Page 1

User Guide

Intelligent Purging System (IPS 8)

Ammonia

230 V AC, 60 Hz

Info for UK customers only

Danfoss Ltd. Oxford Road, UB9

4LH Denham, UK

Other IPS 8 User Guide languages

ir.danfoss.com

ir.danfoss.com148R9653

Page 2

User Guide | Intelligent Purging System (IPS 8) Ammonia

Contents

Legal notice ...................................................................................................................................................................................................................3

Technical data ..............................................................................................................................................................................................................4

Ordering ..........................................................................................................................................................................................................................4

Introduction ..................................................................................................................................................................................................................5

Features ...........................................................................................................................................................................................................................5

Working principle .....................................................................................................................................................................................................6

Working cycle ..............................................................................................................................................................................................................7

Air traps ............................................................................................................................................................................................................................8

Connection locations ..............................................................................................................................................................................................9

Connection points ................................................................................................................................................................................................. 11

Installation ..................................................................................................................................................................................................................12

Electrical wiring ...................................................................................................................................................................................................... 14

Light Indicators ........................................................................................................................................................................................................ 16

Quick Startup ............................................................................................................................................................................................................ 17

General display.........................................................................................................................................................................................................17

Configuring using the LCD ...............................................................................................................................................................................18

Modbus RTU .............................................................................................................................................................................................................. 20

Maintenance/Service/Disposal ......................................................................................................................................................................27

2 | BC344024774466en-000401

© Danfoss | DCS (ms) | 2021.04

Page 3

User Guide | Intelligent Purging System (IPS 8) Ammonia

Legal notice This product information is a part of the documentation for the Danfoss scope of delivery and serves

as product presentation and customer advisory service. It contains important information and

technical data regarding the product.

This product information should be supplemented with the information about the industrial safety

and health related regulations at the site of installation of the product. The regulations vary from

place to place as a result of the statutory regulations applicable at the site of installation and are

therefore not considered in this product information.

In addition to this product information and the accident prevention regulations applicable for the

respective country and area where the product is used, the technical regulations for safe and

professional work must also be observed.

This product information has been written in good faith. However, Danfoss cannot be held responsible

for any errors that this document may contain or for their consequences.

Danfoss reserves the right to make technical changes during the course of further development of the

equipment covered by this product information.

Illustrations and drawings in this product information are simplified representations. As a result of

the improvements and changes, it is possible that the illustrations do not exactly match the current

development status. The technical data and dimensions are subject to change. No claims will be

accepted on the basis of them.

Danfoss A/S

6430 Nordborg

Denmark

CVR nr.: 20 16 57 15

Telephone: +45 7488 2222

Fax: +45 7449 0949

EU DECLARATION OF CONFORMITY

declares under our sole responsibility that the

Product category: Intelligent Purger System (Air Purger)

Type designation(s): IPS 8

Covered by this declaration is in conformity with the following directive(s), standard(s) or other normative

document(s), provided that the product is used in accordance with our instructions.

Machine Directive 2006/42/EC

EN 378-2:2016 Refrigerating systems and heat pumps - Safety and environmental requirements - Part 2: Design,

construction, testing, marking and documentation

IEC 60204-1:2018 Safety requirements for electrical equipment for measurement, control and laboratory use - Part 1:

General requirements

Pressure Equipment Directive 2014/68/EU (PED)

EN 378-2:2016 Refrigerating systems and heat pumps - Safety and environmental requirements - Part 2: Design,

construction, testing, marking and documentation

Ammonia side (R717): Category A4P3. Fluid group: 1. PS = 40 bar. TS: -40 C to 60 C

R452A side: Category 1. Fluid group: 2. PS = 28 bar. TS: -40 C to 60 C

Ambient temperature: -10 C to 43 C

Electromagnetic Compatibility Directive 2014/30/EU (EMC)

IEC 61000-6-2 Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity standard for industrial

environments (IEC77/488/CDV:2015)

EN 61000-6-4 Electromagnetic compatibiliy (EMC) - Part 6-4: Generic standards - Emission standard for industrial

environments

Note: EMC test performed with cable length < 30m.

Date: YYYY.MM.DD

Place of issue:

Signature:

Danfoss only vouches for the correctness of the English version of this declaration. In the event of the declaration being translated into any other

language, the translator concerned shall be liable for the correctness of the translation

ID No: 084R9456

This doc. is managed by 500B0577

Issued by

Name: Su Cheong Ho

Title: Lead Design Engineer

Refrigeration & Air Conditioning Controls

Revision No: AA

Danfoss A/S

Date: YYYY.MM.DD

Place of issue:

Signature:

Approved by

Name: Behzad Parastar

Title: Product Manager

Page

1 of

1

© Danfoss | DCS (ms) | 2021.04

BC344024774466en-000401 | 3

Page 4

User Guide | Intelligent Purging System (IPS 8) Ammonia

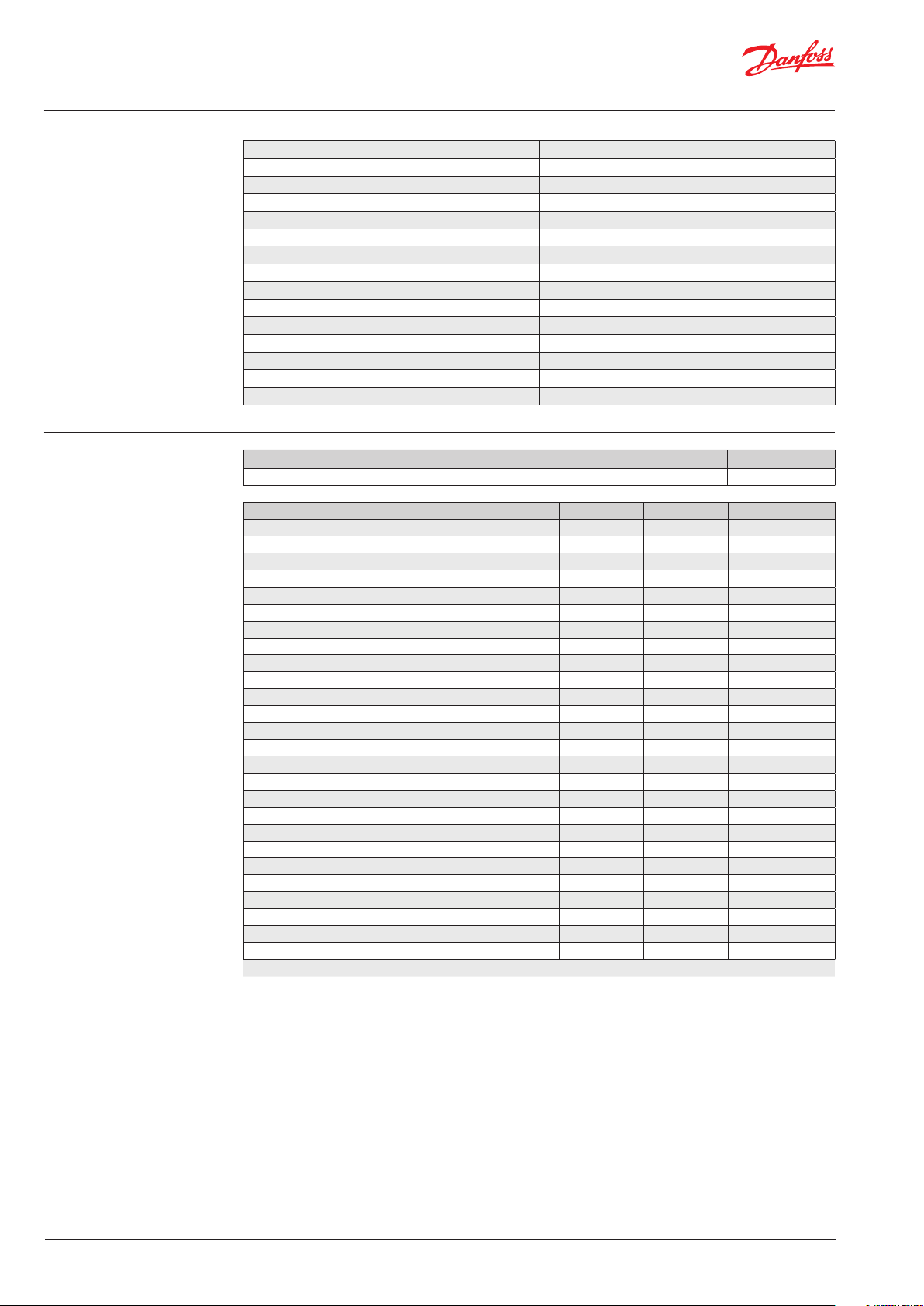

Technical data

Ordering

Supply voltage 230V AC, 1ph, 60Hz

Current 5.7 A (max. 6.5 A)

Power consumption max. 1.3 kW

Short-circuit current rating Icc 10kA

Temperature range ambient -10 °C to +43 °C (14 °F to 109 °F)

Temperature range transport/storage -30 °C to +60 °C (-22 °F to 140 °F)

Enclosure IP55

Weight max. 100 kg (221 lbs)

Dimensions (LxWxH) 1051 x 441 x 703 mm (41.4 x 17.4 x 27.7 inches)

Purger refrigerant R452A 900 gram (31.7 oz)

Max. operating pressure (PS) R452A 28 bar (406 psi)

System refrigerant R717

Min. operating pressure R717 6.5 bar (94 psi)

Max. operating pressure R717 40 bar (580 psi)

Operating temperature R717 -40 °C to +60 °C (-40 °F to 140 °F)

Unit

Danfoss Intelligent Purging System IPS 8 60Hz unit 084H5002

Accessories/Spare parts Accessory Spare part Code

Flange blind blank incl Bolts, nuts and Gaskets* x 084H5053

SV3 Float Valve x 027B2023

ICF 15-4 solenoid, DIN Butt weld 15mm ½ inch x 027L4543

ICF 15-4 solenoid, ANSI Socket weld 15mm ½ inch x 027L4538

ICF 15-4 solenoid, ANSI Butt weld 15mm ½ inch x 027L4602

Welding Flange incl Bolts, nuts and Gaskets x 084H5061

Purger solenoid kit (Armature, tube, Sealing, Orifice, Filter insert) x 084H5051

Solenoid coil, 24V DC for AKV x x 018F6757

PSU, 24V DC - optional for powering purge points x x 080Z0055

Restrictor, purge line x 084H5054

Compressor Cranck case heater x 084H5058

Condenser coil assy incl screws x 084H5059

Fan motor for condenser Incl fan grid and screws x 084H5060

Extraction Fan x 084H5056

Air grid with filter (1 piece) x 084H5057

Pre-programmed MCX 15 x 084H5052

Pressure transmitter evaporator, soldered (AKS 32R) x 060G3552

Compressor including Start relay box and Start and Run Capacitor x 123B2156

Compressor Hi-temp sensor x 084N2003

Expansion valve, R452A x 068U3881

Sight glass x 014-0191

Pressure transmitter - R717, Threaded, AKS2050 x 060G5750

Thermostat for crankcase heater control x 060L111166

Temperature sensor - R717, AKS 21M x 084N2003

Pressure switch for Fan x Contact Danfoss

Pressure safety switch x Contact Danfoss

* For closing system flange during system pressure testing

Code number

4 | BC344024774466en-000401

Note:

All Spare part items are parts already built into

the IPS 8 All accessories are not.

