isave.danfoss.com

Service instruction

Disassembling and assembling

iSave 21

MAKING MODERN LIVING POSSIBLE

Tel:+44(0)1706869777

E‐mail:sales@desal.co.uk

Web:www.desal.co.uk

Service instruction Disassembling and assembling iSave 21

2

180R9219 / 521B1171 / DKCFN.PI.0 03.K3.02 / 11.2013

1. General introduction....................................................................2

2. Disassembling the iSave.................................................................3

3. Disassembling the pressure exchanger ..................................................4

4. Assembling the pressure exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

5. Disassambling the vane pump..........................................................12

6. Assembling the vane pump ............................................................13

7. Assembling the iSave ..................................................................17

8. Exploded view vane pump ...................................................... 18

9. Exploded view pressure exchanger............................................... 19

10. Exploded view iSave ...................................................................20

Table of Contents

This document covers the instructions for

disassembling and assembling the iSave 21.

Important: It is essential that the iSave is

serviced in conditions of absolute cleanliness.

For a better understanding of the iSave, please

see the exploded view in item 8, 9 and 10.

The weight of the iSave is 65 kg / 143 lb

and it must be lifted with suitable lifting

equipment.

The weight of the pressure exchanger alone is

28 kg / 62 lb.

It is essential that the iSave is serviced in

conditions of absolute cleanliness

To prevent cold welding, lubricate threads of

screws with grease screw them into the component and tighten them by the hand. Use PTFE

lubrication type.

