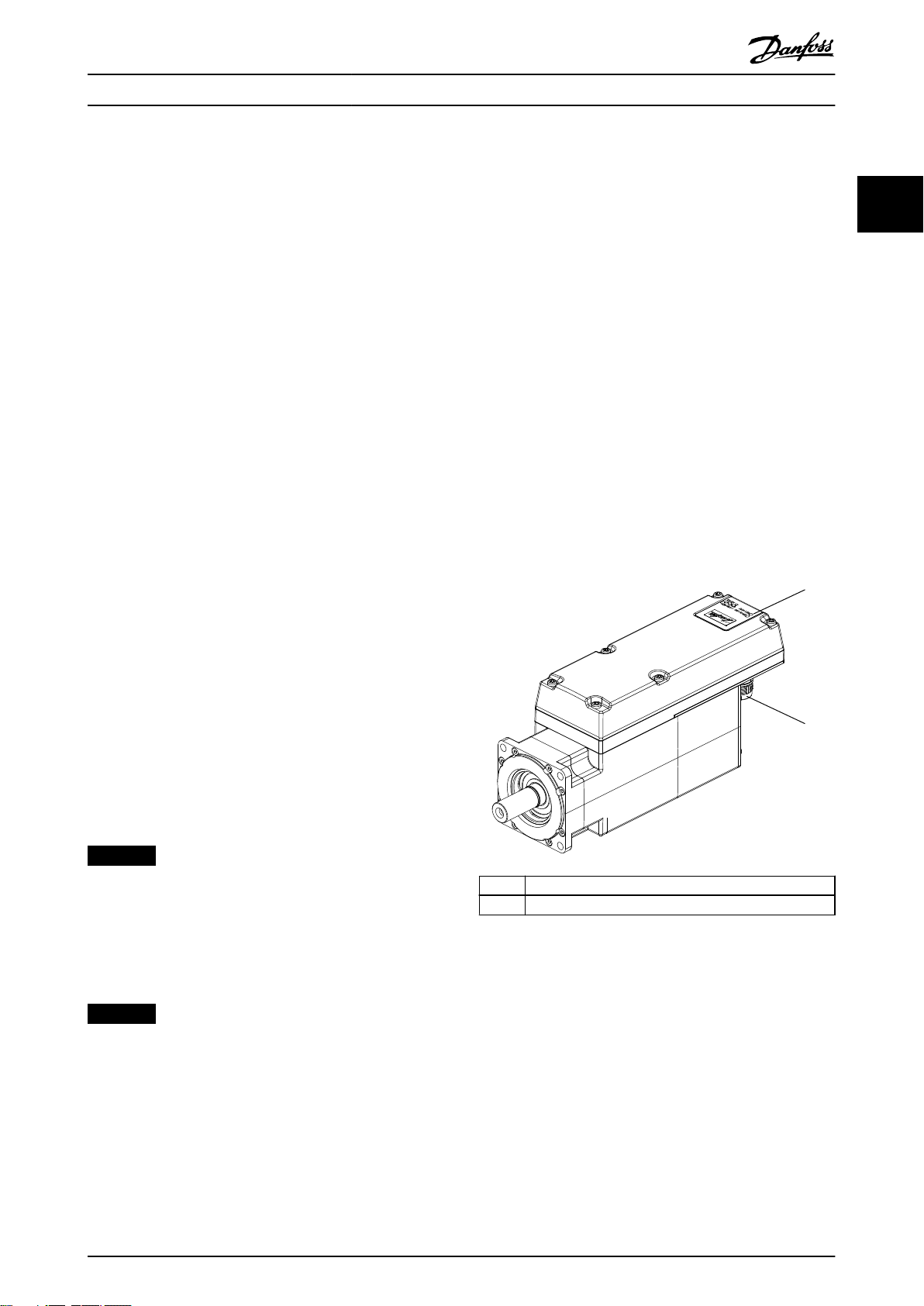

2.2

VLT® Integrated Servo Drive ISD® 510

2 2

The VLT® Integrated Servo Drive ISD® 510 System is a highperformance decentral servo motion solution.

It comprises:

A central power supply: VLT® Servo Access Box

•

(SAB®).

VLT® Integrated Servo Drives ISD® 510.

•

Cabling infrastructure.

•

The decentralization of the drive unit

mounting, installation, and operation. Depending on the

application, the SAB can power up to 64 servo drives in a

servo drive system when using 2 hybrid lines. It generates

a DC-link voltage of 565–680 V DC ±10% and guarantees

high power density. It has a removable local control panel

(LCP), and is based on the proven quality of a Danfoss

frequency converter.

The motion control is integrated into the servo drive so

that the motion sequences can take place independently.

This reduces the required computing power of the central

PLC and oers a highly exible drive concept. Danfoss

oers libraries for various IEC 61131-3 programmable PLCs.

Due to the standardized and certied eldbus interfaces of

the ISD devices, any PLC with an EtherCAT® master

functionality, or Ethernet POWERLINK® managing node

functionality according to the standards can be used.

Hybrid cables are used to connect the servo drives, making

installation fast and simple. These hybrid cables contain

the DC-link supply, the Real-Time Ethernet, U

signals.

oers benets in

, and STO

AUX

ISD is the abbreviation of integrated servo drive, which is a

compact drive with an integrated permanent magnet

synchronous motor (PMSM). This means that the entire

power drive system consisting of motor, position sensor,

mechanical brake, and also power and control electronics

is integrated into 1 housing. Additional circuits, such as low

voltage supply, bus drivers, and functional safety are

implemented within the servo drive electronics. All servo

drives have 2 hybrid connectors (M23) that connect power

and communication signals from a hybrid cable. The

advanced version has 3 additional interfaces for external

encoder or I/Os, eldbus devices, and for the local control

panel (LCP) to be connected directly.

LEDs on the top of the servo drive show the current status.

Data transfer takes place via Real-Time Ethernet.

NOTICE

The ISD 510 servo drives cannot be used in servo

systems from other manufacturers without changing the

cabling infrastructure. Contact Danfoss for further

information.

Drives from other manufacturers cannot be used in the

ISD 510 servo system when using Danfoss hybrid cables.

NOTICE

Only the components described in this manual may be

tted or installed. Third-party devices and equipment

may be used only in consultation with Danfoss.

MG36C102 Danfoss A/S © 08/2017 All rights reserved. 11

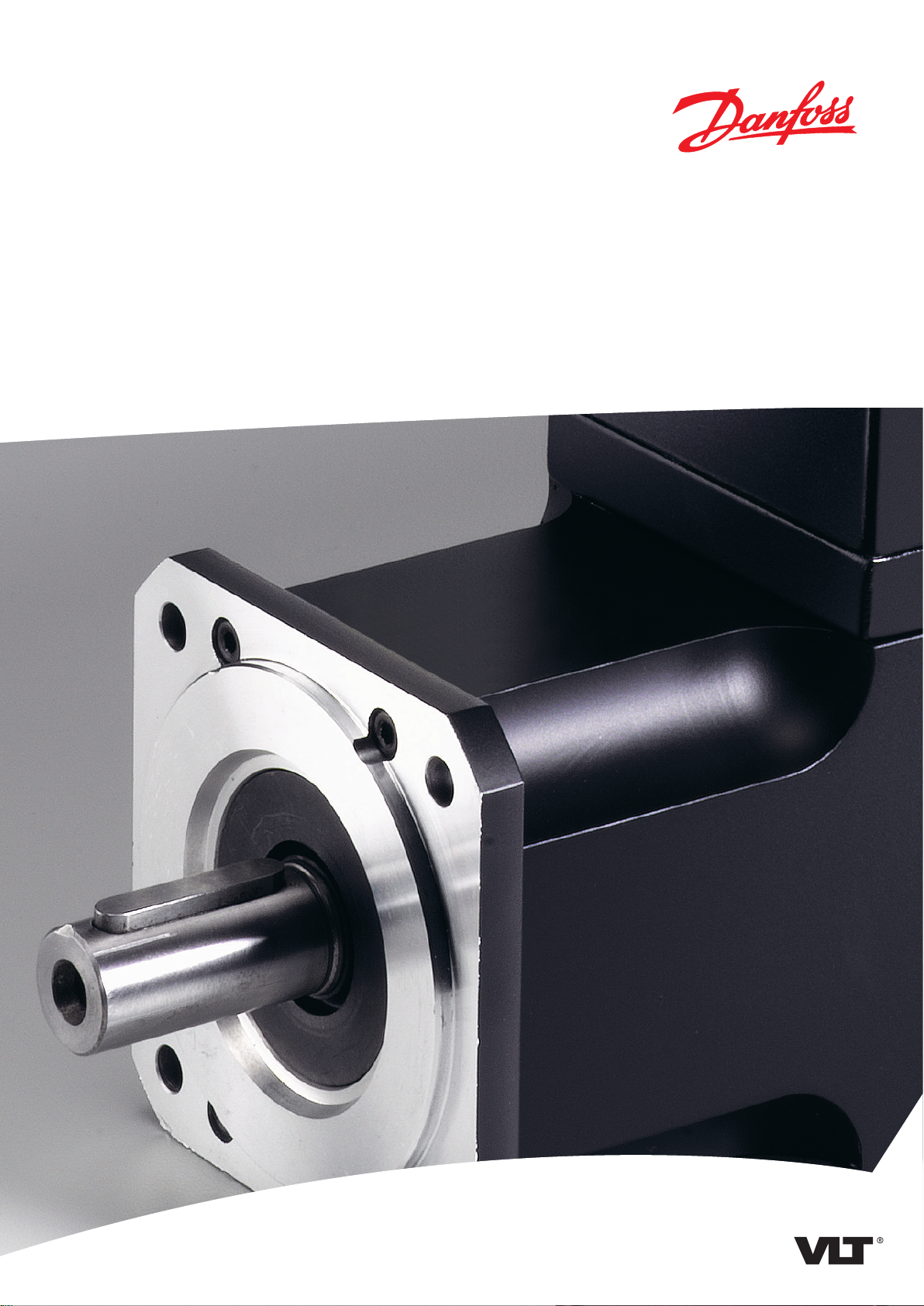

1 Operating LEDs

2 Connectors

Illustration 2.1 ISD 510 Servo Drive

Illustration 2.1 and Table 2.1 show the external interfaces on

the ISD 510 servo drive.

130BE436.10

AUX 1

Status

Hand

On

Reset

Auto

On

OK

Back

Cancel

Info

Quick

Menu

Main

Menu

Alarm

Log

AUX 2

SAFE 1

SAFE 2

Status

Hand

On

Reset

Auto

On

OK

Back

Cancel

Info

Quick

Menu

Main

Menu

Alarm

Log

LCP

SAB

400-480 V AC

Real-Time Ethernet

1

ISD 510

2

. . .

130BE437.10

AUX 1

Status

Hand

On

Reset

Auto

On

OK

Back

Cancel

Info

Quick

Menu

Main

Menu

Alarm

Log

AUX 2

SAFE 1

SAFE 2

Status

Hand

On

Reset

Auto

On

OK

Back

Cancel

Info

Quick

Menu

Main

Menu

Alarm

Log

LCP

SAB

400-480 V AC

Real-Time Ethernet

1

ISD 510

2

. . .

. . .

System Overview

VLT® Integrated Servo Drive ISD® 510 System

Interface Description

Shaft Mechanical interface.

2.3.1.2 Standard Cabling Concept for 2

Lines

Operating LEDs Provides the status of the servo

22

drive.

M23 hybrid input connector Input connector for power and

communication signals.

M23 hybrid output

connector

M8 4-pole connector

(advanced servo drive only)

M12 8-pole connector

(advanced servo drive only)

M8 6-pole connector

Output connector for power and

communication signals.

Input connector for eldbus

devices.

Input connector for external

encoder or I/Os.

Input connector for LCP.

(advanced servo drive only)

Table 2.1 External Interfaces on the ISD 510 Servo Drive

The ISD 510 servo drive has the ange sizes shown in

Table 2.2.

