Application guidelines

Inverter scroll compressors

VZH hybrid manifold VZH Gen3+DSH

R410A

http://cc.danfoss.com

Contents

GENERAL INFORMATION ....................................................................................................4

Scope ...................................................................................................................................................................................... 4

Benefits .................................................................................................................................................................................. 4

PRODUCT INFORMATION ...................................................................................................5

Oil management concept ....................................................................................................5

System configuration .......................................................................................................................................................5

Dimensions ...........................................................................................................................8

Tandem .................................................................................................................................................................................. 8

Design pipe .......................................................................................................................................................................... 9

General requirements ...................................................................................................................................................... 9

Suction separator .............................................................................................................................................................11

Oil equalization design .................................................................................................................................................. 11

Design compressor mounting ..........................................................................................12

General requirements ....................................................................................................................................................12

VZH178H Mounting feet ................................................................................................................................................ 12

VZH208H Mounting feet ............................................................................................................................................... 12

VZH257H / VZH278H Mounting feet .........................................................................................................................12

VZH301H Mounting feet ................................................................................................................................................13

VZH410H / VZH465H Mounting feet .........................................................................................................................13

VZH354H Mounting kit .................................................................................................................................................. 13

Design oil level sensor .......................................................................................................14

General requirements ....................................................................................................................................................14

Manage operating envelope .............................................................................................15

Requirement ...................................................................................................................................................................... 15

Manage speed limit ............................................................................................................16

General requirements ....................................................................................................................................................16

Manage superheat .............................................................................................................17

Requirement ...................................................................................................................................................................... 17

System evaluation ...........................................................................................................................................................17

Test, criteria and solutions ............................................................................................................................................ 17

Manage off-cycle migration ..............................................................................................19

Requirement ...................................................................................................................................................................... 19

System evaluation ...........................................................................................................................................................19

Refrigerant charge limit table ..................................................................................................................................... 19

Manage oil in the circuit ................................................................................................... 20

Oil management system for hybrid manifolding ................................................................................................20

Oil management logic ...................................................................................................................................................20

Requirement ......................................................................................................................................................................21

System evaluation ...........................................................................................................................................................21

Test, criteria and solutions ............................................................................................................................................21

Control logic ...................................................................................................................... 22

Safety control logic requirements .............................................................................................................................22

Short cycle protection....................................................................................................................................................22

Defrost logic recommendations ................................................................................................................................23

Pump-down logic recommendations ......................................................................................................................23

Assembly line procedure .................................................................................................. 24

Handling ..............................................................................................................................................................................24

Ordering information .....................................................................................................................................................25

ORDERING INFORMATION .............................................................................................. 25

Compressor ordering codes ........................................................................................................................................25

Accessory ordering codes .............................................................................................................................................25

Accessories ......................................................................................................................... 26

Annex ................................................................................................................................. 28

3AB298632269085en-000401

General information

Scope

Benefits

The application guideline describes the operating

characteristics, design features and application

requirements for hybrid manifolding of the

Danfoss DSH fixed-speed compressor and the

VZH inverter compressor in air-conditioning and

heat pump applications.

To ensure proper parallel installation and running

conditions, the following recommendations must

be followed:

A parallel compressor installation refers to a

system of interconnected compressors with a

common suction line and a common discharge

line. The technique of mounting compressors

in parallel is also called manifolding. The hybrid

manifolding in this application guideline refers

to the manifolding of the Danfoss inverter

compressor (VZH) and fixed speed compressor

(DSH), which has several benefits.

• It is essential to respect all the instructions

given in these guidelines; please refer to

the instruction leaflet supplied with each

compressor and the application guidelines for

single compressors.

• For additional system components related to

specific application requirements, the supplier

recommendations must always be respected.

The main reason is reduced operating cost

through controlling capacity and power

consumption to a greater extent. This is achieved

by both staggering the compressor switch-on

sequences and regulating the speed of the

inverter compressor which allows the parallel

system to continuously match its power with the

capacity needed.

PRODUCT INFORMATIONSYSTEM DESIGNORDERING INFORMATION GENERAL INFORMATION

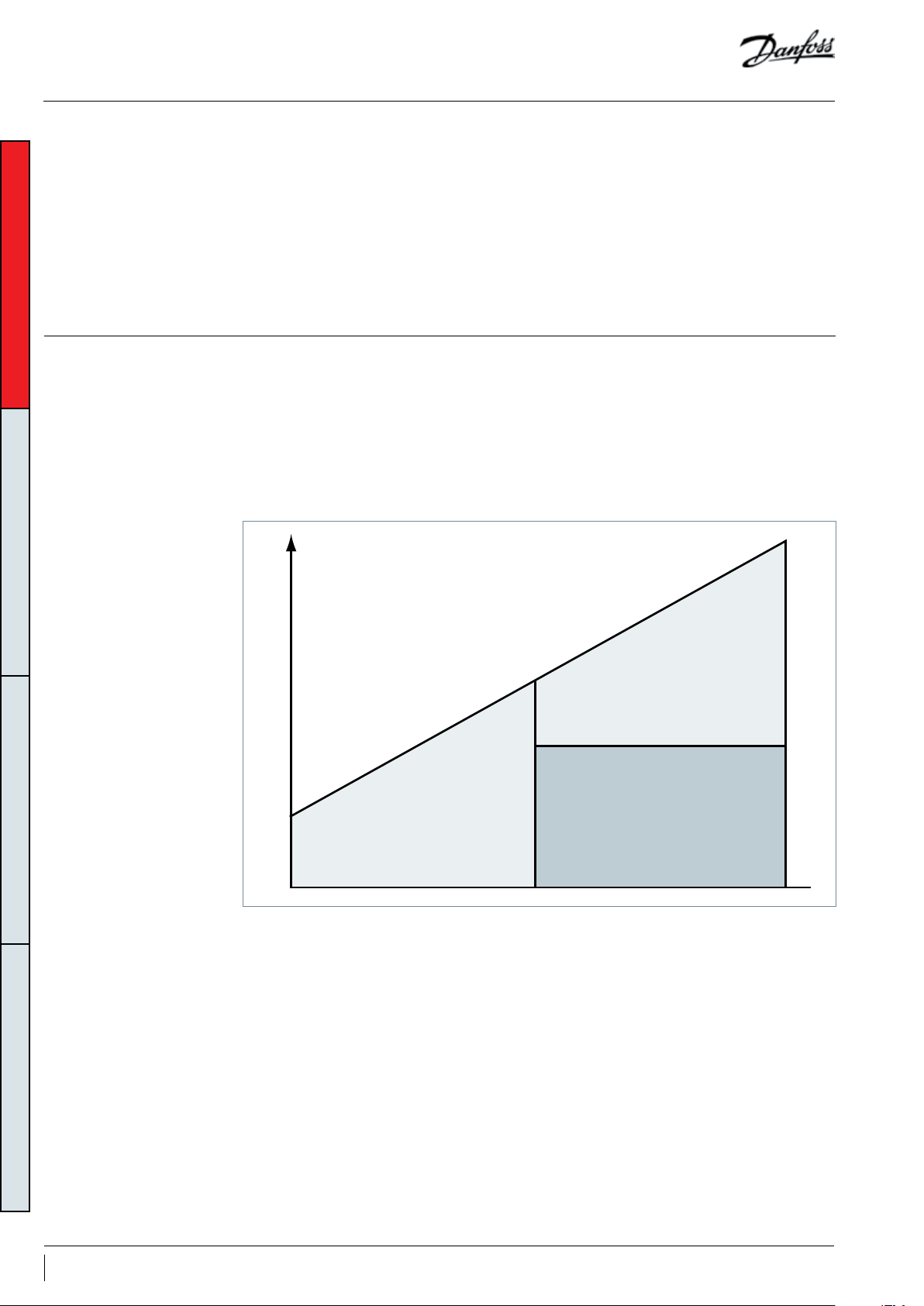

Capacity

Compressor n°1

VZH 25-100 rps

A second reason for manifolding the inverter

compressor and the fixed speed compressor is

improved part-load efficiency. In the variable

speed+fixed speed parallel installation,

the system can run either only the inverter

compressor at lower load or both the inverter and

fixed speed compressors at a higher load with the

fixed speed compressor operating at 100% load.

Compressor n°1

VZH 25-100 rps

Compressor n°2

xed speed DSH

Therefore, it will be possible to achieve a higher

part-load efficiency.

Thirdly, the capacity of the hybrid manifolding

system can be widely regulated, for example 10%

to 100%. The continuous capacity regulation

allows for accurate temperature control and a

comfortable indoor environment.

