Page 1

Gateway InterBus-S

Part 1 ■ Overview . .... ..... ..... .... ..... ..... ..... ..... .... ..... ..... ..... .... ..... .....2

Part 2 ■ P roperties of PROFIBUS-DP ...... ..... .... .... .... .... .... .... ..... ..3

Configuration of the fr equency converter . . .. .. .. .... . .. .. .. .... . .. .. ..4

Notes concerning pr ogramming ............................................5

Control word . .. . . . . . . .. . . . . . . ... . . . . . . ... . . . . . . .. . . . . . . ... . . . . . . .. . . . . . . ... . . . .5

Reference/Actual value . .. .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. .. . . .. . . .. . . ..5

Parameterization . . .. . . .. . . .. . .. . . .. . . .. . .. .. . .. .. . . .. . .. .. . .. .. . . .. . .. . . .. . . .5

Parameter interface in Write.Request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Parameter interface in Read.Request . .. .. .. . .. . .. . .. ... .. ... .. ...7

Part 3 ■ Properties of the Interbus-S . .. . . . .. . . . .. . . . .. . . . . . . . . . . .. . . . .. . . . .. . . .9

ID-Code . ......... ....... ......... ....... ......... ....... ................ ................9

Length codes . ..... ...... ...... ..... ...... ...... ...... ...... ...... ..... ...... ...... ..9

PCP Communication ...........................................................10

Communication objects . .. .. ........ .. .. .. ....... .. .. .. ........ .. .. .. .10

Communication re fe rence list ........ ...... ...... ...... ...... ...... ...... ..13

Error reports in PCP Communication . .... .. ..... .. .... .. .... .. .... .. ..13

Contents

English Deutsch

Part 4 ■ Technical data .. . .. . .. . . .. . .. . .. . . .. . .. . .. . . .. . .. . .. . . .. . .. . .. . . .. . .. . . .. . .14

Example of installation . . . . .. . . .. . . . . . . .. . . . . . . .. . .. . .. . . .. . . . . . . .. . . . . . . .. . . . .14

Connection of the PROFIBUS bus wire. .. ...... .. .. .. .. .. ...... .. .. ..15

Connection of the Interbus-S bus wire . . . .. . . . .. . . . .. . . . .. . . . .. . . . . .. .15

Messages ............................................................................16

Operating units . . . . . . . . .. . . . . . . .. . . . . . . .. . . . . . . .. . . . . . . .. . . . . . . .. . . . . . . .. . . . . . . .. . .16

Terminals and connectors . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . ..16

Housing ............... .................... .................... ................. ... .. ..16

Part 5 ■ Example of program for Siemens S5-115U ...................17

■ Index . .. .. . .. . .. . .. . .. .. . .. . .. . .. .. . .. . .. . .. . .. .. . .. . .. . .. .. . .. . .. . .. . .. .. . .. . ..33

MG.10.G1.51 – VLT i s a r egister ed Danfoss trademark

1

Page 2

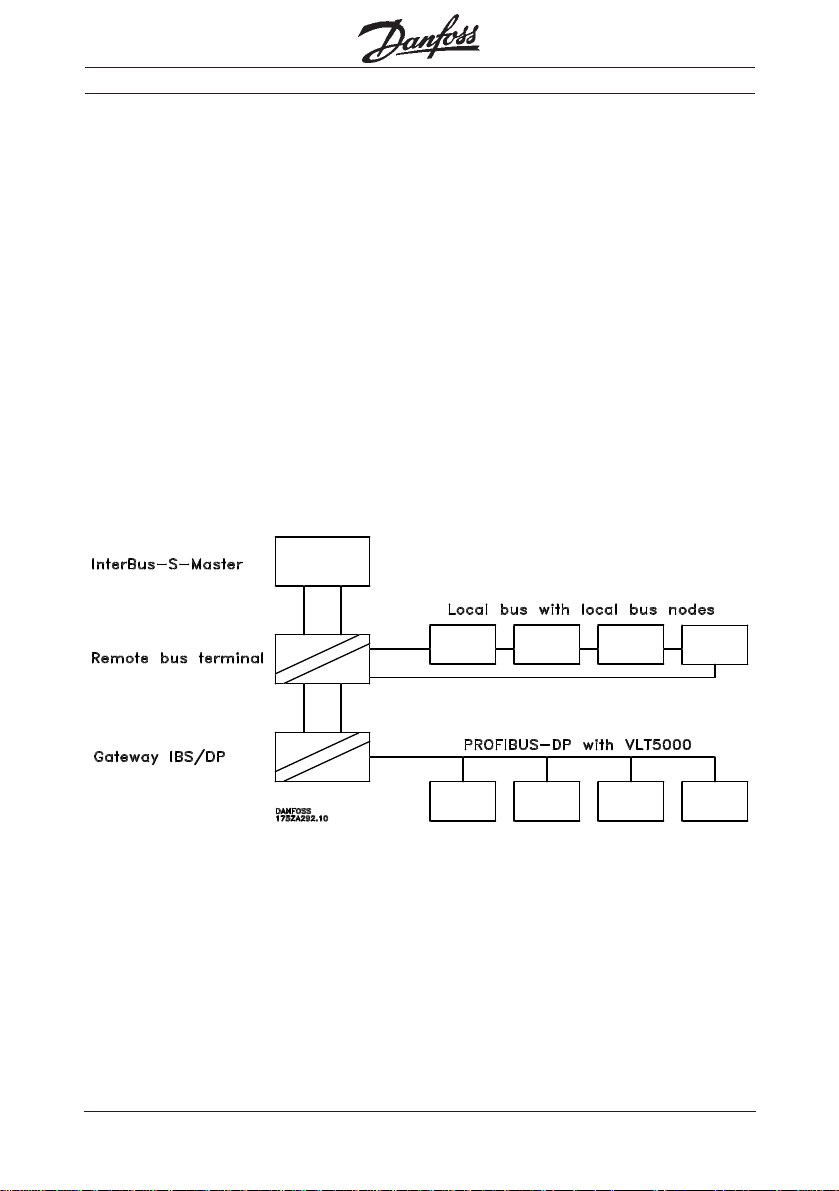

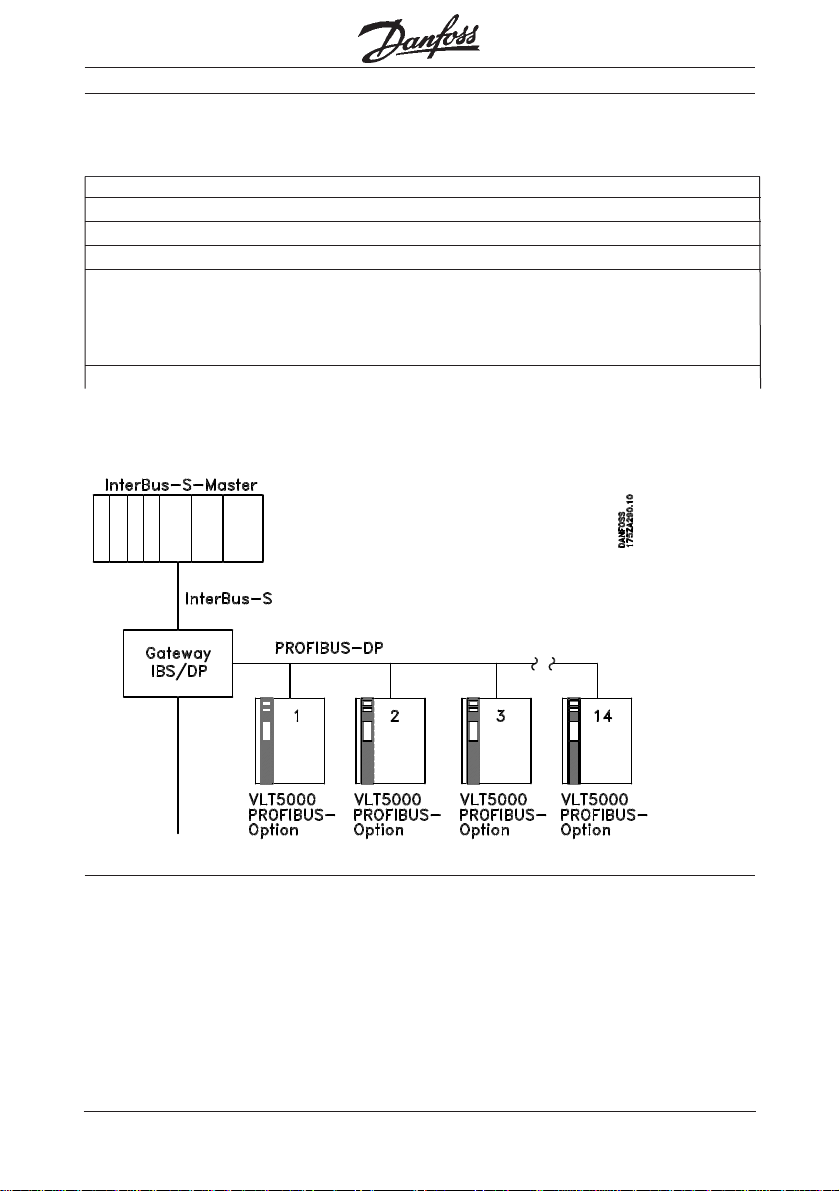

■

Overview

The purpose of the InterBus-S /

PROFIBUS-DP-Gateway is to enable the

®

Danfoss VLT

Overview

5000 Frequency Converter

to be operated with the Field Bus system

InterBus-S. For this purpose, the

Gateway converts the InterBus-S

Telegrams to PROFIBUS-DP-T elegrams,

which are then transmitted to the VLT

Reporting back occurs in the same way.

The Gateway converts the PROFIBUS-

®

DP-T elegrams from the VLT

, which are

then tranmitted to the master via the

InterBus-S.

Gateway InterBus-S

The Gateway enables connection of up to

®

5000 with a PROFIBUS Option

14 VLT

Card. The Gateway sends continuous information of the selected PPO Type with

the actual pr ocess data block and the

actual parameter block to the VLTs .

®

.

As is usual with InterBus-S, connection of

the Gateway occurs in the form of a

r emote bus participant. However, t hi s

does not convert to the InterBus-S Local

Bus, but to PROFIBUS-DP. This also

means that the well-known limitations of

the local buses, such as max. 8 nodes,

r eady-made bus wire, maximum extension

8 metres, etc., no longer apply.

For communication on the PROFIBUS-DP,

ther e is a choice between PPO Types 1

( P rocess data and parameter interface) or

PPO T ypes 3 (process data only). Process

data is handled as I/Os, i.e. it is available

for the user in the I/O-ar ea of the PLC and

is transmitted with

2

every InterBus-S-cycle.

®

Parameterization of the VLT

via the parameter interface is ef fected via PCP Communication.

MG.10.G1.51 – VLT is a r egister ed Danfoss trademark

Page 3

■

P roperties of the PROFIBUS-DP

A maximum of 14 VLTs can be linked up using the PPO Type1 (12Byte) or the PPO

Type3 (4Byte). The selection of PPO Type

goes for all VLTs; mixed operation is not

permissible and will lead to an err or

report.

The InterBus-S in-/output data is

p r ojected on the PROFIBUS-DP without

any interpr etation being of f ered. W ith one

exception, bit 10 of the contr ol wor d

(CW), is inverted. This ensur es that when

the PLC moves to Stop and resets all

outputs, the connected VLT s will stop,

too; also, when the InterBus-S

communication starts, it is ensur ed that

®

the VLT

5000 remain stopped.

Gateway InterBus-S

The PPO Type1 allows parameterization of

the VLTs , r etrieval of all values and parameters - including fault and diagnostic

data, as well as contr ol of the VLT

reporting back on its actual state.

The PPO Type3, on the other hand, allows

only control and r eporting back on the

®

state of the VLT

.

With respect to the functioning and handling of the parameter interface in PPO

Type1, please r efer to the manual on

PROFIBUS Option Card s for VLT

The baudrate on the PROFIBUS-DP is

1.5Mbaud, which means that the

maximum bus cable length is 100 m.

Further information is available fr om the

PROFIBUS manual for VLT

®

5000.

®

with

®

5000.

P roperties of PROFIBUS-DP-Page

English Deutsch

!!! IMPORTANT !!!

Before inserting the PROFIBUS Option Car d, the VLT® should be tur ned on and

parameter 620 should be set to "Initialize". Subsequently, remove the power and

insert the PROFIBUS Option Card. When the unit is turned back on, new

i ni ti al iz at io n is e ffected automatically. Be aware that all parameters will be set to

Factory setting!