© Danfoss | DCS (ms) | 2021.04

Page 5

User Guide | Intelligent Purging System (IPS 8) Ammonia

Introduction

The Danfoss Intelligent Purging System (IPS 8)

is a stand-alone, self-contained purging unit

designed to remove non-condensable gases

(NC gases = air and other unwanted foreign

gases) from industrial ammonia refrigeration

systems.

The IPS control can handle up to 8 purge points

automatically.

The ingress of NC gases into a refrigeration

system is inevitable, regardless of the refrigerant,

pressures, or temperatures. NC gases in the

system will result in a decrease in system

efficiency, both in terms of an increase in power

consumption and reduced cooling capacity.

Due to having a different density than ammonia,

the ingressed air will accumulate in specific areas

of the system, where it can be removed using the

Danfoss IPS 8.

The accumulation areas are identified in the

Connection locations section, along with

recommended connection principles.

The purger unit is an electronically controlled,

self-contained R452A refrigerant system that runs

independent of the main ammonia system and

with only one flange connection to the ammonia

plant.

The flanged opening allows the ammonia gas/

NC gas mix access to the purger’s heat exchanger,

where it is split into ammonia condensate and NC

gases. The ammonia condensate is returned by

gravity to the main plant, while the NC gases are

purged to the atmosphere through e.g. a water

bath.

Through the flanged opening, the purger unit

has access to the parameters from the ammonia

plant required for full electronic control.

The unit runs automatically in 24-hour cycles,

checking for the presence of NC gases and, if

present, removes the NC gases.

To regain and retain the design capacity of the

main ammonia system and prevent future air

accumulation, it is highly recommended to install

the Danfoss IPS 8.

Features

• State-of-the-art electronically controlled unit

based on the Danfoss MCX controller platform

• Reduced power consumption of the ammonia

plant

• Automatic purging response to NC gases in the

refrigeration system

• Continuous and smart monitoring of

differential pressure between the system

refrigerant and the purger’s refrigerant

• Smart purging that minimizes refrigerant

(ammonia) release to the environment

• Self-contained unit operation, which functions

independently from the main plant

• An operation log for easy purging cycle data

monitoring

• Industry standard Modbus RTU

communication for remote monitoring and

system integration

• Reduced purging unit power consumption

compared to other units due to on-demand

operation only

• Self-diagnostics for both unit and system

operation to shut down in the event of

malfunctions

• Cost-effective installation with few mechanical

and electrical connections

• A fully brazed and leak-tested R452A cooling

system, minimizing leakage risks

• A plug-and-play stand-alone design, which

simplifies installation and commissioning while

reducing potential errors

• No need for advanced settings

• A compact and easy-to-handle design

• Patent pending on IPS 8

© Danfoss | DCS (ms) | 2021.04

BC344024774466en-000401 | 5

Page 6

User Guide | Intelligent Purging System (IPS 8) Ammonia

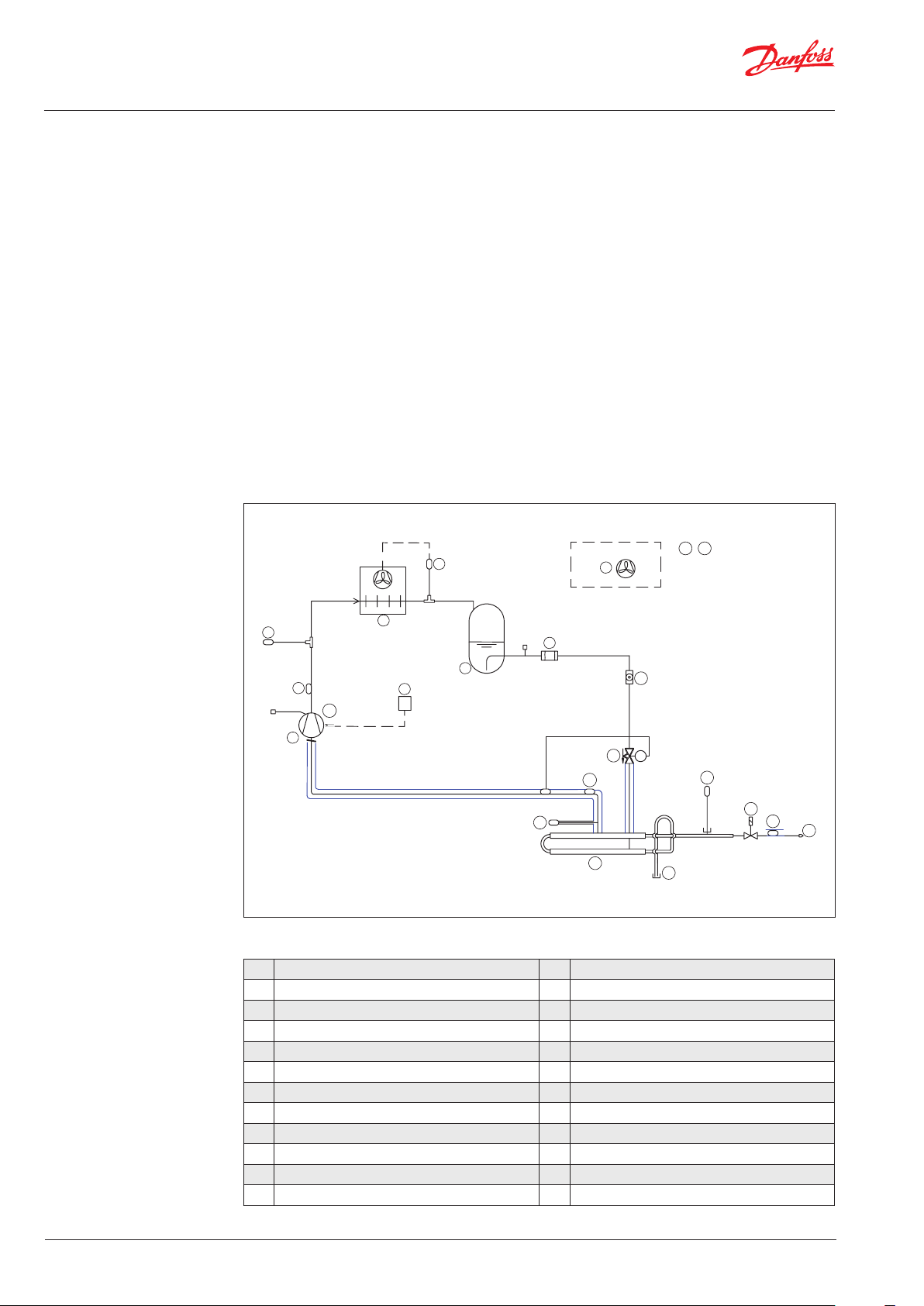

13

Working principle The Danfoss IPS 8 is factory-tested and ready to

use in ammonia plants with a condenser pressure

of more than 6,5 bar (94 psi). The purger is

charged with 900 gram (31.7 oz) of R452A.

Only 2 mechanical connections are needed for

the purger (see fig. 1). The flow of ammonia/NC

gases from the main plant is done through the

flange for ammonia (see 13 in Fig. 1 below), while

the NC gas purge is done through the blow-off

pipe after the purge restrictor (18).

Through the flange for ammonia (13), a mixture

of ammonia gas and NC gases enters the heat

exchanger (12) part of the purger.

The ammonia gas/NC gas mix is cooled down

below the condensing temperature of the

ammonia by the R452A circuit. At this point,

ammonia gas condenses and returns by gravity

to the ammonia plant whereas the NC gases

accumulate in the heat exchanger (12) for

subsequent purging.

7

By condensing the ammonia gas, a new

ammonia/NC gases mix is naturally pulled

through. This new mix is separated through a

continuous process.

As the NC gas concentration in the heat

exchanger (12) increases, the R452A heat

exchanger pressure and temperature will

simultaneously decrease.

The controller continuously monitors the R452A

heat exchanger pressure as well as ammonia

pressure and temperature. When the R452A

pressure reaches a predefined pressure difference

when compared with the ammonia pressure

(temperature) it prepares to purge the NC gases

through the solenoid valve (16). The blow-off

is activated by the solenoid (16) and through

appropriate piping/hosing, should be led into

a water bath. This process is recommended

to retain small amounts of ammonia (see

Installation section).

