Data sheet

iSave® Energy Recovery Device

iSave 50 / iSave 70

hpp.danfoss.com

Data sheet | iSave 50 and iSave 70

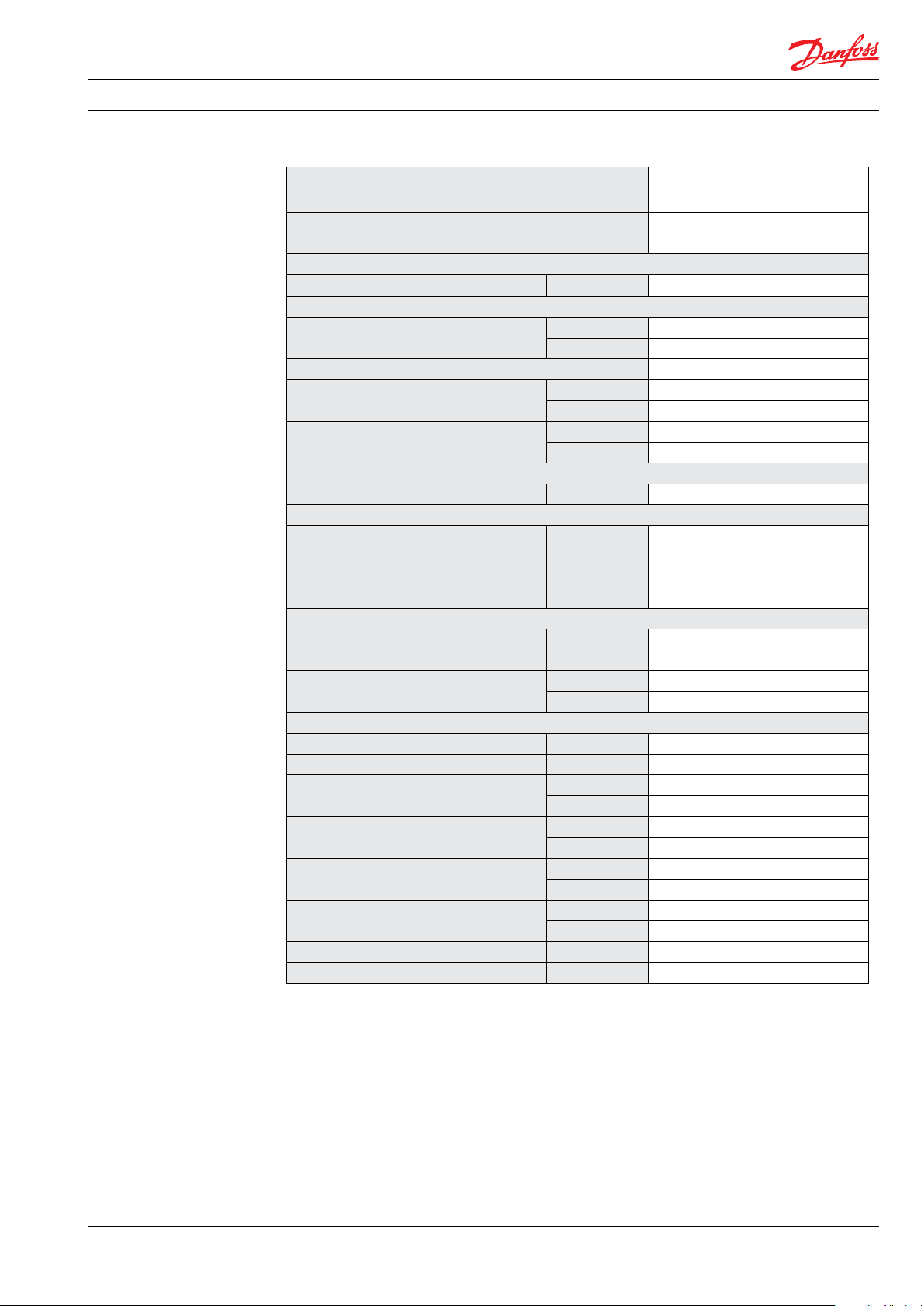

Table of Contents Contents

1. General information.....................................................................3

2. Benets.................................................................................3

3. Applications ............................................................................3

4. Technical data ..........................................................................4

4.1 iSave without motor ....................................................................4

4.2 iSave with IEC motor ....................................................................6

4.3 iSave with NEMA motor .................................................................7

5. Performance curves.....................................................................8

5.1 Flow at dierent rpm....................................................................8

5.2 iSave 50 ow curves.....................................................................8

5.3 iSave 70 ow curves.....................................................................8

5.4 Torque curve for iSave 50 and iSave 70...................................................9

5.5 Mixing curve ............................................................................9

6. Temperature and corrosion.............................................................10

6.1 Operation..............................................................................10

7. Installation.............................................................................10

7.1 Operation and mounting...............................................................10

7.2 Horizontal mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

7.3 Connection to inlet or discharge ports: .................................................11

7.4 Filtration...............................................................................11

7.5 N o ise ..................................................................................11

7.5 RO systems with an iSave...............................................................12

8. Dimensions and connections...........................................................14

8.1 iSave 50-70 without electric motor .....................................................14

8.2 iSave 50-70 with with IE3 motor 18.5 kW on base frame vertical_front mounted .........15

8.3 iSave 50-70 with with IE3 motor 18.5 kW on base frame vertical_back mounted..........16

8.4 iSave 50-70 with with IE3 motor 18.5 kW on base frame horizontal ......................17

8.4 iSave 50-70 th NEMA motor 30 HP on base frame vertical - front mounted ...............18

8.5 iSave 50-70 with NEMA motor 30 HP on base frame vertical - back mounted .............19

8.5 iSave 50-70 with NEMA motor 30 HP on base frame horizontal ..........................20

9. Service.................................................................................21

9.1 Warranty...............................................................................21

9.2 Operational conditions of concern......................................................21

9.3 Maintenance...........................................................................21

9.4 Repair assistance.......................................................................21

10. Accessories ............................................................................21

11. Useful documents......................................................................21

2

AI264763692435en-000901 | Data sheet iSave 50-70 | UK | 04.2021

Data sheet | iSave 50 and iSave 70

1. General information Energy Recovery Devices (ERD) are used in

reverse osmosis (RO) systems to recycle the

energy held in discharged brine from the

membranes. Thus, iSave 50 and iSave 70 are

designed for use with low viscosity and corrosive

uid such as sea water.

