Page 1

Application Guidelines

Danfoss Inverter scroll

compressor, VRJ

For Residential Applications - R410A

http://danfoss.us.com/

Page 2

Page 3

Application Guidelines

Content

Introduction ................................................... 4

Scroll compressor components ....................................4

Compressor size ..................................................................4

Performance .........................................................................4

Compressor model designation ................... 5

Nomenclature ......................................................................5

Label........................................................................................5

Serial number ...................................................................... 5

Technical specications ................................ 6

Compressor specications ..............................................6

Performance data ..............................................................6

Variable speed drive specications .............................6

Bearings lubrication .......................................................... 6

Dimensions .................................................... 7

VRJ 028 - 035 - 044 ............................................................. 7

Mounting grommet ..........................................................7

Electrical data, connections and wiring ....... 8

Supply Voltage ................................................................... 8

Compressor electrical specications ........................... 8

LRA (Locked Rotor Amp)..................................................8

MCC (Maximum Continuous Current) ........................8

Winding resistance ............................................................8

Wiring connections .......................................................... 9

Terminal cover mounting ................................................ 9

Terminal cover removal ....................................................9

IP rating ..................................................................................9

Internal motor protection ............................................... 9

Phase sequence and reverse rotation protection ..9

Approvals and certicates ........................... 10

Approval and certicates ...............................................10

Pressure equipment directive 97/23/EC ..................10

Low voltage directive 73/23/EC, 93/68/EC...............10

Internal free volume .........................................................10

Operating conditions ................................... 11

Refrigerant and lubricants .............................................11

Motor supply.......................................................................11

Compressor ambient temperature .............................11

Application envelope ......................................................12

High and low pressure protection ..............................13

Crankcase heating ............................................................13

Oil return management ..................................................13

On/o cycling (cycle rate limit) ....................................14

Start-up sequence .............................................................14

System design recommendations .............. 15

General ..................................................................................15

Essential piping design considerations .....................15

Refrigerant charge limit .................................................16

Reversible heat pump systems ....................................16

Minimum sump superheat ............................................16

Preventing liquid ood back ........................................16

Water utilising systems ..................................................17

Loss of charge protection...............................................17

Oil level checking and top-up ......................................17

Sound and vibration management ............. 18

Starting sound level .........................................................18

Running sound level ........................................................18

Stopping sound level .......................................................18

Sound generation in a refrigeration system and air

conditioning system ........................................................18

Installation .................................................... 20

System cleanliness ............................................................20

Compressor handling and storage .............................20

Compressor mounting ....................................................20

Compressor holding charge ..........................................20

Tube brazing procedure .................................................20

Brazing material .................................................................20

Compressor connection .................................................21

Vacuum evacuation and moisture removal .............21

Liquid line lter driers ......................................................22

Refrigerant charging ........................................................22

Insulation resistance and dielectric strength ..........22

Compressor replacement after motor burn out ....22

Ordering information and packaging ........ 23

Packaging ............................................................................23

Ordering code numbers .................................................23

3AB141686422149en-US0301

Page 4

Application Guidelines

Introduction

Scroll compressor components

Danfoss VRJ for residential applications

developed by Danfoss is a complete package

consisting of a dedicated variable speed

compressor, variable speed drive, application

controller, electronic expansion valve (EEV), EEV

controller and sensors. Three nominal system

The motor stator is rigidly attached to the shell.

The rotor is shrink-t onto the eccentric shaft. The

shaft is supported by two bearings, one in the

crankcase and the second below the motor.

sizes are available (3, 4 and 5 TR), based on three

compressor models.

These Selection & Application Guidelines focus

on the variable speed scroll compressor.

Compressor size

Performance

Variable speed technology oers more exibility

in compressor selection than xed speed

compressors. Selection of the right variable

speed compressor size can be done by dierent

methods:

• Maximum cooling capacity: select a

compressor size that achieves the peak

load system cooling capacity demand at its

maximum speed.

• Nominal cooling capacity: select a

compressor size that achieves the nominal

system cooling capacity at a rotational

speed of 3000-4200 rpm (50-70Hz).

• Best Seasonal Eciency Ratio: select a

compressor size that achieves the minimum

The Danfoss VRJ compressors referenced in this

guide is a fully compliant scroll and actually

improves with run time in its early commissioning.

system cooling demand at its minimum

speed. Ensure that the compressor is able to

cover the peak load system cooling capacity.

This selection makes the compressor to run

for a maximum of time at part load where

the system eciency is highest.

Danfoss scroll compressors are manufactured

using the most advanced machining, assembly,

and process control techniques. In design of

both the compressor and the factory, very high

standards of reliability and process control

were rst priority. The result is a highly ecient

product with the highest reliability obtainable,

and a low sound level.

A seventy-two hour run-in is recommended to

meet performance expectations.

4 AB141686422149en-US0301

Page 5

Application Guidelines

Compressor model designation

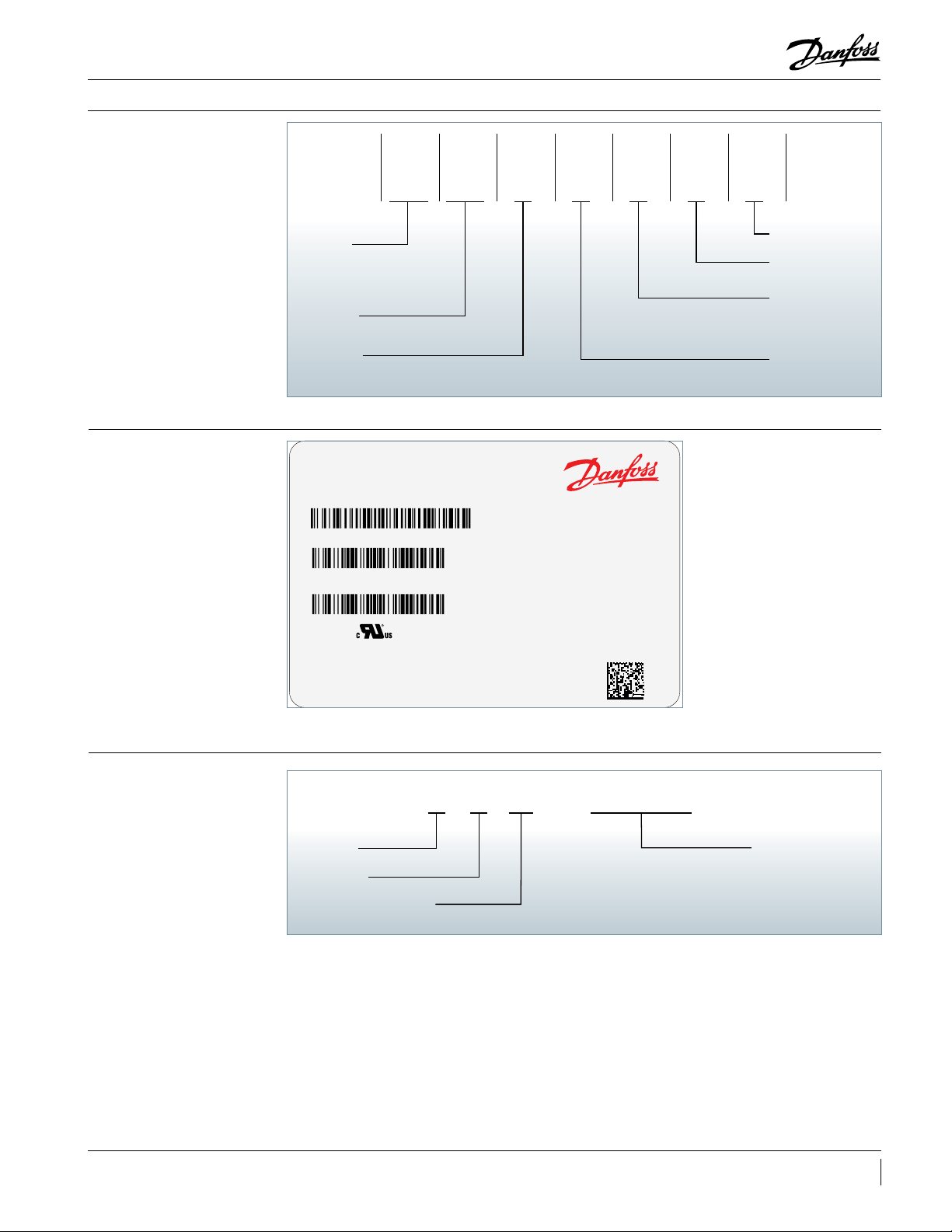

Nomenclature

Label

Application,

Family

& Refrigerant

VRJ

Application, Family

& refrigerant

V: Variable speed

R: Residential

J: R410A, PVE lubricant

Swept Volume

Displacement in cc/rev

Model Variation

U: Design optimised for high SEER

Compressor

Model no : VRJ044UKNP6

Serial no :

