Page 1

Service guide

Instruction

Energy recovery device

iSave 40

Disassembling and assembling

Disassembling and assembling

iSave 40

hpp.danfoss.com

ro-solutions.com

Page 2

Service guide | Disassembling and assembling iSave 40

Table of Contents

1. General information.....................................................................2

2. Disconnect the iSave from electric motor ................................................3

3. Disassembling the booster pump .......................................................5

4. Assembling the booster pump ..........................................................8

5. Disassembling the pressure exchanger .................................................13

6. Assembling the pressure exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7. Assembling the cylinder drum in pressure exchanger ...................................19

8. Changing spring in the rotor ...........................................................20

8.1 Disassembling .........................................................................20

9. Exploded view vane pump .............................................................21

10. Exploded viewpressure exchanger .....................................................22

11. Exploded view iSave ...................................................................23

12. Exploded view iSave on baseplate, horizontal ...........................................24

13. Exploded view iSave on foot, vertical ...................................................25

1. General information

This document illustrates instructions for

disassembling and assembling the iSave 40.

To understand the design of the iSave, see

exploded views starting on page 21.

Always use suitable lifting equipment.

Important!

It is essential that the iSave is serviced in

conditions of absolute cleanliness.

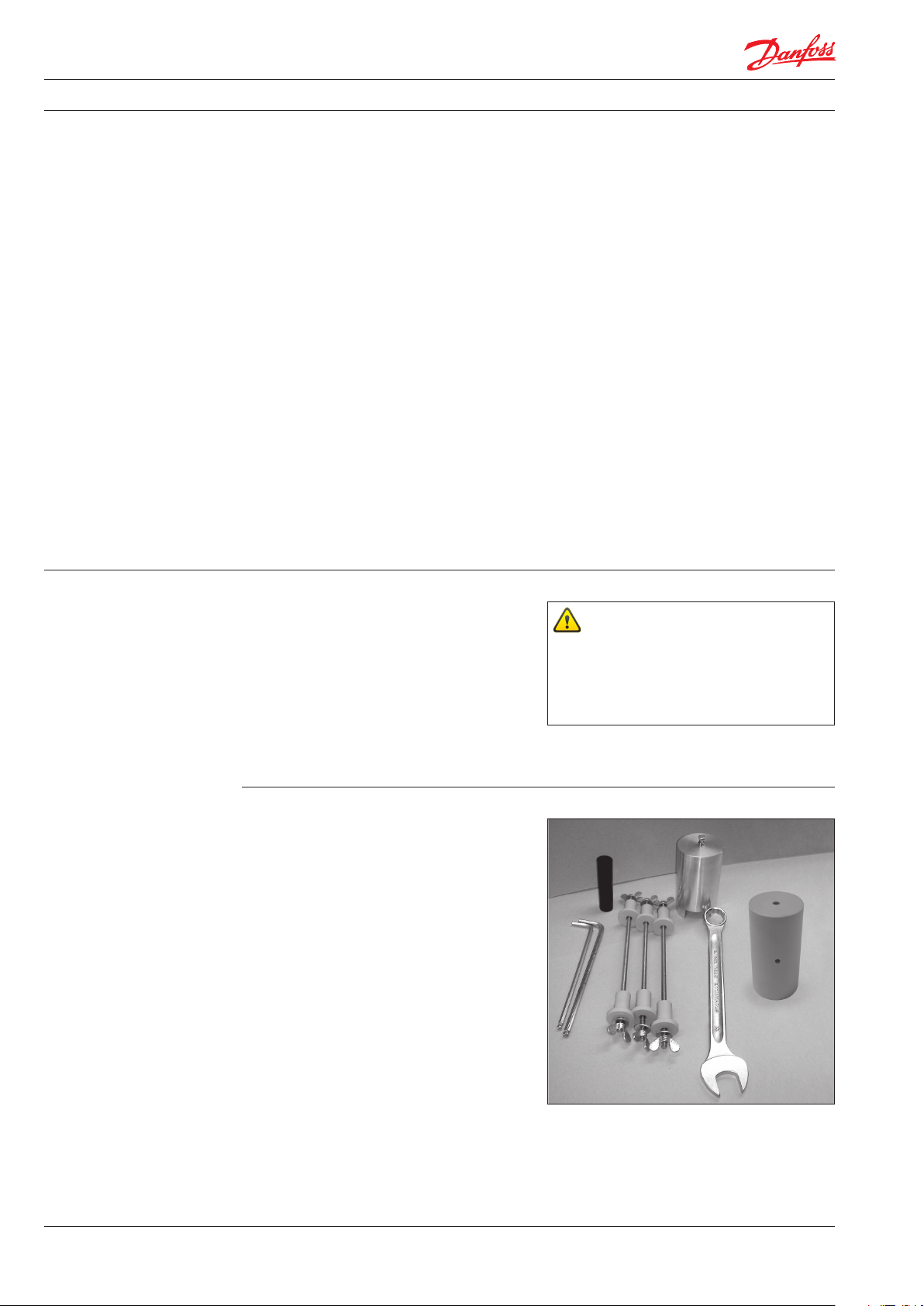

Tools needed to disassemble the iSave:

Parts included in tool set (180F4112):

• 6 mm and 8 mm allen key

• C-wrench 24 mm

• 1 M6 bolt and nut

• Handel for rotor assembly

• Tool for shaft seal assembly

• Tool for retainer assembly

• 3 press bolt-set for valve plate assembly

Parts not included in tool set:

• 2 screwdrivers

• Torque wrench 10-60 Nm

• The weight of the iSave, including

electric motor, is about 260 kg (573 lb).

• The weight of the pressure exchanger

alone is about 75 kg (165 lb).

• The weight of the booster pump

alone is about 50 kg (110 lb).

To prevent cold welding, lubricate threads of the

screws with PTFE lubrication type and screw

them into the component and tighten by hand.

2

180R9242 | AX073186502910 en-000701 | 01.2022

Page 3

Instruction Disassembling and assembling iSave 40

2. Disconnect the iSave

from electric motor

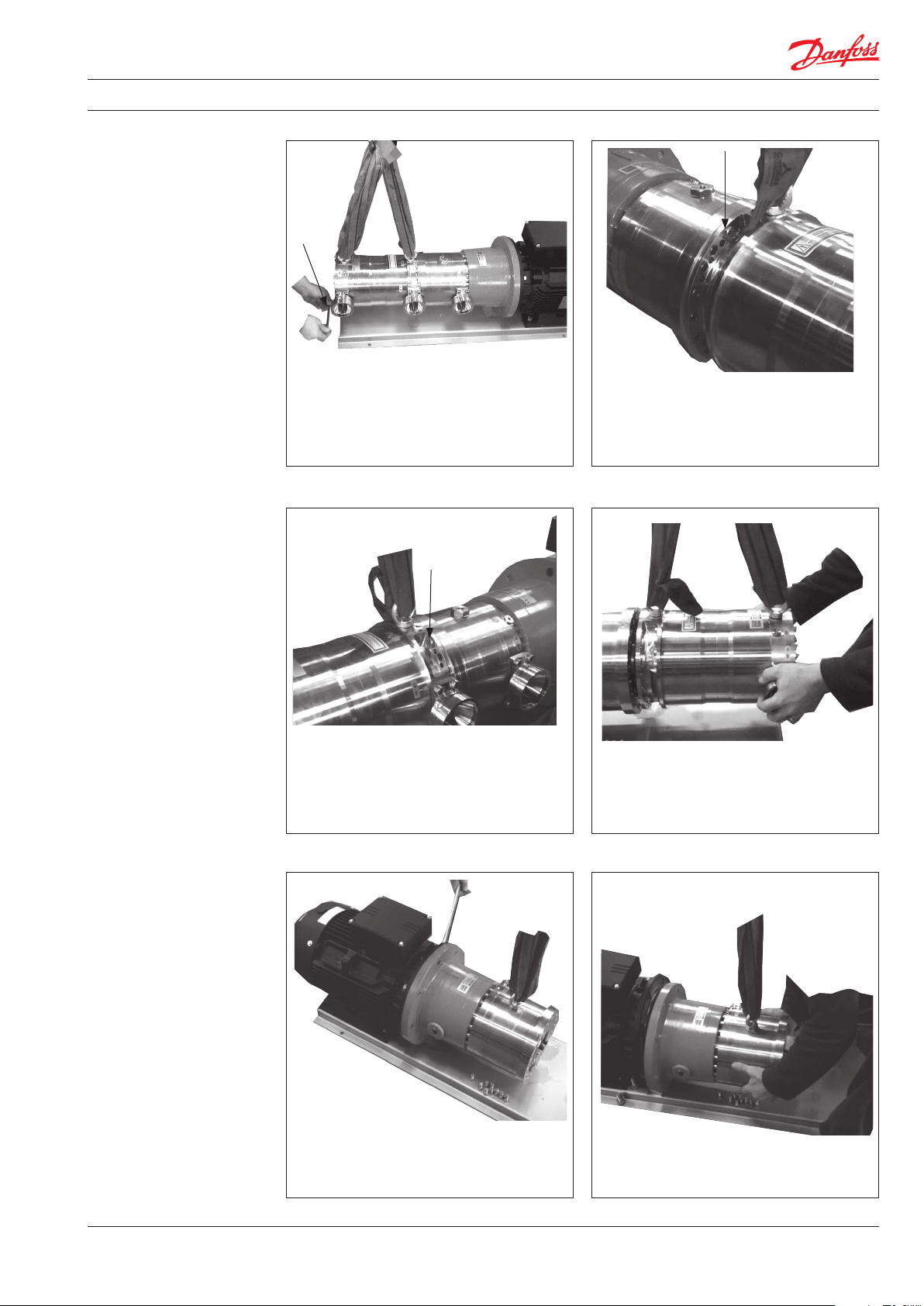

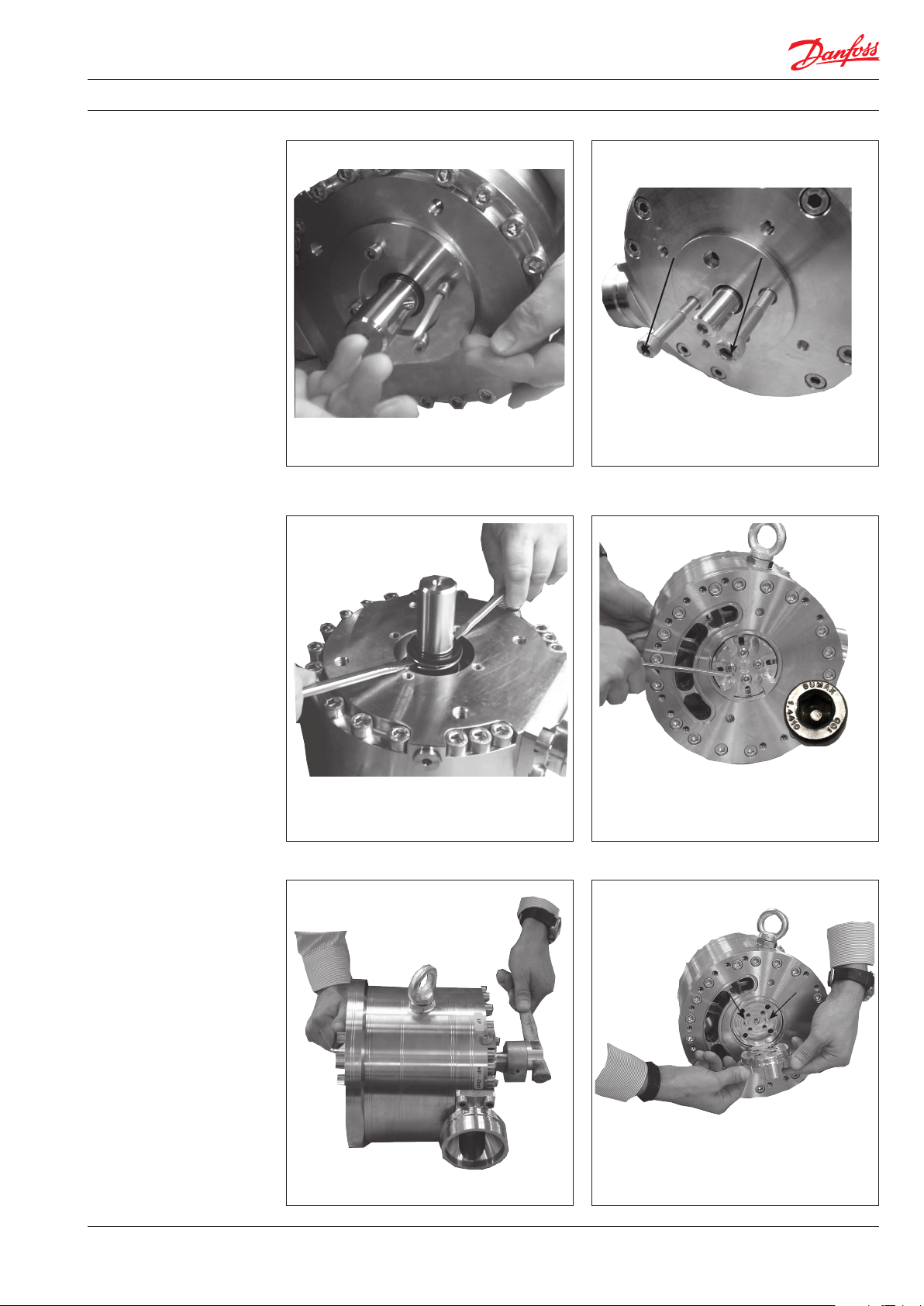

1. Apply a light lifting force on the pressure

exchanger and disconnect the support

bracket between the pressure exchanger

and base plate.

3. Unscrew the 2 upper bolts.

2. Unscrew 10 bolts in the adapter flange

between booster pump and pressure

exchanger. Leave the 2 upper bolts

tighten.

4. Carefully pull and lift the pressure

exchanger from the booster pump.