Size 1,

1.5 Nm

Flange size 76 mm 84 mm

Table 2.2 Motor and Flange Sizes

All dimensions of the servo drive are listed in

chapter 6.1.1 Dimensions.

System Wiring

2.3

Size 2,

2.1 Nm

Size 2,

2.9 Nm

Size 2,

3.8 Nm

1 M23 Feed-in cable

2 M23 Loop cable

Illustration 2.3 Standard Cabling Concept for 2 Lines

2.3.1

Ethernet POWERLINK® without

Redundancy

2.3.1.1 Standard Cabling Concept for 1 Line

1 M23 Feed-in cable

2 M23 Loop cable

Illustration 2.2 Standard Cabling Concept for 1 Line

12 Danfoss A/S © 08/2017 All rights reserved. MG36C102

AUX 1

Status

Hand

On

Off

Reset

Auto

On

OK

Back

Cancel

Info

Quick

Menu

Main

Menu

Alarm

Log

AUX 2

SAFE 1

SAFE 2

Status

Hand

On

Off Reset

Auto

On

OK

Back

Cancel

Info

Quick

Menu

Main

Menu

Alarm

Log

LCP

SAB

400-480 V AC

ISD 510

UDC + Real-Time Ethernet Bus + STO + U

AUX

. . .

. . .

130BF040.10

Real-Time Ethernet

A

B

A

AUX 1

Status

Hand

On

Off

Reset

Auto

On

OK

Back

Cancel

Info

Quick

Menu

Main

Menu

Alarm

Log

AUX 2

SAFE 1

SAFE 2

Status

Hand

On

Off Reset

Auto

On

OK

Back

Cancel

Info

Quick

Menu

Main

Menu

Alarm

Log

LCP

SAB

400-480 V AC

ISD 510

. . .

. . .

130BF041.10

Real-Time Ethernet

A

A

B

B

PLC

UDC + Real-Time Ethernet Bus + STO + U

AUX

130BF042.10

AUX 1

Status

Hand

On

Off

Reset

Auto

On

OK

Back

Cancel

Info

Quick

Menu

Main

Menu

Alarm

Log

AUX 2

SAFE 1

SAFE 2

Status

Hand

On

Off Reset

Auto

On

OK

Back

Cancel

Info

Quick

Menu

Main

Menu

Alarm

Log

LCP

SAB

400-480 V AC

ISD 510

UDC + Real-Time Ethernet Bus + STO + U

AUX

. . .

. . .

Real-Time Ethernet

PLC

AUX 1

Status

Hand

On

Off

Reset

Auto

On

OK

Back

Cancel

Info

Quick

Menu

Main

Menu

Alarm

Log

AUX 2

SAFE 1

SAFE 2

SAB

400-480 V AC

ISD 510

UDC + Real-Time Ethernet Bus + STO + U

AUX

. . .

. . .

Real-Time Ethernet

A

System Overview Design Guide

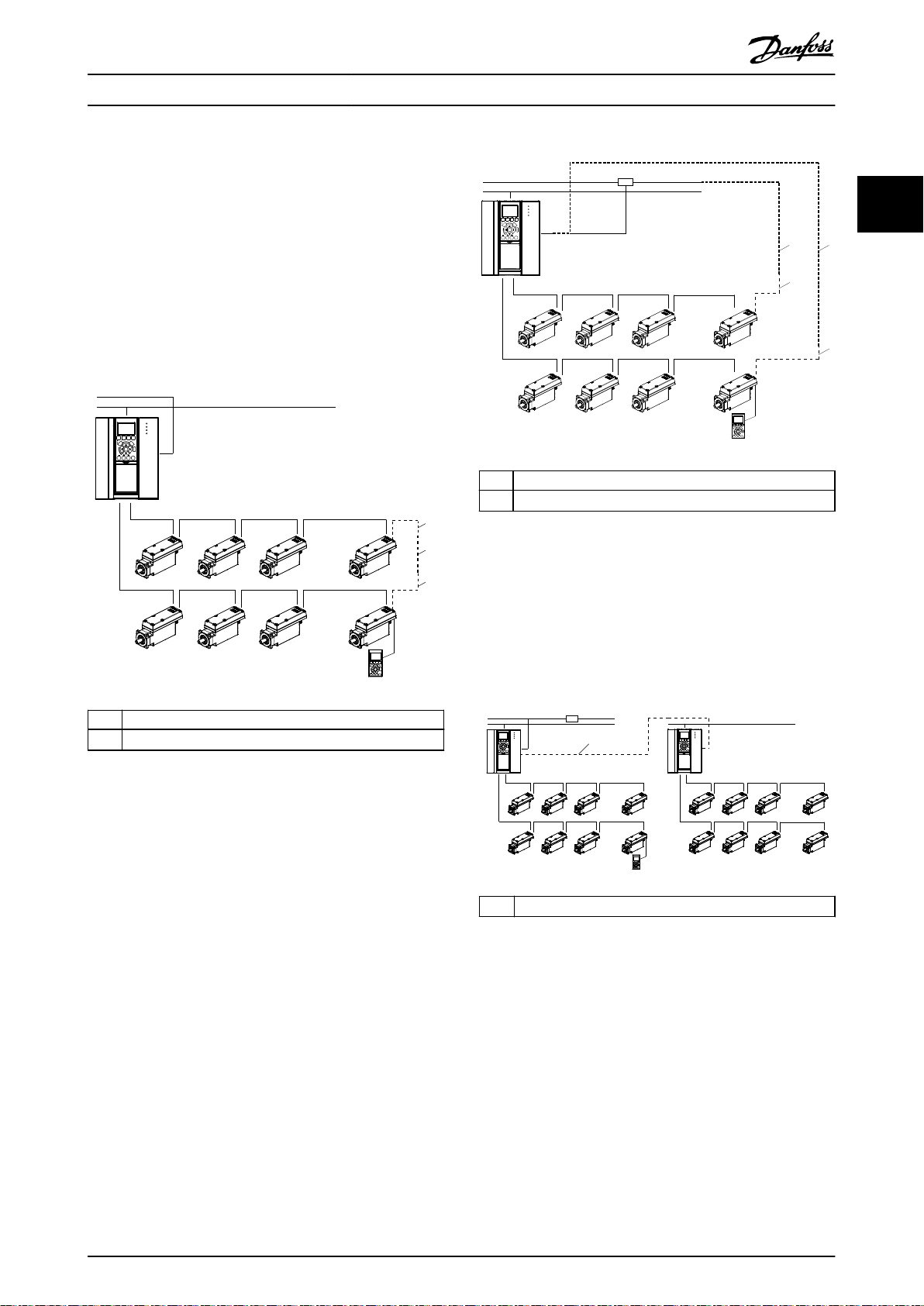

2.3.2

Ethernet POWERLINK® with

Redundancy

There are 2 methods to use Ethernet POWERLINK® with

redundancy:

eldbus extension cable

Via a

•

Via the PLC

•

Illustration 2.4 shows Ethernet POWERLINK® with

redundancy via a eldbus extension cable.

A Fieldbus extension cable

B

3rd party network cable

2 2

A Fieldbus extension cable

B

3rd party network cable

Illustration 2.4 Ethernet POWERLINK® with Redundancy via

Fieldbus Extension Cable

Illustration 2.5 shows Ethernet POWERLINK® with

redundancy via the PLC.

Illustration 2.5 Ethernet POWERLINK® with Redundancy via

PLC

2.3.3 Wiring with more than 1 SAB

Illustration 2.6 shows how to wire the servo system using

>1 SAB.

A

3rd party network cable

Illustration 2.6 Wiring with >1 SAB

MG36C102 Danfoss A/S © 08/2017 All rights reserved. 13

2.3.3.1

To connect additional SAB units in the same Ethernet

POWERLINK® network, use an RJ45 to RJ45 network cable

from the Ethernet X2 connection on the 1st SAB to the

Ethernet X1 connection on the 2nd SAB, and so on.

Ethernet POWERLINK

®

AUX 1

Status

Hand

On

Off

Reset

Auto

On

OK

Back

Cancel

Info

Quick

Menu

Main

Menu

Alarm

Log

AUX 2

SAFE 1

SAFE 2

Status

Hand

On

Off Reset

Auto

On

OK

Back

Cancel

Info

Quick

Menu

Main

Menu

Alarm

Log

LCP

SAB

400-480 V AC

ISD 510

. . .

. . .

130BF043.10

Real-Time Ethernet

PLC

Power

CH. 1

CH. 2

P1

A2 14 24

P2

S11 S12 S21 S22

A1 13 28

P1

S33 S34 Y36 Y37

P2

PNOZ X2P

QUINT POWER

1

2

3

5

4

UDC + Real-Time Ethernet Bus + STO + U

AUX

2

System Overview

VLT® Integrated Servo Drive ISD® 510 System

2.3.3.2

22

To connect additional SAB units in the same EtherCAT

network, use an RJ45 to RJ45 network cable from the

EtherCAT

®

®

Ethernet X2 connection on the 1st SAB to the Ethernet X1

connection on the 2nd SAB, and so on.

2.4

EtherCAT® with Redundancy

Component Description

ISD 510 servo

drive

Motors with integrated signal and power

electronics. They are mounted decentrally in the

application and have advanced motion control

functionality on board.

Servo Access

Box (SAB)

Central supply and access unit for mounting

inside a control cabinet. The SAB is the power

supply for the ISD 510 servo drives and is the

central access point for the eldbus.

Ring redundancy can be achieved using a special cabling

scheme. Connect the eldbus extension cable to the last

servo drive on the line and connect the other end of the

cable with an Ethernet CAT5 cable. Settings must also be

made in the engineering environment; see the

corresponding online help for further information.

2.5 Description of Operation

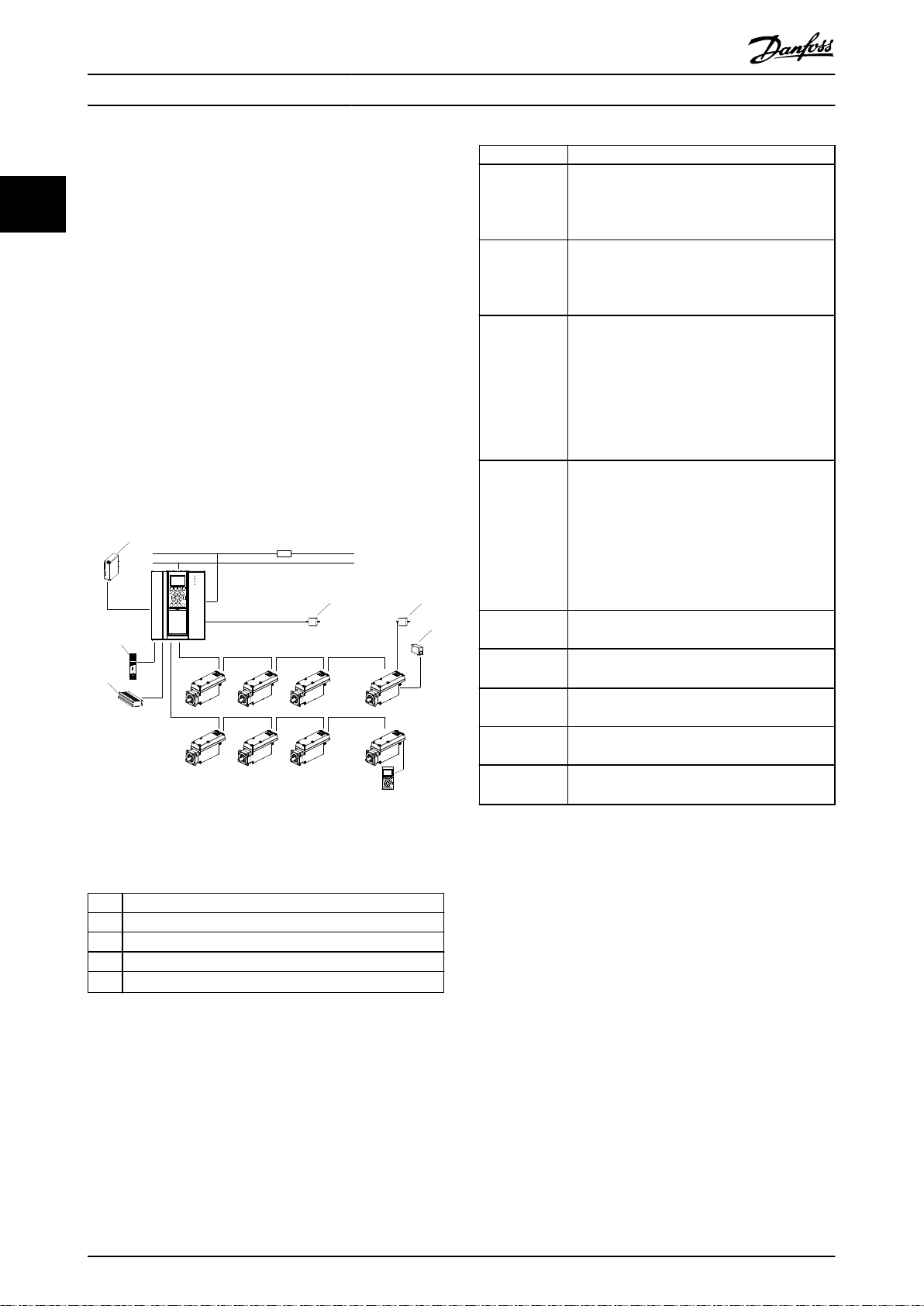

Illustration 2.7 shows the VLT® Integrated Servo Drive

ISD® 510 System and components.