Tech no : VGK46PHA001

LK2500000333

Swept

Volume

028

Model

Variation

U

245 Max Inverter Driven

Drive Model: 178L002

LR: 12.0 A MAX OPER: 30.0A

Lubricant:PVE / 45 oz/1.33 L

VoltageNMotor

K

MADE IN CHINA

Protection

Equipment

Version

P

Other

Features

6

Other features

6: No other features

Equipment version

P: Brased connections,

spade terminals

Motor protection

N: No internal motor

protection (protection by

drive)

Voltage

K: 420V DCL IPM

Serial number

2020

INVERTER PROTECTED

PROTECTED BY DOMESTIC AND FOREIGN PATENTS

1000000052

12345678A 25B

Year code 8 Digit serial number

Month code

Plant assembly line code

5AB141686422149en-US0301

Page 6

Application Guidelines

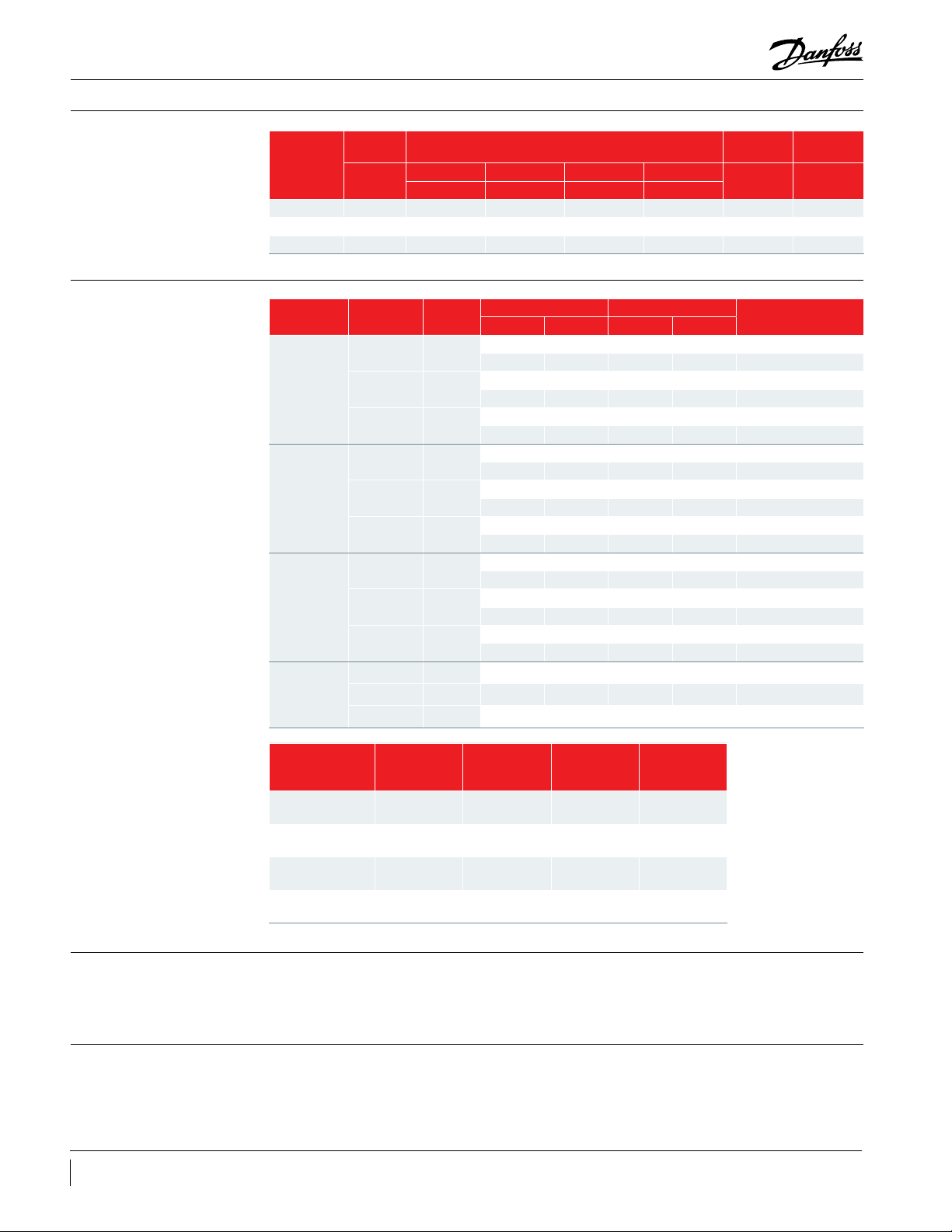

Technical specifications

Compressor specications

Performance data

Compressor

model

VRJ028 1.64 51 103 206 240 36 68

VRJ035 2.12 66 133 265 310 45 71

VRJ044 2.65 83 166 332 387 45 71

Conditions

High SEER

conditions

(H)

CHEER

conditions

Heat Pump

conditions

SEER

conditions (I)

Swept

volume

cu.in/rev

Compressor

model

VRJ028 3 Tons

VRJ035 4 Tons

VRJ044 5 Tons

VRJ028 3 Tons

VRJ035 4 Tons

VRJ044 5 Tons

VRJ028 3 Tons

VRJ035 4 Tons

VRJ044 5 Tons

VRJ028 3 Tons 1800 30 21000 1.75 68.5

VRJ035 4 Tons 1800 30 26800 2.23 69.7

VRJ044 5 Tons 1800 30 34500 2.88 70.9

Min speed 30 Hz 60 Hz Max speed

900 rpm 1800 rpm 3600 rpm 4200 rpm

Nominal

Tons

Displacement Oil charge Net weight

oz lb

Compressor speed Compressor capacity

rpm Hz Btu/hr Ton

3600 60 36700 3.06 66.2

4200 70 42700 3.56 64.9

3600 60 46400 3.87 67.6

4200 70 53400 4.45 65.1

3600 60 57800 4.82 68.3

4200 70 68100 5.68 67.0

3600 60 36500 3.04 65.9

4200 70 42300 3.53 64.3

3600 60 46200 3.85 67.3

4200 70 53000 4.42 64.6

3600 60 57900 4.83 68.8

4200 70 68300 5.69 67.5

3600 60 25100 2.09 59.7

4200 70 29300 2.44 58.8

3600 60 31800 2.65 61.0

4200 70 36700 3.06 59.0

3600 60 40200 3.35 62.2

4200 70 47300 3.94 61.2

Compressor

isentropic eciency

Variable speed drive

specications

Bearings lubrication

6 AB141686422149en-US0301

Conditions

High SEER

conditions (H)

CHEER

conditions

Heat Pump

conditions

SEER

conditions (I)

Evaporating

Temperature

(°F)

50 115 20 15

45 100 20 15

30 110 20 15

55 100 20 15

Condensing

Temperature

(°F)

For dedicated variable speed drive specications,

refer to “Danfoss VRJ Installation and Operation

instructions”.

