Page 1

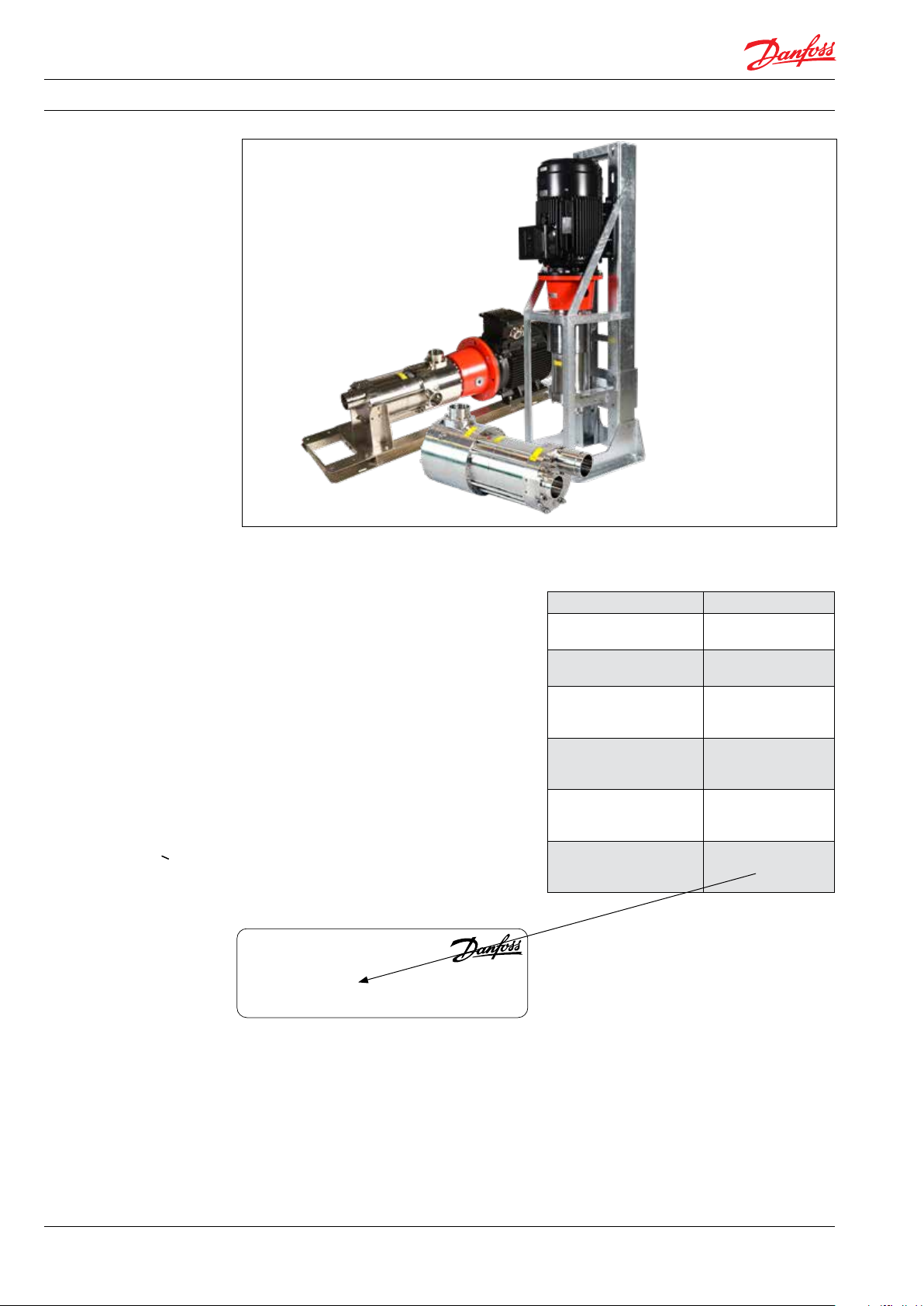

Frontpage

Operating guide

Manual del usuario

Energy Recovery Device

Manual de instalación,

iSave 50-70

Installation, Operation and

funcionamiento y mantenimiento

Maintenance Manual

iSave 40

hpp.danfoss.com

isave.danfoss.com

Page 2

Operating guide | iSave 50 - 70

Table of Contents 1. Validity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2 Target group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Manufacturer and customer service address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.5 Country specific information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5.1 United Kingdom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.6 Additional technical documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.1 General ............................................................................... . 6

3.2 Intended use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.3 Application range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.4 Preferred system design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4. Arrival, inspection, handling and storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

4.1 Arrival inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

4.2 Return to the supplier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

4.3 Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.4 Assembly iSave on electric motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.5 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.6 Outdoor storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

5. Technical data and design review. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

5.1 Design details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

5.2 Sound level of the iSave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

5.3 Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

5.4 Temperature and corrosion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.5 Dimensions and weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.6 Electrical motor data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

5.7 How does the iSave work?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.8 Seawater quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.8.1 Pre-filtration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5.8.2 Air bubbles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5.8.3 Chemicals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5.8.4 Initial start up and flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5.9 Initial start up and setting of safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5.10 Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.11 CIP or membrane cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

5.12 High pressure remains after shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

5.13 Over-pressurisation caused by low pressure isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

5.14 Over-pressurisation caused by high-pressure pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

5.15 Preferred system design and P&ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6. On-site installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

6.1 Design details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

6.2 Installation and alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

6.3 Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

6.4 Piping and joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

6.5 Mounting of coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

6.6 Accessibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

6.7 Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

6.7.1 Electric motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

6.7.2 Speed control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

6.7.3 Starting torque on the iSave. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

6.7.4 Torque overload pretection on the iSave. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

7. Commissioning, start-up and shutdown ................................................16

7.1 Safety regulations......................................................................16

7.2 Support................................................................................16

7.3 Commissioning ........................................................................16

2

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

Page 3

Operating guide | iSave 50 - 70

8. Service/Maintenance...................................................................17

8.1 Safety regulations......................................................................17

8.2 Support................................................................................17

8.3 Maintenance schedule .................................................................17

8.4 Recommended service intervals on internal parts .......................................18

8.5 Lubrication of bearings in electric motor................................................18

9. Trouble shooting.......................................................................19

9.1 Safety regulations......................................................................19

10. Appendices............................................................................21

10.1 Data sheet iSave 50-70 - (521B1378)) ....................................................23

10.2 Start and stop procedures (180R9213). ..................................................45

10.3 Membrane cleaning of the RO system with iSave unit (180R9214) . ......................51

10.4 APP pumps and iSave overload protection(180R9372)...................................57

10.5 Hose assembly and installation (180R9084) .............................................67

10.6 iSave part list 50-70 (521B1428) .........................................................75

10.7 Operating- and maintenance instruction, electric motor (180R9230).....................87

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

3

Page 4

Operating guide | iSave 50 - 70

1. Validity Document information and copyright

Installation, Operation and Maintenance

Manual.

Danfoss can accept no responsibility for possible

errors in the manual and instructions. Danfoss

reserves the right to alter its products without

notice. This also applies to products already on

order provided that such alterations can be

made without subsequential changes being

necessary in specifications already agreed.

All rights reserved. Contents provided herein

must neither be distributed, copied, reproduced,

edited or processed for any other purpose, nor

otherwise translated or published without

Danfoss’ express written consent.

PUMP

Type iSave 50 ERD

Code no. 180FXXXX

Serial no. XXXXXX02-XXX

MADE IN DENMARK

Danfoss A/S, 6430 Nordborg, Denmark

This manual is valid for iSave 50 -70

Code No./Description Serial no.

180F7020

iSave 50 without motor

180F7021

iSave 70 without motor

180F7038

iSave 50 Vertical

(IEC motor)

180F7023

iSave 50 horizontal

(IEC motor)

180F704 0

iSave 70 vertical

(IEC motor)

180F7025

iSave 70 horizontal

(IEC motor)

XXXXXX02-XXX

XXXXXX02-XXX

XXXXXX02-XXX

XXXXXX02-XXX

XXXXXX02-XXX

XXXXXX02-XXX

The serial number is referring to the Serial no. on

the product label. The digits shown (02) indicate

the version number of the pump.

This document is only valid for ERD version 2

and upwards.

4

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

Page 5

Operating guide | iSave 50 - 70

2. Introduction 2.1 General

iSave is manufactured by Danfoss A/S, and is sold

and marketed by a net of authorised distributors

world wide.

This manual contains the necessary instructions

for the installation, operation and service of the

iSave.

All personnel who are responsible for the

operation and maintenance of the iSave unit

must read and fully understand these

instructions, especially the section “Safety”

before:

• Transporting of the iSave unit.

• Lifting the unit.

• Installing the iSave unit on a frame.

• Connecting the iSave unit to the fluid

system.

• Connecting the electrical motor and

instrumentation.

• Commissioning the unit.

• Servicing the iSave unit, mechanics and

electrics.

• Decommissioning the iSave unit.

Ensure that these instructions are always readily

available to all personnel concerned.

2.3 Symbols

Indicates something to be noted by

the reader.

Indicates a situation which will or

couldresult in damage to the iSave

and its function.

Indicates a situation which will or

could result in personal injury and/or

damage to the iSave.

Electrical hazard. Indicates a high-voltage

warning

Safety glasses required

Hearing protection required

Safety shoes required

Safety helmet required

2.4 Manufacturer and customer service

Danfoss A/S

High Pressure Pumps

DK-6430 Nordborg, Dinamarca

Tel.: +45 7488 2222

E-mail: highpressurepumps@danfoss.com

Homepage: hpp.danfoss.com

2.2 Target group

This manual is intended for use by personnel

with qualified training and experience in the

operation and maintenance of a Sea Water

Reverse Osmosis (SWRO) or Brackish Water

Reverse Osmosis (BWRO) system.

2.5 Country specific information

2.5.1 United Kingdom

Danfoss Ltd.

22 Wycombe End

HP9 1NB Beaconsfield

United Kingdom

2.6 Additional technical documents

Below documents are not present in this Operating guide. Please contact Danfoss.

Document name Content

Service guide: 180R9387

Disassembling and assembling

Design guide: 180R9367

Pipe connection

Guide line: 180R9371

Pressure safety valve in SWRO systems

Guide line: 180R9370

Review sheet P&ID

Description of how to disassemble and assemble the iSave

Design guide on how to make har piping

with Victaulic clamps

Guide line on how to evaluate if a safty

valve is needed in a SWRO system

Detailed description about the need for

each individual component in the preferred

P&ID

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

5

Page 6

Operating guide | iSave 50 - 70

3. Safety 3.1 General

The iSave must not be used for other

purposes than those recommended and

specified without first consulting your local

iSave distributor.

This manual must be read and completely

understood by the responsible specialist

personnel prior to installation and

commissioning.

Use of this manual does not relieve operation

and maintenance personnel of the responsibility

of applying normal good judgment in the

operation and care of this product and its

components.

This manual must be available to all personnel

concerned at the site at all time.

An iSave must always be installed and used

in accordance with existing national and local

sanitary and safety regulations and laws. It is the

responsibility of the safety officer or the chief

operator to assure compliance with all local

regulations that are not taken into account in this

manual.

The iSave is a rotating machine that typically

operates at high pressure.

• Improper installation can cause fatal

injuries.

• The iSave must not operate outside the

application range.

• During the initial start-up, slowly raise the

pressure of the system and adjust the

over-pressure protection equipment for

proper limit settings.

• Make sure that the pressure is released

from the iSave before the iSave is

disconnected from any pipe or hose

connections.

• Make sure that the iSave can be drained

without injuring anyone and without

contaminating nearby equipment or the

environment.

• Before intervening in the iSave/system,

the power must be shut off and the

starting device must be locked. When

intervening in the iSave unit, follow the

instructions for Service/Maintenance,

chapter 8.

• A failure not to follow the instructions can

result in personal injury and/or damage to

the iSave. It will also invalidate the

warranty.

Always wear suitable safety and lifting

equipment when handling the iSave.

• Bolt the iSave properly to the base before

start-up to avoid personal injury and/or

damage to the iSave.

• The pipe connections to the iSave must be

stress-free mounted, securely fastened to

the iSave and well supported. Improper

installation will or could result in personal

injury and/or damage to the iSave.

• Proper installation and care of shutdown

devices and over-pressure protection

equipment is essential.

• All electrical installation work must be

carried out by authorised personnel in

accordance with EN60204-1 and/or local

regulations.

• Install a lockable circuit breaker to avoid

inadvertent starting. Protect the motor and

other electrical equipment from overloads

with suitable

• equipment.

• The electric motors must be supplied with

adequate cooling ventilation.

• The iSave must never run dry. Dry running

produces heat and will cause damage to

internal parts.

• If the iSave does not function satisfactorily, contact your local iSave distributor.

Use of this manual does not relieve

operation and maintenance personnel of

the responsibility of applying normal

good judgment in the operation and care

of this product.

3.2 Intended use

The iSave is designed for use as energy recovery

device in Sea Water Reverse Osmosis (SWRO) or

Brackish Water Reverse Osmosis (BWRO) system.

The iSave must not be used for other purposes

than recommended and quoted for without

consulting your local iSave distributor.

3.3 Application range

For application range see data sheet 521B1378

available in appendix 10.1.

Applications not suitable for the iSave

can cause damages to the iSave unit,

with risk of personal injury.

6

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

Page 7

Operating guide | iSave 50 - 70

3.4 Preferred system design

Danfoss recommends building systems with

a high degree of safety. Our preferred system

design can be found in the data heet in appendix

10.1.

• It is always the system builders’

responsibility that the system design does

not cause any form of hazard and are

adapted to local regulations.

• Proper installation and care of shutdown

devices and over-pressure protection

equipment is essential.

4. Arrival inspection,

handling and storage

4.1 Arrival inspection

The iSave is packed in a wood container.

The iSave ports connector are protected by

plastic caps that protect the iSave against dust

and particles. Do not remove the caps before the

system have been flushed and the iSave can be

installed.

Remove all packing materials immediately after

delivery. Immediately check the shipment for

damage on arrival and make sure that the name

plate/type designation is in accordance with the

packing slip and your order.

In case of damage and/or missing parts, a report

should be drawn up and presented o the carrier

at once.

The identification label on the iSave states the

specific type, the serial number and the code

number of the iSave; see fig. below.

The last three digits of the Serial No. indicate the

week and year of production.

PUMP

Type iSave 50 ERD

Code no. 180FXXXX

Serial no. XXXXXX02-XXX

4.2 Return to the supplier

Flush the iSave with clean water. Drain the iSave

and plug the port connections with a cap/cover.

MADE IN DENMARK

Danfoss A/S, 6430 Nordborg, Denmark

4.3 Transport and Handling

•

• Personnel involved in lifting and

transportation of the equipment must be

trained in proper handling and safety

procedures.

• Observe the local regulations regarding

lifting.

• Use suitable, permitted lifting equipment.

• The iSave (set) could slip the lifting

arrangement.