19 20

6

4

3

1a

1

Fig. 1 - Purger R452A lay-out

1 Compressor R452A 11 Expansion valve, R452A

1a Compressor Cranck case heater 12 Heat exchanger Ammonia/R452A

2 Thermostat for crankcase heater control 13 Welding Flange

3 Discharge temp sensor R452A 14 Pressure transmitter R452A

3a Suction temperature sensor R452A 15 Pressure transmitter R717

4 Pressure safety switch 16 Solenoid valve AKVA and coil

5 Condenser 17 NC temperature sensor R717

6 Extraction fan 18 Restrictor, purge line

7 Pressure switch for Fan 19 MCX 15 (Pre-programmed)

8 Receiver 20 PSU, 24V

9 Filter 900 gram (31.7 oz) R452A

10 Sight glass

5

9

8

2

3a

14

10

11

12

15

16

17

18

6 | BC344024774466en-000401

© Danfoss | DCS (ms) | 2021.04

Page 7

User Guide | Intelligent Purging System (IPS 8) Ammonia

Time

On

Off

Time

On

Off

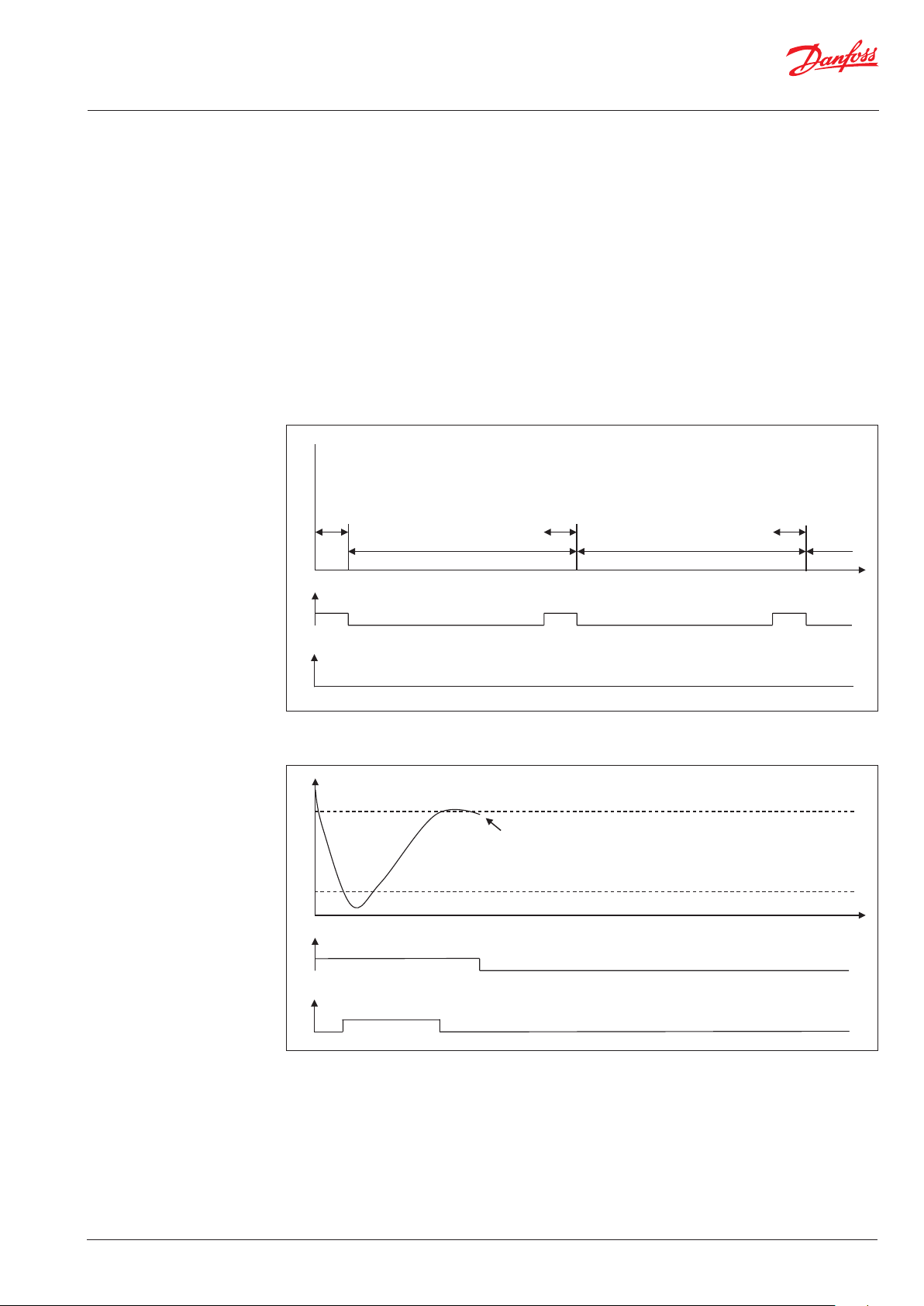

Working cycle The Danfoss IPS 8 operates in 24-hour cycles, of

which 45 minutes are dedicated to an R452A pull

down. At power on, the pull down is initiated

immediately. If no NC gases are detected during

the 45 minute pull down, the system will close

the solenoid valve at purge point 1 and open the

solenoid valve at point 2. After a cycle time of 24

hours/N (Number of purge points), the

compressor will pull down again condensing the

ammonia. After 24 hours, all purge points have

been vented one time.

To identify NC gases, the controller utilizes upper

and lower thresholds for R452A evaporating

temperature. If, during pull down, the

temperature continues decreasing and the lower

threshold is passed, the controller considers

Power on

Purger Pull down

(PDT): 45 min

Cycle (CST) *

this to be a high concentration of NC gases

and opens the purge solenoid valve. The purge

valve will stay open until sufficient condensing

ammonia is present to lift the R452A evaporating

temperature above the upper threshold.

The compressor will continue running and if the

temperature again decreases below the lower

threshold, a new purge will be performed. This

process will be repeated until the R452A heat

exchanger temperature stays above the lower

threshold for >45 minutes following the previous

closure of the purge valve.

Purger Pull down

(PDT): 45 min

Cycle (CST) *

Purger Pull down

(PDT): 45 min

Compressor

On

Off

Purge valve

Fig. 2 - Power on & Cycle at no NC gases present: CST (compressor start time) and PDT (pull down time) are configurable

* Cycle (CST) = 24 hours/N (number of purge points)

Upper Threshold (VClseT)

Non condensables has been purged

- new cycle starts *

Evaporator Temp. (Tsat452)

Compressor

On

Off

Purge valve

Lower Threshold (VClseT)

Fig. 3 - Purging procedure - Low R452A evap. temperature detected during PDT: Thresholds are configurable

* If low evaporator temperature is detected (passing lower threshold), the purging procedure will be repeated immediately

© Danfoss | DCS (ms) | 2021.04

BC344024774466en-000401 | 7

Page 8

User Guide | Intelligent Purging System (IPS 8) Ammonia

Air traps

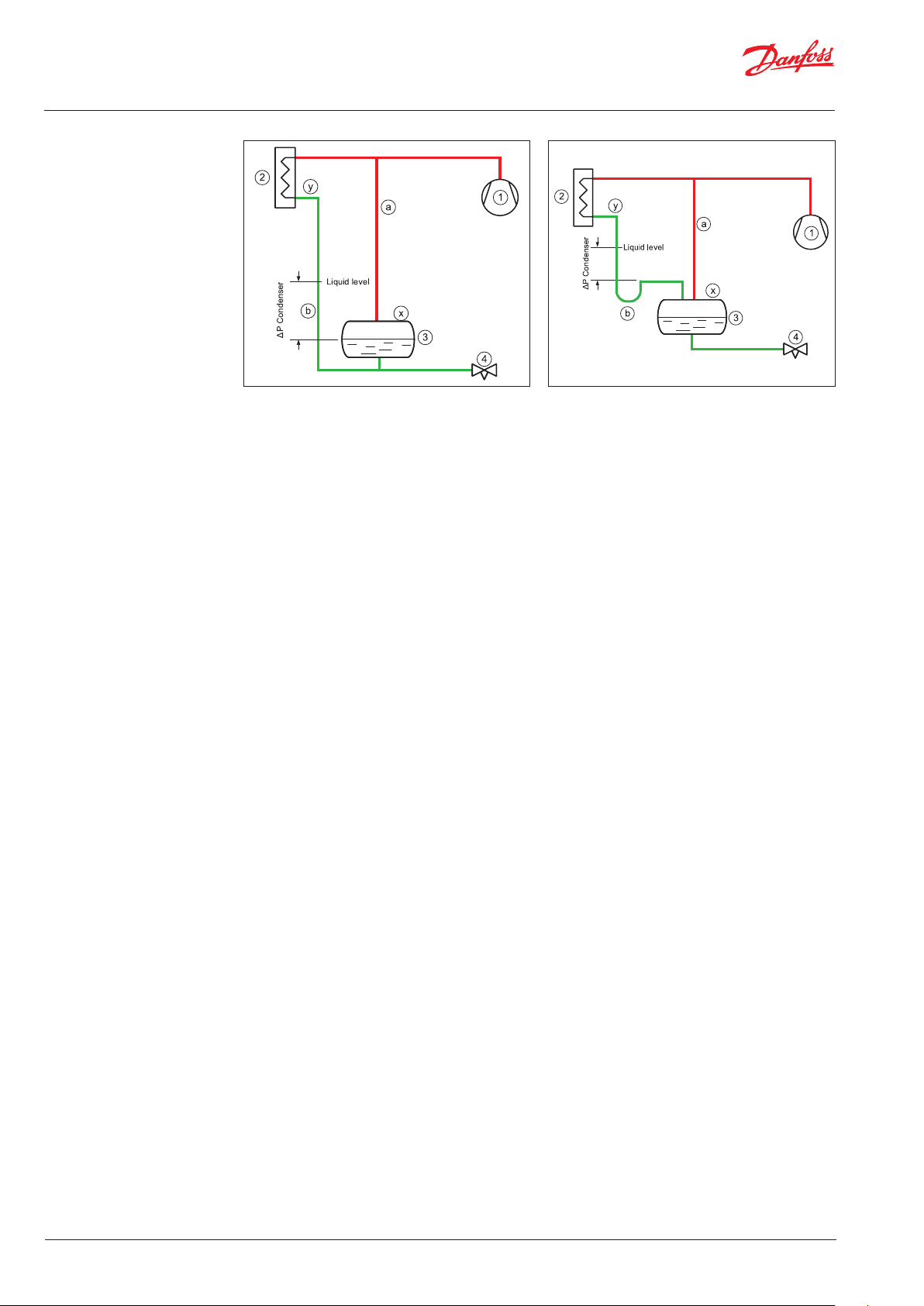

Fig. 4 Liquid level. Bottom connected receiver Fig. 5 Liquid level. Top connected receiver

For systems with low pressure liquid level control,

the correct condenser/ receiver installation is as

shown in Fig. 4 and Fig. 5.

The discharge gas from the compressor (1) is

led to the condenser (2) where it is condensed.

The receiver (3) holds the liquid until there is a

demand for liquid from the LP side, e.g., until the

expansion valve (4) opens. If the expansion valve

is closed, the liquid condensed in the condenser

will need to be stored in the receiver and the

level will increase. To ensure a free flow to the

receiver, the gas must be allowed to leave the

receiver; this process is accomplished through

the pressure equalizing line (a). The pressure

equalizing line makes the pressure in the receiver

the same as in the compressor discharge line.

The pressure in the condenser outlet is lower due

to the pressure loss in the condenser. Since the

condenser outlet pressure is lower than in the

receiver, it is therefore necessary to mount the

condenser higher than the receiver and allow for

a higher liquid level in the piping between the

condenser and the receiver (b).

The liquid column in the line (b) compensates for

the pressure difference between the condenser

outlet and the receiver.

Fig. 4 shows the liquid connection at the bottom

of the receiver.

If the liquid from the condenser is connected to

the top of the receiver (Fig. 5), a slightly different

arrangement must be made.

The liquid line (b) from the condenser to the

receiver will need to have a goose neck/liquid

trap to ensure that the liquid column is actually

established.

As air is heavier than ammonia gas, the air will

collect in two locations in this type of installation:

On top of the liquid in the receiver (x) and/or

on top of the liquid in the drop leg from the

condenser (y).