A specic oil pump ensures optimal bearing

lubrication at all compressor speeds. This to have

sucient bearing lubrication at low speeds as well

Superheat

(°F)

Subcooling

(°F)

as avoid excessive Oil Circulation Ratio (OCR) at

high speeds.

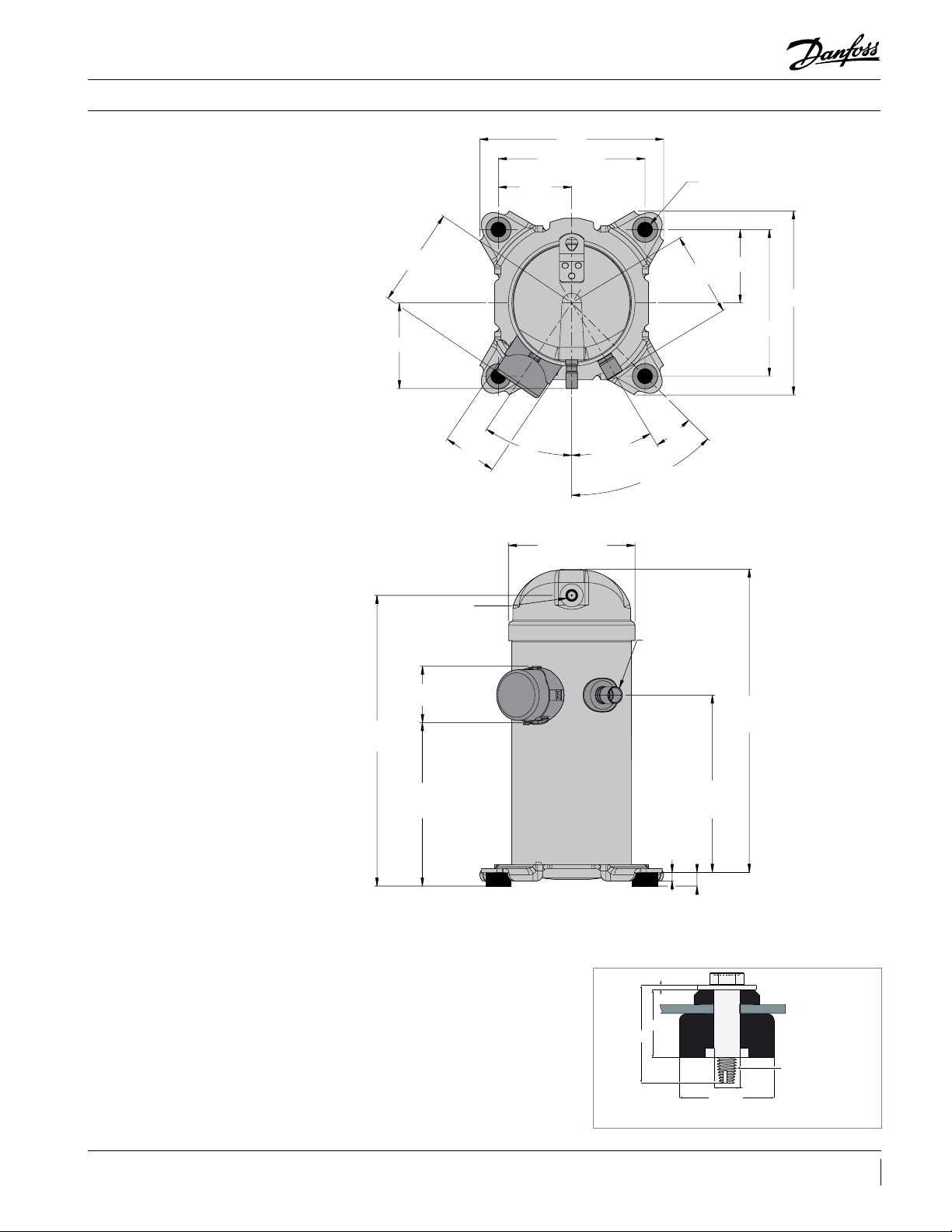

Page 7

Application Guidelines

9.40

All dimensions in inch

Dimensions

VRJ 028 - 035 - 044

4.38

5.06

2.74 - 2.80

7.491 - 7.509

3.750

34°

6.438 - 6.515

31°

45°

4.32

14°

4 x Ø 0.75 - 0.78

3.750

9.40

7.491 - 7.509

14.19

Discharge port

1/2” ODF

2.84 - 2.95

7.76

Suction port

3/4” ODF

9.09

0.42

0.75

Mounting grommet

0.067

1.161

1.614

15.53

5/16” - 18 UNC

self tapping

Ø 0.433

Recommended torque for mounting bolts:

8 ft.lbs (±1ft.lbs)

Ø 1.614

7AB141686422149en-US0301

Page 8

Application Guidelines

Electrical data, connections and wiring

Supply Voltage VRJ compressors must not be connected directly

to the mains supply. They must only be powered

through the dedicated Danfoss variable speed

drive.

Compressor model Variable Speed Drive Model

VRJ028 176L7000

VRJ035 176L7001

VRJ044 176L7002

Compressor electrical

specications

LRA (Locked Rotor Amp)

MCC (Maximum Continuous Current)

Winding resistance

Nominal voltage 208-230V – 1Ph – 60Hz

Voltage range 187 – 253 V

Refer to “Danfoss VRJ Installation and Operation

instructions” for more details about supply

voltage.

Compressor model LRA MCC Winding resistance

A A Ohm

VRJ028 10.2 18 0.255

VRJ035 12 23.5 0.210

VRJ044 12 30 0.210

LRA is the higher average current as measured

on a mechanically blocked compressor tested

under nominal voltage. LRA is printed on the

VRJ compressors, the LRA value is low because the

variable speed drive reacts very rapidly (far below

1 second).

nameplate, according to UL requirements. With

The MCC value is the maximum at which

the compressor can be operated in transient

MCC value is measured based on UL conditions

(max load) and at low voltage.

conditions and out of the operating envelope. The

VRJ scroll compressors are equipped with an IPM

(permanent magnet) motor.

temperature ; If the compressor is stabilised at a

dierent value than 77°F, the measured resistance

must be corrected with following formula:

a + t

Winding resistance is the resistance between

indicated terminal pins at 77°F (resistance value ±

7%).

Winding resistance is generally low and it requires

adapted tools for precise measurement. Use

a digital ohm-meter, a ‘4 wires’ method and

measure under stabilised ambient temperature.

R

= R

tamb

77°F

t

: reference temperature = 77°F

77°F

: temperature during measurement (°F)