The Danfoss iSave Energy Recovery Devices all

consist of an isobaric pressure exchanger and a

positive displacement pump combined into one

compact unit. The high-pressure booster pump

is based on the vane pump principle enabling a

very light and compact design. The vane pumps

are xed displacement pumps in which the ow

is proportional to the number of revolutions

(rpm) of the driving shaft – enabling ow control.

Speed control is made by a VFD. The iSave design

ensures lubrication of the moving parts by the

uid itself.

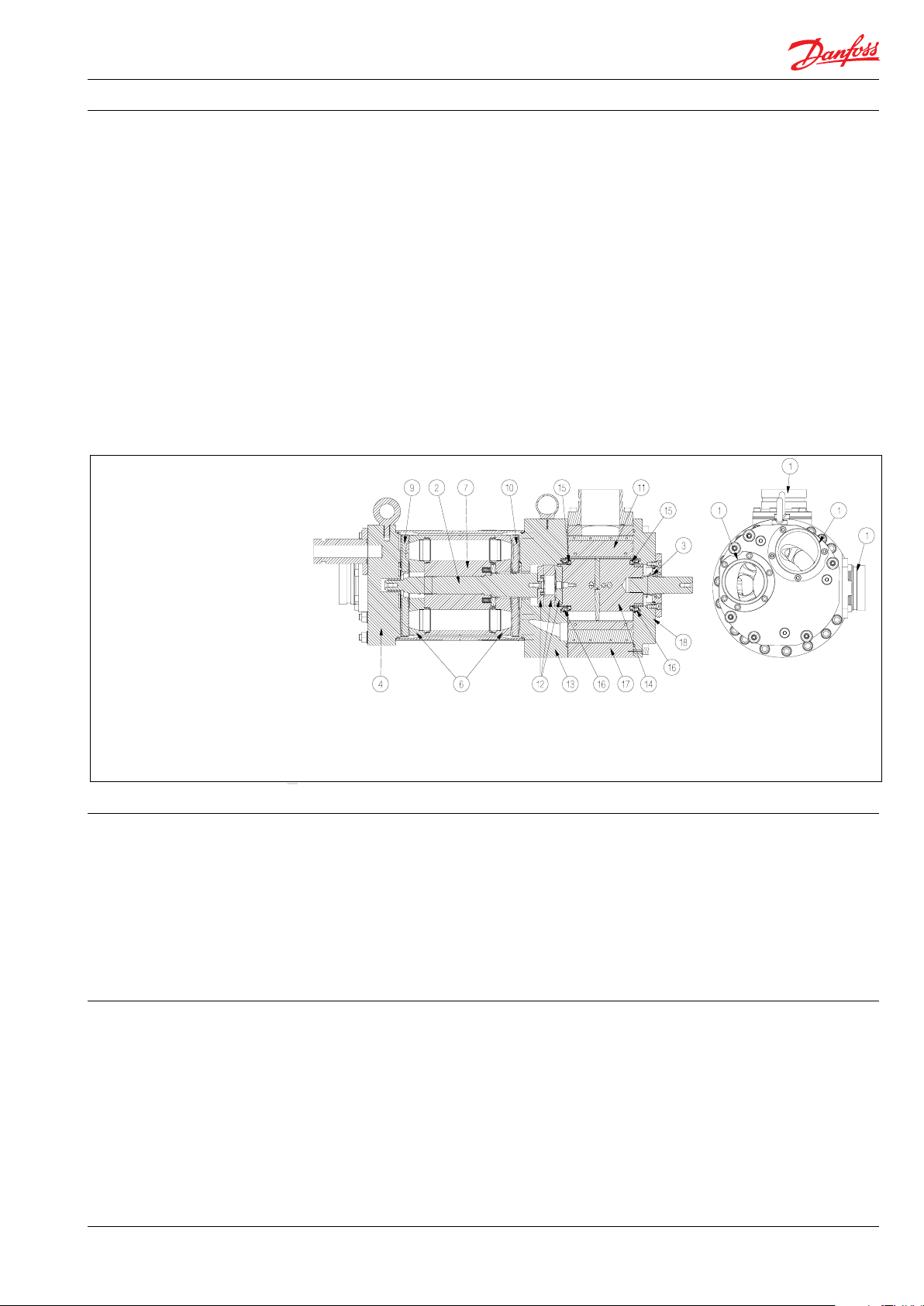

1. 3” Victaulic connections

2. Shaft

3. Low pressure shaft seal

4. Port ange

6. Valve plate

7. Cylinder barrel

9. Port plate (brine)

10. Port plate (sea water)

11. Vane s

12. Coupling

13. Intermediate ange

14. Rotor

15. Rotor element

16. Sealing plate

17. Stat or

18. Motor end ange

All parts included in the iSave 50 & 70 are

designed to provide long service life with a

constant high eciency and minimum service

required.

Unlike a centrifugal pump, it produces a similar

ow at a given speed no matter what discharge

pressure.

2. Benets • Corrossion resistance (all wetted parts are made

• Signicant power savings and low specic

energy consumption (SEC)

• Simple and space-saving installation with

both pump and pressure exchanger in one

of high corrosion-resistant materials e.g. Super

Duplex or Duplex)

• Fewer components

unit

• Simple system design and monitoring

without requirement for high-pressure ow

meters

• Simple operation with design that prevents

overspin/overushing

• Easy modular service

3. Applications

Danfoss iSave ERDs are built into a broad range

of RO desalination plant around the world.