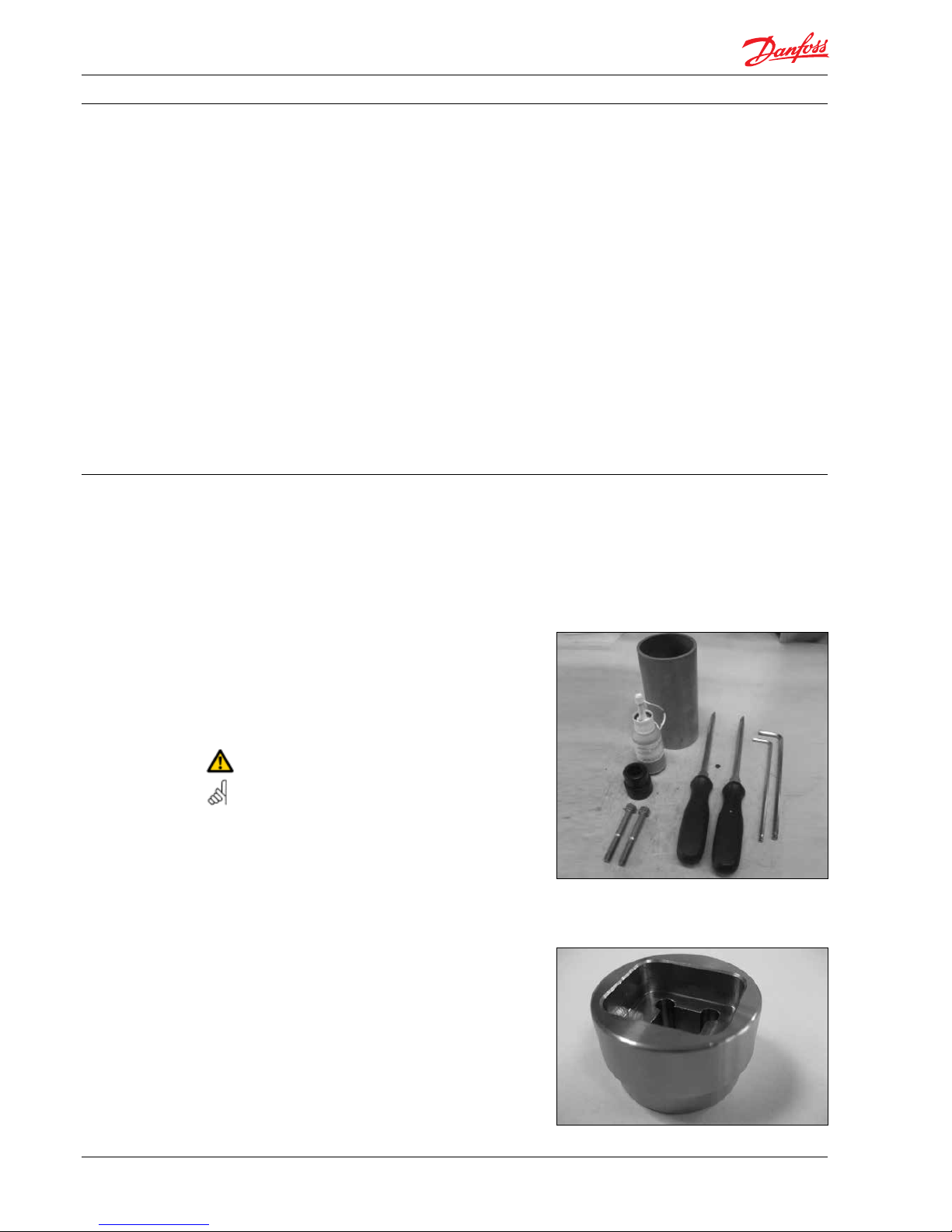

Tools needed for disassembling the iSave:

- 6 mm and 8 mm allen key

- 2 screwdrivers

- 2 M8 bolts

- Plastic tube

- Plastic tool for shaft seal assembly

- Loctite 270

Torque wrench with special socket

Code no. 180Z0610

1. General Introduction

Service instruction Disassembling and assembling iSave 21

3

180R9219 / 521B1171 / DKCFN.PI.0 03.K3.02 / 11.2013

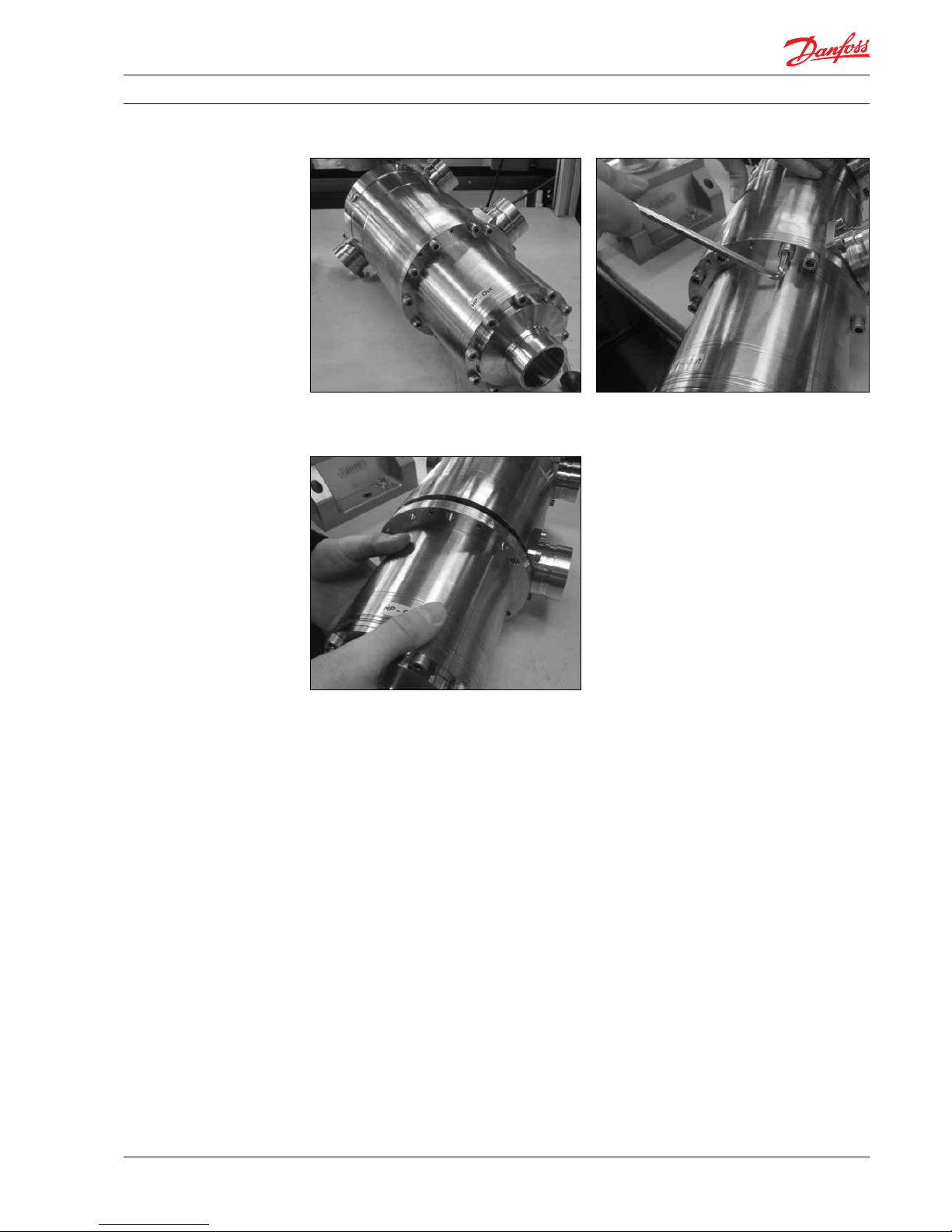

2. Disassembling

the iSave

1. Place the iSave on a clean table.

3. Remove the vane pump.

2. Unscrew the bolts in the ange.