4 AB298632269085en-000401

Oil management concept

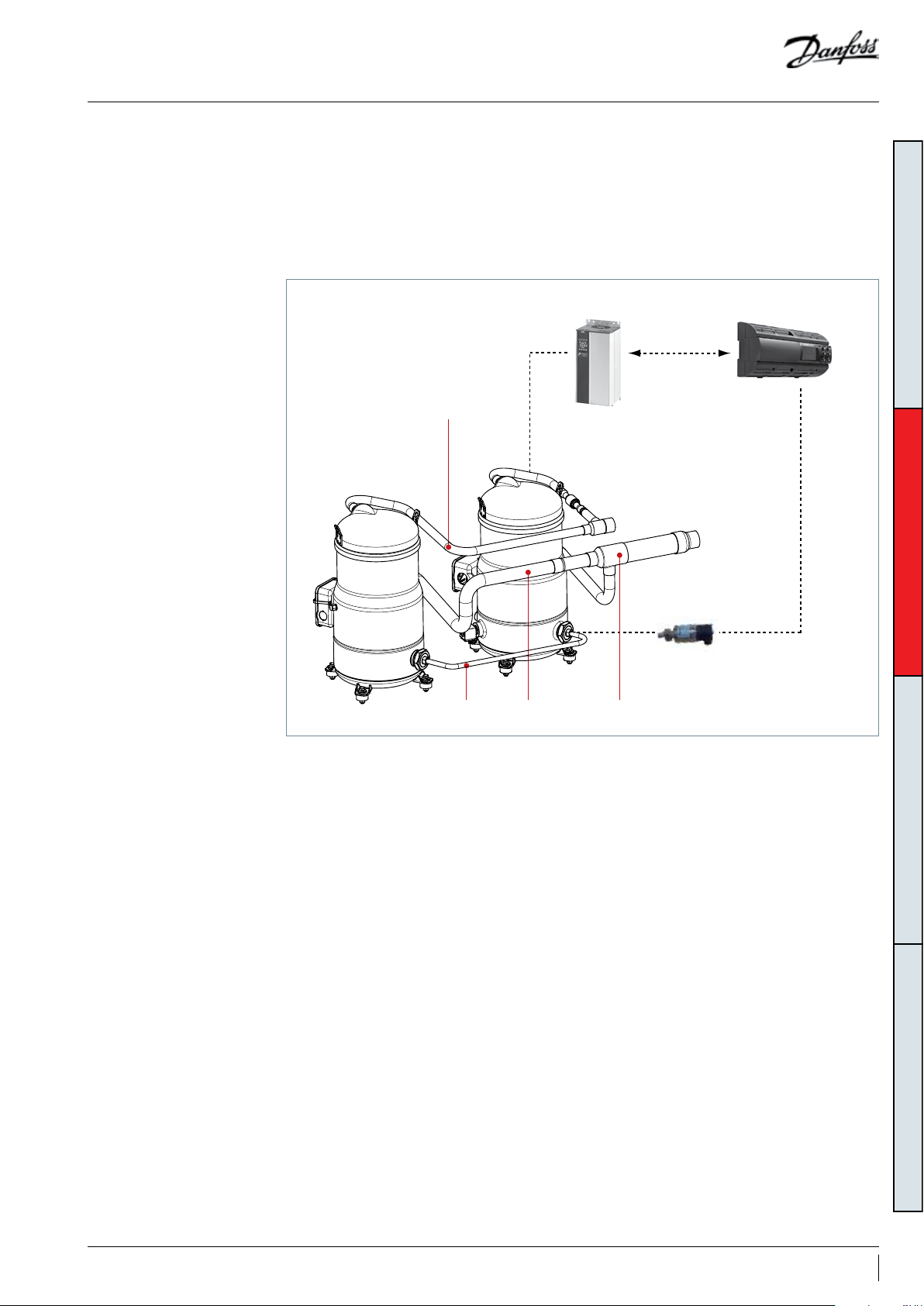

System configuration

Hybrid manifolding systems use the dynamic

system for oil balance. The suction connections

between the two individual compressors are

interconnected by a special suction separator

design that allows most of oil feed into variable

speed compressors.

Discharge line

VZH

VZH

DSH

DSH

An optical-electrical oil level sensor fixed in

a variable speed compressor monitors the

compressor oil level.

If the oil level drops below the limit, the OEM

main controller activates the oil management

logic.

Drive

ModBus

OEM main controller

GENERAL INFORMATIONSYSTEM DESIGNORDERING INFORMATION PRODUCT INFORMATION

Oil equalization tube Suction separatorSuction line

Optical oil

level sensor

5AB298632269085en-000401

Oil management concept

FS

Return

Gas

Oil-rich gas flow

Oil poor gas flow

VS

FS VS

GENERAL INFORMATIONSYSTEM DESIGNORDERING INFORMATION PRODUCT INFORMATION

Downstream

compressor

Upstream

compressor

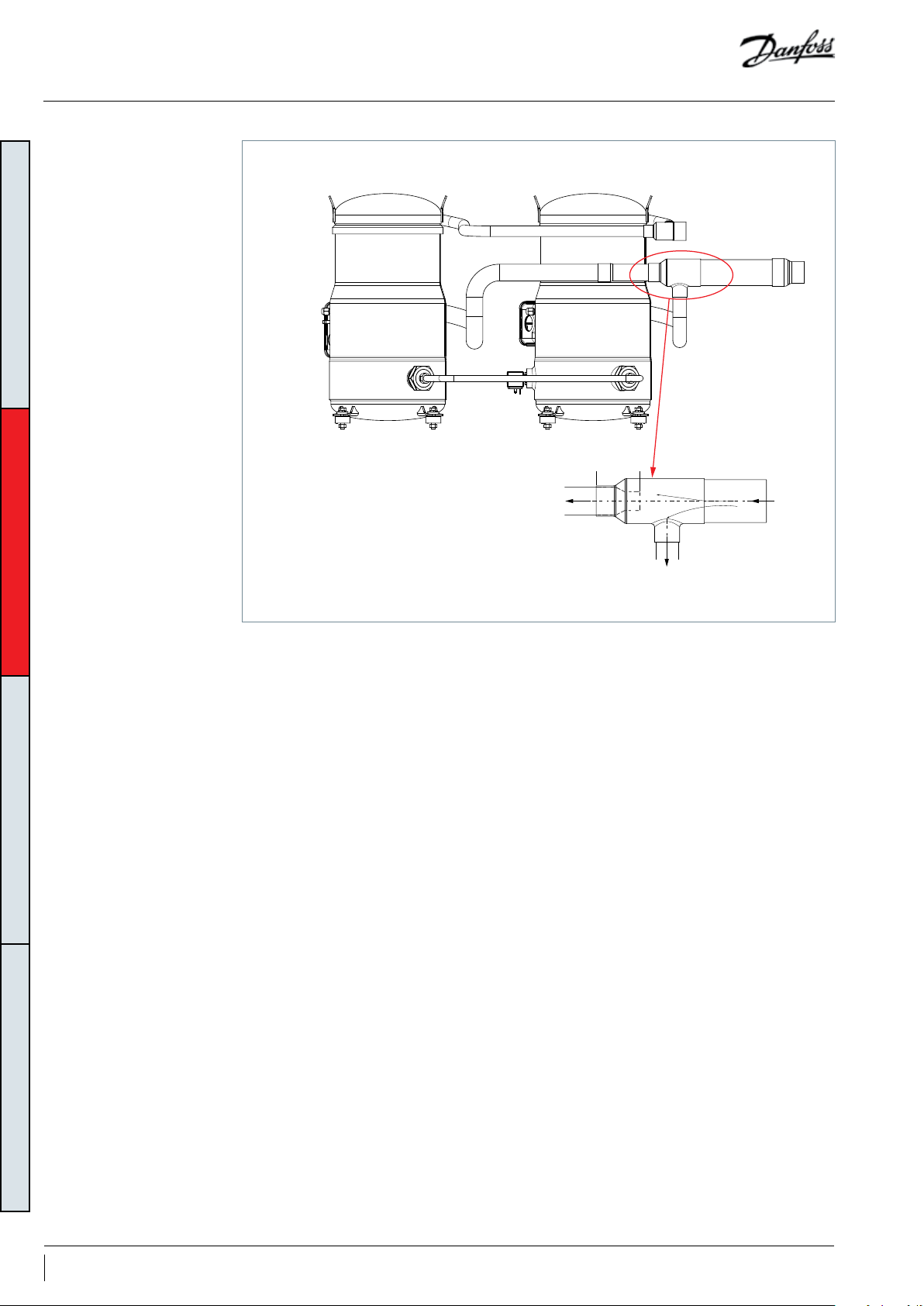

The hybrid manifolding system uses the dynamic

system for oil balance.

The suction connections of the two individual

compressors are interconnected by a suction

separator that integrates with the suction oil

separator and the gas restrictor. The variable

speed compressor (VS) is installed in the

upstream position which appears first on suction

line and fixed speed compressor (FS) is installed

on downstream position.

The oil which clings back along the main suction

line is separated by the suction separator which

Suction separator (Oil separator/gas restrictor)

returns most of the oil in the suction gas to the

upstream compressor. The suction separator

creates a slight pressure drop to ensure lower

sump pressure between two compressors are

well balance when fixed speed compressor

is ON and the inverter compressor is running

at maximum speed. When the variable speed

compressor runs at any frequency below

maximum speed, the sump pressure in the fixed

speed compressor is lower than the variable

speed compressor, and driven by the sump

pressure difference, the excess oil from the

variable speed compressor runs into the fixed

speed compressor sump.

6 AB298632269085en-000401

Oil management concept

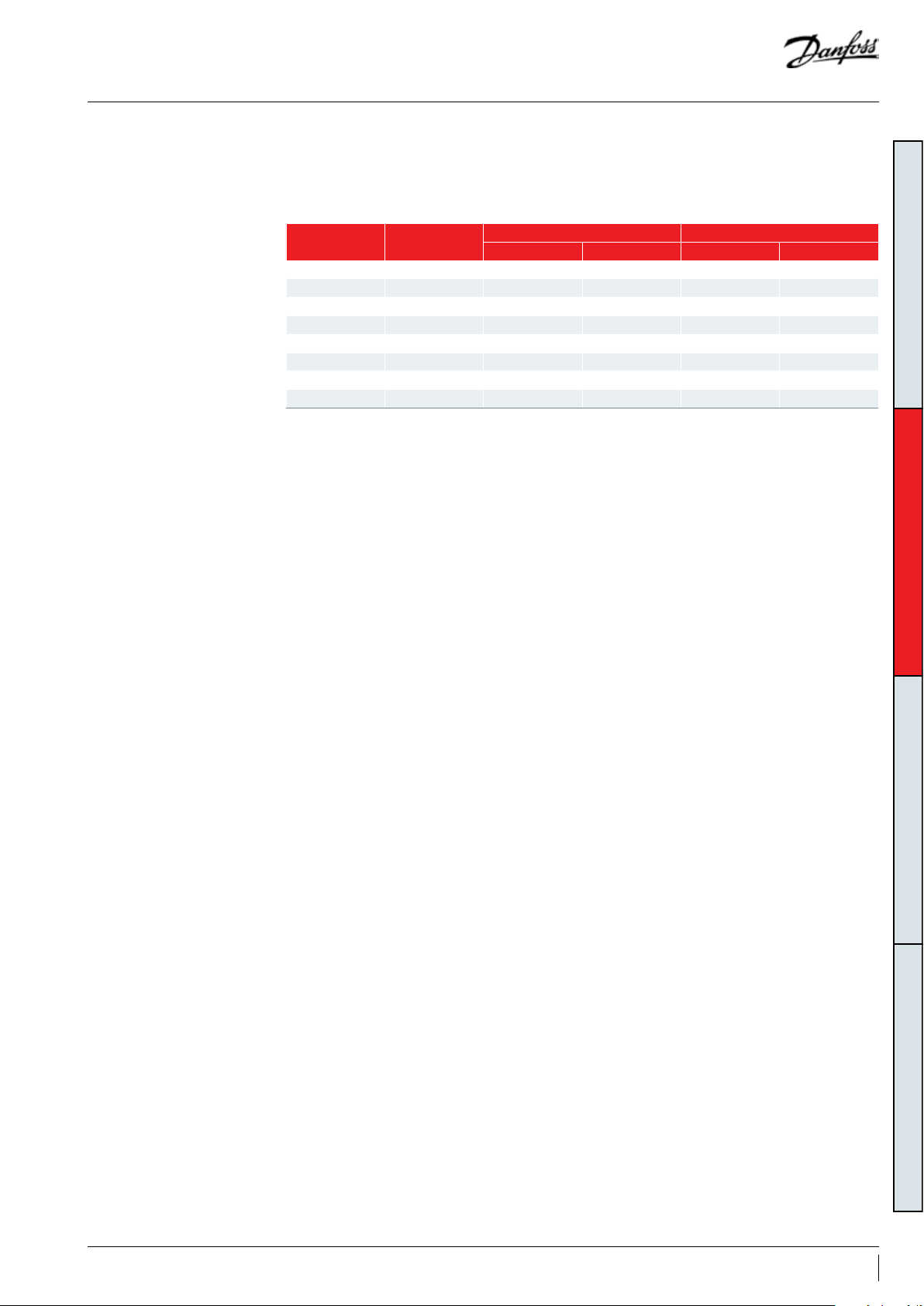

Approved hybrid tandem

configurations and

capacity range

Different configurations of hybrid tandems are possible. All VZH models (high/low pressure ratio/

different voltage) could be manifolded with fixed speed compressors.