If this sequence is not possible, or if the PROFIBUS Option Card has alr eady

been inserted, the keys DISPLAY/STATUS + MENU + OK must be pressed

simultaneously before tur ning on the VLT

keep the three keys pr essed until the message "Manual Initialize" appears in the

bottom line of the display window (see page 136 in MG.50.AX.02).

MG.10.G1.51 – VLT i s a r egister ed Danfoss trademark

®

; subsequently, t u rn on the power and

3

Page 4

Gateway InterBus-S

■

Configuration of the frequency

converter

The following parameters are to be set

or checked, respectively:

Parameter 502-508

Motor coasting, quick-stop, DCbraking, start, reversing, reset, setup

selection, selection of digital refer ence,

this is wher e to decide if contr ol is going

to be via "BUS" only or via "Digital In-

P roperties of PROFIBUS-DP

put" only, or via a combination of the

two. In the case of BUS-selection only,

all parameters should be set to "BUS" at

this point.

Parameter 512

Telegram profile

this is wher e to select the telegram Pr of il e, the profiles ar e descriped in the

PROFIBUS manual for VLT

Danfoss recommend to use Danfoss

profile.

Parameter 801

Baudrate

enter the Bus-Baudrate selected for your

Gateway, or leave the rate at "1.5

MBAUD". At present, the Gateway

baudrate has been set at a fixed rate of

1.5Mbaud.

Parameter 800

FMS/DP-selection,

this is wher e to set "DP"; This is the

factory setting.

Parameter 803

Bus time out,

this time selection determines the delay

The parameters set on the VLT

are not activated until the

power supply has been cut off

and re-cycled.

®

5000.

after a BUS drop-out befor e a r eaction

fr om the fr equency converter is to ensue.

Parameter 804

Bus time out function,

select the r eaction after a BUS drop-out.

Parameter 904

PPO select,

enter the telegram desired, e.g. for PPO

Type1 enter "PPO type1", for PPO Type3

enter "PPO Type3". The PPO types ar e

descriped in the PROFIBUS manual for

®

VLT

5000.

Parameter 918

Station address,

this is wher e the station addr ess is

selected. The range of operation of the

Gateway is from 1-14, with attention

having to be given to thr oughgoing

addressing. The address range basically

begins at "1" and ends at the address of

the maximum number of units available.

This physical position at the BUS has no

influence on addressing.

Parameter 927

Access to parameter change,

this is wher e to select whether the parameter can be altered via the BUS,

("Enable"), or whether this possibility is to

be disabled ("Disable") .

Parameter 928

to p rocess contro l ,

like 927, although this is wher e i t i s t o b e

decided whether control i s going to be effected via the PROFIBUS ("Enable") o r

not ("Disable" ).

®

All other parameters are to be set in

accordance with the intended application,

as described in the product manual.

4

MG.10.G1.51 – VLT is a r egister ed Danfoss trademark

Page 5

Notes concerning programming:

■

The fr equency converter can now be controlled via the BUS; this is ef fected simply

t h r ough setting or r eading of I/O-Bits.

Control w ord

■

As opposed to what is said in the product

manual about the PROFIBUS Option

Car d, bit number 10 has to be set at "0"

to enable control. This will ensur e that the

®

VLT

accepts the control word. The

Gateway automatically converts this bit to

a "1".

The control wo r d f o r:

starting forwar d is

047F Hex or 0000 0010 0111 1111.

starting r everse is

847F Hex or 0100 0100 0111 1111.

stopping with normal ramp (Param. 208) is

044F Hex or 0000 0100 0100 1111,

stopping with alter native ramp (Param.

210) is 064F Hex or 0000 0110 0100

1111.

■

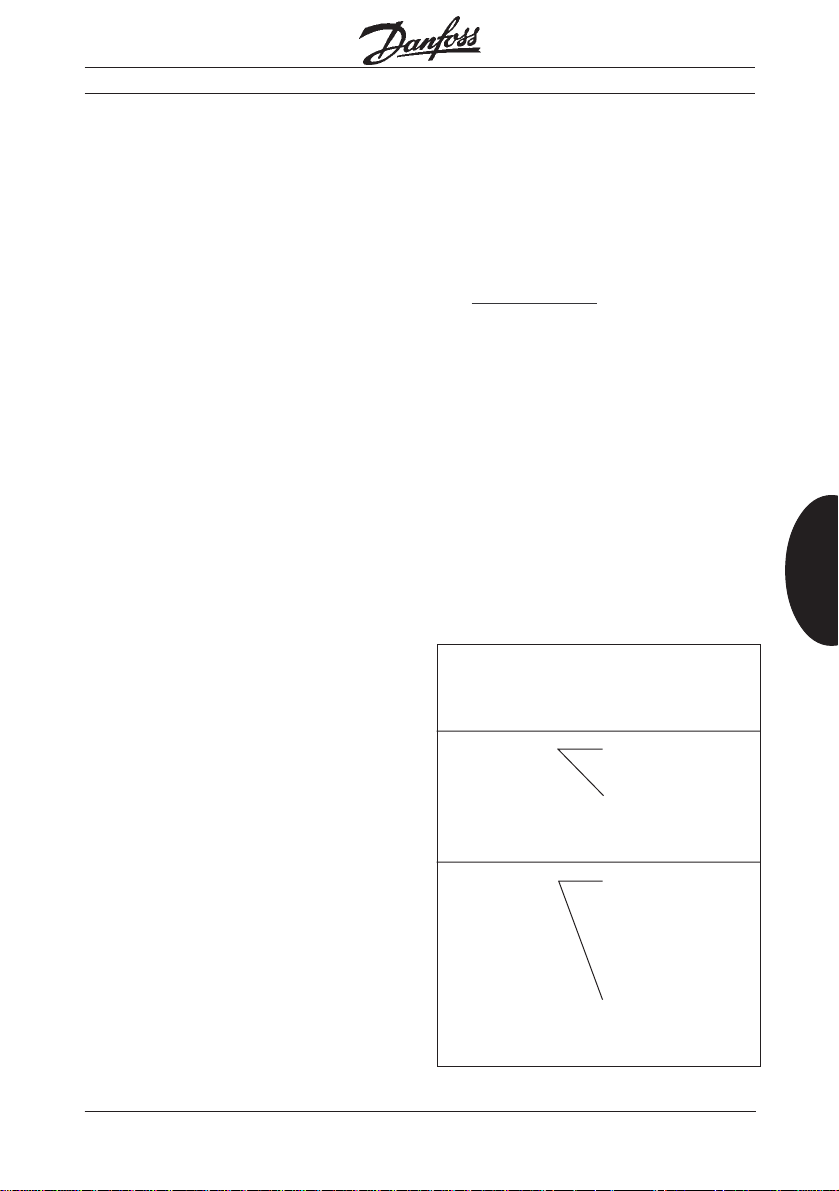

Reference/Actual values

The r efe rence and the actual value of the

®

VLT

r etur ned are handled in a norm-set

format. The setting range goes fro m

-10000 for -100.00% up to +10000 for

+100.00%. The 100.00% corresponds to

4000 hex. Negative re fe r ence ar e

generated through the two's complement.

Example:

Min.fr equency = 0Hz;

Max.frequency = 50Hz

Desir ed is 25Hz corr esponding to 50% of

the max. rpm:

50.00% = 2000 hex =

0010 0000 0000 0000Binary

Gateway InterBus-S

For 25Hz with reversing = -50% of the

max. rpm:

50.00% = 2000 hex =

0010 0000 0000 0000Binary

reversal of a positive to a negative desir ed

value:

0010 0000 0000 0000 Binary

-> 1101 1111 1111 1111 Binary One's complement

->+ 1 Binary

= 1110 0000 0000 0000 Binary Two's complement

-50.00% = E000 hex = 1110 0000 0000 0000Binary

If you would like to know more about

contr ol word, state-machine, ref erence

value, etc, please consult the pr oduct manual for the PROFIBUS Option Card .

■

Parameterization

Parameterization via the Bus is only

possible if using PPO Type1.

Parameterization is ef fected via PCP

Communication. The procedure i s a s

follows:

Order to Report from

IBS-master: VL T

W rite.Request Confirmation

Read.Request Confirmation

®

to master:

positive

Confirmation

negative, r eporting

of er ror code

positive includes

the data of the

r equested parameter of the VLT

Confirmation

negative, r eporting

of er ror code

P roperties of PROFIBUS-DP

English Deutsch

®

MG.10.G1.51 – VLT i s a r egister ed Danfoss trademark

5

Page 6

■

Parameter interface in

W rite.Request

The parameter interface (PCV) of the VLT

5000 contains a total of 4 words. This

enables r eading and writing of paramet e r s, reading of arrays, writing, etc.

The parameter interface can be detailed

as follows:

1. Word (Parameter -Identification-Value,

PCA); in the lower 11 bits (bits 0..10) enter

P roperties of PROFIBUS-DP

the parameter number, i n the upper four

bits (bits 12..15) select the desir ed action.

2. Word (Index/Subindex, IND); the byte

"Index" is only used if wanting to use

elements of an array. I n this case, enter

the index of the element in question. In

normal parameter actions, this byte is not

used. The byte subindex is intended for

subsequent extensions and is not used at

this point.

Gateway InterBus-S

Example:

®

5000, with bus address 2, the

In VLT

®

parameter 202 maximum frequency is to

be changed to 80 Hz,

PCA: 20CA

Parameter CA hex = 202

Action 2 = Change parameter value

IND: 0000

no Subindex

no Index

PVA: 0000 0320

Parameter value_low =

320 hex = 800 = 80.0 x Factor 10

Parameter value_high = 0

3. + 4. Wo rd (Parameter Value, PV A) ; i n

the case of write action, this is where the

value of the selected parameter is enter ed. The thir d word is the High-Wo r d; the

fourth word is the Low-Wor d. The thir d

wor d is only used if parameter values

above 65535 are to b e transmitted.

Since values are not transmitted in

comma format, each parameter value

must be multiplied by a factor. The parameter factor in each case can be seen

from the manual for the PROFIBUS Option

Card .