Service instruction Disassembling and assembling iSave 21

4

180R9219 / 521B1171 / DKCFN.PI.0 03.K3.02 / 11.2013

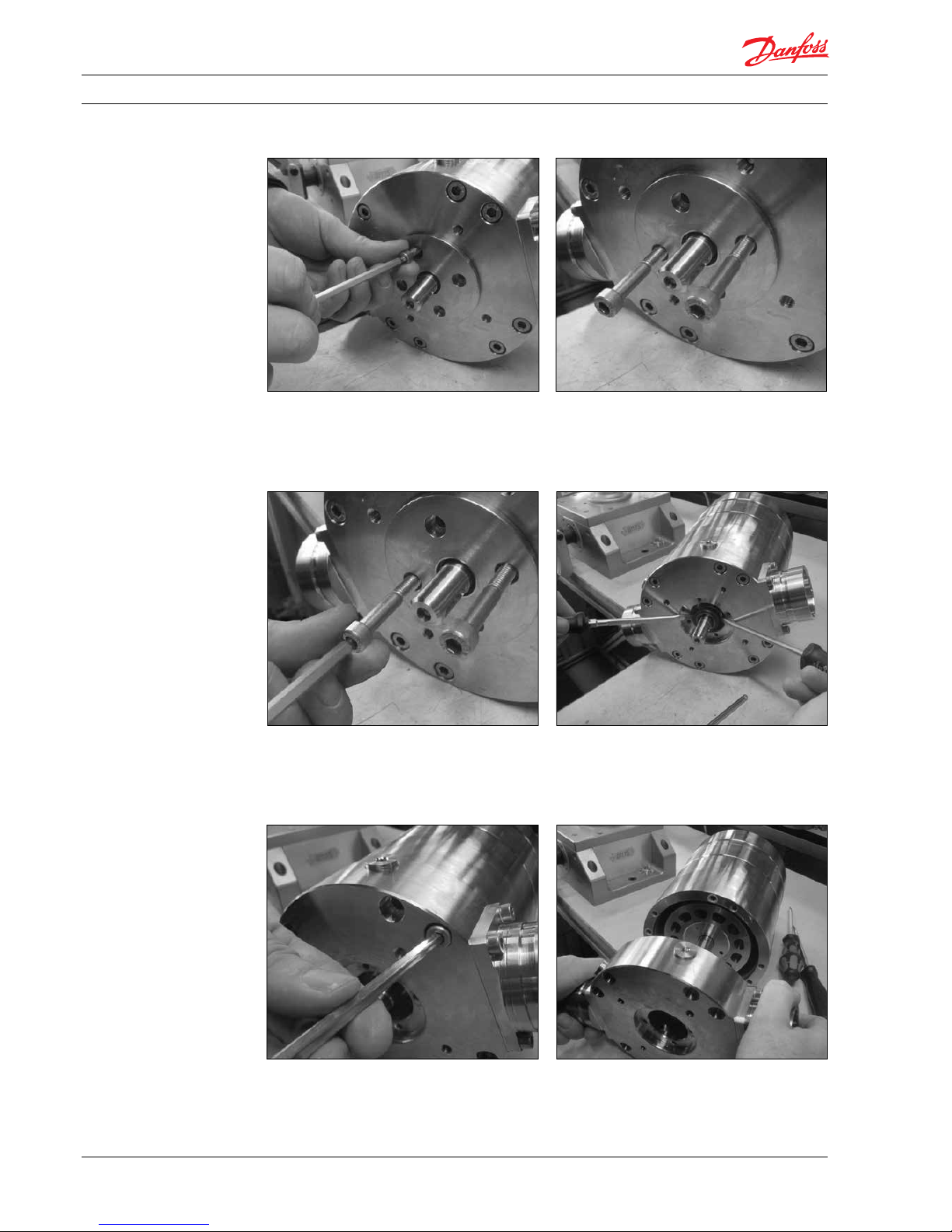

3. Disassembling the

pressure exchanger

1. Unscrew the bolts in the ange.

3. Gently push out the ange.

2. Screw in the two M8 bolts.

4. Wet the shaft and shaft seal with clean

ltered water. Gently lever the shaft

assembly free using 2 screwdrivers.

5. Unscrew the bolts in the ange. 6. Gently remove the ange.

Note: Loose parts on the inside of the ange.