t

amb

: winding resistance at 77°F

R

77°F

: winding resistance at t

R

tamb

a: Coecient a= 390

a + t

amb

77°F

amb

Winding resistance varies strongly with winding

8 AB141686422149en-US0301

Page 9

Application Guidelines

Electrical data, connections and wiring

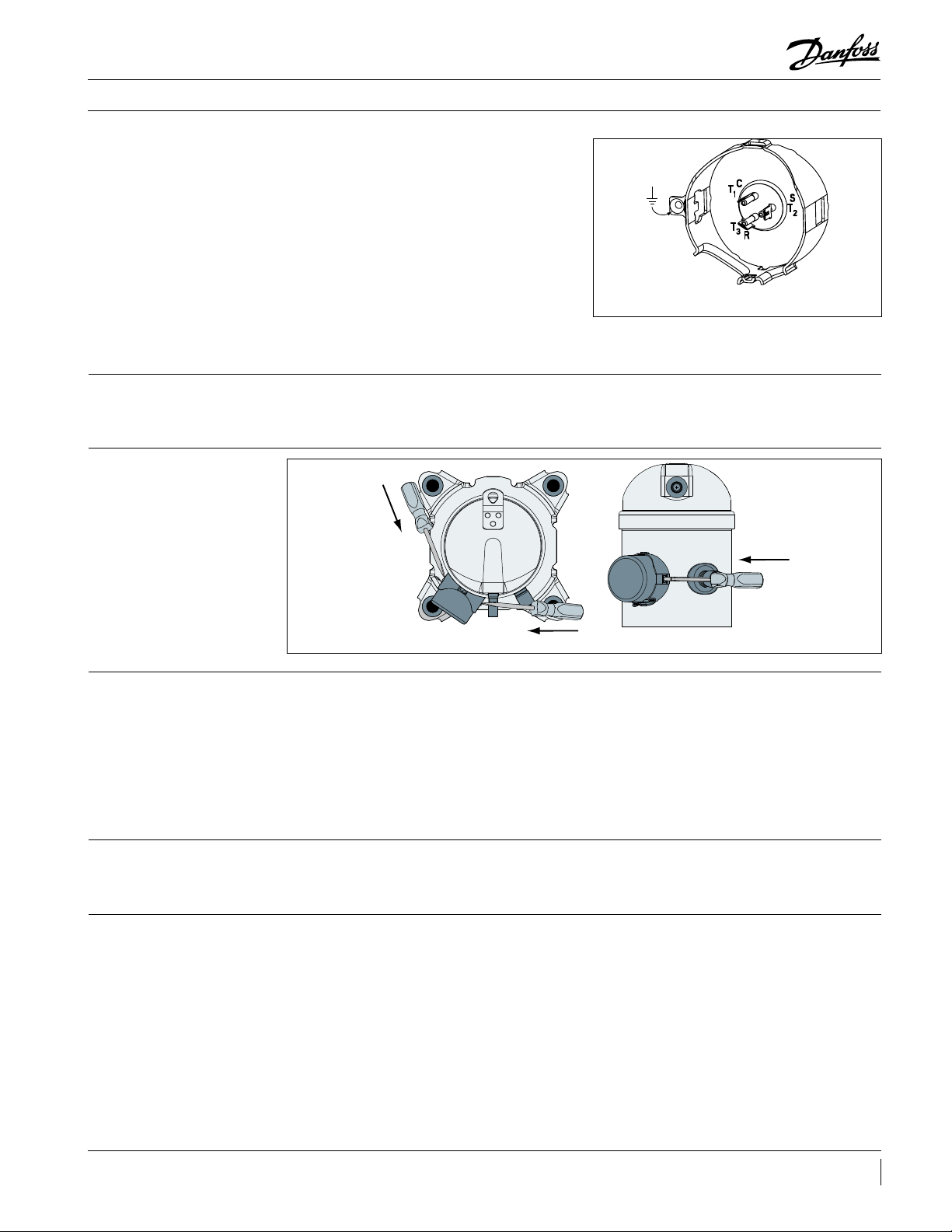

Wiring connections

VRJ scroll compressors will only compress gas

while rotating counter-clockwise (when viewed

from the compressor top).

The drawing shows electrical terminal labelling

and should be used as a reference when wiring the

compressor.

T1, T2 and T3 of the drive and the compressor

must be connected accordingly.

Refer to “Danfoss VRJ Installation and Operation

instructions” for details and cable sizes.

Terminal cover mounting The terminal cover and gasket should be installed

prior to operation of the compressor. The terminal

cover has two outside tabs, 180 degrees apart, that

Terminal cover removal

push

Quick connect spade terminals

P terminal box type

engage the terminal fence. When installing the

cover, check that it is not pinching the lead wires.

push

IP rating

Internal motor protection

Phase sequence and reverse rotation protection

push

The compressor terminal box IP rating according to CEI 529 is IP22 for all models. This IP rating is only

valid when correctly sized cable glands with the same IP rating are applied.

• First numeral, level of protection against contact and foreign objects

2 protection against object size over 1/2 inch (ngers of similar)

• Second numeral, level of protection against water

2 protection against dripping water when tilted up to 15°

VRJ scroll compressors are not equipped with

an internal motor protector. Motor protection

is provided by the variable speed drive. All

The compressor will only operate properly in a

single direction. If electrical connections are done

correctly between the drive and the compressor

terminals (compressor and drive terminals T1, T2

and T3 matching), the drive will provide correct

phase supply to the compressor, and reverse

rotation will be not possible.

motor para-meters are factory preset in order to

guaranty optimal locked rotor or overload current

protection.

If compressor and drive T1, T2 and T3 terminals are

not matching, the compressor can go in reverse

rotation. This results in excessive noise, no pressure

dierential between suction and discharge, and

suction line warming rather than immediate

cooling. The compressor can be rapidly severely

damaged in these conditions.

9AB141686422149en-US0301

Page 10

Application Guidelines

Approvals and certificates

Approval and certicates VRJ scroll compressors comply with the following

approvals and certicates.

Pressure equipment directive 97/23/EC

Low voltage directive 73/23/EC, 93/68/EC

Internal free volume

UL

(Underwriters Laboratories)

Other approvals / certicates Contact Danfoss

Refrigerating uids Group 2

Category PED I

Evaluation module no scope

Manufacturer's declaration of incorporation

ref. EC Machines Directives 98/392/CE

Products Internal free volume at LP side without oil (in.3)

VRJ028 - 035 - 044 179

All models

Contact Danfoss

10 AB141686422149en-US0301

Page 11

Application Guidelines

Operating conditions

Refrigerant and lubricants

General information

PVE

VRJ scroll compressor application range is

inuenced by several parameters which need to

be monitored for a safe and reliable operation.

These parameters and the main

recommendations for good practice and safety

devices are explained hereunder:

When choosing a refrigerant, dierent aspects

must be taken into consideration:

• Legislation (now and in the future)

• Safety

• Application envelope in relation to expected

running conditions

• Compressor capacity and eciency

• Compressor manufacturer

recommendations & guidelines

Polyvinyl ether (PVE) is an innovative refrigeration

lubricant for HFC refrigerant systems. PVE is as

hygroscopic as existing polyolester lubricants

(POE), but PVE does not chemically react with

water; no acids are formed and compressor

evacuation is easier.

Refrigerant and lubricants

Motor supply

Compressor ambient temperature

Application envelope (evaporating

temperature, condensing temperature, return gas

temperature)

Additional points could inuence the nal choice:

• Environmental considerations

• Standardisation of refrigerants and

lubricants

• Refrigerant cost

• Refrigerant availability

The compressor technology applied in Danfoss

VRJ scroll compressors in combination with PVE

lubricant provides the best possible result in

terms of reliability and compressor lifetime.

Residual moisture

Motor supply

Compressor ambient temperature

High ambient temperature

Low ambient temperature

Prior to shipment from the factory, every

compressor is dehydrated, evacuated, and

charged with dry nitrogen. Maximum residual

VRJ scroll compressors can be operated only

connected to the dedicated variable speed

drive, at nominal voltages as indicated in “supply

VRJ scroll compressors can be applied from

-13°F to 125°F ambient temperature. The

compressors are designed as 100 % suction gas

In case of enclosed tting and high ambient

temperature, it is recommend to check the

Although the compressor itself can withstand

low ambient temperature, the system may

require specic design features to ensure safe

moisture levels are 0.0082 oz. for model VRJ028,

and 0.0120 oz. for VRJ035 and VRJ044.

voltage” section. Under-voltage and over-voltage

operation is allowed within the indicated voltage

range.

cooled without need for additional fan cooling.

Ambient temperature has very little eect on the

compressor performance

temperature of power wires and conformity to

their insulation specication.

and reliable operation. See below sections for

recommendations.

11AB141686422149en-US0301

Page 12

Application Guidelines

Operating conditions

Application envelope

The operating envelope for VRJ scroll

compressors is given in the gure below, where

the condensing and evaporating temperatures

represent the range for steady-state operation.

Under transient conditions, such as start-up

and defrost for heat pump applications, the

compressor may operate outside this envelope

for short periods.