5. To disconnect the bell housing, unscrew

the 4 bolts on the electric motor.

180R9242 / 521B1213 / DKCFN.PI.003.R2.02 / 09.2013

6. Carefully pull and lift the booster pump

from the electric motor.

3

Page 4

Service guide | Disassembling and assembling iSave 40

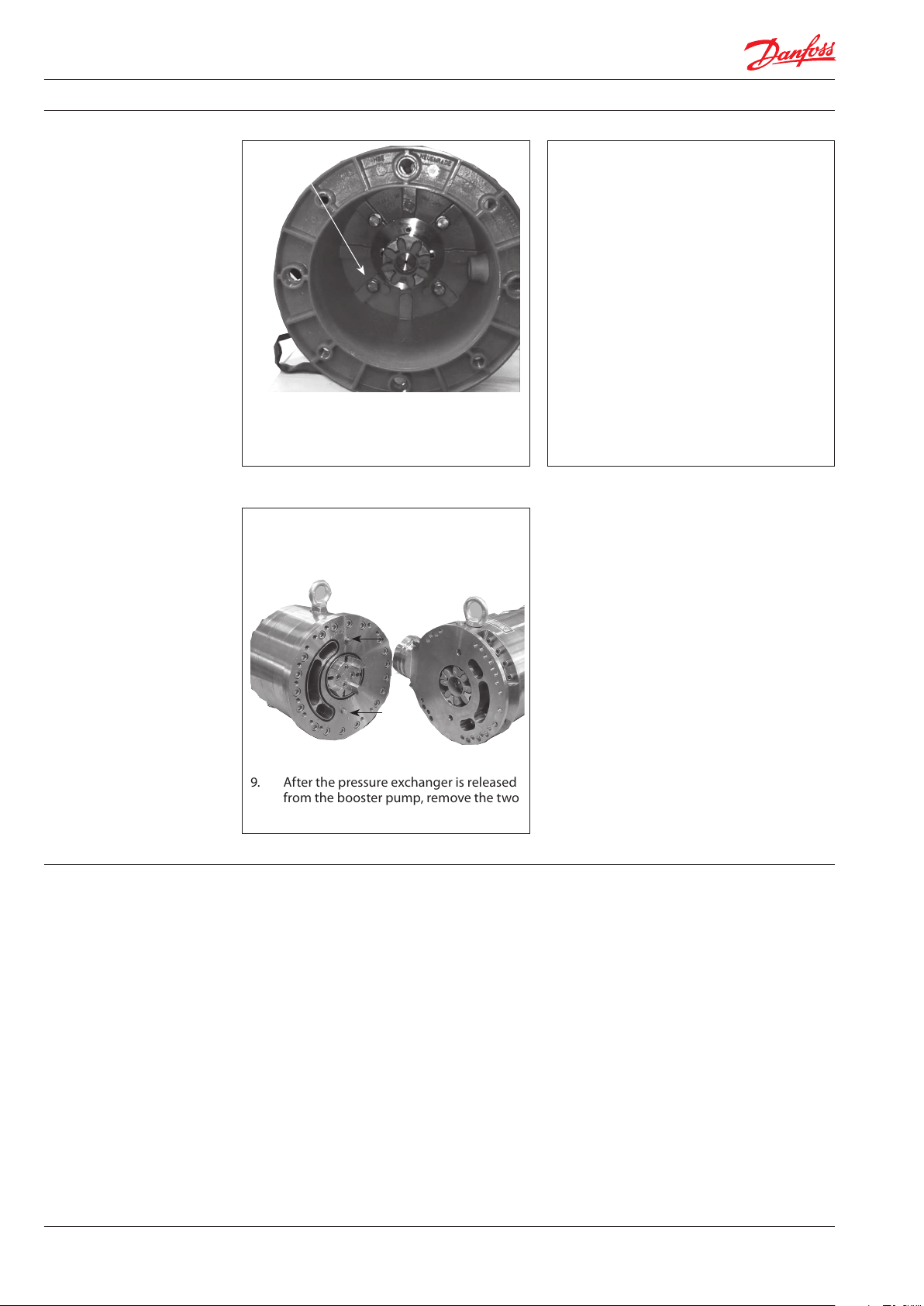

7. Disassemble the bell housing from the

booster pump by unscrewing the 4 bolts

in the bell housing.

9. After the pressure exchanger is released

from the booster pump, remove the two

guide pins.

8. It is also possible to disconnect the

complete unit from the motor first. In this

case, please follow step 1, 5, 6 and 7

afterwards.