6

MG.10.G1.51 – VLT is a r egister ed Danfoss trademark

Page 7

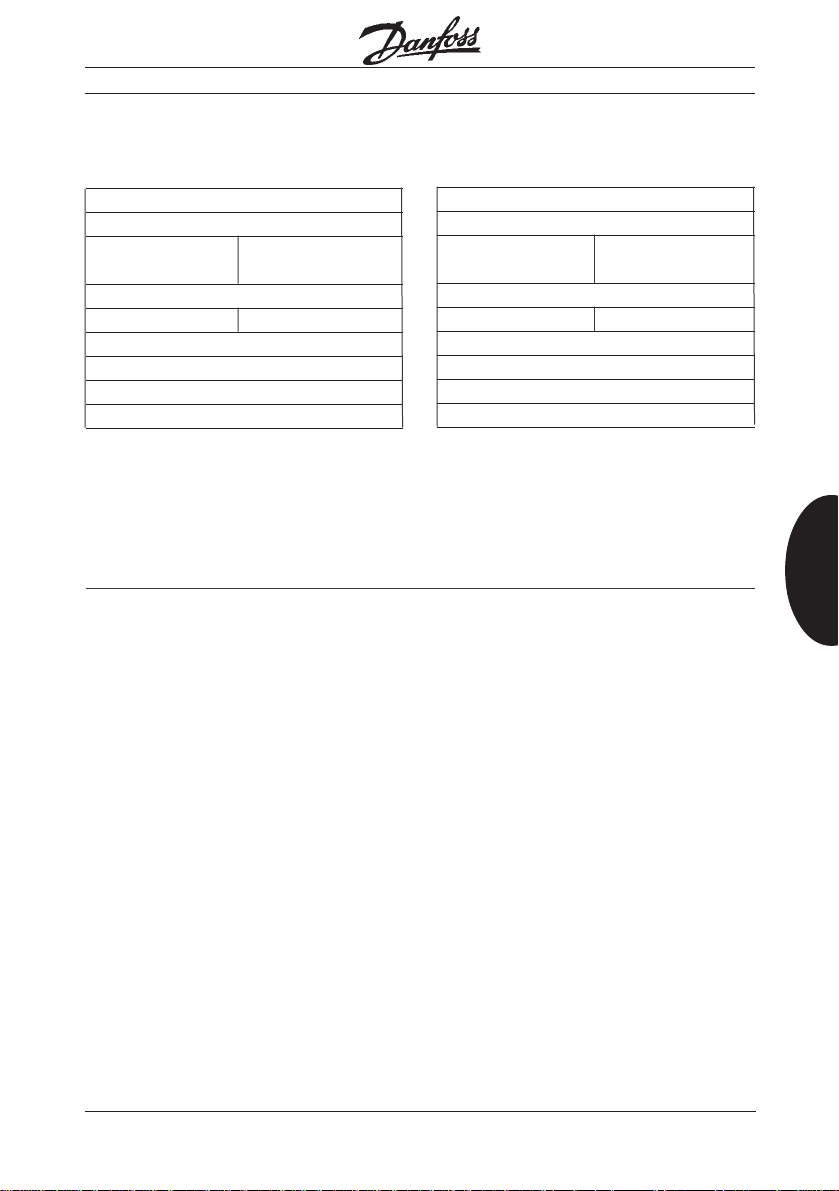

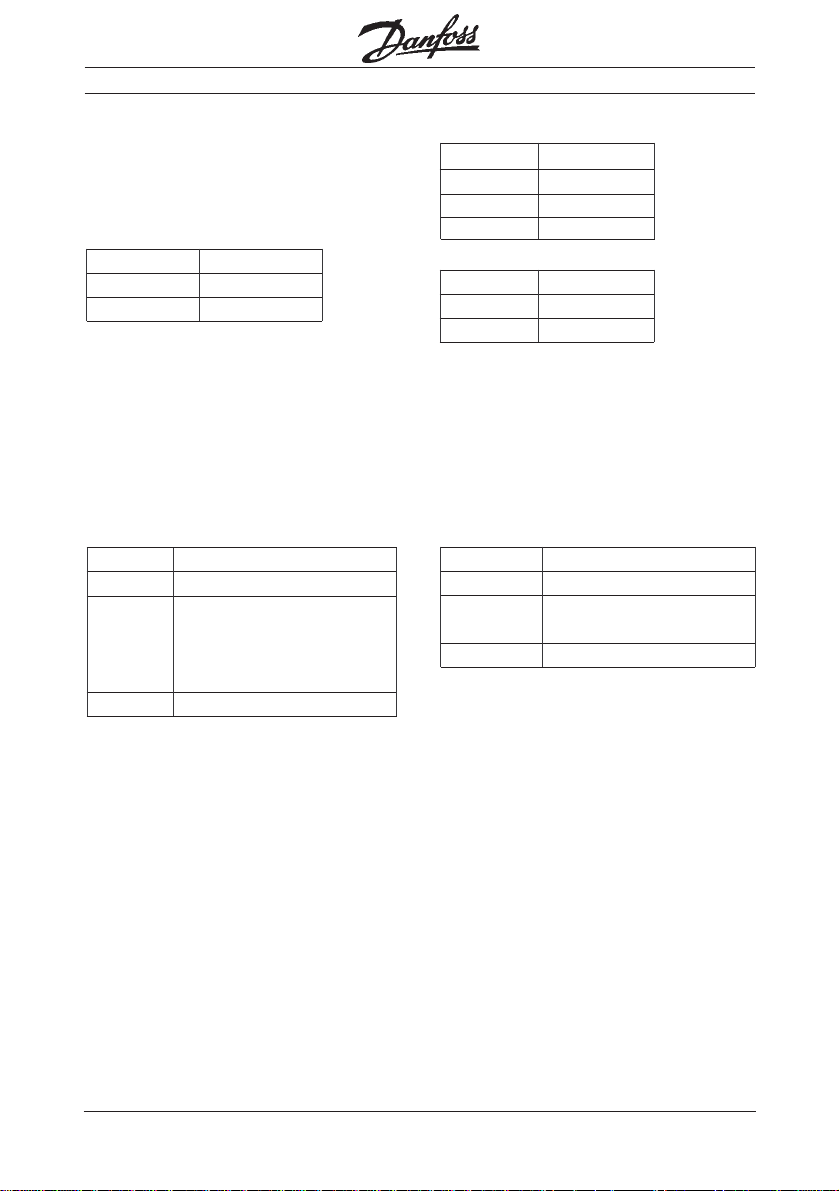

The r equest on the PCP channel now

looks as follows:

All values in hex.

W rite.Request

No. of subsequent values

invoke_id Communications

Reference

index

VLT®-Address No. of Bytes

PCA

IND

High_Parameter value

Low_Parameter value

Successful completion is indicated in the

form of a positive confirmation.

I f al l VLTs a re to be parameterized at the

same time, a zero i s to be enter ed instead

of the VLT-address.

■

Parameter interface in

Read.Request

Responses from the VLT® to an or der

initiated pr eviosly via Write.Request. Data

is only available in the case of a positive

confirmation; if ther e is a negative

confirmation, an err or code is r eported.

1. Word (Parameter-Identification-Value,

PCA); in the lower 11 bits (bits 0..10) the

®

enters the parameter number; in the

VLT

upper four bits (bits 12..15) the type of

r esponse appears.

Gateway InterBus-S

8082

007

00 02

5FA5

02 08

20CA

0000

0000

0320

Now the length of the data has to be

enter ed; since, however, this is only pr epared for the maximum layout, a length of

112 bytes has to be entered here. Now

follows the data of the VLTs, i n the sequence of their addresses.

3. + 4. Wo r d (Parameter value, PVA) ; this

is wher e the VLT

selected parameter. The thir d wor d is the

High-Wor d; the fourth word is the LowWor d. The thir d wor d is only used if parameter values above 65535 have been

transmitted.

Since the values to be transmitted are not

transmitted in comma format, the individual parameter value must be divided by a

factor to obtain the actual value. The individual parameter factor can be seen in the

manual for the PROFIBUS Option Card.

®

enters the value of the

P roperties of PROFIBUS-DP

English Deutsch

2. Word (Index/Subindex, IND); the byte

"Index" is only enter ed if elements of an

array have been accessed. In normal parameter actions, this byte is not used. The

byte subindex is intended for subsequent

extensions and is not used at this point.

MG.10.G1.51 – VLT i s a r egister ed Danfoss trademark

7

Page 8

Gateway InterBus-S

Example:

®

The r esponse fr om the VLT

5000 is to be

r ead onto the above order transmitted via

W rite.Request.

The order on the PCP Channel looks as

follows:

All values in hex.

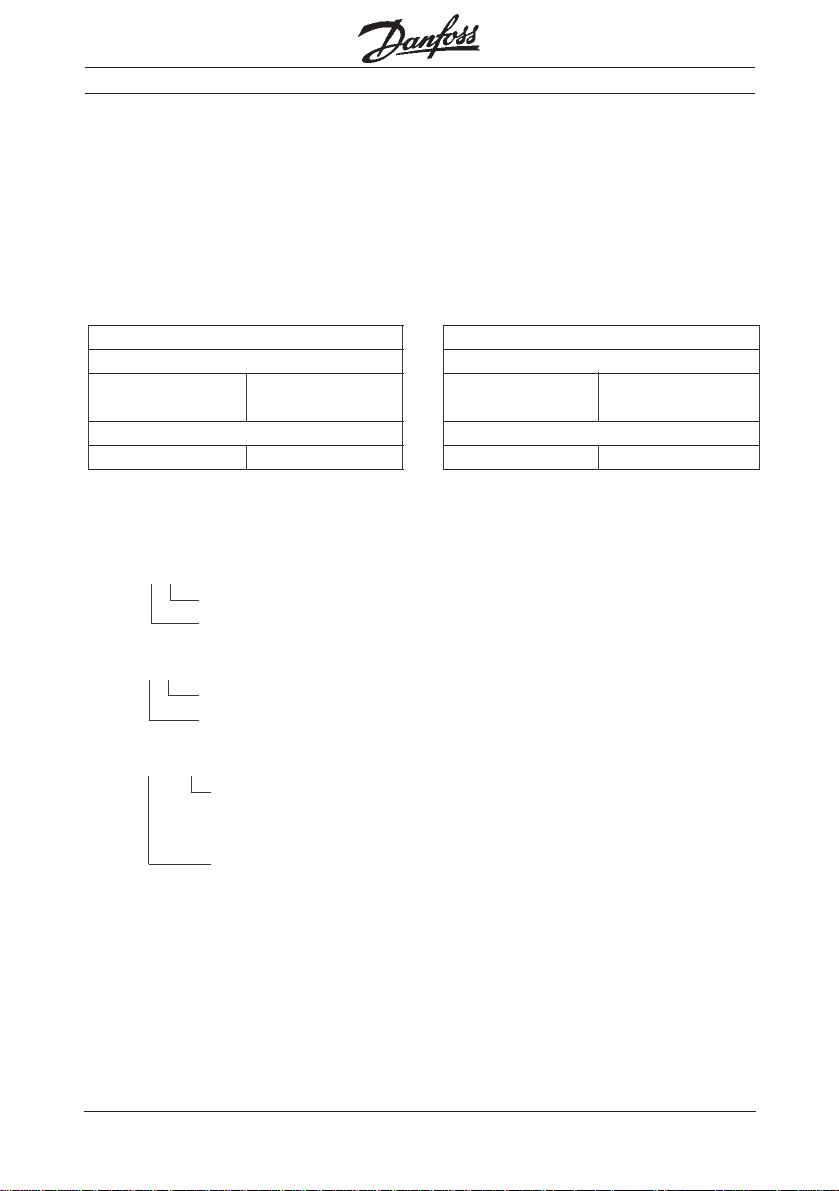

Read.Request

P roperties of PROFIBUS-DP

No. of subsequent values

invoke_id Communications

Refer ence

index

VLT-Addr ess No. of Bytes

After completion of the Read.Request, the

following data is obtained:

PC V: 10CA

Parameter CA hex = 202

Action 1 = Transmission of

parameter value

IND: 0000

no Subindex

no Index

8081

0003

00 02

5FA5

02 00

PVA: 0000 0320

8

Parameter value_low =

320 hex = 800 =

80.0 x Factor 10

Parameter value_high = 0

MG.10.G1.51 – VLT is a r egister ed Danfoss trademark

Page 9

■

Properties of InterBus-S

■

ID-Code

The ID-Code of the Gateway : F1hex 241dec

32 wor ds, of which:

Bus width 4 to 32 wor ds

- 4 w ords PCP

- 0 - 28 words process data channel

(2 w ords per VLT

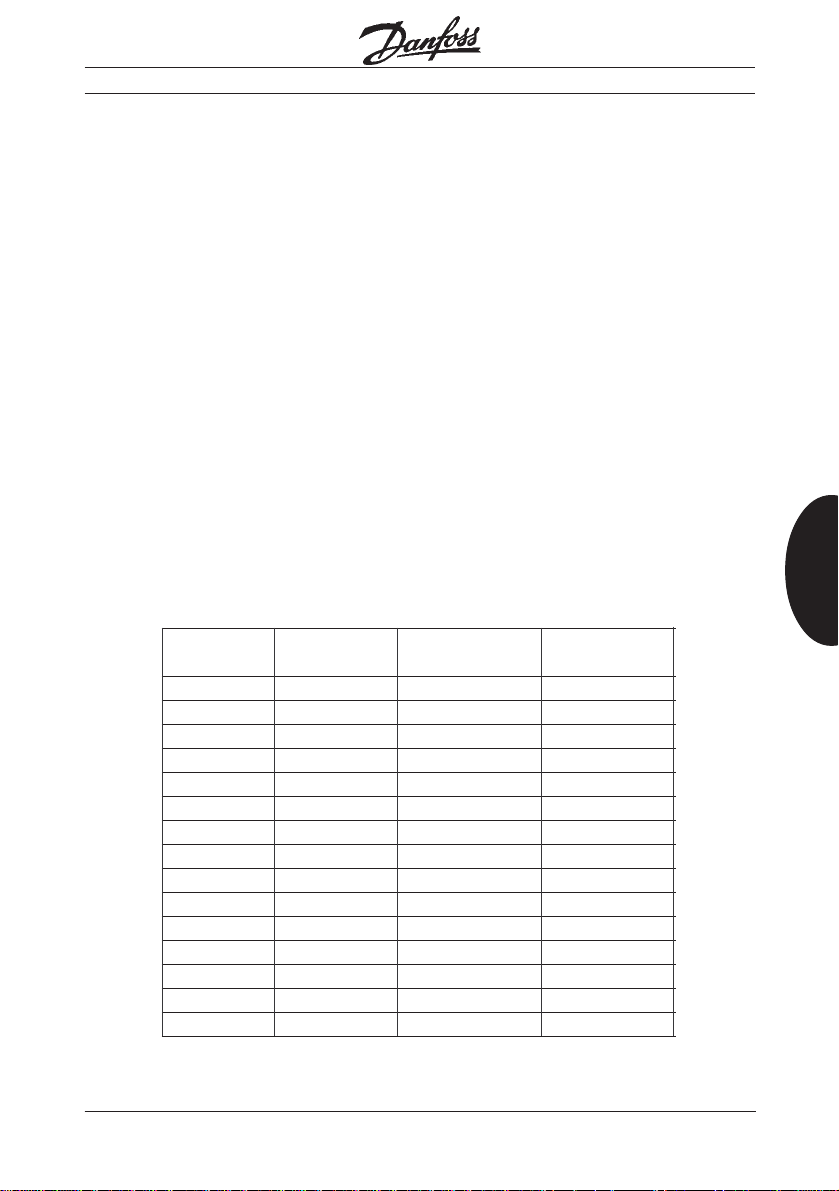

■

Length codes

Since all r egister widths ar e not possible in

InterBus-S, fill wor ds have to be enter ed in

some configurations of the gateway.

