Page 1

MAKING MODERN LIVING POSSIBLE

Introduction to Hydronic Floor Heating

DANFOSS HEATING SOLUTIONS Handbook

Page 2

Handbook Introduction to Hydronic Floor Heating

Index

Page

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Why choose floor heating? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Where can floor heating be used?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Energy consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Comfort and user behaviour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Temperatures in the room. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Optimum floor temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Temperature distribution in the room . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Heat loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Floor heating system dimensioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

For all heat sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Individual room temperature regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Floor construction and system performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2

VGDYA202 © Danfoss 02/2010

Page 3

Handbook Introduction to Hydronic Floor Heating

Introduction

Why choose

floor heating?

In recent years, underfloor heating has become

increasingly popular. This is due to the fact that

underfloor heating provides a range of opportunities

not offered by traditional heating methods both in

residential and commercial buildings.

However, underfloor heating also offers some

challenges and in order to make the very most

of the opportunities it is important to choose the

right solutions with regard to floor construction and

regulation method.

In most countries, floor heating is the preferred

heating method in new buildings. This is particularly

the case in residential properties, but in office

No ‘”ugly’” radiators which require cleaning.

Furniture can be placed as required without having to take radiators into

consideration.

Danfoss offers a versatile range of products for

complete floor heating systems which are all based

on two main principles:

• Danfoss oor heating solutions are optimized for

easy, fast and safe, installation by the installer

• Danfoss oor heating solutions ensure that the

end-users experience optimal thermal comfort at

minimal energy consumption

buildings and other commercial properties it is

also increasingly popular. Floor heating gives the

end-user a number of benefits:

Floor heating provides comfortable heating as your feet are kept warm while your

head is kept slightly cooler. Most people find this difference in temperature between

feet and head most comfortable.

There is currently a tendency to prefer wood and tiled floors over carpeting. It is

exactly for these ‘”cold’” materials that floor heating can provide extra comfort.

As floor heating supplies heat to the entire room, the differences in temperature that

occur between a radiator and the furthest corner of the room are avoided.

Currently, people are focusing much more on their indoor climate. Increasing

numbers are plagued by asthma and allergic problems and it is therefore important

that thorough cleaning of the home is made possible. Floor heating makes cleaning

much easier. In addition – due to the large heating surface – floor heating means that

less air is mixed and thereby less dust occurs in the room.

Everyone is familiar with the problem of water on the bathroom floor. With floor

heating, water evaporates quickly and the floor quickly becomes dry and warm

again.

With floor heating the room temperature can be lowered 1-2 °C which means energy

savings of 6-12 %.

VGDYA202 © Danfoss 02/2010

3

Page 4

Handbook Introduction to Hydronic Floor Heating

Where can floor heating

be used?

Energy consumption

As long as the floor heating system is properly

designed and installed with regard to floor construction, cover, materials, etc., there are practically

no limits to where it can be used.

• Floor heating can be used for all oor nishes, tiled

floors, wood (solid/parquet), linoleum and carpeting (although the output temperature must be

calculated accordingly)

• Floor heating can be used in all new buildings

• For renovation of existing buildings the installation

height may be a limiting factor, but for this type

of application products like the Danfoss SpeedUp™

and SpeedUp Eco™ systems offering very low builtin height are available

The heat consumption of floor heating has been a

much-discussed issue for many years. There have

been many claims about rising heating bills for floor

heating instead of more traditional radiator systems.

When floor heating was originally introduced, house

constructions were not changed and floor heating

was simply installed by running floor heating pipes

in floors, which otherwise were constructed as

usual.

As the floor heating pipes are embedded in the floor,

automatically, there is a greater heat loss downwards

and thereby a negative effect on the heating bill.

• For renovation of single rooms, oor heating connected to the existing heating system and

equipped with a self-acting regulating valve, can

be a good and an economical solution

• For installation of oor heating in the entire property, wireless controls like Danfoss CF2 control system is a great advantage, because no electrical

cables need to be wired

• Floor heating can be used with all heating supply

systems. However, the output temperature must

be adjusted so that the floor surface temperature

never exceeds the recommended value (e.g. recommended by the wooden floor supplier).

Today, things have changed – the floor construction

is insulated far better than before and now special

requirements are in place for the installation of floor

heating.