Service instruction Disassembling and assembling iSave 21

5

180R9219 / 521B1171 / DKCFN.PI.0 03.K3.02 / 11.2013

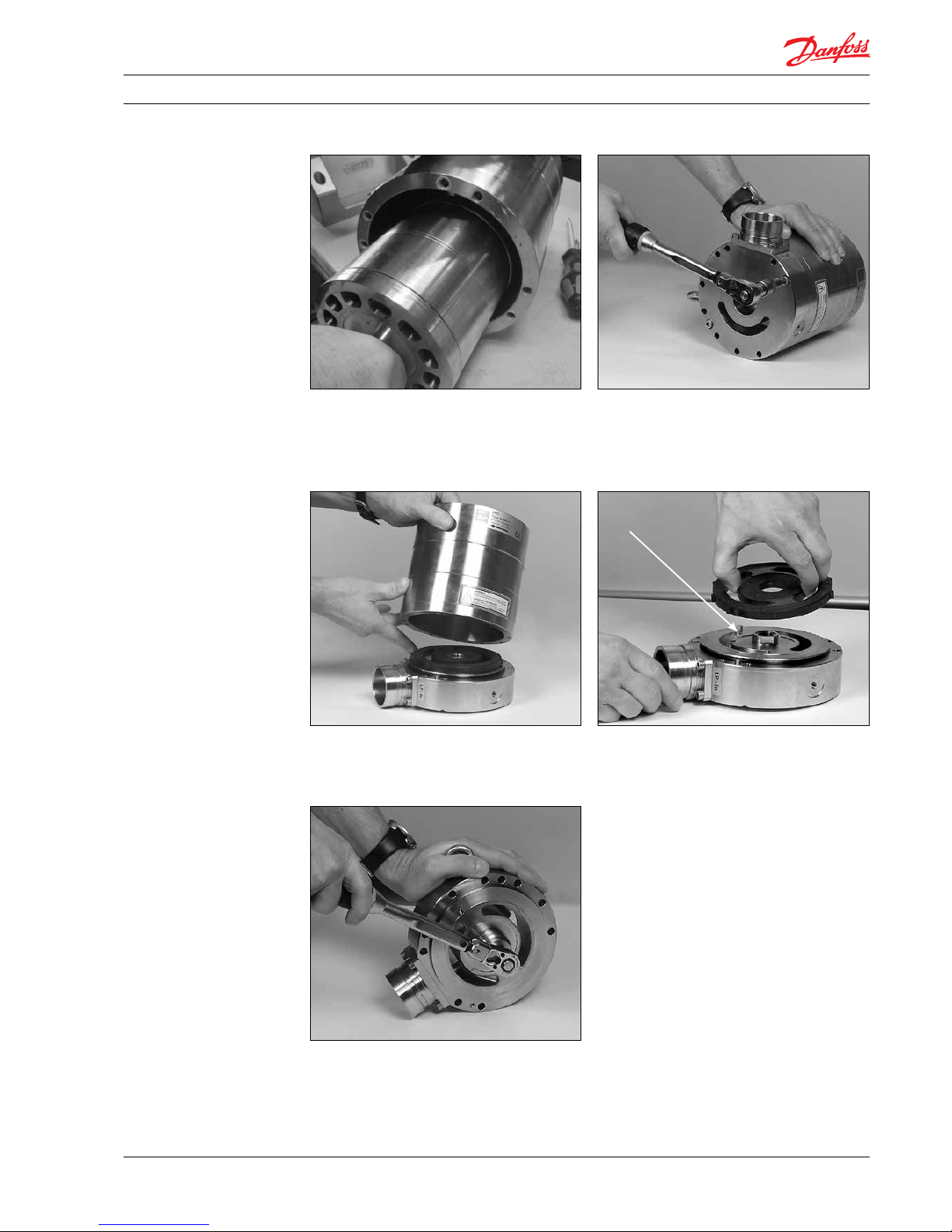

7. Gently remove the cylinder barrel.

9. Gently remove the housing.

Note: Loose parts on the inside of the ange.

8. Unscrew the bolts in the ange.

10. Remove port plate and pin.

Pin

11. Unscrew high-pressure bearing using a

special socket.

Service instruction Disassembling and assembling iSave 21

6

180R9219 / 521B1171 / DKCFN.PI.0 03.K3.02 / 11.2013

13. Remove the high-pressure bearing. 14. Gently lift the valve plate assembly free

with the aid of the screwdrivers.

15. Gently remove both valve plates. 16. Replace the O-rings and the back-up rings

on the valve plate.