Hybrid cable There are 2 types of hybrid cable:

Feed-in cable: Connects the SAB to the 1

•

servo drive.

Loop cable: Connects the servo drives in an

•

application in daisy-chain format. Speed

connectors minimize installation time, cost,

and risk of failures.

Local Control

Panel (LCP)

Graphical user interface for diagnostic and

operating purposes. The LCP is mounted on the

SAB but can be removed and connected to the

st

servo drive via connector X5 (advanced version

only). The LCP can be used for the ID

assignment of the advanced servo drives. The ID

assignment is started via LCP and the LCP also

indicates if the procedure is nished.

External

encoder

PLC

An external encoder can be connected to each

SAB and servo drive in the system.

PLC with Ethernet POWERLINK® and EtherCAT

®

eldbus master functionality.

STO Safe torque o feature can be provided via

external safety circuits.

Analog/Digital

Connection to the servo drives is possible.

Sensor

3rd party

eldbus device

Connection to the M8 4-pole eldbus port on

the servo drive (advanced servo drive only)

Illustration 2.7 Overview of the ISD 510 Servo System and

Table 2.4 ISD 510 System Components

Components

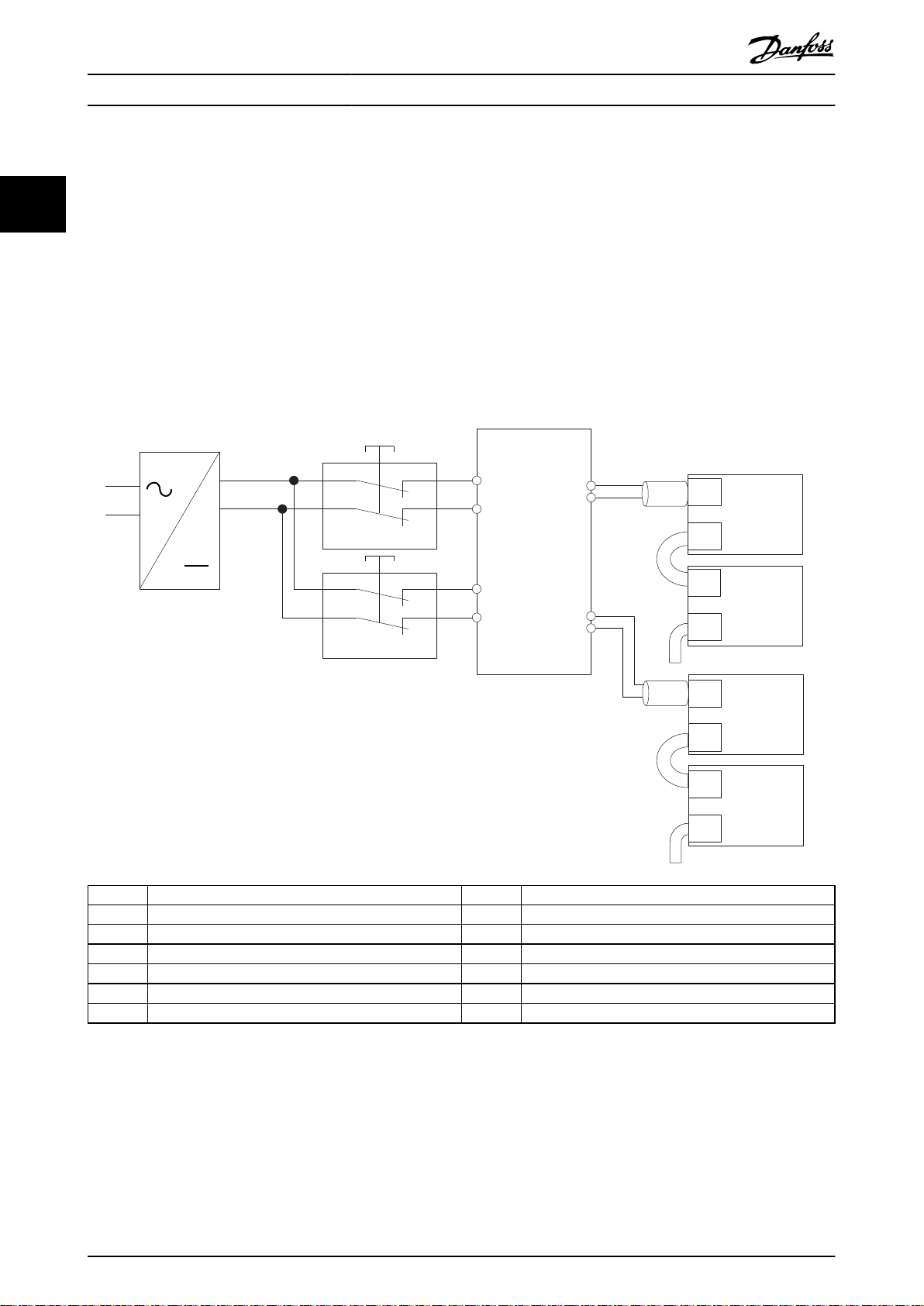

1 24/48 V power supply

2 Encoder

3 I/O

4 Brake resistor

5

Safety relay

1)

Table 2.3 Legend to Illustration 2.7

1) Safety relays that have a plus and minus switching output signal

can be directly connected to the ISD 510 servo system to activate

STO.

14 Danfoss A/S © 08/2017 All rights reserved. MG36C102

1

2

54

6

8

7

3

Ethernet X1

Ethernet X2

AC mains supply

24/48 V IN

STO 1 IN: STO 1 ISD Line 1: STO 1

ISD Line 2: STO 2

ISD Line 2: AUX 2

ISD Line 1: AUX 1

ISD Line 2: UDC 2

ISD Line 1: UDC 1

Ethernet X4

Ethernet X3

STO 2 IN: STO 2

130BF744.10

1

2 3

4

5

6 7 8

STO+

STO–

UDC+

UDC–

AUX+

AUX–

Advanced

servo drive

Ethernet

130BF743.10

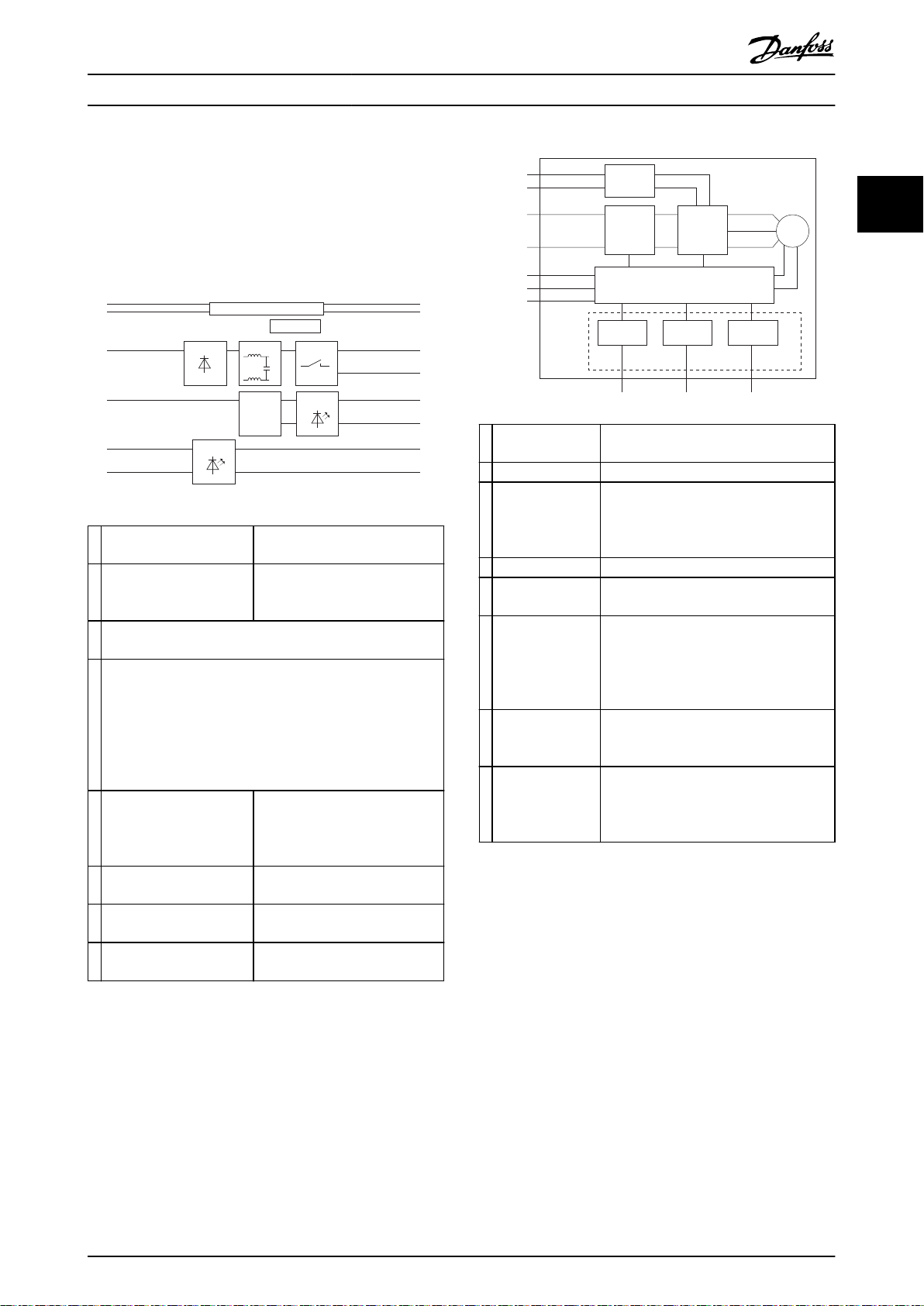

System Overview Design Guide

2.6 Sequence of Operation

2.6.1

VLT® Servo Access Box (SAB)