8 | BC344024774466en-000401

© Danfoss | DCS (ms) | 2021.04

Page 9

User Guide | Intelligent Purging System (IPS 8) Ammonia

Connection locations

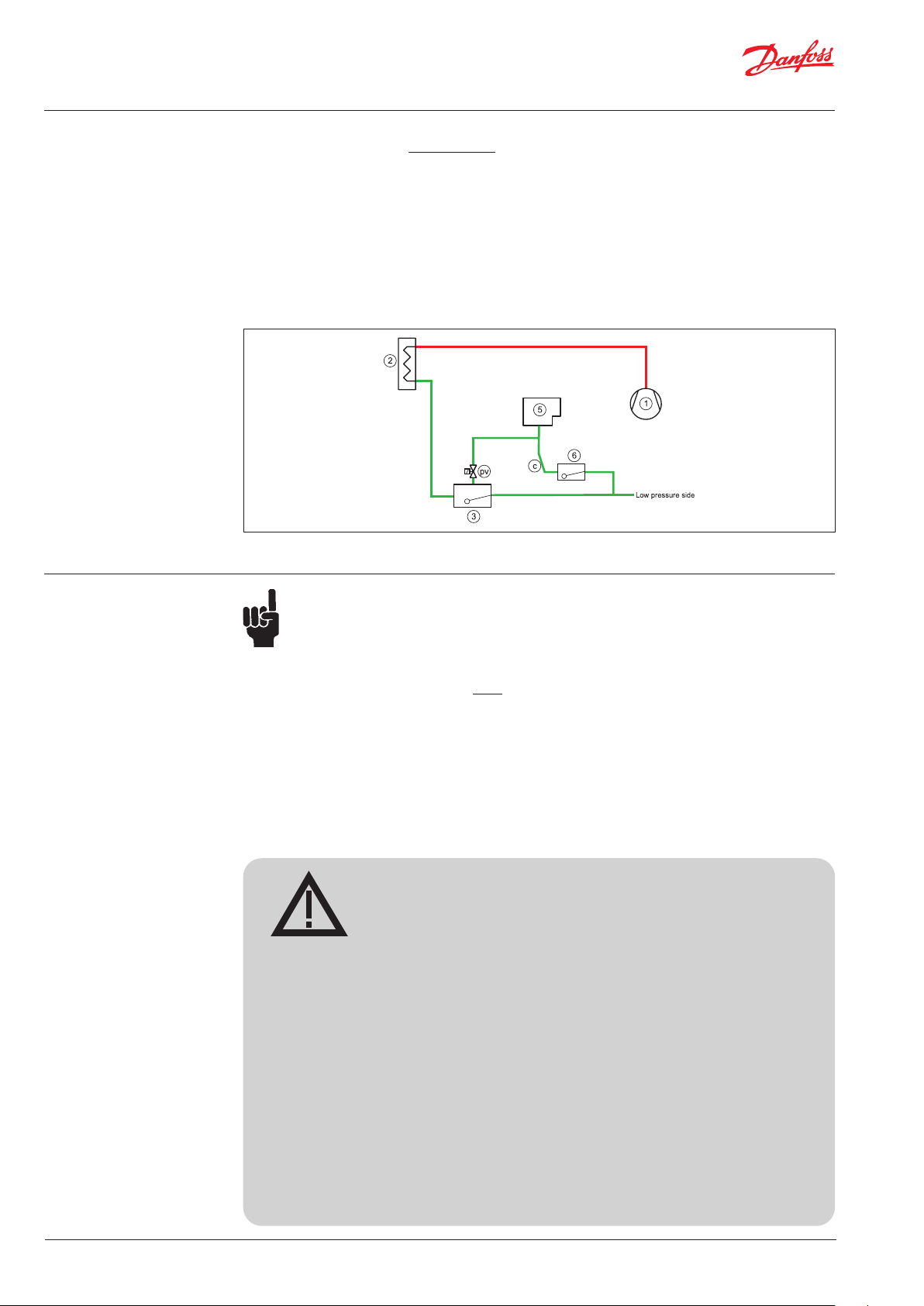

Air purger installation in a low-pressure liquid level controlled installation

The correct locations for the air purger to be

connected to the ammonia plant are:

(See Fig. 6 and Fig. 7)

the condenser will be short-circuited.

The air purger must have its own liquid return

drop leg (c) connected in parallel with the

condenser’s drop legs (b).

- on top of the receiver or

- on top of the liquid in the drop leg from the

condenser.

When the purger is connected to the receiver

i.e. solenoid (px) open, the liquid level in the air

purgers drop leg (c) will be equal to the receiver

The air purger (5) is connected to the two purge

points through solenoid valves (px and py).

Note that only one solenoid should be open at

any given time, otherwise the liquid column in

liquid level (3); when the purger is connected to

the condenser outlet i.e. solenoid (py) open, the

liquid level will

be equal to the liquid level in the

condenser drop leg (b).

Fig. 6 Purger connections (px) & (py). Drain piping (c) must be vertical/downward slope

Alternatively, the air purger draining of liquid can

be achieved effectively through an HP float valve

(6) to the low pressure side (see Fig. 7).

© Danfoss | DCS (ms) | 2021.04

Fig. 7 Purger connections (px) & (py). Drain piping (c) must be vertical/downward slope

BC344024774466en-000401 | 9

Page 10

User Guide | Intelligent Purging System (IPS 8) Ammonia

Connection locations

(continued)

General

Air purger installation in a high-pressure liquid level controlled installation

For systems with a high-pressure liquid level

control, the air will collect in the float valve (3).

(See Fig. 8).

The compressor (1) supplies high-pressure gas to

the condenser (2), where it is condensed.

The float valve (3) will flash any liquid back to

the LP side. The air purger (5) must be connected

to the float valve through a solenoid valve (pv).

Fig. 8 Purger connections (pv). Drain Piping (c) must be vertical/downward slope

The air purger must always be mounted

above the highest liquid level to be able

to drain the ammonia condensed in it.

Otherwise, the air purger can flood and

potentially purge ammonia liquid.

The ammonia liquid condensed in the air purger

must be drained through drain pipe (c) to the LP

side via a float valve (6).

The purger liquid return leg (c) must

always be mounted vertically or at

minimum, with a downward slope.

The solenoid valves at the connection

points must never be activated at the

same time. Finalize purging at one

location before switching to the next.

Cod. 99000572

WARNING !

Follow the installation guide strictly during Purger installation.

Install the Purger unit in a location where the bottom flange level

and any gas inlet connection level is above any possible ammonia

liquid level.

Liquid drain piping from the purger must always have a downward

slope.

Install a shut off valve close to the bottom flange entrance to

enable removal of the unit and closing for high pressure ammonia

gas.

Connect proper resistant piping to the purging outlet pipe and

ensure the purged non-condensables are discharged into a water

bath of max. 200 liter.

10 | BC344024774466en-000401

© Danfoss | DCS (ms) | 2021.04

Page 11

User Guide | Intelligent Purging System (IPS 8) Ammonia

Connection points

Multi-point purging

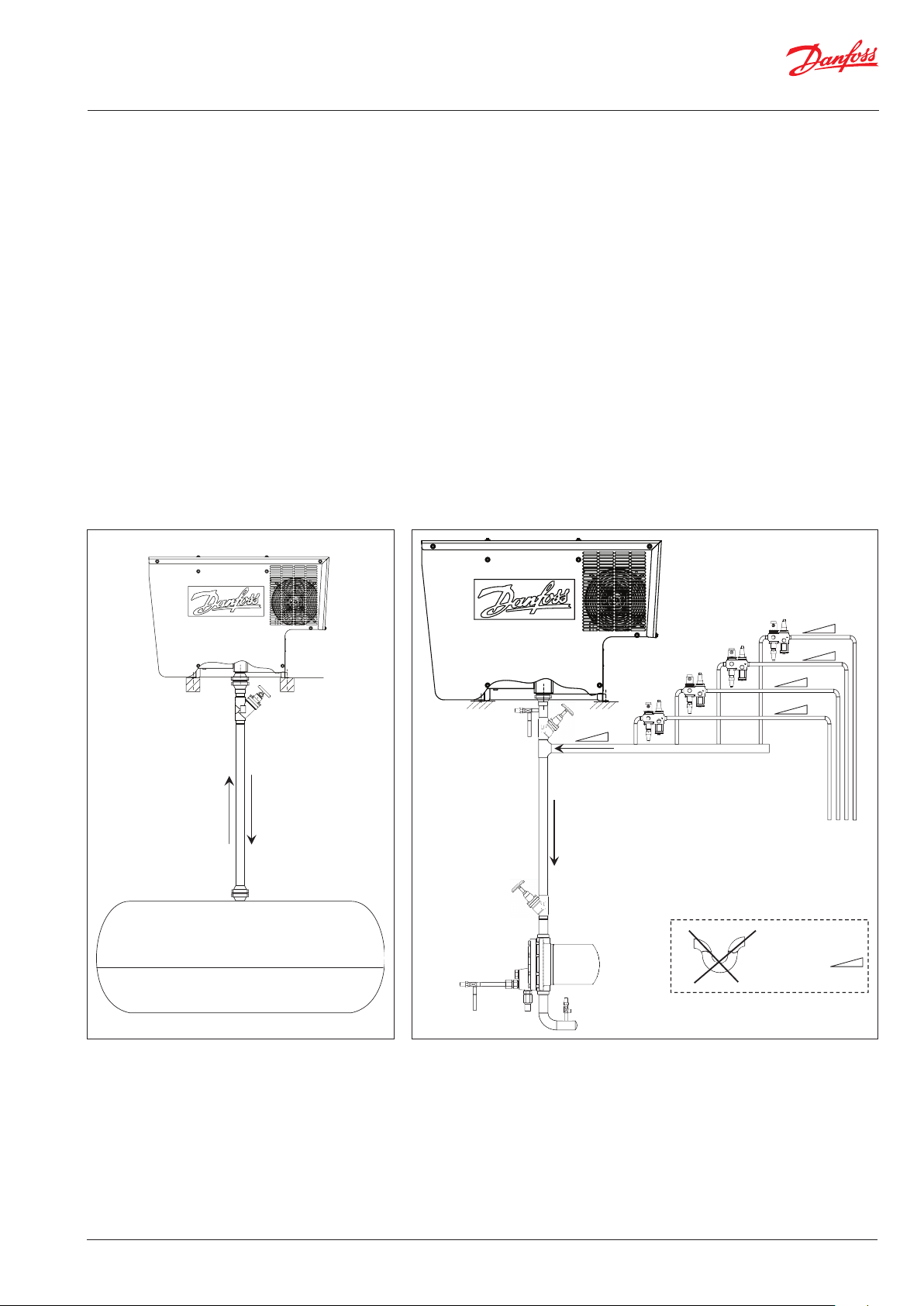

Single point purging setup is possible (Fig. 09) i.e.

no solenoid valves with the Danfoss IPS 8 unit.

This kind of installation should be installed as

shown in Fig. 9 i.e. above the receiver or using a

float valve. (See section on connection locations).

For single point purging as in Fig. 09, the setting

in the MCX for the number of valves to ‘0’ or

switch off the multi-purging functionality in the

general setup (y02).