Furthermor e, not all InterBus-S-Masters

a r e able to serve a 4-wor d-wide PCP

Channel (Firmware versions befor e 4.0).

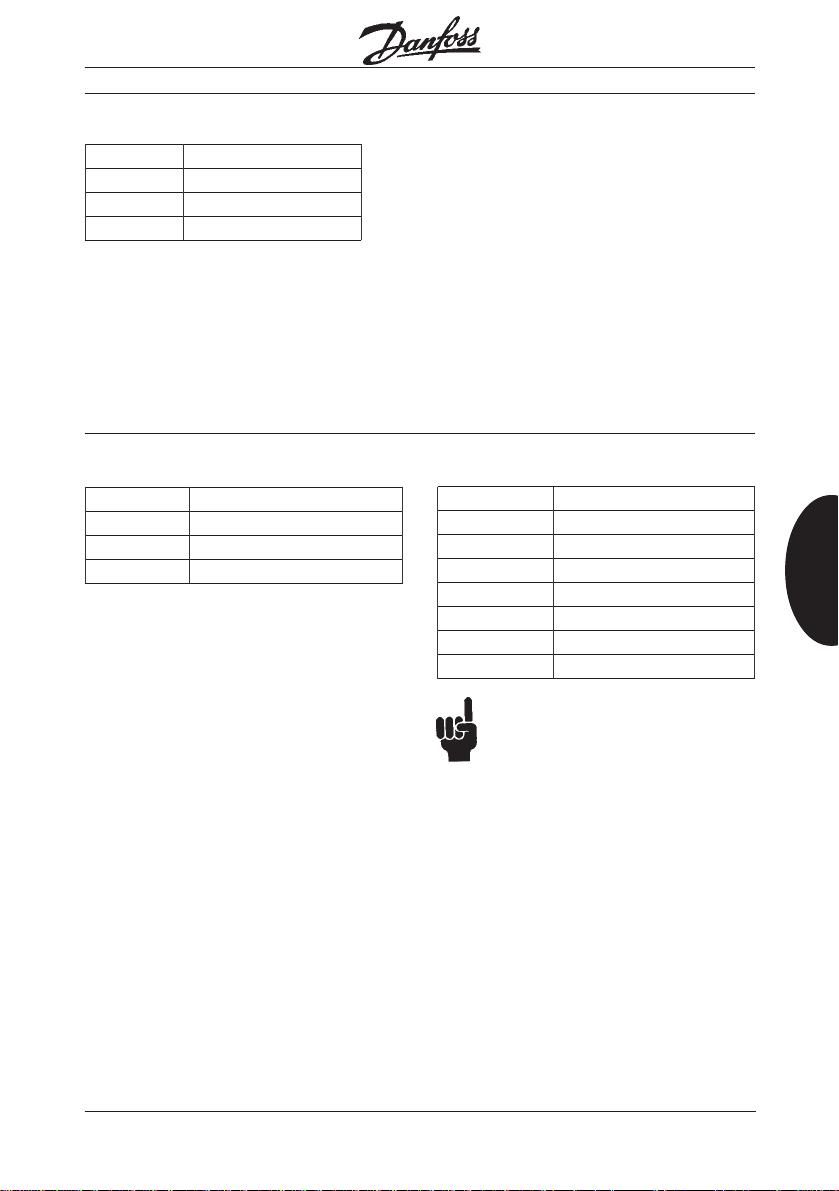

No. of InterBus-S Length code Length code

VLT® 5000 Bus width 1 word PCP 4 words PCP

®

) In- / Output

0 4 03 hex 00 hex

1 6 05 hex 02 hex

2 8 07 hex 04 hex

3 10 09 hex 06 hex

4 12 0B hex 08 hex

5 14 0D hex 0 A hex

6 16 0F hex 0C hex

7 24 17 hex 14 hex

8 24 17 hex 14 hex

9 24 17 hex 14 hex

10 24 17 hex 14 hex

11 32 1F hex 1C hex

12 32 1F hex 1C hex

13 32 1F hex 1C hex

14 32 1F hex 1C hex

Gateway InterBus-S

In this case another 3 words have to be

considered by the PCP Channel when

calculating the length code. The relevant

length codes for your configuration can be

seen fr om the following table:

Properties of InterBus-S

English Deutsch

MG.10.G1.51 – VLT i s a r egister ed Danfoss trademark

9

Page 10

Gateway InterBus-S

■

PCP Communication

■

Communication objects

Number of VLT® 5000

Index: 5F A0 hex

Symbol: inv_count

Data type: Unsigned8

Properties of InterBus-S

This enables reading of the number of

fr equency converters expected on the

PROFIBUS side as set at the rotary

switch. This is not necessarily the number

o f f requency converters actually

connected.

State of the fr equency converter

Index: 5FA2 hex

Symbol: inv_state

Data type: Subindex1: Unsigned

8

Subindex2: Unsigned

8

Access: Read only

®

I f al l VLT

tr oublefr ee at the bus, the two subindices

come out as zer o. I f t h ere is a disturbance of communication, subindex1 gives

the lowest address at which a communication err or occurred, while subindex2

p rovides more detailed information about

the err or in question.

set at the r otary switch work

Selected PPO Type

Index: 5FA1 hex

Symbol: ppo_type

Data type: Unsigned8

Access: Read only

PPO T ype ppo_type

PPO1 0 1 he x

PPO3 0 3 he x

This enables r eading of the PPO Type set

at the slide switch.

inv_state.2 E rror type

01 hex VLT® not found

®

02 hex VLT

not in Data

exchange

03 hex Master not active

10

MG.10.G1.51 – VLT is a r egister ed Danfoss trademark

Page 11

InterBus-S Module err o r

Index: 5FA3 hex

Symbol: stat_err

Data type: Boolean

Access: Read/Write

If an InterBus-S-Slave detects an error,

the slave can r eport the err or to the

InterBus-S-Master. The master then

rejects the latest data cycle and begins an

identification cycle, by which the master

pinpoints the participant that r eported the

module erro r.

Baudrate on the PROFIBUS-DP

Gateway InterBus-S

Using stat_err, it is possible to select

whether, an error on the PROFIBUS-DPside is to trigger a module err or.

stat_err = FF hex module erro r i s

trigger e d

stat_err = 00 hex module error i s not

trigger e d

The pre-set value is FF hex, i.e. module

e r r or is activated as err or r eport.

Properties of InterBus-S

Index: 5FA4 hex

Symbol: baud_rate

Data type: Unsigned8

Access: Read/Write

This enables reading and setting of the

baudrate at which work is carried out on

the PROFIBUS-side. In order to change

the baudrate, the PROFIBUS must be

stopped completely and initialized with

the new transmission speed.

baud_rate Baudrate

00 hex 9.600 Bit/s

01 hex 19.200 Bit/s

02 hex 93.750 Bit/s

03 hex 187.500 Bit/s

04 hex 500.000 Bit/s

05 hex 750.000 Bit/s

06 hex 1.500.000 Bit/s

At pr esent it is not possible to set

the baudrate. The baudrate has

been pr e-set permanently to

1.5MBaud and the object can only

be r ead.

English Deutsch

MG.10.G1.51 – VLT i s a r egister ed Danfoss trademark

11

Page 12

Gateway InterBus-S

P C V -part of PPO1

Index: 5FA5 hex

Symbol: PC V

Data type: 1 4 OCTET_STRING

with 8 Octets each

Access: Read/Write

This object services the purpose of

reading and writing the first 8 Octets

(PCV-part) of PPO Type1. The 14

Properties of InterBus-S

elements of object 5FA5 hex can be read

and written individually or jointly.

In o r der to r ead or write the PCV-part of a

®

connected VLT

, the number of the VLT

is transmitted as a subindex in addition to

the index in connection with

W rite.Request. See example on page 6.

W rite access:

Attempts at writing only r eceive a positive

confirmation handshake if the new value

enter ed can in fact be entered for the

frequency converter in question, i.e. if :

1 . PPO Type1 is used,

2 . the PROFIBUS-DP-Master is in

Operate mode

3.all frequency converters expected at

PROFIBUS-DP are in data exchange

mode.

4. New data has been sent to and re ceived by the PROFIBUS-DP at least

®

once.

Read access:

I n o r der to r etur n the r esponse values of

the VLTs, the structur e must be r ead.

The data is interpr eted as a parameter and

combined with the corresponding value of

the pr ocess data channel to form a telegram. A validity test is not carried

out.

Access to the two PPO objects is only

possible in accor dance with the switch

setting on the fr ont panel, i.e. if the switch

has been set to PPO Type3, the PPO

Type1 object cannot be r ead or written.

12

MG.10.G1.51 – VLT is a r egister ed Danfoss trademark

Page 13

■

Communication reference list

The following changes are requir ed to the

CRL (Communication re fe rence list). This

can be done via the PLC or via the PC

p rogram SYSSWT. The pr ocedur e for a

Siemens-PLC can be seen from the program example.

Maximum PDU length:

high prior r equests / r esponses: 00 hex

low prior r equests / r esponses: 80 h ex

high prior indications /

confirmations: 00 hex

low prior indications /

confirmations: 80 hex

■

Error reporting in PCP

Communication

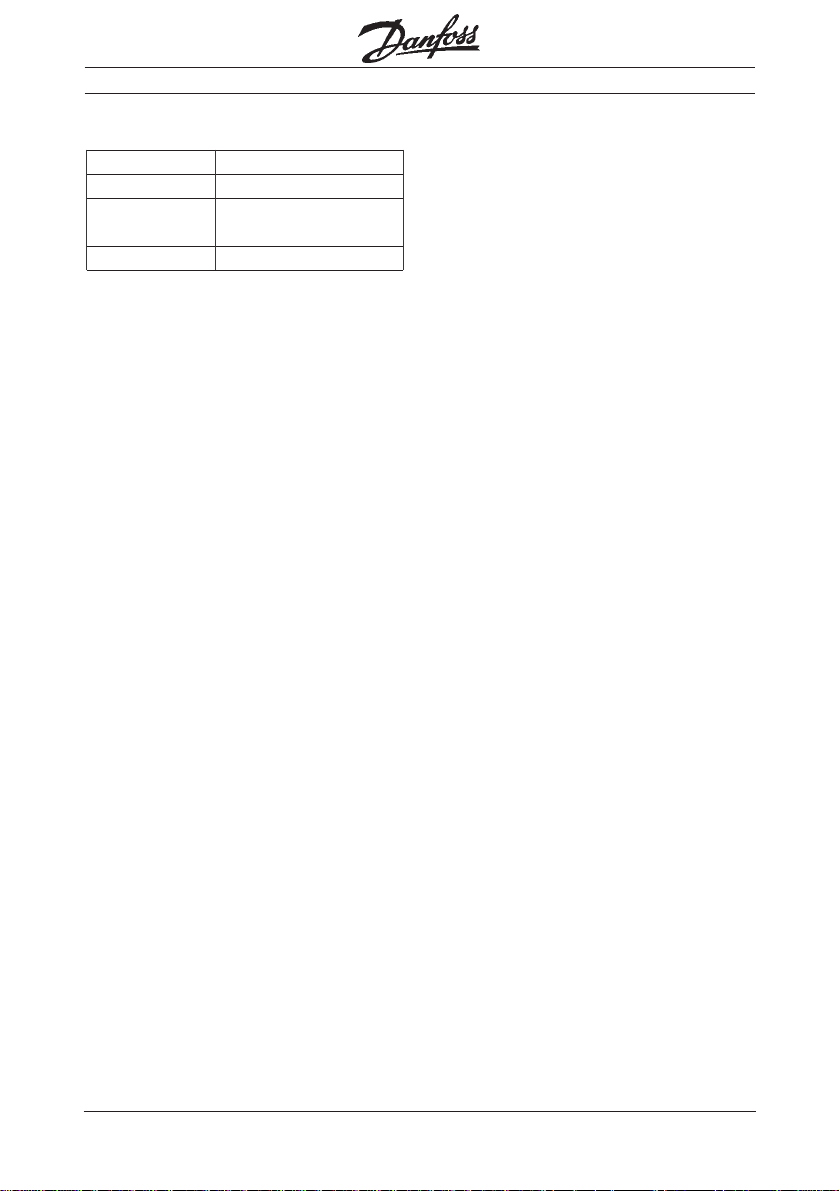

Err or_Class _"Access“ (06 hex):

E rror Code Additional Description

Error Code

05 hex object-attribute-inconsistent

10 hex bad-subindex

The transmitted subindex does not match the object in use

12 hex too-much-data

Mor e data bytes wer e transmitted than can be used for writing

the object

13 hex too-few-data

Fewer data bytes wer e transmitted than were required for writing

the object

08 hex type-conflict

An attempt was made to give a variable a value outside its value range

Gateway InterBus-S

supported services:

r equest / r esponses: 80 hex; 30 hex;

00 hex

indication / confirmation: 00 hex; 00 hex;

00 hex

In server operation the following services

a re supported:

get_OV_long

read_variables

write_variables

Properties of InterBus-S

English Deutsch

E r r or_Class _Access“ (08 hex):

E rror Code Additional Description

Error Code

00 hex other

1 hex not-pr ojected

The transmitted subindex in object PCV was bigger than the

p r e-set VLT

2 hex not-existent

In write access in object PCV at least one VLT

9 hex bad-data-value

The transmitted data value does not match the object intended

for use

MG.10.G1.51 – VLT i s a r egister ed Danfoss trademark

®

number

®

was not found

13

Page 14

Gateway InterBus-S

■

Technical data

Supply voltage: 24 V-DC ±1 0 % 240 mA

Oscillation test [ g ] 0,7

Relative humidity [%] VDE 0160 5.2.1.2.

