Page 1

Data Sheet

Intrinsically Safe Pressure Pilots Control

Series 90

For more than 40 years, Danfoss has been developing

state-of-the-art components and systems for mobile

machinery used in off -highway operations around

the world. We have become a preferred supplier by

offering the best of what really matters: The hardware

inside your vehicle application.

This line of Intrinsically Safe Pressure Control Pilots

receives a low current input signal from a variety of

machine controllers and converts the current signal

into a proportional differential pressure signal

suitable to control larger hydraulic equipment in

hazardous locations. The intrinsically safe controls can

be added to a Series 90 pump as a standard option or

purchased separately.

Danfoss offers five different models of intrinsically

safe pressure control pilots to accommodate a variety

of standard industrial process controllers. Various

combinations of hydraulic nozzle sizes and coil

resistances yields a relationship between electrical

current (input) and hydraulic differential pressure

(output).

Features

•

Standard manual override

•

Withstands mobile equipment vibration

and shock conditions

•

Controls both pilot-operated pumps/

motors and main spool valves

•

Standard MS-style connector

•

Self-contained pressure feedback

•

Constant scale factor with varying pilot

pressure

•

Can be used in either closed loop or

open loop systems

Comprehensive technical literature online

at powersolutions.danfoss.com

©

Danfoss | May 2016 L1317823 | AI00000178en-US0106 | 1

Page 2

Specifications

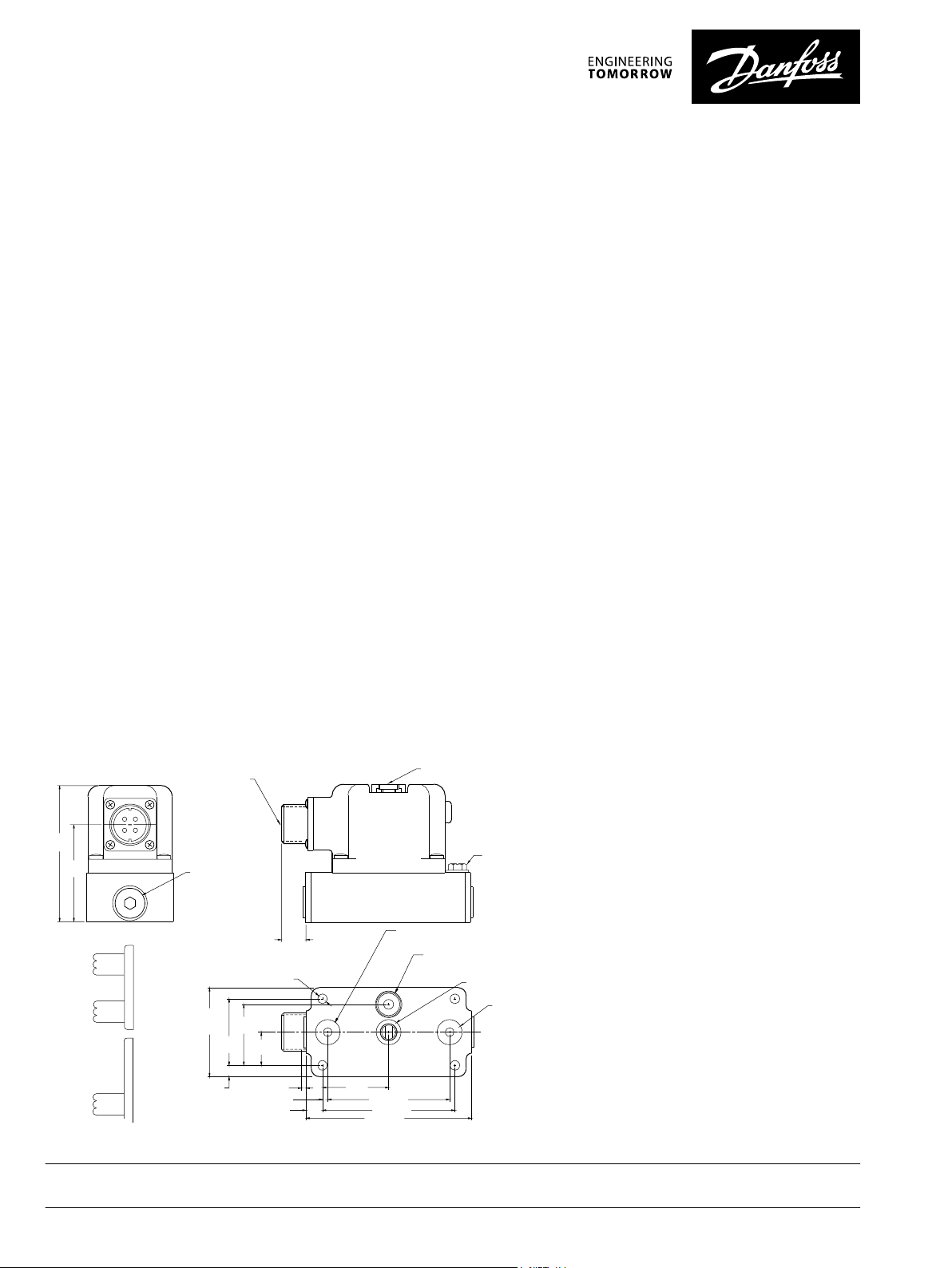

MS Connector

Manual Operator

Output Port - C1 4,8 (0.19) Dia.

12,8 (0.50) O.D. X 1,78 (0.07) O-ring

Pressure Port Thru Filter 5,6 (0.22) Dia.

12,8 (0.50) O.D. X 1,78 (0.07) O-ring

Return Port 4,8 (0.19) Dia.

12,8 (0.50) O.D. X 1,78 (0.07) O-ring

Output Port - C2 4,8 (0.19) Dia.

12,8 (0.50) O.D. X 1,78 (0.07) O-ring

38,1

(1.50)

70,1 (2.76)

76,2 (3.00)

95,2 (3.75)

2,5 (0.10) (2)

3,0 (0.12)

9,5 (0.38)

6,3

(0.25)

50,8

(2.00)

MAX

38,1

(1.50)

34,9

(1.375)

19,0

(0.75)

5,5 (0.217) DIA (4)

12,7

(0.50)

Intrinsically

Safe Device

Enclosure

Grounding

Terminal

P108 659E

A

B

C

D