Danfoss VSD : VZH compressor DriveTM 380-480 Volt

Model Description

VZH178 H VZH088+DSH90 68.9 19.6 73.9 21.0

VZH208H VZH088+DSH120 77.7 22.1 83.7 23.8

VZH257H VZH117+DSH140 9 7. 8 27.8 105. 2 29.9

VZH278H VZH117+DSH161 101.6 28.9 110.1 31.3

VZH301H V ZH117+DSH184 106.2 30.2 115 .7 32.9

VZH354H VZH170+DSH18 4 137 39.1 146 41.9

VZ H410H VZH170+DSH240 151.9 43.2 164.9 46.9

VZH465H VZH170+DSH295 164.6 46.8 179. 3 51

TR: Ton of Refrigeration Refrigerant: R410A

Standard rating conditions: ARI standard Evaporating temperature: 7.2°C Superheat: 11.1k

Condensing temperature: 54.4°C Subcooling: 8.3k

Subject to modification without prior notification

Data given for motor code G compressor – for full data details and capacity tables, please refer to Coolselector2

www.coolselector.danfoss.com

FS: 50Hz, VS:100Hz FS: 60Hz, VS: 100Hz

kW TR kW TR

GENERAL INFORMATIONSYSTEM DESIGNORDERING INFORMATION PRODUCT INFORMATION

7AB298632269085en-000401

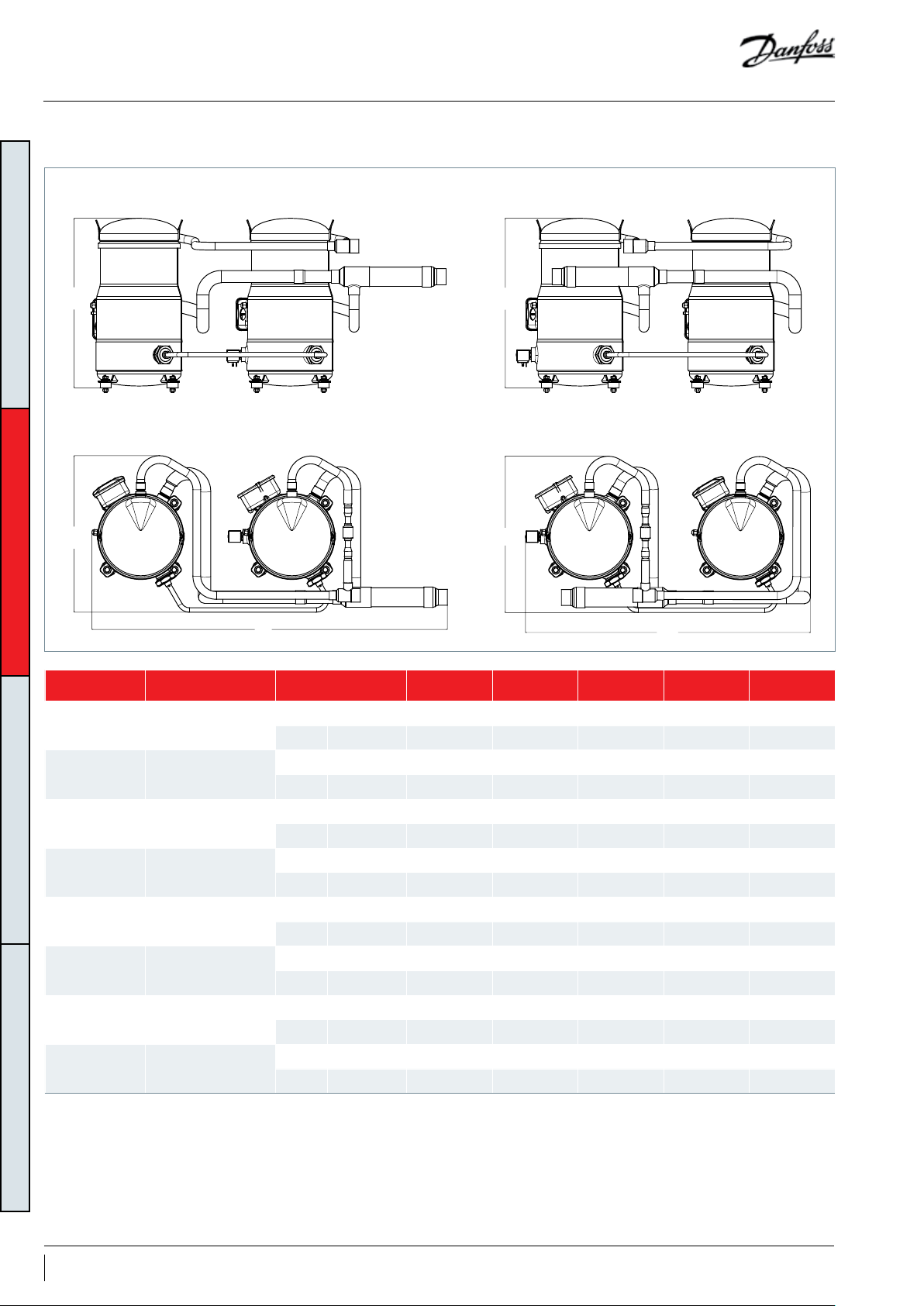

Dimensions

Tandem

GENERAL INFORMATIONSYSTEM DESIGNORDERING INFORMATION PRODUCT INFORMATION

H H

D

L

Tandem model Composition

VZH178 H VZH088+DSH090

VZH208H VZH088+DSH120

VZH257H VZH117+DSH140

VZH278H VZH117+DSH161

VZH301H VZH117+DSH184

VZH354H VZH170+DSH184

VZ H410H VZH170+DSH240

VZH465H VZH170+DSH295

Tandem configurations are achieved by assembling individual compressors

Outline drawing

number

8560156 1" 5/8 1" 3/8 1011 445 482

8560155 1" 5/8 1" 3/8 811 445 482

8560154 1" 5/8 1" 3/8 1011 445 540

8560153 1" 5/8 1" 3/8 811 445 540

8560152 1" 5/8 1" 3/8 1024 445 540

8560151 1" 5/8 1" 3/8 811 445 540

8560152 1" 5/8 1" 3/8 1024 445 540

8560151 1" 5/8 1" 3/8 811 445 540

8560150 1" 5/8 1" 3/8 111 6 445 555

8560149 1" 5/8 1" 3/8 811 445 555

856014 8 2" 1/8 1" 5/8 1241 583 682

8560147 2" 1/8 1" 5/8 890 583 682

8556271 2" 1/8 1" 5/8 1245 583 682

8556270 2" 1/8 1" 5/8 953 583 682

8556271 2" 1/8 1" 5/8 1245 583 682

8556270 2" 1/8 1" 5/8 953 583 682

D

L

Suction Discharge L (mm) D (mm) H (mm)

8 AB298632269085en-000401

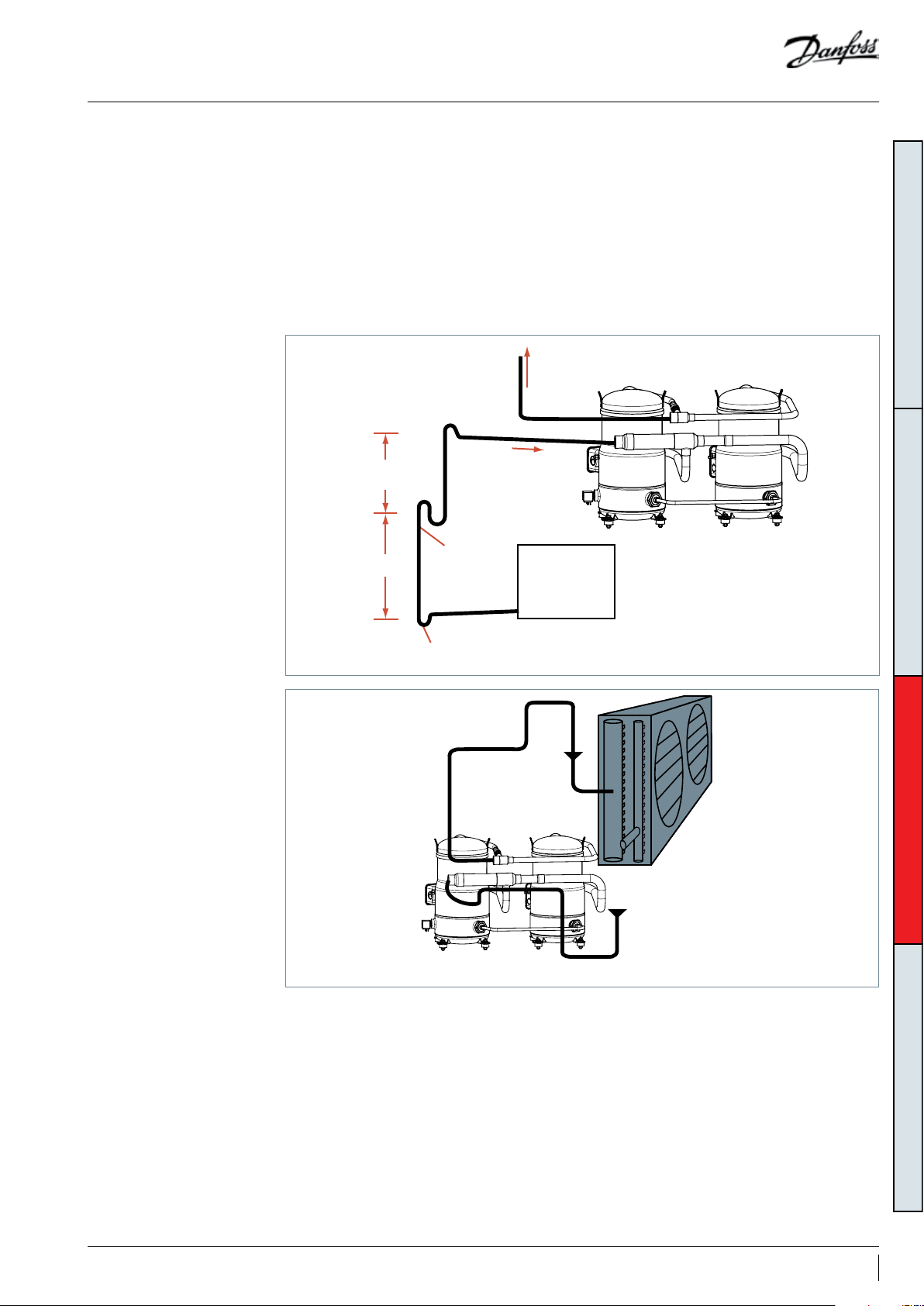

Design pipe

General requirements Proper piping practices should be employed to:

