ENGINEERING TOMORROW

Programming Guide

VLT® Integrated Servo Drive ISD® 510 System

vlt-drives.danfoss.com

Contents Programming Guide

Contents

1 Introduction

1.1 Purpose of the Programming Guide

1.2 Additional Resources

1.3 Copyright

1.4 Software

1.4.1 Software Version 15

1.4.2 Firmware Updates 15

1.5 Approvals and Certications

1.6 Terminology

1.7 Safety

2 Servo Drive Operation

2.1 Overview

2.2 Firmware Update

2.3 Basic Operation

2.3.1 State Machine 19

2.3.2 Factor Group 21

2.3.3 Positions and Osets 22

15

15

15

15

15

15

16

16

18

18

18

19

2.3.4 Position Limits 22

2.3.4.1 Hardware Limit Switch 22

2.3.4.2 Software Position Limit 22

2.3.5 Brake Handling 24

2.3.6 Control Loops 24

2.3.6.1 Position Controller 25

2.3.6.2 Speed Controller 26

2.3.6.3 Current Controller 26

2.4 Operating Modes

2.4.1 Prole Position Mode 26

2.4.2 Prole Velocity Mode 30

2.4.3 Prole Torque Mode 32

2.4.4 Homing Mode 33

2.4.4.1 Homing on Actual Position 35

2.4.4.2 Homing on Positive/Negative Block 36

2.4.4.3 Homing on Positive/Negative Limit Switch 36

2.4.4.4 Homing on Positive/Negative Home Switch 37

26

2.4.4.5 Homing on Current Position 37

2.4.4.6 Error Behavior in Homing Mode 38

2.4.5 CAM Mode 38

2.4.5.1 Activating a CAM prole 40

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 1

Contents

VLT® Integrated Servo Drive ISD® 510 System

2.4.5.2 CAM Conguration: Master Absolute/Relative 41

2.4.5.3 CAM Header Information 41

2.4.5.4 Basic CAM 43

2.4.5.5 Advanced CAM 52

2.4.5.6 Commands During Operation 75

2.4.5.7 Notications from the Servo Drive 76

2.4.6 Gear Mode 77

2.4.7 ISD Inertia Measurement Mode 77

2.4.8 Cyclic Synchronous Position Mode 78

2.4.9 Cyclic Synchronous Velocity Mode 78

2.5 Motion Functions

2.5.1 Digital CAM Switch 79

2.5.2 ISD Touch Probe 82

2.5.2.1 Touch Probe Window 83

2.5.2.2 Touch Probe Edge Counter for Continuous Mode 83

2.5.2.3 Timing Example 84

2.5.3 Guide Value 85

2.5.3.1 Guide Value Reference 85

2.5.3.2 Guide Value Reference Simulation 85

2.6 Peripherals

2.6.1 Inputs 86

2.6.2 Output 86

2.6.3 External Encoder 86

2.7 Monitoring

2.7.1 Errors and Warnings 86

2.7.2 Trace 86

2.7.3 Following Error Detection 87

79

86

86

2.7.4 Standstill Detection 87

2.7.5 Constant Velocity Detection 88

2.7.6 STO and Brake Status 88

3 Servo Access Box (SAB) Operation

3.1 Overview

3.2 Control

3.2.1 Relay Outputs 91

3.3 Monitoring

3.3.1 AUX Output 92

3.3.2 DC Output 92

3.3.3 Brake Control and Monitoring 92

3.3.4 Input Voltages 93

3.3.5 Temperatures 93

2 Danfoss A/S © 01/2017 All rights reserved. MG36D102

89

89

90

92

Contents Programming Guide

3.3.6 Cooling Fans 93

3.4 External Encoder and Guide Value

3.5 Signal Tracing

3.6 Multiple Device ID Assignment

3.7 Software Version

3.8 Firmware Update

4 Local Control Panel (LCP) Operation

4.1 Overview

4.2 Local Control Panel (LCP) Layout

4.3 Graphical User Interface

4.3.1 Supported Languages 96

4.3.2 LCP Display 96

4.3.3 Status Menu (Auto On Mode) 96

4.3.3.1 Default Readouts for ISD 510 Servo Drive 97

4.3.3.2 Default Readouts for SAB 97

4.3.3.3 Alarms and Warnings 98

4.3.4 Main Menu 98

4.3.4.1 Displaying and Editing Values 99

93

93

93

93

93

94

94

94

96

4.3.4.2 ISD 510 Drive Menu 100

4.3.4.3 SAB Menu 100

4.3.5 Hand On Mode 101

4.3.5.1 Servo Drive 101

4.3.5.2 SAB 104

4.3.6 Alarm Log 104

4.4 Keys

4.4.1 Status Key 104

4.4.2 Quick Menu Key 104

4.4.3 Main Menu Key 104

4.4.4 Alarm Log Key 105

4.4.5 Back Key 105

4.4.6 Cancel Key 105

4.4.7 Info Key 105

4.4.8 OK Key 106

4.4.9 Hand On Key 106

4.4.10 O Key 106

104

4.4.11 Auto On Key 106

4.4.12 Reset Key 106

4.4.13 Up [▲] and Down [▼] Keys

4.4.14 Left [◀] and Right [▶] Keys

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 3

106

107

Contents

VLT® Integrated Servo Drive ISD® 510 System

4.5 LCP-specic Parameters

4.5.1 ISD 510 Servo Drive-specic LCP Parameters 107

4.5.2 SAB-specic LCP Parameters 108

5 Operation with ISD Toolbox

5.1 Overview

5.2 ISD Toolbox Installation

5.2.1 System Requirements 109

5.2.2 Installation 109

5.3 ISD Toolbox Communication

5.3.1 Network Settings for Indirect Communication 110

5.3.2 Network Settings for Direct Communication with Ethernet POWERLINK

5.3.3 Network Settings for Direct Communication with EtherCAT

5.4 ISD Toolbox Commissioning

5.5 Look and Feel

5.5.1 Main Window 114

5.5.2 Device Environment Window 116

5.5.2.1 Device Information Window 116

107

109

109

109

109

®

®

111

112

112

113

5.5.3 Watchlist Window 118

5.5.4 Output Window 118

5.5.5 Project File 119

5.5.6 Importing and Exporting Devices 119

5.5.7 Online Help 119

5.5.8 Options Window 119

5.6 Connection and Devices

5.6.1 Connect to Bus 121

5.6.2 Disconnect from Bus 121

5.6.3 Online/Oine Devices 121

5.6.4 Adding/Removing Devices 121

5.6.5 Scan for Devices 122

5.7 Sub-Tools

5.7.1 Parameter List (Servo Drive and SAB) 122

5.7.2 Firmware Update (Single and Multi-device for Servo Drive and SAB) 124

5.7.2.1 Single Device Firmware Update 124

5.7.2.2 Multi-Device Firmware Update 124

121

122

5.7.3 Scope (Single and Multi-device for Servo Drive and SAB) 125

5.7.3.1 Sampling 125

5.7.3.2 Triggering 126

5.7.3.3 Trace Signals 127

5.7.3.4 Status 128

4 Danfoss A/S © 01/2017 All rights reserved. MG36D102

Contents Programming Guide

5.7.3.5 Running a Trace 128

5.7.3.6 Polling 129

5.7.3.7 Canceling a Trace 129

5.7.3.8 Trace Visualization 129

5.7.3.9 Saving and Loading Data 130

5.7.3.10 Online and Oine Mode 131

5.7.3.11 Reports, Document Exporting, and Printing 131

5.7.3.12 Multi-device Scope 131

5.7.4 Drive Control (Servo Drive only) 132

5.7.5 Get Error History (Servo Drive and SAB) 136

5.7.6 Digital CAM Switch (Servo Drive only) 137

5.7.7 CAM Editor (Servo Drive only) 138

5.7.7.1 Menu Bar 138

5.7.7.2 Property Window 141

5.7.7.3 Toolbar 141

5.7.7.4 Wizards 141

5.7.7.5 CAM Prole Window Overview 143

5.7.7.6 Editing Basic CAM Proles 144

5.7.7.7 Editing Advanced CAM Proles 146

5.7.7.8 Standalone Emulation of the CAM Editor 157

5.7.8 CAM Prole Management 157

5.7.9 Touch Probe (Servo Drive only) 158

5.7.10 SAB Control (SAB only) 158

5.7.11 SAB ID Assignment via Ethernet POWERLINK® (SAB only) 159

6 Programming

6.1 ID Assignment

6.1.1 EtherCAT

6.1.2 Ethernet POWERLINK

6.1.2.1 Single Device ID Assignment 161

6.1.2.2 Multiple Device ID Assignment 161

6.2 Basic Programming

6.3 TwinCAT

6.3.1 Programming with TwinCAT

161

161

®

®

161

161

161

®

®

162

162

6.3.1.1 ISD Deliverables 162

6.3.1.2 Creating a TwinCAT® Project 162

6.3.1.3 Conguration as a TwinCAT® NC Axis 167

6.3.1.4 Connecting to the PLC 167

6.4 Automation Studio™

6.4.1 Programming with Automation Studio™

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 5

168

168

Contents

VLT® Integrated Servo Drive ISD® 510 System

6.4.1.1 Requirements 168

6.4.1.2 Creating an Automation Studio™ Project

6.4.1.3 Connecting to the PLC 172

6.5 Function Block Descriptions

6.5.1 Overview PLCopen

®

6.5.1.1 Naming Conventions 172

6.5.1.2 Structure of Library/Package 172

6.5.1.3 PLCopen® State Machine 172

6.5.2 General Input/Output Behavior 174

6.5.2.1 Function Blocks with Execute Input 174

6.5.2.2 Function Blocks with Enable Input 175

6.5.2.3 Error Indication 175

6.5.2.4 Technical Units in the PLC library 176

6.5.3 Programming Guidelines 176

6.5.4 Drive – Administrative 177

6.5.4.1 AXIS_REF_ISD51x 177

6.5.4.2 MC_Power_ISD51x 177

6.5.4.3 MC_Reset_ISD51x 178

168

172

172

6.5.4.4 MC_ReadStatus_ISD51x 179

6.5.4.5 MC_ReadAxisError_ISD51x 179

6.5.4.6 DD_ReadAxisWarning_ISD51x 180

6.5.4.7 DD_ReadVersion_ISD51x 180

6.5.4.8 DD_UpdateFirmware_ISD51x 181

6.5.4.9 MC_ReadAxisInfo_ISD51x 182

6.5.4.10 MC_ReadMotionState_ISD51x 182

6.5.4.11 MC_ReadActualPosition_ISD51x 183

6.5.4.12 MC_ReadActualVelocity_ISD51x 183

6.5.4.13 MC_ReadActualTorque_ISD51x 184

6.5.4.14 MC_ReadDigitalInput_ISD51x 185

6.5.4.15 DD_ReadAnalogInput_ISD51x 185

6.5.4.16 MC_ReadDigitalOutput_ISD51x 186

6.5.4.17 DD_WriteDigitalOutput_ISD51x 186

6.5.4.18 MC_ReadParameter_ISD51x and MC_ReadBoolParameter_ISD51x 187

6.5.4.19 DD_ReadParameter4_ISD51x 188

6.5.4.20 DD_ReadParameter_ISD51x 189

6.5.4.21 MC_WriteParameter_ISD51x 189

6.5.4.22 DD_WriteParameter_ISD51x 190

6.5.4.23 DD_WriteParameter4_ISD51x 190

6.5.4.24 DD_Trace_ISD51x 191

6.5.4.25 DD_BrakeHandling_ISD51x 193

6 Danfoss A/S © 01/2017 All rights reserved. MG36D102

Contents Programming Guide

6.5.4.26 DD_SelectControlParamSet_ISD51x 193

6.5.4.27 MC_TouchProbe_ISD51x 194

6.5.4.28 MC_AbortTrigger_ISD51x 195

6.5.4.29 DD_PrepareDigCamSwitch_ISD51x 195

6.5.4.30 DD_DigitalCamSwitch_ISD51x 196

6.5.4.31 DD_ProduceGuideValue_ISD51x 197

6.5.5 Drive – Motion 197

6.5.5.1 MC_Home_ISD51x 197

6.5.5.2 MC_Stop_ISD51x 200

6.5.5.3 MC_Halt_ISD51x 201

6.5.5.4 MC_MoveAbsolute_ISD51x 202

6.5.5.5 MC_MoveRelative_ISD51x 205

6.5.5.6 MC_MoveAdditive_ISD51x 207

6.5.5.7 MC_MoveVelocity_ISD51x 209

6.5.5.8 MC_TorqueControl_ISD51x 209

6.5.5.9 MC_GearIn_ISD51x 210

6.5.5.10 MC_GearInPos_ISD51x 210

6.5.5.11 DD_GetInertia_ISD51x 212

6.5.6 Drive – CAM Operation 212

6.5.6.1 MC_CamTableSelect_ISD51x 212

6.5.6.2 MC_CamIn_ISD51x 213

6.5.6.3 DD_CamScaling_ISD51x 214

6.5.6.4 DD_SetFollowSegment_ISD51x 215

6.5.6.5 DD_SetSegmentParameter_ISD51x 216

6.5.6.6 DD_RotationStop_ISD51x 216

6.5.6.7 DD_NodeNotication_ISD51x 217

6.5.6.8 DD_GoToSetpoint_ISD51x 217

6.5.6.9 DD_ReadCamInfo_ISD51x 218

6.5.7 Drive – CAM Creation 218

6.5.7.1 Basic CAM 218

6.5.8 SAB 221

6.5.8.1 SAB_REF 221

6.5.8.2 DD_Power_SAB 221

6.5.8.3 DD_Reset_SAB 222

6.5.8.4 DD_ReadSabInfo_SAB 222

6.5.8.5 DD_ReadSabError_SAB 223

6.5.8.6 DD_ReadSabWarning_SAB 223

6.5.8.7 DD_ReadVersion_SAB 224

6.5.8.8 DD_UpdateFirmware_SAB 224

6.5.8.9 DD_ReadDcLinkPower_SAB 225

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 7

Contents

VLT® Integrated Servo Drive ISD® 510 System

6.5.8.10 DD_ReadDcLinkVoltage_SAB 225

6.5.8.11 DD_ReadParameter4_SAB 226

6.5.8.12 DD_ReadParameter_SAB 226

6.5.8.13 DD_WriteParameter4_SAB 227

6.5.8.14 DD_WriteParameter_SAB 228

6.5.8.15 DD_Trace_SAB 228

6.5.8.16 DD_SimulateGuideValue_SAB 229

6.5.8.17 DD_ReadPosGuideValueRef_SAB 230

6.5.8.18 DD_ReadVelGuideValueRef_SAB 231

6.6 Simple Programming Template

7 Servo Drive Parameter Description

7.1 Overview

7.2 Controlword Object

7.2.1 Parameter 16-00 Controlword (0x6040) 232

7.2.1.1 Controlword in Prole Position Mode 233

7.2.1.2 Controlword in Prole Velocity Mode 234

7.2.1.3 Controlword in Prole Torque Mode 234

7.2.1.4 Controlword in Homing Mode 235

7.2.1.5 Controlword in CAM Mode 235

7.2.1.6 Controlword in Gear Mode 236

7.2.1.7 Controlword in ISD Inertia Measurement Mode 236

7.2.1.8 Controlword in Cyclic Synchronous Position Mode 236

7.2.1.9 Controlword in Cyclic Synchronous Velocity Mode 237

7.3 Statusword Object

7.3.1 Parameter 16-03 Statusword (0x6041) 237

7.3.1.1 Statusword in Prole Position Mode 239

231

232

232

232

237

7.3.1.2 Statusword in Prole Velocity Mode 239

7.3.1.3 Statusword in Prole Torque Mode 240

7.3.1.4 Statusword in Homing Mode 240

7.3.1.5 Statusword in CAM Mode 241

7.3.1.6 Statusword in Gear Mode 241

7.3.1.7 Statusword in ISD Inertia Measurement Mode 242

7.3.1.8 Statusword in Cyclic Synchronous Position Mode 242

7.3.1.9 Statusword in Cyclic Synchronous Velocity Mode 243

7.4 Factor Group Objects

7.4.1 Parameters 55-00 and 55-01: Position Encoder Resolution (0x608F) 243

7.4.2 Parameters 55-10 and 55-11: Gear Ratio (0x6091) 244

7.4.3 Parameters 55-20 and 55-21: Feed Constant (0x6092) 245

7.4.4 Parameters 55-30 and 55-31: Velocity Factor (0x6096) 246

7.4.5 Parameters 55-40 and 55-41: Acceleration Factor (0x6097) 246

8 Danfoss A/S © 01/2017 All rights reserved. MG36D102

243

Contents Programming Guide

7.5 Commonly Used Objects

7.5.1 Parameter 52-00: Modes of Operation (0x6060) 247

7.5.2 Parameter 52-01: Modes of Operation Display (0x6061) 248

7.5.3 Parameter: Supported Drive Modes (0x6502) 248

7.5.4 Parameter 50-16: Maximum Prole Velocity (0x607F) 249

7.5.5 Parameter 52-37: Maximum Motor Speed (0x6080) 249

7.5.6 Parameter 52-12: Prole Velocity (0x6081) 250

7.5.7 Parameter 50-11: Prole Acceleration (0x6083) 250

7.5.8 Parameter 50-12: Prole Deceleration (0x6084) 251

7.5.9 Parameter 50-13: Quick Stop Deceleration (0x6085) 251

7.5.10 Parameter 50-14: Maximum Acceleration (0x60C5) 252

7.5.11 Parameter 50-15: Maximum Deceleration (0x60C6) 252

7.5.12 Parameter: Maximum Torque (0x6072) 253

7.5.13 Parameters 52-15, 52-23, and 52-36: Application Torque Limit (0x2053) 253

7.6 Control Parameters

7.6.1 Parameter 51-07 to 51-09: Used Task Cycle Times (0x201D) 254

7.6.2 Parameter 51-01: Control Parameter Blending Time (0x201B) 255

247

254

7.6.3 Parameter 51-00: Control Parameter Usage (0x201C) 255

7.6.4 Position Controller 255

7.6.4.1 Parameters 51-16 and 51-17: Position Controller Parameters (0x2013) 255

7.6.4.2 Parameters 51-26 and 51-27: Position Controller Parameters 2 (0x2015) 256

7.6.5 Speed Controller 257

7.6.5.1 Parameters 51-10 to 51-15: Speed Controller Parameters (0x2012) 257

7.6.5.2 Parameters 51-20 to 51-25: Speed Controller Parameters 2 (0x2014) 258

7.7 Positions and Oset Objects

7.7.1 Parameter: Position Demand Value (0x6062) 260

7.7.2 Parameter: Position Demand Internal Value (0x60FC) 260

7.7.3 Parameter: Drive Position (0x2022) 261