Typical applications for iSave 50 - 70 will be:

• Containerized solutions for hotels and

resorts on islands as well as coastal regions

• Onboard systems for ships

• Oshore platforms for the oil and gas

industry

• Municipal and private waterworks

AI264763692435en-000901 | Data sheet iSave 50-70 | UK | 04.2021

3

Data sheet | iSave 50 and iSave 70

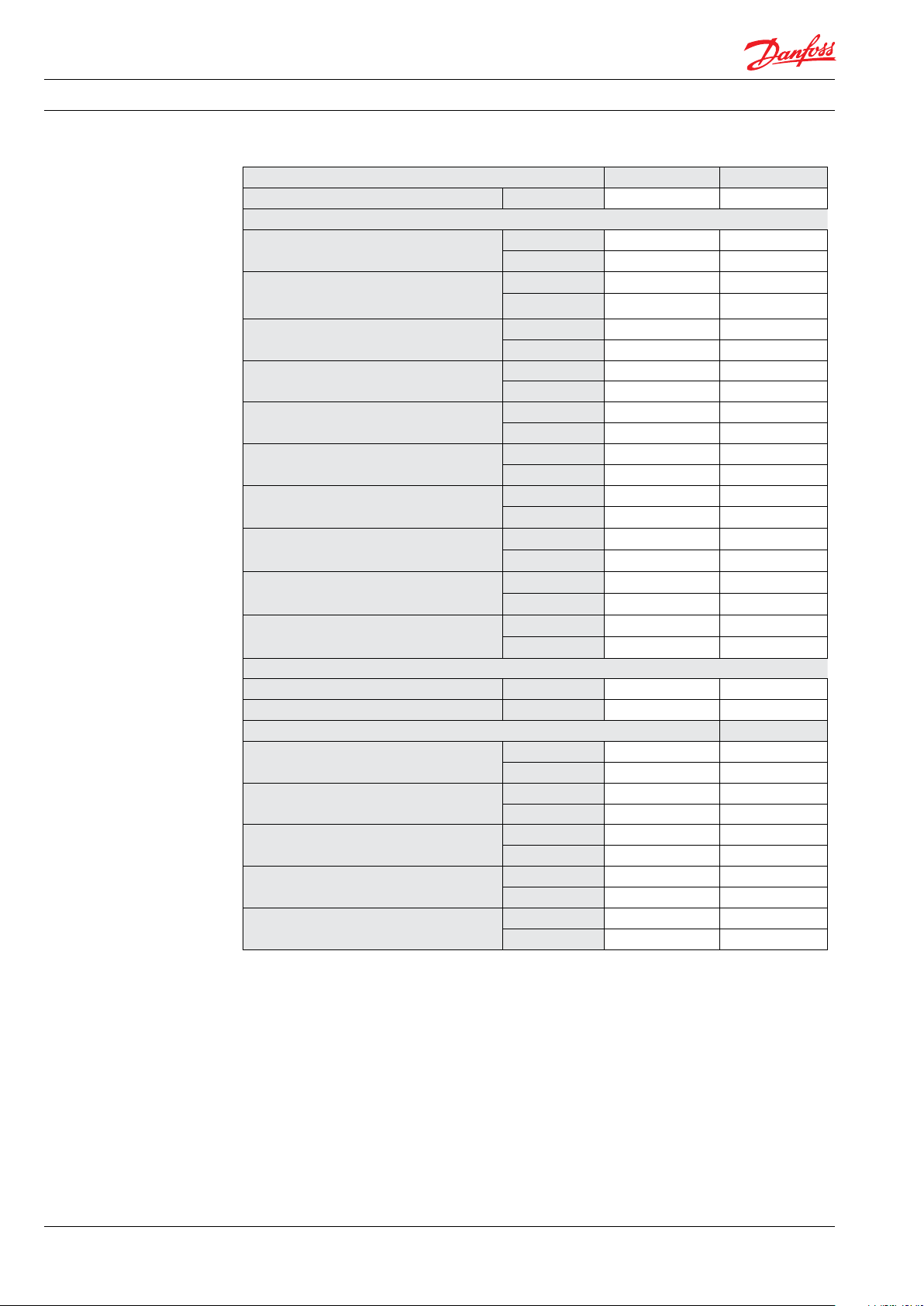

4. Technical data 4.1 iSave without motor

iSave size iSave 50 iSave 70

Code number 180F7020 180F7021

Pressure

Max. dierential pressure (HP out - HP in)

Min. pressure HP out (min. allowable working

pressure)

Max. pressure HP out (Max. allowable working

pressure, MAWP)

Min. pressure on HP in,

intermittent

Max. pressure LP in (MAWP)

Max. pressure LP in, peak

Min. allowable working pressure LP in

Max. dierential pressure (LP in - LP out)

Max. static test pressure (HP in and HP out)

Max. static test pressure (LP in and LP out)

Speed

Min. speed rpm 525 625

Max. speed rpm 650 875

Typical ow

Flow at min. speed, HP out

Flow at max. speed. HP out

Max. lubrication ow at 60 barg (871 psig)

Peak ow, LP in

Max. allowable working ow, LP in

1)

2) 3)

4)