Ambient temperatur e (as in VDE 0160) [° C ]0 → +60

Technical data

EMC Standards applied Emission EN 50081-2, EN 55011

Immunity EN 50082-2, IEC 1000-4-2,

IEC 1000-4-3, IEC 1000-4-4,

ENV 50140

ENV 50141

■

Examples of connection

14

MG.10.G1.51 – VLT is a r egister ed Danfoss trademark

Page 15

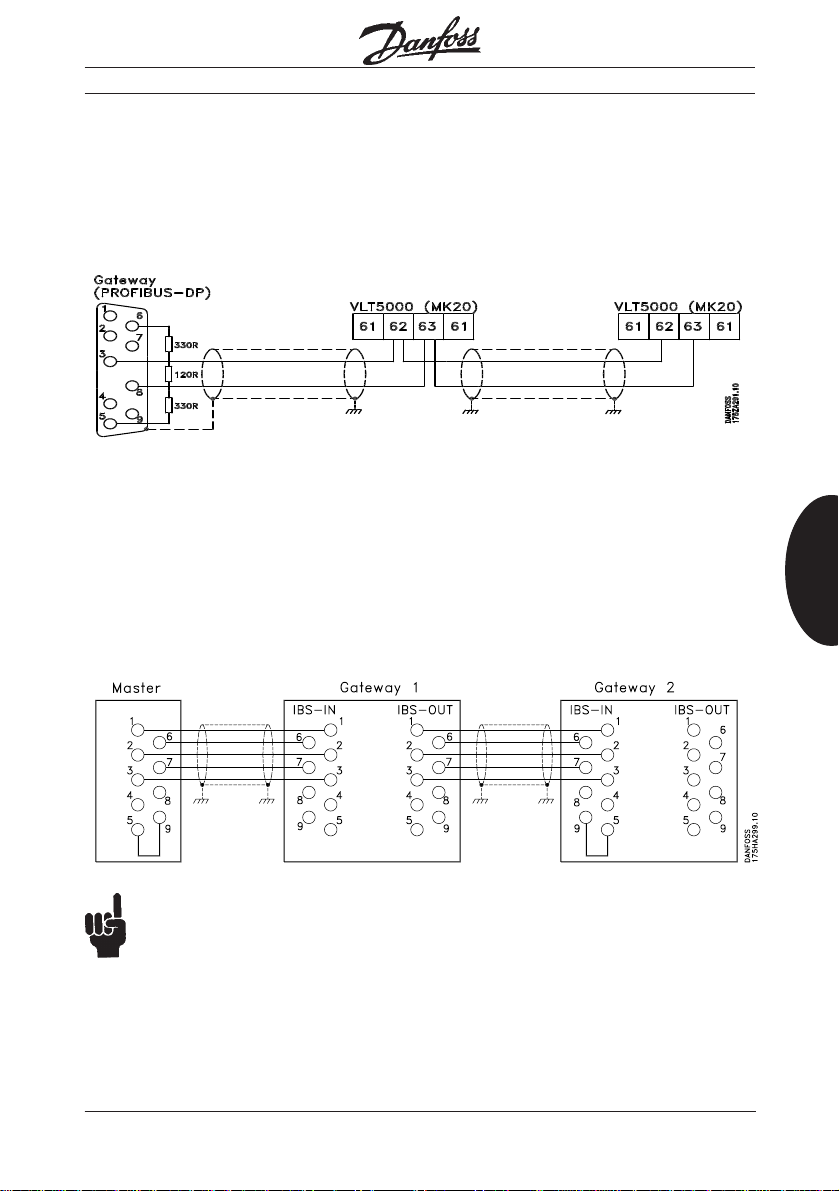

■

Connection of the PROFIBUS

bus wire

On the last VLT® the bus terminating r esistor must be activated; for this purpose,

switches S1 on the PROFIBUS Option

Card is to be switched into the ON position.

Note:

The cable screen must be connected to

the VLT enclosure by means of the clamp

placed beside the control c ard a t the left

side of the VLT.

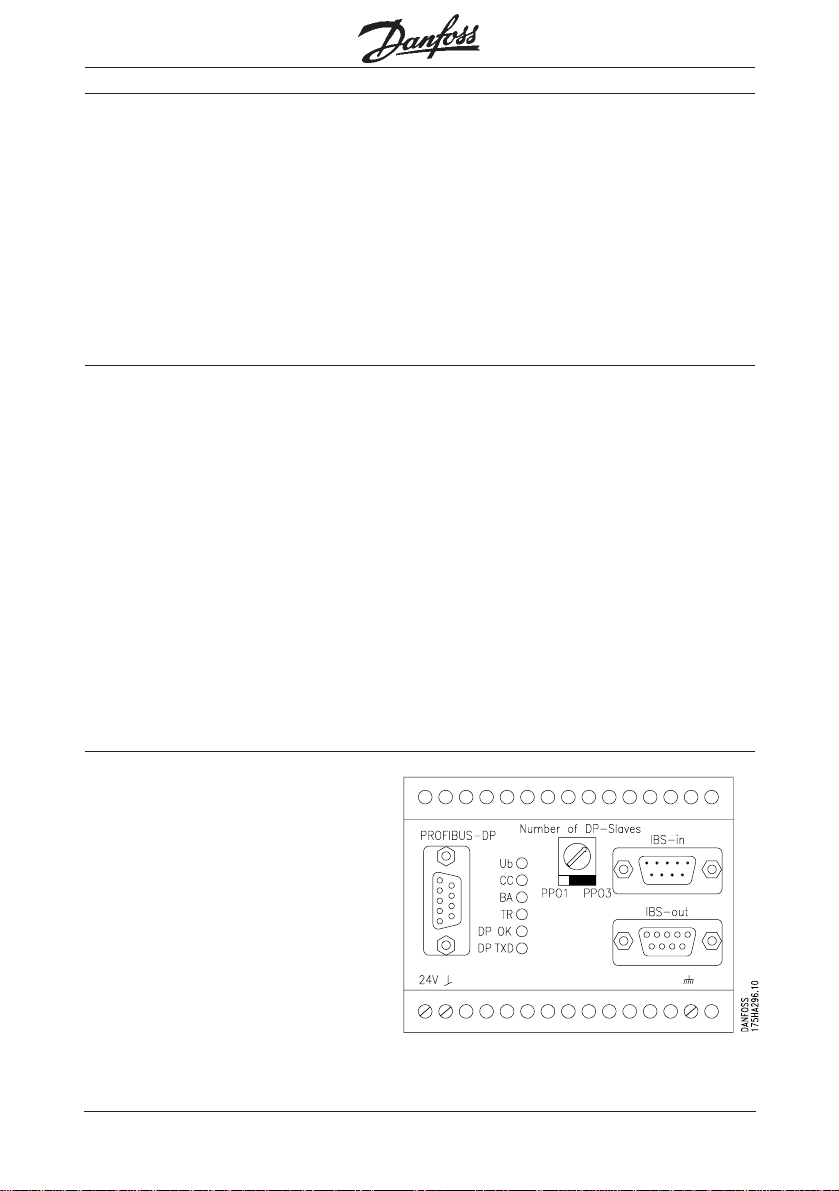

■

Connection of the Interbus-S

bus wire

Gateway InterBus-S

At the Gateway the cable screen must be

connected to the housing of the Sub-D

connectors by means of the clamp inside

the connector.

Technical data

English Deutsch

Pins 5 and 9 must be bridged

in the IBS IN plug, if nothing is

connected to the IBS OUT plug.

(See above regarding connection of the cable screen).

MG.10.G1.51 – VLT i s a r egister ed Danfoss trademark

15

Page 16

Gateway InterBus-S

■

Display messages

Ub

all voltages ar e ok

BA

InterBus-S active, Master is connected

Technical data

and active

CC

InterBus-S is ok, data exchange is

occurring

■

Operating elements

Number of DP-Slaves

Hex-r otary switch for the number of

connected VLTs, setting > 14 leads to a

flashing LED "DP ok"

PPO1 / PPO3

Slide switches for the selection of PPO

Type1 or PPO Type3, all VLT

be set to the same PPO Type.

The positions of these two switches are

adopted at Power-Up. If these ar e

displaced during operation, the LED

"DP ok" flashes

®

3000 must

TR

PCP transmission is in progr ess

DP ok

PROFIBUS-DP is ok, all participants

selected on the rotary switch communicate

DP TXO

the gateway is transmitting via the

PROFIBUS-DP

■

Terminals and plugs

3 terminals:

Voltage supply 24 V-DC (+ ; -);

Earth

1 SUB-D-female plug 9 pol.:

PROFIBUS-DP-connection

1 SUB-D-male plug 9 pol.:

InterBus-S IN

1 SUB-D-female plug 9 pol.:

InterBus-S-OUT

■

Housing

Enclosur e IP20

Terminal rail housing LDG-A30

Dimensions: 112x100x75 (HxLxW)

16

MG.10.G1.51 – VLT is a r egister ed Danfoss trademark

Page 17

■

Example of program for Siemens

S5-115U

The following example shows how the

communication to a VLT

to the gateway is controlled.

®

5000 connected

Gateway InterBus-S

■

P rogram references

DB21

is the Communication-Request-DB; this is

where the or ders for the PCP Communication ar e supported

Example of program for Siemens S5-115U

®

Also, in this example, the VLT

is parame-

terized by way of PCP Communication.

Example layout

■

S5-115U with an Interbus-S-Master

module, IBS/DP-gateway with a VLT

5000 that has a PROFIBUS Option Card.

Setting of the Interbus-S-Master

■

Selection of start Operating mode

and operating controlled

mode: DCB-Mode

W indow 1: Basic address =

P-range upwards of 32

Length = 64 Bytes

W indow 2: Basic address =

P-range upwards of 128

Length = 32 Bytes

W indow 3: Basic address =

P-range upwards of 200

■

Required FBs

(Function Blocks)

For communication via PCP, the following

FCs are r equired - and can be obtained

from Phoenix:

FB 60 INITIB

F B 62 CON/IND

FB 63 CIH

F B 6 6 REQ/RES

FB 68 CONTROL

FB 69 DEFINE

F B 72 ADDRESS

DB23

is the Communication-Confirmation-DB;

this is wher e the PCP Communication

enters the r esponses

®

FW 20

is the activation wor d for PCP Communication

FW 22

is the r eporting wor d for PCP Communication

English Deutsch

F 224.1

activates the Download.

®

The Contr ol word for the VLT

is located

i n QW38, the Desired value in QW40

®

The Status word of the VLT

is located in

IW38, the Actual value in IW40

Starting the VLT

■

®

The VLT® starts when the lower Bit-7 in

QB39 has been set. Stopping can be

achieved by zeroing of this bit. In this

context, ther e is a choice of motor

coasting, quick-stop and normal stop.