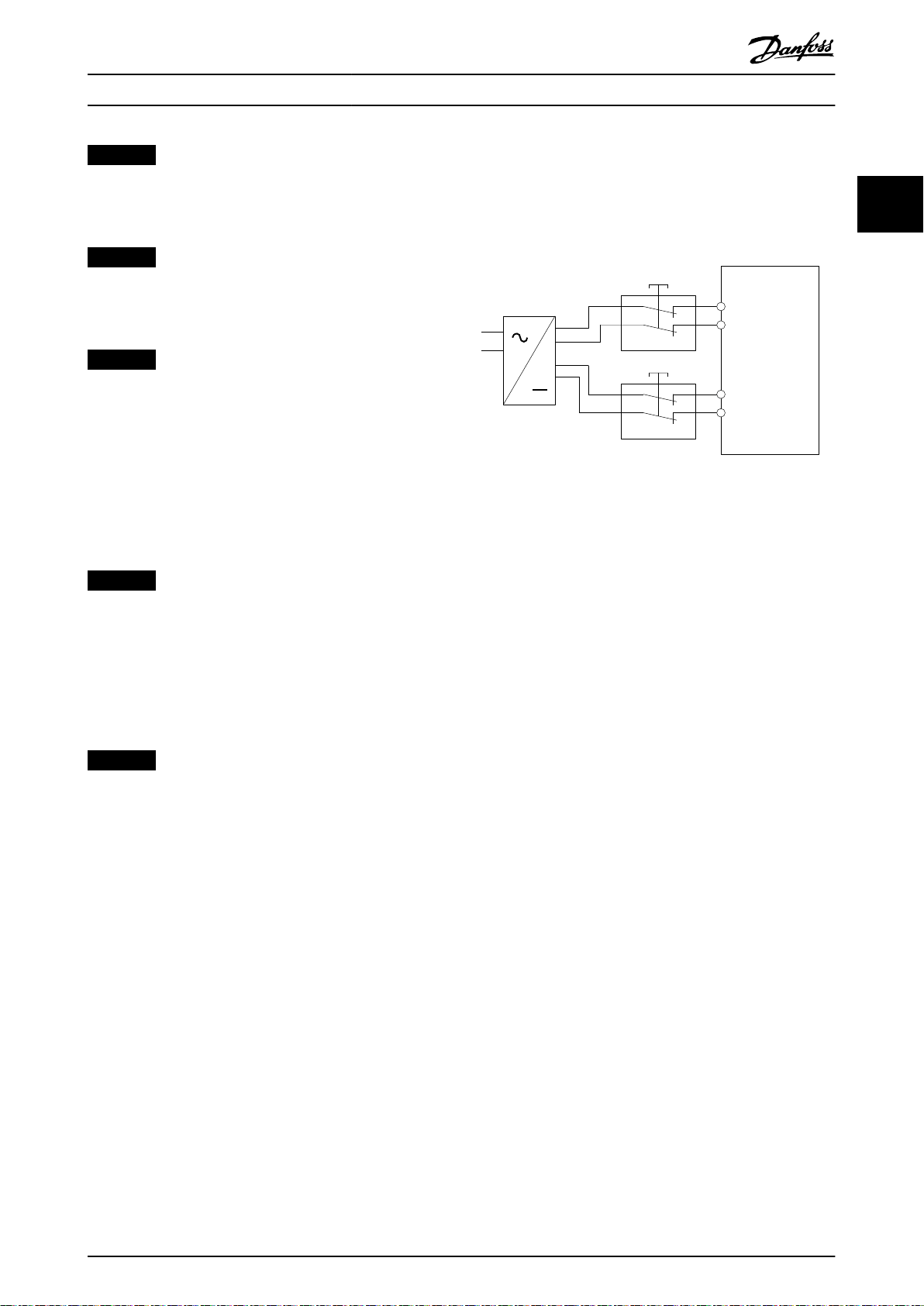

Illustration 2.8 shows a simplied block diagram of the SAB.

1 Control logic Used for communication and

monitors the status of the SAB.

2 SMPS (Switch mode power

supply)

3 When power is rst applied to the SAB, it enters through the

input terminals (L1, L2, and L3) and on to the RFI lter.

4 Following the rectier section, voltage passes to the

intermediate section. This rectied voltage is smoothed by a

sine-wave lter circuit, consisting of the DC bus inductor and

the DC bus capacitor bank. The DC bus inductor provides

series impedance to changing current. This aids the ltering

process while reducing harmonic distortion to the input AC

current waveform normally inherent in rectier circuits.

5 Switch For enabling or disabling the UDC

6 Overvoltage/overcurrent

protection

7 LED indicators Show the presence of the AUX

8 LED indicators Show the presence of the STO

Used to generate the control

voltage from the intermediate

bus.

output lines. Inrush current

limitation for the servo drives is

also done within this section.

For the auxiliary line.

voltage at the outputs of the SAB.

voltage.

1 STO circuit If STO is activated, the STO circuit disables

the inverter.

2 DC bus and lter The DC bus and lter smooth the voltage.

3 Inverter In the inverter section, once run

command and speed/position references

are present, the IGBTs begin switching to

create the output waveform.

4 Motor Synchronous permanent magnet motor.

5 Control circuit Used for generating the PWM pattern and

monitoring the status of the ISD.

6 X4: M12 I/O

and/or encoder

connector

(advanced servo

drive only)

7 X5: LCP connector

(advanced servo

drive only)

8 X3: Ethernet

connector

(advanced servo

drive only)

Illustration 2.9 Simplied Block Diagram of the ISD 510 Servo

Drive

2.6.3

Switching on the VLT® Integrated

This interface can be used to connect

digital inputs/outputs. It can also be used

for analog values. SSI/BISS encoders can

be connected to this interface.

An LCP can be connected to read out

parameters and set-up of the servo drive.

This interface can be used to connect

external real-time Ethernet devices.

Servo Drive ISD 510 System

2 2

Illustration 2.8 Simplied Block Diagram of the Servo Access

Box

2.6.2

Table 2.1 shows a simplied block diagram of the ISD 510

servo drive.

MG36C102 Danfoss A/S © 08/2017 All rights reserved. 15

VLT® Integrated Servo Drive ISD 510

The cabling in the ISD 510 servo system provides the

supply voltage and the communication signals. This is a

fundamental requirement for operation of the servo drives.

The ISD 510 servo system can be switched on in 3 ways:

If the SAB is supplied with mains and U

•

AUX

,

communication to the SAB internal controller is

established and U

is automatically passed on

AUX

to the connected servo drives.

If the SAB is only powered by U

•

, then the SAB

AUX

and servo drive control units are running.

System Overview

VLT® Integrated Servo Drive ISD® 510 System

If the SAB is only supplied with mains power,

•

then only the SAB control unit is running and

power is not passed on to the connected servo

22

drives.

Procedure for switching on the ISD 510 servo system

1. Switch U

power on to enable communication

AUX

to the SAB and servo drives.

2. Switch the mains on.

3. Set the SAB to state Operation Enabled.

4. The SAB and servo drives are now ready for

operation.

2.7 Functional Safety Concept

2.7.1 Notes

Use of the STO function requires that all provisions for

safety, including relevant laws, regulations, and guidelines,

are satised.

The integrated STO function complies with the following

standards:

EN 60204-1: 2006 Stop Category 0 – uncontrolled

•

stop

IEC/EN 61508: 2010 SIL 2

•

IEC/EN 61800-5-2: 2007 SIL 2

•

IEC/EN 62061: 2005 SIL CL2

•

EN ISO 13849-1: 2015

•

The VLT® Integrated Servo Drive ISD 510 System has been

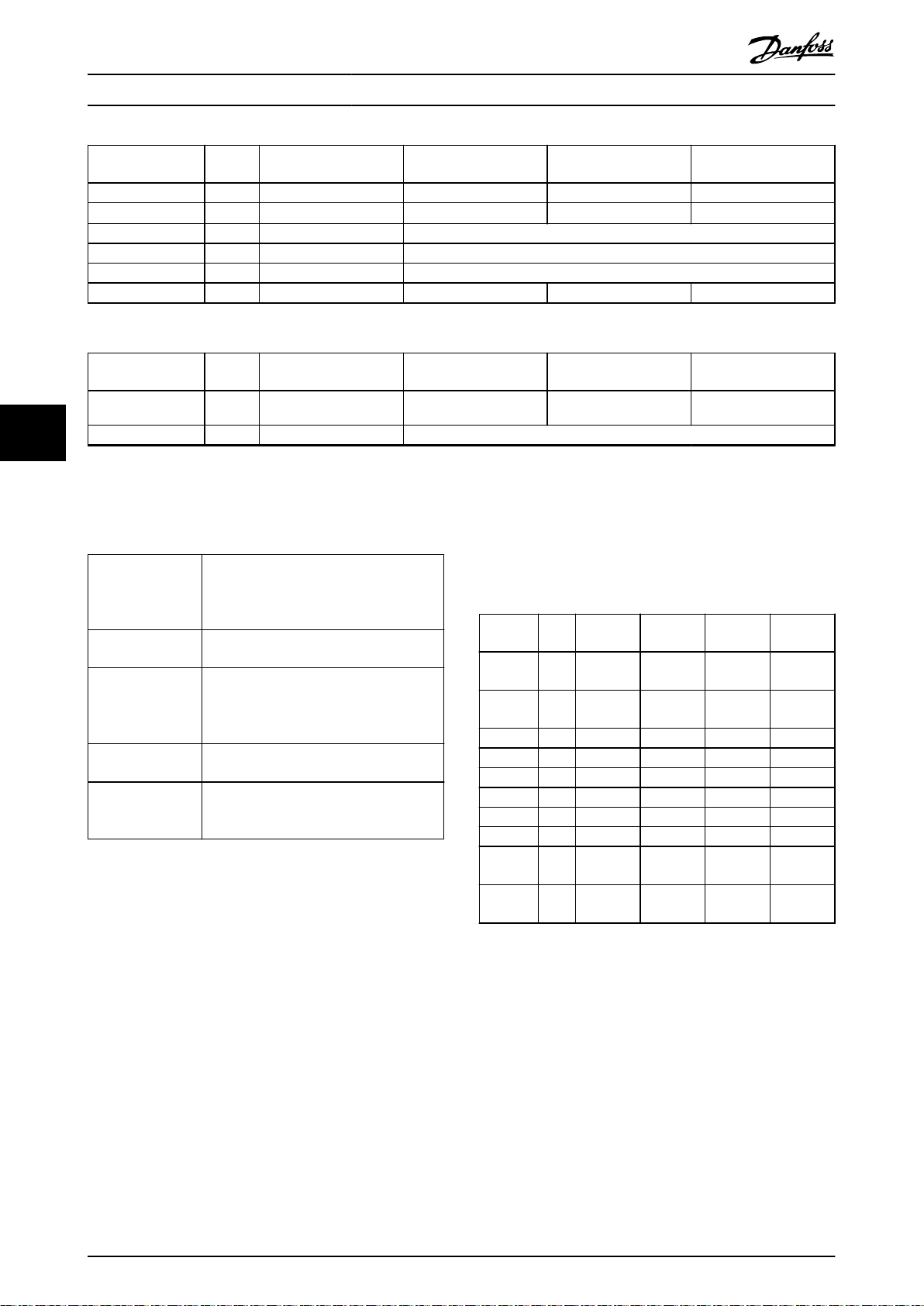

Abbreviation Reference Description

PFH EN IEC 61508 Probability of dangerous failures

per hour

Take this value into account if the

safety device is operated in high

demand mode or in continuous

operating mode, where the

frequency of demands for

operation made on a safety-related

system occurs more than once per

year.

PFD EN IEC 61508 Average probability of failure on

demand

This value is used for low demand

operation.

PL EN ISO

13849-1

SFF EN IEC 61508 Safe Failure Fraction [%]

SIL EN IEC 61508

EN IEC 62061

STO EN IEC

61800-5-2

Table 2.5 Abbreviations and Conventions

Performance level

A discrete level used to specify the

capability of safety-related parts of

a system to perform safetyoriented functions under

foreseeable conditions. Levels: a–e.

Proportion of safe failures and

detected dangerous failures of a

safety function or a subsystem as a

percentage of all possible failures.

Safety Integrity Level

Safe Torque O

tested for higher EMC immunity as described in

EN 61800-5-2:2017.

2.7.3 Functional Description

2.7.2 Abbreviations and Conventions

Abbreviation Reference Description

Cat. EN ISO

13849-1

DC – Diagnostic coverage

FIT – Failure in time

HFT EN IEC 61508 Hardware fault tolerance

MTTF

D

EN ISO

13849-1

Category, level B, 1–4

Failure rate: 1E-9/hour

H = n means that n + 1 faults may

lead to a loss of the safety

function.