10)

barg 5 5

psig 72 72

barg 40 40

psig 580 580

barg 83 83

psig 120 0 120 0

barg 2 2

psig 29 29

1)

barg 5 5

psig 72 72

barg 10 10

psig 145 145

barg 2 2

psig 29 29

barg 0.53 0.79

psig 7.69 11.4 6

barg 108 108

psig 1566 156 6

barg 13 13

psig 189 189

m³/ h 42 50

gpm 184 220

m³/ h 52 70

gpm 228 308

l/min 25 25

gpm 6.6 6.6

m³/ h 120 120

gpm 528 528

7)

m³/ h 57. 2 70

gpm 252 308

4

AI264763692435en-000901 | Data sheet iSave 50-70 | UK | 04.2021

Data sheet | iSave 50 and iSave 70

Technical specications

Media temperature

Ambient temperature

Filtration requirements (nominal)

Salinity increase at membrane at 40% recover y rate at

balanced ow

Weight (dry)

Weight (operation with water)

Noise

Sound pressure level L

Torque data

Max. allowable working torque

Max. starting torque (stick/slip)

o

5)

6)

9)

C 2-35 2-35

o

F 36-95 36-95

o

C 0-50 0-50

o

F 32-122 32-122

3 micron melt-blown

2-3%

kg 164 164

lb 362 362

kg 172 172

lb 379 379

8)

PA

1 m

dB(A) 83 86

Nm 170 190

lbf-ft 125 140

Nm 180 180

lbf-ft 132 132

1)

Max. allowable working pressure of continous

operation. For lower and higher pressure, please

contact Danfoss.

2)

Typical pressure level at start-up and permeate

ush.

3)

Intermittent pressure is acceptable for less than 10

minutes within a period of 6 hours.

4)

Typical average ow at 60 barg and 3 barg

dierential pressure

5)

Dependent on NaCI concentation.

6)

Please see section 7.4 ltration.

7)

Continuous operation: iSave can operate

continuously with up to 10% over ush with the

limitation that the ow rate at LP inlet shall not

exceed 70 m3/h.

8)

A-weighted sound pressure level at 1 m from the

pump unit surfaces (reference box) acc. to EN ISO

20361 section 6.2. The noise measurements are

performed acc. to EN ISO 3744:2010 on a motor-

pump-unit at max. pressure and rpm.

9)

Balanced ow: The mixing rate is dened at

balanced ow when HP-out is equal to LP-in.

10)

At system start-up: iSave can run for up to 10 min.

with 150% of max. rated ow at LP inlet. The time

where max. rated ow is exceeded should be kept

as short as possible to minimize wear.

AI264763692435en-000901 | Data sheet iSave 50-70 | UK | 04.2021

5

Data sheet | iSave 50 and iSave 70

4.2 iSave with IEC motor

i

iSave size iSave 50 iSave 70

Code number (vertical) 180F7038 180F7040

Code number (horizontal) 180F7023 180 F7025

Pressure, Speed, Flow, Temperature and Torwue are identical with 180F7020 and 180F7021

Eciency

Eciency at max. speed at 60 barg (871 psig) % 93.7 92.4

Technical specications

Media temperature

Filtration requirements (nominal)

Weight (dry) vertical/horizontal

Weight (operation with water) vertical/

horizontal

Noise

Sound pressure level L

Footprint

Footprint (vertical position)

Footprint (horizontal position)

Torque data

Max. allowable working torque

Max. starting torque (stick/slip)

Motor data

Nominal speed rpm 985 985

Rated current at 400V A 37 37

Motor size

Frame size

Rated motor torque at nominal speed

Rated motor ambient temperature

Motor insulation Class B B

Motor degrees of protection IP 55 55

5)

°C 2-35 2-35

°F 36-95 36-95

6)

3 micron melt-blown

kg 441/463 441/463

lb 972/1021 972/1021

kg 470/471 470/471

lb 1036/1038 1036/1038

2)

PA

1 m

3)

dB(A) 83 86

m² 0.44 0.44

foot² 4.71 4.71

3)

m² 0.76 0.76

foot² 8.14 8.14

Nm 170 177

lbf-ft 125 130.5

Nm 180 180

lbf-ft 132 132

kW 18.5 18.5

HP 30.0 30.0

IEC 200 L 200 L

Poles 6 6

Nm 177 177

lbf-ft 130. 5 130.5

4)

°C 40 40

°F 104 104

2)

A-weighted sound pressure level at 1 m from the ERD

unit surfaces (reference box) acc. to EN ISO 20361

section 6.2. The noise measurement are performed

acc. to EN ISO 3744:2010 on an ERD with motor

(motor pump unit) from min. to max. pressure and

6)

Please see section 7.4 Filtration

7)

Typical eciency for pressure exchanger, ..

booster pump, electrical motor and VFD at 3

barg dierential pressure after a system has ...

been commissioned and run in.

speed.

3

Area covered with recommended IE3 motor

congurations (excl. of space to service the ERD)

4)

For higher temperature, contact Danfoss.

5)

Dependent on NaCI concentation.

6

AI264763692435en-000901 | Data sheet iSave 50-70 | UK | 04.2021

)