1. Ensure adequate oil return, even under

minimum load conditions (fixed speed

compressor off, variable speed compressor

at minimum speed, minimum evaporating

conditions). If minimum refrigerant velocity

cannot be reached, it is strongly recommended

that an oil separator is used. For a validation test,

the see section “Manage oil in the circuit”.

To condenser

0.5% slope

max. 4 m

max. 4 m

4 m/s or more

U-trap, as short as possible

8-12 m/s

Evaporator

0.5% slope

4 m/s or more

2. Prevent condensed liquid refrigerant from

draining back into the compressor when

stopped (discharge piping upper loop). For

validation tests, see the section “Manage off-cycle

migration”.

General recommendations are described in the

figures below:

GENERAL INFORMATIONPRODUCT INFORMATIONORDERING INFORMATION SYSTEM DESIGN

HP

LP

U trap, as short as possible

Upper loop

HP

LP

3D flexibility

3. Piping should be designed with adequate

three-dimensional flexibility to avoid excess

vibration. It should not be in contact with the

surrounding structure, unless a proper tubing

mount has been installed. For more information

Condenser

on noise and vibration, see the section “Sound

and vibration management” in the application

guideline for Danfoss VZH Gen3 scroll

compressors (AB300034185311en).

9AB298632269085en-000401

Design pipe

Suction on left Suction on right

GENERAL INFORMATIONPRODUCT INFORMATIONORDERING INFORMATION SYSTEM DESIGN

Variable speed

Fixed speed

Fixed speed Variable speed Tandem model Suction direction

DSH090 VZH088 V ZH178H Left/Right

DSH120 VZH088 VZH208H Left/Right

DSH140 VZH117 VZH257H Left/Right

DSH161 VZ H117 VZH278H Left/Right

DSH184 V ZH117 VZH301H Left/Right 50 & 60 120Z0656

DSH184 VZH170 VZH354H

DSH240 V ZH170 VZH410H Left/Right 50 & 60 120Z0657

DSH295 V ZH170 VZH465H Left/Right 50 & 60 120Z0655

Note:

The tandem accessory includes oil equalization kits and oil level sensor. For compressors that need a UL certificate, please order the accessory kit with the 24V oil level sensor.

+

+

+

+

+

Left

+

Right

+

+

+

Hz of FS

compressor

50 120Z0 676

60 12 0Z0675

50 120Z0664

60 120Z0658

50 120Z0666

60 120Z0665

50 120Z0665

60 120Z 0674

50

60

50

60

Fixed speed

Suction

separator code

120Z0683

120Z0683

120Z0655

120Z0655

120Z0 687

120Z0 687

120Z0 687

120Z0 687

Variable speed

Tandem accessory kit code

120Z0653 (with 24V oil level sensor)

120Z0654 (with 230V oil level sensor)

120Z0653 (with 24V oil level sensor)

120Z0654 (with 230V oil level sensor)

120Z0651 (with 24V oil level sensor)

120Z0652 (with 230V oil level sensor)

120Z0651 (with 24V oil level sensor)

120Z0652 (with 230V oil level sensor)

120Z0653 (with 24V oil level sensor)

120Z0654 (with 230V oil level sensor)

120Z0653 (with 24V oil level sensor)

120Z0654 (with 230V oil level sensor)

120Z0653 (with 24V oil level sensor)

120Z0654 (with 230V oil level sensor)

120Z0653 (with 24V oil level sensor)

120Z0654 (with 230V oil level sensor)

120Z0651 (with 24V oil level sensor)

120Z0652 (with 230V oil level sensor)

120Z0682 (with 24V oil level sensor)

120Z0681 (with 230V oil level sensor)

120Z0682 (with 24V oil level sensor)

120Z0681 (with 230V oil level sensor)

120Z0682 (with 24V oil level sensor)

120Z0681 (with 230V oil level sensor)

120Z0682 (with 24V oil level sensor)

120Z0681 (with 230V oil level sensor)

120Z0649 (with 24V oil level sensor)

120Z0650 (with 230V oil level sensor)

120Z0649 (with 24V oil level sensor)

120Z0650 (with 230V oil level sensor)

+

10 AB298632269085en-000401

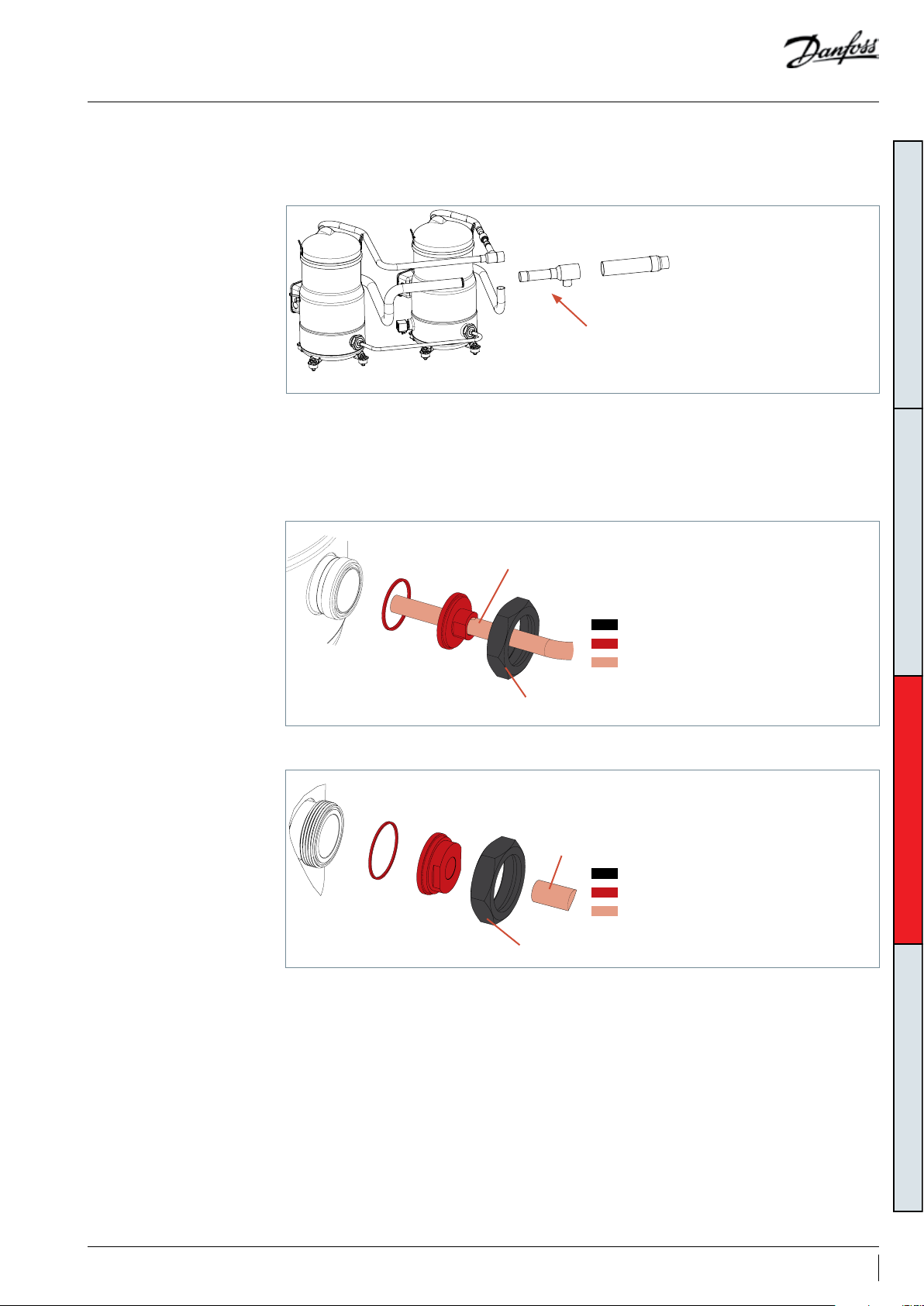

Design pipe

Suction separator

Oil equalization design

The suction connections of the two individual

compressors are interconnected by a suction

separator, which is supplied as an accessory.

The two compressors are connected by a ½" or

¾" oil equalization pipe. To fix the oil equalization

connection rotolock, use the adaptor sleeves

½"

Suction separator

and the seal gasket which were included in the

tandem accessory kit.

Model: VZH178H-208H-257H-278H-301H/-354H

(DSH184 oil equalization line)

GENERAL INFORMATIONPRODUCT INFORMATIONORDERING INFORMATION SYSTEM DESIGN

Tightening torque 100NM

Model: VZH354H-410H-465H

(VZH170 oil equalization line)

¾"

Tightening torque 145Nm

Supplied with the compressor

Included in tandem kit

Not supplied

Supplied with the compressor

Included in tandem kit

Not supplied

11AB298632269085en-000401

Design compressor mounting

Tightening torque

General requirements

VZH178H Mounting feet

GENERAL INFORMATIONPRODUCT INFORMATIONORDERING INFORMATION SYSTEM DESIGN

VZH208H Mounting feet

The tandem is fixed to the frame using the

flexible grommets that are supplied with

The compressors are fixed to the frame using

rubber grommets, mounting sleeves, and

washers (supplied with the compressors).