• Be aware of individuals located in the

operation area while lifting the

component.

The weight of the iSave including electric

motor can be found in the datasheet.

All parts weighing more than 20 kg (44 lb)

must be lifted using lifting slings and suitable

lifting devices, e.g. an overhead crane

or fork lift.

Do not use connections/nozzles for

lifting. Do not use only one sling! Make

sure that the load is balanced before

attempting the lift.

Pack the iSave into a suitable container and make

sure that it is suitably fastened to the container.

Please coordinate the shipment with your local

authorized distributor or contact anfoss direct to

obtain a return shipping address.

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

When lifting the ERD without motor use

the lifting eye

s.

When you have finished using the lifting eyes,

remove them to prevent corrosion.

7

Page 8

Operating guide | iSave 50 - 70

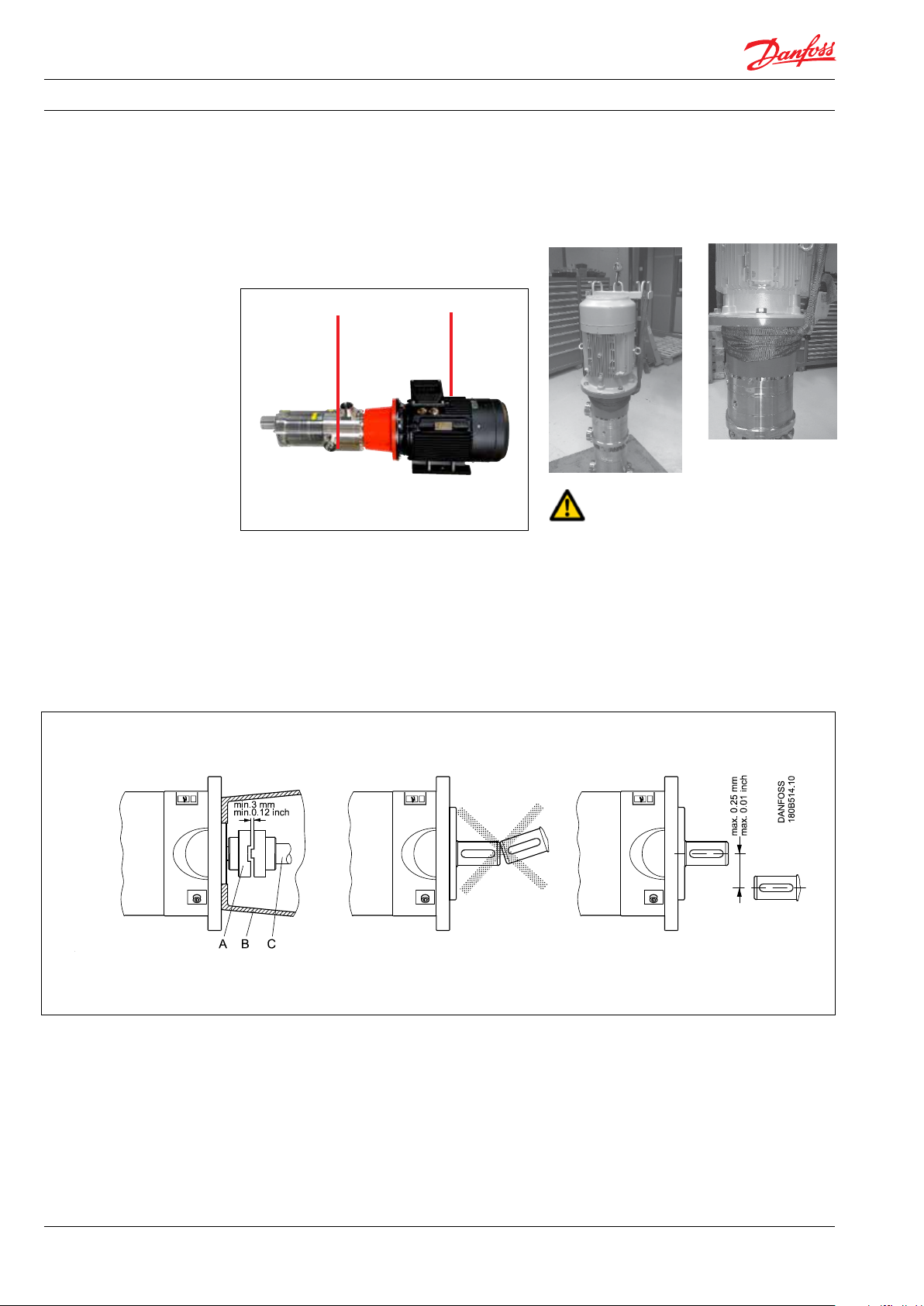

When the iSave is mounted with an electric

motor (horizontal), it must not be lifted in the

lifting eye. An iSave assembled with motor

(horizontal) must be handled by using two slings

around the unit. One sling must be attached to

the electric motor and one sling

around the iSave. Make sure that the unit/load is

balanced before lifting. The centre of the mass

may vary.

Some motors and pumps have specific lifting

eyes.

Do not use connections/nozzles for lifting!

Always use two slings.

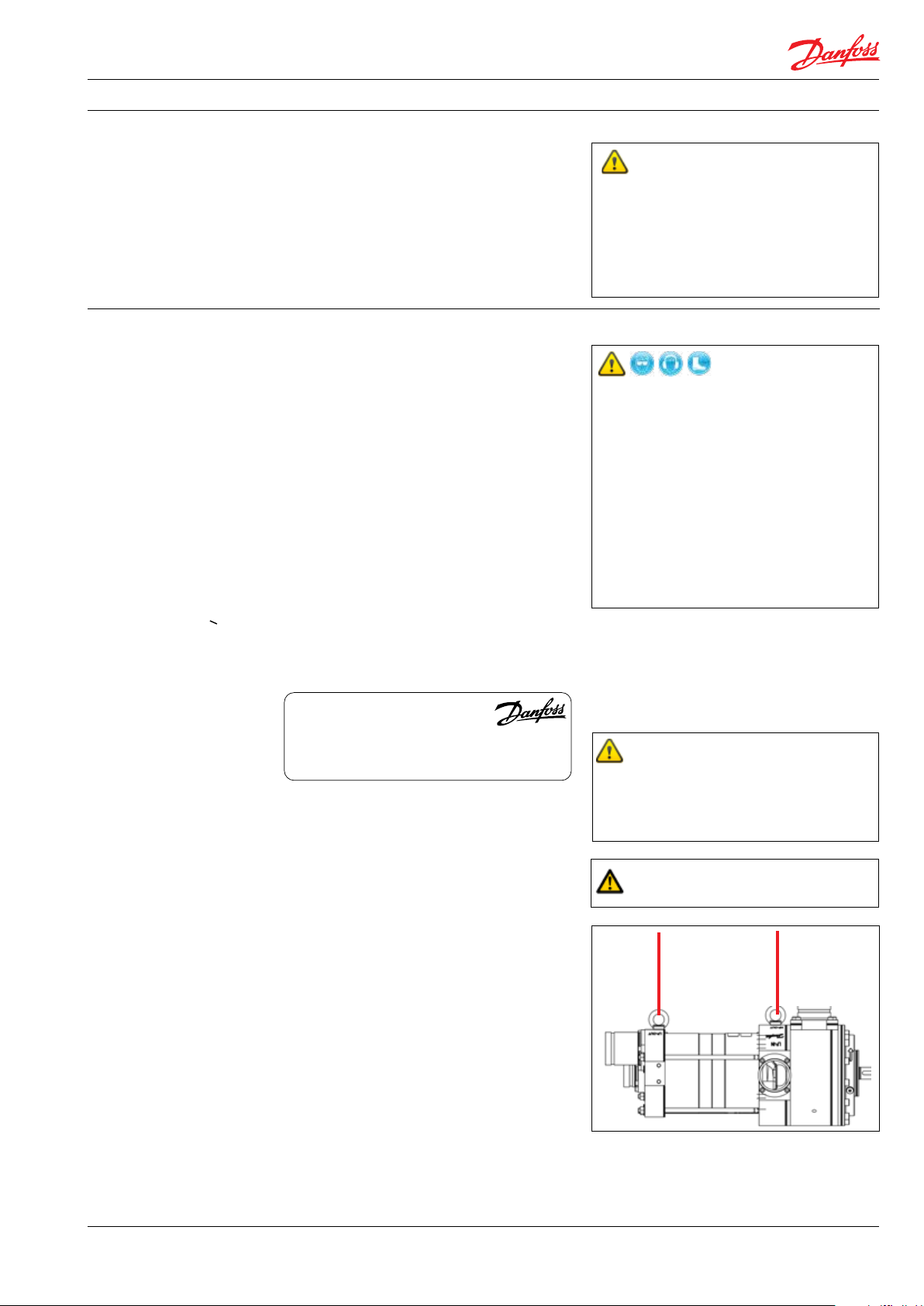

Lifting the iSave with electric motor (vertical):

The two lifting belts around the bell housing

before lifting the unit.

Lift the iSave unit with only one fastening point.

Incorrect lifting can result in personal injury and/

or damage of the unit.

4.4 Assembly iSave to electric motor

A: Elastic coupling

B: Bell housing

C: iSave shaft

D. iSave flange

1. Mount the coupling flush or maximum 1

mm offset from the iSave shaft end. Ensure

an air gap between coupling parts of 3-5

mm (0.12-0.2 inch).

2. Mount the bell housing on iSave. Secure

nuts with the right torque.

3. Measure the longest distance “A” from top

of bell housing to the button of coupling

claw.

4. Mount the coupling on motor shaft. Ensure

the coupling and motor flange are not in

contact with each other.

5. Measure from motor flange to the top of the

coupling. That measurement “B” shall be 3-5

mm (0.12-0.2 inch) shorter than the measure

me nt “A”.

(“A” and “B” can be found on the next page).

8

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

Page 9

Operating guide | iSave 50 - 70

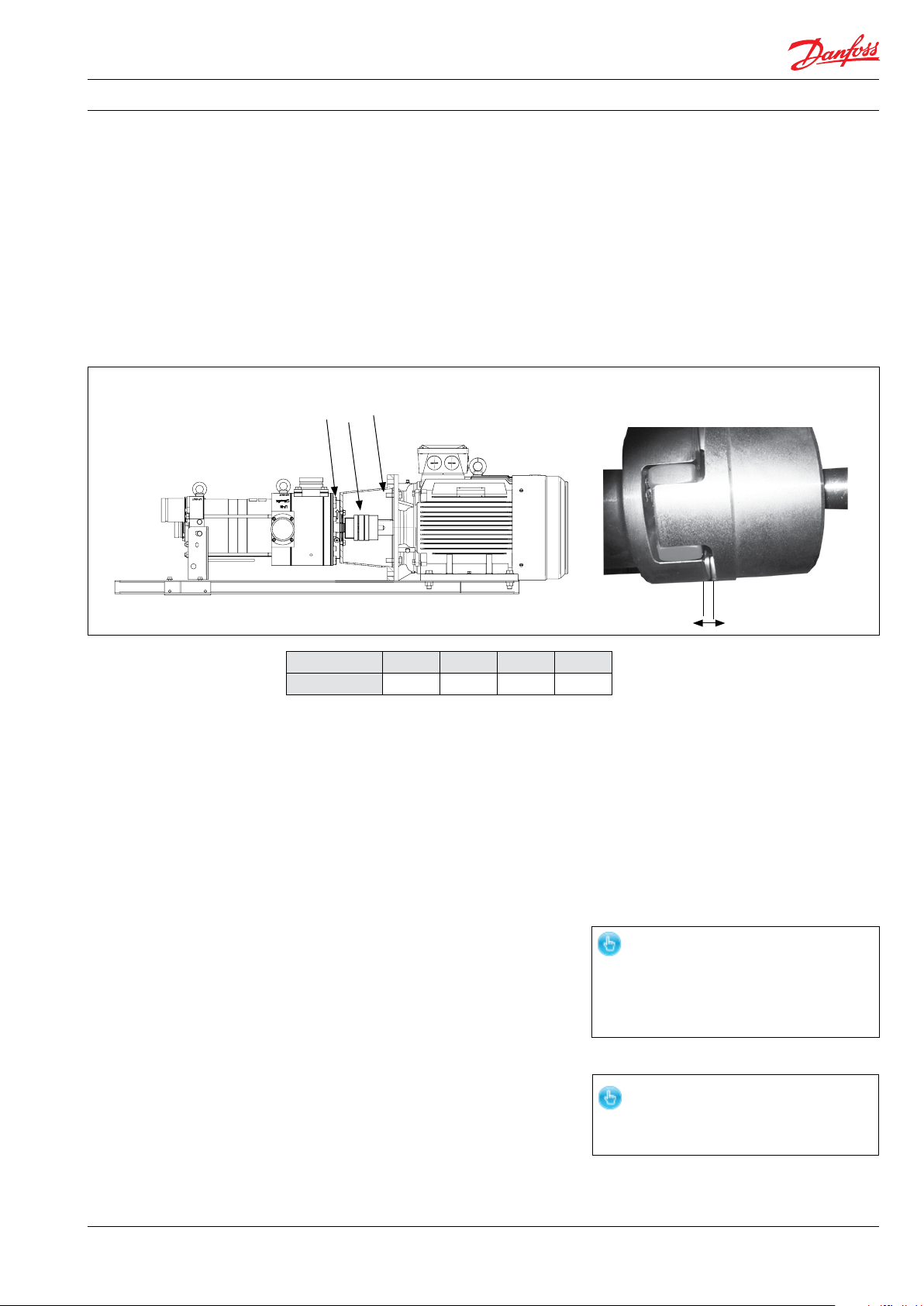

1: Bolts: torque 100 Nm

2: Screw: torque 40 Nm

3: Torque see table below

6. Adjust respectively, verify the measure

ment, and secure both couplings with the

right torques on the locking screws (see

coupling operation & mounting instruc

tion).

7. Mount the elastic gear ring and mount

the bell housing/iSave on the motor.

After mounting it must be possible to

move the elastic gear ring 3-5 mm (0.12 -

0.2 inch) axial “C”. The check can be done

through the inspection hole of bell

housing. Secure flange bolts with the

right torque.

2 3 1

If alternative mounting is desired, please contact

Danfoss High Pressure Pumps.

Choose proper tolerances to ensure an easy

mounting of the elastic coupling without use of

tools.

Please take care to observe the recommended

length tolerances of the chosen coupling, as an

axial force on the pump will damage the pump.

(“C” can be found on the drawing below).

Thread size M5 M6 M8 M10

Torque (Nm) 2 4.8 10 17

Details on how to install iSave 50/70 on Danfoss

vertical and horizontal frame can be found in the

Service guide 180R9387.

4.5 Storage

When each iSave is tested before shipment in

demineralized water. When tested the iSave is

emptied and “plugged”, this will prevent frost

damages.

The storage temperature is is:

-40 °C to +70 °C (-40°F to 158 °F) –

provided that the iSave is drained of fluid and

stored “plugged”.