Mean time to failure – dangerous

Unit: years

The STO function in the VLT® Integrated Servo Drive ISD

510 System features a separate STO function for each line

of servo drives in daisy-chain format. The function is

activated by inputs on the SAB. Using the STO function

activates the STO for all servo drives on that line. Once the

STO is activated, no torque is generated on the axes. Reset

of the safety function and diagnostics can be carried out

via the PLC.

NOTICE

The ISD 510 servo system does not implement a manual

reset function as required by ISO 13849-1. The standard

failure reset from the PLC cannot be used for this

purpose.

For automatic restart without manual reset, observe the

requirements detailed in paragraph 6.3.3.2.5 of ISO

12100:2010 or equivalent standard.

16 Danfoss A/S © 08/2017 All rights reserved. MG36C102

130BE690.10

SAB

STO 1 IN: + STO

STO 1 IN: – STO

STO 2 IN: + STO

STO 2 IN: – STO

System Overview Design Guide

NOTICE

Carry out a risk assessment to select the correct stop

category for each stop function in accordance with

EN 60204-1.

NOTICE

When designing the machine application, consider

timing and distance for coast to stop (Stop Category 2 or

STO). See EN 60204-1 for further information.

NOTICE

All signals connected to the STO must be supplied by a

SELV or PELV supply.

2.7.4 Installation

Only Danfoss cables may be used for the installation of the

servo system, however cables from other suppliers may be

used for the user connection to the STO terminals (STO 1

IN and STO 2 IN) on the SAB.

NOTICE

If the application does not require the Safe Torque O

(STO) functionality, build a bridge by connecting +24 V

from the connector STO 1 IN: +24V to STO 1 IN: +STO,

and from STO 1 IN: –24 V to STO 1 IN: –STO. Repeat this

process for STO line 2 if used.

Safety relays that have a plus and minus switching output

signal can be directly connected to the VLT® Integrated

Servo Drive ISD 510 System to activate STO (see

Illustration 2.10). Route the wires for STO 1 and STO 2

separately and not in a single multicore cable.

Illustration 2.10 Safety Relay with Plus and Minus Switching

Output

Signals with test pulses must not have test pulses of >1

ms. Longer pulses may lead to reduced availability of the

servo system.

2 2

2.7.5 Commissioning Test

NOTICE

Perform a commissioning test after installation of the STO function, after every change to the installed function, or after

a safety fault. Perform the test for each STO line.

There are 2 ways to implement the commissioning test depending on the method used to program the PLC, however the

steps of the test are the same:

Using the Danfoss Library or the TwinCAT® Library.

•

Bit-wise readout of the status.

•

Commissioning test using libraries

Depending on the application, 1 or both of the following libraries are required to program the commissioning test:

Danfoss Library

•

- MC_ReadAxisInfo_ISD51x

- MC_ReadStatus_ISD51x

- MC_ReadAxisError_ISD51x

- MC_Reset_ISD51x

TwinCAT® Library

•

- MC_ReadStatus

- MC_ReadAxisError

- MC_Reset

MG36C102 Danfoss A/S © 08/2017 All rights reserved. 17

System Overview

VLT® Integrated Servo Drive ISD® 510 System

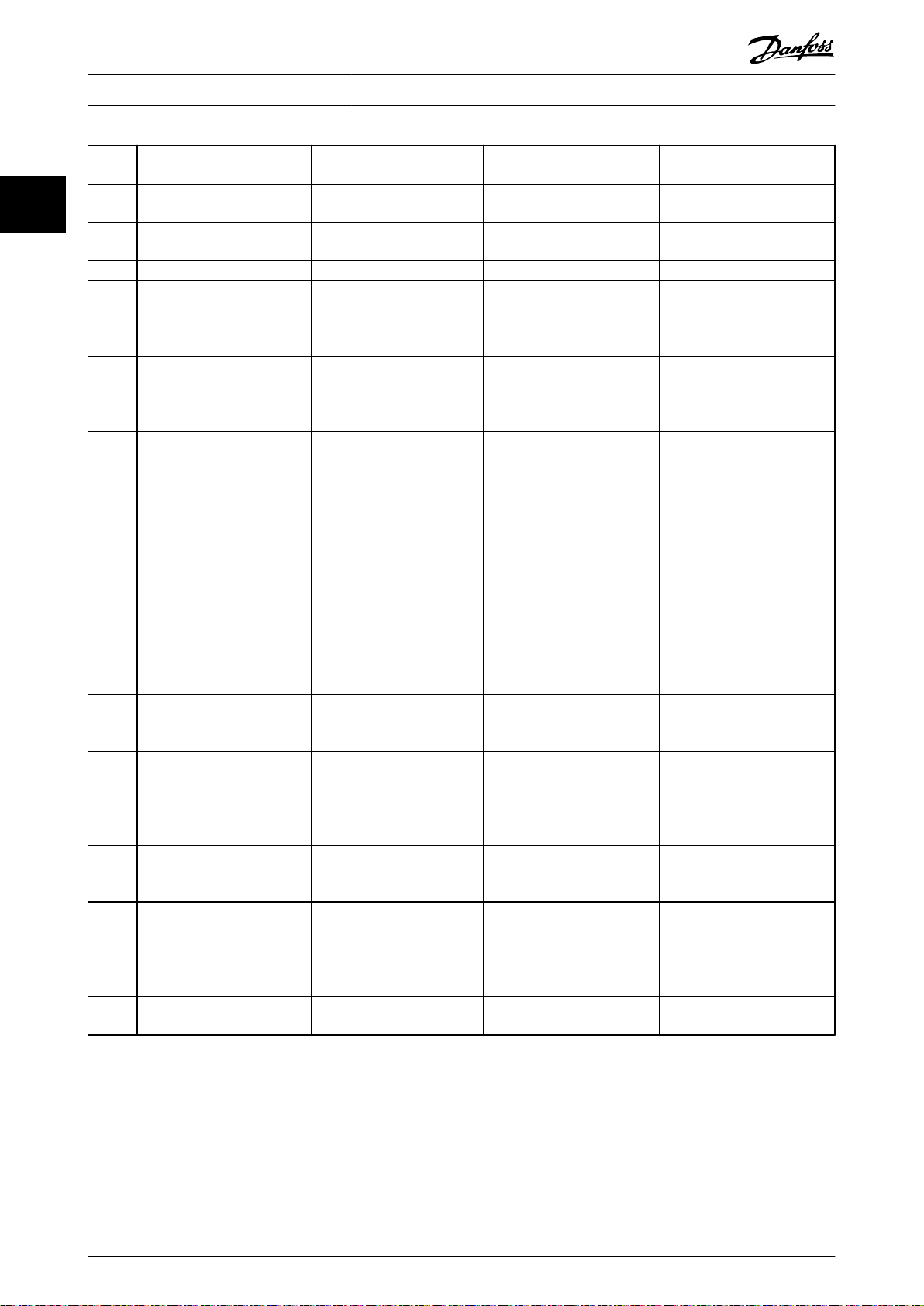

Test steps Reason for the test step Expected result for Danfoss

library

22

1 Run the application (all the

servo drives are enabled).

2 Stop the application. – All servo drives are at speed 0

3 Disable all the servo drives. – All servo drives are disabled. All servo drives are disabled.

4 Enable STO. Check that STO can be

5 Disable STO. Check that STO can be

6 Run the application (all the

servo drives are enabled).

7 Enable STO. Check that errors are

8 Try to run the application

(enable 1 or more servo

drives).

9 Disable STO. Check that the STO start is

10 Try to run the application

(enable 1 or more servo

drives).

11 Send a reset signal via

MC_Reset(_ISD51x).

12 Try to run the application (all

servo drives are enabled).

Check that the application can

run.

activated without error.

deactivated without error. No

reset is required.

– Application runs as expected. Application runs as expected.

generated correctly when STO

is activated while the servo

drives are running.

Checks that the STO function

is working correctly.

still inhibited by the error

signal.

Check whether reset is

required.

– MC_ReadAxisInfo_ISD51x output

– Application runs as expected. Application runs as expected.

Application runs as expected. Application runs as expected.

RPM.

MC_ReadAxisInfo_ISD51x output

SafeTorqueO = True for all

servo drives on the

corresponding line.

MC_ReadAxisInfo_ISD51x output

SafeTorqueO = False for all

servo drives on the

corresponding line.

Motors are torque free. Motors

coast and stop after some

time.

MC_ReadAxisInfo_ISD51x output

SafeTorqueO = True

and

MC_ReadStatus_ISD51x output

ErrorStop = True

and

MC_ReadAxisError_ISD51x

output AxisErrorID = 0xFF80 on

all enabled servo drives.

Application does not run. Application does not run.

MC_ReadAxisInfo_ISD51x output

SafeTorqueO = False

and

MC_ReadStatus_ISD51x output

ErrorStop = True

Application does not run. Application does not run.

SafeTorqueO = False

and

MC_ReadStatus_ISD51x output

ErrorStop = False

Expected result for TwinCAT

library

All servo drives are at speed 0

RPM.

–

–

Motors are torque free. Motors

coast and stop after some

time.

For enabled motors:

MC_ReadStatus output ErrorStop

= True

and

MC_ReadAxisError output

AxisErrorID = 0xFF80 on all

enabled servo drives.

MC_ReadStatus output ErrorStop

= True

MC_ReadStatus output ErrorStop

= False

®

Table 2.6 Commissioning Test using Libraries

18 Danfoss A/S © 08/2017 All rights reserved. MG36C102

System Overview Design Guide

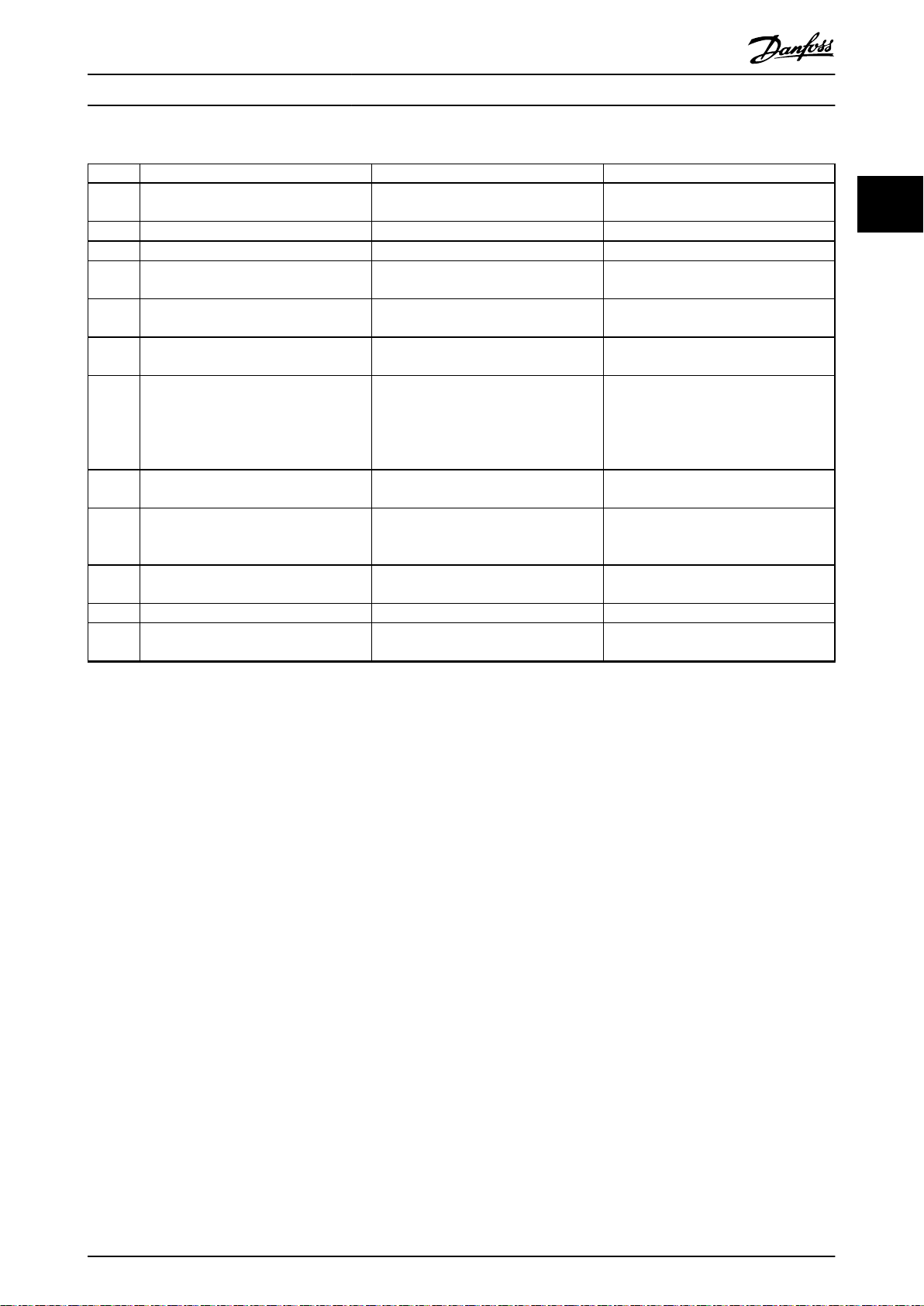

Commissioning test using bit-wise readout

Test steps Reason for the test step Expected result

1 Run the application (all the servo drives

are enabled).

