VLT® Integrated Servo Drive System ISD 410

The integration of servomotor and electronic drive unit in the same housing makes this drive system predestined for applications requiring high exibility and dynamics, such as those in the food & beverage and packaging industries. The decentralisation of the drive unit oers benets in mounting, installation and operation.

Depending on the application, up to 60 drives can be integrated into the servo drive system.

Servo Drive

The motion control is integrated into

the drive so that the motion sequences can take place independently. This

releases the higher-ranking controller

and oers a highly exible drive

concept. The master can be programmed via IEC 61131-3 and hybrid cables

are used to connect the drives,

making installation fast and simple.

Power Supply Module

The system is powered with DC 300 V

via the power supply module. LEDs

on the front of the unit enable easy

monitoring of operating status. The

maximum current output is 10 A and

nominal power is 3 kW.

Ethernet

Power Supply

Module

AC/DC

ISD Power Supply Module

Failure

Warning

Output (300V) OK

Output (90V) OK

Stand-By

90V OK

300V OK

Signal Outputs

Error

Enable

Signal Inputs

300V

10A

Connection

ISD Connection Box

Run/Err

U

ZK

24V

5V

Safe

CAN

Fuse L I CAN 1.In CAN 2.In CAN 3.In CAN 4.In CAN 5.In

Fuse L II CAN 1.Out CAN 2.Out CAN 3.Out CAN 4.Out CAN 5.Out

AC/DC Power Supply 300VDC 8/10A

Box

Warn Err

Safety I Safety II

X11 X12 X13 X14 X15

X21 X22 X23 X24 X25

Master

CAN-ID

6

4

2 8

RS232

0

Service

Set

Connection Box

The connection box creates the link

between the servomotors and the

power supply. Two independent

groups of up to 30 motors can be

connected. The hybrid cable contains

the DC supply, CAN and safety.

Encoder Box

The encoder box enables a master

encoder to be connected, this to be

read with high precision, and time

information to be sent to the drives

via CAN. If no encoders are connected, the encoder box functions as

a virtual axis for the ISD 410 servo

drive system.

Encoder

Box

CAN-ID

ISD Connection Box

6

4

2 8

RS232

0

Service

Set

Warn Err

Master

Encoder

Feature Benet

Compact and decentral servo drive Reduced costs and high exibility

Dynamic servo performance Fast, accurate and energy-ecient

System setup performance

DC supply to drives from a central

power supply module

Simple and fast conguration of

several drives

Fast installation, reduced number of cables

Control via IEC 61131-3 Open system

Hybrid cable

Easy and fast installation, reduced

number of cables

All components support CAN Enhanced diagnostics, reduced downtime

Facts about our products

ISD Servo Drive

Available Options

n Safe Torque O (STO)

n Brake

n Feedback:

– Resolver

– Singleturn

– Multiturn

n Flexible hybrid loop cable

n IEC ange

n Customised ange on request

Available Accessories

n Shaft seal

n Shaft seal change kit

n Connector kits for:

– Power Supply Module

– Connection Box

– Encoder Box

n Terminating resistor

Specications

Servomotor

Rated voltage DC 300 V

Rated torque 1.7-2.1 Nm

Max. torque 8 -11 Nm

Rated current 0. 6 -1.15 A

Max. current 3.95-7.05 A

Rated speed 600-1000 rpm

Max. speed 1000-1500 rpm

Rated power 180 -3 45 W

Inertia 3.5 10

Shaft diameter 19 mm

Enclosure IP 54/IP 65

Power Supply Module

Input voltage

Input current 6 A

Output voltage DC 300 V

Rated power 3000 W

Rated current 10 A

Dimensions (H x W x D) 268 x 130 x 205 mm

Connection Box

Input voltage DC 300 V

Output voltage lines 1 & 2 DC 300 V

Rated power 3000 W

Rated current 10 A

Dimensions (H x W x D) 268 x 130 x 205 mm

Encoder Box

Input voltage DC 24 V

Supported encoder inputs SSI, SSI-CRC, QEP, BiSS

Dimensions (H x W x D) 105.2 x 142.0 x 70.8 mm

-4

to 6.5 10-4 kgm

AC 380-480 V ±10 %,

3-phase: L1, L2, L3, PE

each phase

rms

2

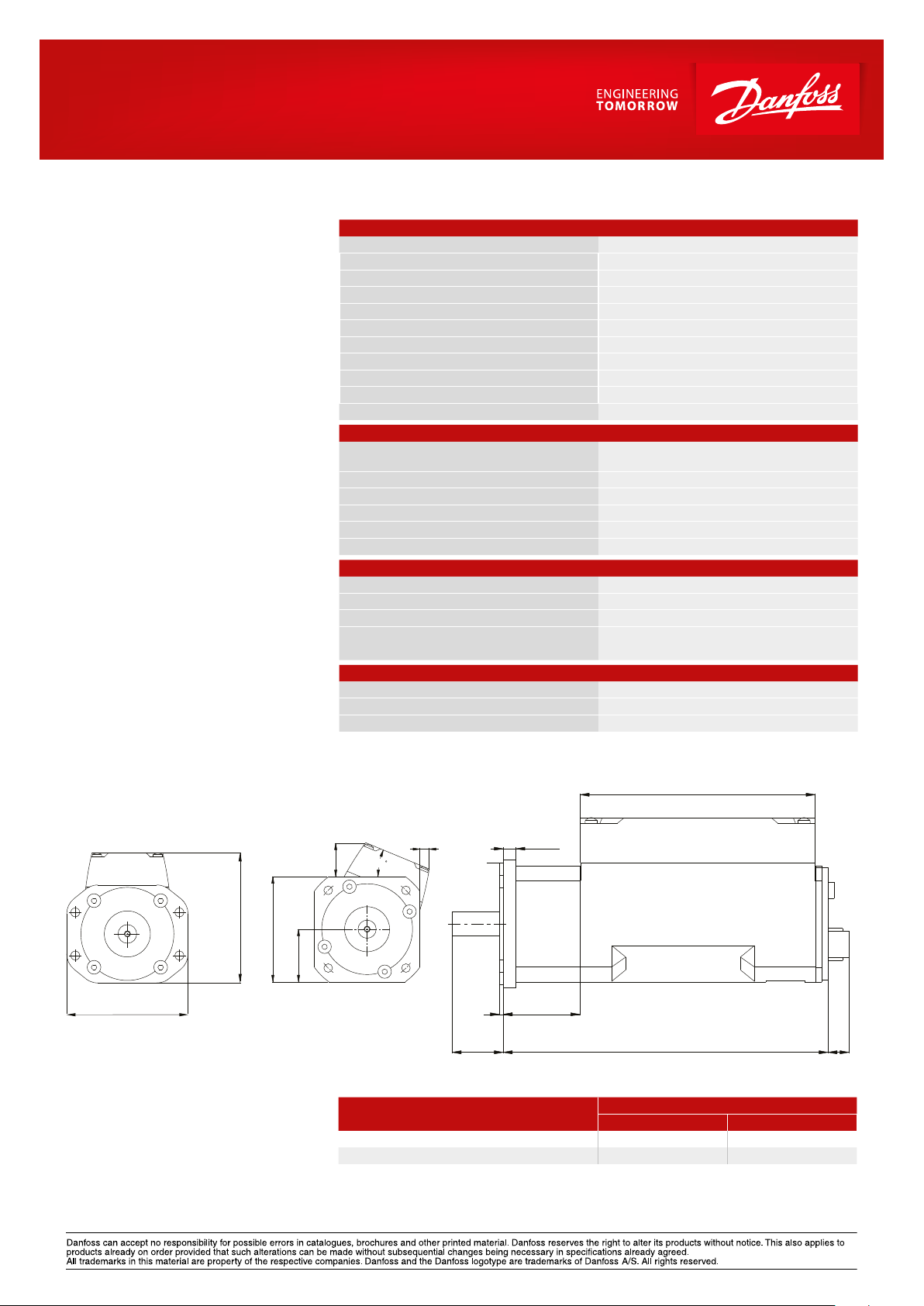

Dimensions

ISD Flange

124 mm

134 mm

110 mm

55 mm

184.5 mm

IEC Flange

35 mm

Motor ISD 410

22.5

10 mm

3 mm

40 mm

10 mm

A

B

Dimensions [mm]

A B

ISD / IEC ange with brake 60 255

ISD / IEC ange without brake 35 230

16 mm

DKDD.PFP.800.A5.02 VLT® is a trademark of Danfoss A/S Produced by PE-MMSC 2014.09

Loading...

Loading...