Frost protection is required if the iSave is not

completely drained of fluids at temperatures

below 1 °C .

Storage of iSave that have been in operation:

For shorter periods of storage flush the iSave

with permeate and store.

For long term storage (more than 2 months)

Danfoss recommends servicing the product

and clean any biological growth of the

surfaces. Store the pump dry witout water

inside.

3-5 mm

Danfoss recommends using DOWFROST from

DOW Chemical Company or Chillsafe mono

propylene glycol from Arco Chemical Company.

For further information on anti-freeze media,

please contact Danfoss High Pressure Pumps.

The iSave is NOT delivered frost-protected

from the factory.

Only remove caps from the openings of the

iSave at the time of installation.

4.6 Outdoor Storage

For outdoor storage cover the iSave (set) with

waterproof material.

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

9

Page 10

Operating guide | iSave 50 - 70

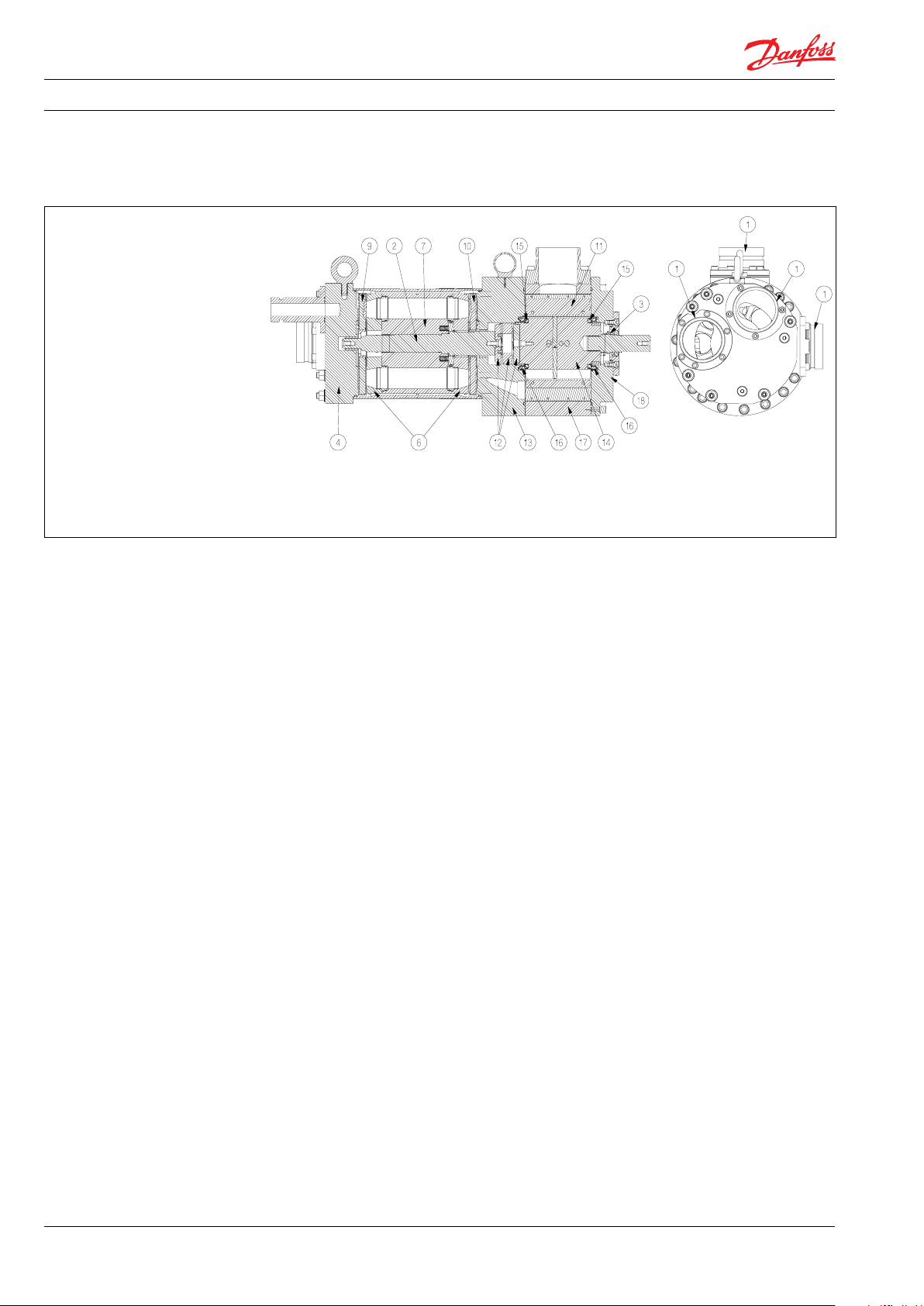

5. Technical data and

design review

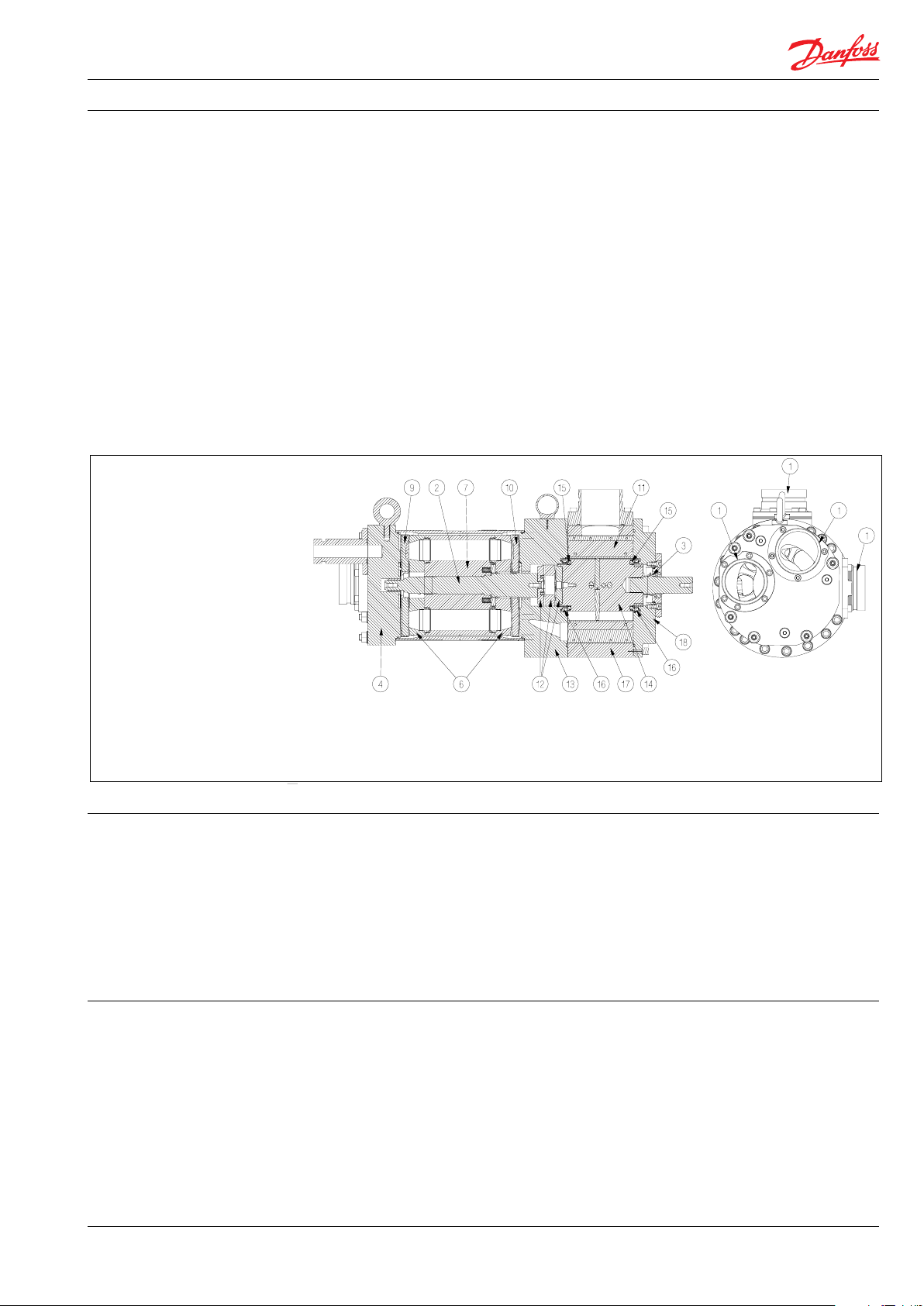

1: 3” Victaulic connections

2: Shaft

3: Low pressure shaft seal

4: Port flange

6: Valve plate

7: Cylinder drum

9: Port plate (brine)

10: Port pllate (sea water)

11: Vanes

12: Coupling

13: Intermediate flange

14: Rotor

15: Rotor element

16: Sealing plate

17: Stator

18: Motor end flange

5.1 Design details

5.2 Sound level of the iSave

The A-weighted sound pressure level @ 1m,

L

is for the iSave including the iSave motor.

PA, 1M

Measurement are according to EN ISO

3744:2010. The test is made under following

conditions:

1. iSave and electrical motor mounted on

Danfoss base plate.

2. Baseplate is isolated from concrete ground

by rubber vibration dampers.

3. Flexible hoses are used on high pressure

and low pressure sides of the iSave.

4. Rotation speed is max. rpm

5. System pressure max. allowable working

pressure and a booster pressure of 3 barg.

Influences

Since the iSave is mounted on a base plate and

connected to the electromotor by a bell housing,

the noise level can only be determined for the

complete unit (system).

It is therefore important that the iSave unit is

mounted correctly on a frame with dampers

to minimise vibrations and noise.

Alternativamente, emplee acoplamientos Victaulic®

flexibles en la tubería rígida.

The noise level is influenced by:

• The speed of the iSave. High speed creates

more noise than low speed.

• Rigid mounting of the iSave baseplate

generates more noise than flexible

mounting

• Pipe mounting directly to the iSave

increases the noise level compared to

flexible hoses.

• Higher pressure provides higher sound

level.

5.3 Materials

All critical parts of the iSave are made of

super-duplex 1.4410/UN S32750/1.4462/

UN S32205/S31803 or the like.

Non-critical parts that are not in contact with sea

water are made of AISI 316.

The shaft to the electrical motor is sealed by

a standardised mechanical seal.

It is also strongly recommended to use highpressure flexible hoses between the hard piping

in the RO plant and the iSave.

See “Hose assembly and installation” 180R9084 in chapter10.5 and Guide line Pipe

connections 180R9367.

Alternative use multiple flexible Victaulic®

couplings on the hard piping.

10

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

Page 11

Operating guide | iSave 50 - 70

5.4 Temperature and corrosion

The chart below illustrates the corrosive

resistance of different types of stainless steel

related to NaCl concentration and temperature.

º

80

C

Duplex

70

60

50

316L

40

30

20

100

1000

160 1600

Depending on the NaCl concentration, the fluid

temperature must be between:

+2 °C y 50 °C (35,6 °F y 122°F).

Super Duplex

10 000

16000

100 000

160000

CI

ppm

NaCI

ppm

-

In order to minimise the risk of crevice

corrosion, always flush the iSave

according to the specified start/stop

procedure.

5.5 Dimensions and weights

For dimensions and weights please refer to the

iSave datasheet. See appendix 10.1

5.6 Electrical motor data

See datasheet in appendix 10.1 and “Operating

and Maintenance instructions, electric motor” in

appendix 10.7

5.7 How does the iSave work?

Figure 5.1 shows a section view of the iSave.

The iSave consists of a rotating isobargic

pressure exchanger and a positive

displacement pump, also called booster

pump. The rotation speed of the pressure

exchanger and the pump is exactly the

same, as they are driven by the same electric

motor.

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

11

Page 12

Operating guide | iSave 50 - 70

5.8 Seawater quality

5.81 Pre-filtration

It is important that the incoming water is filtered

properly to assure optimum service life of the

iSave. A true graded density melt-blown depth

filter cartridge rated at 3 μm is therefore

recommended. Poor pre-filtration of the feed

water will result in reduced service life of the

iSave.

The iSave may request a different pre-filter of the

seawater than the HP pump and other

omponents in the RO system.

It is important to use a proper filter housing that

allows a good seal between housing and filter

cartridge. If there is a high risk of water by-pass it

is recommended to use a second stage filter

solution.

As the various filters on the market differ greatly,

Danfoss High Pressure Pumps recommends using

cartridges with consistent, reliable performance

and high efficiency, in which fibres are blown

continuously onto a central support core.

Danfoss High Pressure Pumps does not

recommend cartridges requiring any type of

binders or resins.

Filters can be purchased from Danfoss High

Pressure Pumps.

5.8.3 Chemicals

The iSave can be flushed with biocide like the

membranes. The biocide must be compatible

with the materials used in the iSave.

iSave material can be found in the parts list,

appendix 10.6.

5.8.4 Initial start up and flushing

Prior to the initial start-up, all piping associated

with the iSave unit should be thoroughly flushed

to assure that no impurities enter the iSave.

Inadequate pre-flushing will strongly affect the

life of the iSave and may lead to its eventual

breakdown.

It is essential that the water used for the final

pre-flush is pre-filtered to a level described in

chapter 5.8

It is recommended to disconnect all connections

to the iSave and to thoroughly flush the piping

before the iSave is connected to the inlet and

outlet connections.It is recommended to install

temporary basket strainers at both inlets to

the iSave during the initial start-up and

commissioning.

Strainers do not eliminate the need for

thoroughly pipe flushing before commissioning.

Also see “Instruction for start and stop of

the SWRO with iSave unit” - 180R9213 in

appendix 10.2.

5.9 Initial start up and settings of safety

equipment

The system designer is responsible to design the

equipment according to the local regulations where

the equipment is running. According to PED

2014/68/ EU a risk assessment must be made to

identify and evaluate hazards which apply to his

equipment on account of pressure.

For more information on the importance of

proper filtration, please consult our

publication “Filtration”,

AI317041322125en-000201 which also will

provide you with an explanation of filtration

definitions and guidance on how to select the

right filter.

5.8.2 A ir bubbles

Large bubbles in a pressurised RO system can

result in damage to piping and equipment. All air

must be bleed from both the LP and HP before

the RO system is pressurised. Special

consideration should also be given to air bubbles

in feed flow, continuously fed into the HP pump

and iSave.

Where under reasonable foreseeable conditions, the

allowable limits could be exceeded, the pressure

equipment must be fitted with, or provision made

for fitting of a suitable protective device.

Dischage pressure on the pump is generated only

by the restriction in the pipelines, valves and

membranes.

The pump can build up pressure that will exceed

the mechanical strength of the membrane

vessels, pipes and other accessories.

The pressure rise can be fast and may exceed the

response time for electrical safety equipment,

like pressure switch and control loop.

12

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

Page 13

Operating guide | iSave 50 - 70

To prevent such over-pressurisation, appropriate relief valves should be used and procedures should be implemented to safeguard

the HP and LP sides of the iSave and/or the

RO system.