4

180R9242 | AX073186502910 en-000701 | 01.2022

Page 5

Service guide | Disassembling and assembling iSave 40

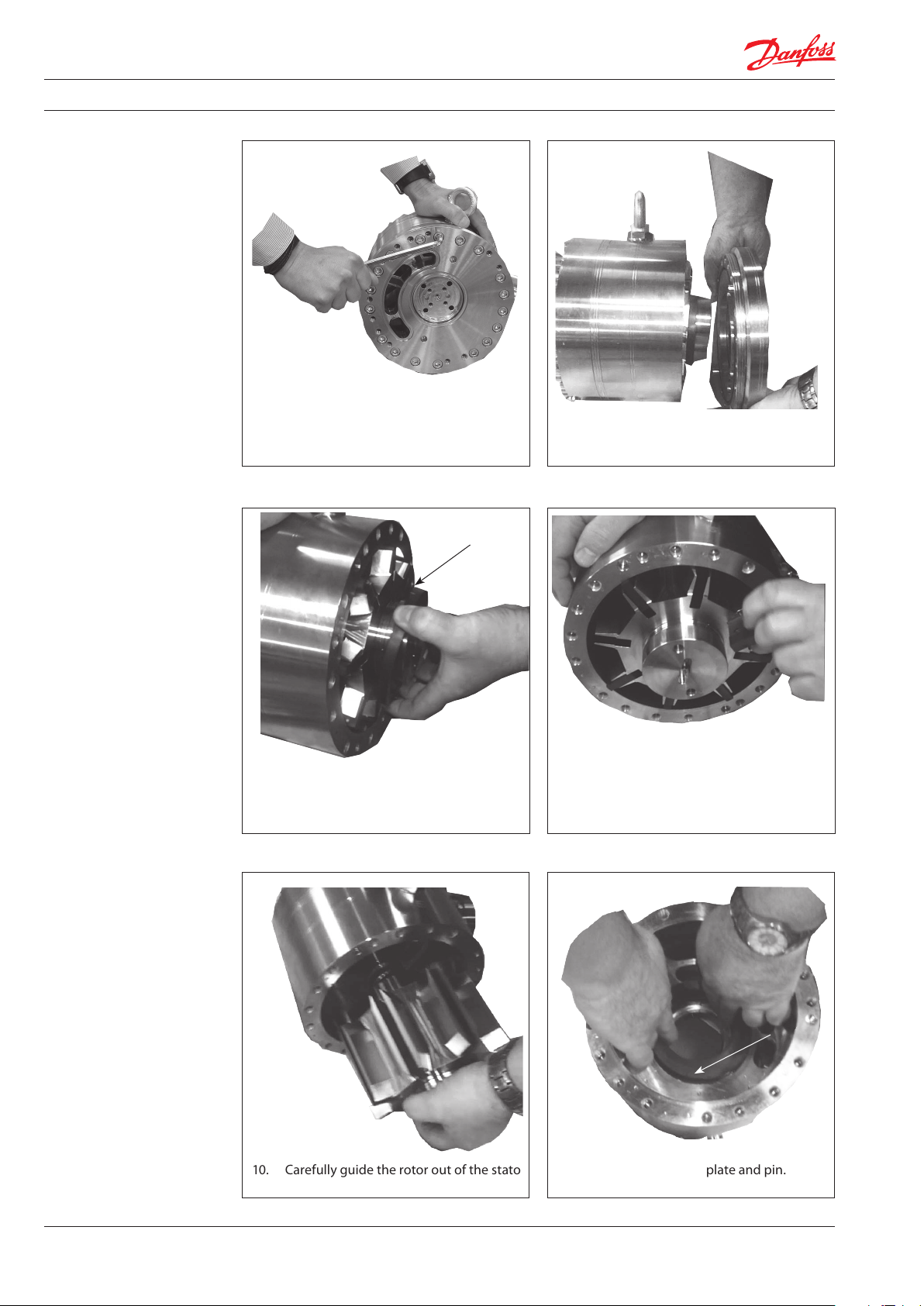

3. Disassembling the

booster pump

M8x20 bolts marked A4

If flange cannot be removed easily, use two

M8 bolts.

1. Disassemble the flange for shaft seal.

3. If coupling has to be changed, follow the

next two steps.

4 x special M8x20 bolts

marked 1.4410

2. Wet the shaft seal first with clean filtered

water. Carefully lift the shaft seal by using

2 screwdrivers.

4. Unscrew the four special M8x20 bolts

marked 1.4410. Use a hammer handle at

the opposite end to prevent the shaft from

turning.

5. Remove coupling and the two pins.

180R9242 | AX073186502910 en-000701 | 01.2022

5

Page 6

Service guide | Disassembling and assembling iSave 40

6. Loosen all the bolts in the adapter flange. 7. Carefully disassemble adapter flange and

port plate from the stator ring.