7.7.4 Parameter: Position Actual Internal Value (0x6063) 261

7.7.5 Parameter 50-03: Position Actual Value (0x6064) 262

7.7.6 Parameters 50-30 and 50-31: Position Range Limit (0x607B) 262

7.7.7 Parameters 50-32 and 50-33: Software Position Limit (0x607D) 263

7.7.8 Parameters 51-02, 52-04, and 52-49: Application Settings (0x2016) 264

7.8 Guide Value Objects

260

265

7.8.1 Parameter: Position Guide Value (0x2060) 265

7.8.2 Parameter: Velocity Guide Value (0x2064) 266

7.8.3 Parameter: Guide Value Option Code (0x2061) 266

7.8.4 Parameter: Guide Value Scaling Factor (0x3808) 267

7.8.5 Parameter: Guide Value Oset (0x3806) 268

7.9 Guide Value Reference Objects

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 9

269

Contents

VLT® Integrated Servo Drive ISD® 510 System

7.9.1 Parameter: Position Guide Value Reference (0x2062) 269

7.9.2 Parameter: Velocity Guide Value Reference (0x2065) 269

7.9.3 Parameter: Guide Value Reference Option Code (0x2063) 269

7.9.4 Parameter: Position Guide Value Reference Set (0x2068) 270

7.9.5 Parameter: Guide Value Plausibility Distance (0x2067) 271

7.9.6 Guide Value Reference Simulation 271

7.9.6.1 Parameter: Guide Value Reference Simulation Control (0x2070) 271

7.9.6.2 Parameter: Guide Value Reference Speed Limit (0x2071) 272

7.9.6.3 Parameter: Guide Value Reference Target Velocity (0x2072) 272

7.9.6.4 Parameter: Guide Value Reference Acceleration (0x2073) 272

7.9.6.5 Parameter: Guide Value Reference Deceleration (0x2074) 273

7.10 Prole Position Mode Objects

7.10.1 Parameter 52-10: Target Position (0x607A) 273

7.10.2 Parameter 52-16: End Velocity (0x6082) 274

7.10.3 Parameter: Positioning Option Code (0x60F2) 274

7.10.4 Parameter: Position Window (0x6067) 277

7.10.5 Parameter: Position Window Time (0x6068) 277

7.11 Prole Velocity Mode Objects

7.11.1 Parameter 52-20: Target Velocity (0x60FF) 277

7.11.2 Parameter: Velocity Demand Value (0x606B) 278

7.11.3 Parameter 50-04: Velocity Actual Value (0x606C) 278

7.11.4 Parameter: Velocity Window (0x606D) 279

7.11.5 Parameter: Velocity Window Time (0x606E) 279

7.12 Prole Torque Mode Objects

7.12.1 Parameter 52-30: Target Torque (0x6071) 279

7.12.2 Parameter: Torque Demand (0x6074) 280

7.12.3 Parameter 50-20: Motor Rated Current (0x6075) 280

7.12.4 Parameter 50-21: Motor Rated Torque (0x6076) 280

273

277

279

7.12.5 Parameter 52-31: Torque Actual Value (0x6077) 281

7.12.6 Parameter 16-14: Current Actual Value (0x6078) 281

7.12.7 Parameter 52-32: Torque Slope (0x6087) 282

7.12.8 Parameter: Torque Window (0x2050) 282

7.12.9 Parameter: Torque Window Time (0x2051) 282

7.13 Homing Mode Objects

283

7.13.1 Parameter 52-40: Home Oset (0x607C) 283

7.13.2 Parameter 52-41: Homing Method (0x6098) 283

7.13.3 Parameters 52-42 and 52-43: Homing Speeds (0x6099) 284

7.13.4 Parameter 52-44: Homing Acceleration (0x609A) 284

7.13.5 Parameter 52-50 to 52-57: Supported Homing Methods (0x60E3) 285

7.13.6 Parameter 52-45 to 52-48: Additional Homing objects (0x2040) 287

10 Danfoss A/S © 01/2017 All rights reserved. MG36D102

Contents Programming Guide

7.14 CAM Mode Objects

7.14.1 Parameter: CAM Prole Memory Layout (0x380F) 288

7.14.2 Parameter: CAM Status (0x3801) 289

7.14.3 Parameter: CAM Control (0x3800) 290

7.14.4 Parameters: CAM Prole 1–8 (0x3810–0x3817) 291

7.14.5 Parameters: CAM Data 1–8 (0x3820–3827) 301

7.14.6 Parameters: CAM Pattern 1–8 (0x3830–3837) 301

7.14.7 Parameter: CAM Prole Selector (0x3804) 302

7.14.8 Parameter: CAM Prole Status (0x3805) 303

7.14.9 Parameter: CAM Slave Oset (0x3807) 304

7.14.10 Parameter: CAM Slave Scaling (0x3809) 305

7.14.11 Parameter: Minimum Blending Distance (0x380A) 306

7.14.12 Parameter: Logical CAM Position (0x2020) 307

7.14.13 Parameter: Logical CAM Set Point (0x2021) 307

7.14.14 Parameter: Active Segment ID (0x2019) 307

7.14.15 Parameter: Last Node ID (0x201A) 308

7.14.16 Parameter: Logged Values (0x3870) 308

288

7.14.17 Parameter: Digital Input Counters (0x3860) 309

7.15 Gear Mode Objects

7.15.1 Parameter: Gear Ratio (0x3900) 309

7.15.2 Parameter: Gear Synchronization Option Code (0x3901) 310

7.15.3 Parameter: Gear Master Start Distance (0x3902) 311

7.15.4 Parameter: Gear Master Sync Position (0x3903) 312

7.15.5 Parameter: Gear Slave Sync Position (0x3904) 312

7.16 ISD Inertia Measurement Objects

7.16.1 Parameter 52-60: Measured Inertia (0x2009) 313

7.16.2 Parameters 52-61 and 52-62: Inertia Measurement Parameters (0x200A) 314

7.17 Digital CAM Switch Objects

7.17.1 Parameter: On Compensation (0x3840) 314

7.17.2 Parameter: O Compensation (0x3841) 315

7.17.3 Parameter: Hysteresis (0x3842) 315

7.17.4 Parameters: Digital CAM Switch Parsing Control (0x3843) 316

7.17.5 Parameter: Digital CAM Switches Data (0x3844) 318

7.18 Touch Probe Objects

309

313

314

318

7.18.1 Parameter: Touch Probe Function (0x60B8) 318

7.18.2 Parameter: Touch Probe Status (0x60B9) 319

7.18.3 Parameter 51-51: Touch Probe 1 Positive Edge (0x60BA) 320

7.18.4 Parameter 51-54: Touch Probe 1 Negative Edge (0x60BB) 321

7.18.5 Parameter 51-61: Touch Probe 2 Positive Edge (0x60BC) 321

7.18.6 Parameter 51-64: Touch Probe 2 Negative Edge (0x60BD) 321

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 11

Contents

VLT® Integrated Servo Drive ISD® 510 System

7.18.7 Parameters 51-50 and 51-60: Touch Probe Source (0x60D0) 322

7.18.8 Parameter: First Position (0x3853) 322

7.18.9 Parameter: Last Position (0x3854) 323

7.18.10 Parameter 51-53: Touch Probe Time Stamp 1 Positive Value (0x60D1) 324

7.18.11 Parameter 51-56: Touch Probe Time Stamp 1 Negative Value (0x60D2) 324

7.18.12 Parameter 51-63: Touch Probe Time Stamp 2 Positive Value (0x60D3) 324

7.18.13 Parameter 51-66: Touch Probe Time Stamp 2 Negative Value (0x60D4) 325

7.18.14 Parameter 51-52: Touch Probe 1 Positive Edge Counter (0x60D5) 325

7.18.15 Parameter 51-55: Touch Probe 1 Negative Edge Counter (0x60D6) 326

7.18.16 Parameter 51-62: Touch Probe 2 Positive Edge Counter (0x60D7) 326

7.18.17 Parameter 51-65: Touch Probe 2 Negative Edge Counter (0x60D8) 327

7.19 Tracing Objects

7.19.1 Parameter: Signal Tracer Control (0x5000) 327

7.19.2 Parameter: Signal Trace Channel IDs (0x5001) 329

7.19.3 Parameter: Trace Data (0x5002) 330

7.19.4 Parameter: Trace Signal Info (0x5004) 330

7.20 Option Code Objects

7.20.1 Parameter 50-41: Fault Reaction Option Code (0x605E) 331

7.20.2 Parameter 50-42: Target Reached Option Code (0x2054) 331

7.20.3 Parameter 50-43: Following Error Option Code (0x2055) 332

7.20.4 Parameter 50-44: Enable in Positioning Option Code (0x2052) 333

7.20.5 Parameter 50-45: Abort Connection Option Code (0x6007) 333

7.20.6 Parameter 50-46: Quick Stop Option Code (0x605A) 334

7.20.7 Parameter 50-47: Halt Option Code (0x605D) 334

7.20.8 Parameter 50-48: Shutdown Option Code (0x605B) 335

7.20.9 Parameter 50-49: Disable Operation Option Code (0x605C) 335

7.21 Peripherals

7.21.1 Parameter 16-60: Digital Inputs (0x60FD) 336

327

331

336

7.21.2 Parameters 16-62 and 16-64: Analog Inputs (0x200D) 337

7.21.3 Parameter: Dual Analog User Inputs Conguration (0x200F) 337

7.21.4 Parameter 16-66: Digital Outputs (0x60FE) 338

7.21.5 Parameter 52-05: Digital Output Conguration (0x2FFF) 339

7.21.6 External Encoder Objects 340

7.21.6.1 Parameters 51-30 and 51-34 to 51-40: External Encoder Conguration

(0x3000) 340

7.21.6.2 Parameter 51-32 and 51-33: External Encoder (0x2011) 342

7.21.6.3 Parameter 51-31: External Encoder Enable (0x3001) 343

7.22 Monitoring Objects

343

7.22.1 Following Error Detection Objects 343

7.22.1.1 Parameter: Following Error Window (0x6065) 343

12 Danfoss A/S © 01/2017 All rights reserved. MG36D102

Contents Programming Guide

7.22.1.2 Parameter: Following Error Time Out (0x6066) 344

7.22.1.3 Parameter: Following Error Actual Value (0x60F4) 344

7.22.2 Standstill Detection Objects 345

7.22.2.1 Parameter: Velocity Threshold (0x606F) 345

7.22.2.2 Parameter: Velocity Threshold Time (0x6070) 345

7.22.3 Constant Velocity Detection Objects 346

7.22.3.1 Parameter 51-70: Constant Velocity Window (0x2030) 346

7.22.3.2 Parameter 51-71: Constant Velocity Window Time (0x2031) 346

7.22.4 Parameters 15-40, 15-41, and 15-43: Version log (0x4000) 346

7.22.5 Parameter 15-51: Serial String (0x4004) 348

7.22.6 Parameters 12-00 to 12-05: Communication Settings (0x400A) 349

7.22.7 Parameters 15-01 and 15-02: Total Running Time (0x5807) 350

7.22.8 Parameter 50-09: STO Voltage and Brake Status (0x2007) 351

7.22.9 Parameter 15-30: Error Code (0x603F) 352

7.22.10 Parameter 16-92: Warning Code (0x5FFE) 352

7.22.11 Parameter: Control Source (0x5020) 352

7.22.12 Parameter 50-08: Motion and Input Status (0x2006) 353

7.22.13 Parameter 50-07: Overlaying Motion Status (0x2005) 354

7.22.14 Parameter: Physical Limits (0x5100) 354

7.22.15 Voltage Objects 356

7.22.15.1 Parameter 16-30: DC Link Voltage (0x2003) 356

7.22.15.2 Parameter 50-06: Auxiliary Voltage (0x200E) 356

7.22.16 Parameter 16-19, 16-31, 16-34, 16-39: Temperature (0x2000) 356

8 SAB Parameter Description

8.1 Object 0x4040: Controlword

8.2 Object 0x4041: Statusword

8.3 Object 0x2000: SAB Temperatures

8.4 Object 0x2001: DC-link Related Values

8.5 Object 0x2003: U

8.6 Object 0x2008: ISD Power Consumption

8.7 Object 0x2009: Fan Speed Power Card

8.8 Object 0x200D: Relay 1 Control

Related Values

AUX

358

358

358

359

359

360

360

361

361

8.9 Object 0x200E: Relay 2 Control

8.10 Object 0x2030: Brake Control

8.10.1 Object 0x2030: Brake Control 362

8.11 Object 0x2031: Brake Resistor

8.12 Object 0x2032: Brake Resistor Power Limit

8.13 Object 0x2033: Brake Resistor Power Monitoring

8.14 Object 0x2034: Brake Check

8.15 Object 0x2035: Brake Duty Cycle Monitoring

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 13

361

362

362

362

362

363

363

Contents

VLT® Integrated Servo Drive ISD® 510 System

8.16 Object 0x2036: Brake Resistor Power 120 s

8.17 Object 0x2062: Position Guide Value Reference

8.18 Object 0x2063: Guide Value Reference Option Code

8.19 Object 0x2065: Velocity Guide Value Reference

8.20 Object 0x2068: Position Guide Value Reference Set

8.21 Object 0x2070: Guide Value Reference Simulation Control

8.22 Object 0x2071: Guide Value Reference Speed Limit

8.23 Object 0x2072: Guide Value Reference Target Velocity

8.24 Object 0x2073: Guide Value Reference Acceleration

8.25 Object 0x2074: Guide Value Reference Deceleration

8.26 Object 0x3000: External Encoder Conguration

8.27 Object 0x3001: External Encoder Enable

8.28 Object 0x4004: Serial String

8.29 Object 0x400A: Communication Settings

8.30 Object 0x5020: Control Source

8.31 Object 0x5807: Total Running Time

8.32 Object 0x503F: Error Code

363

363

363

363

363

363

364

364

364

364

364

364

364

364

365

365

366

8.33 Object 0x5FFE: Warning Code

9 Diagnostics

9.1 System Monitoring

9.2 Drive

9.2.1 Troubleshooting 367

9.2.2 Error Codes 368

9.2.3 Trace Signals 370

9.3 SAB

9.3.1 Troubleshooting 372

9.3.2 Warnings and Alarms 374

9.3.3 Trace Signals 377

9.4 Operating Status Indicators

9.4.1 Operating LEDs on the Servo Drive 378

9.4.2 Operating LEDs on the Servo Access Box 378

10 Appendix

10.1 Glossary

366

367

367

367

372

378

380

380

10.2 General XML Conventions

Index

14 Danfoss A/S © 01/2017 All rights reserved. MG36D102

381

383

Introduction Programming Guide

1 Introduction

1.1 Purpose of the Programming Guide

The purpose of this programming guide is to describe the

programming of the VLT® Integrated Servo Drive ISD® 510

System.

This programming guide contains information about:

Software installation

•

Programming

•

Operation

•

Applications

•

Troubleshooting

•

This programming guide is intended for use by qualied

personnel. Read the document in full in order to use the

servo system safely and professionally, and pay particular

attention to the safety instructions and general warnings.

This programming guide is an integral part of the ISD 510

servo system so keep it available with the servo system at

all times.

Compliance with the information in this document is a

prerequisite for:

Trouble-free operation

•

Recognition of product liability claims

•

Therefore, read this document before working with the

servo system.

Additional Resources

1.2

Available manuals for the VLT® Integrated Servo Drive ISD

510 System:

Software

1.4

The software for the ISD 510 servo system comprises:

The rmware of the VLT® Integrated Servo Drive

•

ISD® 510 that is already installed on the device.

rmware of the VLT® Servo Access Box that is

The

•

already installed on the device.

A package of PLC libraries for Automation

•

Studio™ for operating the ISD 510 devices (see

chapter 6.4.1 Programming with Automation

Studio™ for further information).

A PLC library for TwinCAT® 2 for operating the

•

ISD 510 devices (see chapter 6.3.1 Programming

®

with TwinCAT

ISD Toolbox: A Danfoss PC-based software tool for

•

commissioning and debugging the devices.

for further information).

1.4.1 Software Version

This programming guide can be used for the following

software versions onwards:

ISD 510 Servo Drive: Version 1.4.0

•

Servo Access Box (SAB): Version 1.2.0

•

ISD Toolbox: Version 2.0

•

PLC libraries (Powerlink / EtherCAT): Version 1.0

•

The software version number can be read from object

0x4000 (see chapter 7.22.4 Parameters 15-40, 15-41, and

15-43: Version log (0x4000)).