The operating limits serve to dene the

envelope within which reliable operations of the

compressor are guaranteed:

-40 -36 -32 -28 -24 -20 -16 -12 -8 -4 0 4 8 12 16 20 24

155

145

135

125

115

105

95

85

75

65

2300 - 2850 RPM

2200 - 3300 RPM

2100 - 3750 RPM

1800 - 4200 RPM

1500 - 4200 RPM

1300 - 4500 RPM

1100 - 4500 RPM

Saturated condensing temp. (°F)

55

45

35

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Saturated evaporating temp. (°F)

• Maximum discharge gas temperature: +275°F

• Suction superheat is dedictated by the

minimum sump superheat (see graph p16).

• Maximum superheat of 40°F

• Minimum and maximum evaporating

and condensing temperatures, as per the

operating envelopes.

All the below limits, temperatures and speeds,

are secured by the parameters in the drive and

application controller software’s.

(°C)

2400 RPM Derated

900 - 4500 RPM

70

66

62

58

54

50

46

42

38

34

30

26

22

18

14

10

6

2

(°C)

Maximum discharge gas

temperature

12 AB141686422149en-US0301

The discharge temperature depends mainly on

the combination of evaporating temperature,

condensing temperature and suction gas

superheat and speed. Discharge gas temperature

should be controlled with an insulated sensor

attached to the discharge line, 6 in. from the

compressor shell. Maximum discharge gas

temperature must not exceed 275°F when the

compressor is running within the approved

operating envelope.

Refer to “Danfoss VRJ Installation and Operation

instructions” for connection details, and to

“Sensor Selection Guideline” manual for

selection details and technical brochures about

temperature sensors.

Page 13

Application Guidelines

Operating conditions

High and low pressure protection

Pressure settings

High pressure

Low pressure

Suction and discharge pressure transmitters have

to be installed and connected to the variable

speed drive to ensure the compressor operates

within the application envelope described above.

Refer to “Danfoss VRJ Installation and Operation

instructions” for connection details, and to

“Sensor Selection Guideline” manual for selection

details and technical brochures about pressure

transmitters.

R410A

Working pressure range high side psig 119 - 645

Working pressure range low side psig 28 - 202

Maximum high pressure safety switch setting psig 653

Minimum low pressure safety switch setting

psig 22

: LP safety switch shall never be bypassed

According to UL requirements, a high pressure

safety switch is still mandatory in any system,

even with high pressure transmitters connected

and used via the variable speed drive.

depending on the application and ambient

conditions. The HP switch must either be placed

in a lockout circuit or consist of a manual reset

device to prevent cycling around the high-

pressure limit. If a discharge valve is used, the HP

HP switch settings shall not exceed the maximum

service pressure of any system components. The

switch must be connected to the service valve

gauge port, which must not be isolated.

high-pressure switch can be set to lower values

A low pressure (LP) safety switch is

recommended. Deep vacuum operations of a

scroll compressor can cause internal electrical

arcing and scroll instability. Danfoss scroll

compressors exhibit high volumetric eciency

and may draw very low vacuum levels, which

could induce such a problem. The minimum

low-pressure safety switch (loss of charge safety

switch) setting is given in the above table. Either

the LP safety switch must be a manual lockout

device or an automatic switch wired into an

electrical lockout circuit. The LP switch tolerance

must not allow for vacuum operations of the

compressor.

High pressure ratio

Crankcase heating

Oil return management

Scroll compressors are machines with xed

volume ratio, and operate more eciently

near the design pressure ratio. In the extreme,

do not exceed a 7.5:1 pressure ratio (absolute

discharge pressure to absolute suction pressure)

A crankcase heating function can be provided

by injecting a DC current in the motor of the

compressor, to keep the compressor warm, and

avoid liquid migration during o cycle.

A specic function can be enabled to secure

the oil return to the compressor. When the

compressor is running at minimum speed for

for extended periods. The Danfoss VRJ scroll

compressor is equipped with an internal pressure

relief valve for protection against blocked

condenser and fan failure conditions.

Refer to “Danfoss VRJ Installation and Operation

instructions” for details.

extended periods, every half hour, speed will be

increased to 2400 rpm for a 80 seconds period.

13AB141686422149en-US0301

Page 14

Application Guidelines

Operating conditions

On/o cycling

(cycle rate limit)

Start-up sequence To ensure correct lubrication of all the

The on/o cycling protection is included in the

variable speed drive. There is no need for extra

on/o cycling protection.

mechanical parts, VRJ compressors start with

a dened ramp-up, and stay at a xed speed

for some seconds. Then the compressor speed

increases up to the desired set point according to

capacity request.

14 AB141686422149en-US0301

Page 15

Application Guidelines

U-trap, as short as possible

System design recommendations

General

Essential piping design considerations

Successful application of scroll compressors

is dependent on careful selection of the

compressor for the application. If the compressor

is not correct for the system, it will operate

Proper piping practices should be employed to

ensure adequate oil return, even under minimum

load conditions with special consideration given

to the size and slope of the tubing coming

from the evaporator. Tubing returns from the

evaporator should be designed so as not to trap

oil and to prevent oil and refrigerant migration

back to the compressor during o-cycles.

It is particularly important and critical with

variable capacity systems, where very low

velocities can be achieved for long periods of

time, generating oil return issues.

If the evaporator lies above the compressor, as

is often the case in split or remote condenser

systems, the addition of a pump-down cycle

is strongly recommended. If a pump-down

cycle were to be omitted, the suction line must

have a loop at the evaporator outlet to prevent

refrigerant from draining into the compressor

during o-cycles.

If the evaporator were situated below the

compressor, the suction riser must be trapped so

as to prevent liquid refrigerant from collecting at

the thermal bulb location (see g. 1).

beyond the limits given in this manual. Poor

performance, reduced reliability, or both may

result.

When the condenser is mounted at a higher

position than the compressor, a suitably sized

«U»-shaped trap close to the compressor is

necessary to prevent oil leaving the compressor

from draining back to the discharge side of the

compressor during o cycle. The upper loop also

helps avoid condensed liquid refrigerant from

draining back to the compressor when stopped

(see g. 2). The maximum elevation dierence

between the indoor and outdoor section

cannot exceed 26 feet. System manufacturers

should specify precautions for any applications

that exceed these limits to ensure compressor

reliability.

Piping should be designed with adequate three-

dimensional exibility. It should not be in contact

with the surrounding structure, unless a proper

tubing mount has been installed. This protection

proves necessary to avoid excess vibration, which

can ultimately result in connection or tube failure

due to fatigue or wear from abrasion. Aside from

tubing and connection damage, excess vibration

may be transmitted to the surrounding structure

and generate an unacceptable noise level within

that structure as well (for more information on

noise and vibration, see the section on: “Sound

and vibration management” section.

g.1

max. 13 ft

max. 13 ft

0.5 % slope,

13 ft/s or more

U-trap, as short as possible

26 to 40 ft/s

0.5 % slope,

13 ft/s or more

U-trap

Evaporator

To condenser

g. 2

Upper loop

Condenser

HP

U-trap

LP

3D exibility

15AB141686422149en-US0301

Page 16

Application Guidelines

Saturated suction temp. °F

System design recommendations

Refrigerant charge limit

Reversible heat pump systems

Minimum sump superheat

Scroll compressors can tolerate liquid refrigerant

up to a certain extend without major problems.

However, excessive liquid refrigerant in the

compressor is always unfavourable for service

life. Besides, the installation cooling capacity may

be reduced because of the evaporation taking

place in the compressor and/or the suction line

Transients are likely to occur in reversible heat

pump systems, i.e. a changeover cycle from

cooling to heating, defrost or low-load short

cycles. These transient modes of operation may

lead to liquid refrigerant carryover (or ood

back) or excessively wet refrigerant return

conditions. As such, reversible cycle applications

The minimum sump temperature is in the range

from 10°F to 30°F above saturated suction

Floodback requirement

40

35

instead of the evaporator. System design must be

such that the amount of liquid refrigerant in the

compressor is limited. In this respect, follow the

guidelines given in the section: “Essential piping

design recommendations” in priority.

require specic precautions for ensuring a long

compressor life and satisfactory operating

characteristics. Specic tests for repetitive ood

back are required to conrm whether or not

special system design considerations should be

considered.

temperature. Refer to the ood back test criteria.