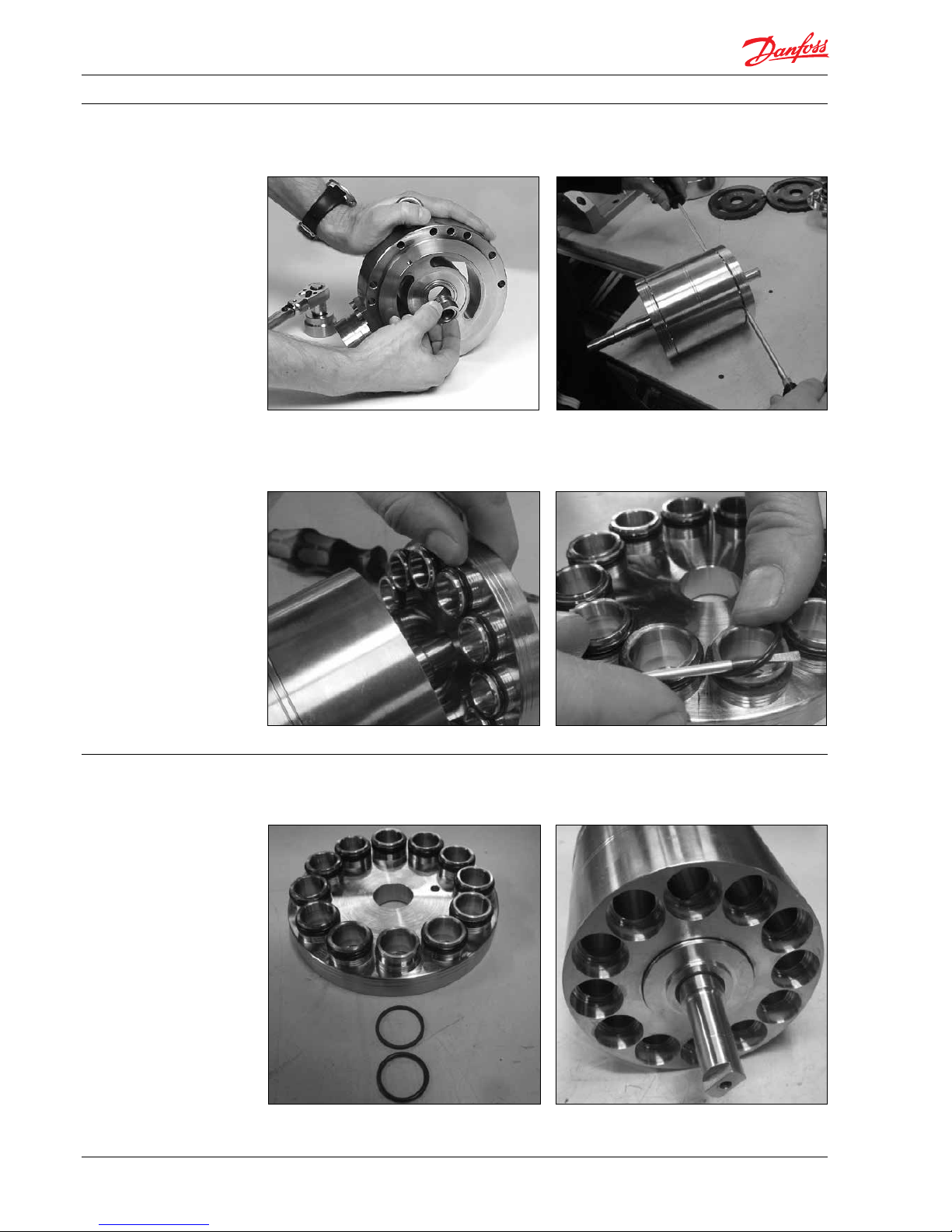

4. Assembling the

pressure exchanger

2. Lubricate all the bores in the cylinder barrel

with grease and clean ltered water.

1. Mount the new back-up rings on the valve

plate rst and then the new O-rings.

Service instruction Disassembling and assembling iSave 21

7

180R9219 / 521B1171 / DKCFN.PI.0 03.K3.02 / 11.2013

18. Adjust the distance between the cylinder

drum and the secon d valve plate.

The distance must be about 4-6 mm.

This is not critical.

3. Gently press, by hand, the rst valve plate

onto the cylinder barrel.

Note: don’t scratch the valve plate when

placing it on the plastic tube.

4. Gently press, by hand, the second valve

plate onto the cylinder barrel by placing it

on the plastic tube.

Note: don’t scratch the valve plate when

placing it on the plastic tube.

The distance must be about 4-6 mm.

This is not critical.

5. Adjust the distance between the cylinder barrel

and the second valve plate (short shaft end).

Service instruction Disassembling and assembling iSave 21

8

180R9219 / 521B1171 / DKCFN.PI.0 03.K3.02 / 11.2013

7. Tighten the high-pressure bearing using

special socket and torque wrench with

70Nm±7

6. Mount the high-pressure bearing

8. Remove old O-ring with a new one 9. Position the housing over the guide pin

10. Mount all bolts in the ange and tighten

them all with 30Nm±3

11

Service instruction Disassembling and assembling iSave 21

9

180R9219 / 521B1171 / DKCFN.PI.0 03.K3.02 / 11.2013

11. Fit the guide pin in the ange.

13. Position the port plate over the guide pin.

Note: Make sure that the guide pin is located

in the locating hole in the port plate.

There are two dierent port plates in the iSave. One of them can be mounted on both anges in

the pressure exchanger. Make sure that they are assembled on the right ange.

12. Location hole in port plate.

14. Gently guide the cylinder barrel into the

bearing in the ange.

16. Wrong! large center hole.15. Check the next port plate is correct.

Correct small

center hole

Wrong! large

center hole

Service instruction Disassembling and assembling iSave 21

10

180R9219 / 521B1171 / DKCFN.PI.0 03.K3.02 / 11.2013

21. Mount all bolts in the ange and tighten

them to a torque of 30 Nm ± 3 Nm.

20. Position the port ange over the guide pin.

22. Wet the shaft seal with clean ltered water.

Do not use silicone grease.

Fit the shaft seal with the carbon surface upward.

17. Position the port plate over the guide pin.

19. Change the O-ring in the ange and

position the guide pin.

O-ring

Guide pin

18 Check that the port plate ts the center

bearing and the guide pin.

Service instruction Disassembling and assembling iSave 21

11

180R9219 / 521B1171 / DKCFN.PI.0 03.K3.02 / 11.2013

23. Shaft seal NOT mounted correct.

The rubber seal face must turn into the ange.

25. Shaft seal in right position:

24. Using the plastic assembly tool provided,

large diameter rst, press the seal home

against the shoulder, by hand.

Be careful not to damage the carbon seal face

on the shaft seal.

26. Remove the old ceramic ring from the

ange. Position the O-ring on the seal ange.

27. Push the new ceramic ring into the ange

using plastic tool provided. Make sure the

face with the rubber seal is positioned

against the shoulder in the ange.

Before assembly wet the parts with clean

ltered water.

28. Position the ange and the bolts. Tighten

the 4 bolts with 12 Nm ±1.2 N m.