MG.10.G1.51 – VLT i s a r egister ed Danfoss trademark

17

Page 18

■

Setting the PDU length in PCP

On the basis of the possibility of having 14

VLTs connected to the gateway, t h e re is a

need for an extended PDU length. The

following example shows how in the SPS

start-up the PDU length can be changed

in CRL. For further information concer ning

the PCP Communication please see the

manual for the InterBus-S-Master.

All start-up components first branch into

FB210, which carries out the configuration of the InterBus-S-Master assembly.

Example of program for Siemens S5-115U

Gateway InterBus-S

18

MG.10.G1.51 – VLT is a r egister ed Danfoss trademark

Page 19

Gateway InterBus-S

OB 20

:JU F B 210 ;Initialization of the IBS-module

NAME :ANLAUF

:BE

OB 21

:JU F B 210 ;Initialization of the IBS-module

NAME :ANLAUF

:BE

OB 22

:JU F B 210 ;Initialization of the IBS-module

NAME :ANLAUF

:BE

OB1

: JU FB 62

NAME :CON/IND

IBDB : DB 9 InterBus Data block

CIDB : FY 18 CON/IND caption table

T : T 1 T imer

T O : F 8.3 Time Out

: L KB 1

:T FY 201

:O F 0.0

: O N F 0.0

:= F 0.1

:

:A F 224.1 Activation for Download

: A F 200.5 Activation for FB1

:JC FB 1 Parameterization VLT1

NAME:VLT-PARA

STRC : F 200.0 Auxiliary flag

STR1 : F 200.1 Auxiliary flag

STR2 : F 200.2 Auxiliary flag

R D B : DB 23 Request-DB

C D B : D B 21 Confirmation-DB

VLT : FY 201 VLT Addres s

AKTI : F 21.0 Activation for PCP Communication

PKEW : F W 210 PCA to the VLT

PA RW : F W 212 Parameter value to the VLT

Example of program for Siemens S5-115U

English Deutsch

MG.10.G1.51 – VLT i s a r egister ed Danfoss trademark

19

Page 20

PKER : F W 214 PCA from the VLT

PA R R : F W 216 Parameter value from the VLT

PCPR : F 200.3

E R R : F 200.6

O K : F 200.7

:

:O F 200.6 ;If error, r everse activation

:R F 200.5

:

: A F 200.7 ;OK-report fr o m FB 1

:A F 224.1 ;Activation for Download

:JC F B 2

NAME:PARAMETE

P D B : D B 100 DB with Download data

COUN: F W 220 Parameter counter

Example of program for Siemens S5-115U

ANZA : KF +17 Number of parameters

PKEW: F W 210 PCA to the VLT

PA R W : F W 212 Parameter value to the VLT

O K : F 200.7 OK-report fr o m F B1

STRT : F 200.5 Start for FB1

ZEIG : F W 222 Parameter indicator

INIT : F 224.0 Download initialized

:

: JU FB 66

NAME:REQ/RES

IBDB : D B 9 InterBus Data block

RRDB : FY 19 REQ/RES caption table

T : T 3 Timer

T O : F 8.4 Time Out

:BE

Gateway InterBus-S

FB 210

NAME:ANLAUF

:A F 8.0

:ON F 8.0

:S F 8.0 Activation bit: INITIB

:S F 10.0 ADDRESS

:L K Y 20,22 CON/IND,REQ/RES

:T F W 18 DB PCP caption tables

M002 :A F 8.0

:JC FB 60

NAME:ANLAUF

IBDB : D B 9 InterBus Data block

20

MG.10.G1.51 – VLT is a r egister ed Danfoss trademark

Page 21

Gateway InterBus-S

FEN3 : KF +200 Basic address: Window 3

AV : KF +1 Controlled operation / r eport r eleased

RRST : D B 23 REQ/RES Standard DB

CIST : DB 21 CON/IND Standard DB

RRMW: KF +20 Activation wor d

CIMW: K F + 22 Report word

CIFB : FY 63 Auxiliary driver CON/IND

T : T 0 Timer

STEP : FY 9 Inter nal flag byte

BUSY : F 8.0 Activation bit

T O : F 8.1 Time Out

R E T : F 8.2 Return value

: A F 8.0

:ON F 8.2

:JC =M001

:STS

:BEU

M001 :JU FB 62

NAME:CON/IND

IBDB : D B 9 InterBus Data block

CIDB : FY 1 8 Caption-DB-CON/IND

T : T 1 Timer

T O : F 8.3 Time Out

Example of program for Siemens S5-115U

English Deutsch

: **** Change PDU length ********

: change in CRL, here o nl y !! !

:LKF+8

:T F Y 100 Function 8

: L KF +25

:T FY 101 DB-Number is 25

:LKF+0

:T FY 102 upwards o f D W 1

: AN F 8.0 No BUSY-Signal fr o m FB60

:A F 10.0 Pseudo-cycle

:JC FB 69 DEFINE from IBS

NAME:DEFINE

IBDB : D B 9 InterBus DB

T : T 5 Timer No.5

FKT : FY 100 Function (8) Receive CRL

D B : FY 101 DB-Number

D W : FY 102 upwards of D W

BUSY : F 103.0

T O : F 103.1

MG.10.G1.51 – VLT i s a r egister ed Danfoss trademark

21

Page 22

RET : F 103.2

:

:AN F 103.0 No BUSY from DEFINE FB69

:AN F 8 . 0 No BUSY from FB60

:A F 10.0 Pseudo-cycle

:JC F B 72

NAME :ADDRESS

IBDB : D B 9 InterBus Data block

BUSY : F 10.0 Activation bit

T : T 2 T imer

IDDB : D B 10 DB: ID-Code list

IDDW : KF +0 D W:

LBDB : D B 11 DB: Bus segment list

LBDW : KF +0 D W:

INDB : D B 12 DB: IN-Addre s s l i st

Example of program for Siemens S5-115U

INDW : KF +0 D W:

OUDB : D B 13 DB: OUT -Address List

OUDW: KF +0 D W:

KRDB : D B 14 DB: KR-Address List

KRDW: KF +0 D W:

GRDB : D B 0 DB: Group definitions

GRDW: KF +0 DW:

MODE: F 10.5 Mode of indication

EREG : FY 12 Error Register

T O : F 10.1 Time Out

R E T : F 10.2 Retur n value

:

:JU F B 66

NAME :REQ/RES

IBDB : D B 9 InterBus Data block

RRDB : FY 19 Caption-DB-REQ/RES

T : T 3 T imer

T O : F 8. 4 Time Out

: A F 8.0 INITIB

:O F 10.0 ADDRESS

:JC =M002

:AN F 10.2

:BEB

:STS

:BE

Gateway InterBus-S

22

MG.10.G1.51 – VLT is a r egister ed Danfoss trademark

Page 23

Gateway InterBus-S

FB1

NAME:VLT-PARA ;Parameterization via IBS/DP

DECL :STRC IBI

DECL :STR1 IBI

DECL :STR2 IBI

DECL :RDB B

DECL :CDB B

DECL :VLT IBY

DECL :AKTI I B I

DECL :PKEW IW

DECL :PA RW IW

DECL :PKER Q W

DECL :PARR Q W

DECL :PCPR IBI

DECL :ERR IBI

DECL :OK IBI

Example of program for Siemens S5-115U

:AN =STRC Initiate Request alr eady sent?

:JC =INIT NO-> Inititate Request

: A =STR1 Ctrl1=1 AND Ctrl2=0

:AN =STR2 -> wait for W rite_Conf

:JC =WCON

:AN =STR1 Ctrl1=0 AND Ctrl2=1

: A =STR2 -> wait for Read_Conf

:JC =RCON

:DO =RDB

:L KH 8082 Identification Write_Request

: T DW 0

:L KH 0007 ParameterCounter = 7

:T DW 1

:L KH 0002 CR=2

:T DW 2

:L KH 5FA5 P C V-Object

:T DW 3

:L =VLT VLT-Address is Subindex

: T DL 4

:L KB 8 No. of bytes = 8

: T DR 4

:L =PKEW retrieve or der for VLT

: T DW 5

:L =PARW retrieve Para-value for VLT

: T DW 8

:A F 0 .1 VKE"1"

English Deutsch

MG.10.G1.51 – VLT i s a r egister ed Danfoss trademark

23

Page 24

:S =STR1 W rite_Request executed

:JU =CON0 Delete conf and send order

:

WCON : **** Wait for W rite_Confirm.

:DO =CDB Open confirmation DB

:L D W 0 Retrieve conf_identification

:L KH 0000

:!=F ;is 0 then wait again

:BEB

:L DL 3 retrieve Result

:><F is not ZERO

: JC =FAUL - > FAULT

:

READ : *** execute READ-REQUEST ****

:DO =RDB Open Request DB

Example of program for Siemens S5-115U

:L KH 8081 O rder identification Read_Request

: T DW 0

:L KH 0003 Parametercounter = 3

: T DW 1

:L KB 0

:T DR 4 No. of bytes = 0

: CR; Object and VLT remain

:A F 0.1 VKE"1"

: R B =STR1 STR1=0 AND STR2=1

:S =STR2 - > wait for Read_confirmation

:JU =CON0 Delete conf and send order

:

RCON: *** wait for READ-Confirmation

:DO =CDB Open confirmation DB

:L D W 0 Retrieve confirmation identification

: L KH 0000

:!=F is 0 then wait again

:BEB

:L DL 3 Retrieve Result-Code

:><F i s not 0

: JC =FAUL - > FAULT

:L D W 4 Retrieve PCA received

:S LW 5 only Para-number

:L =PKEW Retrieve Para-number sent

:S LW 5 Only Para-number

:!=F equal then OK

:JC = O K Enter value

:JU =READ if NOT ZERO, then READ again

Gateway InterBus-S

24

MG.10.G1.51 – VLT is a r egister ed Danfoss trademark

Page 25

Gateway InterBus-S

OK :

:L DW 4

:T =PKER

:L DW 7 Retrieve parameter value r eceived

:T =PARR

:A F 0. 1 VKE"1"

: S = O K Set OK-flag

:RB =STR1

:RB =STR2

:BEU

INIT : *** INITIA T E REQUEST ***

:A =STR1 is not first run

:JC =INI1

:DO =RDB Open Request component

:L KH 808B Order identification Inititate Request

: T DW 0

:L KH 0002 PC and CR

:T DW 1 Parameter Counter

:T DW 2 Invoke ID / CommRef

:L KY 0,0

:T DW 3 Control word, Access Group

: A F 0. 1 VKE"1"

: S =STR1

CON0: *** Delete confirmation ***

:DO =CDB Search Confirmation module

:L KH 0000 Delete entries

: T DW 0

:T DW 1

:T DW 2

:T DW 3

:T DW 4

:T DW 5

:A F 0 .1 VKE"1"

: S =AKTI Set activation marker

:BEU

INI1 **** W ait for Response ****

:B =CDB Confirmation DB on

:L D W 0 Fetch confirmation identification

: L KH 0000

:!=F is equal to 0-> no Confirmation

:BEC then continue searching

: L DL 3 Retrieve quitting code

: L KH 0000

Example of program for Siemens S5-115U

English Deutsch

MG.10.G1.51 – VLT i s a r egister ed Danfoss trademark

25

Page 26

Gateway InterBus-S

:!=F is 0 -> no fault

:JC =INI2

FAUL : **** F A U LTS ****

:A F 0.1 VKE"1"

: S =ERR Fault occurr ed

:RB =STRC Reset first run

:RB =STR1

:RB =STR2

:BEU

INI2 : *** Initiate Request OK ***

:A F 0.1 VKE"1"

: S =STRC Set Inititate successful

:RB =STR1 Reset flag

:BE

Example of program for Siemens S5-115U

FB2

NAME:PARAMETER

DECL :PDB B

DECL :COUN IW

DECL :ANZA DKF

DECL :PKEW IW

DECL :PA RW IW

DECL :OK IBI

DECL :STRT IBI

DECL :ZEIG IW

DECL :INIT IBI

:

:DO =PDB Open data-DB

:AN =INIT

:JC =INIT

STRT :

:LW =ANZA retrieve number

:L =COUN retrieve pr esent number

:>F not end yet

: J C =WEIT - > continue

:RB = O K FINISHED

:RB =INIT Reverse INIT

: R F 224.1

:BEU and END

26

MG.10.G1.51 – VLT is a r egister ed Danfoss trademark

Page 27

Gateway InterBus-S

WEIT :L =ZEIG Retrieve indicator

: T FW 250

:DO FW 250

:L D W 0 Retrieve DW from indicator address

: L KH 2000

:+F +2000, for write identification

: T =PKEW is new PKEW

:L =ZEIG

:I1

:T FW 250

:DO FW 250

:L D W 0 load DW to indicator address

: T = PA R W is new parameter value

: L =ZEIG

:L KF +2

:+F

: T =ZEIG

:L =COUN

:I1

:T =COUN Counter + 1

:RB = O K OK for FB1 reset

: S =STRT and FB1 start anew

:BEU

INIT :L KH 0000

:T =ZEIG

:T =COUN

:S =INIT

:JU =STRT

:BE

Example of program for Siemens S5-115U

English Deutsch

DB9

0 : KH 0000;