This means heat loss from the building is now typically equally good for houses heated with floor

heating systems as for houses heated with more

traditional heating systems.

But other factors affect energy consumption when

comparing floor heating to other heating options

namely user behaviour and personal comfort. Most

people find it most comfortable to keep their head

a couple of degrees cooler than their feet and the

room temperature when using floor heating can

therefore advantageously be reduced by 1-2 °C in

comparison to traditional radiators, which means

energy savings of 6-12 %.

Comfort and

user behaviour

4

In contrast, most people feel comfortable with warm

fe et – an d the floo r tem per ature can t hen be so h igh

th at t he roo m te mp er atu re b ec ome s u nco mfo rt ab le,

e.g. in bathrooms with tiled floors.

The above examples of user behaviour pull in

different directions when it comes to energy

consumption and show that it can be difficult to

provide an unambiguous answer to what floor

heating means for energy consumption as this will

depend very much on the individual consumer.

However, it can be concluded that compared

to other heating systems floor heating - if used

correctly - will save energy and at the same time

provide better comfort for the end-user.

VGDYA202 © Danfoss 02/2010

Page 5

Handbook Introduction to Hydronic Floor Heating

23 ˚C

21 ˚C

19 ˚C

19 ˚C

21 ˚C

23 ˚C

0

5 10 15 20 25 27,5 30 35 40 45 °C22,5

20

40

60

80

%

Dissatisfied %

Floor Temperature

Temperatures

in the room

The temperature experienced in a room is the result

of two different factors, air temperature and ambient

radiation, i.e. from the heated elements in the room.

It can be an advantage in many ways that heat

radiation constitutes a relatively high part of the

”overall” temperature or the operative temperature

as it is also called. If a large part of the operative

temperature is made up of the air temperature, it

means that there will be a high convection or mixing

of air in the room.

If there is high mixing, air is whirled around which

can be bothersome as well as mean a higher dust

content in the air and thereby a poorer air quality.