5.12 High pressure remains after shutdown

The HP line of the RO system equipped with an iSave

can remain pressurised for a long time after

shutdown. Pressure decreases as water slowly leaks

through the iSave. If more rapid system

depressurisation is required, the system should be

bled through a suitable valve on the HP concentrate

line.

trado HP.

5.10 Flushing

RO membranes require periodic flushing to

limit biological fouling.

There are two types of flushing: feed water

(Seawater) flush and fresh water (Permeate)

flush.

Regardless of the flush water used, the water

must be pre-filtered to the level described

in chapter 5.8. All parts of the iSave must be

flushed, i.e. LP- and HP flow channels.

Follow the guide line 180R9213 “Start and stop of

the SWRO with iSave in appendix 10.2.

It is required to flush with permeate:

• After chemical treatment

• For stop more than 1 day the iSave must be

rotated during permeate flush

• Before long time shut down

It is required to flush with fresh sea water prior to

every shut down.

Special attention should be given to the

pressure in the HP line (7) as the iSave may

start to cavitate when it runs at high speed

and the pressure in the P line (7) drops below 2

bargs. This can be avoided by reducing the

speed of the iSave and keeping the pressurein

the HP line at the minimum of 2 barg.

At this low pressure the iSave may only

run for a maximum of 10 minutes.

Always check the pressure in the high-pressure

lines before making service in the HP lines or

pressurised equipment.

5.13 Over-pressurisation caused by low

pressure isolation

If the low-pressure side of the iSave is blocked

and the iSave is exposed to high-pressure, there

is a risk that the iSave or the LP piping could be

damaged by over-pressurisation.

To prevent such over-pressurisation, appropriate

relief valves should be used and procedures should

be implemented to assure that the HP of the iSave is

depressurised prior to the isolation of the LP side..

5.14 Over-pressurisation caused by the

high-pressure pump.

Discharge pressure on the pump is generated

only by the restriction in the pipelines, valves

and membranes. The pump can build up

pressure that will exceed the mechanical

strength of the membrane vessels, pipes

and other accessories. The pressure rise can be

fast and may exceed the response time for

electrical safety equipment, like pressure

switch and control loop.

Failing to flush the iSave with fresh water before

extended shutdowns may result in extensive

biological growth and cause corrosion in the

iSave and other equipment in the RO system.

5.11 CIP or membrane cleaning

The purpose of membrane cleaning is to reduce

scaling and fouling in the membranes. For optimal

performance specific chemicals are required,

depending on the cause of the pollution. After

chemical treatment the system must be

flushed with permeate.

The flush water coming out of the membranes may

consist of a large amount of suspended inorganic

particles. It is important to assure that hese particles

must not enter the iSave as the waste product of

flushing exceed the iSave filtration.

Also see instruction “Membrane cleaning of

RO system with iSave unit” in appendix 10.3.

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

To prevent such over-pressurisation, appropriate

relief valves should be used and procedures should

be implemented to assure that the HP of

the iSave is protected against excess pressure.

5.15 Explanation of P&ID set-up

See data sheet in appendix 10.1.

13

Page 14

Operating guide | iSave 50 - 70

!

6. On-site installation 6.1 Design details

For safety instruction see chapter 3.

6.2 Installation and alignment

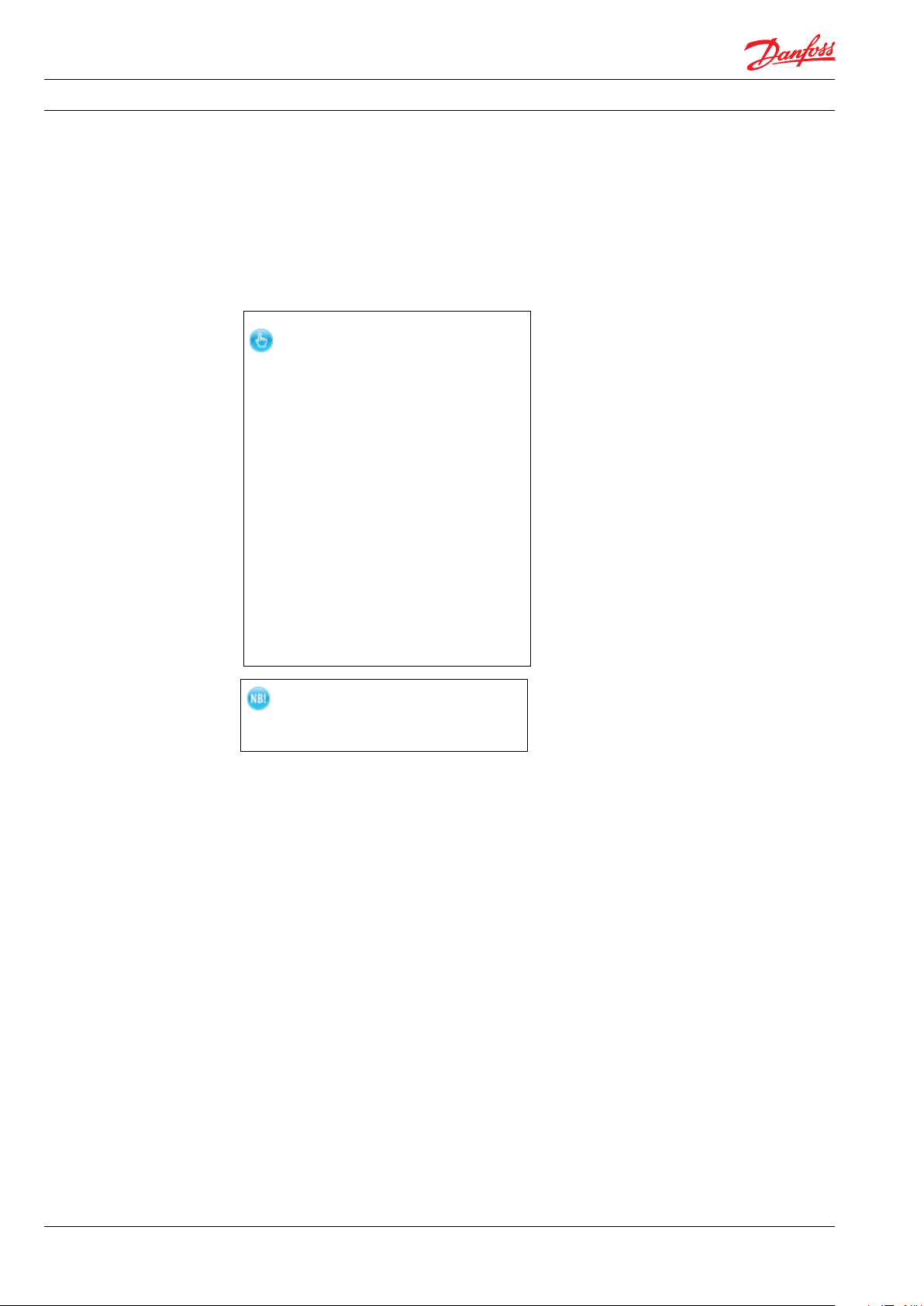

The figure below illustrates the major iSave

components.

An unlocked bolt can result in personal injury

and/or damage to the iSave

Misalignment of the base frame to the iSave may

cause stress and/or damage.

6.3 Orientation

The iSave can be mounted horizontally and

vertically.

When mounted vertically, the electric motor

must be placed above the iSave.

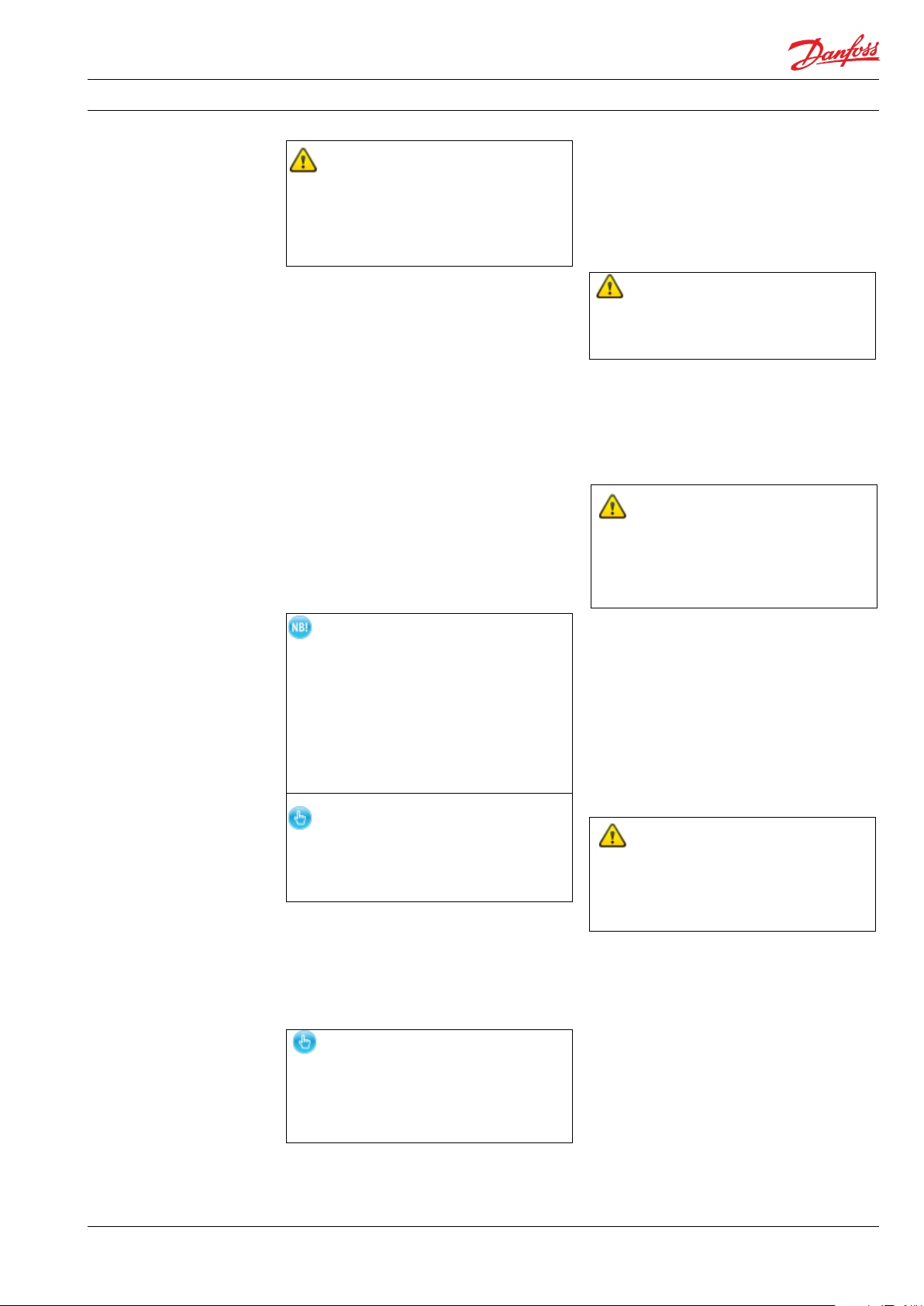

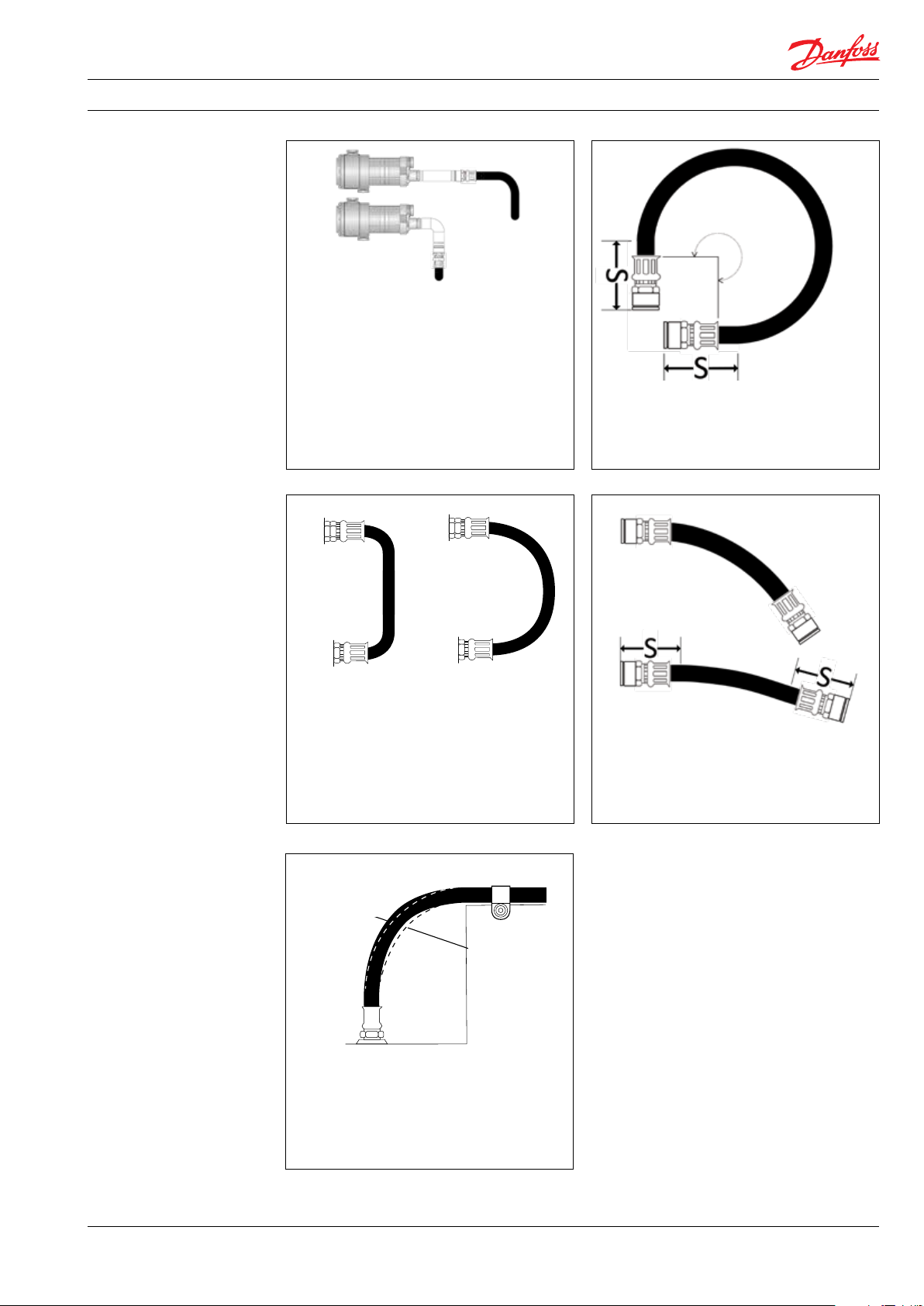

6.4 Piping and joints

Piping material and schedule is of high

importance. The strength of the Victaulic®

connections is influenced by the material used

for both the Victaulic® clamps and the hard

piping.