2 Stop the application. – All servo drives are at speed 0 RPM.

3 Disable all the servo drives. – All servo drives are disabled.

4 Enable STO. Check that STO can be activated without

5 Disable STO. Check that STO can be deactivated

6 Run the application (all the servo drives

are enabled).

7 Enable STO. Check that errors are generated correctly

8 Try to run the application (enable 1 or

more servo drives).

9 Disable STO. Check that the STO start is still inhibited

10 Try to run the application (enable 1 or

more servo drives).

11 Send a reset signal via the PLC. – Statusword bit 3 = 0 in all servo drives.

12 Try to run the application (all servo drives

are enabled).

Check that the application can run. Application runs as expected.

Statusword bit 3 = 0 and bit 14 =1 in all

error.

without error. No reset is required.

– Application runs as expected.

when STO is activated while the servo

drives are running.

Checks that the STO function is working

correctly.

by the error signal.

Check whether reset is required. Application does not run.

– Application runs as expected.

servo drives.

Statusword bit 3 = 0 and bit 14 =0 in all

servo drives.

Motors are torque free. Motors coast and

stop after some time.

Statusword bit 3 = 1, bit 14 = 1 and

object 0x603F shows fault 0xFF80 in all

servo drives.

Application does not run.

Statusword bit 3 = 1, bit 14 = 0 and

object 0x603F shows fault 0xFF80 in all

servo drives.

2 2

Table 2.7 Commissioning Test using Bit-Wise Readout

MG36C102 Danfoss A/S © 08/2017 All rights reserved. 19

+24 V DC

GND

130BE689.11

8a

8b

9a

9b

4

2

3

1

X1

X2

X1

X2

X1

X2

X1

X2

6

6

7

5

System Overview

2.7.6 Application Example

VLT® Integrated Servo Drive ISD® 510 System

22

Illustration 2.11 shows an example of an installation for 2 lines that can be put in Safe Torque O mode by separate safety

circuits for each line.

The safety circuits may be remote from each other and are not supplied from the VLT® Integrated Servo Drive ISD 510

System.

The 2 lines in the example are controlled separately. If the Safe Torque

normal operation and the servo drives on this line are not aected. There may still be a hazard from the servo drives on

line 2.

Select the safety switch devices in accordance with the requirements of the application.

O function is triggered on line 1, line 2 remains in

1a/1b ISD 510 servo drive on line 1 8 Line 2 emergency stop button

2a/2b ISD 510 servo drive on line 2 9 Line 2 safety device contacts

3 Servo Access Box (SAB) 10 Line 1 hybrid cable

4 Safety device on line 1 11 Line 2 hybrid cable

5 Line 1 emergency stop button 12 Feed-in cable

6 Line 1 safety device contacts 13 Loop cable

7 Safety device on line 2 14 24 V DC supply

Illustration 2.11 Application Example: Safe Torque O Function with 2 Lines

20 Danfoss A/S © 08/2017 All rights reserved. MG36C102

EtherCAT

Slave Controller

(ESC)

OUT

Port 1 (B)

OUT

Port 2 (C)

IN

Port 0 (A)

X2X1

X3

130BE695.10

System Overview Design Guide

2.7.7 Safety Function Characteristic Data

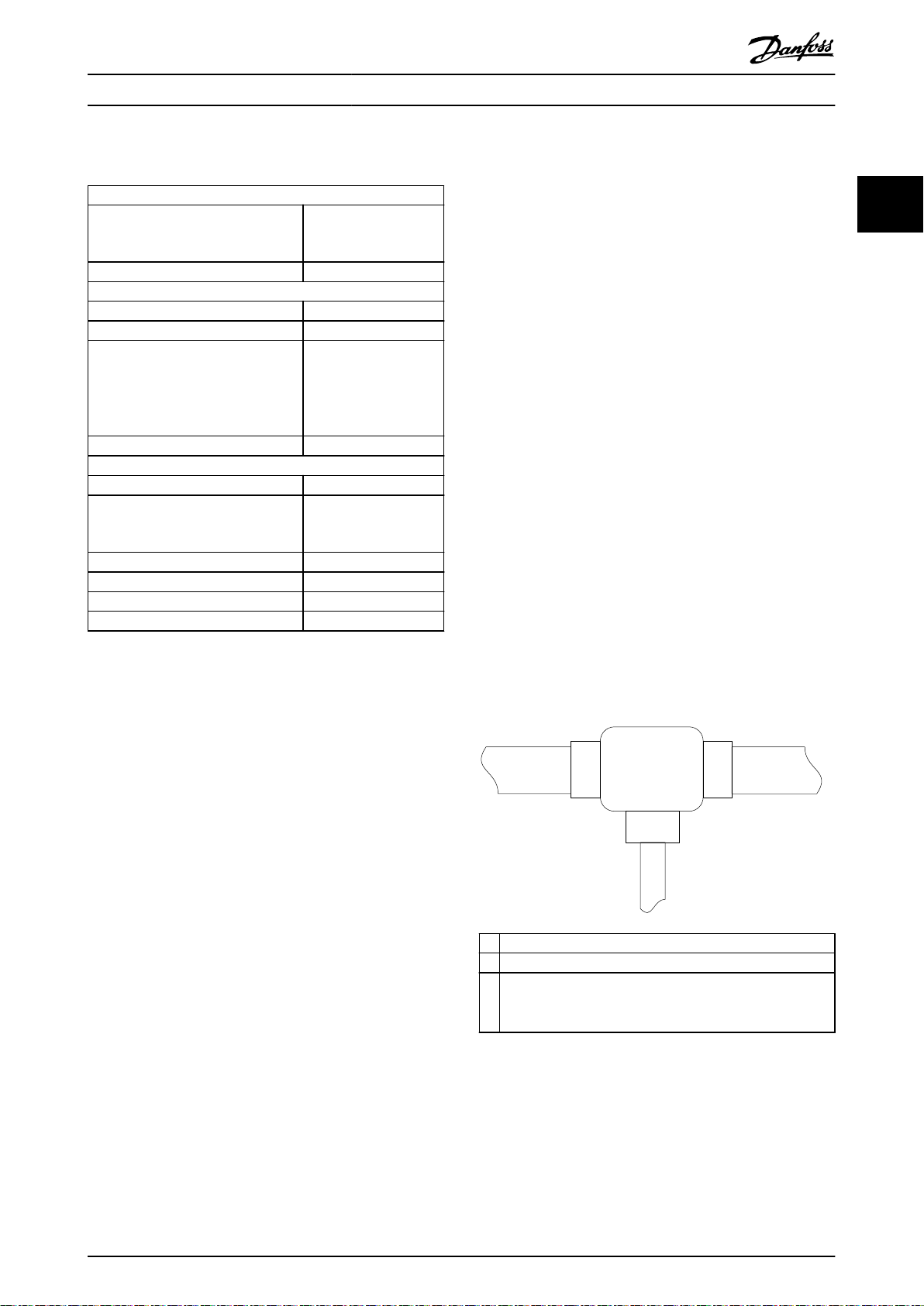

General information

Response time (from switching on the

input until torque generation is

disabled)

Lifetime 20 years

Data for EN/ISO 13849-1

Performance level (PL) d

Category 3

Mean time to dangerous failure

(MTTFd) for maximum system size of

32 servo drives on each STO line

Diagnostic coverage (DC) 60%

Data for EN/IEC 61508 and EN/IEC 62061

Safety integrity level (SIL) 2

Probability of failure per hour (PFH) for

maximum system size of 32 servo

drives on each STO line

Safe failure fraction (SFF) >95%

Hardware fault tolerance (H) 0

Subsystem classication Type A

Proof test interval 1 year

Table 2.8 Safety Function Characteristic Data

<100 ms

233 years (limited to 100

years if the VLT

Integrated Servo Drive

ISD 510 System forms an

entire safety channel)

<5 x 10-8/h

®

The servo drives and the SABs can be operated with the

following cycle times (for both eldbuses):

400 µs and multiples of it (for example, 800 µs,

•

1200 µs, and so on).

500 µs and multiples of it (for example, 500 µs,

•

1 ms, and so on).

When the cycle time is a multiple of 400 µs and 500 µs,

the time base of 500 µs is used.

The servo drive and the SAB are certied for both

eldbuses according to the corresponding rules and

regulations. The servo drive conforms to the CANopen

CiA DS 402 Drive

2.8.1.1

EtherCAT

Prole.

®

®

The servo drive and the SAB support the following

EtherCAT® protocols:

CANopen over EtherCAT® (CoE)

•

File Access over EtherCAT® (FoE)

•

Ethernet over EtherCAT® (EoE)

•

The servo drive and the SAB support distributed clocks. To

compensate for the failure of a communication cable

section in the system, cable redundancy is available for

both eldbuses.

2 2

Communication

2.8

2.8.1 Fieldbus

The VLT® Integrated Servo Drive ISD 510 System has an

open system architecture realized by fast Ethernet

(100BASE-T) based communication. The system supports

both EtherCAT® and Ethernet POWERLINK® eldbuses. See

the VLT® Integrated Servo Drive ISD® 510 System

Programming Guide for further information.

In productive environments, communication to the devices

always takes place via a PLC that acts as a master. The

servo drives and the SABs can be controlled by these

communication methods:

Using the Danfoss VLT® Servo Motion library

•

(available for TwinCAT® and Automation

Studio™).

Using the NC axis functionality of TwinCAT® for

•

the servo drives.

Using the CANopen® CiA DS 402 standard by

•

reading and writing to objects.