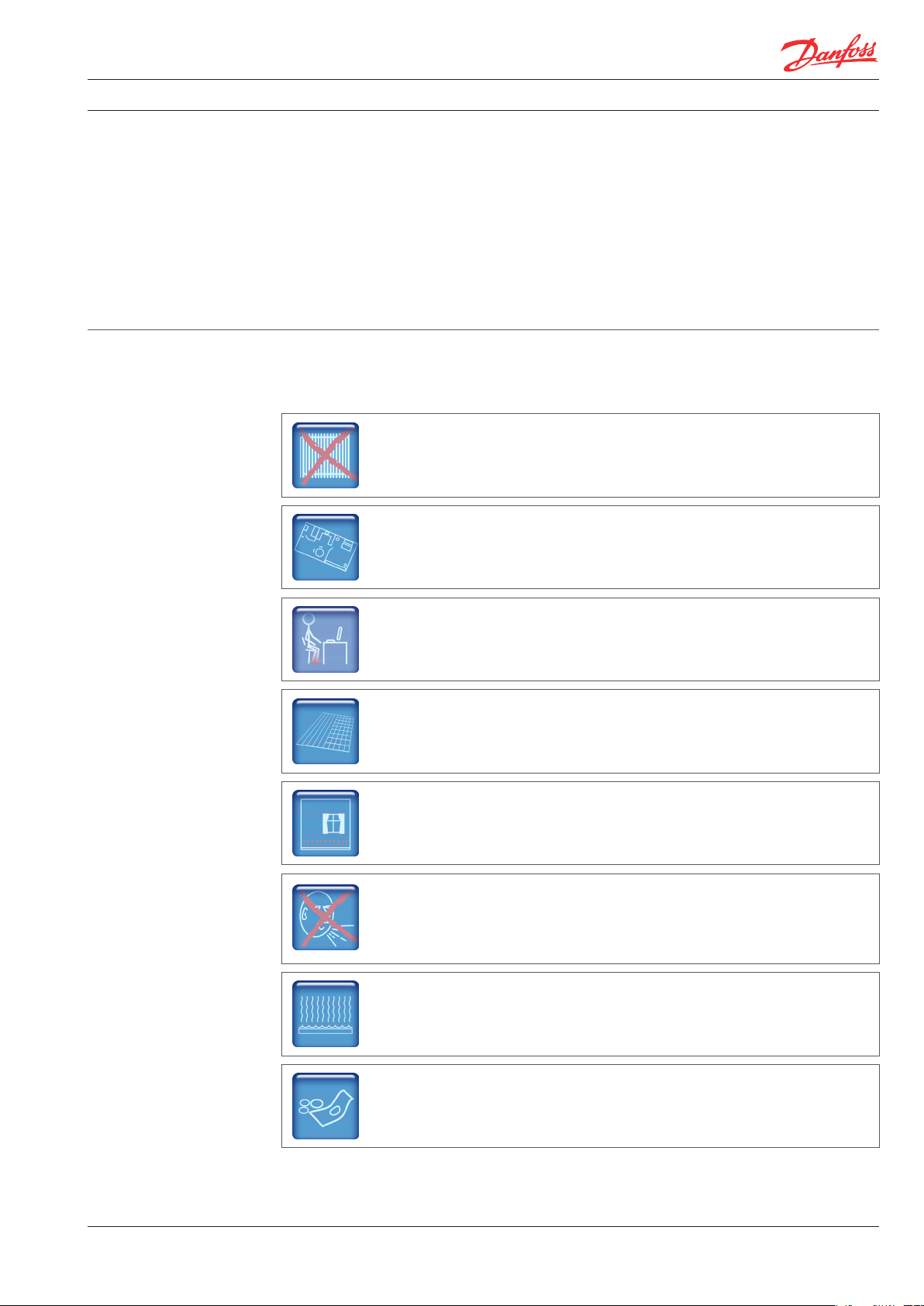

The way convection/ radiation occurs with radiators

and floor heating respectively can be seen below.

As can be seen, with radiator systems the air

temperature or convection makes up approx. 70 % of

the operative temperature. This is also logical if you

think about how a radiator has quite a small surface

from which to transfer heat to the whole room.

Conversely, floor heating supplies heat through a

very large surface evenly distributed in the room

which means that the ratio is just the reverse with

70 % of the operative temperature being added

by radiation.