As factory default, the Danfoss IPS 8 is configured

to handle 8 purge points. The correct amount of

purge points connected needs to be setup in the

MCX controller after power-up. Both power and

control wiring of the installed solenoid valves

coils should take place prior to first power up.

NEVER HAVE MORE THAN 1 PURGE POINT

OPEN AT A TIME.

Always close one purge valve before opening

the next.

This is done by turning the purger unit power

on (label y02) and entering the number of

actual purge points in the program. See section

“Programming/configuration”.

SVA

Ammonia Liquid

Ammonia gas + NC gases

Receiver

Liquid drain to Low

pressure side

Fig. 9 Single point purging from receiver Fig. 10 Multi-point purging from up to 8 purging points

SNV

SNV

SVA

NH₃ gas + NC gases

NH₃ bypass for

draining purger

Ammonia Liquid

SVA

SV3

SNV

ICF 15-4

Purge Points

- up to 8 points

Be aware of liquid traps

Where slope is

shown above, ensure

downward sloping

pipe flowing towards

purger drop leg.

© Danfoss | DCS (ms) | 2021.04

BC344024774466en-000401 | 11

Page 12

User Guide | Intelligent Purging System (IPS 8) Ammonia

* F

and ser

installed between 0,05 to 1,1 m (2 to 43 in)

above ser

Installation The Danfoss IPS 8 must be installed in

accordance with locations recommended in the

Connection locations and Connection points

sections of this document.

The unit has a protection rating of IP55 and may

be installed outside, in ambient temperature

ranges from from -10 °C to 43 °C / 14 °F to 109 °F).

Avoid installation in direct sunlight as this may

lead to excessive sunlight exposure and ambient

temperatures above allowed limits. For ambient

temperatures below -10 °C (14 °F) the air purger

must be installed in a heated and ventilated

area. The unit must be installed in a non-ATEX

atmosphere as the purger unit is not explosion proof.

The purger unit should be kept in an upright

position at all times - from receipt to final

installation.

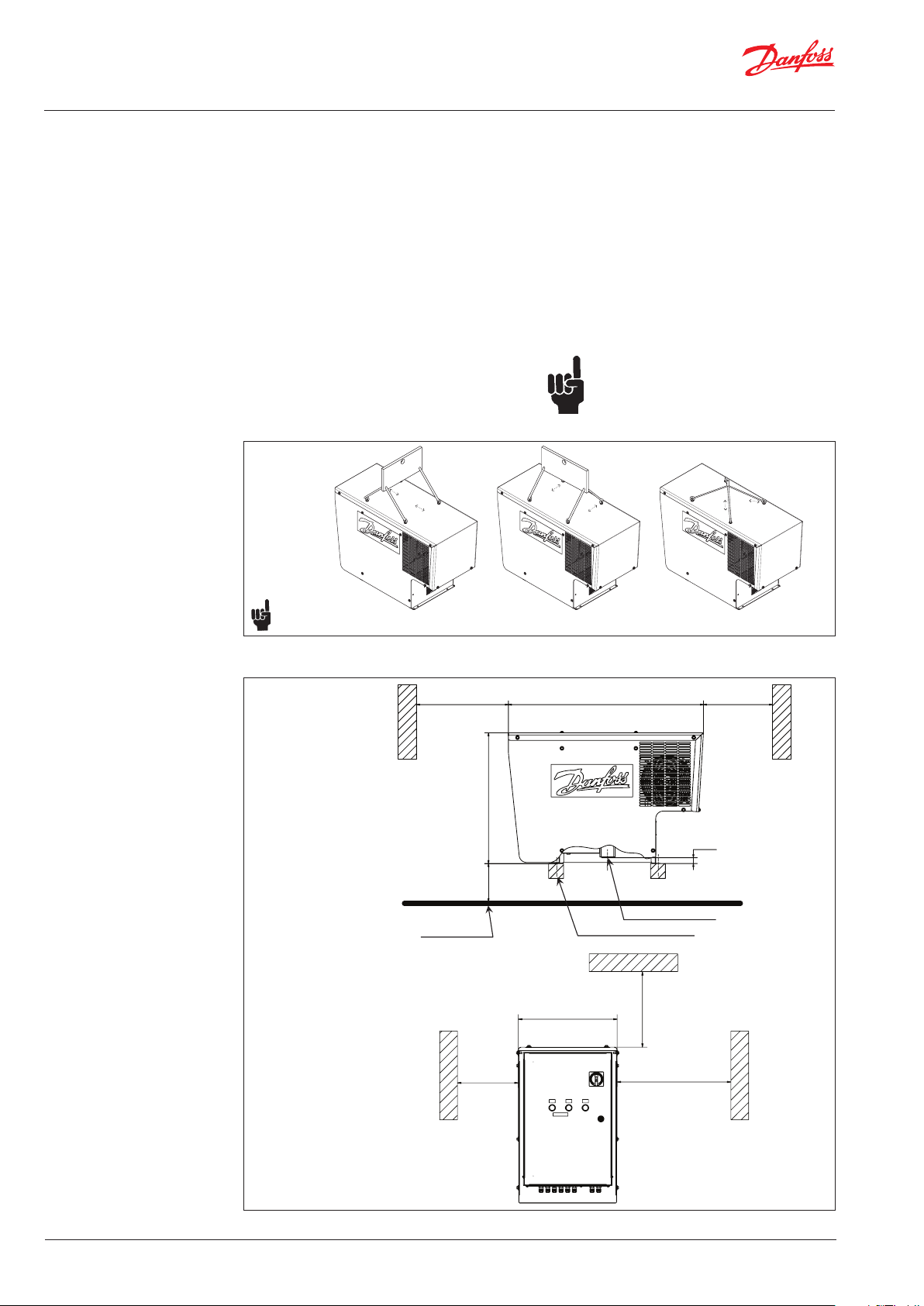

Lifting Procedure

.

All 4 lifting eyes must be positioned correctly, to match the actual used lifting gear

All 4 lifting eyes must be used

Fig. 11

Use all 4 lifting eyes and suitable lifting gear

during installation (unit weight = 100 kg/220 lbs).

Install the unit on an even horizontal base 0.05

to 1.1 meter (2 to 43 in) above a service platform

with sufficient support and allowing the purger

subframe to be bolted to the support (see

example in Fig. 12). Maintain recommended

distances in all directions (Fig. 12) to allow fan

cooling and servicing.

Always leave the unit off for at least 12 hours

from finished installation to first time power up.

It is important that the support

construction is level to ensure the

internal liquid trap is properly filled.

Angle to horizontal < 2 degrees

Min. 900 mm 1051 mm Min. 500 mm

or easy access to the main switch

* For easy access to the main switch

vicing, the Purger unit shall be

and servicing, the Purger unit shall be

installed between 0,05 to 1,1 m (2 to 43 in)

above service platform level.

vice platform level.

Service platform

703

32 mm

*

Flange for R717 access

Support for 100 kg/ 220 lbs

446 mm

Min. 300 mm

Min. 300 mm Min. 900 mm

12 | BC344024774466en-000401

Fig. 12 Installation dimensions

© Danfoss | DCS (ms) | 2021.04

Page 13

User Guide | Intelligent Purging System (IPS 8) Ammonia

Installation (continued)

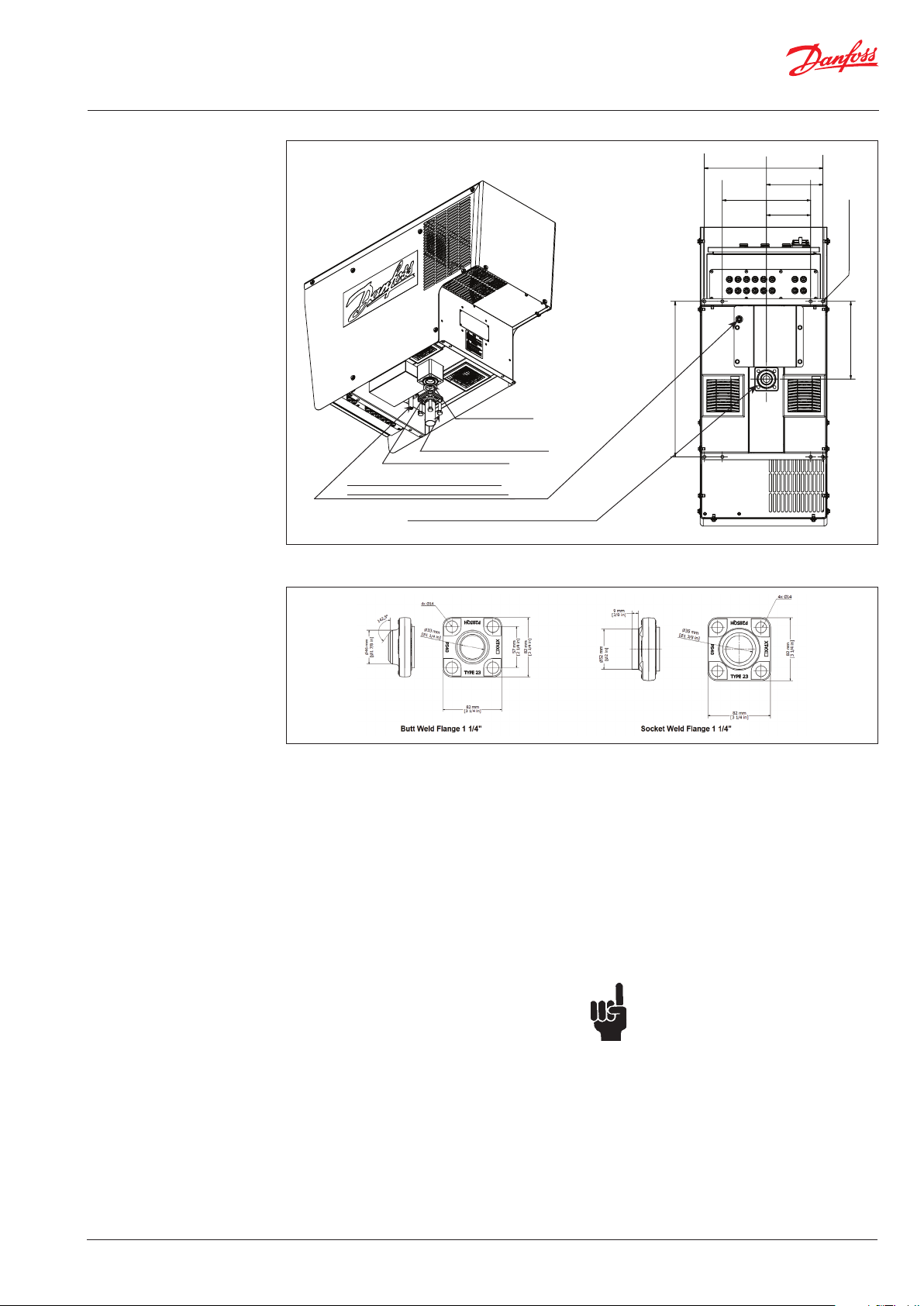

Purging pipe OD 17.2 for rubber hose to water bath

Do not unscrew restrictor inside pipe.