®

1.4.2 Firmware Updates

1 1

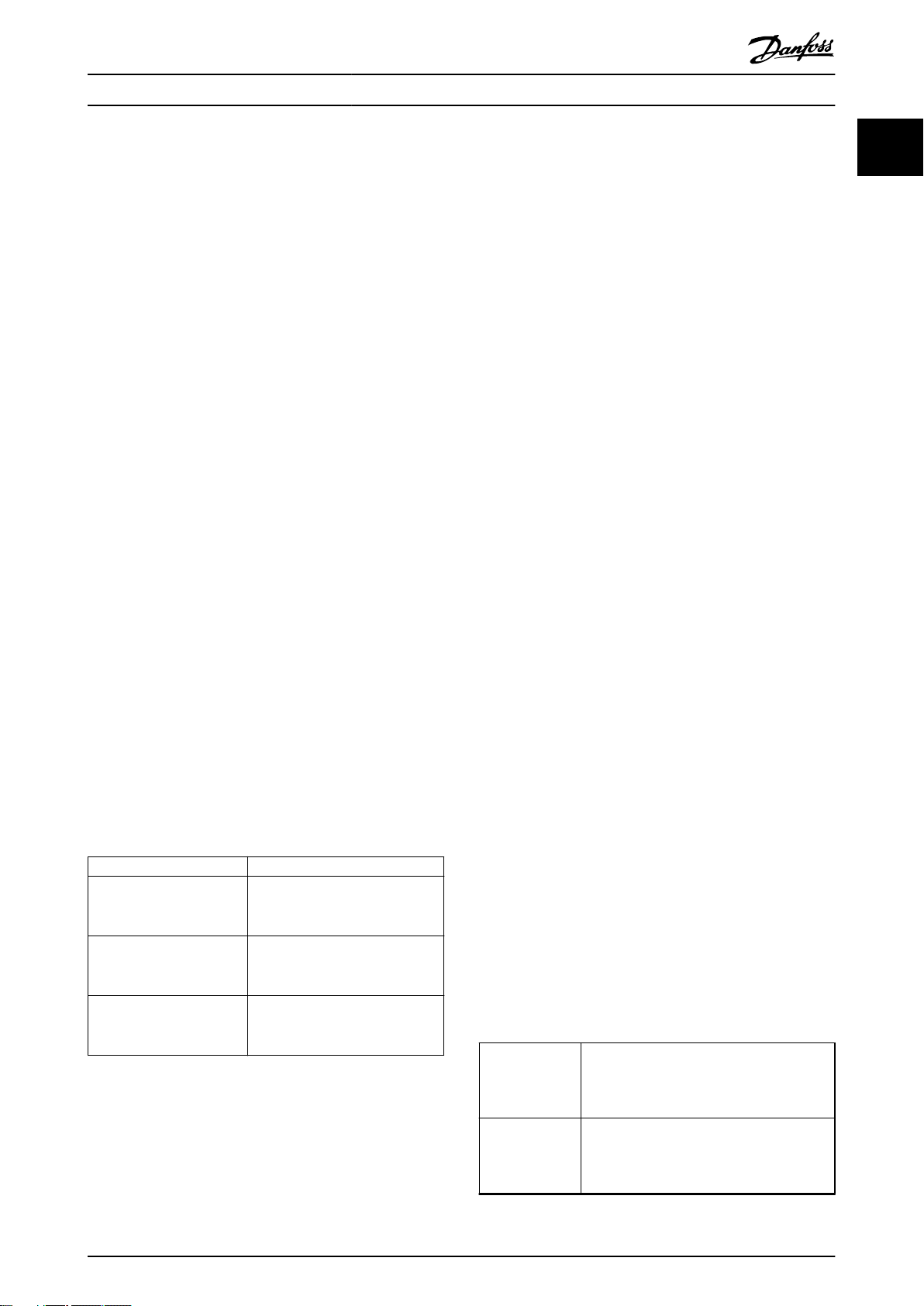

Document Contents

VLT® Integrated Servo Drive

ISD® 510 System Operating

Instructions

VLT® Integrated Servo Drive

ISD® 510 System Design

Guide

VLT® Integrated Servo Drive

ISD® 510 System

Programming Guide

Table 1.1 Available Manuals for the ISD 510 Servo System

Technical literature for Danfoss drives is also available

online at drives.danfoss.com/knowledge-center/technical-

documentation/.

Copyright

1.3

VLT®, ISD®, and SAB® are Danfoss registered trademarks.

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 15

Information about the installation,

commissioning, and operation of

the ISD 510 servo system.

Information about the set-up of

the ISD 510 servo system and

detailed technical data.

Information about the

programming of the ISD 510 servo

system.

Firmware updates may be available. When rmware

updates are available, they can be downloaded from the

danfoss.com website. Use the ISD Toolbox software to

install the rmware in the servo drives.

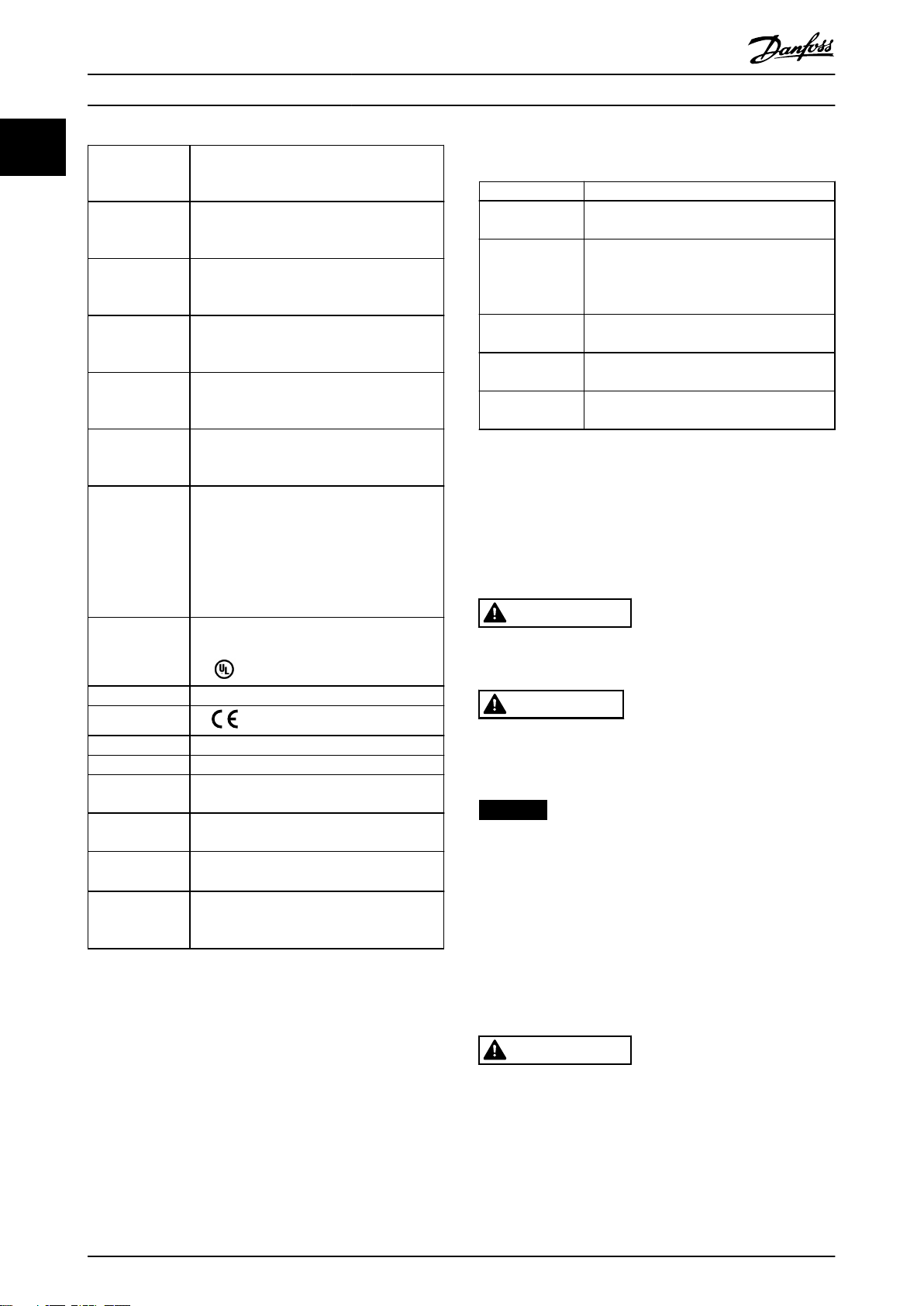

Approvals and Certications

1.5

The ISD 510 servo system fullls the standards listed in

Table 1.2.

IEC/EN 61800-3 Adjustable speed electrical power drive

systems.

Part 3: EMC requirements and specic test

methods.

IEC/EN 61800-5-1 Adjustable speed electrical power drive

systems.

Part 5-1: Safety requirements – Electrical,

thermal and energy.

Introduction

VLT® Integrated Servo Drive ISD® 510 System

11

IEC/EN 61800-5-2 Adjustable speed electrical power drive

systems.

Part 5-2: Safety requirements – Functional.

IEC/EN 61508 Functional safety of electrical/electronical/

programmable electronic safety-related

systems.

EN ISO 13849-1 Safety of machinery – Safety-related parts of

control systems.

Part 1: General principles for design.

EN ISO 13849-2 Safety of machinery – Safety-related parts of

control systems.

Part 2: Validation.

IEC/EN 60204-1 Safety of machinery – Electrical equipment of

machines.

Part 1: General requirements.

IEC/EN 62061 Safety of machinery – Functional safety of

safety-related electrical, electronic, and

programmable electronic control systems.

IEC/EN 61326-3-1 Electrical equipment for measurement,

control, and laboratory use – EMC

requirements.

Part 3-1: Immunity requirements for safetyrelated systems and for equipment intended

to perform safety-related functions (functional

safety) – General industrial applications.

UL508C UL Standard for Safety for Power Conversion

Equipment.

Terminology

1.6

ISD Integrated servo drive

ISD 510 Servo

Drive

VLT® Servo Access

Box (SAB)

PLC External device for controlling the ISD 510

Loop cable Hybrid cable for connecting drives in daisy-

Feed-in cable Hybrid cable for connection from the SAB to

Table 1.3 Terminology

Decentral servo drive

Unit that generates the DC-link voltage and

passes the U

signals to the ISD 510 servo drives via a

hybrid cable.

servo system.

chain format.

the 1st servo drive.

, Real-Time Ethernet, and STO

AUX

An explanation of all terminology and abbreviations can be

found in chapter 10.1 Glossary.

1.7 Safety

The following symbols are used in this guide:

WARNING

Indicates a potentially hazardous situation that could

result in death or serious injury.

2006/42/EC Machinery Directive

CE

2014/30/EU EMC Directive

2014/35/EU Low Voltage Directive

RoHS

(2002/95/EC)

EtherCAT

Ethernet

POWERLINK

PLCopen

®

®

Table 1.2 Approvals and Certications

Restriction of hazardous substances.

Ethernet for Control Automation Technology.

Ethernet-based eldbus system.

Ethernet-based eldbus system:

®

Technical specication.

Function blocks for motion control (formerly

Part 1 and Part 2) Version 2.0 March 17, 2011.

CAUTION

Indicates a potentially hazardous situation that could

result in minor or moderate injury. It can also be used to

alert against unsafe practices.

NOTICE

Indicates important information, including situations that

can result in damage to equipment or property.

The following safety instructions and precautions relate to

the ISD 510 servo system.

Read the safety instructions carefully before starting to

work in any way with the ISD 510 servo system or its

components.

Pay particular attention to the safety instructions in the

relevant sections of this manual.

WARNING

HAZARDOUS SITUATION

If the servo drive, SAB, or the bus lines are incorrectly

connected, there is a risk of death, serious injury, or

damage to the unit.

Always comply with the instructions in this manual and

national and local safety regulations.

16 Danfoss A/S © 01/2017 All rights reserved. MG36D102

Introduction Programming Guide

WARNING

GROUNDING HAZARD

The ground leakage current is >3.5 mA. Improper

grounding of the ISD 510 servo system components may

result in death or serious injury.

For reasons of operator safety, ground the

•

components of the ISD 510 servo system

correctly in accordance with national or local

electrical regulations and the information in this

manual.

WARNING

HIGH VOLTAGE

The ISD 510 servo system contains components that

operate at high voltage when connected to the electrical

supply network.

A hazardous voltage is present on the servo drives and

the SAB whenever they are connected to the mains

network.

There are no indicators on the servo drive or SAB that

indicate the presence of mains supply.

Incorrect installation, commissioning, or maintenance can

lead to death or serious injury.

Installation, commissioning, and maintenance

•

may only be performed by qualied personnel.

WARNING

UNINTENDED START

The ISD 510 servo system contains servo drives and the

SAB that are connected to the electrical supply network

and can start running at any time. This may be caused

by a eldbus command, a reference signal, or clearing a

fault condition. Servo drives and all connected devices

must be in good operating condition. A decient

operating condition may lead to death, serious injury,

damage to equipment, or other material damage when

the unit is connected to the electrical supply network.

Take suitable measures to prevent unintended

•

starts.

WARNING

DISCHARGE TIME

The servo drives and the SAB contain DC-link capacitors

that remain charged for some time after the mains

supply is switched o at the SAB. Failure to wait the

specied time after power has been removed before

performing service or repair work could result in death

or serious injury.

To avoid electrical shock, fully disconnect the

•

SAB from the mains and wait for at least the

time listed in Table 1.4 for the capacitors to fully

discharge before carrying out any maintenance

or repair work on the ISD 510 servo system or

its components.

Number Minimum waiting time (minutes)

0–64 servo drives 10

Table 1.4 Discharge Time

NOTICE

Never connect or disconnect the hybrid cable to or from

the servo drive when the ISD 510 servo system is

connected to mains or auxiliary supply, or when voltage

is still present. Doing so damages the electronic circuitry.

Ensure that the mains supply is disconnected and the

required discharge time for the DC-link capacitors has

elapsed before disconnecting or connecting the hybrid

cables or disconnecting cables from the SAB.

NOTICE

Full safety warnings and instructions are detailed in the

VLT® Integrated Servo Drive ISD 510 System Operating

Instructions.

1 1

WARNING

UNINTENDED MOVEMENT

Unintended movement may occur when parameter

changes are carried out immediately, which may result in

death, serious injury, or damage to equipment.

When changing parameters, take suitable

•

measures to ensure that unintended movement

cannot pose any danger.

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 17

Servo Drive Operation

VLT® Integrated Servo Drive ISD® 510 System

2 Servo Drive Operation

22

2.1 Overview

The CiA CANopen standard DS402 Drives and Motion

Control Device Prole is supported by both Ethernet

POWERLINK® and EtherCAT®.

2.2 Firmware Update

The products are delivered with the most recent

version. See chapter 1.4.2 Firmware Updates for information

on upgrading.

The servo drive rmware can be updated via the eldbus.

The download of new rmware is only allowed in the

unpowered drive state Switch on disabled. If the servo drive

is in another state, the transfer is refused. While the update

is in progress, the servo drive signals the warning Firmware

update in progress. After nishing, the servo drive signals

the warning Firmware update occurred. Power cycle the

servo drive to resume normal operation.

If the servo drive state machine is switched to another

state than Switch on disabled after the rmware update has

begun (that is, during le transfer or after ashing without

a power-cycle), the servo drive switches to state Fault. This

error indicates that a power-cycle is needed before the

servo drive can resume operation. If, for example, a power

failure occurs during upgrading, the servo drive remains in

a state that allows the update process to resume. The

currently installed version can be read from object 0x4000

(see chapter 7.22.4 Parameters 15-40, 15-41, and 15-43:

Version log (0x4000)).

rmware

NOTICE

To change the supported eldbus, update to the

corresponding rmware. After changing the eldbus, the

original product code is no longer valid.

18 Danfoss A/S © 01/2017 All rights reserved. MG36D102

Start

Not ready to

switch on

Switch on

disabled

Fault

Fault reaction

active

Ready to

switch on

Switched on

Operation

enabled

Quick stop

active

0

1

2 7

8 9

63

4 5

16

11

10

12

13

15

14

130BF157.10

Servo Drive Operation Programming Guide

2.3 Basic Operation

2.3.1 State Machine

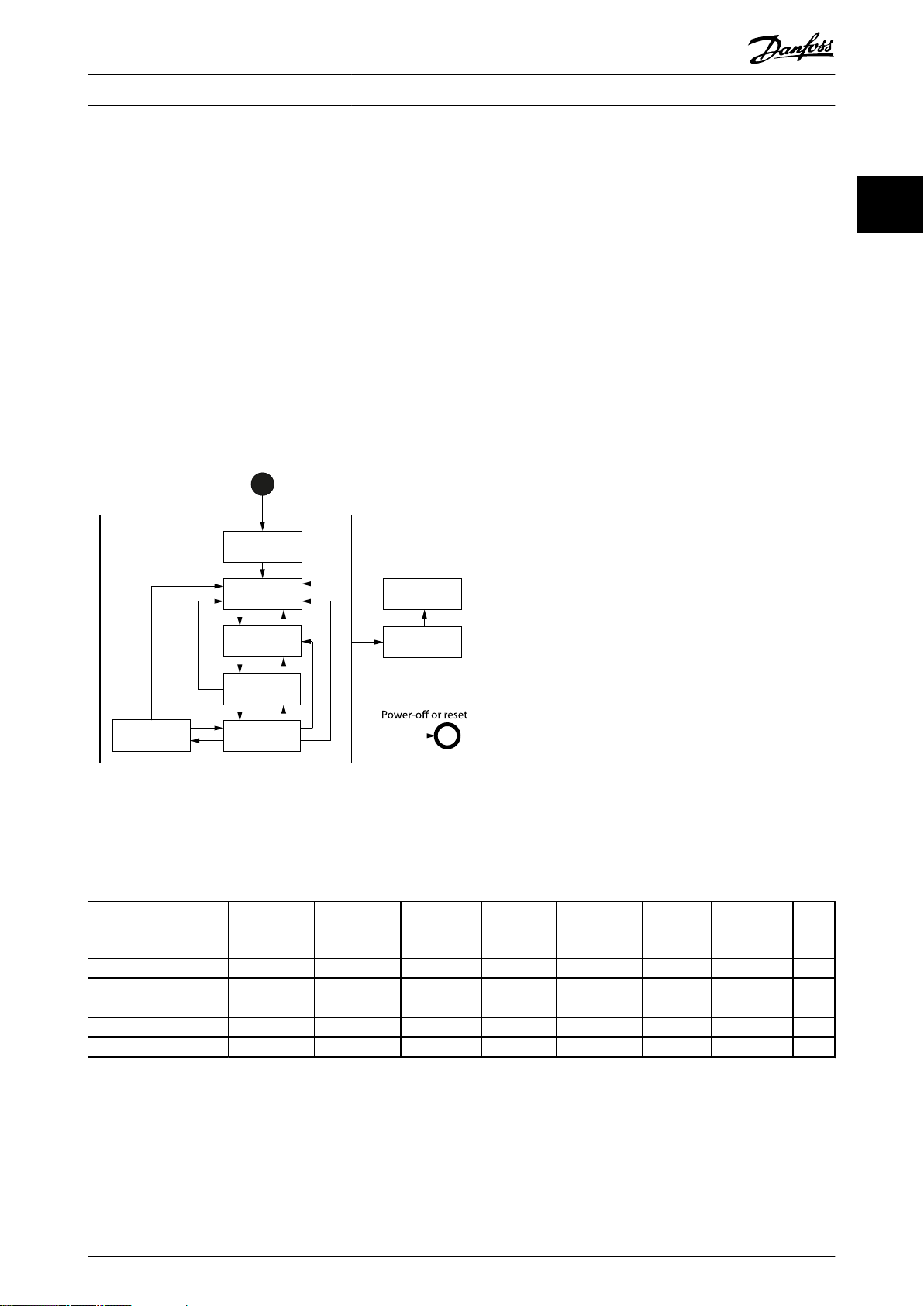

The servo drive uses the state machine described in the CiA DS402 standard. The state machine is operated either locally via

the LCP or remotely via the network.