The hard piping and connections used must

be of proper design and must be installed in

accordance with the manufacturer’s

recommendations.

Hard piping to the iSave must be properly

aligned to avoid stress on the iSave port

connections.

Pipe connection must be aligned as

shown in the figures next page. Don’t use the

iSave as a strain for hard piping.

The iSave is connected to the electric motor

by the bell housing and a flexible coupling.

If not using Danfoss base frame both the

iSave and the motor must be supported

without applying stress/load to the bell

Ccrrect piping alignment Incorrect piping alignment

housing.

Danfoss provides the iSave with a base

frame and support brackets. Although the

base frame is of a sturdy design, it can flex

or bend when it is bolted to the foundation.

The base frame thus requires a solid

foundation such as concrete or rigid steel

frame. The base frame itself must be aligned

to avoid bending caused by bolting to an

uneven foundation.

Incorrect piping alignment

A rigid foundation for the iSave assembly is

important, and must fulfil Eurocode 2:

EN1992-1-1, and the iSave assembly must

be bolted to the foundation with M12 bolts.

The bolts used must be of proper design

and must be installed in accordance with

bolt manufacturer’s recommendations.

To reduce noise it is recommended to use

resilient mounts between the baseplate and

The hard piping and connections used must

be of proper design and must be installed in

accordance with the manufacturer’s recom-

mendations.

the foundation. Make sure that the bolts are

properly locked and will stay locked over time.

A failure to comply with this will or may result

in personal injury and/or damage the iSave.

14

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

Page 15

Operating guide | iSave 50 - 70

Misalignment of the hard pipes may place

stress on the iSave port connections and may

damage the iSave.

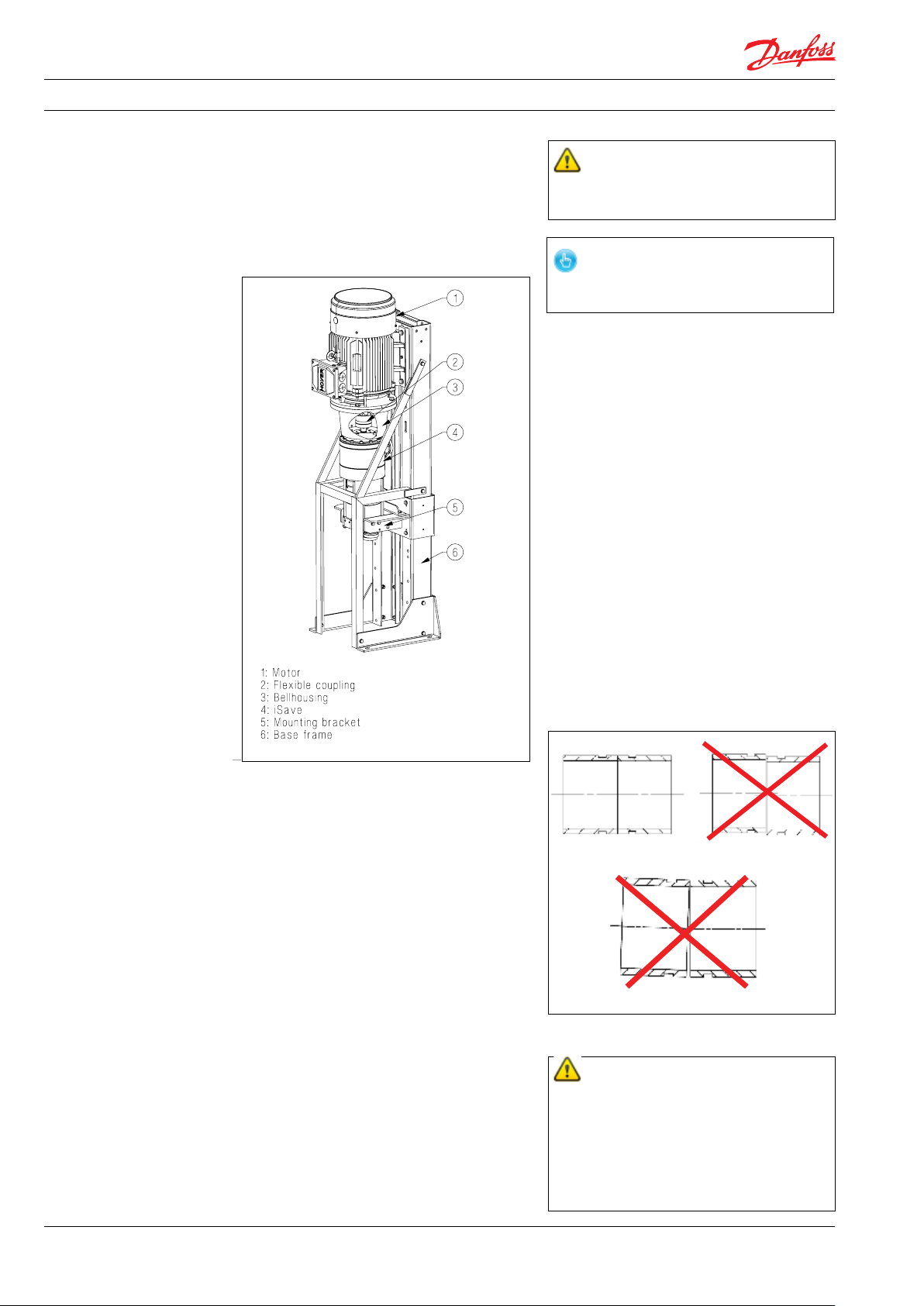

6.5 Mounting of coupling

The figure below illustrates how to mount the

flexible coupling between the iSave and to

connect it to the electric motor..

100 NM ± 10 NM

Min. 3 -5 mm air space

A

PUMP

Type iSave 50 ERD

Code no. 180FXXXX

Serial no. XXXXXX02-XXX

MADE IN DENMARK

Danfoss A/S, 6430 Nordborg, Denmark

When connecting to the power supply, check the

direction of rotation. The rotation can only be

checked with water connected and iSave

bleeded. This can be made by:

1. Looking at the fan in the end of the electric

motor.

2. Removing the plug in the bell housing and

watch the rotation of coupling.

3. Before assembling the iSave on the electric

motor, check the rotation of the shaft on the

electric motor.

C

B

A: Flexible coupling

40 NM ± 4 NM

B: Bell housing

C: Motor shaft

Any axial and radial load on the shaft must be

avoided.

6.6 Accessibility

With respect to the service and replacement

of the complete iSave unit, it is recommended to

maintain sufficient space around the unit.

The space must be sufficient enough to allow for

safe lifting of the equipment, with no risk for

personal injury and/or damage to the iSave.

6.7 Drives

6.7.1 Electric motor

The iSave must only be driven by an electric

motor.

Special attention has to be on NON

PROTECTED - FREE ROTATING shaft on

the electric motor. Ignorance will or

could result in personal injury.

Running the iSave in the wrong direction for

more than a few minutes can cause unintended wear on the iSave. If the electric

motor is running at a lower speed, extra care

must be taken to ensure that the electric

motor is NOT overheated. External cooling

may be necessary.

6.7.3 Starting torque for the iSave

Because of the inertia and stick-slip friction of the

iSave internal parts, the torque may exceed the

maximum allowable operation torque for the

iSave when the speed is ramped up from zero to

maximum.

It is required to use a VFD. See Danfoss guide line

180R9372 “APP pumps and iSave overload

protection”.

Using anything other than an electric motor

can lead to an irreparable fracture of the

iSave’s internal parts.

6.7.2 Speed control

The rotation speed on the electric motor can

be controlled by a VFD. The VFD must be able to

operate at constant torque over the whole range

of speed. The direction of rotation can be seen

on the identification label.

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

15

Page 16

Operating guide | iSave 50 - 70

7. Commissioning,

start-up and shutdown

6.7.4 Torque overload protection on the

iSave

The electric motor and iSave must always be

protected against overload.

As continuously operation the maximum

torque on the iSave must be monitored.

The electric motor must be shut off if the

maximum torque of the iSave exceeds the

defined limit.

If more electric motors are powered by the

same VFD, each electric motor must be

equipped with “torque limit equipment” to

protect the iSave against overload.

Below are examples of equipment which

can measure the load on the electric motor

or limit the torque on the iSave.

7.1 Safety regulations

The operator ensures that all inspection and

installation work is performed by authorised,

qualified specialized personnel who are

thoroughly familiar with the manual..

• Before starting up the iSave and the

high-pressure pump, make sure that the

following requirements are met:

• The iSave has been properly connected to

the electric power supply and is quipped

with all protection devices in accordance

with EN 60204-1

• Check that all motor protections are

properly set.

• All safety equipment, auxiliary equipment

and connection required are properly

connected and operational.

• Check all bolts in all connections and in the

foundation of the iSave and the pumps.

7.2 Support

Danfoss A/S offers commissioning and service at

system manufacturer’s location.

Rated quotes are offered upon request.

1. VFD with integrated current monitoring

relays.

2. External current monitoring relays suitablefor VFD control.

The electric motor and iSave must always be

protected against overload.

See Danfoss guide line 180R9372 “APP pumps

and iSave overload protection” in the appendix

10.4.

If torque exceeds the maximum operation

torque, it may lead to an irreparable fracture of

the iSave’s internal parts.

7.3 Commissioning

Before starting up the iSave and the highpressure pump, make sure the following

requirements are met:

• All pipes are flushed, free from debris and

full of water.

• The iSave has been bled and is full of

water.

• At pressure lower that 10 barg, check the

system for leakage.

Slowly raise the pressure in the system and set

all pressure switches to the correct limit and

continually check all connections.

• If pressure relief valve is present, set

pressure relief valve on both low and

high-pressure at the maximum system

pressure.

• Check high-pressure hoses for proper

assembly and inspect for external leakage

for all connections.

• At low pressure, start the iSave and check

direction of rotation.

• “Start and stop procedure” Guide line

180R9213. - appendix 10.2.

16

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

Page 17

Operating guide | iSave 50 - 70

8. Service/Maintenance 8.1 Safety regulations

The operator ensures that all maintenance,

inspection and installation work is performed

by authorised, qualified specialist personnel

who are thoroughly familiar with the manual.

Before intervening in the iSave/system:

• The power must be shut off and the main

switch must be locked.

• The pressure in the high-pressure lines

must be drained to the low-pressure side.

• The water in all connected pipes must be

drained.

Always use suitable safety and lifting equipment when handling the iSave, and follow the

instructions in chapter 4.3.

• Assure correct settings of safety equipment before start-up.

• When the system is re-started after

service and maintenance follow the

instruction in chapter 8 and in “Start and

stop procedures” in guide line 180R9213

in appendix 10.2.

Three months after commissioning:

1. Re-check bolts in the foundation and the

base plate of the iSave and tighten the

bolts to specified torque if necessary.

2. Re-check alignment of the iSave base

plate and iSave.

3. Visually inspect all pipe connections/

couplings for external leakage.

4. Re-check bolts in all pipe connections/

couplings and tighten the bolts to

specified torque if necessary.

1. Replace filters if necessary.

2. Clean the filter housing and install the new

filter. Make sure no debris enters the

system.

3. Audibly inspect the iSave assembly. If there

is irregular sounds or vibration inspect the

internal parts of the iSave and replace if

necessary.

Half year:

1.

For vertical mounted electric motor

lubricate motor bearings.

8.2 Support

Danfoss A/S offers commissioning and service

at the system manufacturer’s location.

Tates/quotes are offered upon request.

8.3 Maintenance schedule

The schedule of preventive maintenance below

will help ensure that the iSave provides years of

trouble-free performance.

One day after commissioning:

1. Re-check bolts in the foundation and the

base plate of the iSave and tighten the

bolts to specified torque if necessary.

2. Visually inspect all pipe connections/

couplings for external leakage.

3. Re-check bolts in all pipe connections/

couplings and tighten the bolts to

specified torque if necessary.

1. Replace filters if necessary.

2. Clean the filter housing and reinstall

filters. Make sure no debris enters the

system.

Annually:

1. Re-check bolts in the foundation and the

baseplate of the iSave and tighten the

bolts to specified torque if necessary.

2. Re-check alignment of iSave base plate

and iSave.

3. Visually inspect all pipe connections/

couplings for external leakage.

4. Re-check bolts in all pipe connections/

couplings and tighten the bolts to

specified torque if necessary.

1. Replace filters if necessary.

2. Clean the filter housing and nstall the new

filter. Make sure no debris enters the

system.

3. Visually inspect iSave coupling and

replace if necessary.

4. Audibly inspect the iSave assembly. If

there is irregular sounds or vibrations

inspect the internals parts of the iSave

and replace if necessary.

5. Check power consumption. If there are

irregular parts of the iSave and replace if

necessary.

6. Lubricate motor bearings.

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

17

Page 18

Operating guide | iSave 50 - 70

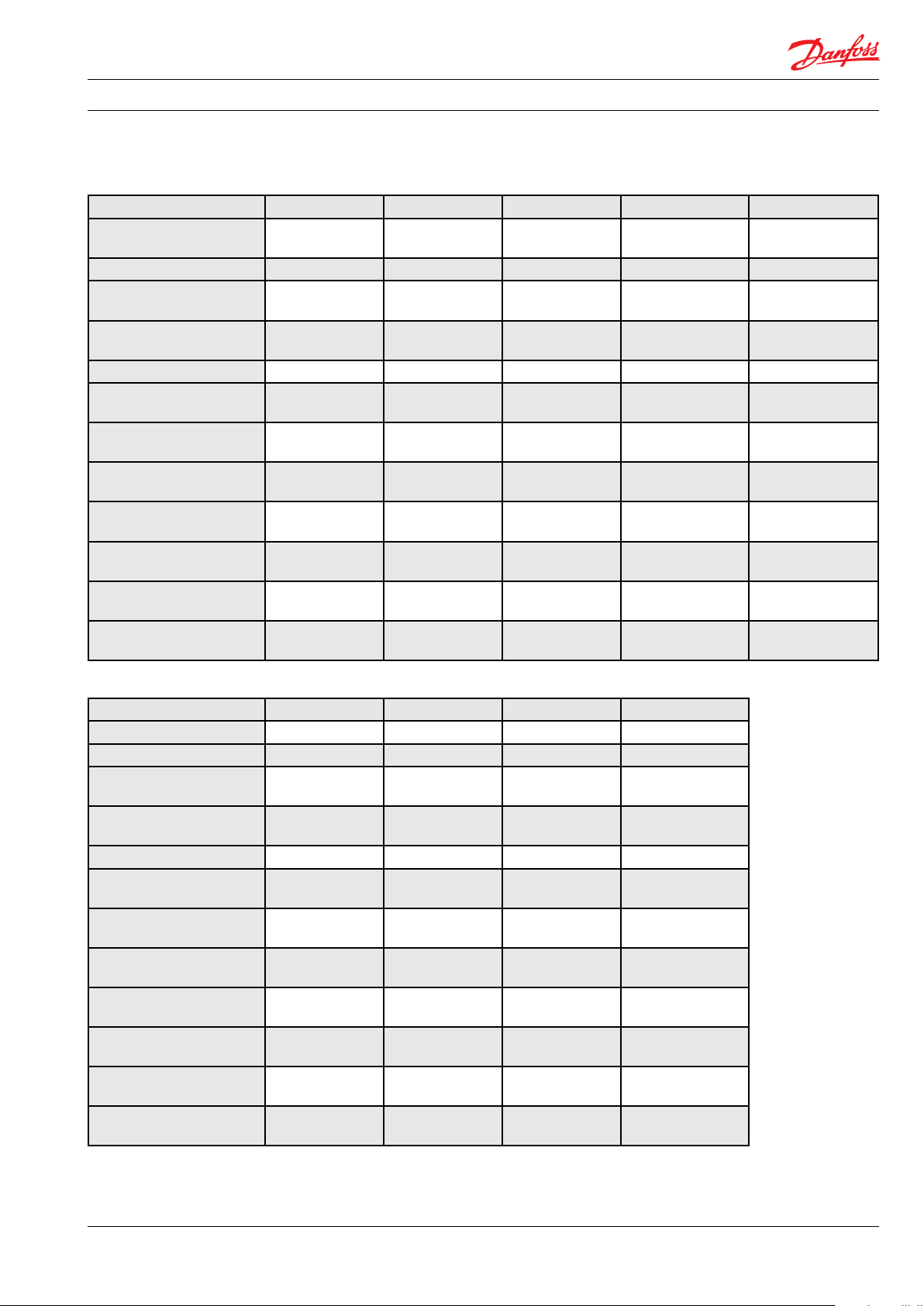

8.4 Recommended service intervals on

internal parts

Se below table.