C

R

R

C

Radiators: 70 % convection/30 % radiation

R

R

R

Floor heating: 30 % convection/70 % radiation

Optimum floor

temperature

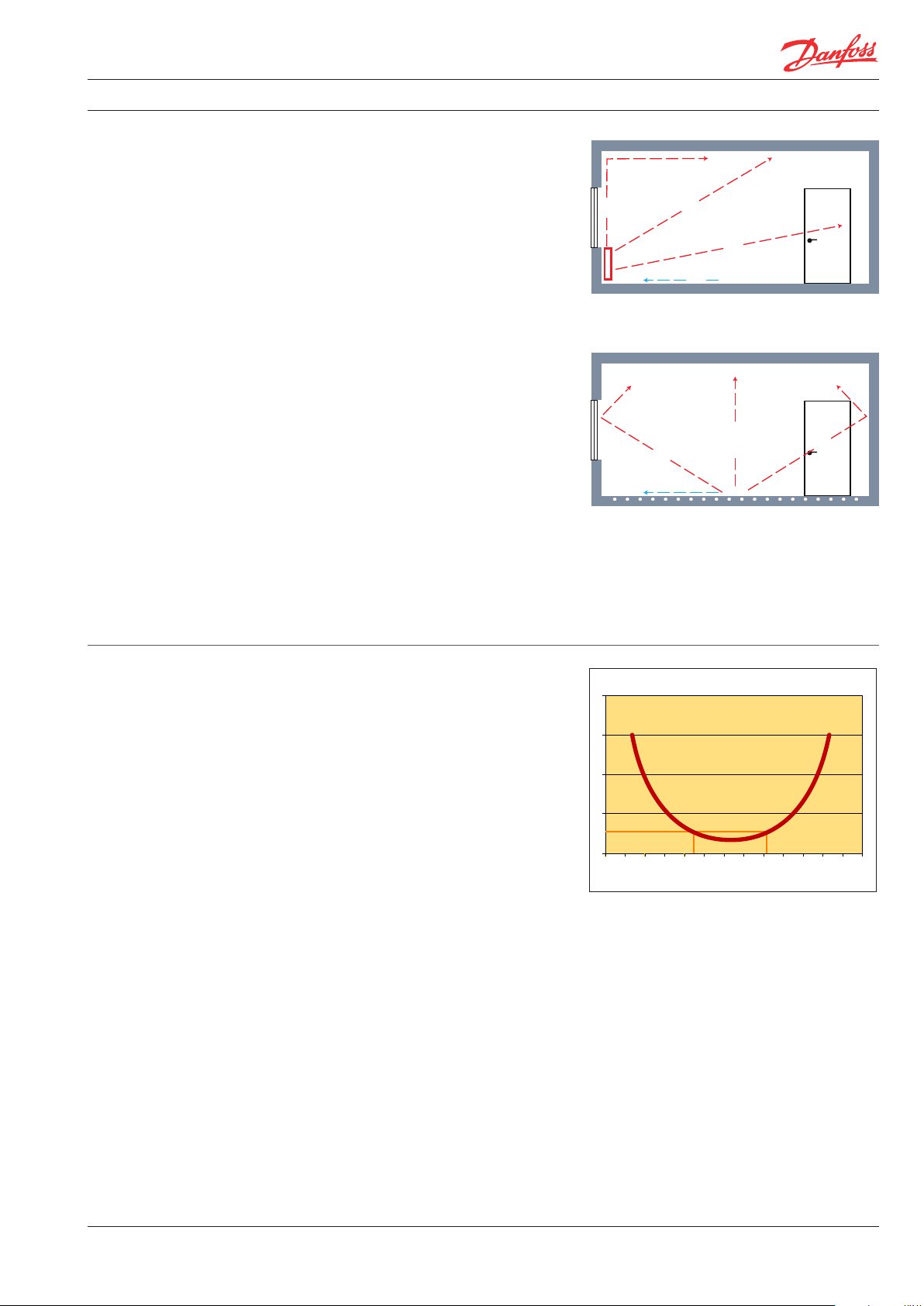

People differ in their perception of what a

comfortable temperature is. It is therefore not

possible to define an optimum floor temperature

to suit everyone. Recommendations for floor surface

temp era ture s can o nly be prov ide d to e nsure that a

minimum number of people are ‘dissatisfied’.

The figure illustrates that at any given temperature

there will always be approx. 10% who will not think

that the temperature is comfortable.

Typically, it is recommended that floor heating

temperatures should fall within the following ranges:

living areas 19-24 °C and bathrooms 24-29 °C.

A minimum number of dissatisfied people will be

found in these ranges.

VGDYA202 © Danfoss 02/2010

5

Page 6

Handbook Introduction to Hydronic Floor Heating

18 19 20 21 22

1.8 m

0.1 m

2.7 m

18 19 20 21 22 18 19 20 21 22 18 19 20 21 22

Ideal heating Floor heating Ceiling heating Radiators

0

21 3 4 5 7 8 9 10 116

20

10

30

50

70

40

60

80

Dissatisfied %

Vertical temperature differens

Temperature

distribution

in the room

In practice, it is not possible to maintain the same

temperature everywhere in a room. As warm air

rises, there will always be a flow of warm air from

the heat source towards the ceiling.

This temperature difference should not be too

large. For vertical temperature differences, it is

recommended that a difference of approx. 2 °C

between floor and head height should be maintained.

This is because most people want to have warm feet

while keeping ‘a cool head’.

But the difference in temperature should not exceed

approx. 3 °C as the body will become ‘confused’ and

comfort is reduced.

The diagram below illustrates how the temperature

is distributed vertically with different types of

heating. As can be seen, the vertical temperature

distribution for floor heating is almost identical to

the ideal distribution.

This means that the average temperature for floor

heating can often be reduced without compromising

on comfort and this means that energy consumption

falls.

Heat loss

Sudden heat loss may occur - especially in older

buildings or in commercial buildings with large/

high windows.

Heat losses occur when insulation in part of a

building - e.g. a window - is not efficient and a large

difference in temperature arises between the areas

near the ceiling of the room and the floor surface.

This temperature difference means that the air is

cooled significantly near the building’s ceiling and as cold air is heavier than warm air - the air ‘falls’ down

towards the floor at a relatively high speed.

This can be a nuisance and create draught problems.

To counteract this problem, the heat source is

typically placed in the location where heat loss is

expected so that an opposite, upward air flow is

created to offset it.

With floor heating this option is not possible as the

6

heat output covers the whole floor. However, several

options exist to alleviate any such problems:

• Low energy windows with more ecient insulation

can be used.