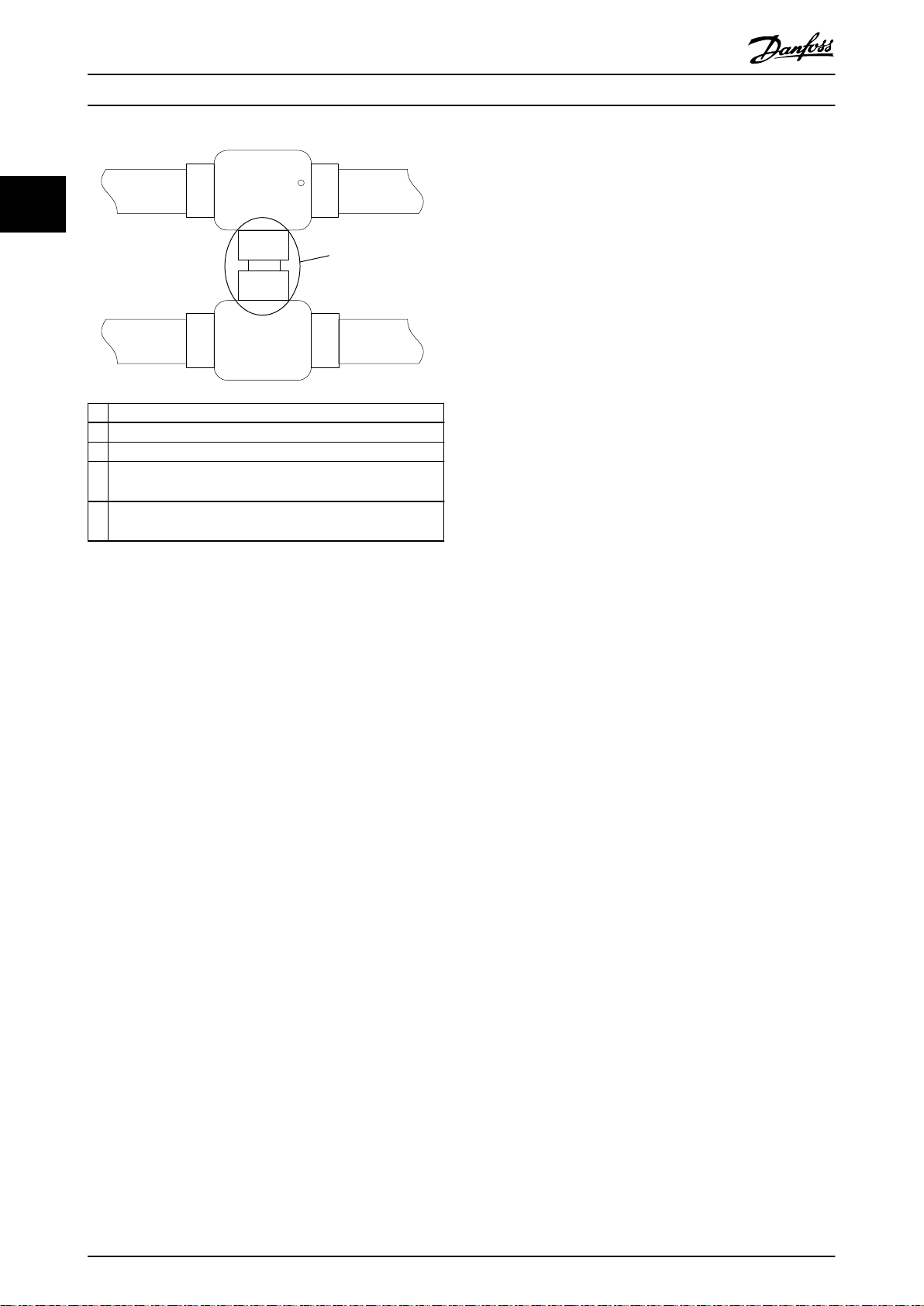

The EtherCAT® port assignment for the servo drive and

SAB is shown in Illustration 2.12 and Illustration 2.13.

X1 M23 hybrid cable connector to SAB or previous servo drive.

X2 M23 hybrid cable connector to the next servo drive.

X3

M8 Ethernet cable connector to other EtherCAT® slaves, for

example EtherCAT® encoder.

The connector is only available on the advanced servo drive.

Illustration 2.12 EtherCAT® Port Assignment for the ISD 510

Servo Drive

MG36C102 Danfoss A/S © 08/2017 All rights reserved. 21

ESC SAB L1

Main EtherCAT

slave

OUT

Port 2 (C)

OUT

Port 1 (B)

IN

Port 0 (A)

X1

ESC SAB L2

AL emulated

junction slave

IN

Port 0 (A)

OUT

Port 1 (B)

OUT

Port 2 (C)

X2

X3

X4

1

R

130BE696.10

System Overview

22

VLT® Integrated Servo Drive ISD® 510 System

CAM editor for designing CAM proles for the

•

servo drives.

The detailed description of the DDS Toolbox functionality

and the full parameter lists can be found in the VLT

Integrated Servo Drive ISD® 510 System Programming Guide.

®

2.8.2.1 System Requirements

To install the DDS Toolbox software, the PC must meet the

following requirements:

Supported hardware platforms: 32-bit, 64-bit.

•

®

1 Ports always connected internally in the SAB.

X1 RJ45 cable connector to the PLC or previous slave.

X2 RJ45 cable connector to the PLC or next slave.

X3

M23 feed-in cable to the 1st servo drive on line 1 with RJ45

connector.

X4

M23 feed-in cable to the 1st servo drive on line 2 with RJ45

connector.

Illustration 2.13 EtherCAT® Port Assignment for the SAB in

Line Topology Mode (default)

Supported operating systems: Microsoft

•

Windows XP Service Pack 3, Windows 7, Windows

8.1.

.NET framework version: 3.5 Service Pack 1.

•

Minimum hardware requirements: 512 MB RAM,

•

Intel Pentium 4 with 2.6 GHz or equivalent, 40 MB

hard disk space.

Recommended hardware requirements: Minimum

•

1 GB RAM, Intel Core i5/i7 or compatible.

2.8.1.2

The servo drive and the SAB are certied according to

DS301 V1.1.0. The following features are supported for the

servo drive and the SAB:

Specic ports are not assigned for Ethernet POWERLINK®.

Ethernet POWERLINK

Work as controlled node.

•

Can be operated as multiplexed stations.

•

Support of cross-communication.

•

Ring redundancy is supported for media

•

redundancy.

®

2.8.2 PC-Software

The DDS Toolbox is a standalone PC software designed by

Danfoss. It is used for parameterization and diagnostics of

the servo drives and the SAB and can also be used to

operate the devices in a non-productive environment. The

DDS Toolbox contains several functionalities, called subtools, which in turn provide various functionalities.

The most important sub-tools are:

Scope for visualization of the tracing functionality

•

of the servo drives and SAB.

•

•

•

Parameter list for reading/writing parameters.

Firmware update

ISD 500 Drive control/SAB control to operate the

servo drives and/or SAB for testing purposes.

22 Danfoss A/S © 08/2017 All rights reserved. MG36C102

System Overview Design Guide

2.9 Operating Modes

The VLT® Integrated Servo Drive ISD 510 implements several modes of operation. The behavior of the servo drive depends

on the activated mode of operation. It is possible to switch between the modes while the servo drive is enabled. The

supported modes of operation are according to CANopen® CiA DS 402 and there are also ISD-specic modes of operation.

All supported modes of operation are available for EtherCAT® and Ethernet POWERLINK®.

The various modes of operation are described in detail in the VLT® Integrated Servo Drive ISD® 510 System Programming

Guide.

Mode Description

2 2

ISD Inertia measurement

mode

Prole velocity mode In prole velocity mode, the servo drive is operated under velocity control and executes a movement with

Prole position mode In prole position mode, the servo drive is operated under position control and executes absolute and

Prole torque mode In prole torque mode, the servo drive is operated under torque control and executes a movement with

Homing mode In homing mode, the application reference position of the servo drive can be set. Several homing methods,

CAM mode In CAM mode, the servo drive executes a synchronized movement based on a master axis. The synchroni-

Gear mode In gear mode, the servo drive executes a synchronized movement based on a master axis by using a gear

Cyclic synchronous position

mode

Cyclic synchronous velocity

mode

This mode measures the inertia of an axis. It is used to measure the inertia of the servo drive and the

external load, and to optimize the control loop settings. The friction eects are eliminated automatically.

constant speed. Additional parameters, such as acceleration and deceleration, can be parameterized.

relative movements. Additional parameters, such as velocity, acceleration, and deceleration, can be parameterized.

constant torque. Linear ramps are used. Additional parameters, such as torque ramp and maximum

velocity, can be parameterized.

such as homing on actual position, homing on block, limit switch, or home switch are available.

zation takes place by means of a CAM prole that contains slave positions corresponding to master

positions. CAMs can be designed graphically with the DDS Toolbox software, or can be parameterized via

the PLC. The guide value can be provided by an external encoder, virtual axis, or the position of another

axis.

ratio between the master and the slave position. The guide value can be provided by an external encoder,

virtual axis, or the position of another axis.

In cyclic synchronous position mode, the trajectory generator of the position is located in the control

device, not in the servo drive.

In cyclic synchronous velocity mode, the trajectory generator of the velocity is located in the control

device, not in the servo drive.

Table 2.9 Operating Modes

MG36C102 Danfoss A/S © 08/2017 All rights reserved. 23

System Overview

VLT® Integrated Servo Drive ISD® 510 System

2.10 Automated Operational Functions

2.10.1 Short Circuit Protection

22

2.10.1.1 Servo Access Box Features

The SAB has several protection functions for limiting the

current:

IN 100% (15 A

•

100–200% current is limited by an I2t function. A

•

load of 160% is allowed for 1 minute. The RMS

current must be lowered to ≤100% before a new

overload is allowed. The time taken to reset the

I2t function depends on the load current. A 2 A

overload for 10 s (17 A) requires a nominal

current of ≤13 A for 10 s to reset the I2t function.

IDC protection (UDC)

Imax0: At 200% RMS, the output will be discon-

•

nected within 1.5 s.

Imax1: At 51 A peak current, the output will be

•

disconnected within 500 μs.

Imax2: At 125 A peak current, the output will be

•

disconnected within 10 μs.

I

protection

AUX

Software limit range: 0–15 A

•

- A warning and alarm is issued at

These software limits are disabled by default. See

•

parameters AUX line 1 user current limit and AUX

line 2 user current limit in the VLT® Integrated Servo

Drive ISD 510 System Programming Guide.

A low-pass lter is implemented in the rmware

•

to avoid unintended warnings or alarms due to

inrush currents.

2.10.1.2 ISD 510 Servo Drive Features

To protect the servo drive and the machinery attached to

the servo drive shaft, a current limit protection is

implemented in the servo drive.

Current limit protection is implemented on the servo drive

and the currents are constantly monitored. If an

overcurrent occurs, an error is issued and the servo drive

coasts to stop as default. For servo drives with the

mechanical brake option, the brake engages.

), no limitation.

RMS

user-

specied levels. A warning is issued at

90% of the selected value. An alarm is

issued when the measured value has

exceeded the software limit.

2.10.2 Ground Fault Protection

When a ground fault current of >3 A is present, a warning

is issued immediately. The SAB issues an error if the

warning is present for 10 s.

2.10.3 Temperature-controlled Fans

The SAB has 2 built-in forced air convection fans to ensure

optimum cooling. The main fan forces the airow along

the cooling ns on the heat sink, ensuring cooling of the

internal air. A secondary fan cools the SAB power control

board. Both fans are controlled by the internal temperature

and speed increases. The fans not only ensure maximum

cooling when required, but also reduce noise and energy

consumption when the workload is low.

If overtemperature occurs in the SAB, an error/warning is

issued, resulting in a coast and trip lock.

2.10.4 Thermal Protection

Thermal protection exists for both the servo drive and the

SAB. See chapter 4.6.3 Thermal Protection for further

information.

2.10.5 Additional Protection Features

2.10.5.1 Servo Access Box

The SAB has the additional protection features detailed in

Table 2.10.

Function Description Limits/errors

UDC

overvoltage

UDC

undervoltage

When the DC-link

voltage rises above

a certain level, a

warning/error is

issued.

A brake resistor can

be connected to

the SAB and

activated via

parameter 0x2030 in

the DDS Toolbox

software.

When the DC-link

voltage drops

below a certain

level, a warning/

error is issued.

Brake active: >778 V

•

Warning: >810 V

•

Error: >820 V

•

Warning: <410 V

•

Error: <373 V

•

24 Danfoss A/S © 08/2017 All rights reserved. MG36C102

System Overview Design Guide

Function Description Limits/errors

AUX

overvoltage

AUX

undervoltage

AUX

overcurrent

Brake error The SAB reports

Inrush fault The SAB can handle

Mains phase

loss

STO 1 & STO

2 indicators

Table 2.10 Additional Protection Features for SAB

2.10.5.2

When the AUX

voltage rises above

a certain level, a

warning/error is

issued.

When the AUX

voltage drops

below a certain

level, a warning/

error is issued.

When the AUX

current rises above

a certain level, a

warning/error is

issued.

various brakerelated errors.

up to 2 inrush

cycles per minute.