For detailed information on parts see Service

guide 180R9392 Parts list.

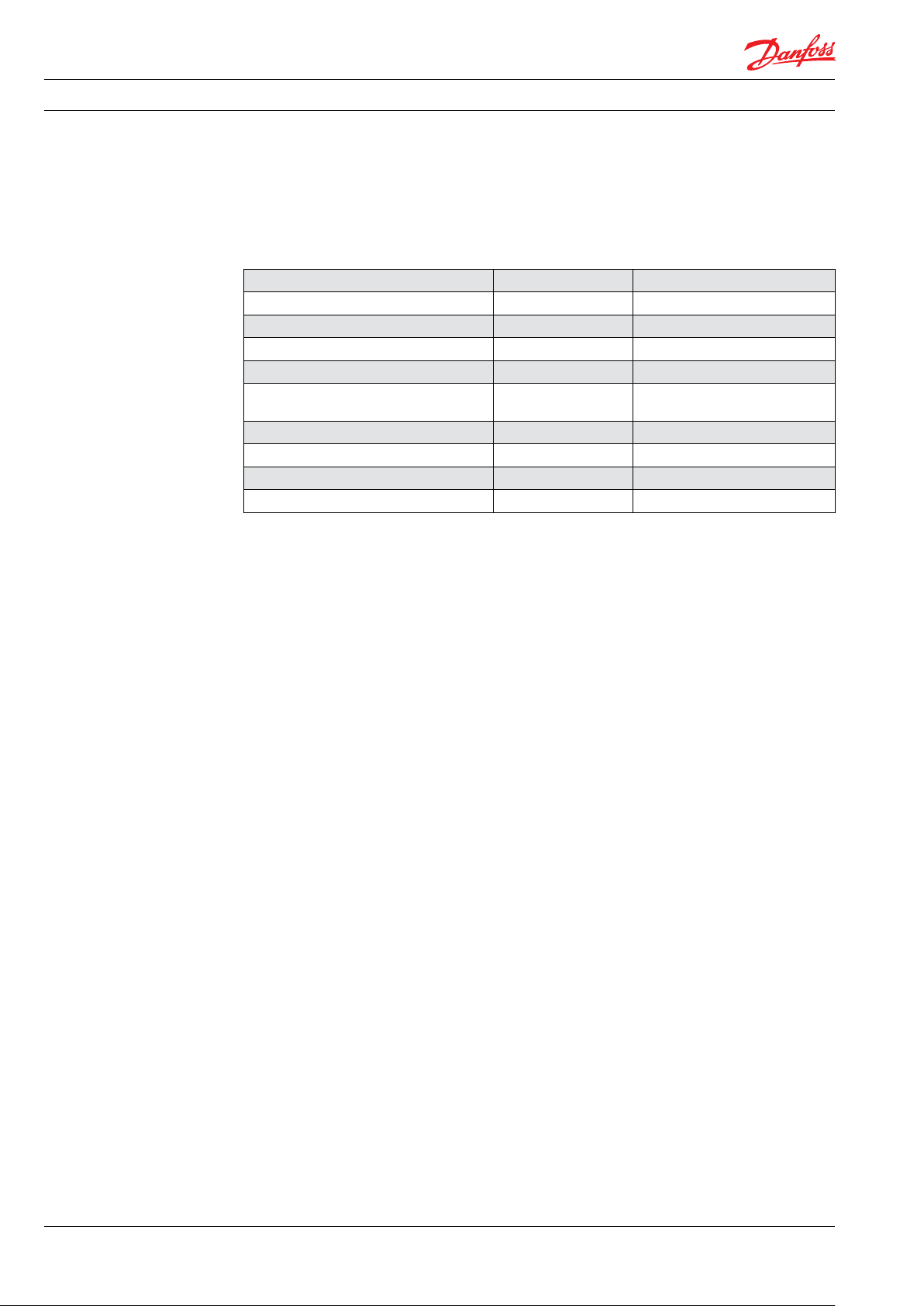

Description Service interval Service interval (2nd, 3rd)

Tool kit

Screw and seal kit 32.000 hours 26.000 hours

Shaft seal kit 32.000 hours 26.000 hours

Coupling kit 56.000 hours 56.000 hours

Port plate kit (PE), iSave 50

32.000 hours 26.000 hours

Port plate kit (PE), iSave 70 32.000 hours 26.000 hours

Vane kit (8 pcs)

Valve kit, Pressure exchanger 32.000 hours 26.000 hours

Rotor element and sealing plates kt 32.000 hours 26.000 hours

8.5 Lubrication of bearings in electric

motor

Motors with a re-greasing system must be

lubricated with high quality lithium complex

grease, NLGI grade 2 or 3 with a temperature

range between -40 °C to 150 °C.

For electric motors in vertical mount; grease

every 6 months.

For electric motor in horizontal mount;

grease every 12 months.

If the motor has increased vibrations or

sound check the bearings.

Follow manufacturer’s recommendations for

electric motor service and maintenance, see

appendix 10.7.

18

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

Page 19

Operating guide | iSave 50 - 70

9. Trouble-shooting 9.1 Safety regulations

Before intervening in the iSave/system:

The operator ensures that all inspection and

installation work is performed by authorised,

qualified specialist personnel who are

thoroughly familiar with the manual.

• The power must be shut off and the

starting device be locked.

• The pressure in the high-pressure lines

must be drained to lowpressure side.

• The water in all connected pipes must be

drained.

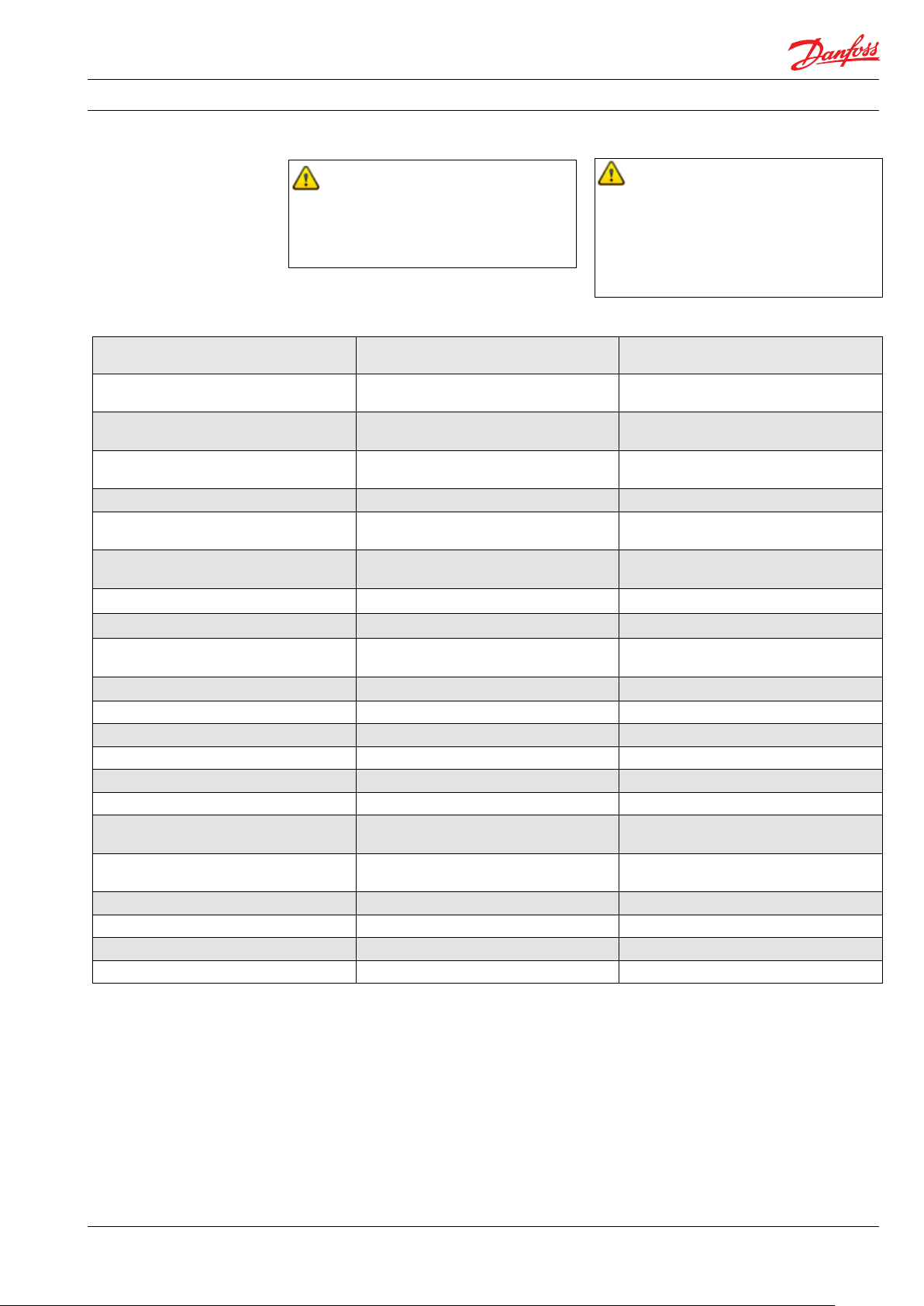

The numbers in () correspond to the preferred system design and P&ID (see data sheet)

Problem Possible cause Action

VFD cannot start the iSave at initial start-up VFD is not designed for constant torque

VFD cannot deliver sufficient start torque

Ramp-up settings in the VFD are not correct. VFD is tilting

Choose a VFD that is designed for constant

torque

Choose a VFD that is designed for sufficient

start torque. See guide line 180R9372

Set ramp-up parameters correct. See guide

line 180R9372

Valve (9) is closed Open valve (9)

Start the iSave only when the pressure in

the HP line is low

Clean or change membranes

Torque on iSave is too high during operation

Pressure in the HP line (5) is too high

Pressure difference from HP-out (5) to HPin (10) is too high

Debris in the booster pump or iSave Clean the system

Wear in the booster pump or iSave Repair or change the parts

Design of the basic plant does not fit the

performance of the iSave

Change design to fit the iSave performance

Permeate production is too low (17) Valves (6), (7), (8) or (16) are leaking Repair or change valve(s)

Internal leakage in iSave Repair iSave

HP pump flow (2) is too small Correct speed on the HP pump

Check the HP pump and repair if necessary

Pressure on the membranes (5) is too high

Fouling on the membranes Clean the membranes

Mixing in the iSave is too high Check flow on LP-in (12) and adjust flow

Flow out of the iSave is too low and causes

a recovery rate that is too high

Check speed on iSave and change if necessary

Booster pump in the iSave is worn out.

Perform service on the VP

Pressure on the membranes (5) is too low

Valves (6), (7), (8) or (16) are leaking Repair or change valve (s)

Internal leakage in iSave Repair iSave

Pressure on the membranes (5) is too low Incorrect speed on the HP pump

Check the HP pump and repair, if necessary

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

19

Page 20

Operating guide | iSave 50 - 70

20

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

Page 21

Appendices

Energy Recovery Device

iSave 50-70

Appendices - Installation, Operation

and Maintenance Manual

hpp.danfoss.com

Page 22

Operating guide | iSave 50 - 70

10. Appendices............................................................................21

10.1 Data sheet iSave 50-70 - (521B1378)) ....................................................23

10.2 Start and stop procedures (180R9213). ..................................................45

10.3 Membrane cleaning of the RO system with iSave unit (180R9214) . ......................51

10.4 APP pumps and iSave overload protection(180R9372)...................................57

10.5 Hose assembly and installation (180R9084) .............................................67

10.6 iSave part list 50-70 (521B1428) .........................................................75

10.7 Operating- and maintenance instruction, electric motor (180R9230).....................87

22

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

Page 23

Data sheet

iSave® Energy Recovery Device

iSave 50 / iSave 70

hpp.danfoss.com

Page 24

Data sheet | iSave 50 and iSave 70

Table of Contents Contents

1. General information....................................................................25

2. Benefits................................................................................25

3. Applications ...........................................................................25

4. Technical data .........................................................................26

4.1 iSave without motor ...................................................................26

4.2 iSave with IEC motor ...................................................................28

4.3 iSave with NEMA motor ................................................................29

5. Performance curves....................................................................30

5.1 Flow at different rpm...................................................................30

5.2 iSave 50 flow curves....................................................................30

5.3 iSave 70 flow curves....................................................................30

5.4 Torque curve for iSave 50 and iSave 70..................................................31

5.5 Mixing curve...........................................................................31

6. Temperature and corrosion.............................................................32

6.1 Operation..............................................................................32

7. Installation.............................................................................32

7.1 Operation and mounting...............................................................32

7.2 Horizontal mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

7.3 Connection to inlet or discharge ports: .................................................33

7.4 Filtration...............................................................................33

7.5 N o ise ..................................................................................33

7.5 RO systems with an iSave...............................................................34

8. Dimensions and connections...........................................................36

8.1 iSave 50-70 without electric motor .....................................................36

8.2 iSave 50-70 with with IE3 motor 18.5 kW on base frame vertical_front mounted .........37

8.3 iSave 50-70 with with IE3 motor 18.5 kW on base frame vertical_back mounted..........38

8.4 iSave 50-70 with with IE3 motor 18.5 kW on base frame horizontal.......................39

8.4 iSave 50-70 with NEMA motor 30 HP on base frame vertical - front mounted .............40

8.5 iSave 50-70 with NEMA motor 30 HP on base frame vertical - back mounted .............41

8.5 iSave 50-70 with NEMA motor 30 HP on base frame horizontal ..........................42

9. Service.................................................................................43

9.1 Warranty...............................................................................43

9.2 Operational conditions of concern......................................................43

9.3 Maintenance...........................................................................43

9.4 Repair assistance .......................................................................43

10. Accessories ............................................................................43

11. Useful documents......................................................................43

24

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

Page 25

Data sheet | iSave 50 and iSave 70

1. General information Energy Recovery Devices (ERD) are used in

reverse osmosis (RO) systems to recycle the

energy held in discharged brine from the

membranes. Thus, iSave 50 and iSave 70 are

designed for use with low viscosity and corrosive

fluid such as sea water.