The state machine is operated by local signals and by the Controlword sent over the eldbus. The state of the state machine

is reported by the Statusword produced by the servo drive.

A single state represents a special internal or external behavior. The state of the state machine also determines which

commands are accepted.

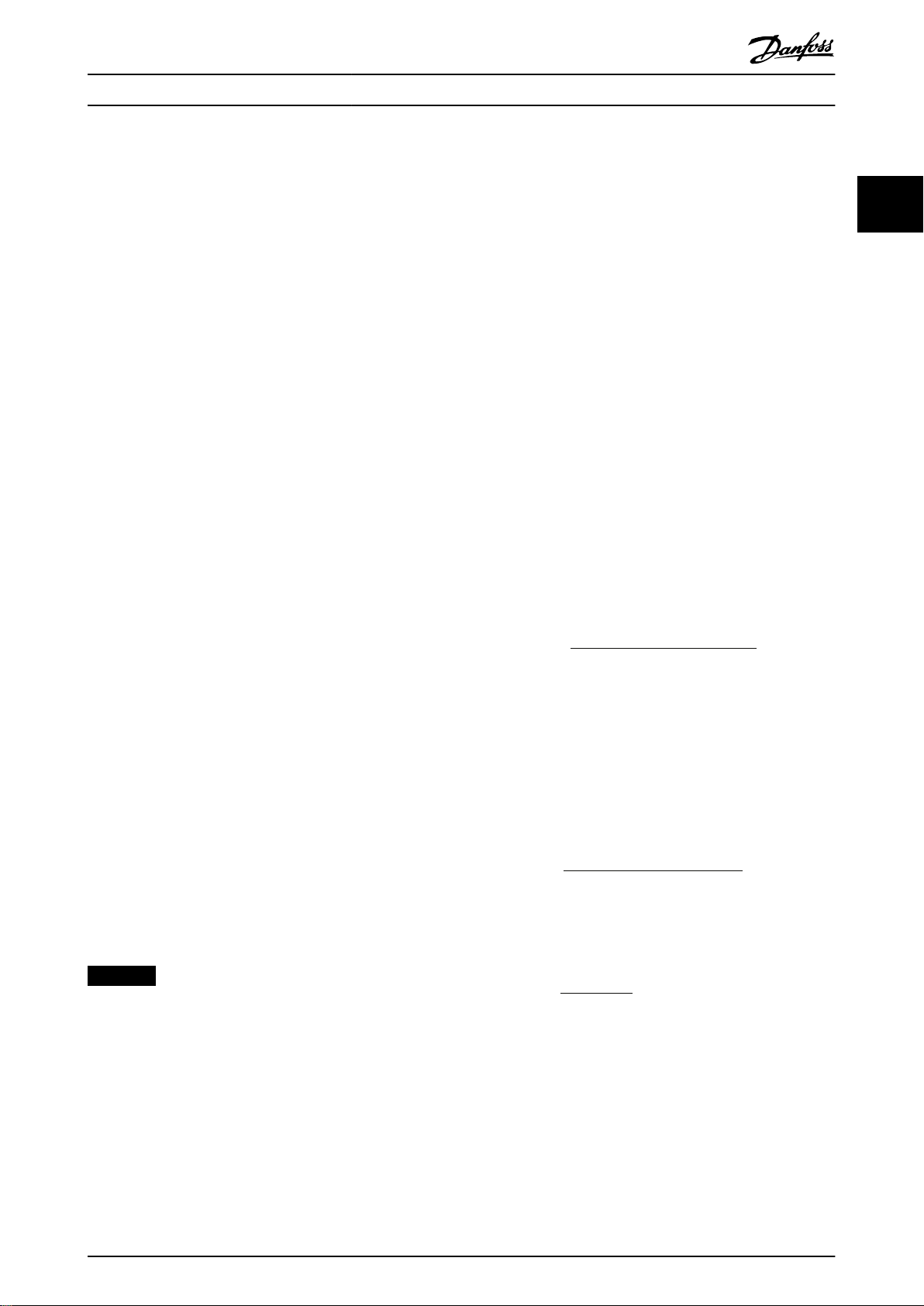

Illustration 2.1 shows the state machine of the servo drive with regard to control of the power electronics as a result of

commands and internal servo drive faults.

2 2

Illustration 2.1 DS402 State Machine

The states support the functions shown in Table 2.1. The Start state is a pseudo state indicating the start when the state

machine is activated during the start-up sequence of the device drives application software.

Function

Brake applied, if present Yes Yes Yes Yes No No No Yes

Low-level power applied Yes Yes Yes Yes Yes Yes Yes Yes

High-level power applied Yes/no Yes/no Yes/no Yes Yes Yes Yes Yes/no

Drive function enabled No No No No Yes Yes Yes No

Conguration allowed Yes Yes Yes Yes Yes Yes Yes Yes

Table 2.1 DS402 States and Supported Functions

Quick stop active state is implemented, which is optional according to the standard. When entering this state, the behavior

of the servo drive is according to the option code

Option Code (0x605A)).

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 19

Not ready to

switch on

Switch on

disabled

Ready to

switch on

Switched on

Operation

enabled

Quick stop

active

dened in object 0x605A (see chapter 7.20.6 Parameter 50-46: Quick Stop

Fault

reaction

active

Fault

Servo Drive Operation

VLT® Integrated Servo Drive ISD® 510 System

The transition from state Quick stop active to state Operation enabled (Transition 16 in Illustration 2.1) is not available, as

recommended by the standard.

22

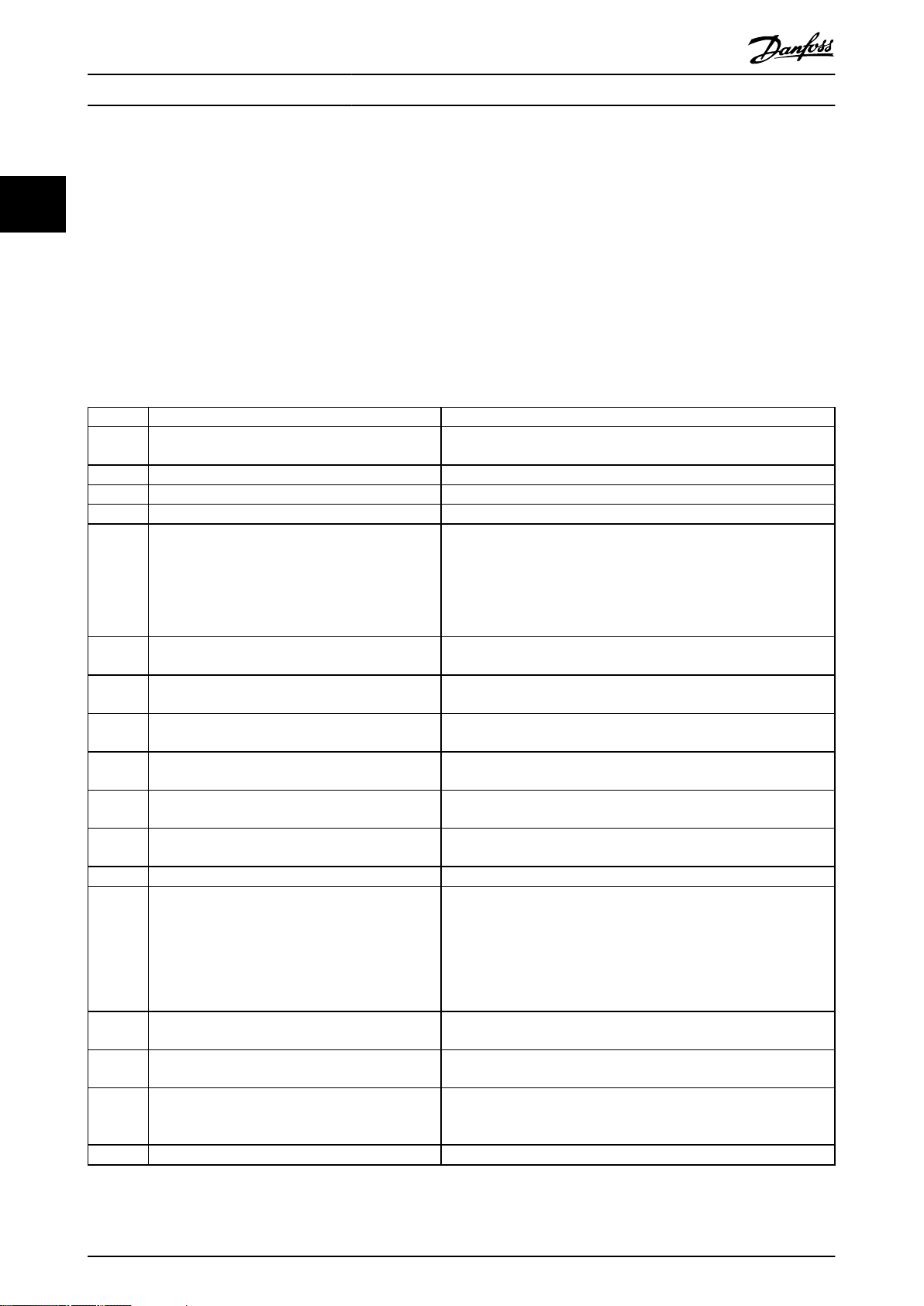

The servo drive supports the transitions and actions as given in Table 2.2. The events initiate the transition. The transition is

terminated after the action has been performed.

High-level power applied means that UDC is applied at the input of the servo drive. Yes/No means that it is allowed but not

necessary.

Conguration allowed means that the following conguration is allowed:

Changes to the option code objects (see chapter 7.20 Option Code Objects).

•

Changes to the mode of operation object (see chapter 7.5.1 Parameter 52-00: Modes of Operation (0x6060)).

•

Transition Event Action

0 Automatic transition after power-on or reset

application.

1 Automatic transition. Communication is activated.

2 Shutdown command received from control device. –

3 Switch on command received from control device. High-level power is switched on, if possible.

4 Enable operation command received from control

device.

5 Disable operation command received from control

device.

6 Shutdown command received from control device. The congured shutdown reaction function is executed (see

7 Quick stop or disable voltage command received

from control device.

8 Shutdown command received from control device. The servo drive function is disabled and high-level power is switched

9 Disable voltage command received from control

device.

10 Disable voltage or quick stop command received

from control device.

11 Quick stop command received from control device. The quick stop function is started.

12 Automatic transition when:

Quick stop function is completed (see

•

chapter 7.20.6 Parameter 50-46: Quick Stop Option

Code (0x605A)).

Disable voltage command received from control

•

device.

13 Fault signal. The congured fault reaction function is executed (see

14 Automatic transition. The servo drive function is disabled and high-level power is switched

15 Fault reset command received from control device. If no fault exists on the servo drive, the fault condition is reset. After

16 Not supported. –

Servo drive self-test and self-initialization are performed.

The servo drive function is enabled and all internal setpoints are

cleared.

If the servo drive is rotating when the command to carry out transition

4 is received, the behavior is dened by option code

chapter 7.20.4 Parameter 50-44: Enable in Positioning Option Code

(0x2052).

The congured disable operation reaction function is executed (see

chapter 7.20.9 Parameter 50-49: Disable Operation Option Code (0x605C)).

chapter 7.20.8 Parameter 50-48: Shutdown Option Code (0x605B)).

–

o, if possible.

The servo drive function is disabled and high-level power is switched

o, if possible.

High-level power is switched o, if possible.

The congured quick stop reaction function is executed (see

chapter 7.20.6 Parameter 50-46: Quick Stop Option Code (0x605A)).

chapter 7.20.1 Parameter 50-41: Fault Reaction Option Code (0x605E)).

o, if possible.

leaving state Fault, clear the fault reset bit in the Controlword via

eldbus or the LCP.

Table 2.2 Transition Events and Actions

20 Danfoss A/S © 01/2017 All rights reserved. MG36D102

Position value =

position internal value x feed constant

position encoder resolution x gear ratio

Velocity value = x velocity factor

velocity internal value x feed constant

velocity encoder resolution x gear ratio

Velocity value = x velocity factor

position value

s

Servo Drive Operation Programming Guide

If a state transition is requested, the related actions are processed completely before transitioning to the new state. For

example, in state Operation enabled, when the disable operation command is received, the servo drive remains in state

Operation enabled until the disable operation function (see chapter 7.20.9 Parameter 50-49: Disable Operation Option Code

(0x605C)) is completed.

Drive function is disabled means that no energy is supplied to the motor. Target or setpoint values (for example, torque,

velocity, position) are not processed. Drive function is enabled means that energy is supplied to the motor. Target or setpoint

values are processed.

If a fault is detected in the servo drive, a transition to state Fault reaction active takes place. In this state, the state machine

executes a special fault reaction (see chapter 7.20.1 Parameter 50-41: Fault Reaction Option Code (0x605E)). After the execution

of this fault reaction, the servo drive automatically switches to state Fault. This state can only be left by using the fault reset

command, but only if the fault is no longer active.

2 2

If a fatal error occurs, the servo drive is no longer able to control the motor, so the servo drive must be switched

immediately. If a fatal error has occurred, the servo is trip-locked and cannot be reset via eldbus.

The behavior of drive disabling, quick stop, halt, and fault reaction functions are congurable via the objects dened in

chapter 7.20 Option Code Objects.

If a brake is present, the high-level power is switched o after a delay time in order to apply the brake.

2.3.2 Factor Group

Use the factor group to set the user-dened units required

in the application.

The user-dened units are:

Position units

•

Velocity units

•

Acceleration units

•

These units are used for all objects that support userdened units (for example, position actual value, prole

velocity, and prole acceleration).

Changing the objects in the factor group has an

immediate eect on all objects that support user-dened

units. Their numerical values stay the same, but they are

interpreted dierently (according to the new scaling factors

of the factor group). All numerical values are interpreted

using the current settings of the factor group.

Position units:

The position value is calculated as:

Position value means all objects containing values in user-

dened position units.

Position internal value is given in encoder increments.

Velocity units:

The velocity value is calculated as:

Velocity internal value is the position internal value(s),

resulting in the following formula:

o

NOTICE

If the factor group is changed, then the default values

are interpreted dierently.

The formulae in this chapter show the calculation of the

units. Objects, whose values are not dependent on the

factor group, have xed units specied with the objects.

The objects of the factor group can be found in

chapter 7.4 Factor Group Objects.

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 21

Velocity value means all objects containing values in user-

dened velocity units.

Acceleration value = x acceleration factor

velocity value

s

Internal Encoder Position

(-)

TRC_ROTOR_POS_RAW

[increments]

Physical (Absolute) Position

(-)

TRC_ROTOR_POS

[increments]

Drive Position

(0x2022)

[user-dened position unit]

TRC_POS_ACT_REAL

[revolutions]

Position Actual Value

(0x6064)

TRC_POS_ACT_ABS

[user-dened position unit]

Logical CAM Position

(0x2020)

TRC_CAM_POS

[revolutions]

Only up to date if CAM

mode is active;

otherwise, the last value

remains

Position Actual Internal

Value

(0x6063)

[increments]

Encoder oset

(set during callibration)

Position oset

(set during homing)

Factor

group

Factor group +

Position range limit

(0x6078)

CAM osets

130BF158.10

Position

Hardware

limit switch

Velocity

Quick-stop

deceleration

130BF159.10

Servo Drive Operation

VLT® Integrated Servo Drive ISD® 510 System

Acceleration units:

The acceleration value is calculated as:

2.3.4 Position Limits

2.3.4.1 Hardware Limit Switch

22

One method to limit the positions of the servo drive is to

use limit switches (left/negative or right/positive), which

are also referred to as hardware limit switches. The limit

Acceleration value means all objects containing values in

user-dened acceleration units. The acceleration unit is also

used for deceleration.