• The oor heating pipes can be laid at smaller

intervals to increase the effect where required

(please note that any stipulated max. surface

temperature must still not be exceeded).

VGDYA202 © Danfoss 02/2010

• It can be ensured that the oor heating supply pipe

is placed in the problem area.

• Window constructions can be optimised - e.g. a

projection to break the cold air flow.

• Supplementary heating can be installed in the

form of convectors.

Page 7

Handbook Introduction to Hydronic Floor Heating

Floor heating system

dimensioning

Floor heating is a low-temperature heating

system and there will usually be a need to mix

the temperature from the primary heat source to

typically 30-40 °C via a mixing circuit like Danfoss

Compact Mixing Shunt.

For a full dimensioning of a floor heating system, a

calculation programme will be required as e.g. the

calculation of supply temperature is complex and

requires detailed knowledge of heat transmission

in the floor’s different materials, etc.

In order to help the installer dimension, install and

commission the floor heating system correctly

Danfoss can - based on relevant input from the

customer - provide a number of services for the

complete floor heating system:

The main products for controlling a floor heating

system on the secondary side (low temperature

side) will typically be as illustrated below.

Master regulator

Room thermostats

Supply manifold

Return manifold

Circulation pump

Bypass valve

Supply temperature regulator

• Drawings and pipe lay out

• Product training

• Dimensioning and parts list

• Ekstensive technical documentation

• Technical and after-sales support

• Direct on-site support

Danfoss - behind you all the way

VGDYA202 © Danfoss 02/2010

7

Page 8

Handbook Introduction to Hydronic Floor Heating

3 6 9 12 15 18 21 24

20

23

17

˚C

For all heat sources

Individual room

temperature regulation

The floor heating system is a low temperature system

with a typical supply temperature of 30-40 °C. This

means floor heating systems can be supplied from

alternative heat sources such as solar heat and heat

pumps. The efficiency of a heat pump varies very

much depending on what supply temperature is

required. If the water temperature supplied by the

heat pump can be reduced the efficiency of the heat

pump increases significantly, as per table.

As an example if a floor heating system is designed

for a supply temperature of 35 °C and a traditional

heating system requires e.g. 55 °C. Then the

coefficient of performance (COP) for the heat pump

will - in accordance with the table - be respectively

5.0 and 3.2. Or in other words the efficiency of the

heat pump will be 56 % better when used together

The temperatures in the rooms in which we live and

work play an important role in our wellbeing. It should

not be too hot or too cold, and the temperature must

be adjusted in relation to what we are wearing and

what we are doing at the time.

For example, office workers typically wear lighter

clothes and have a lower body temperature than

personnel packing products in the warehouse. The

room temperature should therefore be higher in the

areas where office workers carry out their tasks.

Typical room temperatures in a residential building:

23 °C

17 °C

17 °C

20 °C

20 °C

Activities and clothing vary from room to room,

which is why the temperature should be adjusted

accordingly.

with a floor heating system compared to use with a

traditional heating system.

Therefore, the Danfoss floor heating systems

combined with a Danfoss heat pump will make up

the optimal heating system with regard to energy

savings considering both the heat source and the

floor heating system.

Brine temperatur from the collector

°C -5 0 5

35 3.9 4.5 5.0

40 3.5 4.0 4.5

45 3.1 3.5 4.0

50 2.8 3.2 3.6

Supply temperature

to the housebuilding

55 2.5 2.8 3.2

The ultimate goal of temperature regulation is to

ensure maximum comfort combined with minimal

energy consumption.

This means that the heating system must constantly

ensure that the temperature is always suitable in

the different rooms, without

noticeable variations.

There are a range of factors that

must be taken into account, such

as the activities and clothing of the

people in the room, heat loss and

heat gain through windows, lights,

computers and other sources of

heat.

As a minimum, the temperature must be regulated

individually in the separate rooms or zones.

Independent tests and simulations have been carried

out with the purpose of establishing the importance

of regulating temperature in individual rooms for

people’s comfort and for energy consumption. The

results vary, depending on the house/apartment in

question, its construction and user patterns, as well

as on the test method used. However, the results

are all clear on one point – namely, they generally

support the importance of individual room temperature regulation for both comfort and energy

consumption.

It has been shown that energy savings of ~ 25% can

be gained without compromising comfort.