A

B

C

D

Dual Coil

Single Coil

Upper Coil

Lower Coil

Dimensions mm (inches)

78,7

(3.10)

56,1

(2.21)

17,5 DIA (2)

(0.69)

NEC 500 Rating: Exi, Class I, Division 1, Groups C & D, T4

•

Exi – Intrinsically Safe Explosion Protected

•

Class I – Gas applications as defined by Gas Group Designation

•

Division 1 – Area Classification, Gases defined by Gas Group Designation may be present more than 1000 hours per year

•

Gas Group Designation C & D – Approved for use in Ethylene and Propane Applications

•

T4 – This equipment will not exceed 135°C under normal operating conditions

NEC 505 Rating: Class I, Zone 0, Ex ia / AEx ia, Gas Group IIB, T4

•

Class I – Gas applications as defined by Gas Group Designation

•

Zone 0 – Area Classification, Gases defined by Gas Group Designation may be present more than 1000 hours per year

•

Ex ia / AEx ia – Intrinsically Safe Explosion Protected

•

Gas Group Designation IIB - Approved for use in Ethylene and Propane Applications

•

T4 – This equipment will not exceed 135°C under normal operating conditions

ATEX Rating per IEC 60079-11: Equipment Group II, Equipment Category 1, Environment G, Ex, ia, IIB, T4

•

Equipment Group II – Non-Mining Applications

•

Equipment Category 1 – Hazardous material defined by Environment Designation may be present more than 1000 hours per year

•

Environment G – Gases defined by Gas Group Designation

•

Ex – Explosion Protected Equipment

•

ia – Intrinsically Safe Protection Method

•

Gas Group Designation IIB - Approved for use in Ethylene and Propane Applications

•

T4 - This equipment will not exceed 135°C under normal operating conditions

IECEx Rating per IEC 60079-11: Ex ia, Gas Group IIB, T4 - Temperature Rating, Ga - Zone 0

•

Ex – Explosion Protected Equipment

•

ia – Intrinsically Safe Protection Method

•

Gas Group Designation IIB - Approved for use in Ethylene and Propane Applications

•

T4 – This equipment will not exceed 135 deg C under normal operation conditions

•

Ga – Area Classification, Gases defined by Gas Group Designation may be present more then 1000 hours per year

Schematic

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

2 | © Danfoss | May 2016 L1317823 | AI00000178en-US0106

Loading...

Loading...