1 : KH 0000;

254 : KH 0000;

255 : KH 0000;

DB10 ;Ident-code list

0 : KY 0,3 ;Number of parameters

1: KY 5,241 ;IBS-PB Gateway

2: KY 0,16 ;Diagnose Bit Register

3 : KY 0,17 ;Diagnose Parameter Register

4: KY 0,0 ;Length code 1Unit PPO1=5

5: KY 0,0 ;" 6UnitsPPO1=15

MG.10.G1.51 – VLT i s a r egister ed Danfoss trademark

27

Page 28

DB11 ;Bus segment list

0: KY 0,3 ;Number of parameters

1: KY 0 ,0 ;IBS<>PB Gateway

2: KY 0,0 ;Diagnose Bit Register

3 : KY 0,0 ;Diagnose Parameter Register

DB12 ;IN address list

0: KY 0,3 ;Number of parameters

1: KY 0,32 ;IBS<>PB Gateway

2: KY 0,126 ;Diagnose Bit Register

3 : KY 0,128 ;Diagnose Parameter Register

DB13 ;OUT address list

0: KY 0,3 ;Number of parameters

1: KY 0,32 ;IBS-PB Gateway

Example of program for Siemens S5-115U

2: KY 0,0 ;Diagnose Bit Register

3 : KY 0,0 ;Diagnose Parameter Register

DB14 ;KR list

0: KY 0,3 ;Number of parameters

1: KY 0 ,2 ;IBS<>PB Gateway

2: KY 0,0 ;Diagnose Bit Register

3 : KY 0,0 ;Diagnose Parameter Register

Gateway InterBus-S

DB20 ;CON/IND caption table

0: KH 0000 ;1. CODE;

1: KH 0000 ; PC ;

2: KH 0000 ; KR ;

3: KY 0,0 ; DB,DW;

4: KH 0000 ;2. CODE;

5: KH 0000 ; PC ;

6: KH 0000 ; KR ;

7: KY 0,0 ; DB,DW;

8: KH 0000 ;3. CODE;

52 : KH 0000 ;14.CODE;

53 : KH 0000 ; PC ;

54 : KH 0000 ; KR ;

5 5 : KY 0,0 ; DB,DW;

56 : KH 0000 ;15.CODE;

57 : KH 0000 ; PC ;

58 : KH 0000 ; KR ;

5 9 : KY 0,0 ; DB,DW;

60 : KH 0000

28

MG.10.G1.51 – VLT is a r egister ed Danfoss trademark

Page 29

Gateway InterBus-S

DB21 ;CON/IND-Standard-DB

0: KH 0000 ;CODE ;

1: KH 0000 ; PC ;

2: KH 0000 ; KR ;

3 : KH 0000 ;Body ;

4 : KH 0000

30 : KH 0000

31 : KH 0000

32 : KH 0000

33 : KH 0000

34 : KH 0000

DB22 ;REQ/RES caption table

0: KH 0000 ;1. CODE;

1: KH 0000 ; PC ;

2: KH 0000 ; KR ;

3: KY 0,0 ; DB,DW;

4: KH 0000 ;2. CODE;

5: KH 0000 ; PC ;

6: KH 0000 ; KR ;

7: KY 0,0 ; DB,DW;

8: KH 0000 ;3. CODE;

Example of program for Siemens S5-115U

English Deutsch

52 : KH 0000 ;14.CODE;

53 : KH 0000 ; PC ;

54 : KH 0000 ; KR ;

5 5 : KY 0,0 ; DB,DW;

56 : KH 0000 ;15.CODE;

57 : KH 0000 ; PC ;

58 : KH 0000 ; KR ;

5 9 : KY 0,0 ; DB,DW;

60 : KH 0000

DB23 ;REQ/RES-Standard-DB

0: KH 808B ;CODE ;

1: KH 0002 ; PC ;

2: KH 0002 ; K R

3: KH 0000 ;Body ;

4 : KH 0000

MG.10.G1.51 – VLT i s a r egister ed Danfoss trademark

29

Page 30

58 : KH 0000

59 : KH 0000

60 : KH 0000

61 : KH 0000

62 : KH 0000

DB25 ;Setting of the PDU length

0: KH 0003 ;Length 3 words

1 : KH 0002 ; 0.entry CR=2

2 : KH 0A80 ;10.entry 80 hex

3 : KH 0C80 ;12.entry 80 hex

DB100 ;Download Data

0: KF +201 ;Parameter 201 Min.Frequency

1: KF +100 ;Value 100 = 10.0 Hz

Example of program for Siemens S5-115U

2 : KF +202 ;Parameter 202 Max.Frequency

3: KF +1000 ;Value 1000 = 100.0 Hz

4: KF +205

5: KF +1

6: KF +206

7: KF +2

8: KF +207

9: KF +3

1 0: KF +208

1 1 : KF +4

1 2: KF +209

1 3 : KF +30

1 4: KF +215

1 5: KF +111

1 6: KF +216

1 7: KF +222

1 8: KF +217

1 9: KF +333

2 0: KF +218

2 1: KF +444

2 2 : KF +0

2 3 : KF +0

2 4 : KF +0

Gateway InterBus-S

30

MG.10.G1.51 – VLT is a r egister ed Danfoss trademark

Page 31

2 5 : KF +1

2 6 : KF +0

2 7 : KF +2

2 8 : KF +0

2 9 : KF +3

3 0 : KF +0

3 1 : KF +4

3 2 : KF +0

3 3 : KF +5

Gateway InterBus-S

Example of program for Siemens S5-115U

English Deutsch

MG.10.G1.51 – VLT i s a r egister ed Danfoss trademark

31

Page 32

Page 33

A

Access to parameter change . .. .. .. ................4

B

Baudrate .. .. ... .. .. ....... .. .. ....... .. .. ....... .. .. ....... .. .4

Bus time out . . . . . . . . . . .. . . . . . . . . . . . .. . . . . . . . . . . . . .. . . . . . . . . .4

Bus time out function . . . . . . . . . . . . .. . . . . . . . .. . . . . . . . .. . . .4

C

Communication objects . . .. .. . .. .. . .. .. . .. .... . .. . ..10

Communication re f e rence list .....................13

Configuration of the fr equency converter .... .4

Connection of the Interbus-S wire . . . . . . . . . . . . . .15

Connection of the PROFIBUS bus wire . .. ...15

Control word . . . .. . . .. . . .. . ... . ... . . .. . ... . ... . . .. . ... . ... . . .5

D

Display messages . .. .. . .. .. . .. ........ .. .. . .. .. . .. .. . ..16

E

Error Code ..... ....... ........ ....... ........ ....... .......13

Error reporting in PCP Communication .. ... .13

Example of program for

Siemens S5-115U . ........ .. ........ .. ..... ... .. ..... .17

Example layout . . . .. . . . . .. . . . .. . . . . .. . . . .. . . . .. . . . . .. . . . .17

Example of connection . .. .. . .. . . .. . .. . . .. . .. . . .. . .. .14

F

FMS/DP-selection .. .. ..... ...............................4

Functional components . . .. . .. .... .. .. . .. . .. .. . .. . ..17

H

Housing . .. .. .. .. .. .. .. ...... .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..16

I

ID-Code .. ..... .. .... ..... .. .... .. .... ..... .. .... .. .... .. .... ..9

Index/Subindex, IND . . . .. . . . .. . . . .. . . .. . . . .. . . . .. . . . .. . .6

InterBus-S Module erro r.............................11

Gateway InterBus-S

L

Length codes ............ .. .. ...................... .. .. ....9

M

Maximum PDU length ................................13

N

Notes concerning pr ogramming ..................5

Number of VLT® 5000 . .. .. ...........................10

O

Operating elements . .. . . .. . . .. . . .. . . . .. . . .. . . .. . . . .. . . .16

Overview .. .... .. .. . .. .. . .. .... .. .. . .. .. . .. .... .. .. . .. .. . .. ....2

P

Parameter 502-512 .... .. ...... .. ....... .. ....... .. .... 4

Parameter 800 . .. ........................ .. ................4

Parameter 801 . .. ........................ .. ................4

Parameter 803 . .. ........................ .. ................4

Parameter 804 . .. ........................ .. ................4

Parameter 904 .............................................4

Parameter 918 .............................................4

Parameter 927 .............................................4

Parameter 928 .............................................4

Parameter interface in Write.Request . . . . . . . . . . .6

Parameter interfaces in Read.Request .. . .. .. ..7

Parameter Value, PV . . . . .. . . . . . . . .. . . . . . . . .. . . .. . . . . . . . .6

Parameter-Identification-Value, PIV . .. .. . .. .. .. . .6

Parameterization . . . . . .. . . . . . . .. . . . . . . . .. . . . . . . . .. . . . . . . . ..5

PCP-Communication .................................10

P C V-part of PPO1 . . . . . .. . . . .. . . . . .. . . . .. . . . . .. . . . .. . . .12

PPO select . ... .. . .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. ..4

PPO Types 1/PPO Types 3 . . . .. . . .. . . .. . . .. . . .. . . . 2

Pr ogram re f erences ..... .. .. .. ...... .. .. .. ...... .. .. ..17

Pr operties of InterBus-S . . . . .. . . . . .. . . . . .. . . . . .. . .. . . . .9

Properties of PROFIBUS-DP . .. .. .. .. .. .. .. .. .. .. .. .3

Index

English Deutsch

MG.10.G1.51 – VLT i s a r egister ed Danfoss trademark

33

Page 34

R

Read access . .... .... ..... .... .... ..... .... .... ..... .... ..12

Index

Read.Request .... .... ... ............... ................... .5

Refer ence/Actual values . . . .. . . . . . . .. . . . . . .. . . . . . . .. . .5

Reporting back . . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .2

S

Selected PPO Type ..... .... .... .... ... .... .... .... ... .10

Setting of the Interbus-S-Masters . . . . . . . . . . .. . .17

Setting the PDU length in PCP . .. . . . .. . . . .. . . . . ..18

Starting the VLT®. .. .. .. .. .. . . .. .. .. .. .. . . .. .. .. .. . . .. .. .17

State of the fr equency converter . .. ..... .. .. ....10

Station addr ess . . . . . . .. . .. . .. . .. . . .. . . . . . . .. . . . . . . .. . . . . . . .4

Supported services . . .. . . . .. . . . .. . . .. . . . .. . . .. . . . .. . . ..13

T

Technical data .. . .. . . . . .. . . . . .. . . . . .. . . . . .. .. . .. . .. . . . . .. .14

Terminals and plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

W

W rite access . .. . .. . ... .. . .. .. . .. . .. . ... .. . .. .. . .. . .. . ... ..12

W rite.Request . . . .. . . . . .. . . . .. . .. . . . .. . .. . . . .. . .. . . . .. . .. . . .5

Gateway InterBus-S

34

MG.10.G1.51 – VLT is a r egister ed Danfoss trademark

Page 35

Gateway InterBus-S

Te i l 1 ■ Überblick . . .. . . . . .. . . . . .. . . . . . .. . . . . .. . . . . . .. . . . . .. . . . . .. . .. . . . . .. . . . . . .. . . . . .36

Te i l 2 ■ Eigenschaften der PROFIBUS-DP-Seite .... ........ ... .... ....37

Konfiguration des Frequenzumrichters . ...... .. ..... .. ..... .. ..... .. ..38

Anmerkungen für die Programmierung ...............................39

Steuerwort . .. .. .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .. .39

Soll- / Istwert ........ .................................................. .......39

Parametrierung .. ... .. .. .. .. .. . .. .. . .. .. .. .. .. . .. .. . .. .. .. .. .. . .. .. . .. .. .. .. .39

Parameterschnittstelle bei Write.Request . . . .. . . . . . . . . .. . . . . . . .40

Parameterschnittstelle bei Read.Request . ... .. ... .. .. . .. .. .. .41

Te il 3 ■ Eigenschaften der InterBus-S-Seite . .. . .. . .. . .. . .. . ... .. . .. . .. . ..43

ID-Code ...............................................................................43

Längencodes ......................................................................43

PCP-Kommunikation ...........................................................44

Kommunikationsobjekte ..... ....... ...... ...... ...... ...... ...... .....44

Kommunikationsbeziehungsliste ... .. ....... .. ...... .. ....... .. ...... .. ..47

Fehlermeldungen bei PCP-Kommunikation ........................47

Inhaltsverzeichnis

English Deutsch

Te il 4 ■ T echnische Daten .. . .. .. . .. .. . .. .. . .. . .. .. . .. .. . .. .. . .. . .. .. . .. .. . .. .. . ..48

Anschlußbeispiel . . . .. . . .. . . .. . . .. . . .. . . .. . . ... . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .48

Anschluß der PROFIBUS Busleitung ... ..... .... ..... .... ..... .... .....49

Anschluß der Interbus-S Busleitung .. .. . .. . .. . .. . .. .. . .. . .. . .. .. . .. . .. .49

Anzeigen .... ....... ....... .. ..... .. ..... .. ..... .. ..... .. ..... .. ...... ....... ....... ..50

Bedienelemente .. ............................................ ... .................50

Klemmen und Stecker .........................................................50

Gehäuse..............................................................................50

Te i l 5 ■ Beispielpr ogramm für Siemens S5-115U ......................51

■ Stichwortsverzeichnis . . . .. . . . . .. . . . .. . . . .. .. .. .. .. .. . .. . . . .. . . . .. .. .. ..67

MG.10.G1.51 – VLT i s a r egister ed Danfoss trademark

35

Page 36

Gateway InterBus-S

■

Überblick

Das InterBus-S / PROFIBUS-DP-Gateway

®

dient dazu, Danfoss VLT

Frequenzumrichter am Feldbus-System

Überblick

5000

InterBus-S betreiben zu können. Dazu

setzt das Gateway die InterBus-S

Telegramme auf PROFIBUS-DPTelegramme um, welche dann zum VLT

gesendet werden.