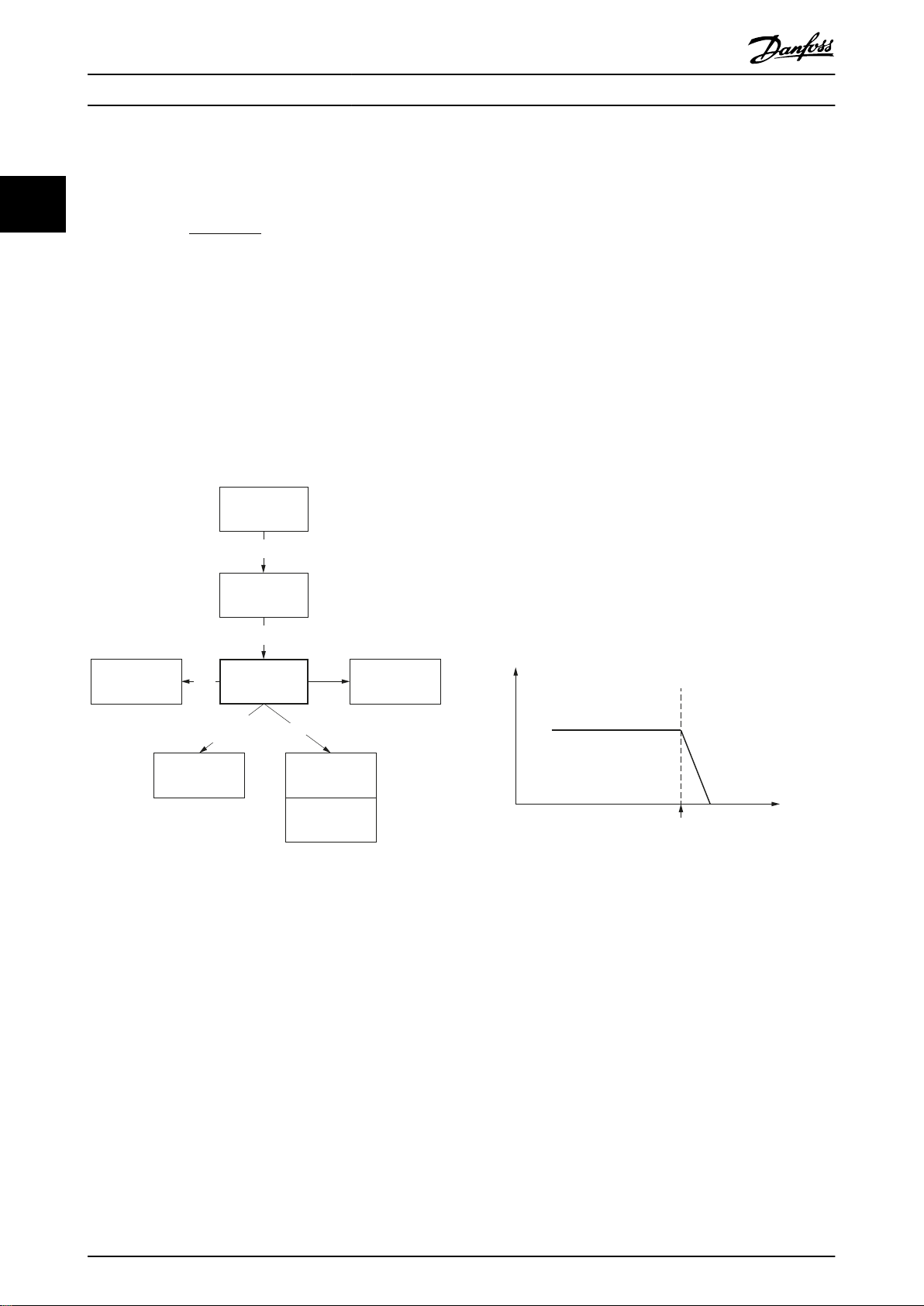

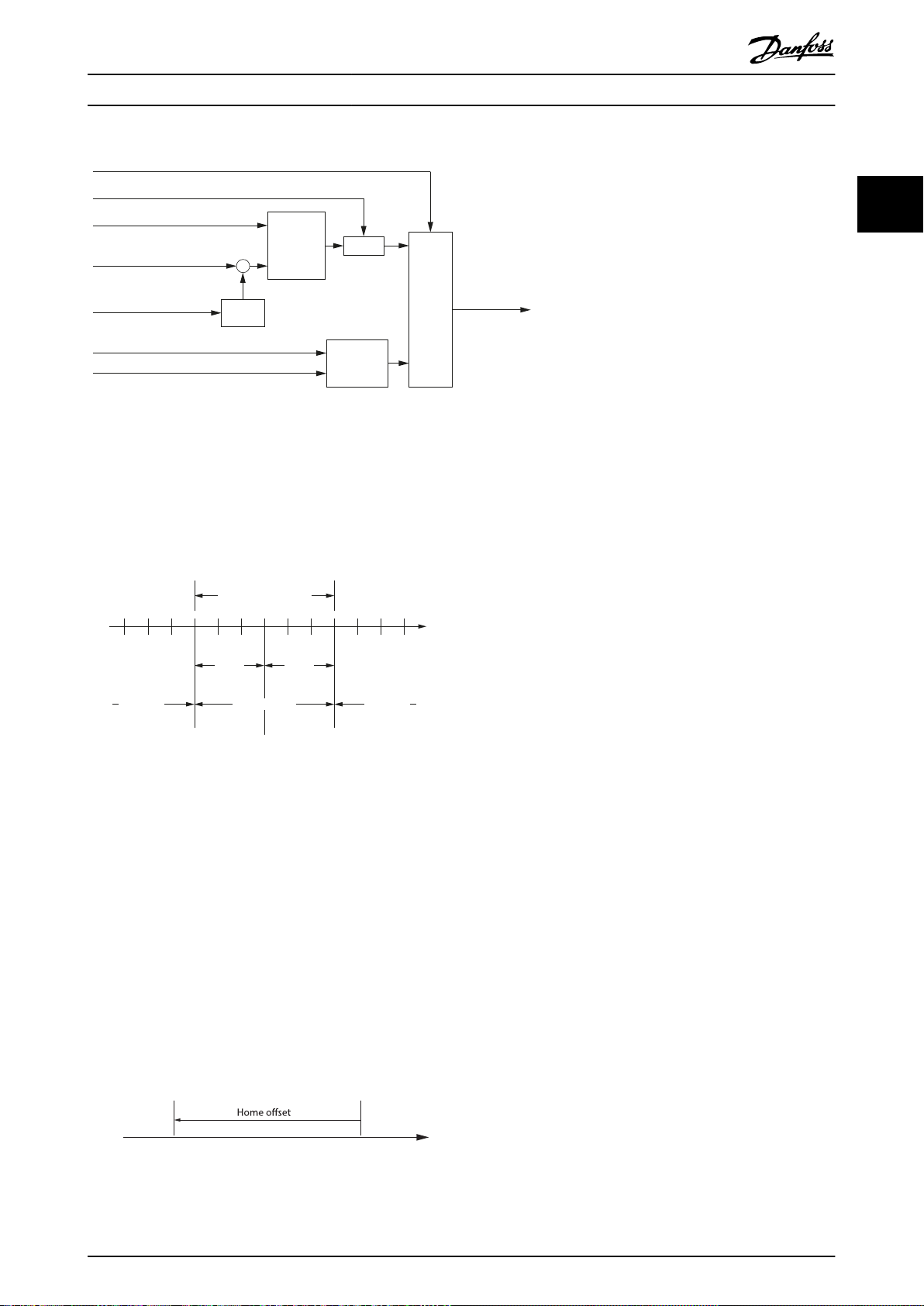

2.3.3 Positions and Osets

Inside the servo drive, there are several logical positions.

Illustration 2.2 shows the relationships between them.

switches must be congured using object 0x200F (see

chapter 7.21.3 Parameter: Dual Analog User Inputs Conguration (0x200F)). When the servo drive reaches the Left

(Right) Limit switch, it ramps down to standstill using the

value set in object 0x6085 (see chapter 7.5.9 Parameter

50-13: Quick Stop Deceleration (0x6085)). It is possible to

command the servo drive out of the limit switch in the

opposite direction. The states of the limit switches are

indicated in object 0x2006 (see chapter 7.22.12 Parameter

50-08: Motion and Input Status (0x2006)).

The servo drive remains in state Operation enabled. If a

motion command is issued that would direct the servo

drive further in the wrong direction, the command is

rejected by setting the command error bit in the

Statusword. The monitoring of the limit switch is edgetriggered because the signal does not need to remain high

for the duration of the servo drive ramp-down time.

The hardware limit switch is monitored in all modes of

operation.

Illustration 2.2 Servo Drive Logical Positions

The object index is given in round brackets. The positions

oset is the oset that is calculated during a

without index numbers are not available in the object

dictionary but are used internally in the rmware of the

servo drive. The units are given in square brackets.

The Position

homing procedure (see chapter 2.4.4 Homing Mode). For

applications where the zero position only needs to be set

once during the lifetime of the servo drive, this oset can

be saved to non-volatile memory (see

chapter 7.7.8 Parameters 51-02, 52-04, and 52-49: Application

Settings (0x2016)).

22 Danfoss A/S © 01/2017 All rights reserved. MG36D102

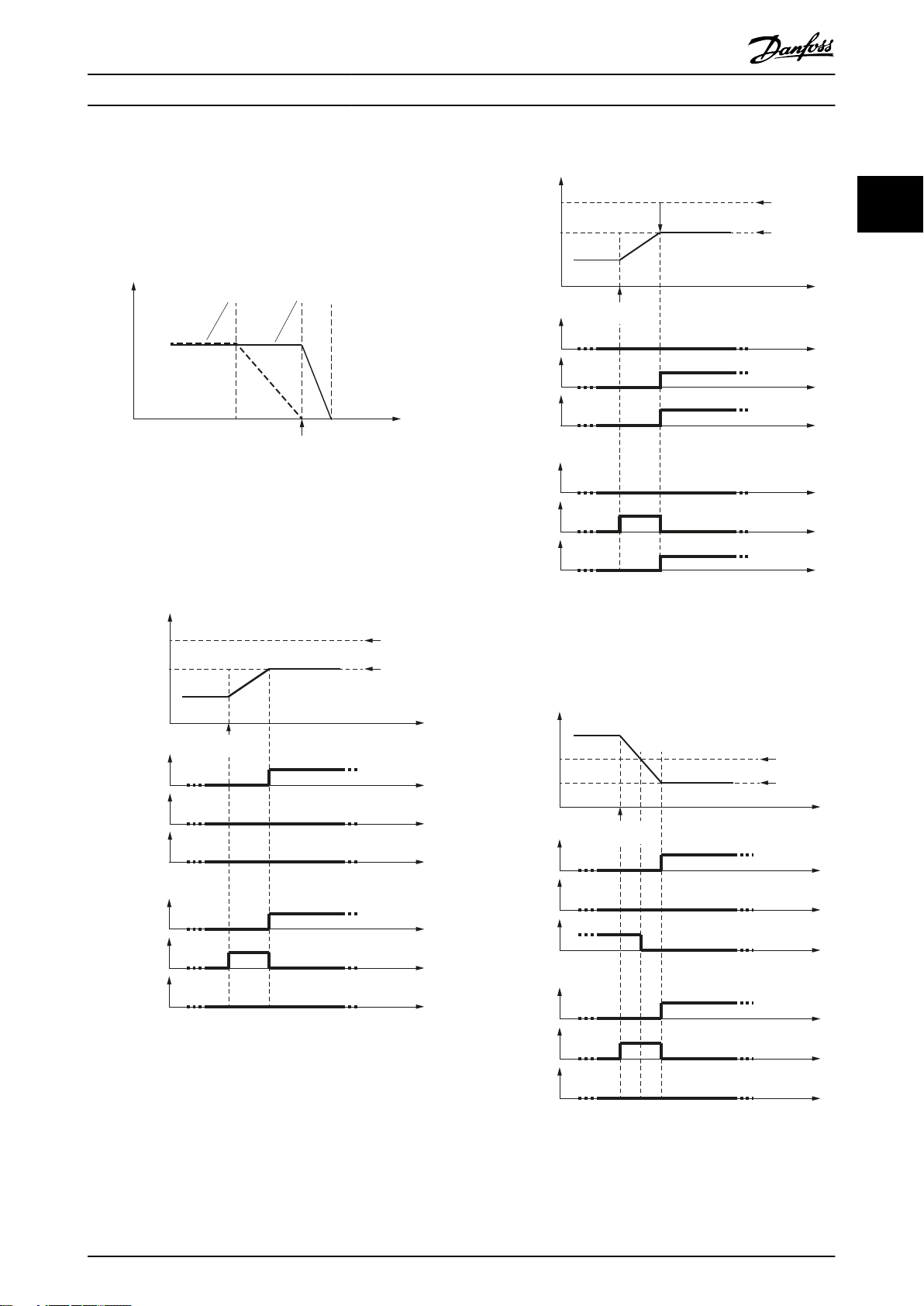

Illustration 2.3 Hardware Limit Switch

2.3.4.2 Software Position Limit

The valid positions of the servo drive can also be limited

using software position limits (object 0x607D: Software

position limit). This object indicates the congured

maximum and minimum software position limits and is

used to monitor the position limits in all available modes

of operation.

Supervision of software position limits requires a dened

home position (the Is homed bit in the Statusword must be

set).

The behavior of the servo drive in a position-controlled

mode of operation diers to other modes. In a positioncontrolled mode of operation, the drive does not pass over

the software position limit. The target position is limited to

Position

Software

position limit

Velocity

Quick-stop

deceleration

Prole

deceleration

130BF160.10

Position

controlled

Velocity

controlled

Target

reached

Position

Command

Error

Positive software

limit active

Done

PLC

Fieldbus

Busy

Error

Positioning

command

Time

Software

position limit

Target

position

130BF161.10

Target

reached

Position

Command

Error

Positive software

limit active

Done

PLC

Fieldbus

Busy

Error

Positioning

command

Positioning only to

Software position limit

Time

Target

position

Software

position limit

130BF162.10

Target

reached

Position

Command

Error

Positive software

limit active

Done

PLC

Fieldbus

Busy

Error

Positioning

command

Software

position limit

Target

position

Time

130BF163.10

Servo Drive Operation Programming Guide

the software position limit. In all other modes of operation,

the servo drive immediately ramps down using the Quick

stop deceleration value (see chapter 7.5.9 Parameter 50-13:

Quick Stop Deceleration (0x6085)) when the software

position limit is passed. This means that the servo drive

always stops after the Software position limit.

Illustration 2.4 Software Position Limit

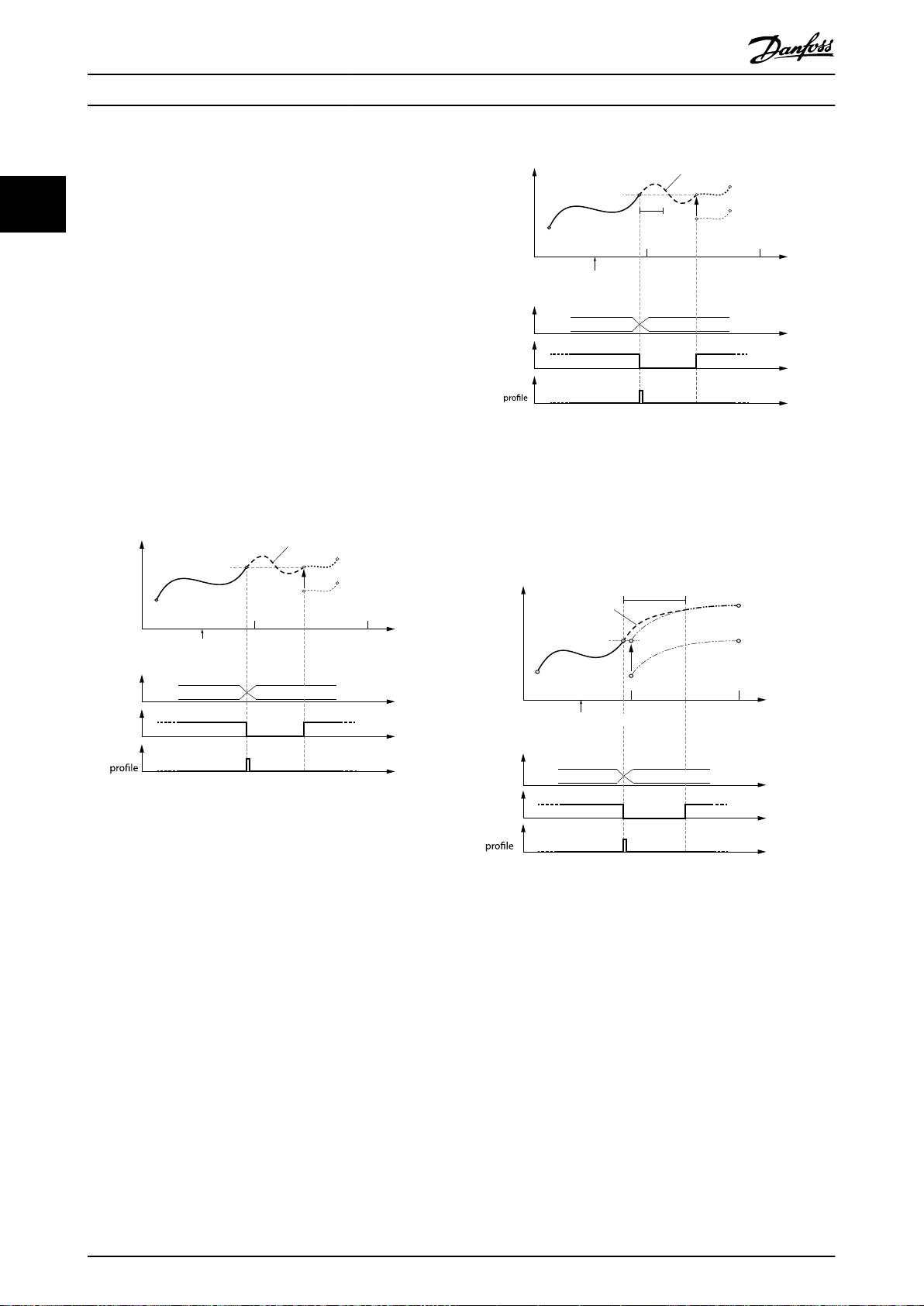

Illustration 2.5 to Illustration 2.9 show the behavior of the

servo drive around the position limits.