Preventing liquid ood back

30

25

Acceptable

20

15

Sump superheat, °F

10

5

0

-10 0 10 20 30 40 50 55

Danfoss recommends the use of an electronic

expansion valve for all air conditioning and heat

pump applications with VRJ compressors. An

Exceptions to the use of EXV’s with Danfoss

VRJ must be approved by Danfoss application

engineering.

EXV has two key benets: it provides modulating

control of the system under varying load

conditions, and it protects the compressors from

ood back during adverse running conditions.

Unacceptable

16 AB141686422149en-US0301

Page 17

Application Guidelines

System design recommendations

Water utilising systems Apart from residual moisture in the system

after commissioning, water could also enter the

refrigeration circuit during operation. Water in

the system shall always be avoided. Not only

because it can shortly lead to electrical failure,

sludge in sump and corrosion but in particular

because it can cause serious safety risks.

Common causes for water leaks are corrosion and

freezing.

Corrosion: Materials in the system shall be

compliant with water and protected against

corrosion.

Loss of charge protection

Oil level checking and top-up

VRJ scroll compressors together with the variable

speed drive include a loss of charge protection

function. This protection is ensured if pressure

In installations with good oil return and line

runs up to 50 ft, no additional oil is required. If

installation lines exceed 50 ft, additional oil may

be needed. 1 or 2% of the total system refrigerant

charge (in weight) can be used to roughly dene

the required oil top-up quantity.

Freezing: When water freezes into ice its volume

expands which can damage heat exchanger

walls and cause leaks. During o periods water

inside heat exchangers could start freezing when

ambient temperature is lower than 32°F. During

on periods ice banking could occur when the

circuit is running continuously at too low load.

Both situations should be avoided by connecting

a pressure and thermostat switch in the safety

line.

and temperature sensors are connected to the

drive.

Always use oil from new cans.

Top-up the oil while the compressor is idle. Use

any accessible connector on the compressor

suction line and a suitable pump.

17AB141686422149en-US0301

Page 18

Application Guidelines

Sound and vibration management

Starting sound level

Running sound level

During start-up transients, it is natural for the

compressor sound level to be slightly higher

than during normal running. Danfoss scroll

VRJ scroll compressors are designed with

optimised discharge ports and wrap geometry

Sound level vs Speed

78

76

74

72

70

68

66

64

62

Sound power level (dBA)

60

58

56

45/130

4200

45/130

3600

Condition (Tsat(suction) / Tsat (discharge) and speed (RPM)

45/100

compressors exhibit very little increased start-up

transient sound.

to reduce the sound level when a compressor is

running.

3600

45/100

2400

45/100

1800

45/100

900

Stopping sound level

Sound generation in a refrigeration system and air conditioning system

Compressor sound radiation

VRJ scroll compressors have very low shutdown

sound due to minimal volume of discharge

volume to push scrolls in reverse at shutdown.

Typical sound and vibration in refrigeration and

air conditioning systems encountered by design

and service engineers may be broken down into

the following three source categories.

Sound radiation: This generally takes an

airborne path.

Mechanical vibrations: These generally extend

For sound radiating from the compressor, the

emission path is airborne and the sound waves

are travelling directly from the machine in all

directions.

The VRJ scroll compressor is designed to be quiet

and the frequency of the sound generated is

pushed into the higher ranges, which not only

are easier to reduce but also do not generate the

penetrating power of lower-frequency sound.

Use of sound-insulation materials on the inside of

unit panels is an eective means of substantially

Due to this small re-expansion, there is no

internal break mechanism required to prevent

reverse spin of the scroll set.

along the parts of the unit and structure.

Gas pulsation: This tends to travel through the

cooling medium, i.e. the refrigerant.

The following sections will focus on the causes

and methods of mitigation for each of the above

sources.

reducing the sound being transmitted to the

outside. Ensure that no components capable

of transmitting sound/vibration within the unit

come into direct contact with any non-insulated

parts on the walls of the unit.

Because of the Danfoss unique design of a full-

suction gas & oil cooled motor, compressor body

insulation across its entire operating range is

possible.

18 AB141686422149en-US0301

Page 19

Application Guidelines

Sound and vibration management

Mechanical vibrations

Speed bypass

Gas pulsation

Vibration isolation constitutes the primary

method for controlling structural vibration. VRJ

scroll compressors are designed to produce

minimal vibration during operations. The use

of rubber isolators on the compressor base

plate is very eective in reducing vibration

being transmitted from the compressor to

the unit. Rubber grommets are supplied with

all Danfoss compressors. Once the supplied

rubber grommets have been properly mounted,

vibrations transmitted from the compressor base

plate to the unit are held to a strict minimum.

In addition, it is extremely important that the

frame supporting the mounted compressor be

of sucient mass and stiness to help dampen

any residual vibration potentially transmitted to

the frame. The tubing should be designed so as

If vibrations still occur at some typical

frequencies, a speed bypass function is available

within the VRJ. This function allows avoiding

The VRJ scroll compressor has been designed

and tested to ensure that gas pulsation has been

optimised for the most commonly encountered

air conditioning pressure ratio. On heat pump

installations and other installations where the

pressure ratio lies beyond the typical range,

testing should be conducted under all expected

to both reduce the transmission of vibrations to

other structures and withstand vibration without

incurring any damage. Tubing should also be

designed for three-dimensional exibility.

During unit development, the complete

compressor speed range should be covered, in

order to dene if abnormal vibrations occur or

not. As ultimate solution, speed bypass can be

applied.

For more information on piping design, please

see the section entitled “Essential piping design

considerations”.

some frequency ranges and avoiding vibrations

to occur. Refer to “Danfoss VRJ Installation and

Operation instructions” for setting details.

conditions and operating congurations to

ensure that minimum gas pulsation is present. If

an unacceptable level is identied, a discharge

muer with the appropriate resonant volume

and mass should be installed. This information

can be obtained from the component

manufacturer.

19AB141686422149en-US0301

Page 20

Application Guidelines

Installation

Each VRJ scroll compressor is shipped with

printed Instructions for installation.

System cleanliness

Compressor handling and storage

The refrigerant compression system, regardless

of the type of compressor used, will only provide

high eciency and good reliability, along with a

long operating life, if the system contains solely

the refrigerant and oil it was designed for. Any

other substances within the system will not

improve performance and, in most cases, will be

highly detrimental to system operations.

The presence of non-condensable substances

and system contaminants, such as metal

shavings, solder and ux, has a negative impact

on compressor service life. Many of these

contaminants are small enough to pass through a

mesh screen and can cause considerable damage

within a bearing assembly. The use of highly

hygroscopic PVE oils in R410A compressors

requires that the oil be exposed to the

atmosphere just as little as possible.

Compressors are provided with a lifting lug. This

lug should always be used to lift the compressor.

Once the compressor is installed, the lifting

lug should never be used to lift the complete

installation. The compressor must be handled

System contamination is one of main factors

aecting equipment reliability and compressor

service life. It is important therefore to take

system cleanliness into account when assembling

a refrigeration system.

During the manufacturing process, circuit

contamination may be caused by:

• Brazing and welding oxides,

• Filings and particles from the removal of

burrs in pipe-work,

• Brazing ux,

• Moisture and air.

Consequently, when building equipment and

assemblies, the following precautions must be

taken: never drill holes into the pipe-work after

installation.

with caution in the vertical position, with a

maximum inclination of 15° from vertical. Store

the compressor between -30°F and 120°F, not

exposed to rain or corrosive atmosphere.