Data sheet | iSave 50 and iSave 70

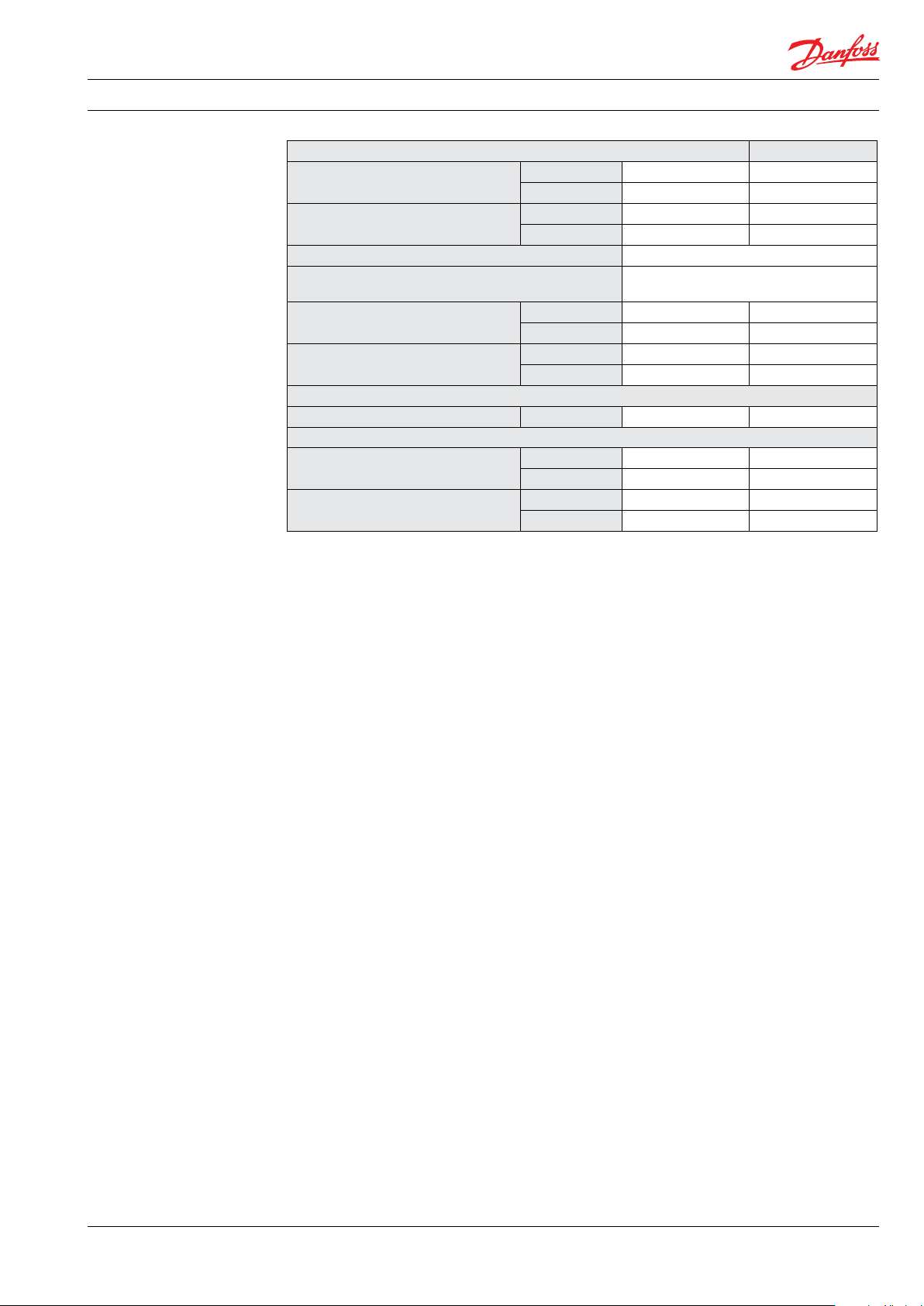

4.3 iSave with NEMA motor

iSave size iSave 50 iSave 70

Code number (vertical) 180U0062 180U0064

Code number (horizontal) 180U0003 180U0005

Pressure, Speed, Flow, Temperatue and Torque are identical with 180F7020 180F7021

Eciency

Eciency at max. speed at 60 barg (871 psig)

Technical specications

Media temperature

Filtration requirements (nominal)

Weight (dry) vertical/horizontal

Weight (operation with water) vertical/

horizontal

Noise

Sound pressure level L

Footprint

Footprint (vertical position)

Footprint (horizontal position)

Torque data

Max. allowable working torque

Max. starting torque (stick/slip)

Motor data

Nominal speed rpm 118 0 118 0

Rated current at 400V A 36.2 36.2

Motor size

Frame size

Rated motor torque at nominal speed

Rated motor ambient temperature

Motor insulation Class B B

Motor degrees of protection IP 55 55

2)

A-weighted sound pressure level at 1 m from the ERD

unit surfaces (reference box) acc. to EN ISO 20361

section 6.2. The noise measurement are performed

acc. to EN ISO 3744:2010 on an ERD with motor

(motor pump unit) from min. to max. pressure and

speed.

3

Area covered with recommended IE3 motor

congurations (excl. of space to service the ERD)

4)

For higher temperature, contact Danfoss.

5)

Dependent on NaCI concentation.

7)

% 93.7 92.4

5

)

6)

°C 2-35 2-35

°F 36-95 36-95

3 micron melt-blown

kg 484/506 484/506

lb 10 67/1116 10 67/1116

kg 513/535 513/535

lb 1131/1179 1131/117 9

2)

PA

1 m

3)

dB(A) 83 86

m² 0.44 0.44

foot² 4.71 4.71

3)

m² 0.76 0.76

foot² 8.14 8.14

Nm 170 177

lbf-ft 125 130.5

Nm 180 180

lbf-ft 132 132

kW 22.5 22.5

HP 30.0 30.0

NEMA 324/6T 324/6T

Poles 6 6

Nm 179 179

lbf-ft 132 132

4)

°C 40 40

°F 104 104

6)

Please see section 7.4 Filtration

7)

Typical eciency for pressure exchanger, ..

booster pump, electrical motor and VFD at 3

barg dierential pressure after a system has ...

been commissioned and run in.