The SAB detects

the mains phase

loss and issues a

warning/error when

limits are reached.

The SAB indicates

the presence of the

STO 1 & STO 2

voltage.

Warning: >53 V

•

Error: >56 V

•

Warning: <21.6 V

•

Error: <19 V

•

Warning: >90% of user-

•

dened limit

Error: >100% of user-

•

dened limit

The default value of

15 A is used if no limits

are dened by the user.

Shorted brake resistor

•

Shorted brake IGBT

•

Thermal overload

•

Disconnected brake

•

resistor

Error issued if >2 inrush

cycles occur per minute.

Warning: 3–10% mains

•

phase imbalance

Error:

•

- >10% mains

phase

imbalance

- 3–10% mains

phase

imbalance for

>10 minutes

LED on: STO deactivated

LED o: STO activated

VLT® Integrated Servo Drive

ISD 510

The VLT® Integrated Servo Drive ISD 510 has the additional

protection features detailed in Table 2.10.

Function Description Limits/errors

UDC

overvoltage

UDC

undervoltage

Overcurrent at

output

Motor

position

Brake control The brake current is

Maximum

shaft speed

Torque limit The application peak torque

When the DC-link voltage

rises above a certain level, a

warning/error is issued.

When the DC-link voltage

drops below a certain level, a

warning/error is issued.

To protect the servo drive

and any machinery attached

to the servo drive shaft, a

current limit protection is

implemented. The current

limit protection on the servo

drive is available for motor

phase current. All 3 phase

currents are constantly

monitored. If an overcurrent

occurs, the servo drive stops

the actual operation. The

servo drive stops the shaft

rotation, engages the brake

(if present), and an error is

issued.

CRC check of each encoder

value, resolver amplitude, and

consistency check.

controlled by the servo drive

rmware.

The shaft speed of each

servo drive type is limited to

protect the motor mechanical

parts.

limit [M

parameters 52-15, 52-23, and

52-36 Application Torque Limit

(0x2053).

The maximum torque per

servo drive is calculated as:

Maximum phase current x

torque factor

] can be set via

max

Warning:

•

>810 V

Error: >820 V

•

Warning:

•

<410 V

Error: <373 V

•

Size 1: >8 A

•

Size 2: >9 A

•

–

–

Maximum motor

speed:

Size 1, 1.5 Nm:

•

7000 RPM

Size 2, 2.1 Nm:

•

6000 RPM

Size 2, 2.9 Nm:

•

5000 RPM

Size 2, 3.8 Nm:

•

4000 RPM

Peak torque M

Size 1, 1.5 Nm:

•

6.1 Nm

Size 2, 2.1 Nm:

•

7.8 Nm

Size 2, 2.9 Nm:

•

10.7 Nm

Size 2, 3.8 Nm:

•

12.7 Nm

max

2 2

:

Table 2.11 Additional Protection Features for ISD 510

Servo Drive

MG36C102 Danfoss A/S © 08/2017 All rights reserved. 25

91 92 93 95

L1 L2 L3 PE

Line1Line

2

SAB

MCE 101

Brake resistor

T1

T2

RB1

RB2

R–81

R+82

PE99

PE

L1

L2

L3

N

PE

F1

S1 K1

F2

S2

K1

K1

130BF779.10

System Overview

VLT® Integrated Servo Drive ISD® 510 System

2.11 Custom Application Functions

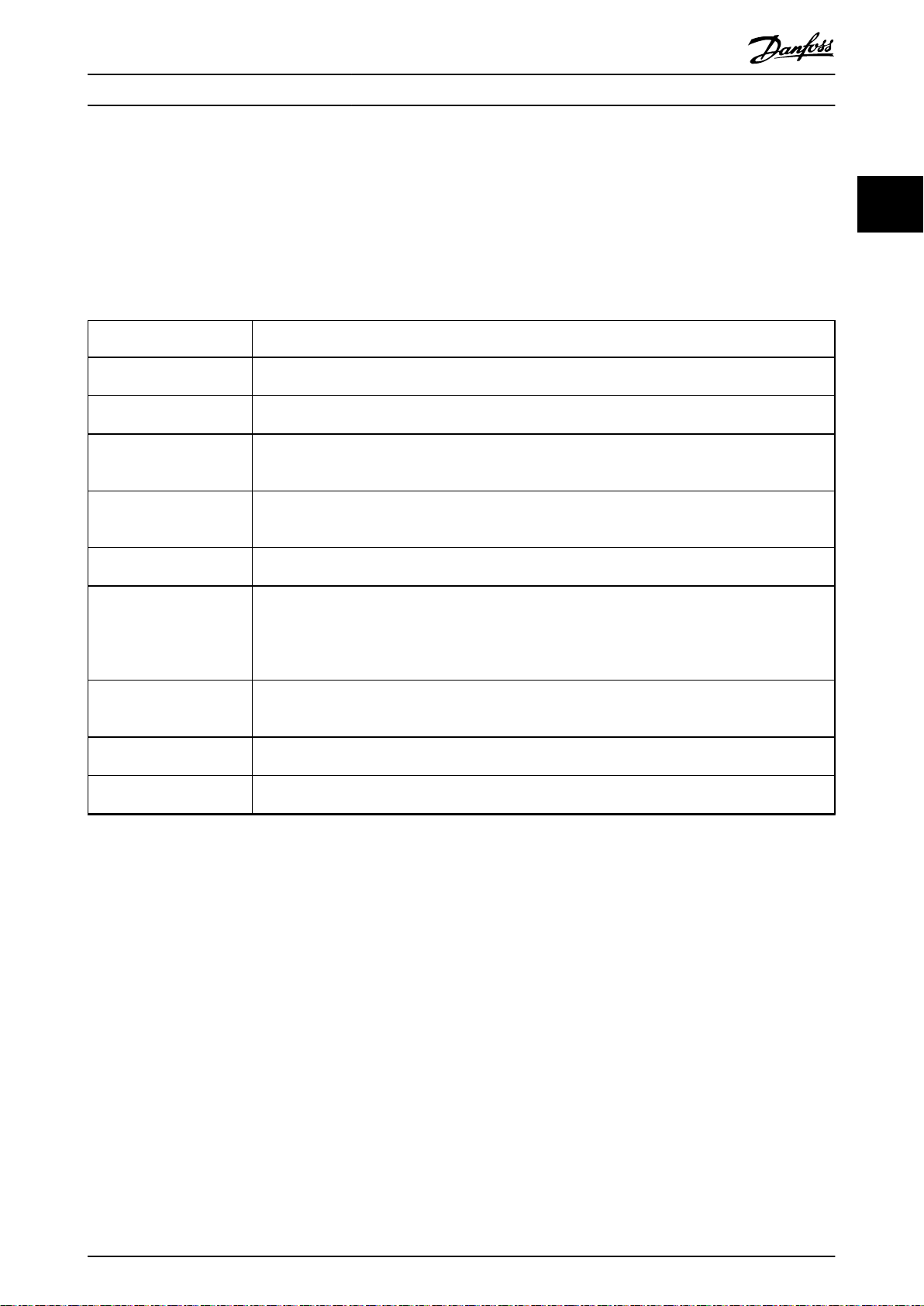

The temperature switch can be used as an overtemperature protection feature to prevent damage to the

2.11.1 Brake Resistor

22

When the servo drives are decelerating, the motors act like

a generator. This means that the energy coming back from

the servo drives is collected in the DC-link. The function of

the brake resistor is to provide a load on the DC-link

during braking, thereby ensuring that the brake power is

absorbed by the brake resistor. If no brake resistor is used

and the servo drives are decelerating, the DC-link voltage

will rise to a dangerous level. The SAB disconnects the ISD

lines when the DC-link voltage is too high. A DC-link

overvoltage will result in damage to the SAB and the servo

drives.

brake resistor caused by overtemperature.

The temperature switch can also be used to disable the

mains supply to the SAB by a contactor.

1. Connect the built-in thermal switch on the brake

resistor to the K1 input contactor.

2. Connect the start and stop push buttons in series

with the thermal switch.

3. Connect to a contactor in the mains supply on

the front of the SAB.

Thermal overheating in the brake resistor disables the

mains supply of the SAB.

2.11.1.1 Mechanical Installation

The brake resistors are cooled by natural convection.

The ventilation must be ecient enough to dispatch the

regenerative power in the brake resistor.

2.11.1.2 Electrical Installation

EMC precautions

The following EMC precautions are recommended to

achieve interference-free operation of eldbus cables, and

digital and analog inputs and outputs.

Observe any relevant national and local regulations, for

example regarding protective earth connection.

Keep the eldbus cables away from the brake resistor

cables to avoid coupling of high frequency noise from one

cable to the other. The minimum distance of 200 mm is

Illustration 2.14 Temperature Switch Disconnecting the Mains

from the SAB

sucient, however a greater distance between the cables

is recommended, especially where the cables run in

parallel over long distances. When crossing is unavoidable,

the eldbus cables must cross the brake cable at an angle

of 90°.

Cable connection

To comply with the EMC emission and immunity specication, the use of shielded/armored cables is mandatory.

Brake cable

Maximum length: 20 m shielded cable

Ensure that the connection cable to the brake resistor is

shielded. Use cable clamps to connect the shielding to the

conductive decoupling plate of the SAB, and to the brake

resistor metal cabinet.

Protective functions

The VLT® Brake Resistor MCE 101 is equipped with a

galvanic isolated temperature switch (PELV) that is closed

under normal operating conditions and opens if the brake

resistor overheats.

26 Danfoss A/S © 08/2017 All rights reserved. MG36C102

In addition, the brake power monitor function enables

readouts of the momentary power and the mean power

for a selected period. A brake power limit can be set and if

the brake power exceeds the set limit, the SAB issues a

warning or an error. When the SAB issues a warning, the

UDC output remains enabled. However, when an error is

issued, the UDC output to the servo drives is disconnected.

The brake is protected against short-circuiting of the brake

resistor, and the brake transistor is monitored to ensure

that short-circuiting of the transistor is detected.

2.11.1.3 Brake Resistor Calculation

To select the most suitable brake resistor for a given

application, the following information is required:

The number of servo drives in the application.

•

The inertia connected to the servo drives.

•

The braking/accelerating prole.

•

130BF780.10

AUX 1

Status

Hand

On

Reset

Auto

On

OK

Back

Cancel

Info

Quick

Menu

Main

Menu

Alarm

Log

AUX 2

SAFE 1

SAFE 2

SAB

400-480 V AC

Real-Time Ethernet

UDC

2

ISD 510

3

. . .

. . .

1

4

R

brake

P

peak brake

=

UDC

2

P

peak brake

UDC

2

R

brake min

778 V x 778 V

54.6 Ω

=== 11086 W

P

peak ISD

=

η

ISD x ωStart

x j x

Δt

Δω

P

peak ISD

=

η

ISD x nStart

x

x

j

x

60

2 x π

Δt

Δn

( )

System Overview Design Guide

Brake set-up

Illustration 2.15 shows the brake set-up in the VLT

Integrated Servo Drive ISD 510 System.

®

Calculation of brake power

When calculating the brake power, ensure that the brake

resistor is scaled for the average power as well as for the

peak power.

The peak brake power depends on the number of

•

2 2

servo drives that are in acceleration mode and

deceleration mode. The torque used to accelerate

and decelerate is also important.

The average power is determined by the process

•

period time, for example the length of the

braking time in relation to the process period

time.

Calculation of brake resistor peak power

The brake active voltage for the SAB is 778 V. When using

the minimal brake resistance of 54.6 Ω, a current of

14.25 A will ow at 778 V.

The brake resistor peak power is then calculated as follows:

1 I

brake

2 P

Line

3 P

ISD

4 Brake resistor R

: Absorbs brake power P

brake

Illustration 2.15 Brake Set-up

brake

.

If the application does not require braking with the

maximum current, a higher brake resistance can be

selected. A higher brake resistance results in a lower brake

peak power.

When the servo drives are accelerating, P

When the servo drives are decelerating, P

If the sum of all P