2 2

Illustration 2.6 Position Command: Target Position is Behind

the Software Position Limit

Illustration 2.5 Normal Positioning: Target Position is in the

Valid Position Range

Illustration 2.7 Servo Drive is Outside the Valid Position Limit

and the Target Position is in a Valid Area

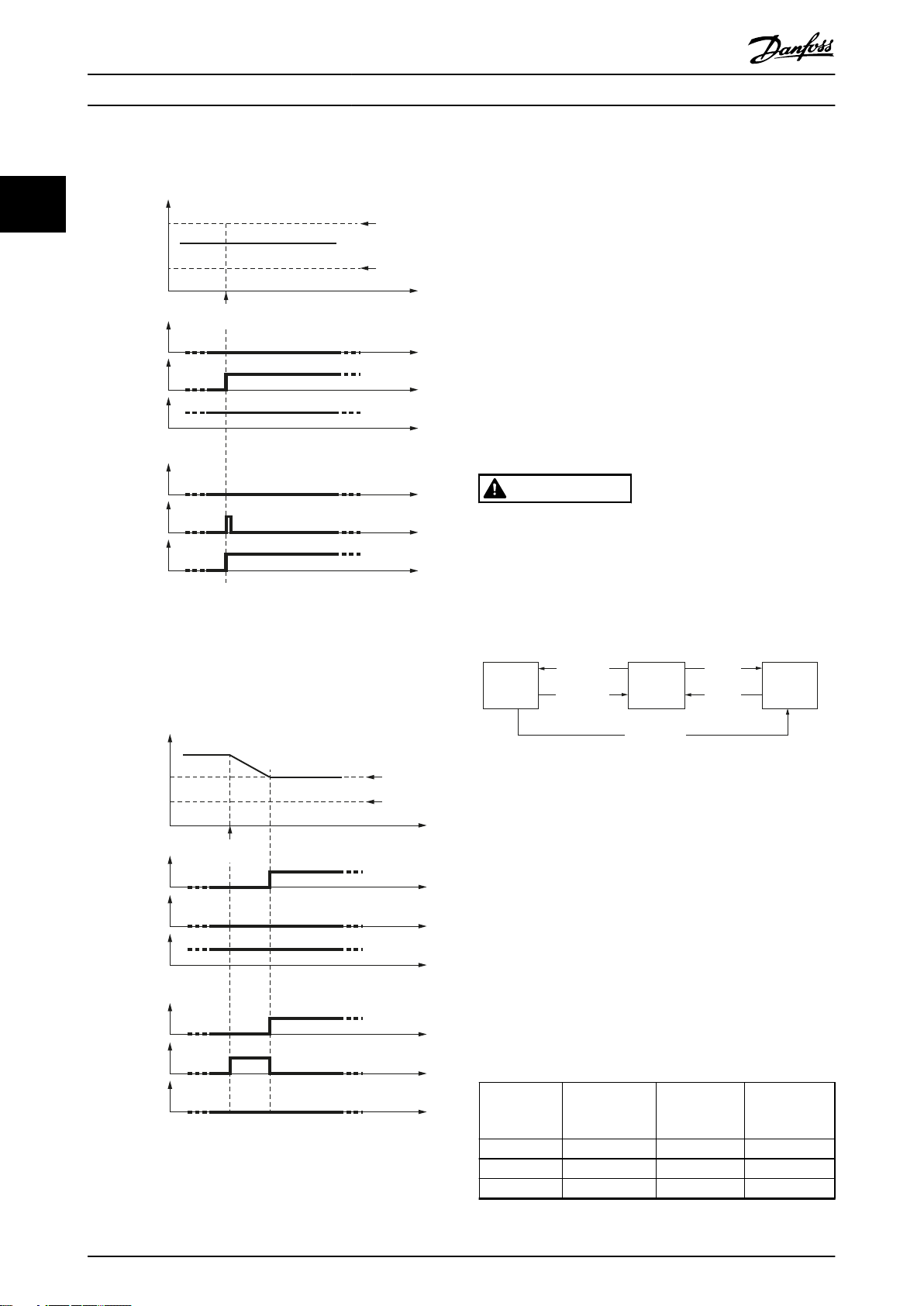

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 23

Target

reached

Position

Command

Error

Positive software

limit active

Done

PLC

Fieldbus

Busy

Error

Positioning

command

Target

position

Software

position limit

Time

130BF164.10

Target

reached

Position

Command

Error

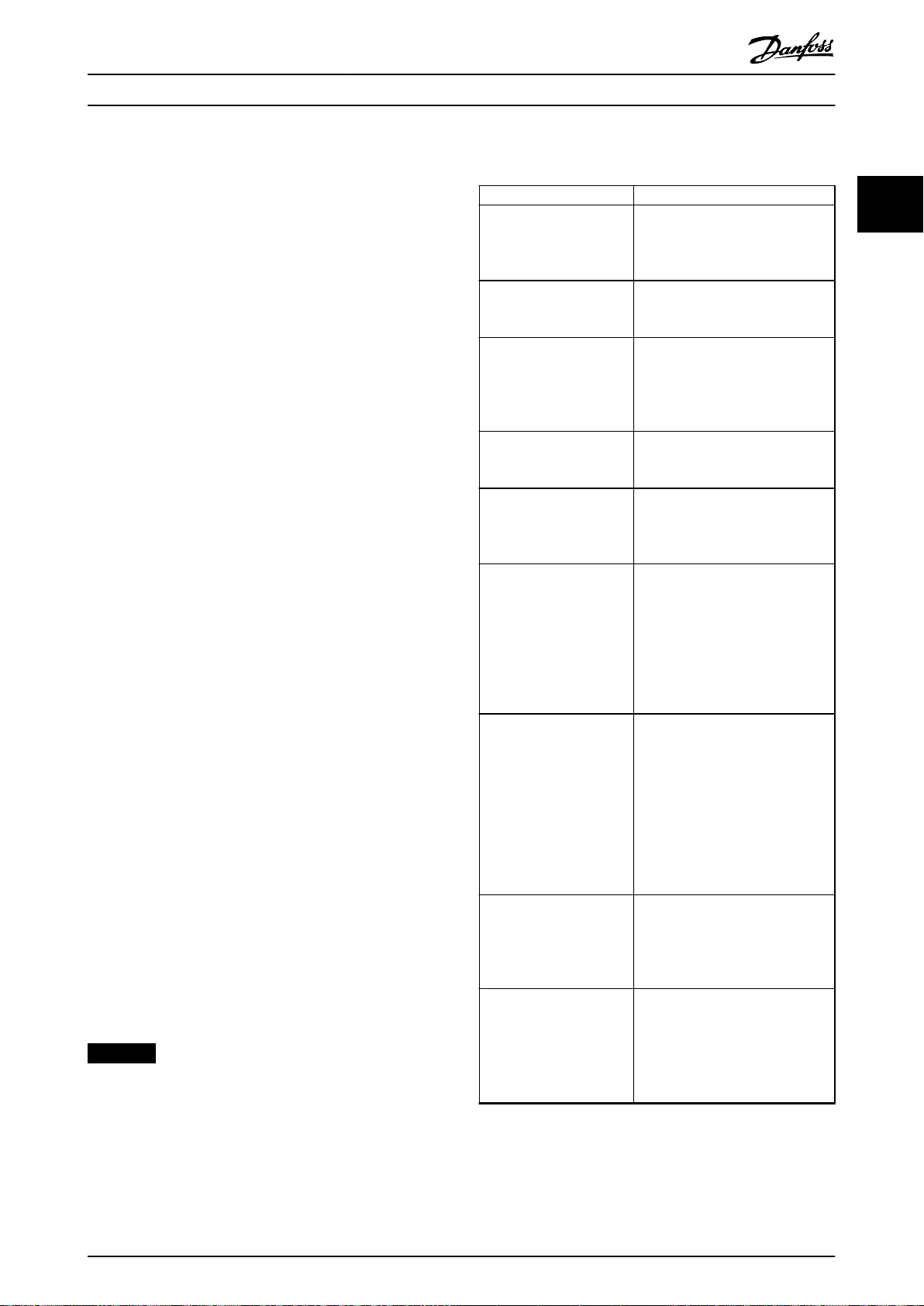

Positive software

limit active

Done

PLC

Fieldbus

Busy

Error

Time

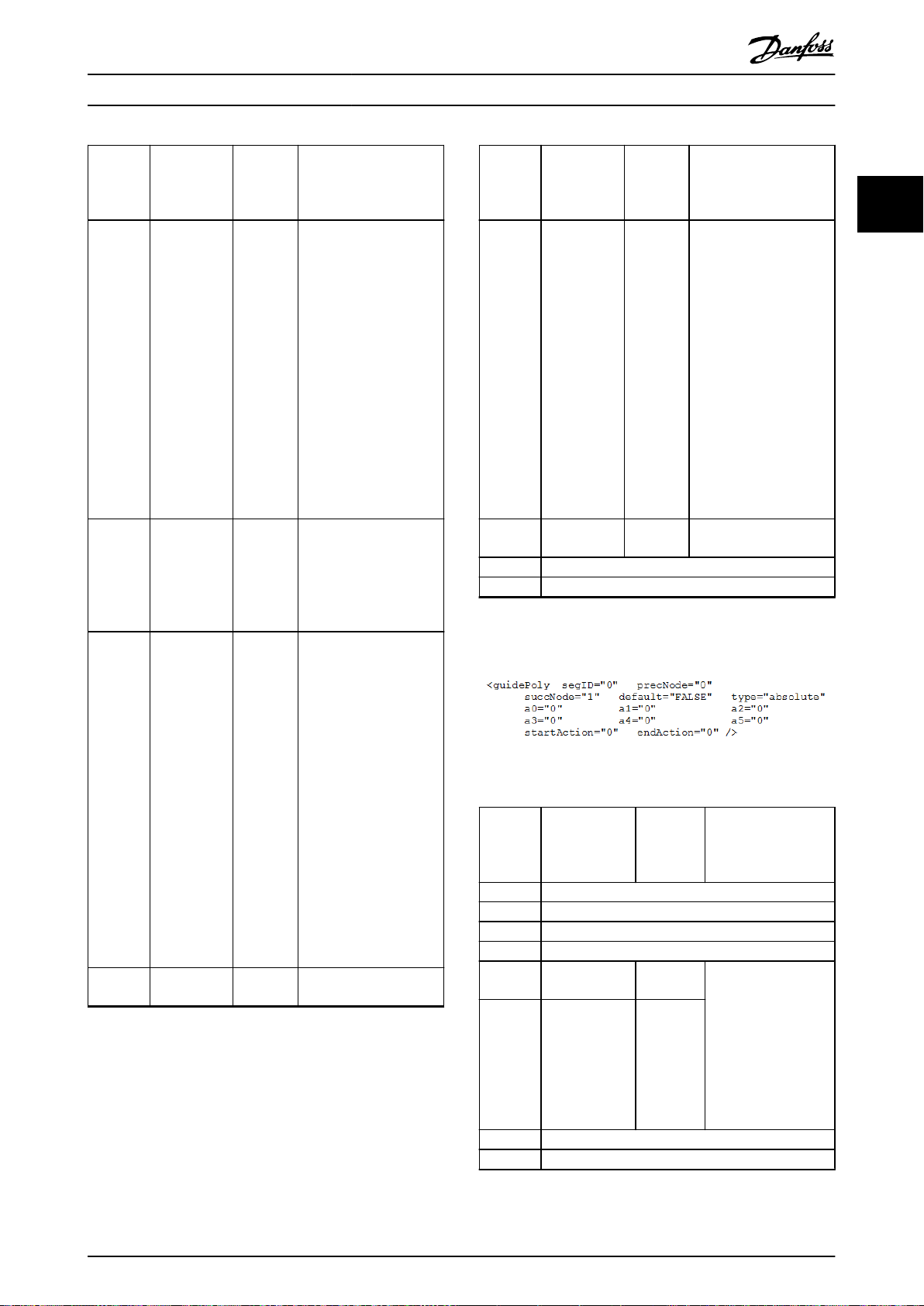

Target

position

Software

position limit

Positioning

command

130BF165.10

Motor in

unpowered

state

Brake is open

Motor in

unpowered

state

Brake is closed

Motor is

energized

Brake is open

User command:

Close brake

Energize

motor

Unpower

motor

User command:

Open brake

Energize motor

130BF166.10

Servo Drive Operation

VLT® Integrated Servo Drive ISD® 510 System

2.3.5 Brake Handling

22

automatically lifts the brake. The servo drive reports the

new state after the brake is lifted.

When the servo drive leaves state Operation enabled, it

automatically releases the brake so that the axis cannot

sag down. The servo drive reports the new state after the

brake is unreleased.

The brake state can be overwritten using the digital output

object (see chapter 7.21.4 Parameter 16-66: Digital Outputs

(0x60FE)). This is only allowed in unpowered state. The

valid commands and the reactions are shown in

Illustration 2.10.

WARNING

UNINTENDED MOTION

Releasing the brake in an unpowered state may result in

unintended motion leading to death, serious injury,

damage to equipment, or other material damage.

Do not release the brake in an unpowered state.

When the servo drive enters state Operation enabled, it

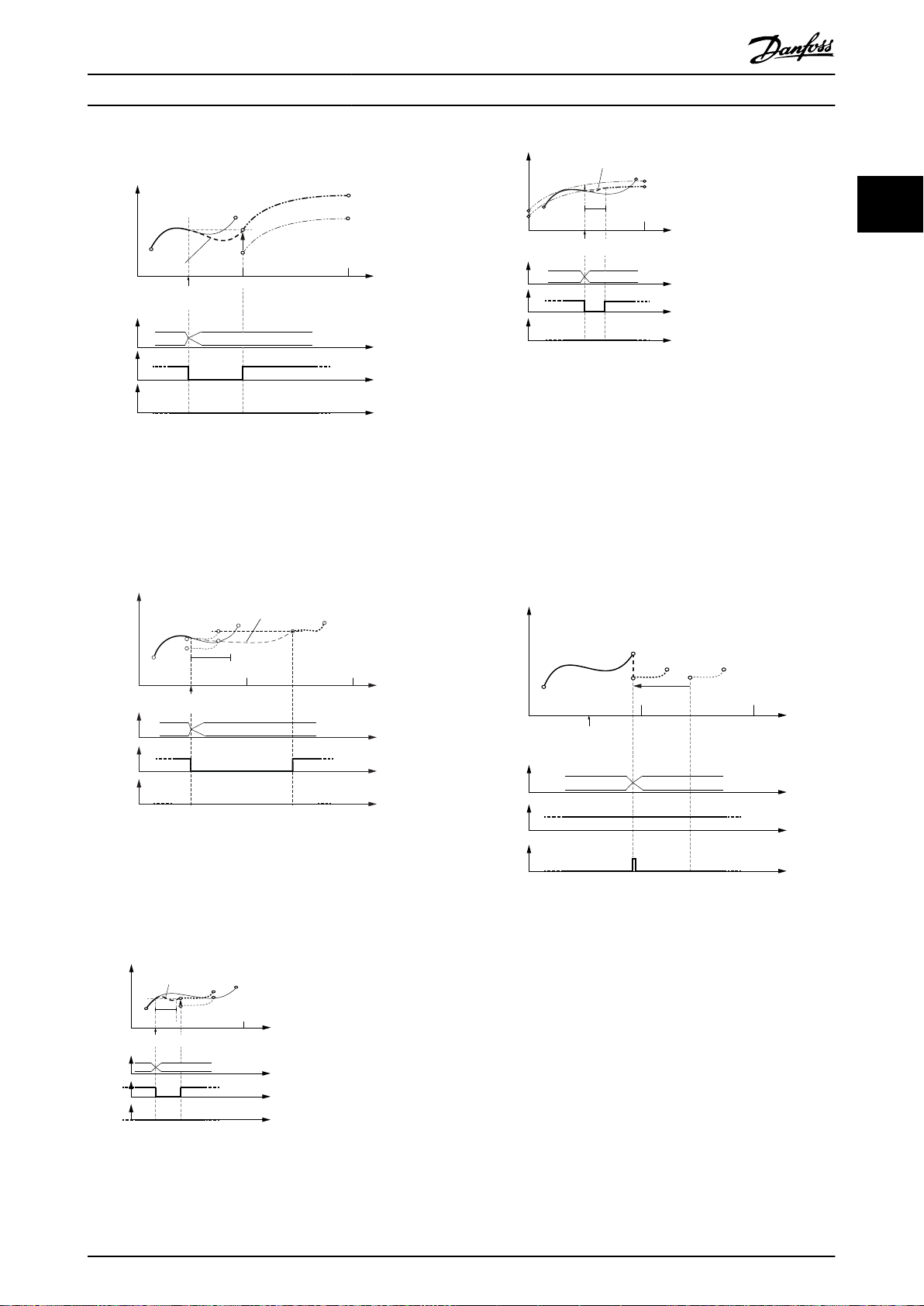

Illustration 2.8 Servo Drive is Outside the Valid Position Limit

and the Target Position is in the Wrong Direction

•

Illustration 2.10 Valid Brake Commands and Reactions

It is not possible to have an energized motor with a closed

brake. For further information about the current state, see

chapter 7.22.8 Parameter 50-09: STO Voltage and Brake Status

(0x2007).