9. Remove the 8 vanes.8. Remove the sealing plate.

10. Carefully guide the rotor out of the stator. 11. Remove the sealing plate and pin.

6

180R9242 | AX073186502910 en-000701 | 01.2022

Page 7

Service guide | Disassembling and assembling iSave 40

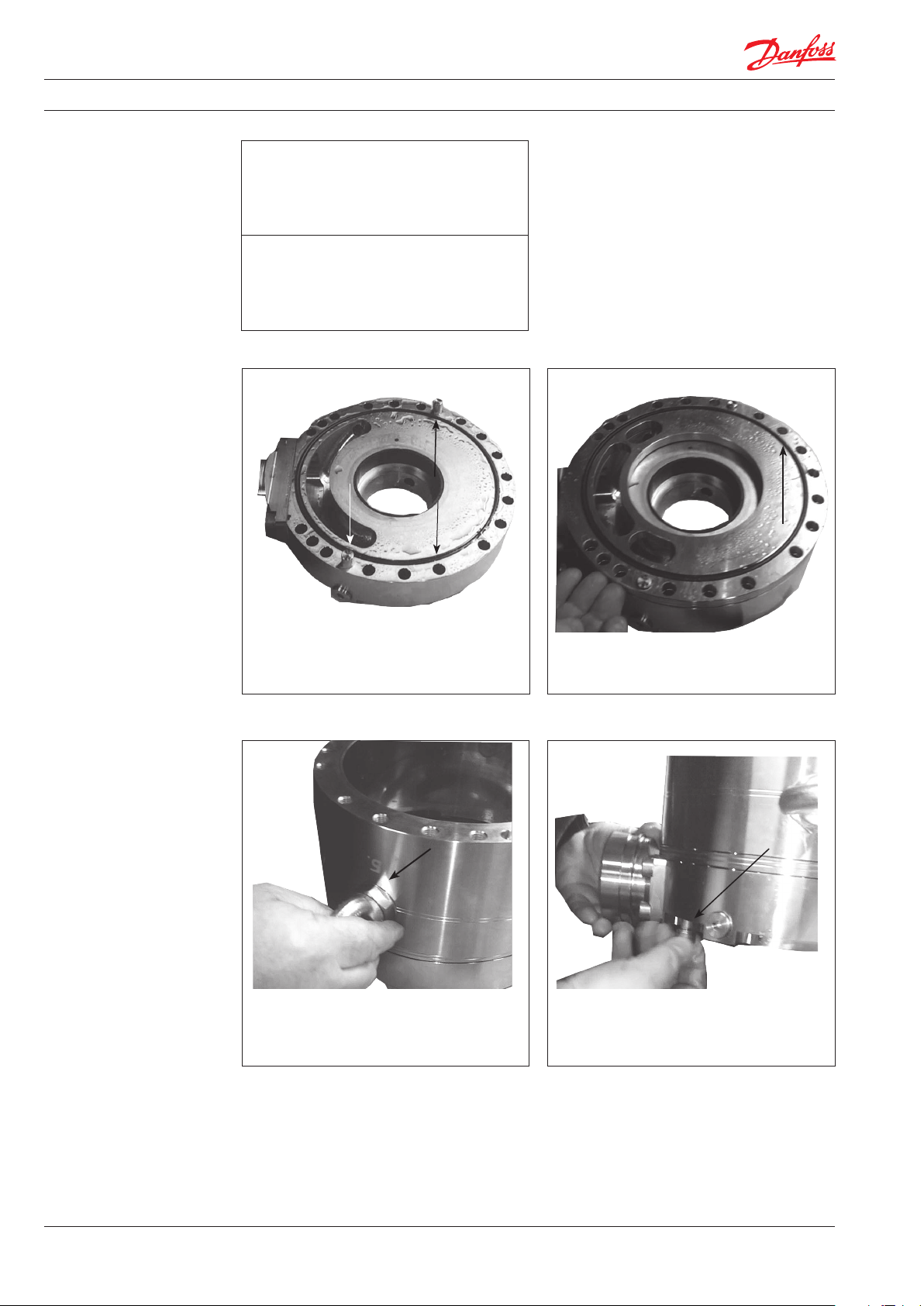

12. Remove the O-ring from the sealing

13. Unscrew the bolts in the outlet flange.

plate.

14. Remove the HP outlet flange. 15. Remove the port flange.

180R9242 | AX073186502910 en-000701 | 01.2022

7

Page 8

Service guide | Disassembling and assembling iSave 40

4. Assembling the

booster pump WARNING:

Do not use silicone when assembling the

iSave. Do not reuse disassembled O-rings;

they might be damaged. Always use new

O-rings.

Important:

It is essential that the pump is serviced in

conditions of absolute cleanliness. All parts

must be absolutely clean before mounting.

Lubrication:

• To prevent seizing-up, lubricate all threads

with PTFE lubrication type.