HM 8 bolt

Lock washer

Flat washer

Steel mounting

sleeve

Rubber grommet

Nut

Base plate, frame, etc. with sucient rigidity

Mounting for DSH090 and VZH088

15Nm

15 mm

The compressors are fixed to the frame using

rubber grommets, mounting sleeves, and

washers (supplied with the compressors).

Because VZH088 is 7 mm smaller than DSH120,

in order to ensure that the oil equalization

Tightening torque

HM 8 bolt

Lock washer

Flat washer

Steel mounting

sleeve

Rubber grommet

15Nm

15 mm

the compressor or which are included in the

accessory kit.

connection is at the same level for both

compressors, an additional 7mm rigid spacer

must be added under VZH088 (see drawing. The

7 mm rigid spacer is supplied with the tandem

accessory kit).

Tightening torque

15Nm

Rigid spacer

VZH257H / VZH278H Mounting feet

Nut

Base plate, frame, etc. with sucient rigidity

Mounting for DSH120

The compressors are fixed to the frame using

rubber grommets, mounting sleeves, and

washers (supplied with the compressors).

Tightening torque

HM 8 bolt

Lock washer

Flat washer

Steel mounting

sleeve

Rubber grommet

Nut

Base plate, frame, etc. with sucient rigidity

Mounting feet

15Nm

15 mm

Mounting for VZH088

12 AB298632269085en-000401

Design compressor mounting

Tightening

torque 21Nm

28mm

HM8 bolt

VZH301H Mounting feet

VZH410H / VZH465H Mounting feet

The compressors are fixed to the frame using

rubber grommets, mounting sleeves, and

washers (supplied with the compressors).

Because VZH117 is 7 mm smaller than DSH184,

in order to ensure that the oil equalization

Tightening torque

HM 8 bolt

Lock washer

Flat washer

Steel mounting

sleeve

Rubber grommet

Nut

Base plate, frame, etc. with sucient rigidity

Mounting for DSH184

15Nm

15 mm

The compressors are fixed to the frame using

rubber grommets, mounting sleeves, and

washers. The VZH mounting kits are supplied

connection is at the same level for both

compressors, an additional 7mm rigid spacer

must be added under VZH117 (see drawing. The

7 mm rigid spacer is supplied with the tandem

accessory kit).

Tightening torque

15Nm

GENERAL INFORMATIONPRODUCT INFORMATIONORDERING INFORMATION SYSTEM DESIGN

Rigid spacer

Mounting for VZH117

with the VZH compressor, and DSH mounting kits

are included in the tandem accessory kit.

VZH354H Mounting kit

Tightening

HM 8 bolt

Lock washer

Flat washer

Steel mounting sleeve

Rubber grommet

Nut

Mounting feet

torque 21Nm

Compressor

base plate

28 mm

The compressors are fixed on the frame using

rubber grommets, mounting sleeves, washers

(delivered with the compressors).

Tightening

torque 15Nm

Lock washer

Steel mounting

sleeve

Nut

HM8 bolt

Flat

washer

Rubber

grommet

Rigid

spacers

Because DSH184 is 14mm smaller than VZH170,

in order to have oil equalization connection at the

same level for both compressors, two additional

7mm rigid spacers must be added under DSH184

(See below drawing, two 7mm rigid spacers are

provided in Tandem accessory kit).

HM8 bolt

Tightening

torque 21Nm

28mm

Base plate, frame, etc. with enough rigidity

Mounting for DSH184 Mounting for VZH170

13AB298632269085en-000401

Design oil level sensor

General requirements Oil level sensor is a special component which

assembles on variable speed compressor. It is

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNORDERING INFORMATION

GENERAL INFORMATION

VZH088 VZH117 VZH170

provided in oil level sensor accessory kit.

14 AB298632269085en-000401

Manage operating envelope

Requirement The operating envelope for hybrid manifolding is

shown below, and guarantees reliable operation

of the compressor for steady-state operation.

VZH088/117 C Operating Map - 575V/400V/208V

75

70

65

60

55

50

45

40

Tc (°C)

35

30

25

20

15

10

5

-35 -30 -25 -20 -15 -10 -5 0 5 1510 30 352520

50-90 rps

50-100 rps

30-90 rps

The steady-state operation envelope is valid for a

suction superheat of between 5K and 30K.

30-90 rps

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNORDERING INFORMATION

25-90 rps

25-100 rps

Te (°C)

VZH170 C Operating Map - 575V/400V/208V

75

70

65

60

55

50

45

40

Tc (°C)

35

30

25

20

15

10

5

-35 -30 -25 -2 0 -15 -10 -5 0 5 1510 30 352520

50-90 rps

50-100 rps

25-100 rps

30-90 rps

30-90 rps

25-90 rps

Te (°C)

Note:

1) The solid line envelope is valid for a suction superheat within 5K (9°F) at nominal voltage. Higher suction superheat may lead to

discharge temperatures above 135°C (275°F)

For superheat between 5K and 11K, this top left envelope might be reduced by condensing temperature of 1°C or 2°C (1. 6°F to

3.2°F) in order to keep discharge T° below 135°C (275°F)

For superheat above 11K (20°F), the envelop will further be reduced based on 135°C (275°F) discharge temperature restriction.

2) For 380V power input, permitted highest condensing temperature will decrease accordingly: 25-100rps, condensing temperature

from 60°C to 56°C(140°F to 133°F); 30-90rps, condensing temperature from 68°C to 65°C(154°F to 149°F).

SYSTEM DESIGN

Pressure settings

bar (g) psi (g)

R410A

Working pressure range low side 2. 3~15. 7 33.36~227.7

Maximum high pressure safety switch setting 48.7 706.33

Minimum low pressure safety switch setting 1.5 21.75

Recommended pump-down switch settings

1.5 bar below nominal

evaporating pressure

21 psi below nominal

evaporating pressure with

minimum of

Minimum low pressure pump-down switch setting 2.3bar(g) 33 psig

15AB298632269085en-000401

Manage speed limit

General requirements

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNORDERING INFORMATION GENERAL INFORMATION

Speed limit guarantees compressor

reliability and must be respect. Details refer to

single VZH M/L GEN3 guideline”Manage speed

limit”

16 AB298632269085en-000401

Manage superheat

Requirement

System evaluation

Basic unit

single exchanger

as evaporator and

condenser

X X Optional Pass liquid flood back test

X - X Recommended

During normal operation, refrigerant enters the

compressor as a superheated vapour. Liquid

flood back occurs when some of the refrigerant

entering the compressor is still in a liquid state.

In the steady-state condition, the expansion

device must ensure a suction superheat of

between 5k and 30k.

Advance unit

Multiple exchangers as evaporator or

condenser (heat-recovery, exchanger,

four-pipe chiller…)

X X Mandatory Pass liquid flood back test

X X Mandatory

Liquid flood back can cause oil dilution and, in

extreme situations, lead to liquid slugging that

can damage compression parts.

GENERAL INFORMATIONPRODUCT INFORMATIONORDERING INFORMATION

Tes t

Non-reversible

Reversible

Suction accumulator

Pass liquid flood back test

Pass defrost test

Pass liquid flood back test

Pass defrost test

Test, criteria and solutions

Tes t No Purpose Test condition Pass criteria Solutions

Liquid flood back testing must be

carried out under expansion valve

threshold operating conditions:

Variable speed On at min.speed /

fixed speed Off

Running conditions corresponding

to the lowest foreseeable

evaporation, and highest

foreseeable condensation

In case of reversible system, the test

must be done in both cooling and

heating mode

If advanced unit, test in all possible

configurations

Tests must be carried out in the

most unfavourable conditions:

• fan staging

• compressor ramping up and down

The defrost test must be carried out

in the most unfavorable conditions

(at 0°C evaporating temperature)

Suction superheat >5k

The oil superheat must not be more

than 30 sec below the safe limit

defined in the dilution chart (see

graph below)

The oil superheat must not be more

than 30 sec below the safe limit

defined in the dilution chart (see

graph below)

1. Check expansion valve selection

and setting

(EXV) check measurement chain and

PID.

2. Add a suction accumulator*

1. In reversible systems, the defrost

logic can be worked out to limit the

liquid flood back effect. (For more

details see “Control logic”)

2. Add a suction accumulator*

Liquid flood

back test

Defrost test

Steady-state

Trans ient

Check liquid

flood back

during defrost

cycle

SYSTEM DESIGN

* A suction accumulator offers protection by trapping the liquid refrigerant upstream from the compressor. The accumulator should be

sized at least 50% of the total system charge. The suction accumulator dimensions can impact oil return (gas velocity, oil return, hole size

etc.), and therefore the oil return has to be checked according to the “Manage oil in the circuit” section.

17AB298632269085en-000401

Manage superheat

GENERAL INFORMATIONPRODUCT INFORMATIONORDERING INFORMATION

The oil temperature sensor

must be placed between the oil

sight glass and the compressor

baseplate for fixed speed

compressor, and beside the oil

level sensor for the variable speed

compressor.

Use a little thermal paste to

improve conductivity. The sensor

must also be thermally insulated

correctly from the ambience.

Oil superheat is defined as:

(Oil temperature - Evaporating temperature)

VZH088 117 170/R410A

SYSTEM DESIGN

Dilution chart (reference at 20°C / 68°F ambient temperature)

15

14

13

12

Safety area

11

10

9

8

7

6

5

Oil superheat (K)

4

3

Unsafety area Max 60secs per event

2

1

0

-25

-20 -15 -10 0510 15 20 25

Saturated Suction temperature °C

18 AB298632269085en-000401

Manage off-cycle migration

Off-cycle refrigerant migration happens:

• when the compressor is located at the coldest

part of the installation, and refrigerant vapour

then condenses in the compressor, or

Requirement

The amount of liquid refrigerant in the

compressors must not exceed the charge limit.

System evaluation

Non split Split Below charge limitAbove charge limit

X X Optional Mandatory Mandatory Optional

X X Mandatory Mandatory Mandatory Recommended

X - - Mandatory Mandatory Mandatory Recommended

*Surface sump heater

The surface sump heaters are designed to

protect the compressor against off-cycle

refrigerant migration.

Additional heater power or thermal insulation

is needed in case the ambient temperature falls

below -5°C and the wind speed is above 5 m/sec.