2.3.6 Control Loops

Servo motor control takes place using 3 cascaded control

loops (position controller, speed controller, and current

controller) with trajectory generators for position and

velocity. The control loops run synchronously with the

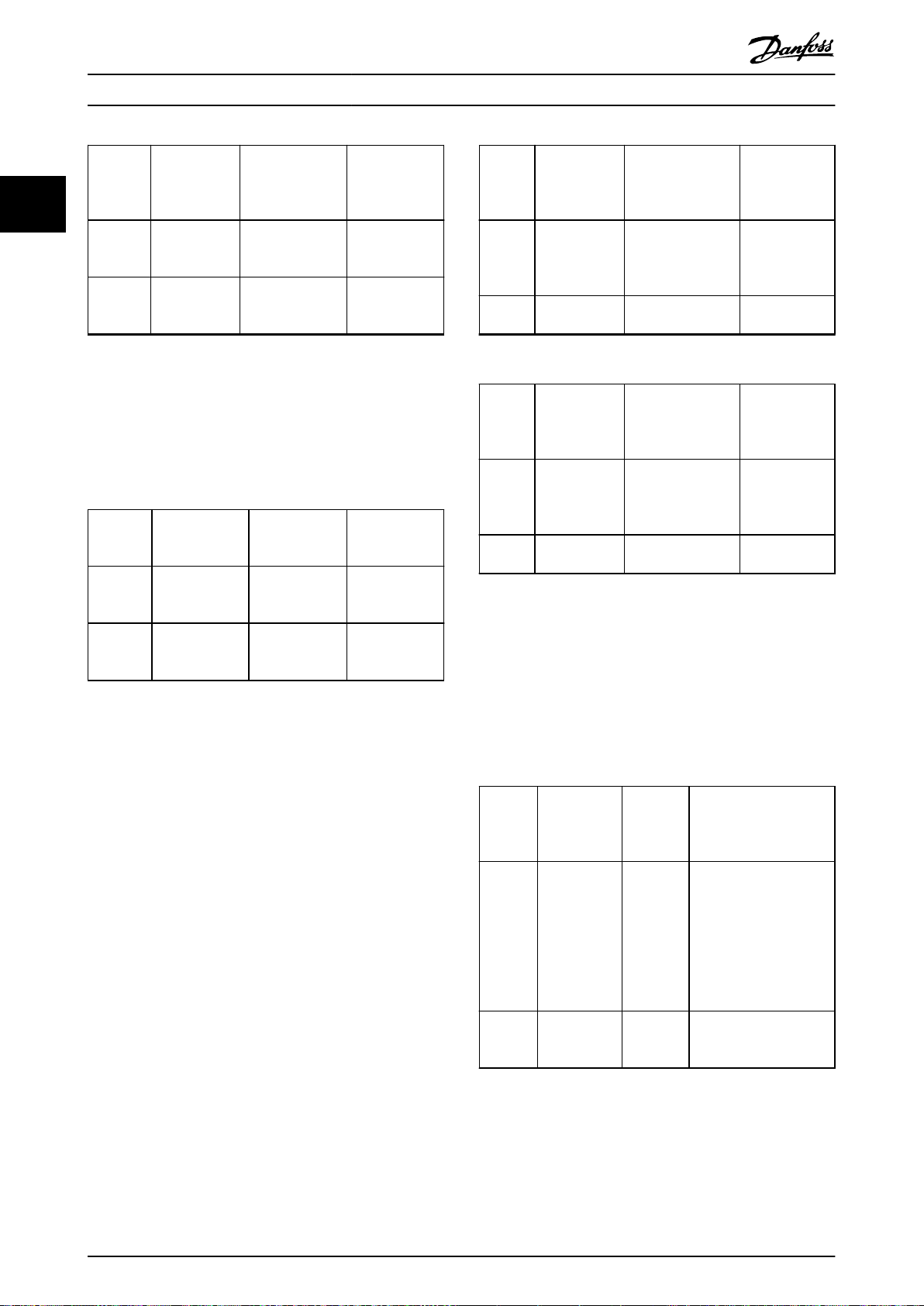

eldbus cycles. The cycle times shown in Table 2.3 are

possible with Ethernet POWERLINK® and EtherCAT®:

Fieldbus cycle

[µs]

Illustration 2.9 Servo Drive is Outside the Valid Position Limit.

The Target Position is Still Not in a Valid Area, but is Nearer to

it than the Previous Position

24 Danfoss A/S © 01/2017 All rights reserved. MG36D102

400 200 200 100

500 250 250 125

800 200 200 100

Position control

cycle

[µs]

Speed control

cycle

[µs]

Current control

cycle

[µs]

Limit

function

Limit

function

Torque

control

Velocity

control

Position

control

Selector

Application torque limit (0x2053)

Max torque (0x6072)

Max motor speed (0x6080)

Feed forward torque

Feed forward velocity

Position demand

Internal value (0x60FC)

Controlword (0x6040)

Position controller parameters (0x2013)

Speed controller parameters (0x2012)

Position controller parameters 2 (0x2015)

Speed controller parameters 2 (0x2014)

+

+

+

+

– – –

+

P D

P D

Notch

Inertia

M

S

130BF167.10

I

Servo Drive Operation Programming Guide

Fieldbus cycle

[µs]

1000 250 250 125

Table 2.3 Ethernet POWERLINK® and EtherCAT® Cycle Times

Position control

cycle

[µs]

Speed control

cycle

[µs]

Current control

cycle

[µs]

Linear blending occurs from the parameter of the currently

active set to the new one. The blending time is dened in

object 0x201B (see chapter 7.6.2 Parameter 51-01: Control

Parameter Blending Time (0x201B)).

No blending takes place when writing to a value of the

currently active control parameter set. The new value is

The used cycle times can be read using object 0x201D (see

used immediately, which could cause a jerk on the shaft.

chapter 7.6.1 Parameter 51-07 to 51-09: Used Task Cycle

Times (0x201D)). The values are given in microseconds.

Blending is used when updating a whole set of parameters

at the same time (for example, when activating CAM mode,

There are 2 control parameter sets in the servo drive,

which uses its own sets of control parameters).

however only 1 of them can be active at any time. Use bit

15 (cs) in the Controlword to switch from 1 set to the other.

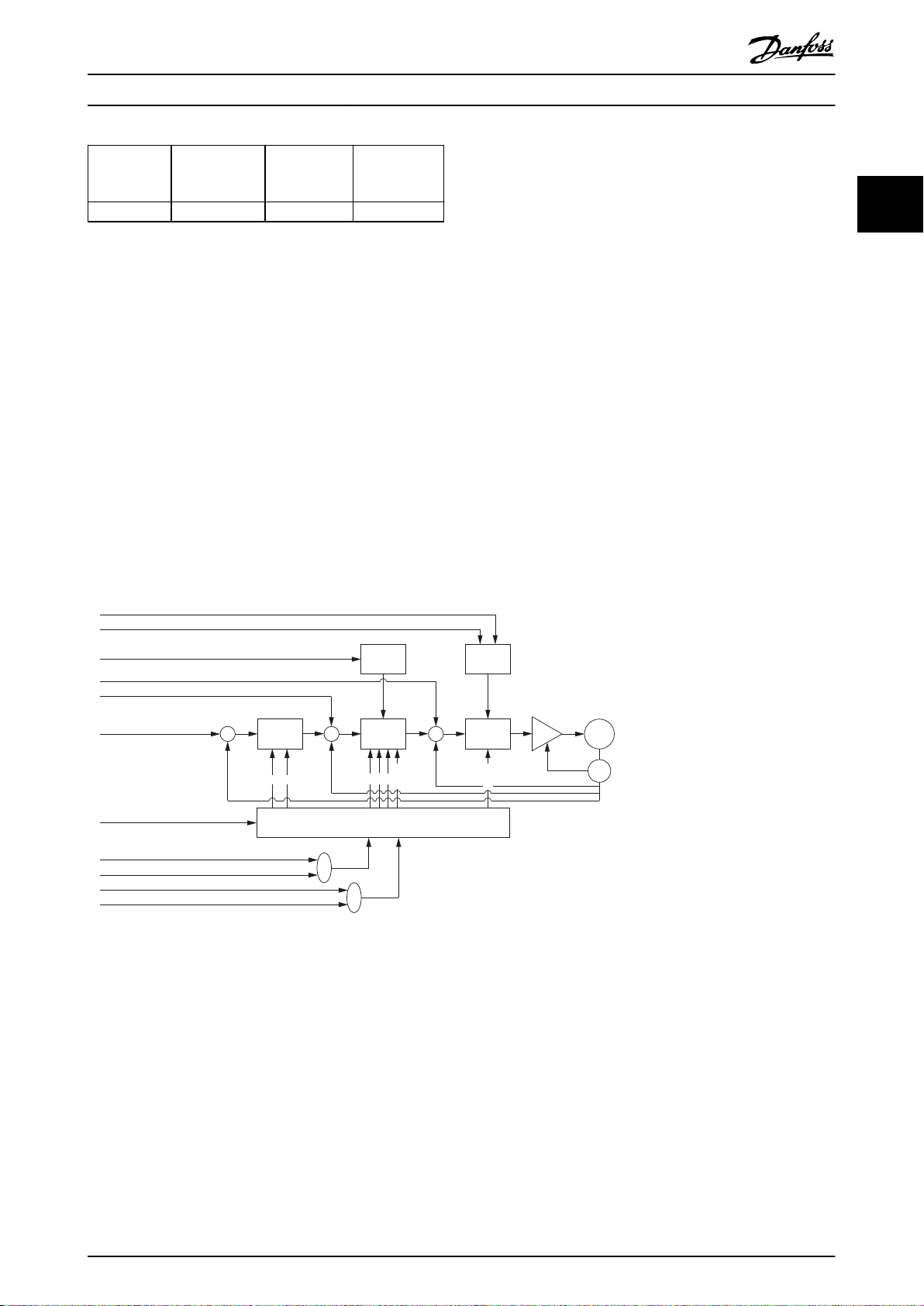

2.3.6.1 Position Controller

The controller uses PD control. The D constant is the derivative time constant. The controller provides 2 sets of control

parameters that can be switched during operation (see chapter 7.7.8 Parameters 51-02, 52-04, and 52-49: Application Settings

(0x2016) and chapter 7.6.4.2 Parameters 51-26 and 51-27: Position Controller Parameters 2 (0x2015)).

Both sets are available as read-write objects in the object dictionary. Use a manufacturer-specic bit in the Controlword to

switch between the 2 sets of parameters.

2 2

Illustration 2.11 Position Control Loop

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 25

Limit

function

Limit

function

Torque

control

Velocity

control

Selector

Application torque limit (0x2053)

Max torque (0x6072)

Max motor speed (0x6080)

Feed forward torque

Feed forward velocity

Controlword (0x6040)

Position controller parameters (0x2013)

Speed controller parameters (0x2012)

Position controller parameters 2 (0x2015)

Speed controller parameters 2 (0x2014)

+ +

+

– –

P D

Notch

Inertia

M

S

130BF168.10

I

Servo Drive Operation

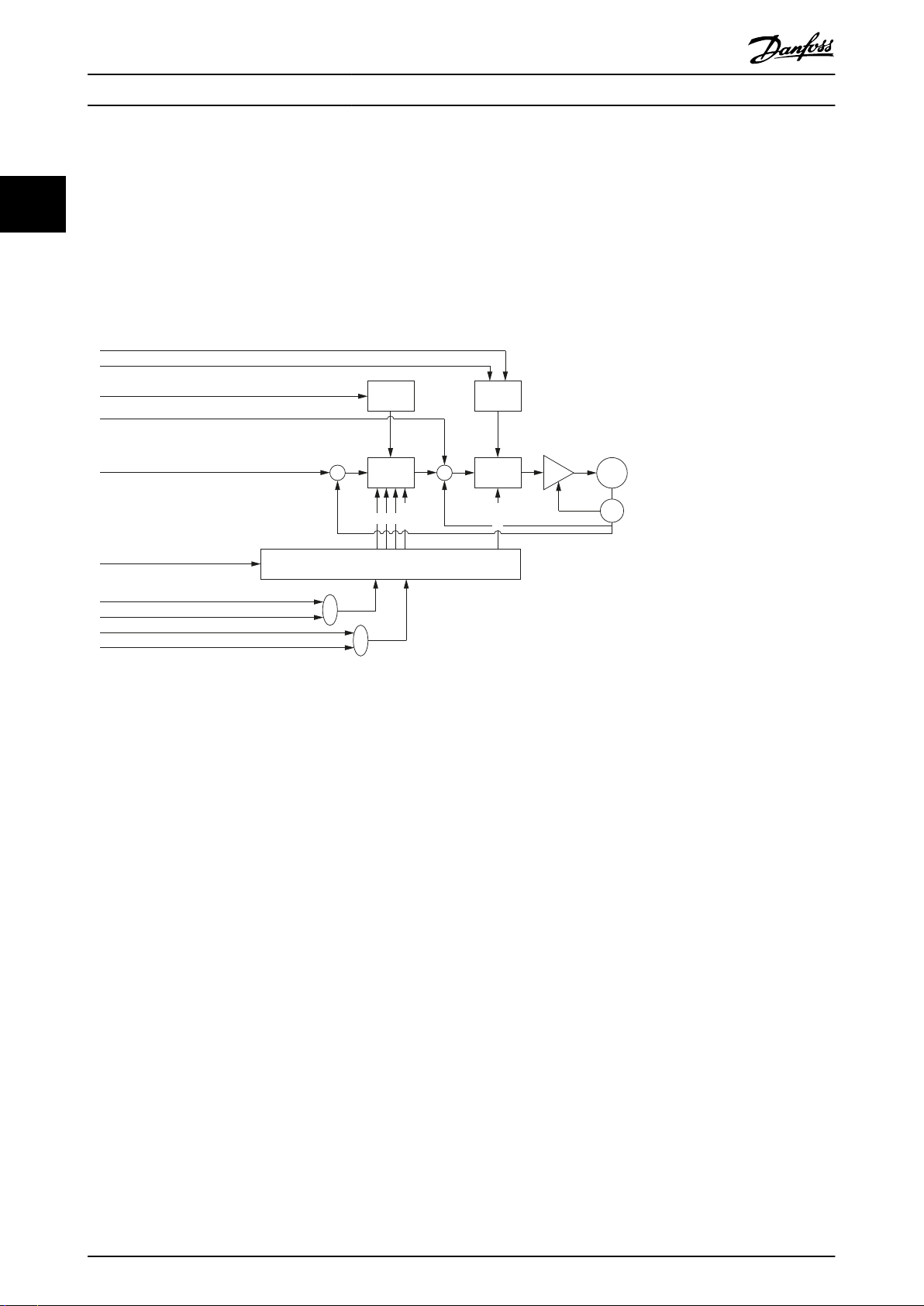

2.3.6.2 Speed Controller

VLT® Integrated Servo Drive ISD® 510 System

22

that can be parameterized (center frequency/bandwidth) to suppress resonance. The controller provides 2 sets of control

parameters (see chapter 7.6.5.1 Parameters 51-10 to 51-15: Speed Controller Parameters (0x2012) and chapter 7.6.5.2 Parameters

51-20 to 51-25: Speed Controller Parameters 2 (0x2014)) that can be switched spontaneously.

Both sets are available as read-write objects in the object dictionary. Use a manufacturer-specic bit in the Controlword to

switch between the 2 sets of parameters.

The controller uses PID control. The D constant is the derivative time constant. The speed controller has a Notch-Filter (IIR)

Illustration 2.12 Speed Control Loop

2.3.6.3 Current Controller

The current controller runs synchronous to the eldbus cycle time. It cannot be parameterized.

Operating Modes

2.4

The servo drive implements several modes of operation. The behavior of the servo drive depends on the activated mode of

operation. It is possible to switch between the modes while the servo drive is enabled. The supported modes of operation

are according to CANopen® CiA DS402 and there are also ISD-specic modes of operation. All supported modes of

operation are available for EtherCAT® and Ethernet POWERLINK®.

2.4.1 Prole Position Mode

In Prole position mode, the servo drive is operated under position control and executes absolute and relative movements.

Parameters such as velocity, acceleration, and deceleration can be parameterized. The servo drive provides a buer to queue

a following move while another move is already executing.

This functionality can be commanded using the function blocks MC_MoveAbsolute_ISD51x (see chapter 6.5.5.4 MC_MoveAb-

solute_ISD51x) and MC_MoveRelative_ISD51x (see chapter 6.5.5.5 MC_MoveRelative_ISD51x). This functionality can also be

used via the LCP (see section Position mode in chapter 4.3.5.1 Servo Drive).

When switching to Prole position mode from Prole velocity mode, CAM mode, Gear mode, or Prole torque mode, the servo

drive continues rotating with the current velocity. As soon as there is a new setpoint (handed over using the handshaking

between Controlword and Statusword), the new setpoint is processed with the corresponding parameters.

26 Danfoss A/S © 01/2017 All rights reserved. MG36D102

Tragectory

generator

Minimum

comparator

Minimum

comparator

Limit

function

Limit

function

Limit

function

Multiplier

Multiplier

Target position (0x607A)

Position range limit (0x607B)

Software position limit (0x607D)

Drive mirror mode (0x2016, 02)

Drive mirror mode (0x2016, 02)

End velocity (0x6082)

Max motor speed (0x6080)

Quick-stop deceleration (0x6085)

Max acceleration (0x60C5)

Quick-stop option code (0x605A)

Positioning option code (0x60F2)

Max torque (0x6072)

Application torque limit (0x2053)

Torque limit

Position demand

internal value

(0x60FC)

Feed forward

velocity

Feed forward

torque

Max deceleration (0x60C6)

quick-stop deceleration

Target position

Velocity limit

or End velocity

130BF169.10

Servo Drive Operation Programming Guide

When switching from a torque or velocity controlled mode to Prole position mode, the last target position is set to the

position actual value. This is relevant when starting a relative movement from the last target position after switching to this

mode, because no last target position from the previous mode is available. If the previous mode ended with a velocity

unequal to 0, the last target position is the position actual value at the time of the mode switch.

If the trajectory is completed (target position is reached) and the end velocity (see chapter 7.10.2 Parameter 52-16: End

Velocity (0x6082)) is unequal to 0, the servo drive continues rotating at the specied end velocity until a further trajectory is

set.

2 2

Illustration 2.13 Prole Position Mode Control Function

Target position activation

The activation of a setpoint is controlled by the timing of:

The new setpoint bit and the change set immediately bit in the Controlword.

•

The setpoint acknowledge bit in the Statusword.

•

If the Change set immediately bit of the Controlword is set to 1, a potentially ongoing motion is interrupted and the new

setpoint is used immediately. If the Change set immediately bit of the Controlword is set to 0, the ongoing positioning

command is nished rst and the new setpoint is executed afterwards.

After a setpoint is applied to the servo drive, the control device signals that the setpoint is valid by a rising edge of the new

setpoint bit in the Controlword. The servo drive sets the setpoint acknowledge bit in the Statusword to 1. Afterwards, the

servo drive with the setpoint acknowledge bit set to 0 signals its ability to accept new setpoints. An example is shown in

Illustration 2.14.