The Danfoss iSave Energy Recovery Devices all

consist of an isobaric pressure exchanger and a

positive displacement pump combined into one

compact unit. The high-pressure booster pump

is based on the vane pump principle enabling a

very light and compact design. The vane pumps

are fixed displacement pumps in which the flow

is proportional to the number of revolutions

(rpm) of the driving shaft – enabling flow control.

Speed control is made by a VFD. The iSave design

ensures lubrication of the moving parts by the

fluid itself.

1. 3” Victaulic connections

2. Shaft

3. Low pressure shaft seal

4. Port flange

6. Valve plate

7. Cylinder barrel

9. Port plate (brine)

10. Port plate (sea water)

11. Vane s

12. Coupling

13. Intermediate flange

14. Rotor

15. Rotor element

16. Sealing plate

17. Sta t or

18. Motor end flange

All parts included in the iSave 50 & 70 are

designed to provide long service life with a

constant high efficiency and minimum service

required.

Unlike a centrifugal pump, it produces a similar

flow at a given speed no matter what discharge

pressure.

2. Benefits • Corrossion resistance (all wetted parts are made

• Significant power savings and low specific

energy consumption (SEC)

• Simple and space-saving installation with

both pump and pressure exchanger in one

of high corrosion-resistant materials e.g. Super

Duplex or Duplex)

• Fewer components

unit

• Simple system design and monitoring

without requirement for high-pressure flow

meters

• Simple operation with design that prevents

overspin/overflushing

• Easy modular service

3. Applications

Danfoss iSave ERDs are built into a broad range

of RO desalination plant around the world.

Typical applications for iSave 50 - 70 will be:

• Containerized solutions for hotels and

resorts on islands as well as coastal regions

• Onboard systems for ships

• Offshore platforms for the oil and gas

industry

• Municipal and private waterworks

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

25

Page 26

Data sheet | iSave 50 and iSave 70

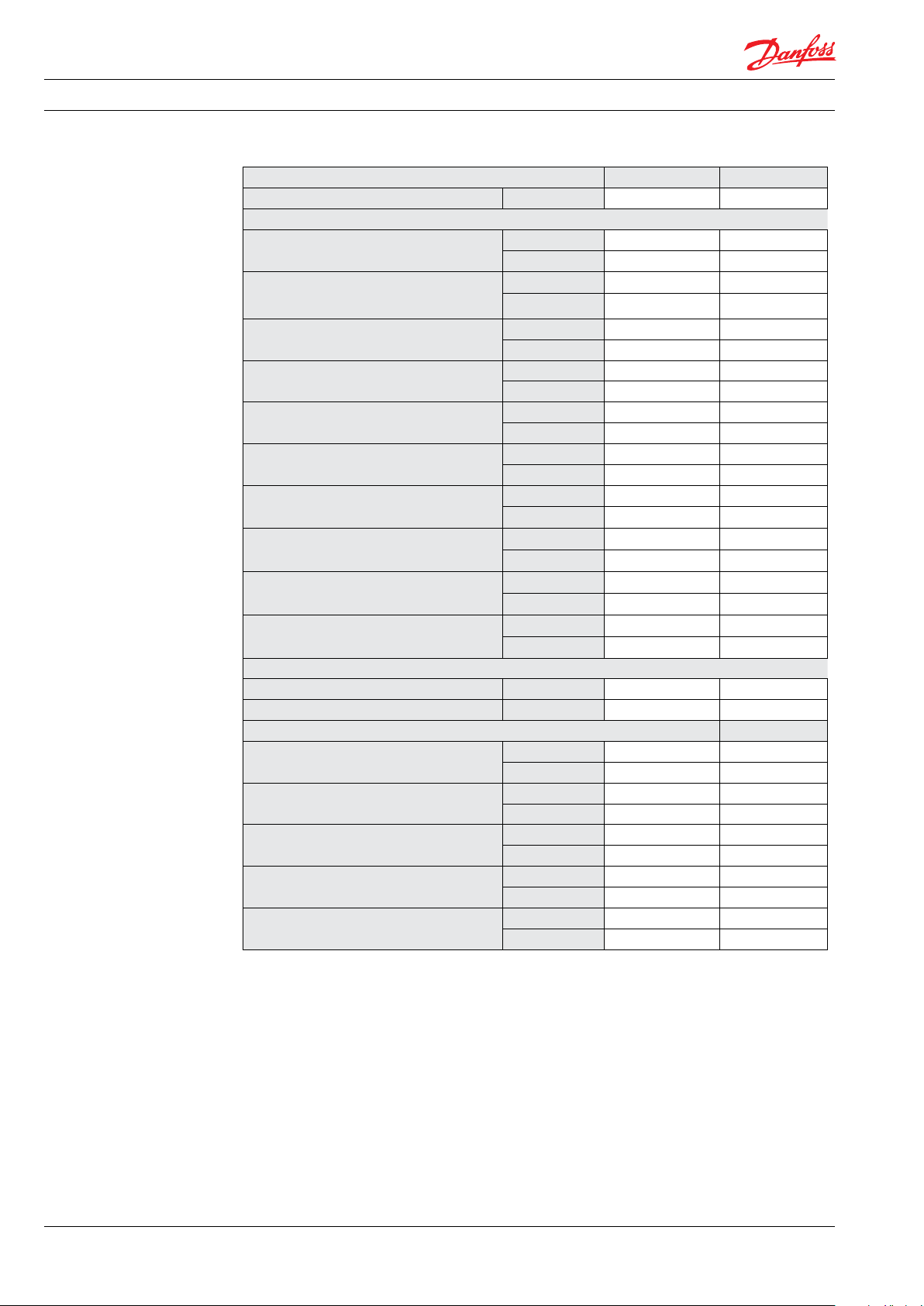

4. Technical data 4.1 iSave without motor

iSave size iSave 50 iSave 70

Code number 180F7020 180F7021

Pressure

Max. differential pressure (HP out - HP in)

Min. pressure HP out (min. allowable working

pressure)

Max. pressure HP out (Max. allowable working

pressure, MAWP)

Min. pressure on HP in,

intermittent

Max. pressure LP in (MAWP)

Max. pressure LP in, peak

Min. allowable working pressure LP in

Max. differential pressure (LP in - LP out)

Max. static test pressure (HP in and HP out)

Max. static test pressure (LP in and LP out)

Speed

Min. speed rpm 525 625

Max. speed rpm 650 875

Typical flow

Flow at min. speed, HP out

Flow at max. speed. HP out

Max. lubrication flow at 60 barg (871 psig)

Peak flow, LP in

Max. allowable working flow, LP in

1)

2) 3)

4)

10)

barg 5 5

psig 72 72

barg 40 40

psig 580 580

barg 83 83

psig 120 0 120 0

barg 2 2

psig 29 29

1)

barg 5 5

psig 72 72

barg 10 10

psig 145 145

barg 2 2

psig 29 29

barg 0.53 0.79

psig 7. 69 11.46

barg 108 108

psig 1566 1566

barg 13 13

psig 189 189

m³/h 42 50

gpm 184 220

m³/h 52 70

gpm 228 308

l/min 25 25

gpm 6.6 6.6

m³/h 120 120

gpm 528 528

7)

m³/h 57. 2 70

gpm 252 308

26

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

Page 27

Data sheet | iSave 50 and iSave 70

Technical specifications

Media temperature

Ambient temperature

Filtration requirements (nominal)

Salinity increase at membrane at 40% recovery rate at

balanced flow

Weight (dry)

Weight (operation with water)

Noise

Sound pressure level L

Torque data

Max. allowable working torque

Max. starting torque (stick/slip)

o

5)

6)

9)

C 2-35 2-35

o

F 36-95 36-95

o

C 0-50 0-50

o

F 32-122 32-122

3 micron melt-blown

2-3%

kg 164 164

lb 362 362

kg 172 172

lb 379 379

8)

PA

1 m

dB(A) 83 86

Nm 170 19 0

lbf-ft 12 5 140

Nm 18 0 180

lbf-ft 132 132

1)

Max. allowable working pressure of continous

operation. For lower and higher pressure, please

contact Danfoss.

2)

Typical pressure level at start-up and permeate

flush.

3)

Intermittent pressure is acceptable for less than 10

minutes within a period of 6 hours.

4)

Typical average flow at 60 barg and 3 barg

differential pressure

5)

Dependent on NaCI concentation.

6)

Please see section 7.4 filtration.

7)

Continuous operation: iSave can operate

continuously with up to 10% over flush with the

limitation that the flow rate at LP inlet shall not

exceed 70 m3/h.

8)

A-weighted sound pressure level at 1 m from the

pump unit surfaces (reference box) acc. to EN ISO

20361 section 6.2. The noise measurements are

performed acc. to EN ISO 3744:2010 on a motor-

pump-unit at max. pressure and rpm.

9)

Balanced flow: The mixing rate is defined at

balanced flow when HP-out is equal to LP-in.

10)

At system start-up: iSave can run for up to 10 min.

with 150% of max. rated flow at LP inlet. The time

where max. rated flow is exceeded should be kept

as short as possible to minimize wear.

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

27

Page 28

Data sheet | iSave 50 and iSave 70

4.2 iSave with IEC motor

i

iSave size iSave 50 iSave 70

Code number (vertical) 180F7038 180F7040

Code number (horizontal) 180F7023 180F7025

Pressure, Speed, Flow, Temperature and Torwue are identical with 180F7020 and 180F7021

Efficiency

Efficiency at max. speed at 60 barg (871 psig) % 93.7 92.4

Technical specifications

Media temperature

Filtration requirements (nominal)

Weight (dry) vertical/horizontal

Weight (operation with water) vertical/

horizontal

Noise

Sound pressure level L

Footprint

Footprint (vertical position)

Footprint (horizontal position)

Torque data

Max. allowable working torque

Max. starting torque (stick/slip)

Motor data

Nominal speed rpm 985 985

Rated current at 400V A 37 37

Motor size

Frame size

Rated motor torque at nominal speed

Rated motor ambient temperature

Motor insulation Class B B

Motor degrees of protection IP 55 55

5)

°C 2-35 2-35

°F 36-95 36-95

6)

3 micron melt-blown

kg 441/463 441/463

lb 972/1021 972/1021

kg 470/471 470/471

lb 1036/1038 1036/1038

2)

PA

1 m

3)

dB(A) 83 86

m² 0.44 0.44

foot² 4.71 4.71

3)

m² 0.76 0.76

foot² 8.14 8.14

Nm 170 177

lbf-ft 125 130.5

Nm 180 180

lbf-ft 132 132

kW 18. 5 18.5

HP 30.0 30.0

IEC 200 L 200 L

Poles 6 6

Nm 177 177

lbf-ft 130.5 130.5

4)

°C 40 40

°F 104 104

28

2)

A-weighted sound pressure level at 1 m from the ERD

unit surfaces (reference box) acc. to EN ISO 20361

section 6.2. The noise measurement are performed

acc. to EN ISO 3744:2010 on an ERD with motor

(motor pump unit) from min. to max. pressure and

speed.

3

Area covered with recommended IE3 motor

configurations (excl. of space to service the ERD)

4)

For higher temperature, contact Danfoss.

5)

Dependent on NaCI concentation.

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

)

6)

Please see section 7.4 Filtration

7)

Typical efficiency for pressure exchanger, ..

booster pump, electrical motor and VFD at 3

barg differential pressure after a system has ...

been commissioned and run in.

Page 29

Data sheet | iSave 50 and iSave 70

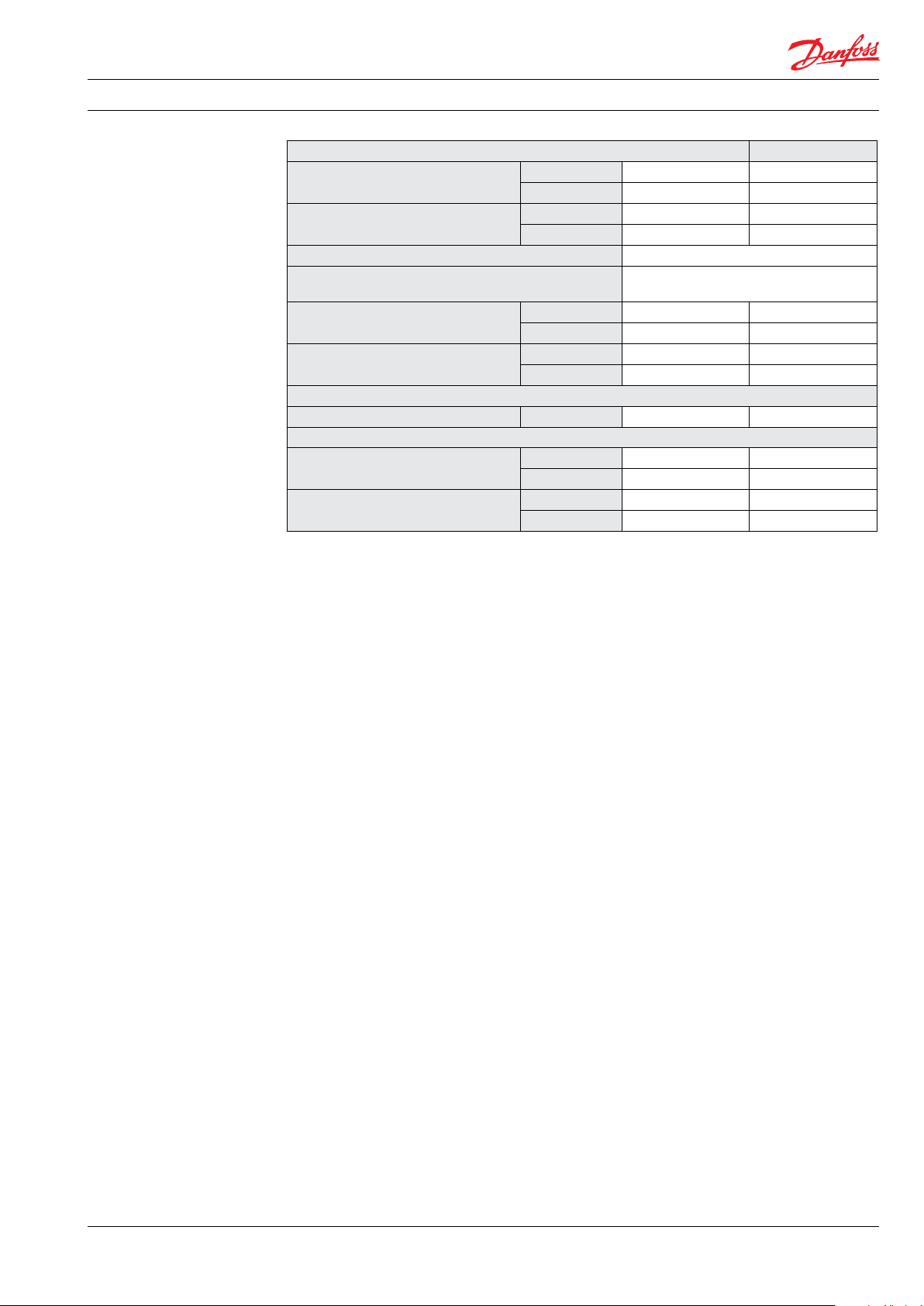

4.3 iSave with NEMA motor

iSave size iSave 50 iSave 70

Code number (vertical) 180U0062 180U0064

Code number (horizontal) 180U0003 180U0005

Pressure, Speed, Flow, Temperatue and Torque are identical with 180F7020 180 F7021