)

AI264763692435en-000901 | Data sheet iSave 50-70 | UK | 04.2021

7

Data sheet | iSave 50 and iSave 70

0

10

20

30

40

50

60

525 650

Flow [GPM]

Flow [m

3

/h]

Motor speed [rpm]

Flow curve iSave50®

5 bar

2

bar

220

176

0,0

10,0

20,0

30,0

40,0

50,0

60,0

70,0

80,0

625 875

Flow [GPM]

Flow [m

3

/h]

Motor speed [rpm]

Flow curve iSave70®

2

bar

5 bar

220

308

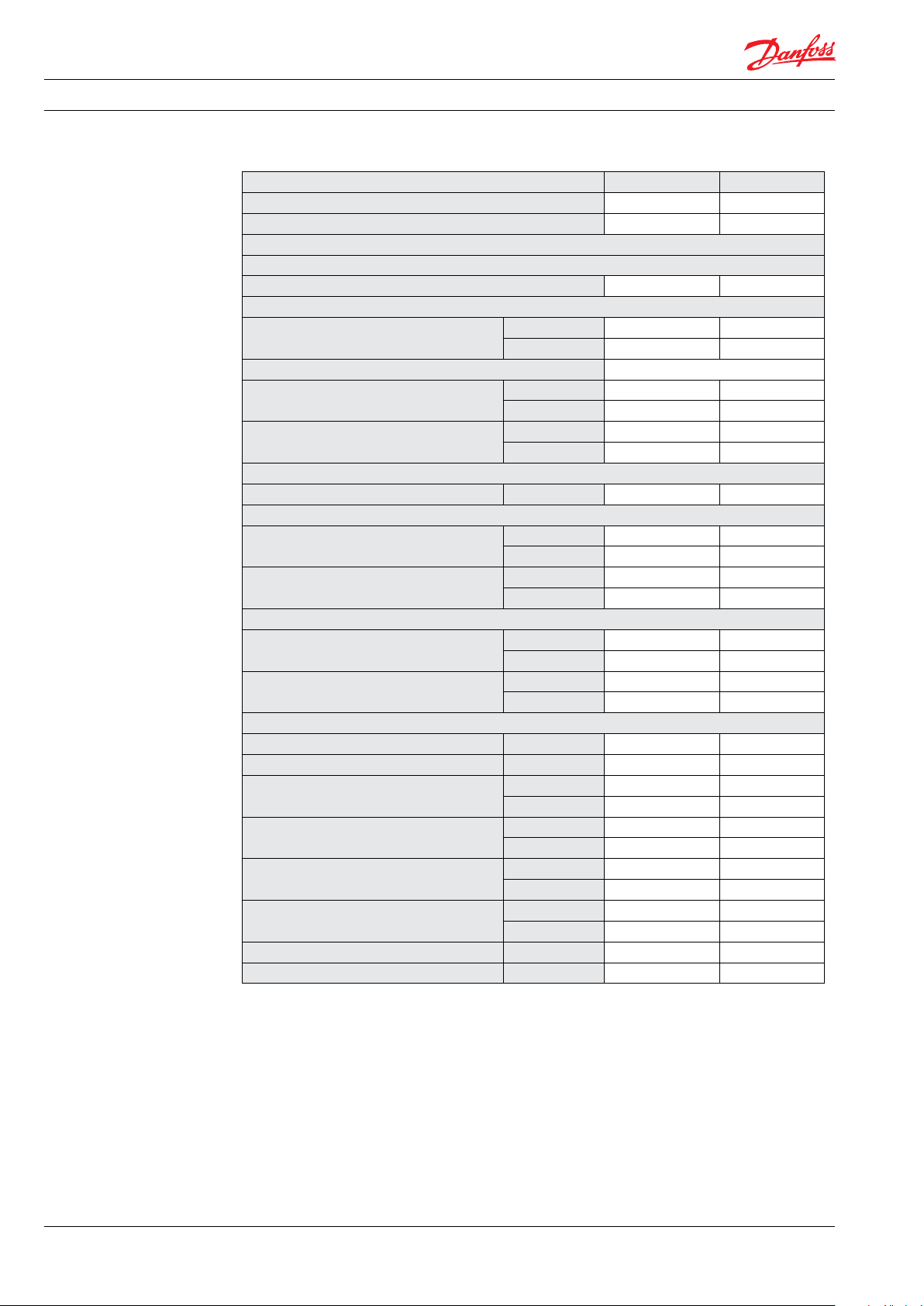

5. Performance curves 5.1 Flow at dierent rpm

The diagram shows that the HP ow can be

changed by changing the rotation speed of the

iSave. The ow/rpm ratio is constant, the

required ow is obtainable by changing the

rotation speed to a required value.

5.2 iSave 50 ow curves

For accurate data and advise, please contact

Danfoss High Pressure Pumps.

The iSave is delivered with a 3.1 performance

certicate according to EN10204.

5.3 iSave 70 ow curves

8

AI264763692435en-000901 | Data sheet iSave 50-70 | UK | 04.2021

Data sheet | iSave 50 and iSave 70

5.4 Torque curve for iSave 50 and iSave 70

Below curve illustrates typical values.

Torque [Nm]

200

180

160

140

120

100

80

60

40

Torque on iSave50 and iSave70

Starting torque

delta-P: 5 bar

delta-P: 4 bar

delta-P: 3 bar

delta-P: 2 bar

delta-P: 1 bar

20

0

5.5 Mixing curve

525 645 765 875

Motor speed [rpm]

Volumetric mixing versus flushing

14,0

12,0

10,0

8,0

6,0

Volumetric mixing [%]

4,0

2,0

0,0

-10 -5 0 5 10

Flush ratio (larger than 0 means overflush) [%]

AI264763692435en-000901 | Data sheet iSave 50-70 | UK | 04.2021

9

Data sheet | iSave 50 and iSave 70

6. Temperature and

corrosion

6.1 Operation

The chart below illustrates the corrosive

resistance of dierent types of stainless steel

related to NaCl concentration and temperature.

All critical parts of the iSave is made of

Super Duplex 1.4410/UNS 32 750 or Duplex

1.4462/UNS 32803.

º

80

C

Duplex

70

60

50

316L

40

30

20

100

1000

160 1600

Always ush the iSave with fresh water at

operation stop in order to minimize the risk of

crevice corrosion.