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 27

Actual

speed

New

setpoint

(bit 4)

Target

position

(setpoint)

Setpoint

acknowledge

(bit 12)

Target

reached

(bit 10)

t

t

t

t

t

130BF170.10

A A B B B E

B

B C

C

C D

New

setpoint

(bit 4)

Change set

immediately

(bit 5)

Setpoint

ac

knowledge

(bit 12)

Target

reached

(bit 10)

Setpoint

setpoint

Processed

setpoint

1 2 3 4 5

t

t

t

t

130BF171.10

A

E

Servo Drive Operation

VLT® Integrated Servo Drive ISD® 510 System

22

Illustration 2.14 Handshaking Procedure for Setpoint

Activation

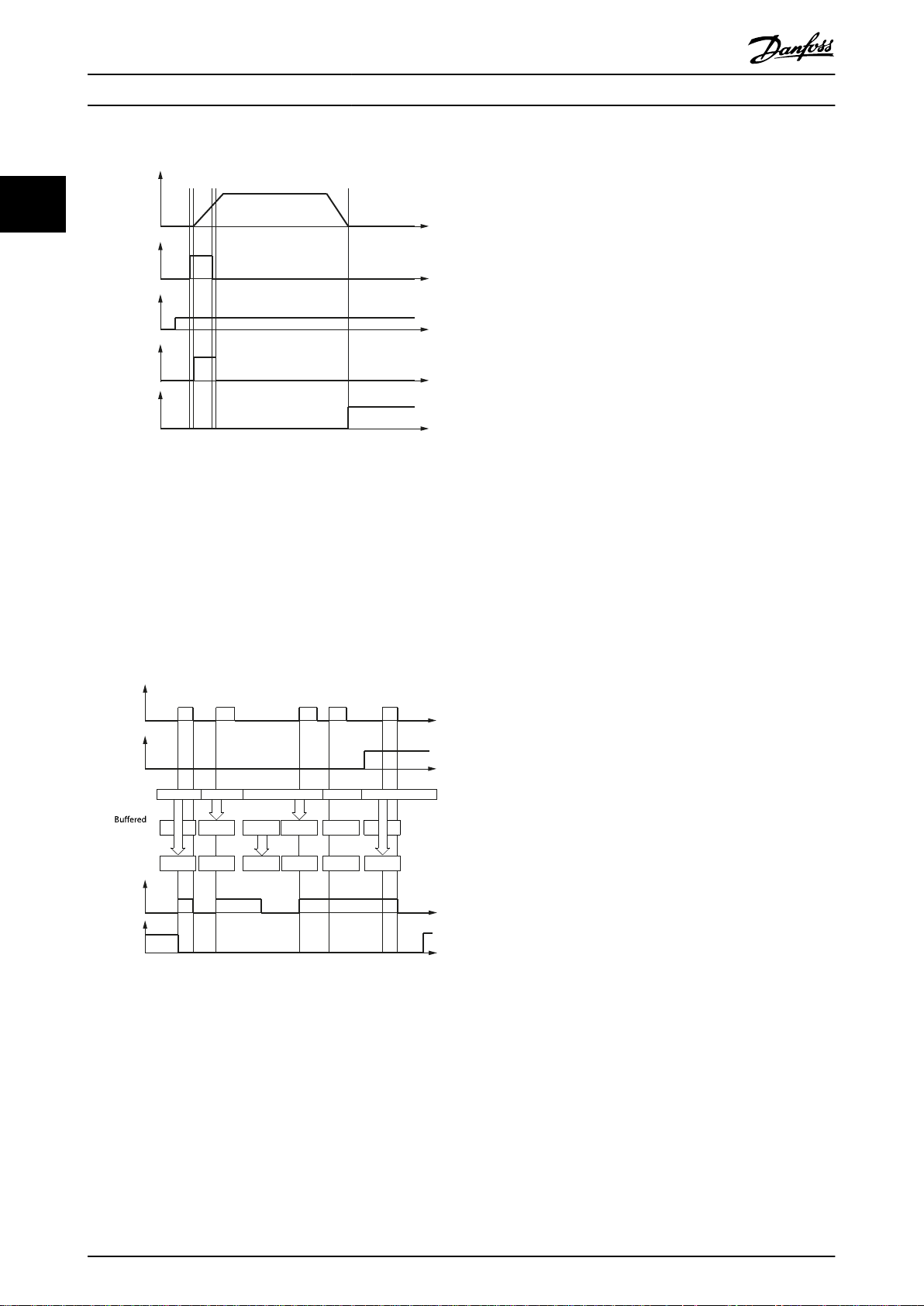

The servo drive supports 2 setpoints: a setpoint that is currently being processed, and a buered setpoint. If a setpoint is

still in progress (has not been reached) and a new setpoint is activated by the new setpoint bit in the Controlword, 2

methods of handling are supported. The new setpoint is activated immediately if the Change set immediately bit of the

Controlword is set to 1. If the Change set immediately bit of Controlword is set to 0, the currently active setpoint is nished

rst and the new setpoint is started afterwards.

Illustration 2.15 Setpoint Handling for 2 Setpoints

New setpoints are buered as long as a free setpoint buer is available in the axis. If no setpoint is in progress, the new

setpoint becomes active immediately (case 1 in Illustration 2.15). If a setpoint is in progress, the new setpoint is stored in the

setpoint buer (cases 2 and 3 in Illustration 2.15).

If all setpoint buers are busy (Setpoint acknowledge bit is set to 1), the reaction depends on the Change set immediately bit.

If the Change set immediately bit is set to 0, the new setpoint is rejected (case 4 in Illustration 2.15). If the Change set

immediately bit is set to 1, the new setpoint is processed immediately. The currently running setpoint prole is discarded

(case 5 in Illustration 2.15).

28 Danfoss A/S © 01/2017 All rights reserved. MG36D102

Actual

speed

New

setpoint

(bit 4)

Target

position

(setpoint)

Current target

position

processed

Setpoint

acknowledge

(bit 12)

Target

reached

(bit 10)

t

t

t

t

t

t

130BF172.10

Window

comparator

Limit

function

Comparator

Selector

Timer

Target reached option code (0x2054)

Position window time (0x6068)

Position window (0x6067)

Drive position (0x2022)

Position range (0x607B)

Target reached

Software position (0x607D)

Target position (0x607A)

Position demand value (0x6062)

Target position (0x607A)

–

130BF173.10

Servo Drive Operation Programming Guide

The Target reached bit in the Statusword remains as 0 until all setpoints are processed.

The Buered setpoint is not available as an object for readout.

When a setpoint is in progress and a new setpoint is set to start afterwards (New setpoint bit is set to 0), the new setpoint is

only processed after the previous setpoint has been reached. The handshaking procedure shown in Illustration 2.16 is used

for this scenario. The additional gray line in the graph Actual speed shows the actual speed if the Change of setpoint bit (bit

9 in the Controlword) is set to 1.

2 2

Illustration 2.16 Inuence of Change of Setpoint Bit in Prole

Position Mode

Position reached function

The position reached function oers the possibility to dene a range around a position demand value to be regarded as

valid. If the position of the servo drive is within this area for a specied time (the position window time), the related control

bit Target reached (bit 10) in the Statusword is set to 1.

Illustration 2.17 Position Reached – Functional Overview

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 29

Accepted position range

Position

window

Position not

reached

Position not

reached

Position reached

Target

position

Position

Position

window

130BF174.10

Drive mirror mode (0x2016,02)

Target velocity (0x60FF) Limit

function

Limit

function

Trajectory

generator

d/dt

Minimum

comparator

Minimum

comparator

Multiplier

Max motor speed (0x6080)

Position actual value (0x6064)

Max torque (0x6072)

Torque limit

Feed forward

torque

Velocity demand

value (0x6068)

Velocity limit

quick-stop deceleration

Application torque limit (0x2053)

Max acceleration (0x60C5)

Max deceleration (0x60C6)

Quick-stop deceleration (0x6085)

Quick-stop option code (0x605A)

130BE847.10

Servo Drive Operation

VLT® Integrated Servo Drive ISD® 510 System

Illustration 2.18 shows the denition of the sub-function position reached. A window is dened for the accepted position

range symmetrically around the target position. If a servo drive is situated in the accepted position range over the time

position window time, the bit Target reached (bit 10) in the Statusword is set to 1.

22

Illustration 2.18 Position Reached Window

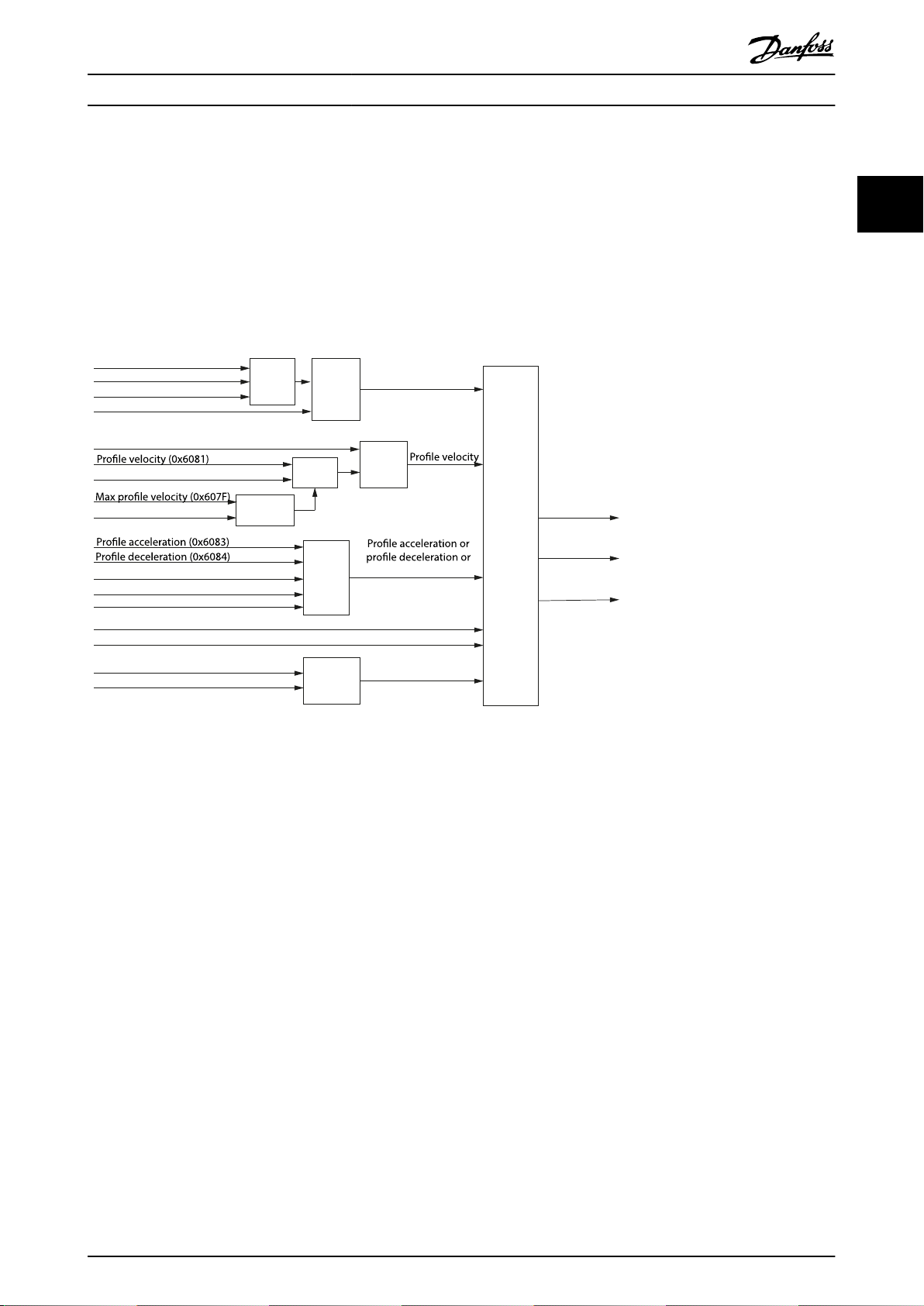

2.4.2 Prole Velocity Mode

In Prole velocity mode, the servo drive is operated under velocity control and executes a movement with a dened velocity

(see chapter 7.11.1 Parameter 52-20: Target Velocity (0x60FF)). Parameters such as acceleration (see chapter 7.5.7 Parameter

50-11: Prole Acceleration (0x6083)) and deceleration (see chapter 7.5.8 Parameter 50-12: Prole Deceleration (0x6084)) can be

parameterized. Parameters that inuence the Prole velocity mode can be found in Illustration 2.19.

This functionality can be commanded using function block MC_MoveVelocity_ISD51X (see chapter 6.5.5.7 MC_MoveVe-

locity_ISD51x). This functionality can also be used via the LCP (see the Velocity mode section in chapter 4.3.5.1 Servo Drive). In

Prole velocity mode, the velocity control loop is used to reach the target velocity (see chapter 7.11.1 Parameter 52-20: Target

Velocity (0x60FF)).

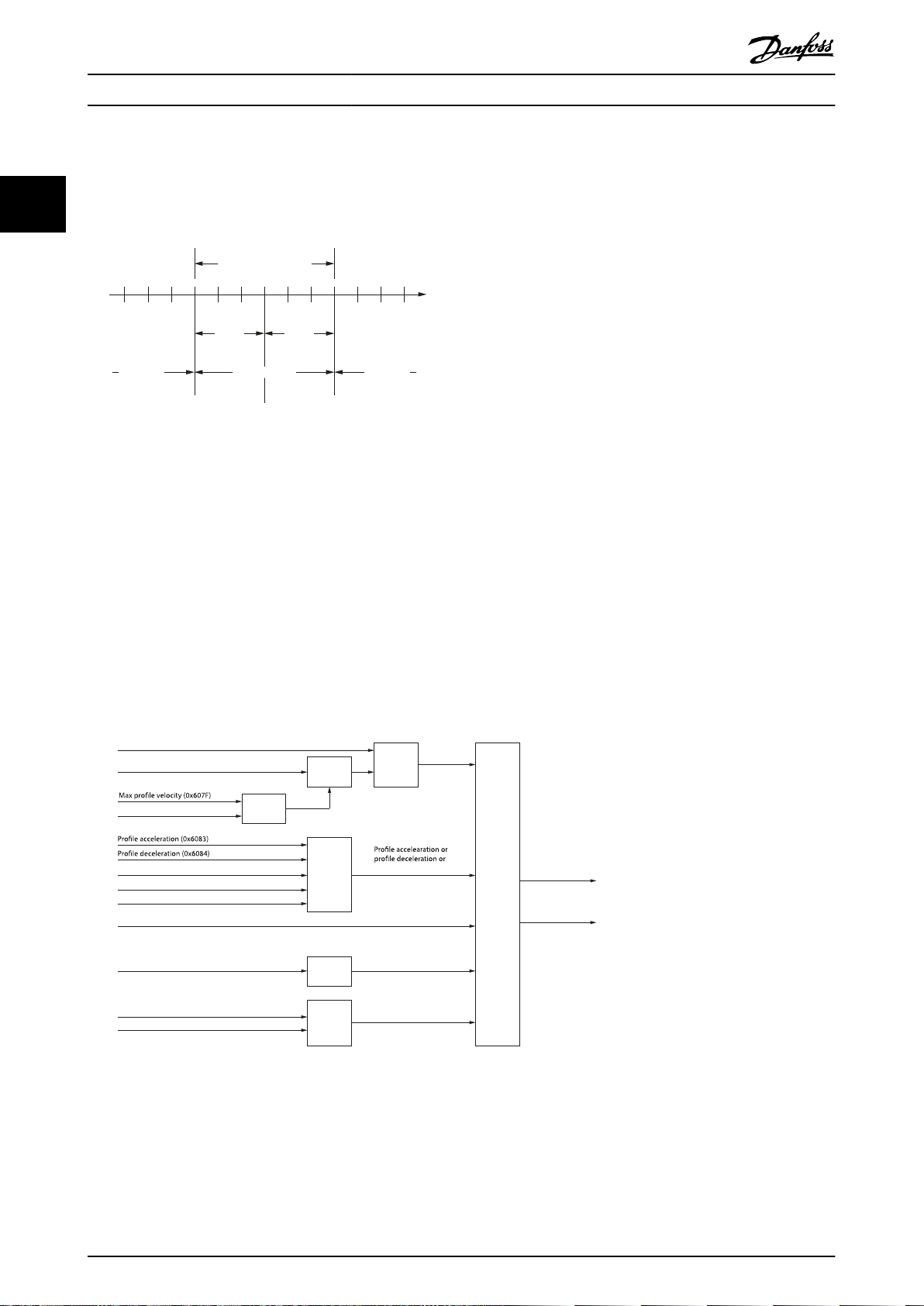

Illustration 2.19 Prole Velocity Mode Control Function

The usage of acceleration and deceleration for the calculation of the trajectory is shown in Illustration 2.20.

30 Danfoss A/S © 01/2017 All rights reserved. MG36D102

Target velocity

Velocity

acc

0

dec

acc dec acc dec

acc dec

130BE848.10

Target reached option code (0x2054)

Velocity window time (0x606E)

Velocity window (0x606D)

Velocity actual value (0x606C)

Velocity demand value (0x606B)

Target velocity (0x60FF)

Target velocity (0x60FF)

Target reached

Comparator

Window

comparator

Limit

function

Timer

Selector

130BE849.10

Servo Drive Operation Programming Guide

Illustration 2.20 Usage of Acceleration and Deceleration in

Velocity Control

This principle on using the acceleration and deceleration value applies to all velocity controlled modes of operation. The

ramp bends when reversing the velocity. If this behavior is undesired, set the value of the acceleration and deceleration to

the same value.

Velocity reached function

The velocity reached function oers the possibility to dene a velocity range around a velocity demand value to be

regarded as valid. If the velocity of the servo drive is within this area for a specied time (see chapter 7.11.4 Parameter:

Velocity Window (0x606D)), the velocity window time (see chapter 7.11.5 Parameter: Velocity Window Time (0x606E)), the

related control bit Target reached (bit 10) in the Statusword is set to 1.

2 2

Illustration 2.22 shows the denitions of the sub-function Velocity reached. A window is dened for the accepted velocity

range symmetrically around the velocity. If a servo drive is running within the accepted velocity range over the time velocity

window time, the bit Target reached (bit 10) in the Statusword is set to 1.

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 31

Illustration 2.21 Velocity Reached - Functional Overview

Accepted velocity range

Velocity

window

Velocity not

reached

Velocity not

reached

Velocity reached

Target

velocity

Velocity

Velocity

window

130BE850.10

Trajectory

generator

Limit

function

Torque

control

and

power

stage

Target torque (0x6071)