• It is important to lubricate ALL parts to be

assembled with clean filtered water

(Especially all PEEK parts).

1. Place the HP outlet flange on the desk

and mount the O-ring and 2 pins.

3. Turn the stator with the two holes for the

lifting eye closest to the port plate and

position the stator on the 2 pins.

2. Align the port plate-out on the two pins

and mount the O-ring on the port plate.

4. From down side up and by hand, screw in

two bolts in the stator.

8

180R9242 | AX073186502910 en-000701 | 01.2022

Page 9

Service guide | Disassembling and assembling iSave 40

5. Tighten the bolts by using an allen key.

6. Tilt the flange and stator; assemble and

screw in the rest of the bolts in the flange.

Tighten bolts to a torque of 60 ±6 Nm.

7. Assemble and position the two pins in the

pin holes.

9. Mount the O-ring in the sealing plate and

guide pin in flange.

It is important to lubricate to ensure the

O-ring does not drop out.

180R9242 | AX073186502910 en-000701 | 01.2022

9

Page 10

Service guide | Disassembling and assembling iSave 40

10. Position the sealing plate on the guide

pin.

Ensure correct choice of sealing plate.

Only one sealing plate fits the guide pin.

12. By using the handle tool provided, carefully

lever the rotor into the stator.

11. Position the 8 pins in the rotor. 2 pins in

each hole.

13. Fit the 8 vanes into each slot. Notice vane

position. Place the straight site of the

vane onto the pin with the mark down

ward.

No mark on

this side

14. Orient the vanes with correct end into

rotor. See the arrow below.

10

180R9242 | AX073186502910 en-000701 | 01.2022

15. Assemble the new O-ring on the adapter

flange.

Page 11

Service guide | Disassembling and assembling iSave 40

16. Assemble the new O-ring on the port

plate-in.

18. Assemble the new O-ring on the correct

sealing plate.

It is important to lubricate to ensure the

O-ring does not drop out.

17. Position the port flange in on the adapter

flange and position the two guide pins.

19. Position the guide pin in the adapter

flange.

20. Position the sealing plate over the guide

pin.

180R9242 | AX073186502910 en-000701 | 01.2022

21. Carefully position the adapter flange

assembly into the two guide pin holes.

11

Page 12

Service guide | Disassembling and assembling iSave 40

22. Mount two bolts in the adapter flange. 23. Mount all bolts in the adapter flange.

Tighten the bolts to a torque of 60±6 Nm.

24. Turn the pump with shaft upwards.

Lubricate the shaft and shaft seal with

clean filtered water. Mount the shaft seal

with the carbon ring upwards.

26. Lubricate and press new ceramic ring into

the shaft seal cover by using the press

bush tool.

WARNING:

Ensure that the face with rubber seal is

positioned against shoulder in shaft seal

flange.

25. Using the shaft tool provided, carefully

press down the shaft seal to the shoulder

of the shaft.

M8x20 bolts marked A4

27. Mount a new O-ring on the flange for

shaft seal and assemble the minor flange

on top of the flange. Tighten M8x20 bolts

marked A4 to a torque of 30 ±3 Nm.

12

180R9242 | AX073186502910 en-000701 | 01.2022

Page 13

Service guide | Disassembling and assembling iSave 40

4 x special M8x20 bolts

marked 1.4410

5. Disassembling the

pressure exchanger

28. Mount the two pins and the coupling

part.

3 x special M8x20 bolts

marked 1.4410

1. Unscrew the 3 special M8x20 bolts marked

1.4410.

29. Mount the four special M8x20 bolts

marked 1.4410 and tighten them to a

torque of 35 ±3.5 Nm.

2. Remove coupling and the 3 pins.

3. Unscrew all the bolts. 4. Carefully lever the flange and port plate

from the casing.

180R9242 | AX073186502910 en-000701 | 01.2022

13

Page 14

Service guide | Disassembling and assembling iSave 40

5. Carefully take the cylinder barrel assem bly out of the casing.

6. Remove port plate and the two pins.

7. Carefully lever the 2 valve plate assembly

free with help from 2 screwdrivers.

14

180R9242 | AX073186502910 en-000701 | 01.2022

Page 15

Service guide | Disassembling and assembling iSave 40

6. Assembling the

pressure exchanger

WARNING:

Do not use silicone when assembling the

iSave. Do not reuse disassembled O-rings;

they might be damaged. Always use new

O-rings.

Important:

It is essential that the pump is serviced in

conditions of absolute cleanliness. All parts

must be absolutely clean before mounting.

Lubrication:

• To prevent seizing-up, lubricate all threads

with PTFE lubrication type.

• It is important to lubricate ALL parts to be

assembled with clean filtered water

(Especially all PEEK parts).

Assembling cylinder barrel in pressure

exchanger, see page 19.