The heater must be turned on whenever all the

compressors are off.

Surface sump heater accessories are available

from Danfoss (see the “Accessories” section).

Surface sump

heater*

• directly in the liquid phase as the result of

gravity. When the compressor starts running

again, the refrigerant diluted in the oil generates

poor lubrication conditions. In extreme

situations, this leads to liquid slugging that can

damage compressor parts.

Non-return valve

Liquid line

solenoid valve**

Pump-down

cycle***

**Liquid line solenoid valve (LLSV)

An LLSV is used to isolate the liquid charge

on the condenser side, thereby preventing

refrigerant being transferred to the compressor

during off-cycles. The electronic expansion valve

that closes automatically including in power

shut down situation can replace the LLSV. The

quantity of refrigerant on the low-pressure side

of the system can be further reduced by using a

pump-down cycle in association with the LLSV.

***Pump-down cycle

By decreasing pressure in the sump, pump down:

• evacuates refrigerant from the oil

• sets the sump saturating pressure much lower

than the ambient temperature, and as a result,

refrigerant condensation is avoided in the

compressor.

Pump-down switch setting must be set higher

than 2.3 bar(g).

GENERAL INFORMATIONPRODUCT INFORMATIONORDERING INFORMATION

SYSTEM DESIGN

Refrigerant charge limit table

For more details on pump-down cycle see the

section “Control logic”.

Tandem models Refrigerant charge limit(kg)

VZH178H/VZH208H 8.0

VZH257H/VZH278H/VZH301H 10.0

VZH354H/VZH410H/VZH465H 15. 0

19AB298632269085en-000401

Manage oil in the circuit

Non return valve

GENERAL INFORMATIONPRODUCT INFORMATIONORDERING INFORMATION

Oil management system for hybrid manifolding

Non-return valve at discharge prevents

R

from liquid or gas migration. Selection of nonreturn valve is a trade-off between pressure

dropping at high speed, and the state of the

valve stability while at low speed.

See Section Prevent off cycle migration §Test and

components required per application to know

when to use non return valve

The oil management system architecture for

hybrid manifolding is described below.

An oil equalization tube between the variable

speed compressor and the fixed speed

compressor is used to maintain the oil balance.

OEM main controller Drive

ModBus

The following table displays present Danfoss

non-return valve selection per each specific

compressor. DSH are with internal NRV, no need

external NRV.

Compressor model NRV model

VZH088 NRV 16

VZH117 NRV 19

VZH170 NRV 22

An oil level sensor need to be installed on the

variable speed compressor. The oil level sensor

monitors the compressor oil level and send oil

level signal to OEM main controller. When oil

level is below the minimal, OEM controller enter

in oil management mode to recover a proper

oil level in compressor. If oil level cannot be

recovered, controller stop the system.

SYSTEM DESIGN

Oil management logic

FS

Power supply

Oil equalization tube

In order to maintain the proper oil level in the

compressors, an oil management control logic

needs be implemented in the OEM controller.

The oil management control logic must include

three steps.

1. In the case of low oil level detection, an oil

balance mode (Variable speed on, Fixed speed

off) is activated to recover oil from fixed speed

to variable speed.

VS

Optical oil

level sensor

2. If oil level cannot be recovered in VS

compressor, controller go to Oil boost Mode

(Variable speed on, Fix Speed on) in order to

recover oil trapped in system.

3. If the oil level is still below the limit after a full

oil balance action and oil boost action have

been completed, the controller must enter in

protection mode, and stop the system in alarm.

For more detailed oil management logic, please

refer to “Oil management logic” in the annex.

20 AB298632269085en-000401

Manage oil in the circuit

Requirement

Fixed speed compressor: The oil level must

be visible or full in the sight glass when the

compressor is running and when all the

compressors in the circuit are stopped.

Variable speed compressor: This compressor is

equipped with an oil level switch located at the

minimum acceptable level. If the oil level drops

below this limit, the controller must follow the oil

logic (See “Oil management logic” in the annex).

R

Fixed speed compressor oil returned status

need be monitored in qualification test by

normal OSG on FS compressor or additional oil

level switch placed on FS OSG, the OEM should

make sure enough oil in FS compressor by test on

their own unit.

System evaluation

Basic unit

Single exchanger

as evaporator and

condenser

X - - X Optional Pass tests 1 & 2

- - - - - X Mandatory Pass tests 1, 2 & 3

Advance unit

Multiple exchangers as

evaporator or condenser

(heat-recovery, exchanger,

four-pipe chiller…)

X - - X Recommended Pass tests 1 & 2

Split

Non-reversible

Reversible

Non-split

Oil separator

Test, criteria and solutions

Tes t no. Purpose Test condition Pass criteria Solutions

Variable speed On at minimum

speed / Fixed speed Off

Running condition corresponds to

lowest foreseeable evaporation,

and highest foreseeable

condensation on the system

Running for 6 hours

For a reversible system, perform

the test in both heating and cooling

Oil return

1

2

3

test under

minimum mass

flow

Check oil

management

control logic is

working

Oil return in

split system

modes. If it is an advanced unit, test

in all possible configurations

Variable speed On at minimum

speed / Fixed speed On

Running condition corresponding

to lowest foreseeable evaporation,

and highest foreseeable

condensation on the system

Running for 6 hours

For a reversible system, perform

the test in both heating and cooling

modes. If it is an advanced unit, test

in all possible configurations

Variable speed On at 50 rps for

VZH088-117 or 40 rps for VZH170 /

Fixed speed On

Running conditions corresponding

to the lowest foreseeable

evaporation, and the highest

foreseeable condensation on the

system.

Running for 6 hours

For a reversible system, perform

the test in both heating and cooling

modes. If it is an advanced unit, test

in all possible configurations

Since each installation is unique,

tests 1 and 2 cannot fully validate

the oil return

The oil level must be checked and

adjusted at commissioning

Variable speed: No lack of oil alarm

No more than two oil boost cycles

per hour

Variable speed: No lack of oil alarm

Fixed speed: Oil visible in sight glass

No more than two oil balance cycles

per hour

Fixed speed: Oil visible in sight glass

Fix speed: Oil visible in sight glass

No more than two oil balance cycles

per hour

Look for potential oil trap

Increase oil boost duration

Top up with oil, generally 4% of the

total system refrigerant charge (in

weight)

Oil separator can be added

Look for potential oil trap

Increase oil boost duration

Top up with oil, generally 4% of the

total system refrigerant charge (in

weight). If more than 4% is used,

look for a potential oil trap in the

system

Oil separator can be added

The oil separator is mandatory

Pay special attention to “Piping

design”

Top-up with oil, generally 4% of the

total system refrigerant charge (in

weight). If more than 4% is used,

look for a potential oil trap in the

system

GENERAL INFORMATIONPRODUCT INFORMATIONORDERING INFORMATION

Tes t

SYSTEM DESIGN

21AB298632269085en-000401

Control logic

Safety control logic requirements

Safeties

HP switch

LP safety switch

GENERAL INFORMATIONPRODUCT INFORMATIONORDERING INFORMATION

Electronic module (only for

SH180-240 -295)

See the pressure settings

table in the “Manage

operating envelope section”

Contact M1-M2 opened

Short cycle protection Minimum run time is necessary to ensure proper

oil return to the compressor. A 3 minutes

minimum run time is usually recommended but

some systems may require more time to establish

a proper superheat and a stable oil return.

Additionally, compressor must not exceed a

maximum of 12 starts per hour. 12 starts per

Tripping conditions Re-start conditions

Value Time Value Time

Manual reset

Immediate, no delay

No by-pass

Conditions back to normal

Switch closed again

Max. 5 auto resets during a

12-hour period, then manual

reset

Max. 5 auto resets during a

12-hour period, then manual

reset

is the maximum number of starts acceptable for

a limited period to ensure enough time for oil

return after start-up.

Short cycle protection can be done either by the

drive or the unit controller. The following table

describes the parameters to adjust depending on

short cycle protection selected

hour must not be considered as an average, this

Drive parameters Description Value Default

Short cycle protection is done by unit controller

28.00 Short cycle protection

Short cycle protection is done in drive; LP (low pressure) protection must be connected to T27 to keep LP protection during minimum running time.

Terminal 27 (Par 5.12) must be set to “Coast inverse”

If Modbus is used it is not necessary to connect terminal 27, but a “Coasting” command must be sent to be able to stop compressor in case of an alarm

during minimum run time

Short cycle protection done in unit controller: (preferred

option)

Disable Enable

28.00 Short cycle protection Short cycle protection done by the drive. Enable Enable

28.01 Interval between starts

28.02 Minimum Run time

SYSTEM DESIGN

5.12 Terminal 27 Digital input Designated for the LP switch.

The diagram below demonstrates how the function works:

(a) Start signal is given by the unit controller

(b) Compressor started

(c) Compressor stop requested by the unit controller

(d) Stop command is ignored. Stop delay warning (W97).

(e) Compressor stops when minimum run time (180s) has

elapsed.

(f) Start signal is given by the unit controller

Start command is ignored until the timer (300s) has

elapsed. Only then, can the compressor start.

The compressor cannot stop until the set time (180s) has

elapsed.

The timer starts counting following a compressor start.

Stop command is ignored.

Only a coast (inverse) command can override the time

and stop the compressor.

Interval between starts 300sec

(g) Start delay (W96)

(b) Compressor started

(c) Stop signal

(d) Stop delayed (W97)

(e) Compressor Stoped

300 sec 300sec

180 sec 12se c

[2]* Coast

inverse

(h) Compressor start

(g) Start command is ignored

(h) Compressor starts after the timer interval between starts

(300s) has elapsed.

(i) Compressor Coast (stop) This command can override

the time minimum run time and stop the compressor

immediately.

(a) Start signal

Note:

The short cycle protection function is not functional during Hand On control of the

frequency converter via the LCP. If selecting Hand On or Off, the two timers will be reset to

0, and not start counting until Auto is pressed and an active start command applied. The

counters are not available for display or monitoring.

(f) Star t signal (i) Compressor Coast

Stop inverse

22 AB298632269085en-000401

Control logic

Defrost logic recommendations

Variable speed 1

Fixed speed 2

4WV

EXV

ON

ON

Heating

100%

In reversible systems, the defrost logic can be

worked out to limit the effects of liquid flood

back by:

1. Running at full load during defrost to share the

liquid refrigerant between all the compressors.

The following defrost logic combines both

advantages:

Defrost

2. Transferring the liquid refrigerant from one

exchanger to the other thanks to pressures.