Super Duplex

-

10 000

16000

100 000

160000

CI

ppm

NaCI

ppm

7. Installation

7.1 Operation and mounting 7.2 Horizontal mount

The iSave 50 and iSave 70 can be mounted

horizontally and vertically. When mounted

vertically, the electric motor must be placed at

the top of the iSave

The iSave is delivered with a standard port

orientation. The port orientation can be changed

by the customer by rotating the combined iSave

and bell housing around the center of the motor

shaft.

10

AI264763692435en-000901 | Data sheet iSave 50-70 | UK | 04.2021

Data sheet | iSave 50 and iSave 70

See example below on how to mount the pump

and connect it to an electrical motor.

A: Flexible coupling

B: Bell housing

C: Motor shaft

7.3 Connection to inlet or discharge ports:

• When using hard piping, it is important to

follow the Guideline 180R9367 - Pipe

connection.

• When using exible hoses, it is recommened

to use Hose Whip Restraint. Also follow the

guideline 180R9084 - Right and Wrong Hose

assembly.

Note: Any axial and radial load on the shaft

must be avoided.

min. 3 - 5 mm air space

A B C

7.4 Filtration

High quality water extends the service life of the

whole system.

Water to the iSave must be ltered to 3 μm

nominal, using melt-blown depth lter with

good end sealings. Consult Danfoss for correct

choice of lter.

It is important with selection of a proper lter

and lter housing to ensure good cartridge end

sealing.

If there is a high risk of water by-pass it is

recommended to use a second stage lter

solution.

7.5 Noise

Since the iSave is mounted on a bell housing and

electric motor, the noise level should be

determined for a complete system. To minimize

vibrations and noise throughout the system, it is

improtant that a horizontal iSave unit is mounted

correctly on a frame with dampeners.

Rigid designs with metal pipes cause vibration

and noise. It is therefore recommended to use

high-pressure exible hoses between the hard

piping in the RO-plant and the iSave or to used

multiple connections with Victaulic clamps

where possible.

The noise level is inuenced by:

Speed:

• High rpm makes more uid/structure-borne

pulsations/vibrations than low rpm due to

higher frequency.

AI264763692435en-000901 | Data sheet iSave 50-70 | UK | 04.2021

As the various lters on the market dier greatly,

Danfoss High Pressure Pumps recommends

using cartridges with consistent, reliable

performance and high eciency and where

bres are blown continuously onto a central

support core. High Pressure Pumps does not

recommend cartridges requiring any type of

binders or resins.

Filters can be purchased from Danfoss

High Pressure Pumps. For more information on

the importance of proper ltration, please

consult our publication “Filtration” (code number

521B1009), which also will provide you with an

explanation of ltration denitions and a

guidance on how to select the right lter.

Pressure:

• High pressure makes more noise than low

pressure.

Mounting:

• Rigid mounting makes more noise than

exible mounting due to structure-borne

vibrations.

Connections to iSave:

• Pipes connected directly to the iSave make

more noise than exible hoses due to

structure-borne vibrations.

• Variable frequency drives (VFD):

Motors regulated by VFDs can increase noise

level if the VFD does not have the right

settings.

11

Data sheet | iSave 50 and iSave 70

7.5 RO systems with an iSave

VFD

22

M

4

2

26

Media filter

A

B C

Filter

3 micron

nominel

PI

Fresh water

permeate flush

Filter

10 micron

absolut

PI

F

*

12

PI

PS

21

24

19

*

Second stage filter: If recommended housing des ign and cartridges are not used, a second stage filt er is required

3

LP in

PI

PS

F

1

HP out

11

M

4

26

iSave

HP in

M

VFD

23 23

25

18

25

18

HP out

HP in

M

VFD

VFD

5

PI

PS

13

14

PS

PI

6

7

20

F

22

Full flow

cleaning/CIP

1011

PI

15

17

Permeate

F

Flowmeter

8

9

16

28

CIP

27

Drain

Explanation of P&ID setup

D. Inlet ow control and mixing:

A. Inlet lter:

Place inlet lters on LP string in front of the

iSave (11). Please see Guide line 521B1009 on

Filtration.

To balance LP ow up against HP ow on the

iSave and control mixing, place a

owmeter on low-pressure inlet (12) or low

pressure outlet (20) of the iSave.

If recommended housing design and

cartridges are not used, a second stage

lter is required, see above (*).

Thoroughly clean pipes and ush system

prior to start-up.

E. Outlet pressure control:

In order to control the inlet pressure ne eded a

back pressure valve (15) must be installed in

the common outlet pipe from the iSaves. The

valve should be designed to control ow.

B. Inlet pressure:

Must assure that iSave is running according to

specications. Refer to iSave data sheet.

It is recommended to use a manual valve with

lock function or an automatic controlled

valve.

Required: Must assure min. pressure to avoid

cavitation.

Recommended: Must assure max. pressure to

avoid hydraulic and mechanical overload.

(13) used for iSave 21 and iSave 40.

(24) used for iSave 50 and iSave 70.

F. Variable speed and overload protection:

Install a VFD to control the speed of the iSave

and protect it against mechanical overload.

See instruction 180R9372 for guidance of VFD

settings.

C. Piping and hoses:

Dimension the piping to obtain minimum

G. LP discharge ow control:

See “E”.

pressure loss (large ow, minimum pipe

length, minimum number of bends/

connections and ttings to prevent pressure

loss and ow turbulence). Use exible hoses

to minimize vibrations and noise. Please

consult the Danfoss Hoses and Hose Fittings

H. Air venting:

Install an air bleed valve (8) on the highest

point of the high-pressure piping to ensure

the air is purged from the system before

startup.

data sheet (521B0909 ) and Right and wrong

Hose assembly (180R9084) for guidance.