Compressor mounting

Compressor holding charge

Tube brazing procedure

Brazing material

Maximum inclination from the vertical plane,

while operating must not exceed 7 degrees.

All compressors are delivered with 4 rubber

Each compressor is shipped with a nominal dry

nitrogen holding charge between 6 psi and 10

psi, and is sealed with elastomeric plugs. The

plugs should be removed with care to avoid oil

loss when the holding charge is released. Remove

the suction plug rst and the discharge plug

Do not bend the compressor discharge or suction

lines or force system piping into the compressor

connections, because this will increase

For copper suction and discharge ttings, use

copper-phosphorus brazing material. Sil-Fos® and

other silver brazing materials are also acceptable.

grommets and metal sleeves. Compressors must

always be mounted with these grommets.

afterwards. The plugs shall be removed only

just before connecting the compressor to the

installation in order to avoid moisture entering

the compressor. When the plugs are removed, it

is essential to keep the compressor in an upright

position to avoid oil spillage.

stresses that are a potential cause of failure.

Recommended brazing procedures and material,

are described on following page.

If ux is required for the brazing operation, use

coated rod or ux core wire. To avoid system

contamination, do not brush ux on.

20 AB141686422149en-US0301

Page 21

Application Guidelines

Installation

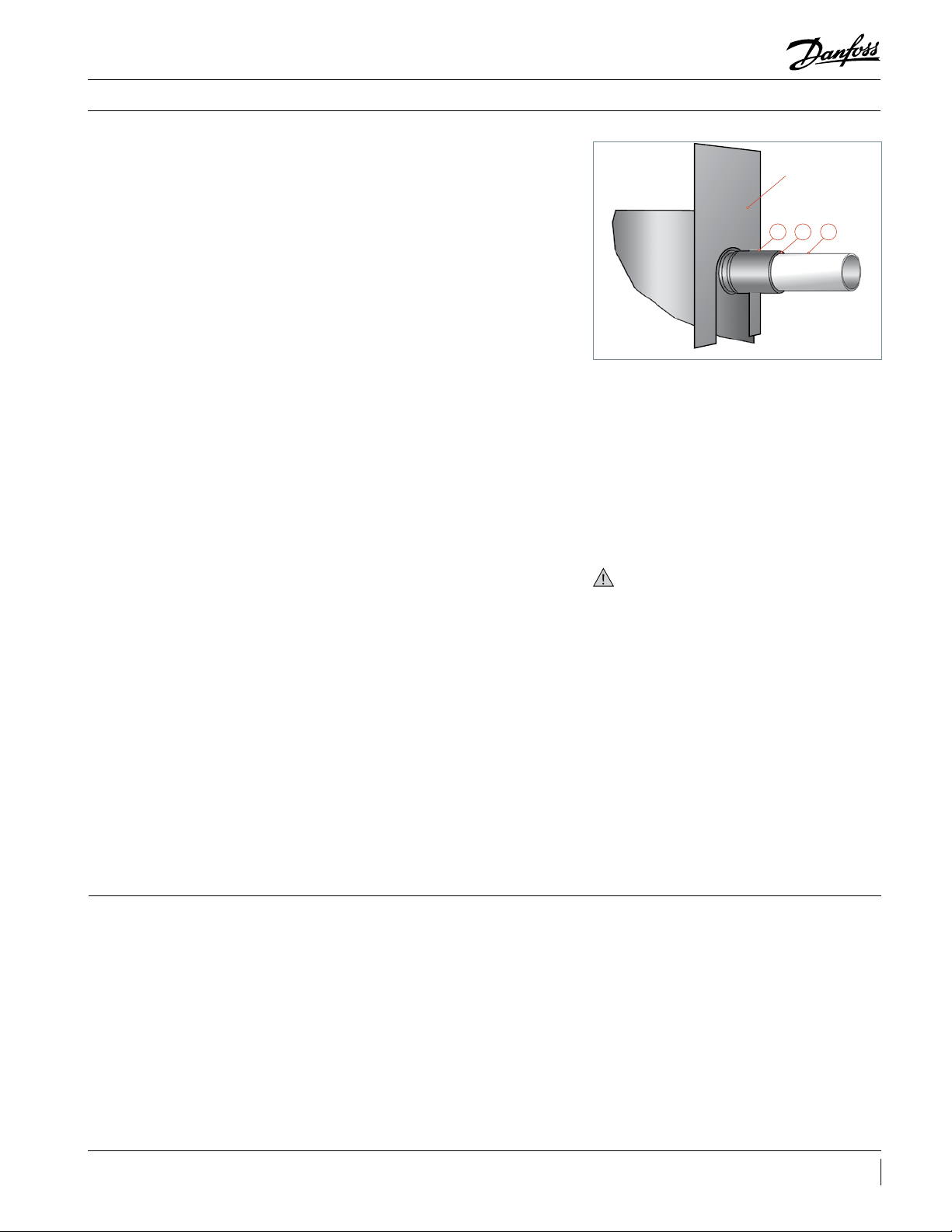

Compressor connection

When brazing the compressor ttings, do not

overheat the compressor shell, which could

severely damage certain internal components

due to excessive heating. Use of a heat shield

and/or a heat-absorbent compound is highly

recommended. For brazing the suction and

discharge connections, the following procedure

is advised:

• Make sure that no electrical wiring is

connected to the compressor.

• Protect the terminal box and compressor

painted surfaces from torch heat damage

(see diagram).

• Use only clean refrigeration-grade copper

tubing and clean all connections.

• Purge nitrogen or CO2 through the

compressor in order to prevent against

oxidation and ammable conditions. The

compressor should not be exposed to the

open air for extended periods.

• Use of a double-tipped torch is

recommended.

• Apply heat evenly to area A until the brazing

temperature is reached. Move the torch

to area B and apply heat evenly until the

brazing temperature has been reached there

as well, and then begin adding the brazing

material. Move the torch evenly around

the joint, in applying only enough brazing

material to ow the full circumference of the

joint.

• Move the torch to area C only long enough

to draw the brazing material into the joint,

but not into the compressor.

• Remove all remaining ux once the joint has

been soldered with a wire brush or a wet

cloth. Remaining ux would cause corrosion

of the tubing.

Heat shield

C B A

Ensure that no ux is allowed to enter into the

tubing or compressor. Flux is acidic and can cause

substantial damage to the internal parts of the

system and compressor.

The PVE oil used in VRJ compressors is highly

hygroscopic and will rapidly absorb moisture

from the air. The compressor must therefore not

be left open to the atmosphere for a long period

of time. The compressor tting plugs shall be

removed just before brazing the compressor.

Before eventual unbrazing the compressor

or any system component, the refrigerant charge

must be removed from both the high and low

pressure sides. Failure to do so may result in

serious personal injury. Pressure gauges must be

used to ensure all pressures are at atmospheric

level.

For more detailed information on the appropriate

materials required for brazing or soldering, please

contact the product manufacturer or distributor.

For specic applications not covered herein,

please contact Danfoss Commercial Compressors

for further information.

Vacuum evacuation and moisture removal

Moisture obstructs the proper functioning

of both the compressor and the refrigeration

system.

Air and moisture reduce service life and

increase condensing pressure, which causes

abnormally high discharge temperatures that

are then capable of degrading the lubricating

properties of the oil. The risk of acid formation

is also increased by air and moisture, and this

condition can also lead to copper plating. All

these phenomena may cause both mechanical

and electrical compressor failures. The typical

method for avoiding such problems is a vacuum

pump-down executed with a vacuum pump, thus

creating a minimum vacuum of 0.02 in Hg (500

µm Hg). Please refer to Bulletin “Vacuum pump

down and dehydration procedure”.

Be sure to follow all government regulations

regarding refrigerant reclamation and storage.