GENERAL INFORMATIONPRODUCT INFORMATIONORDERING INFORMATION

Pump-down logic recommendations

4 Way Valve (4WV) stays in heating mode.

Defrost start. Stop all compressors

EXV opens to transfer liquid from outdoor

to indoor exchanger thanks to pressure

difference

* EXV opening degree and time have to be set to keep a minimum pressure for 4 way valve moving.

Pump down is initiated prior to shutting

down the last compressor on the circuit by

de-energizing a liquid line solenoid valve or

closing electronic expansion valve. When suction

pressure reaches the cut-out pressure, the

compressor is stopped.

When the pressures are almost bal-

anced*, 4WV changes to cooling mode

Restart variable speed and fixed speed

Defrost end. Stop all compressors

4 WV stays in cooling mode.

EXV opens to transfer liquid from

indoor to outdoor exchanger thanks

to pressure difference

When pressures are almost balanced*,

change 4WV to heating mode.

Restart variable speed and fixed speed

Two types of pump-down exist:

• One-shot pump down (preferred): When the

last compressor in the circuit stops, the suction

presssure is falls by 1.5 bar below the nominal

evaporating pressure with a minimum of 2,3

bar(g). Even if the suction pressure increases

again, the compressor will not restart.

• Continuous pump-down: Compressor restarts

automatically when the suction pressure

increases.

SYSTEM DESIGN

23AB298632269085en-000401

Assembly line procedure

The installation and service procedure for a

parallel system are similar to basic single-system

installations. The selection of additional system

components for parallel installations follows the

Handling Danfoss Commercial Compressors recommends

using the lift and handling devices as shown on

the right, and that the following procedure be

used to prevent damage:

• There are two lifting rings on each compressor.

GENERAL INFORMATIONPRODUCT INFORMATIONORDERING INFORMATION

Use all four rings.

• Maximum loads authorized per sling and for the

hoist hook must not be lower than the weight

of the assembly.

• If the tandem unit is already installed as a

complete installation, it must never be lifted

using the lifting rings on the compressors.

basic system common rules. Please refer to the

application guidelines for Danfoss VZH Gen3

scroll compressors (AB300034185311en) for

detailed installation and service procedures.

SYSTEM DESIGN

24 AB298632269085en-000401

Ordering information

To build a complete tandem installation,

the customer must order two must order 2

Compressor ordering codes

Danfoss VZH and DSH scroll compressors can

be ordered in either industrial packs or in single

packs. Please refer to the single compressor

Accessory ordering codes

The suction separator and tandem kit can

be ordered using the code numbers listed in

the table below. The suction separator and

Tandem model

VZH178 H VZH088 DSH090 Left/Right

VZH208H VZH088 DSH120 Left/Right

VZH257H VZH117 DSH140 Left/Right

VZH278H VZH117 DSH161 Left/Right

VZH301H V ZH117 DSH184 Left/Right

VZH354H VZ H170 DSH184

VZ H410H VZH170 DSH240 Left/Right

VZH465H VZH170 DSH295 Left/Right

Variable speed

compressor

Fixed speed

compressor

Suction

direction

Left

Right

Suction separator Tandem accessory kit

Hz (FS

compressor)

50 Hz 120Z0676 1

60 Hz 120Z0675 1

50 Hz 120Z0664 1

60 Hz 120Z0658 1

50 Hz 120Z0666 1

60 Hz 120Z0665 1

50 Hz 120Z0665 1

60 Hz 120Z0674 1

50 Hz 120Z0656 1

60 Hz 120Z0656 1

50 Hz

60 Hz 120Z0655 1

50 Hz 120Z 068 7 1

60 Hz 120Z 0687 1

50 Hz 120Z0657 1

60 Hz 120Z0657 1

50 Hz 120Z0655 1

60 Hz 120Z0655 1

Code Pack size

120Z0683

compressors, one suction separator and one

tandem accessory kit.

application guideline for compressor ordering

information (AB300034185311en for VZH Gen3,

AB288965961751en for DSH).

the tandem kit selection should be based on

compressor model, frequency of fixed speed

compressor and oil level switch voltage.

Voltage of oil

level switch

24V 120Z0653 1

230V 120Z0654 1

24V 120Z0653 1

230V 120Z0654 1

24V 120Z0651 1

230V 120Z0652 1

24V 120Z0651 1

230V 120Z0652 1

24V 120Z0653 1

230V 120Z0654 1

24V 120Z0653 1

230V 120Z0654 1

24V 120Z0653 1

230V 120Z0654 1

24V 120Z0653 1

230V 120Z0654 1

24V 120Z0651 1

230V 120Z0652 1

24V 120Z0651 1

230V 120Z0652 1

1

24V 120Z0 682 1

230V 120Z0681 1

24V 120Z0 682 1

230V 120Z0681 1

24V 120Z0 682 1

230V 120Z0681 1

24V 120Z0 682 1

230V 120Z0681 1

24V 120Z0 649 1

230V 120Z0650 1

24V 120Z0 649 1

230V 120Z0650 1

24V 120Z0 649 1

230V 120Z0650 1

24V 120Z0 649 1

230V 120Z0650 1

Code Pack size

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGN

ORDERING INFORMATION

25AB298632269085en-000401

Accessories

Suction separator

Code no. Description Application Packaging

120Z0655 Hybrid manifold suction separator

120Z0657 Hybrid manifold suction separator VZH410H-50/60Hz right/left suction Single pack 1

120Z0656 Hybrid manifold suction separator VZH301H-50/60Hz right/left suction Single pack 1

120Z0666 Hybrid manifold suction separator VZH257H-50Hz right/left suction Single pack 1

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGN

120Z0665 Hybrid manifold suction separator VZH257H-60Hz VZH278H-50Hz right/left suction Single pack 1

120Z0658 Hybrid manifold suction separator VZH208H-60Hz right/left suction Single pack 1

120Z0 664 Hybrid manifold suction separator VZH208H-50Hz right/left suction Single pack 1

120Z0 674 Hybrid manifold suction separator VZH278H-60Hz right/left suction Single pack 1

120Z0 675 Hybrid manifold suction separator VZH178H-60Hz right/left suction Single pack 1

120Z0 676 Hybrid manifold suction separator VZH178H-50Hz right/left suction Single pack 1

120Z0683 Hybrid manifold suction separator VZH354H-50Hz left suction Single pack 1

120Z0 687 Hybrid manifold suction separator VZH354H-50/60Hz right suction Single pack 1

Tandem accessory kit

Code no. Description Application Packaging Pack size

120Z0653 Oil level sensor 24V AC/DC, sleeves, gaskets

120Z0654 Oil level sensor 230V AC, sleeves, gaskets

120Z0651 Oil level sensor 24V AC/DC, sleeves, gaskets

120Z0652 Oil level sensor 230V AC/DC, sleeves, gaskets

120Z0 649

120Z0650

120Z0 681

120Z0 682

VZH465H-50/60Hz right/left suction

Oil level sensor 24V AC/DC, sleeves, gaskets, grommets,

washers, bolts

Oil level sensor 230V AC, sleeves, gaskets, grommets,

washers, blots

Oil level sensor 230V AC, sleeves, gaskets, grommets,

washers, blots

Oil level sensor 24V AC, sleeves, gaskets, grommets, washers,

blots

VZH354H-60Hz left suction

VZH178H -257H-278H

with 24V oil level sensor

VZH178H -257H-278H

with 230V oil level sensor

VZH208 H-301H

with 24V oil level sensor

VZH208 H-301H

with 230V oil level sensor

VZ410H-465H

with 24V oil level sensor

VZ410H-465H

with 230V oil level sensor

VZH354H

with 230V oil level sensor

VZH354H

with 24V oil level sensor

Pack

size

Single pack 1

Single pack 1

Single pack 1

Single pack 1

Single pack 1

Single pack 1

Single pack 1

Single pack 1

Single pack 1

Oil level sensor

Code no. Description Application Packaging Pack size

120Z0 561 Oil level sensor 24V AC/DC VZH088-117-170 manifolding version Single pack 1

120Z0 562 Oil level sensor 230V AC VZH088-117-170 manifolding version Single pack 1

ORDERING INFORMATION

26 AB298632269085en-000401

Accessories

Surface Sump Heater

Code no. Description Application Packaging Pack size

120Z0 388 Surface sump heater, 80W, 24V, CE, UL

120Z0 389 Surface sump heater, 80W, 230V, CE, UL Multipack 8

120Z0 390 Surface sump heater, 80W, 400V, CE, UL Multipack 8

120Z0 391 Surface sump heater, 80W, 460V,CE, UL Multipack 8

120Z0 402 Surface sump heater, 80W, 575V, CE, UL Multipack 8

120Z0 360 Surface sump heater + bottom insulation, 56 W, 24 V, CE, UL

120Z0 376 Surface sump heater + bottom insulation, 56 W, 230 V, CE, UL Multipack 6

120Z0 377 Surface sump heater + bottom insulation, 56 W, 400 V, CE, UL Multipack 6

120Z0378 Surface sump heater + bottom insulation, 56 W, 460 V, CE, UL Multipack 6

120Z0 379 Surface sump heater + bottom insulation, 56 W, 575 V, CE, UL Multipack 6

120Z0 667 48W 24V surface sump heater CE and UL

120Z0 668 48W 230V surface sump heater CE and UL Single pack 1

120Z0669 48W 400V surface sump heater CE and UL Single pack 1

120Z0 670 48W 460V surface sump heater CE and UL Single pack 1

120Z0 671 48W 575V surface sump heater CE and UL Single pack 1

120Z0 388 80W 24V surface sump heater CE and UL Multipack 8

120Z0 389 80W 230V surface sump heater CE and UL Multipack 8

120Z0 390 80W 400V surface sump heater CE and UL Multipack 8

120Z0 391 80W 460V surface sump heater CE and UL Multipack 8

120Z0 402 80W 575V surface sump heater CE and UL Multipack 8

120Z070 3 56W 24V surface sump heater + bottom insulation, CE & UL DSH240-295-381-485 Multipack 6

120Z070 4 56W 230V surface sump heater + bottom insulation, CE & UL DSH240-295-381-485 Multipack 6

120Z070 5 56W 400V surface sump heater + bottom insulation, CE & UL DSH240-295-381-485 Multipack 6

120Z070 6 56W 460V surface sump heater + bottom insulation, CE & UL DSH240-295-381-485 Multipack 6

120Z0707 56W 575V surface sump heater + bottom insulation, CE & UL DSH240-295-381-485 Multipack 6

VZH088-117

VZH170

DSH090 to 184

Multipack 8

Multipack 6

Single pack 1

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGN

Model Configration NRV code

VZH178 H VZH088 + DSH090

VZH208H VZH088 + DSH120

VZH257H VZH117 + DSH140

VZH278H VZH117 + DSH161

VZH301H VZH117 + DSH184

VZH354H VZH170 + DSH184

VZ H410H VZH170 + DSH240

VZH465H VZH170 + DSH295

VZH088 DSH090

NRV16 (020B1059) -

VZH088 DSH120

NRV16 (020B1059) -

VZH117 DSH140

NRV19(020 B1054) -

VZH117 DSH161

NRV19(020 B1054) -

VZH117 DSH184

NRV19(020 B1054) -

VZH170 DSH184

NRV22 (020 -1060) -

VZH170 DSH240

NRV22 (020 -1060) -

VZH170 DSH295

NRV22 (020 -1060) -

ORDERING INFORMATION

27AB298632269085en-000401

Annex

Oil Management logic

1. Oil management for

hybrid manifolding

system

An oil level sensor needs to be installed on

the variable speed compressor. The oil level is

permanently monitored by OEM main controller.