Efficiency

Efficiency at max. speed at 60 barg (871 psig)

Technical specifications

Media temperature

Filtration requirements (nominal)

Weight (dry) vertical/horizontal

Weight (operation with water) vertical/

horizontal

Noise

Sound pressure level L

Footprint

Footprint (vertical position)

Footprint (horizontal position)

Torque data

Max. allowable working torque

Max. starting torque (stick/slip)

Motor data

Nominal speed rpm 118 0 118 0

Rated current at 400V A 36.2 36.2

Motor size

Frame size

Rated motor torque at nominal speed

Rated motor ambient temperature

Motor insulation Class B B

Motor degrees of protection IP 55 55

2)

A-weighted sound pressure level at 1 m from the ERD

unit surfaces (reference box) acc. to EN ISO 20361

section 6.2. The noise measurement are performed

acc. to EN ISO 3744:2010 on an ERD with motor

(motor pump unit) from min. to max. pressure and

speed.

3

Area covered with recommended IE3 motor

configurations (excl. of space to service the ERD)

4)

For higher temperature, contact Danfoss.

5)

Dependent on NaCI concentation.

7)

% 93.7 92.4

5

)

6)

°C 2-35 2-35

°F 36-95 36-95

3 micron melt-blown

kg 484/506 484/506

lb 10 67/1116 10 67/1116

kg 513/535 513/535

lb 1131/1179 1131/ 1179

2)

PA

1 m

3)

dB(A) 83 86

m² 0.44 0.44

foot² 4.71 4.71

3)

m² 0.76 0.76

foot² 8.14 8.14

Nm 170 177

lbf-ft 125 130.5

Nm 18 0 180

lbf-ft 132 132

kW 22.5 22.5

HP 30.0 30.0

NEMA 324/6T 324/6T

Poles 6 6

Nm 179 179

lbf-ft 132 132

4)

°C 40 40

°F 104 104

6)

Please see section 7.4 Filtration

7)

Typical efficiency for pressure exchanger, ..

booster pump, electrical motor and VFD at 3

barg differential pressure after a system has ...

been commissioned and run in.

)

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

29

Page 30

Data sheet | iSave 50 and iSave 70

0

10

20

30

40

50

60

525 650

Flow [GPM]

Flow [m

3

/h]

Motor speed [rpm]

Flow curve iSave50®

5 bar

2

bar

220

176

0,0

10,0

20,0

30,0

40,0

50,0

60,0

70,0

80,0

625 875

Flow [GPM]

Flow [m

3

/h]

Motor speed [rpm]

Flow curve iSave70®

2

bar

5 bar

220

308

5. Performance curves 5.1 Flow at different rpm

The diagram shows that the HP flow can be

changed by changing the rotation speed of the

iSave. The flow/rpm ratio is constant, the

required flow is obtainable by changing the

rotation speed to a required value.

5.2 iSave 50 flow curves

For accurate data and advise, please contact

Danfoss High Pressure Pumps.

The iSave is delivered with a 3.1 performance

certificate according to EN10204.

5.3 iSave 70 flow curves

30

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

Page 31

Data sheet | iSave 50 and iSave 70

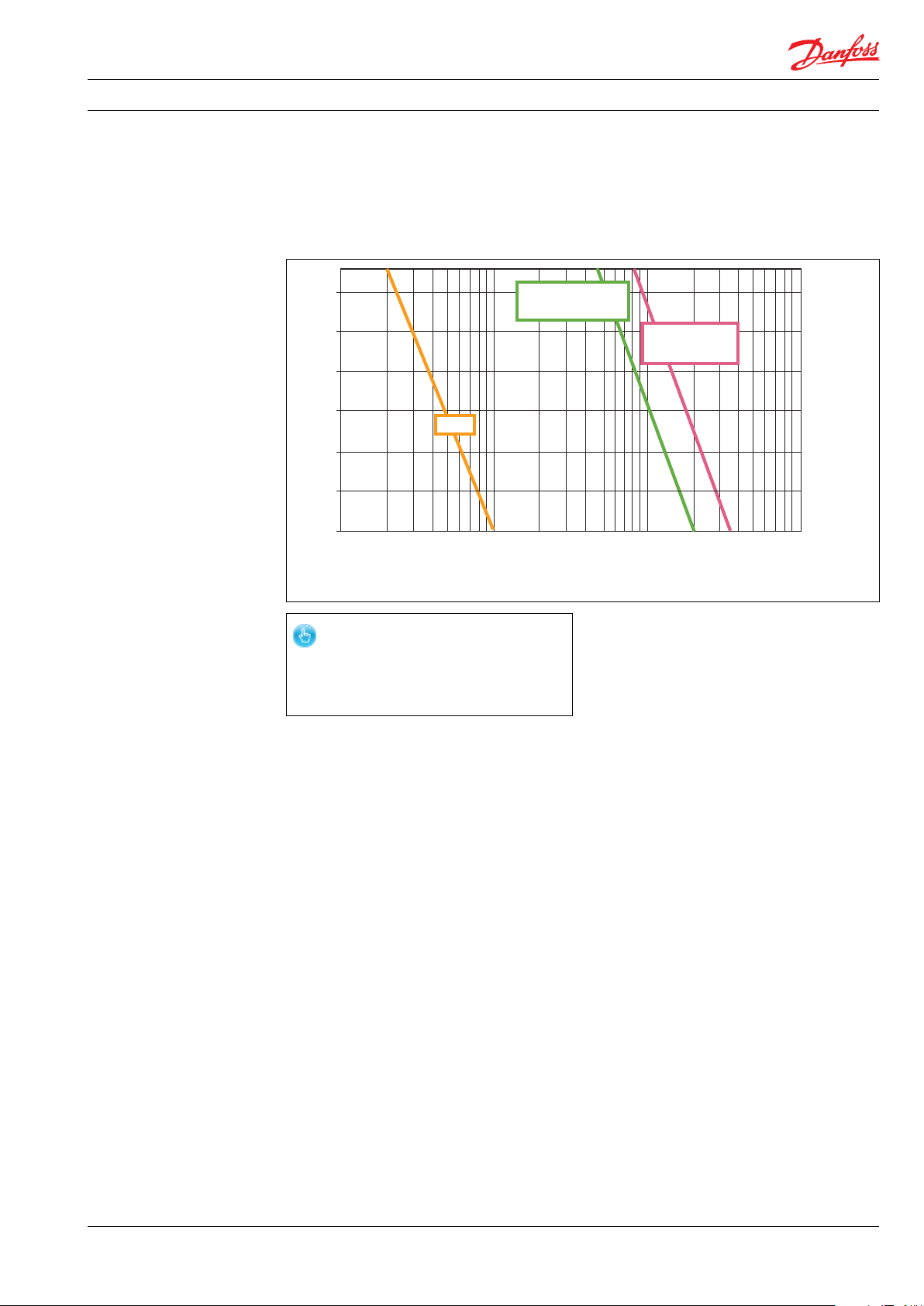

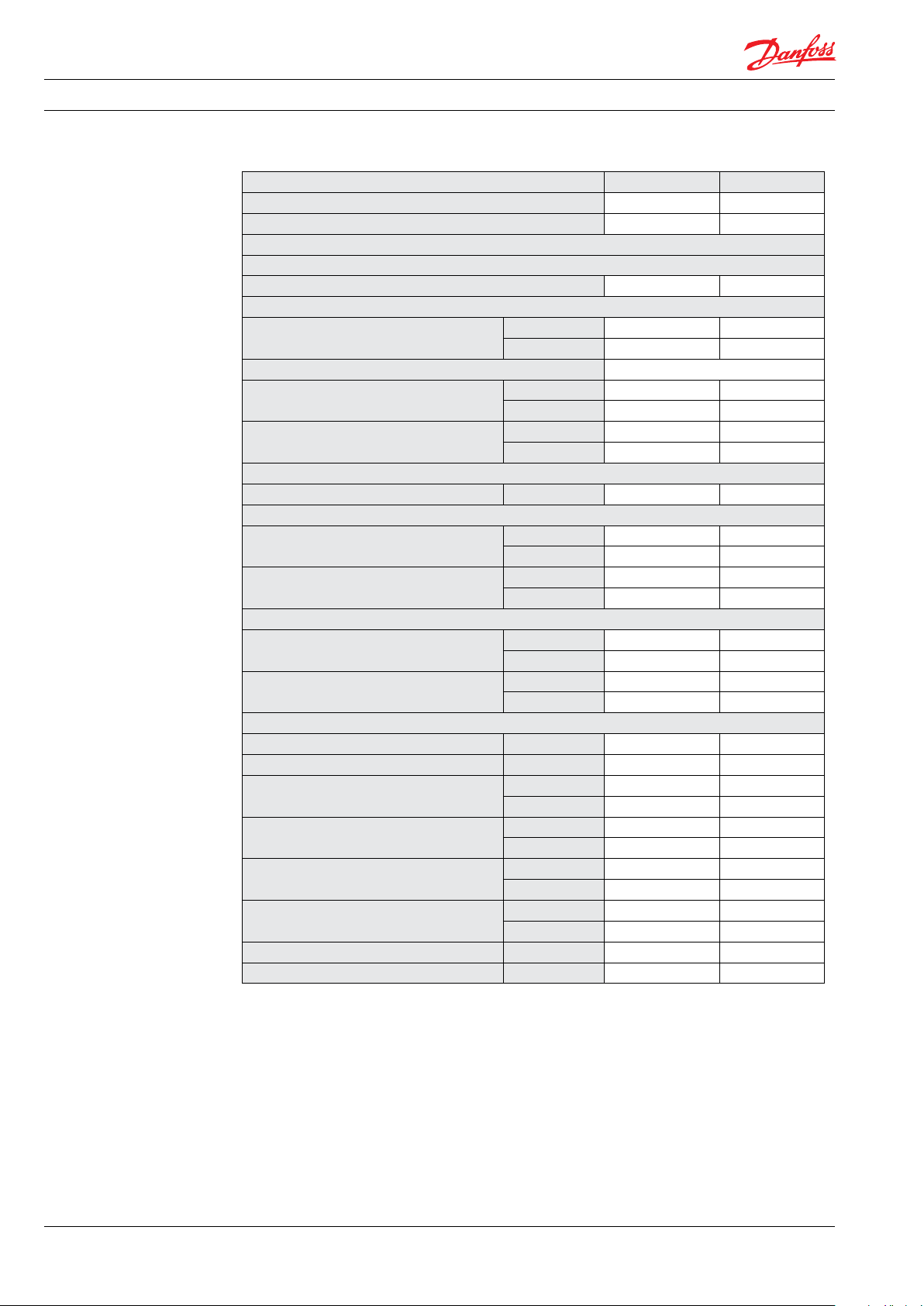

5.4 Torque curve for iSave 50 and iSave 70

Below curve illustrates typical values.

Torque [Nm]

200

180

160

140

120

100

80

60

40

Torque on iSave50 and iSave70

Starting torque

delta-P: 5 bar

delta-P: 4 bar

delta-P: 3 bar

delta-P: 2 bar

delta-P: 1 bar

20

0

5.5 Mixing curve

525 645 765 875

Motor speed [rpm]

Volumetric mixing versus flushing

14,0

12,0

10,0

8,0

6,0

Volumetric mixing [%]

4,0

2,0

0,0

-10 -5 0 5 10

Flush ratio (larger than 0 means overflush) [%]

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

31

Page 32

Data sheet | iSave 50 and iSave 70

6. Temperature and

corrosion

6.1 Operation

The chart below illustrates the corrosive

resistance of different types of stainless steel

related to NaCl concentration and temperature.

All critical parts of the iSave is made of

Super Duplex 1.4410/UNS 32 750 or Duplex

1.4462/UNS 32803.

º

80

C

Duplex

70

60

50

316L

40

30

20

100

1000

160 1600

Always flush the iSave with fresh water at

operation stop in order to minimize the risk of

crevice corrosion.

Super Duplex

-

10 000

16000

100 000

160000

CI

ppm

NaCI

ppm

7. Installation

7.1 Operation and mounting 7.2 Horizontal mount

The iSave 50 and iSave 70 can be mounted

horizontally and vertically. When mounted

vertically, the electric motor must be placed at

the top of the iSave

The iSave is delivered with a standard port

orientation. The port orientation can be changed

by the customer by rotating the combined iSave

and bell housing around the center of the motor

shaft.

32

180R9357 | AQ265943679828en-001001 IOM iSave 50 - 70 | 02.2022

Page 33

Data sheet | iSave 50 and iSave 70

See example below on how to mount the pump

and connect it to an electrical motor.

A: Flexible coupling

B: Bell housing

C: Motor shaft

7.3 Connection to inlet or discharge ports:

• When using hard piping, it is important to

follow the Guideline 180R9367 - Pipe

connection.

• When using flexible hoses, it is recommened

to use Hose Whip Restraint. Also follow the

guideline 180R9084 - Right and Wrong Hose

assembly.

Note: Any axial and radial load on the shaft

must be avoided.

min. 3 - 5 mm air space

A B C

7.4 Filtration

High quality water extends the service life of the

whole system.

Water to the iSave must be filtered to 3 μm

nominal, using melt-blown depth filter with

good end sealings. Consult Danfoss for correct

choice of filter.

It is important with selection of a proper filter

and filter housing to ensure good cartridge end

sealing.

If there is a high risk of water by-pass it is

recommended to use a second stage filter