21AB141686422149en-US0301

Page 22

Application Guidelines

Installation

Liquid line lter driers A properly sized lter drier is required for all

Danfoss scroll applications. Danfoss recommends

DML (100% molecular sieves) driers for HFC

refrigerants R410A with PVE oil. For servicing

of existing installations where acid formation is

present the Danfoss DCL solid core lter driers

Refrigerant charging

Insulation resistance and dielectric strength

It is recommended that system charging be

done using the weighed charge method, adding

refrigerant to the high side of the system.

Charging the high and low sides of a system with

gas simultaneously at a controlled rate is also an

acceptable method.

Insulation resistance must be greater than 1

megohm when measured with a 500 volt direct

current megohm tester.

Each compressor motor is tested at the factory

with a high potential voltage (hi-pot) that

exceeds the UL requirement both in potential

and in duration. Leakage current is less than 0.5

mA.

VRJ scroll compressors are congured with

the pump assembly at the top of the shell,

and the motor below. As a result, the motor

containing activated alumina are recommended.

The drier is to be over sized rather than under

sized. When selecting a drier, always take into

account its capacity (water content capacity),

the system refrigeration capacity and the system

refrigerant charge.

Never exceed the recommended system charge

mentioned by the unit manufacturer, and never

charge liquid to the low pressure side.

can be partially immersed in refrigerant and

oil. The presence of refrigerant around the

motor windings will result in lower resistance

values to ground and higher leakage current

readings. Such readings do not indicate a faulty

compressor, and should not be cause for concern.

In testing insulation resistance, Danfoss

recommends that the system be rst operated

briey to distribute refrigerant throughout the

system. Following this brief operation, retest the

compressor for insulation resistance or current

leakage.

Compressor replacement after motor burn out

If there has been a motor burnout follow the

evacuation procedure described on previous

page. Remove and replace the liquid line lter

drier and install a Danfoss type DAS burnout drier

of appropriate capacity.

Refer to the DAS drier instructions and technical

information on correct use and monitoring of the

burnout drier and the liquid line and suction line

lter driers.

22 AB141686422149en-US0301

Page 23

Application Guidelines

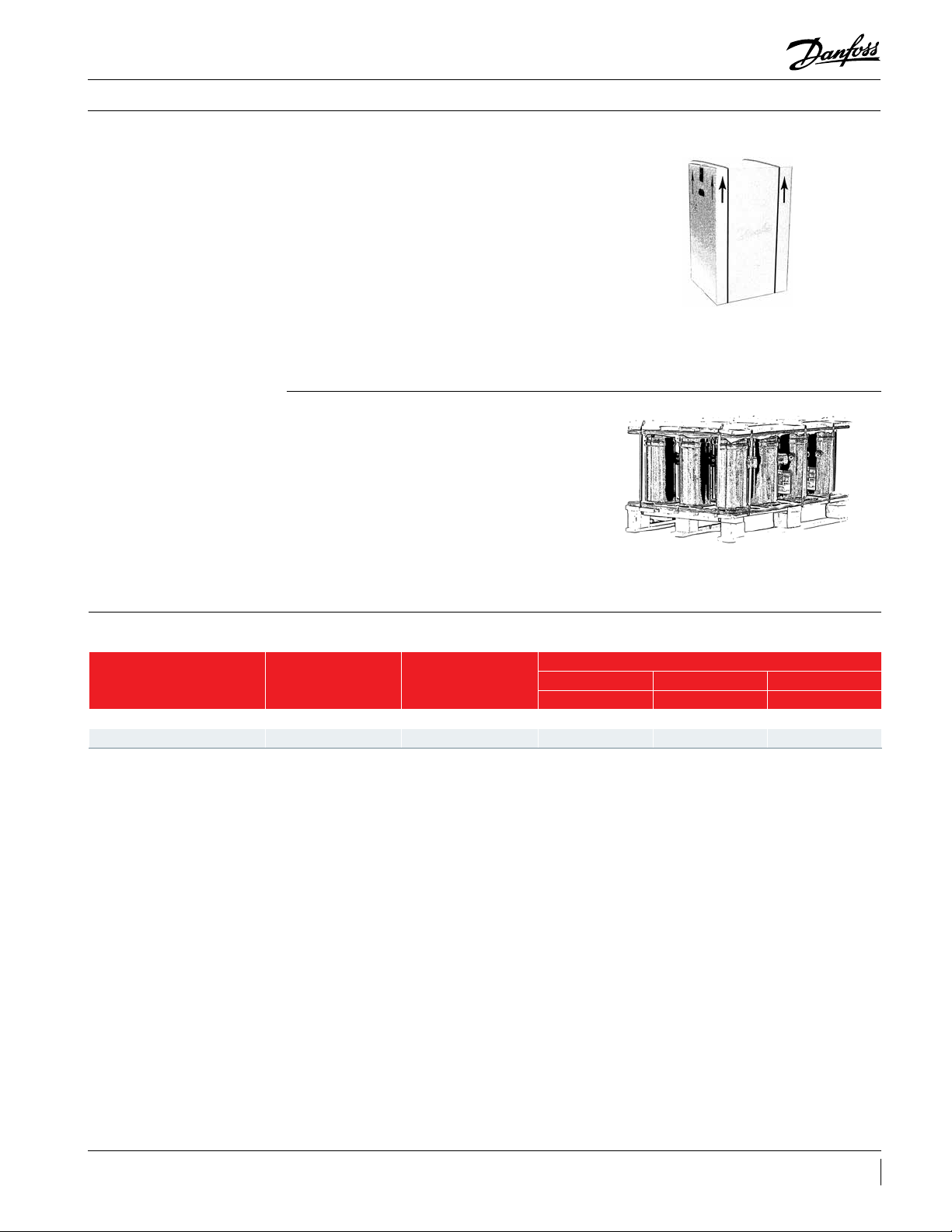

Packaging

Single pack

Ordering information and packaging

Compressors are packed individually in a

cardboard box. They can be ordered in any

quantity. Minimum ordering quantity = 1.

As far as possible, Danfoss will ship the boxes on

full pallets of 9 compressors.

Each box contains following accessories:

• 4 grommets

• 4 assemblies of self tapping US thread bolts,

washers and sleeves

Industrial pack

Ordering code numbers

Compressor model

Single pack Yes 1 120G0283 120G0291 120G0299

Industrial pack Yes 12 120G0284 120G0292 120G0300

Compressors are not packed individually but are

shipped all together on one pallet. They can be

ordered in quantities of full pallets only, multiples

12 compressors.

Industrial pack pallet, with mounting hardware,

contains following accessories:

• 4 grommets per compressor

• 4 sleeves per compressor

Mounting hardware

included

Qty of compressors

Code number

3 Tons 4 Tons 5 Tons

VRJ028 VRJ035 VRJ044

23AB141686422149en-US0301

Page 24

Danfoss Commercial Compressors

Danfoss Inverter Scrolls

is a worldwide manufacturer of compressors and condensing units for refrigeration and HVAC applications. With a wide range of

high quality and innovative products we help your company to find the best possible energy efficient solution that respects the

environment and reduces total life cycle costs.

We have 40 years of experience within the development of hermetic compressors which has brought us amongst the global

leaders in our business, and positioned us as distinct variable speed technology specialists. Today we operate from engineering

and manufacturing facilities spread across three continents.

Danfoss Turbocor Compressors

Our products can be found in a variety of applications such as rooftops, chillers, residential air conditioners,

heatpumps, coldrooms, supermarkets, milk tank cooling and industrial cooling processes.

http://danfoss.us.com

Danfoss Commercial Compressors, BP 331, 01603 Trévoux Cedex, France | +334 74 00 28 29

AB141686422149en-US0301

Danfoss Scrolls

Danfoss Optyma Condensing Units

Danfoss Maneurop Reciprocating Compressors

Secop Compressors for Danfoss

© Danfoss | DCS | 2020.12

Loading...

Loading...