When oil level is below the minimal, OEM

OEM main controller Drive

ModBus

FS

controller enters in oil management mode to

recover a proper oil level in compressor. If oil level

cannot be recovered, controller stops the system.

VS

2. Oil management

description

2.1 Basic rules

Power supply

Oil equalization tube

Oil management system for hybrid manifolding

This specification describes the control logic to

implement in OEM controller. This control logic

must be implemented and thoroughly tested by

OEM.

The variable speed compressor (VS) is primary

and the fixed speed compressor (FS) is Secondary.

FS must not run alone.

Optical oil

level sensor

As oil balancing logic needs to start / stop

compressor as well as increase / decrease speed,

make sure expansion device is fast enough to

maintain liquid flood back within acceptable

limit during those transients (Manage super heat

chapter).

28 AB298632269085en-000401

Annex

2S

2.2 Oil management modes

The oil management control logic must include

3 steps.

Less than every

20min (TD2*)

Max 45 sec

(TD1*)

Fix speed ON

Oil

balance

Fix speed OFF

Partial Oil

boos (VS only)

Step 1Step

Normal

operation

Low oil level

>5 sec

Low oil

level

Step 1 (Oil balance or partial oil boost)

In case of low oil level detection by Oil level

sensor on VS, there is 2 possible actions

according to fix speed state:

• Fix speed is ON: Oil can be trapped in fix speed

compressor due to pressure unbalance. Oil

balance mode is activated. FS is stopped and

VS speed is increased; pressure in VS become

lower than FS oil is coming back through oil

equalization line.

• Fix speed is OFF: Oil is trapped in the system.

Partial oil boost is activated. VS speed is

increased to slightly increase refrigerant velocity

in the system and recover oil, FS remain OFF

Less than every

45min (TD4*)

Max 5min

(TD3*)

Oil level

not

recovered

Oil

Boost

(FS + VS)

Oil level

not

recovered

than TD2 after last step 1, switch immediately to

step 2.

Step 2 (Full oil boost)

If oil level cannot be recovered within defined

time, oil is trapped in the system. Full oil boost

is activated. (VS speed is increased and fix starts

(if not already ON). It considerably increases

refrigerant velocity in the system and recovers oil.

TD3 is the maximum time to complete step 2. If

oil is not recovered within TD3 switch to step 3. If

oil is recovered within TD3 come back to normal

operation. TD4 is the minimum interval between

two step 2. In case of low oil level detection

within a time <TD4, switch to step 3.

Protection

tep 3

TD1 is the maximum time to complete

Step 1: If oil is not recovered within TD1, switch to

Step 2: If oil is recovered within TD1 come back to

normal operation. TD2 is the minimum interval

between two step 1. If step 1 is requested in less

Step 3 (Protection)

If oil is still lower than limit after completed step

1 & 2, or if oil level drop within a time <TD4,

controller must enter in protection mode, and

stop the system in alarm.

Note: TD time is adjustable. Please refer to “Parameter and variable table” in page 31.

29AB298632269085en-000401

Annex

2.3 Steps description

2.3.1 Oil balance Function description

Balance oil from FS compressor to VS Compressor.

Enter condition

Low oil level in VS compressor detected by oil

level sensor.

AND

FS compressor is ON

AND

t2>TD2, Interval between two Oil balance / Oil

boost is > TD2

Cancel condition

High oil level in VS compressor detected by oil

level sensor.

OR

t1>TD1, Oil balance duration exceed TD1

Control sequence

1. At the initial state, VS and FS compressor are

ON.

2. Low oil level detected in VS compressor. Reset

and Start t1.

3. FS compressor must stop. VS compressor speed

must increase to Fboost.

4. When high oil level detected in VS compressor.

• VS compressor speed must be decreased to

minimal speed Fmin.

• Reset and Start t2

• Reset t1

5 When VS compressor speed reaches FStart, FS

compressor must restart.

Max TD1

Oil level signal

VS speed

FS speed

t1

Oil lack

2

Fboost

1

3

Oil balance

from FS to VS

compressor

4

t2

FstartFstart

5

30 AB298632269085en-000401

2.3.2 Partial oil boost Function description

Return oil trapped in the system to compressors

by increasing refrigerant mass-flow in the system.

Enter condition

Low oil level in VS compressor detected by oil

level sensor.

AND

FS compressor is OFF

AND

t2>TD2, Interval between two Oil balance / Oil

boost is > TD2

Cancel condition

High oil level in VS compressor detected by oil

level sensor.

OR

t1>TD1,Partial oil Boost duration exceed TD1

Oil level signal

Control sequence

1 At the initial state, VS compressor is ON and FS

compressor is OFF.

2 Low oil level detected in VS compressor. Reset

and start t1

3 VS compressor speed must increase to Fboost.

4 When high oil level detected in VS compressor

• VS compressor speed must be decreased to the

initial speed (Fstart)

• Reset and start t2

• Reset t1

Max TD1

t1

Oil lack

t2

VS speed

FS speed

2

1

3

Fboost

4

31AB298632269085en-000401

Annex

2.3.3 Oil boost Function description

Return oil trapped in the system to compressors

by increasing refrigerant mass-flow in the system.

Enter condition

Low oil level in VS compressor detected by oil

level sensor.

AND

(t1>TD1, Oil balance / boost duration t1 > TD1 OR

t2<TD2, Interval between two Oil balance / Oil

boost is < TD2)

Cancel condition

High oil level in VS compressor detected by oil

level sensor.

OR

t1>TD3, Oil balance / boost duration exceeds

Maximum Oil boost duration

Control sequence

1. At initial state, oil level is low .Partial oil boost

/Oil balance was not successful or was aborted

because minim interval criteria. VS compressor is

at FStart and FS compressor is either ON or OFF.

2. VS compressor speed must increase to Fboost,

FS compressor must start if not already ON

Reset and start t1

3. When High oil level detected in VS compressor.

• VS compressor speed must be decreased to the

initial speed (Fstart)

• FS compressor to initial state.

• Reset and start t2

• Reset and start t3

• Reset t1

4. When VS compressor speed reaches FStart, FS

compressor must restart (if was ON before)

Max TD3

t1

2

Oil lack

t2

VS comp

FS comp

1

Fboost

3

FstartFstart

32 AB298632269085en-000401

Annex

24VDC MODEL

24VAC MODEL

24VDC MODEL

2.3.4 Protection

Function description

Stop compressors to prevent short of oil running.

Enter condition

Low oil level in VS compressor detected by oil

level sensor.

AND

(t1>TD3, Oil balance / boost duration exceeds

Cancel condition

Manual Reset

Control sequence

Stop FS and VS compressor

Reset t1

Reset t2

Reset t3

TD3 OR t3<TD4, Interval between two Oil boost

is < TD4)

2.4 Parameter and variable

table

Name Tex t Attribute Range Default Unit

Fboost Boost action frequency parameter 25~100 70 Hz

TD1 Maximum oil balance / Partial oil boost duration parameter 10~240 30 second

TD2 Interval minimum between two oil balance / Partial oil boost parameter 10~60 20 minutes

TD3 Maximum boost duration parameter 5~12 5 minutes

TD4 Interval minimum between two oil boost parameter 45~120 45 minutes

t1 Oil balance/ Partial oil boost timer Variable second

t2 Interval between two oil balance / Partial oil boost Variable minutes

t3 Interval between two oil boost Variable minutes

2.5 Sensor Wiring diagram

230VAC MODEL

24VAC MODEL

An TEKLAB LC-XN optical-electrical level sensor

is fixed on the inverter compressor. The oil

level sensor monitors the compressor oil level

and sends oil level signal to an external relay

(provided by OEM ). Regarding this oil level

signal, a 5±2 seconds delay is recommended to

flowing through load or coil of external relay.

For relay, output is open.

- Enough oil: Circuit between 2 and 3 will be

closed internally, there will be current flowing

through load or coil of external relay. For relay,

output is closed

24VDC MODEL

be used to consider the oil level fluctuation which

may trigger false alarms.

For customers who needs UL certificates, please

order 24V AC/DC sensor.

- Lack of oil: Circuit between 2 and 3 will be

opened internally, there will be no current

33AB298632269085en-000401

Danfoss Commercial Compressors

Danfoss Inverter Scrolls

is a worldwide manufacturer of compressors and condensing units for refrigeration and HVAC applications. With a wide range

of high quality and innovative products we help your company to find the best possible energy efficient solution that respects

the environment and reduces total life cycle costs.

We have 40 years of experience within the development of hermetic compressors which has brought us amongst the global

leaders in our business, and positioned us as distinct variable speed technology specialists. Today we operate from engineering

and manufacturing facilities spanning across three continents.

Danfoss Turbocor Compressors

Danfoss Scrolls

Danfoss Optyma Condensing Units

Danfoss Maneurop Reciprocating Compressors

Danfoss Light Commercial Refrigeration

Compressors

Our products can be found in a variety of applications such as rooftops, chillers, residential air conditioners,

heatpumps, coldrooms, supermarkets, milk tank cooling and industrial cooling processes.

http://cc.danfoss.com

Danfoss Commercial Compressors, BP 331, 01603 Trévoux Cedex, France | +334 74 00 28 29

AB298632269085en-000401 © Danfoss | DCS (CC) | 2020.07

Loading...

Loading...