Risk of purging high NH₃ concentration

Fig. 13 Ammonia connection

Enclosed gasket

Enclosed bolts, Torque: 60 Nm

(44.3 ft lb) diagonal tension

Enclosed weld flange (fig. 14)

Flange for NH₃ connection. Remove rubber plug

547

416,4

198

310

155

8 x 11 mm (hole)

274

Fig. 14 Enclosed weld flange

1. Prepare the ammonia pipework with the weld

flange according to Fig. 13 and Fig. 14. The

main/drain piping should never be smaller

than inner diameter Ø37 mm (1.5 in).

2. Complete the supporting structure able to

carry 100 kg (221 lbs).

3. Lift the purger into position using the lifting

eyes on each side of the purger’s cabinet.

Remove the rubber plug from the flange

opening.

4. Connect the weld flange with the purger flange

using the enclosed flat gasket and tighten the

supplied 4 bolts diagonally to a torque of 60 Nm

(44.3 ft-lb).

5. Insert 4 bolts (not supplied) through the purger

frame and the support construction and tighten.

6. Perform a leak test to ensure an airtight

connection.

7. In the event the purger unit needs to be

dismantled please contact Danfoss for

instructions.

8. Correctly install a suitable pipe/hose from the

purge solenoid valve for blow-off of NC gases

in accordance with local or national

regulations.

9. Prepare an outside water tank with a maximum

of 200 liters (53 gal.) and ensure the piping

allows the purged gas to be immersed in the

water.

10. Regularly check the pH level of the tank’s

contents.

11. The pH level should never exceed 12.6.

Otherwise the water content must be renewed.

12. Dispose of concentrated waste water in

accordance

with to local/national regulations.

Note: Prior to replacing the water in the

water tank ensure that the purger is

switched off and the shut off valve at the

flanged purger inlet is closed. Leave the

unit in this condition for a period to allow

the remaining gas in the piping to be

dissolved/released.

Watch out for bubbles.

Establish a procedure for regular

checking the pH level and bubble

If continuous bubbles are observed

water tank during ‘‘stand by” (Green light

indicator) in normal operation, one or

more of the purge solenoid valves needs

repair or replacement.

pattern.

in the

© Danfoss | DCS (ms) | 2021.04

BC344024774466en-000401 | 13

Page 14

User Guide | Intelligent Purging System (IPS 8) Ammonia

Electrical wiring

The internal wiring of the purger is done at the

factory. Only the electrical wiring for the main

power supply, the purge point solenoids and

optional bus communication needs wiring on site.

It is highly recommended that all external cables

coming from the IPS 8 to the power supply and

to all purge point solenoids are protected by

metallic pipes.

WARNING

Electrical

hazards.

Authorized

personnel only.

STANDBY

RUN ERROR

PURGING

Fig. 15 Controller box external

Controller box cover can only be opened at key unlock and with the main switch off.

Note: Authorized personel only

ON/OFF Switch

Key Lock

Compressor/condenser

fan On/Off

Purge valve

ANALOG OUTPUT 5-6

AO5

DIGITAL INPUT 2

COM

DI 2

DI 2H

AO6

COM

DIGITAL INPUT 1DIGITAL OUTPUT 14

DIGITAL INPUT 3

COM

DI 3H

Compressor relay24V Converter

Main Power

230V 60 Hz

L

N

Earth

Main Switch

Solenoid valves

On/Off

MCX15B Controller

On/Off

AI3

AI1

AI2

DI 1

D1 H

COM

COM

NO 15

NO 14

NC 14

NC 15

DIGITAL OUTPUT 15

DIGITAL INPUT 4

DI 3

DI 4

COM

COM

DI 4H

DIGITAL INPUT 9-12

DIGITAL INPUT 5-8

DI 5

DI 9

DI 7

DI 6

DI 8

COM

DI 10

COM

5V+

ANALOG INPIT 1-6

DIGITAL INPUT 13-16

COM

DI 11

DI 12

COM

DI 13

DI 15

DI 14

DI 16

AI7

AI8

AI9

AI10

AI6

AI4

AI5

COM

5V+

COM

5V+

12V+

ANALOG INPUT 7-10

MCX

CAN RJ

DIGITAL INPUT 17-18

COM

COM

DI 17

DI 18

CAN

L

N

POWER

MCX15B Controller

14 | BC344024774466en-000401

Fig. 16 Controller box internal

Optional 24V DC

power supply for (8)

purge solenoids

(not included)

Output terminals for:

Up to 8 purge points

ICFD drain valve

© Danfoss | DCS (ms) | 2021.04

Page 15

User Guide | Intelligent Purging System (IPS 8) Ammonia

Electrical wiring

(continued)

230V AC

QS1

L

N

QM1 QM2

L/1

N/1

L/4

QM3

L/5

KL1 KL1

L/3

Crankcase

heater

GD1 GD2

24V DC

0V DC

Power supply

MCX15B

9

8

Power supply

Solenoid valves*

L/2

Press.

Switch

M1 M2 VR1

1 1 1

Compressor

Condenser

Fan

Extraction

air fan

TR

RC

*When using GD2 24V DC, remove 1-2 and 3-4 bridges between the terminals and connect power supply

Fig. 17 Power Supply

MCX15B OUTPUT

C 1

NO 1

N1

L 1

NO 2

C 3

C 2

NO 3

NO 4

5

C 4

C

C 6

NO 5

NO 6

C 7

NO 7

NO 8

C 9

C 8

NO 9

C 10

NO 10

NC 10

11

NO

C 12

NC 12

NO 12

C 13

NO 13

NC 13

C 14

NC 14

NO 14

C 15

NC 15

NO 15

C 11

NC 11

24V DC

12

345

Solenoid valve

0V DC

Fig. 18 Controller MCX15B Inputs and Outputs

8

6

7

10

11

12

13

Solenoid valve

Solenoid valve

Solenoid valve

Solenoid valve

System running

System running

System error

14

15

Solenoid valve

16

Solenoid valve

Solenoid valve

17

Solenoid valve

18

Solenoid valve

9

© Danfoss | DCS (ms) | 2021.04

BC344024774466en-000401 | 15

Page 16

User Guide | Intelligent Purging System (IPS 8) Ammonia

Electrical wiring

(continued)

24V DC 24V DC

0V DC 0V DC

6

AO

AO 5

COM

DI COM

DI 2DI 2HDI 3DI 3H

DI COM

Fig. 19 Controller MCX15B Inputs

Light Indicators

DI COM

KL1

Compressor

relay

26

DI 1

DI 4

DI 4H

Discharge

Temp. sensor

Suction

Temp. sensor

Temp.

sensor

Low

pressure

transmitter

High

pressure

transmitter

R717

XT1

ST1

212223

19

20

AI 1AI 2

L1

N 1

DI 1H

AO 1

AO 4

AO 2

AO 3

COM

AI 3

5V+

12V+

5V+

ST2

ST3

COM

BPL

AI 7

24

25

4

AI

AI 5

AI 6

COM

BPH

AI 8

AI 9

AI 10

5V+

MCX15B INPUT

DI COM

DI 5DI

6

DI 7

DI 9

COM

DI 8

DI 12

DI 10

COM

DI 11

DI 13

DI 14

DI 15

DI 16

COM

COM

DI 17

DI 18

COM

GND

D +

D +

GND

D -

D -

ON/OFF Switch

R120

CAN GND

CAN H

CAN L

CAN HIDCAN L

CAN GND

STANDBY RUN ERROR

Green

Yellow

light

PURGING

Red

light

light

Key Lock

Fig. 20

Lights ON Status

Compressor ONCompressor

OFF

Purge Valve ONPurge Valve

OFF

Green Stand by x x

Yellow Run x x

Green & Yellow Purging x x

Green & Yellow

& Red

Red

* The purger continuous purging until max running period (default 160 h) is reached and the purger compressor will stop

** The purger compressor stops when alarm occurs

Uninterupted Long time

purging (> 150 h)

Occurs when: Check list

of alarms description

x x*

(x**) x** x

Alarm

16 | BC344024774466en-000401

© Danfoss | DCS (ms) | 2021.04

Page 17

User Guide | Intelligent Purging System (IPS 8) Ammonia

Upper Threshold for Purge Valv

Log of purging events

Quick Startup

Navigation - built in MCX

controller

(Placed at the rear of the front

panel door)

R717 low Pres limit

Actual R717 Pres

Actual R452A Pres

Lower Threshold for Purge Valve

Actual R452A Temp

e

For the fastest possible system configuration after connecting all purge points to the IPS and following

first power up of the IPS, follow these simple instructions:

1. Navigate from the Main Menu to Login

2. Enter password '200'.

3. Choose 'Parameters'.

4. Choose 'Unit Config'

5. Choose 'Valve Settings'

6. Enter the amount of purge solenoid valves connected to the IPS.

After switching on the controller, a display

window will momentarily show the actual

software version, followed by the default main

While in operation mode, the Up/Down arrow

buttons lead the user to the status windows

described in Table 01 below.

operating window shown in Fig. 26.

Up

Down Enter

Compressor on Error/Alarm Purge valve open Purge point (1-8)

Esc

.