Follow step 1-3 if LP in flange has been disassembled from casing.

1. Assemble the O-ring on the LP in port

flange.

M8x20 bolts marked A4

3. Position the LP in flange on the guide pin

and assemble all the bolts into the casing.

Tighten the bolts to a torque of 30 ±3 Nm.

2. Position the guide pin into the casing.

4. Turn the assembly and position the two

guide pins in the flange inside the casing.

180R9242 | AX073186502910 en-000701 | 01.2022

15

Page 16

Service guide | Disassembling and assembling iSave 40

5. Position the port plate on the flange

using the two guide pins as guide. Only

one port plate fits.

7. Carefully guide the cylinder barrel into the

flange bearing.

6. Mount the provided M6 threaded rod into

the shaft of the cylinder barrel.

8. Assemble the O-ring on the HP/LP flange

and position the two guide pins into the

flange.

9. Position the port plate on the HP/LP

10. Position the guide pin into the casing.

flange using the two guide pins as guide.

Only one port plate fits.

16

180R9242 | AX073186502910 en-000701 | 01.2022

Page 17

Service guide | Disassembling and assembling iSave 40

11. Carefully position the flange assembly

onto the guide pin in the casing.

12. Carefully assemble a bolt into the casing

to ensure that flange assembly stays in

place.

13. Assemble all the bolts and tighten them to

a torque of 30 ±3 Nm.

4 x special M8x20 bolts

marked 1.4410

15. Tighten four special M8x20 bolts marked

1.4410 to a torque of 35 ±3,5 Nm.

180R9242 | AX073186502910 en-000701 | 01.2022

14. Mount the 3 pins in shaft and place the

coupling part.

16. Assemble booster pump and pressure

exchanger. Mount the two guide pins

and coupling spacer.

17

Page 18

Service guide | Disassembling and assembling iSave 40

17. Tighten bolts to a torque of 60 ±6 Nm.

7. Assembling the

cylinder barrol in

pressure exchanger

O-ring

Back-up ring

The shaft is normally not a wear part and can

only be changed by Danfoss.

1. Assemble back-up rings and O-rings on

the valve plates. Back-up rings first.

2. Lubricate the O-rings and back-up rings

with clean filtered water and position the

two valve plates into the rotor ends.

3. Using the tools provided gently screw in

the valve plates.

4. Check the distance between the two valve

plates and the cylinder barrel. Adjust the

distance if necessary.

18

180R9242 | AX073186502910 en-000701 | 01.2022

Page 19

Service guide | Disassembling and assembling iSave 40

Small shaft diameter: No distance. Large shaft diameter: Distance 4-5 mm.

8. Changing springs in

the pressure exchange

rotor.

It is basically not necessary to change the

springs in the rotor. If needed, follow the

guidelines below:

8.1 Disassembling

Using the tool provided, press down the

retainer and remove/cut the O-ring, and

remove retainer. 1. Replace springs in the rotor.

180R9242 | AX073186502910 en-000701 | 01.2022

19

Page 20

Service guide | Disassembling and assembling iSave 40

2. Assemble the retainer over the springs. 3. Assemble the O-ring over the retainer.

4. Using the tool provided, press down the

retainer by tightening the nut until the

O-ring is placed in the recess.

5. Carefully lever the bolt and tool assembly

and check the O-ring assembly.

20

180R9242 | AX073186502910 en-000701 | 01.2022

Page 21

Service guide | Disassembling and assembling iSave 40

9. Exploded view

vane pump

M8x20 Bolts marked A4

180R9242 | AX073186502910 en-000701 | 01.2022

21

Page 22

Service guide | Disassembling and assembling iSave 40

10. Exploded view

pressure exchanger

22

M8x20

bolts

marked A4

180R9242 | AX073186502910 en-000701 | 01.2022

Page 23

Service guide | Disassembling and assembling iSave 40

11. Exploded view iSave

Special M8x20

bolts marked

1.4410

180R9242 | AX073186502910 en-000701 | 01.2022

23

Page 24

Service guide | Disassembling and assembling iSave 40

12. Exploded view

iSave on base plate,

horizontal

24

180R9242 | AX073186502910 en-000701 | 01.2022

Page 25

Service guide | Disassembling and assembling iSave 40

13. Exploded view

iSave on foot, vertical

180R9242 | AX073186502910 en-000701 | 01.2022

25

Page 26

Service guide | Disassembling and assembling iSave 40

26

180R9242 | AX073186502910 en-000701 | 01.2022

Page 27

Service guide | Disassembling and assembling iSave 40

180R9242 | AX073186502910 en-000701 | 01.2022

27

Page 28

© Danfoss | DCS (im) | 2022.01

180R9242 | AX073186502910 en-000701 | 28

Loading...

Loading...