Service instruction Disassembling and assembling iSave 21

12

180R9219 / 521B1171 / DKCFN.PI.0 03.K3.02 / 11.2013

1. Gently adjust the spanner wrench around

the coupling and use it as back stop.

3. Remove all bolts in the HP out connection

ange.

2. Unscrew the bolt in the middle of the

coupling and remove the coupling.

4. Remove the ange.

5. Disassambling the

vane pump

5. Remove side plate and pin

Service instruction Disassembling and assembling iSave 21

13

180R9219 / 521B1171 / DKCFN.PI.0 03.K3.02 / 11.2013

7. Gently remove the rotor.

Note: Loose parts inside the rotor.

6. Side plate removed.

8. Remove vanes.

1. Position the guide pin.

9. Gently remove side plate.

2. Location hole in the side plate:

6. Assembling the

vane pump

Service instruction Disassembling and assembling iSave 21

14

180R9219 / 521B1171 / DKCFN.PI.0 03.K3.02 / 11.2013

4. Place the 4 pins in the rotor.3. Position the side plate over the guide pin.

Note: Make sure that the guide pin is located

in the locating hole in the port plate. See #2

5. Gently place the rotor in the bearing.

7. Check that all vanes are positioned

correctly.

6. Position the 8 vanes in the rotor.

The pins may be moved by using a

screwdriver.

Service instruction Disassembling and assembling iSave 21

15

180R9219 / 521B1171 / DKCFN.PI.0 03.K3.02 / 11.2013

10. Position the side plate over the guide pin.

9. Replace the O-ring on the ange and wet

the ange properly with clean ltered water.

11. Make sure that the guide pin is located in the

locating hole in the side plate. See #10.

13. Make sure that the guide pin is located in

the location hole.

12. Fit the ange into both the bearing in the

ange and the location pin in the stator.

8. One vane is NOT positioned correctly.

Service instruction Disassembling and assembling iSave 21

16

180R9219 / 521B1171 / DKCFN.PI.0 03.K3.02 / 11.2013

14. Change the O-ring in the HP out

connection ange.

16. Fit the coupling into the pump.

Glue the threat on the bolt with “Loctite

270” and tighten the bolt with 10 Nm±1 Nm.

17. Change the two O-rings in the ange.

15. Bolt the ange onto the vane pump.

Tighten the bolt with 30 Nm ±3 Nm.

Service instruction Disassembling and assembling iSave 21

17

180R9219 / 521B1171 / DKCFN.PI.0 03.K3.02 / 11.2013

1. Fit the steel coupling onto the shaft of the

pressure exchanger.

3. Orient both the steel coupling and the

2 guide holes on the vane pump to t into

the pressure exchanger.

2. Fit the polymer coupling on the steel

coupling.

4. Mount the bolts into the ange and tighten

them with 30 Nm ±3 Nm.

7. Assembling the

iSave

Service instruction Disassembling and assembling iSave 21

18

180R9219 / 521B1171 / DKCFN.PI.0 03.K3.02 / 11.2013

8. Exploded view

vane pump

Service instruction Disassembling and assembling iSave 21

19

180R9219 / 521B1171 / DKCFN.PI.0 03.K3.02 / 11.2013

9. Exploded view

pressure exchanger

Service instruction Disassembling and assembling iSave 21

20

180R9219 / 521B1171 / DKCFN.PI.0 03.K3.02 / 11.2013

10. Exploded view iSave

Service instruction Disassembling and assembling iSave 21

21

180R9219 / 521B1171 / DKCFN.PI.0 03.K3.02 / 11.2013

Service instruction Disassembling and assembling iSave 21

22

180R9219 / 521B1171 / DKCFN.PI.0 03.K3.02 / 11.2013

Danfoss ca n accept no responsi bility for poss ible errors in ca talogues, bro chures and other pr inted material. D anfoss reserve s the right to alter it s products wit hout notice.

This also ap plies to produc ts already on orde r provided that su ch alterations ca n be made without su bsequential cha nges being nece ssary in speci cations alread y agreed.

All trade marks in this mater ial are proper ty of the respec tive companies . Danfoss and the Danf oss logotyp e are trademark s of Danfoss A/S. Al l rights reser ved.

Danfoss A/S

High Pressure Pumps

DK-6430 Nordborg

Denmark

Loading...

Loading...