Not

Used

Main screen, current informaon on IPS status

Status of purging process and purging counters

Temperature and superheat status

Informaon on Purge points acvity

Fig. 21 - Default main window. Operating (start) mode. (Examples only)

Table 01 - Status windows

Purge Point percentage Distribution of the actual purging on the various purge points

Dis. temp. Actual R452A discharge temperature (°C)

Main Window default See above

Cycle info Acc. time Purge valve open (h)

Past events Last 7 purging events (min)

© Danfoss | DCS (ms) | 2021.04

BC344024774466en-000401 | 17

Page 18

User Guide | Intelligent Purging System (IPS 8) Ammonia

Configuring using the LCD

By pressing the main menu will show up with the options below

Table 02

Main menu navigation

Main Menu Submenu Submenu/status Submenu/status Min Max Default Description Label

Active alarms

Alarms

Login Password *** 200 N/A

Start

Parameters

Input/Output Input / Output Display & Config

Reset alarms Reset all actual alarms

Log history View log history

Clear log

history

Turn On Main swith ON

Turn Off Main swith OFF

Unit config

No alarm

up to 15 alarms

(see table

below)

Compressor

Limits settings

Up to 15 possible alarms listed by arrow up/down

Clear log history

0 sec 100 sec 20 sec SDT (Compressor start delay) CM2

5 min

180 min

24 hours

0 bar 5 bar 0.5 bar Comp Diff (Hysteresis min allowed ammonia pressure) CM5

0 bar 12 bar 6.5 bar Setpoint to start compressor CM1

2000

45 min PDT (Pull down time) CM3

min

2000

hours

min

768

1440

CST (Cycle time) CM4

min

160

PLT (Endless purging max time) VA5

hours

18 | BC344024774466en-000401

© Danfoss | DCS (ms) | 2021.04

Page 19

User Guide | Intelligent Purging System (IPS 8) Ammonia

Table 03

Occurring active alarms, possible reasons and recommended action

Label Parameter Name Description Possible Reason Recommended action

ALARMS

A01 General alarm Input from AI3 Leads to shut down of IPS 8 Fault in system connected to the DIO4 Input from AI3 Leads to shut down of IPS 9

E01 Temp Sensor Fault

E01 Temp Sensor Fault

E01 Temp Sensor Fault

E02 BPL Sensor Fault

E02 BPL Sensor Fault

E02 BPL Sensor Fault

E03 BPL Sensor Fault

E03 BPL Sensor Fault

E03 BPL Sensor Fault

E04 Low temperature

E05 High temperature

E05 High temperature Low R452a charge because of possible leak Locate and repair leak Evacuate Move the IPS to a lower ambient temperature

E06 Low pressure BPL Indicates too low R452a pressure Choked restrictor / wrong connection

E07 High pressure BPL Indicates too high R452a pressure R452s system pressure too high

E08 Low pressure BPH Indicates too low R717 pressure Closed stop valve

E09 High pressure BPH Indicates too high R717 pressure R717 system pressure too high Pressure is 24 bar

E10 System is OFF Indicates status of the main switch Main switch is OFF Switch ON the main switch

E11 Memory is full A memor y reset is required Memory is full from long time operation

E12 Totla purge time error

E13 Compressor ERROR

E14 Liquid alarm

E15 Memory wrong!

E16 Discharge sensor error Indicates no signal from temperature sensor

E17 Suction sensor error Indicates no signal from temperature sensor

All alarms except (*) activates red light on box outside

For alarms not resettable and/or cause not identified, please contact Danfoss

Level legend: 0 = Read view, 2 = Installer view (code 200) 3 = Danfoss Service view (Contact Danfoss)

Indicates no signal from temperature sensor

(R452a)

Indicates no signal from temperature sensor

(R452a)

Indicates no signal from temperature sensor

(R452a)

Indicates no signal from pressure transmitter

(R452a)

Indicates no signal from pressure transmitter

(R452a)

Indicates no signal from pressure transmitter

(R452a)

Indicates no signal from pressure transmitter

(R717)

Indicates no signal from pressure transmitter

(R717)

Indicates no signal from pressure transmitter

(R717)

Indicates too low ambient temperature

(<-10 °C)

Indicates too high ambient temperature

(>120 °C)

This occurs when PLT is activated System will

automatically restart when CST has expired

Indicates no status is being received from

relay KL01

Signal from the LLS that there is liquid in the

evaporator

Wrong counter values The unit will

automatically repair itself

Broken wire to R452a temperature sensor

Electrical supply failure supplying R452a

temperature sensor

Temperature measurement of the R452a line

is out of range

Broken wire to R452A pressure transmitter

Electrical supply failure to the R422a pressure

transmitter

Pressure measurement of the R452a line is out

of range

Broken wire to R717 pressure transmitter

Electrical supply failure to the R717 pressure

transmitter

Pressure measurement of the R717 line is out

of range

Too low ambient temperature Move the IPS to a higher ambient temperature

Too high ambient temperature Move the IPS to a lower ambient temperature

Restrictor is blocked Replace the restrictor

Possible broken wire from the MCX Repair broken wire from the MCX

Repair temperature sensor wire or replace

temperature sensor

Repair or replace power source

Compare temperature with another

temperature sensor reading and replace

temperature sensor if needed

Repair pressure transmitter wire or replace

pressure transmitter

Repair or replace power source

Compare pressure with another pressure

reading and replace pressure transmitter if

needed

Repair pressure transmitter wire or replace

pressure transmitter

Repair or replace power source

Compare pressure with another pressure

reading and replace pressure transmitter if

needed

Factory setting 0.3 bar, we can have several

problems: a) Restrictor is blocked (clean it).

b) Wrong piping and as addition ammonia is

draining, so check piping’s. c) Check SV float

a) Expansion valve is not working

b) To high ambient temperature (24 bar /54 ºC)

Purge points are blocked, or flange is blocked

with rubber plug

Clean MCX memory by means of finding

Parameters_UnitConfig_

© Danfoss | DCS (ms) | 2021.04

BC344024774466en-000401 | 19

Page 20

User Guide | Intelligent Purging System (IPS 8) Ammonia

Modbus RTU

Good Practice

The wiring of Modbus RTU (RS485) must be carried out in accordance with the standard ANSI/TIA/EIA-485-A-1998.

Galvanic separation shall be provided for segments crossing buildings.

Common ground shall be used for all devices on the same network inclusive router, gateways etc.

All bus connections in the cables are made with twisted pair wires.

The recommended cable type for this is AWG 22/0.32 mm². If used for longer distances please use a AWG 20/0.5mm² or AWG 18/0.75mm²

cable. The cables characteristic impedance shall be between 100 – 130Ω The capacitance between conductors shall be less than 100 pf

per meter.

Note: the length of the cables influence the communication speed used. Longer cable lengths mean lower baud rate should be used.

Maximum cable length allowed is 1200m.

Use a minimum 20 cm distance between 110V/230V/400V power line cables and bus cables.

Table 04

Modbus RTU Registers

Register Parameter Name Description

GENERAL > SETUP

3001 ON/OFF

3002 Activate Multipurger

3003

3007

3008

3009

3010 Password level 1

3011 Password level 2

3014 PDT

3015 CST

3016 PLT

Restore default

parameters

GENERAL > SERIAL

SETTINGS

Serial address (Modbus

and CAN)

Serial baudrate

(Modbus)

Serial settings

(Modbus)

GENERAL >

PASSWORD

UNIT CONFIG >

COMPRESSOR

0: Main switch off

1: Main switch on

Switch on/off

multipurging

functionality

0: No

1: Yes, switch on

multipurging

functionality

0: No

1: Yes, restore default

parameters

2 1 100 1 N/A RW 3/6 Short Yes

TThe rate at which

information is

transferred in the

RS485 communication

channel

0: 0

1: 12

2: 24

3: 48

4: 96

5: 144

6: 192

7: 288

8: 384

0: 8N1

1: 8E1

2: 8N2

password for user

level 1

password for user

level 2

Pull down time of

compressor

Delay between purge

cycles (single purge)

Alarm for endless

purging

User

Level

Min Value Max Value

2 0 1 1 Enum 1 RW 3/6 Short Yes

2 0 1 1 Enum 2 RW 3/6 Short Yes

2 0 1 0 Enum 2 RW 3/6 Short Yes

2 0 8 6 Enum 3 RW 3/6 Short Yes

2 0 2 1 Enum 4 RW 3/6 Short Yes

3 0 999 100 N/A RW 3/6 Short Yes

3 0 999 200 N/A RW 3/6 Short Yes

2 5 CM4 45 min RW 3/6 Short Yes

2 180 2000 1440 min RW 3/6 Short Yes

2 24 768 24 h RW 3/6 Short Yes

Default

Value

Unit/

Type

Read/

Write

Modbus

Function

Code

Modbus

Data Type

Persistent

Yes/No

20 | BC344024774466en-000401

© Danfoss | DCS (ms) | 2021.04

Page 21

User Guide | Intelligent Purging System (IPS 8) Ammonia

Register Parameter Name Description

3022 Max_PP

3034 Setpoint

3035 Tsh Setpoint for superheat 2 5,0 40,0 15 °C R/W 3/6 Short Yes

1859 Reset Alarms Reset alarm 0 0 2 0 N/A R/W 3/6 Short Yes

8101 SystemOnOff

8102 ValveStatus

8103 CompressorStatus

8104 ALARActive

8105 PressTotemp

8106 ValveCount

8108 ComprTime

8110 COmprStartAfter

9901

8112 ValveHour

8114 StatusKL

8115 WaringCompr

8116 ValveSetpoint

8117 ValveClose

8119 Event1

8121 Event2

UNIT CONFIG >

VALVE SETTINGS

UNIT CONFIG >

LIMITS SETTINGS

STATUS VAR > MCX

DESIGN HOTSPOTS

Advanced Setting ResetMem

Used amount of purge

points - part of initial

setup

Pressure threshhold

for compressor

Feedback from the

main switch

Feedback from the

purge valve - open/

closed

Feedback from the

compressor - on/off

Any alarm active

indicator

Suction temperature

(calculated from

pressure on suction)

The amount of purge

valve activations

Remaining time for

compressor pull-down

for the actual purge

pointr cycle

The delay between

the purging cycles

Recommend default

setting only - All

logged values are

reset

0: NO

1: YES

The amount of hours

that the main purge

valve has been active

Status of KL01 relay

(compressor and

crankcase heater)