Bathroom

Living room

8

Bedroom

Hour

Temperature achieved with individual room temperature regulation

Temperature achieved without individual room temperature regulation

VGDYA202 © Danfoss 02/2010

Page 9

Handbook Introduction to Hydronic Floor Heating

17.0

18.0

19.0

20.0

21.0

22.0

23.0

24.0

25.0

26.0

27.0

28.0

Date: 2002-02-07

0

2 4 6 8

10 12

14

16

18

20

22

24

Temp Setpoint,

Floor surface, Deg-C

Oper. temp Livi ng room[1], D eg-C

TAIRMEAN

17.0

18.0

19.0

20.0

21.0

22.0

23.0

24.0

25.0

26.0

27.0

Date: 2002-02-07

0 2 4 6 8 10 12 14 16 18 20 22 24

Temp Setpoint,

Floor surface temp., Deg-C

Oper. temp Livi ng room[1], Deg-C

TAIRMEAN

Floor construction and

system performance

In order to achieve best possible comfort for the

end-user, main purpose for the heating system is

to provide exactly the right amount of heat at the

right time and in the specific needed room. In order

to do so the floor heating controls must be able to

regulate each room individually.

However, this is not enough, the heat emitter - in this

case the floor - must also be taken into consideration.

Typically, floor heating systems have been based

on pipes embedded in concrete, thus making the

amount of energy stored in the heating system

very large.

Typical heavy floor with pipes embedded in concrete

This means when a room has reached the desired

temperature and the room thermostat shuts down,

the supply of warm water to the room, the floor will

still continue supplying heat until the floor surface

temperature reaches the room temperature.

This is a process which can take several hours

during which the room temperature will continue

to increase. In order to overcome this problem it is

necessary that the heat emitter reacts quickly to

sudden temperature changes in the room.

As opposed to traditional concrete floors which

are “heavy” in terms of reaction time “light” floors

constructed by insulation material and heat

distribution plates - as Danfoss SpeedUp™ and

SpeedUp Eco™ - are much quicker and allows for

a more precise control of the temperatures in the

room.

Light floor (Danfoss SpeedUp™)

Example

In this example a traditional “heavy” floor is compared with the “light” Danfoss SpeedUp™ floor, both

installed in a typical one-family house.

The graphs show the development in actual temperatures over a period of 24 hours including two

set-back periods where the set-point temperature is changed from 21 °C to 17 °C.

The performance of each system is illustrated by how well the actual temperature ( ) follows

the desired set-point temperature ( ). When analyzing the graphs it is evident that the light

floor is better capable of following the desired set-point temperature than the heavy floor which is

too slow for a set-back period to have any effect. Main reason for the difference is also clearly illustrated by the graph showing floor temperature ( ) which for the light floor increase and decrease

very quickly compared to the one of the heavy floor.

"Heavy" floor construction Danfoss SpeedUp™ "light" floor construction

The simulations are worked out in the simulation programme, IDA Indoor Climate and Energy 3.0.

VGDYA202 © Danfoss 02/2010

9

Page 10

Handbook Introduction to Hydronic Floor Heating

Summary

The Danfoss floor heating systems ensure optimum

comfort at all times.

The precise regulation of the CF2 wireless controls

together with the rapid response of the SpeedUp

floor panels provides you with the desired temperature in minutes; not hours, thus providing you with

energy savings and reduced costs.

10

VGDYA202 © Danfoss 02/2010

Page 11

Handbook Introduction to Hydronic Floor Heating

VGDYA202 © Danfoss 02/2010

11

Page 12

Handbook Introduction to Hydronic Floor Heating

Your Key to Optimum Floor Heating

Floor heating is much more than pipes!

The optimum floor heating solution

provides accurate temperature control,

instant heat, comfort and energy efficiency.

Danfoss will provide you with optimum

floor heating solutions.

12

The Danfoss solutions rank among the

best and the most advanced in the

world; combining years of experience

with development and technical

know-how. We provide floor heating

solutions which are both quickly and

easily installed for you.

VGDYA202 © Danfoss 02/2010

Our wide range of products and our

technical expertise make Danfoss your

one-stop provider, saving you both time

and worries. And the more time you save

on installation and servicing, the more

time you have to optimise your business

opportunities.

Loading...

Loading...