12

AI264763692435en-000901 | Data sheet iSave 50-70 | UK | 04.2021

Data sheet | iSave 50 and iSave 70

I. Pressure relief (high pressure):

The pressure relief valve (6) protects the whole

system against pressure overload and relieves

the water if the pressure exceeds the maximum set pressure. If the high-pressure pump

is a positive displacement pump, the pump

can built up a very high pressure that will

exceed mechanical strength of the membrane

housing, pipes and other accessories. When

using Danfoss APP pumps with Danfoss VCM

check valves, it is recommended to place a

pressure relief valve or pressure safety valve as

illustrated. In case the Danfoss check valves

are not used, the valve must be placed

between pump and check valve (See

180R9371, Design Guide Pressure saftey valve

in seawater RO sytem for more details).

J. Pressure relief (low pressure):

The pressure relief valve or pressure safety

valve (19) protects the low-pressure pipes

against pressure overload and relieves the

water if the pressure exceeds the maximum

allowable pressure.

For a more eleborate description of the P&ID

setup, please consult the Danfoss Design Guide

Piping & Instrumentation Diagram (P&ID)

(180R9370) or contact Danfoss.

The iSave 50 and iSave 70 can be mounted in

parallel. For more information, please see

“Design Guide Parallel-coupled APP and iSave”

-180R9354 or contact Danfoss.

AI264763692435en-000901 | Data sheet iSave 50-70 | UK | 04.2021

13

Data sheet | iSave 50 and iSave 70

8. Dimensions and

connections

8.1 iSave 50-70

without electric motor

14

AI264763692435en-000901 | Data sheet iSave 50-70 | UK | 04.2021

Data sheet | iSave 50 and iSave 70

8.2 iSave 50-70 with with IE3 motor 18.5 kW

on base frame vertical_front mounted

AI264763692435en-000901 | Data sheet iSave 50-70 | UK | 04.2021

15

Data sheet | iSave 50 and iSave 70

8.3 iSave 50-70 with with IE3 motor 18.5 kW

on base frame vertical_back mounted

16

AI264763692435en-000901 | Data sheet iSave 50-70 | UK | 04.2021

Data sheet | iSave 50 and iSave 70

8.4 iSave 50-70

with with IE3 motor 18.5 kW

on base frame horizontal

AI264763692435en-000901 | Data sheet iSave 50-70 | UK | 04.2021

17

Data sheet | iSave 50 and iSave 70

8.4 iSave 50-70 with NEMA motor 30 HP

on base frame vertical - front mounted

AI264763692435en-000901 | Data sheet iSave 50-70 | UK | 04.2021

18

Data sheet | iSave 50 and iSave 70

8.5 iSave 50-70 with NEMA motor 30 HP

on base frame vertical - back mounted

AI264763692435en-000901 | Data sheet iSave 50-70 | UK | 04.2021

19

Data sheet | iSave 50 and iSave 70

8.5 iSave 50-70

with NEMA motor 30 HP

on base frame horizontal

20

AI264763692435en-000901 | Data sheet iSave 50-70 | UK | 04.2021

Data sheet | iSave 50 and iSave 70

9. Service 9.3 Maintenance

9.1 Warranty

The Danfoss iSave is designed for long operation,

low maintenance and reduced lifecycle costs.

Periodic inspections are required to ensure worn

parts (if any), are replaced in due time. Opera-

tional conditions such as water quality should be

Provided that the iSave has been running

according to the Danfoss specications, Danfoss

guarantees one year service-free operation,

taken into consideration when determining the

frequency of the inspections. Danfoss recom-

mends yearly inspections.

however, max. 18 months from date of

production.

It is recommended to order the purpose-

designed tool kit.

9.2 Operational conditions of concern

Particular attention should be paid to the

following factors to avoid increased wear and

spare parts costs:

9.4 Repair assistance

In case of irregular function of the Danfoss RO

components, please contact Danfoss High

Pressure Pumps.

- Insucient ltration

- Insucient bleeding and venting

- Running at speeds outside specicat

tions

- Wrong direction of rotation

- Insu cient ushing or periods o f standstill with

sea water inside the iSave.

10. Accessories

Description Type Code no.

11. Useful documents

3” Inlet hose kit - 2 m (79”) 6 barg (87 psig) 3” Victaulic, style 77 180Z0144

3” Outlet hose - 1 m (39.4”) 80 barg (1160 psig) 3” Victaulic, style 77 180Z0611

3” Outlet hose - 1.79 m (70.0”) 80 barg (1160 psig) 3” Victaulic, style 77 180Z0612

Coupling iSave 50 - iSave 70 Softex 55H7-32H7 180Z4003

Base plate horizontal IEC200/NEMA324TC 180Z4007

Base plate vertical IEC200/NEMA324TC 180Z4025

Literature number Description

180R9213 Start and stop of the SWRO with iSave

180 R9214 Membrane cleaning of the RO system with the iSave

180R9354 Parallel coupled APP and iSave

180R9367 Pipe connections

180R9371 Pressure safety valve in the SWRO system

180R9372 APP and iSave overload protection

180R9370 Review sheet P&ID

521B1009 Filtration

iSave selection tool (hpp.danfoss.com)

AI264763692435en-000901 | Data sheet iSave 50-70 | UK | 04.2021

21

Danfoss A/S

High Pressure Pumps

DK-6430 Nordborg

Denmark

Danfoss ca n accept no respons ibility for pos sible errors in ca talogues, bro chures and other pr inted material. Da nfoss reserves t he right to alter its p roducts with out notice.

This also a pplies to produc ts already on ord er provided that su ch alterations ca n be made without su bsequential cha nges being nece ssary in speci cations alread y agreed.

All trade marks in this mate rial are proper ty of the respec tive companies . Danfoss and the Dan foss logotyp e are trademark s of Danfoss A/S. Al l rights reserv ed.

© Danfoss | DCS (IM) | 2021.04

AI264763692435en-000901 | Data sheet iSave 50-70 | UK | 22

Loading...

Loading...