Indicates problem

with compressor

status

Temperature

threshhold for the

opening of the main

purge valve

Temperature

threshhold for the

closing of the main

purge valve

Purge cycle event counts the minutes

that the purge valve

has been open on a

finished cycle

Purge cycle event counts the accumative

minutes that the

purge valve has been

open on a finished

cycle

User

Level

Min Value Max Value

2 0 8 8 N/A RW 3/6 Short Yes

2 0,0 12,0 6.5 bar R/W 3/6 Short Yes

0 -32768 32767 0 Enum 1

0 -32768 32767 0 Enum 1

0 -32768 32767 0 Enum 1 R/W 3/6 Short Ye s

0 -32768 32767 0 Enum 2

0 -327,7 327,7 0 °C

0 -2147483648 2147483647 0 N/A

0 -2147483648 2147483647 0 Minutes

0 -2147483648 2147483647 0 Minutes

0 0 1 0 Enum 2 R/W 3/6 Short Ye s

0 -214748364,8 214748364,7 0 Hours

0 -32768 32767 0 Enum 2

0 -32768 32767 0 Enum 2

0 -2147483648 2147483647 0 °C

0 -2147483648 2147483647 0 °C

0 -3276,8 3276,7 0 Minutes

0 -3276,8 3276,7 0 Minutes

Default

Value

Unit/

Type

Read/

Write

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Modbus

Function

Code

Modbus

Data Type

3 Short No

3 Short No

3 Short No

3 Short No

3 Long No

3 Long No

3 Long No

3 Long No

3 Short No

3 Short No

3 Short No

3 Long No

3 Long No

3 Long No

Persistent

Yes/No

© Danfoss | DCS (ms) | 2021.04

BC344024774466en-000401 | 21

Page 22

User Guide | Intelligent Purging System (IPS 8) Ammonia

Register Parameter Name Description

Purge cycle event counts the accumative

8123 Event3

8125 Event4

8127 Event5

8129 Event6

8131 Event7

8133 PP1

8135 PP2

8137 PP3

8139 PP4

8141 PP5

8143 PP6

8145 PP7

8147 PP8

8149 Val1

8150 Val2

8151 Val3

8152 Val4

8153 Val5

8154 Val6

8155 Val7

8156 Val8

8158 TempStatus

8159 BPLStatus The pressure on R452 0 -32768 32767 0 bar

8160 BPHStatus The pressure on R717 0 -2147483648 2147483647 0 bar

minutes that the

purge valve has been

open on a finished

cycle

Purge cycle event counts the accumative

minutes that the

purge valve has been

open on a finished

cycle

Purge cycle event counts the accumative

minutes that the

purge valve has been

open on a finished

cycle

Purge cycle event counts the accumative

minutes that the

purge valve has been

open on a finished

cycle

Purge cycle event counts the accumative

minutes that the

purge valve has been

open on a finished

cycle

The time percentage

for this purge point

The time percentage

for this purge point

The time percentage

for this purge point

The time percentage

for this purge point

The time percentage

for this purge point

The time percentage

for this purge point

The time percentage

for this purge point

The time percentage

for this purge point

This indicates if the

purge point is active

This indicates if the

purge point is active

This indicates if the

purge point is active

This indicates if the

purge point is active

This indicates if the

purge point is active

This indicates if the

purge point is active

This indicates if the

purge point is active

This indicates if the

purge point is active

The measured

temperature on the

discharge line of

compressor

User

Level

Min Value Max Value

0 -3276,8 3276,7 0 Minutes

0 -3276,8 3276,7 0 Minutes

0 -3276,8 3276,7 0 Minutes

0 -3276,8 3276,7 0 Minutes

0 -3276,8 3276,7 0 Minutes

0 -32768 32767 0 %

0 -32768 32767 0 %

0 -32768 32767 0 %

0 -32768 32767 0 %

0 -32768 32767 0 %

0 -32768 32767 0 %

0 -32768 32767 0 %

0 -32768 32767 0 %

0 -32768 32767 0 N/A

0 -32768 32767 0 N/A

0 -32768 32767 0 N/A

0 -32768 32767 0 N/A

0 -32768 32767 0 N/A

0 -32768 32767 0 N/A

0 -32768 32767 0 N/A

0 -32768 32767 0 N/A

0 -32768 32767 0 °C

Default

Value

Unit/

Type

Read/

Write

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Modbus

Function

Code

Modbus

Data Type

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Short No

3 Short No

3 Short No

3 Short No

3 Short No

3 Short No

3 Short No

3 Short No

3 Short No

3 Short No

3 Short No

Persistent

Yes/No

22 | BC344024774466en-000401

© Danfoss | DCS (ms) | 2021.04

Page 23

User Guide | Intelligent Purging System (IPS 8) Ammonia

Register Parameter Name Description

8161 DisTemp

8162 SuctionTemp

8163 TshValveStatus

8164 TshCalculate

ALARMS

1901 .08 General alarm

1901 .09 Temp Sensor Fault

1901 .10 BPL Sensor Fault

1901 .11 BPH Sensor Fault

1901 .12 Low temperature

1901 .13 Hi temperature

1901 .14 Low pressure BPL

1901 .15 Hi pressure BPL

1901 .00 Low pressure BPH

1901 .01 Hi pressure BPH

1901 .02 System is OFF

1901 .03 Memory is full

1901 .04 Totla purge time error

1901 .05 Compressor EROR

1901 .06 Liquid alarm

1901 .07 Memory wrong!

1902 .08 Discharge sensor error

1902 .09 Suction sensor error

The measured

temperature on the

purge valve

The measured

temperature on the

suction line

The measured value of

the superheat

The calculated value

of the superheat from

the refrigerant type

Input from AI3. Leads

to shut down of IPS 8

Indicates no signal

from temperature

R452A sensor

Indicates no signal

from pressure sensor

(R452a)

Indicates no signal

from pressure sensor

(R717)

Indicates too low

ambient temperature

(<-10 °C)

Indicates too high

ambient temperature

(>120 °C)

Indicates too low

R452a pressure

Indicates too high

R452a pressure

Indicates too low R717

pressure

Indicates too high

R717 pressure

Indicates status o the

main switch

A memory reset is

required

This occurs when PLT

is activated. System

will automatically

restart when CST has

expired

Indicates no status is

being received from

KL01

Signal from the LLS

that there is liquid in

the evaporator

Wrong counter

values. The unit will

automatically repair

itself

Indicates no signal

from temperature

sensor

Indicates no signal

from temperature

sensor

User

Level

Min Value Max Value

0 -32768 32767 0 °C

0 -2147483648 2147483647 0 °C

0 -32768 32767 0 °C

0 -2147483648 2147483647 0 K

0 0 1 0 AUTO R.

0 0 1 0 AUTO R.

0 0 1 0 AUTO R.

0 0 1 0 AUTO R.

0 0 1 0 AUTO R.

0 0 1 0 AUTO R.

0 0 1 0 AUTO R.

0 0 1 0 AUTO R.

0 0 1 0 AUTO R.

0 0 1 0 AUTO R.

0 0 1 0 AUTO R.

0 0 1 0 AUTO R.

0 0 1 0 AUTO R.

0 0 1 0 AUTO R.

0 0 1 0 AUTO R.

0 0 1 0 AUTO R.

0 0 1 0 AUTO R.

0 0 1 0 AUTO R.

Default

Value

Unit/

Type

Read/

Write

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Modbus

Function

Code

Modbus

Data Type

3 Short No

3 Short No

3 Short No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

Persistent

Yes/No

© Danfoss | DCS (ms) | 2021.04

BC344024774466en-000401 | 23

Page 24

User Guide | Intelligent Purging System (IPS 8) Ammonia

Register Parameter Name Description

I/O CONFIGURATION

ANALOG INPUTS

1005 BPL-1/34

1006 BPH-1/59

1007 Dis. Temp

1008 TempSuction

1009 NC Temp

DIGITAL INPUTS

1001.08 Status KL1

1001.09 On/Off

1001.10 General Alarm General Alarm input 2 0 1 0 N.O.

1001.11 LiquidAlarm Liquid Alarm input 2 0 1 0 N.O.

DIGITAL OUTPUTS 0 = OFF ; 1 = ON

1003.08 Compressor Compressor relay 2 0 1 N/A N.O.

1003.09 Valve Main purge valve relay 2 0 1 N/A N.O.

1003.10 Green Status LED 2 0 1 N/A N.O.

1003.11 Yellow Status LED 2 0 1 N/A N.O.

1003.12 DO_Red Status LED 2 0 1 N/A N.O.

1003.13 ICFD_Valve

1003.14 Valve1 Purge point valve relay 2 0 1 N/A N.O.

1003.15 Valve2 Purge point valve relay 2 0 1 N/A N.O.

1003.00 Valve3 Purge point valve relay 2 0 1 N/A N.O.

1003.01 Valve4 Purge point valve relay 2 0 1 N/A N.O.

1003.02 Valve5 Purge point valve relay 2 0 1 N/A N.O.

1003.03 Valve6 Purge point valve relay 2 0 1 N/A N.O.

1003.04 Valve7 Purge point valve relay 2 0 1 N/A N.O.

1003.05 Valve8 Purge point valve relay 2 0 1 N/A N.O.

1003.06 Alarm Alarm relay N/A 0 1 N/A N.C.

Pressure at the R452a

suction line

Condensing pressure

of R717

Measured discarge

temperature of

compressor

Measured suction

temperature

Measured non

Condensable gas

temperature

Compressor status

(KL01)

0: Compressor off

1: Compressor on

Main switch input

0: Main switch off

1: Main switch on

ICFD relay (solenoid

valve)

User

Level

Min Value Max Value

2 -1.0 34.0 N/A 0-5 V

2 -1.0 59.0 N/A 0-5 V

2 -50.0 170.0 N/A PT1000

2 -50.0 170.0 N/A PT1000

2 -50.0 170.0 N/A PT1000

2 0 1 1 N.O.

2 0 1 1 N.O.

2 0 1 N/A N.O.

Default

Value

Unit/

Type

Read/

Write

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Read

only

Modbus

Function

Code

N/A N/A N/A

Modbus

Data Type

3 Short No

3 Short No

3 Short No

3 Short No

3 Short No

3 Short No

3 Short No

3 Short No

3 Short No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

3 Long No

Persistent

Yes/No

24 | BC344024774466en-000401

© Danfoss | DCS (ms) | 2021.04

Page 25

User Guide | Intelligent Purging System (IPS 8) Ammonia

Maintenance/Service/

Disposal

Table 05

Maintenance checklist - Perform once a year minimum

1 Use P&I dagram and check that all powered components are working properly

2 Check for alarms in the MCX controller

3 Fans, air filters and fins must be cleaned for dirt and dust

4 Expansion valve must be inspected and must be replaced if damaged

5 Ensure expansion valves sensor bulb has good contact with suction line

6 Replace water in water bubble bath. Check pH level frequently and replace when pH > 12.6

7 Check cover is mounted correctly and all bolts are tightened accordingly

8 Check and verify the amperage of the unit

9 Check for abnormal compressor noises in normal operating conditions (may indicate loose bolts, worn bearings or pistons)

Table 06

Procedure to isolate IPS for servicing

Multipoint Single point purging from receiver

Close all supply lines from the purge points of the ammonia

1

system.

Do not close any stop valve between IPS 8 and float valve

2 Restart the controller to force pump-down Wait 20 minutes

3 Wait 20 minutes

Stop the compressor by turning the compressor switch QM1 to

4

the off position

Close the SVA shut-off valve in the drain line (located under

5

the IPS 8)

Release the remaining system pressure to atmosphere

by opening the SNV drain valve. This can also be done by

6

attaching a permanent magnet on the AKVA 10 valve for forced

opening

Restart the controller to force pump-down

Stop the compressor by turning the compressor switch QM1 to

the off position

Close the SVA shut-off valve in the drain line (located under

the IPS 8)

Release the remaining system pressure to atmosphere

by opening the SNV drain valve. This can also be done by

attaching a permanent magnet on the AKVA 10 valve for forced

opening

Disposal of the IPS 8

If an IPS 8 unit is worn out and has to be replaced,

the disposal must be done in accordance with

national legislation and only done by competent

personnel.

© Danfoss | DCS (ms) | 2021.04

BC344024774466en-000401 | 25

Page 26

26 | BC344024774466en-000401

© Danfoss | DCS (ms) | 2021.04

Loading...

Loading...