In gleicher Weise erfolgt die Rückmeldung, hierbei setzt das Gateway die

PROFIBUS-DP-T elegramme des VLT

um, welche dann mittels des InterBus-S

wieder zur Steuerung übertragen werden.

Das Gateway ermöglicht den Anschluß

®

von bis zu 14 VLT

5000 mit PROFIBUSOptionskarte. Das Gateway sendet permanent Nachrichten des gewählten PPOTyps mit dem aktuellsten Prozeßdatenblock und dem aktuellsten Parameter-

®

block an die VLT

®

‘s .

Der Anschluß des Gateways erfolgt wie

am InterBus-S üblich als Fernbusteilnehmer. Jedoch setzt dieser nicht auf den

InterBus-S-Lokalbus um, sondern a u f

®

PROFIBUS-DP. Daher entfallen auch die

bekannten Beschränkungen des Lokalbusses wie, maximal 8 Teilnehmer,

vorkonfektionierte Leitungen, maximale

Ausdehnung 8 Meter usw..

Für die Kommunikation auf der

PROFIBUS-DP-Seite kann man zwischen

dem PPO-Typen 1 (Prozeßdaten und

Parameterschnittstelle) oder PPO-Typen 3

(nur Pr ozeßdaten) wählen.

Die Pr ozeßdaten wer den wie E/A’s

behandelt, d.h. sie liegen für den

36

Anwender im E/A-Bereich der SPS und

wer den mit jedem InterBus-S-Umlauf

versendet.

®

Die Parametrierung des VLT

über die

Parameterschnittstelle wird mittels PCPKommunikation rea li si ert .

MG.10.G1.51 – VLT is a r egister ed Danfoss trademark

Page 37

■

Eigenschaften der PROFIBUSDP-Seite

Es können maximal 14 VLT’s

angeschlossen werden, diese können mit

dem PPO-Typ1 (12Byte) bzw. PPO-Typ3

(4Byte) betrieben werden. Die Wahl des

PPO-Typs erfolgt für alle VLT ’s, ein Mischbetieb ist nicht zulässig und führt zu einer

Fehlermeldung.

Die InterBus-S Ein/Ausgabedaten wer den

ohne Interpretation auf dem PROFIBUSDP abgebildet. Mit einer Ausnahme, das

Bit 10 des Steuerwortes (STW) wird

invertiert. So wir d erreicht, daß wenn die

SPS in Stopp geht und alle Ausgänge

zurücksetzt die angeschlossenen VLT’s

ebenfalls stoppen, ebenfalls wir d e rreicht,

daß wenn der InterBus-S anläuft die VLT

5000 sicher gestoppt bleiben.

Gateway InterBus-S

Der PPO-Typ1 erlaubt die Parametrierung

der VLT’s, das Abfragen aller W erte und

Parameter, inklusive Stör- und Diagnosewerten, sowie die Steuerung des VLT’ s mit

Rückmeldung des Zustands.

Das PPO-Typ3 hingegen erlaubt nur die

Steuerung und Rückmeldung des

Zustands.

Für die Funktion und die Handhabung der

Parameterschnittstelle beim PPO-Typ1

benutzen Sie bitte das Handbuch zur

PROFIBUS-Optionskarte für VLT

Die Baudrate auf der PROFIBUS-DP Seite

ist 1,5mbaud, daß bedeutet das die maximale Buskabellänge 100 m beträgt,

weiter e Informationen können Sie dem

Handbuch zur PROFIBUS für VLT 5000

®

entnehmen.

®

5000.

Eigenschaften der PROFIBUS-DP-Seite

English Deutsch

!!! WICHTIG !!!

Vor dem einsetzen der PROFIBUS-Option-Card sollte der VLT eingeschaltet

wer den und der Parameter 620 auf „Initialisier en“ eingestellt sein. Danach das

Gerät spannungslos schalten und die PROFIBUS-Option-Card einsetzen.

Beim er neuten einschalten erfolgt sodann eine automatische NeuInitialisierung.

Sollte dies in dieser Reihenfolge nicht möglich sein, bzw. ist die PROFIBUSOption-Card b ereits eingesetzt, so müssen vor dem einschalten des VLT ’s die

Tasten DISPLAY/STATUS + MENU und OK gleichzeitig betätigt werden, dann

das Netz einschalten und die dre i Tasten solange gedrückt halten bis in der

untersten Zeile des Displays die Meldung „Manuel Initialize“ erscheint (Siehe

Seite 136 in MG.50.AX.03).

MG.10.G1.51 – VLT i s a r egister ed Danfoss trademark

37

Page 38

Gateway InterBus-S

■

Konfiguration des

F requenzumrichters

Folgende Parameter sind einzustellen,

b z w . zu kontr ol li eren:

Parameter 502-508

Motorfreilauf, Schnellstopp, DCBremsung, Start, Drehrichtung,

Quittierung, Parametersatzanwahl,

Drehzahlanwahl,

hier legen Sie für den jeweiligen Parameter fest, ob die Ansteuerung nur über

"BUS", oder nur über "KLEMME", oder

aus einer Kombination der beiden

erfolgen soll. Bei r einer BUSAnsteuerung sollten hier alle Parameter

a uf B U S eingestellt wer den.

Eigenschaften der PROFIBUS-DP-Seite

Parameter 512

Telegramm profil

hier kann das Telegramm profil gewählt

wer den, die Pr ofile sind im PROFIBUS

Handbuch für VLT 5000 beschrieben.

Danfoss empfehlen dass Danfoss

Telegramm profil.

Parameter 801

Baudrate,

tragen Sie hier die Baudrate des

Gateways ein, oder belassen Sie diese

a u f AUTO. Zur Zeit ist die Baudrate des

Gateways fest auf 1,5 Mbaud gestellt.

Parameter 800

FMS/DP-Wahl,

hier stellen Sie D P ein, dies ist ebenfalls

in der Werkseinstellung vor eingestellt.

Parameter 803

Zeit nach Busausfall,

diese eingestellte Zeit legt fest, wann

nach einem BUS-Ausfall eine Reaktion

Die am VLT® eingestellten Parameter werden erst nach dem

Abschalten und erneuten

Wiedereinschalten aktiv.

des Frequenzumrichters erfolgen soll.

Parameter 804

Funktion nach Bus-Fehler,

hier legen Sie die Reaktion nach einem

BUS-Ausfall fest.

Parameter 904

Aktuelles PPO-Write,

tragen Sie hier das von Ihnen gewünschte

Telegramm ein. Z.B. für PPO-Typ1 tragen

S i e 900, für PPO-Typ3 9 02 ein. Die PPOTypen sind im Handbuch zur PROFIBUS

für VLT 3000 beschrieben.

Parameter 918

Teilnehmer Adresse,

hier legen Sie die Stationsadresse fest.

Der Bereich für den Betrieb am Gateway

ist von 1-14, wobei auf eine durchgehende Adressierung zu achten ist. Der

Adressbereich beginnt immer bei „1“ und

endet bei der Adresse der maximal

vorhandenen Geräte. Die physikalische

Lage am BUS hat keinen Einfluß auf die

Adr essierung.

Parameter 927

Bedienhoheit PKW ,

hier können Sie festlegen ob die Parameter über den BUS geändert werden

können, (Mit PROFIBUS) , bz w . ob diese

Möglichkeit unterdrückt werden soll,

( Ohne PROFIBUS).

Parameter 928

Führungshoheit,

wie 927 jedoch legen Sie hier fest ob die

Steuerung über denn PROFIBUS erfolgen

sol l (Mit PROFIBUS), oder nicht ( Ohne

PROFIBUS).

Alle übrigen Parameter sind entsprechend

der Anwendung, die man betreiben

möchte, wie im Produkthandbuch

beschrieben einzustellen.

38

MG.10.G1.51 – VLT is a r egister ed Danfoss trademark

Page 39

■

Anmerkungen für die Programmierung:

Der Frequenzumrichter kann nun über den

BUS gesteuert werden, dies erfolgt durch

einfaches setzen oder lesen von E/A-Bits.

■

Steuerwort

Das Bit Nummer 10 muß entgegen der

Aussage im Produkthandbuch zur

PROFIBUS-Optionskarte zum Steuern au f

„0“ gesetzt sein, damit der VLT das

Steuerwort akzeptiert. Das Gateway

invertiert dann dieses Bit automatisch in

eine „1“ um.

Das Steuerwort für:

starten mit Rechtsfeld lautet

047F hex bzw. 0000 0010 0111 1111.

starten mit Linksfeld lautet

847F hex bzw. 0100 0100 0111 1111.

stoppen mit normaler Rampe (Param.

208) lautet 044F hex bzw. 0000 0100

0100 1111,

stoppen mit alternativ Rampe (Param.

210) lautet 064F hex bzw. 0000 0110

0100 1111.

■

Soll- / Istwert

Der Sollwert sowie auch der

zurückgelieferte Istwert des VLT ’s , wird in

normierter Form gehandhabt. Der

Einstellber eich erstreckt sich von -10000

für -100,00% bis auf +10000 für

+100,00%. Wobei 100,00% 4000 hex

entsprechen. Negative Sollwerte werden

du rch bilden des Zweierkomplements

erzeugt.

Beispiel:

Min.Fr equenz = 0Hz;

Max.Frequenz = 50Hz

Gewünscht sind 25Hz Rechtsfeld

entsprechend 50% der Maximaldrehzahl:

50,00% = 2000 hex =

0010 0000 0000 0000Binär

Gateway InterBus-S

Für 25Hz Linksfeld = -50% der Maximald rehzahl:

50,00% = 2000 hex =

0010 0000 0000 0000Binär

umwandeln des positiven in einen negative

Sollwert:

0010 0000 0000 0000 Binär

-> 1101 1111 1111 1111 Binär Einer -Komplement

-> + 1 Binär

= 1110 0000 0000 0000 Binär Zweier-Komplement

-50,00% = E000 hex = 1110 0000 0000 0000Binär

W enn Sie mehr über das Steuerwort,

Zustandsmaschine , Sollwert usw. Wissen

möchten so verweisen wir auf das

P rodukthandbuch zur PROFIBUS-Optionskarte.

■

Parametrierung

Die Parametrierung über den Bus ist nur

bei Verwendung des PPO-Typ1 möglich.

Die Parametrierung erfolgt über PCPKommunikation. Die Vorgehensweise ist

folgende:

Auftrag zum Meldung

IBS-Master: Von VLT an

den Master:

W rite.Request Confirmation

positiv

Confirmation

negativ, Meldung

des Fehlercodes

Read.Request Confirmation

positiv enthält die

Daten der Rückmeldung des VLT

Confirmation

negativ, Meldung

des Fehlercodes

Eigenschaften der PROFIBUS-DP-Seite

English Deutsch

®

MG.10.G1.51 – VLT i s a r egister ed Danfoss trademark

39

Page 40

■

Parameterschnittstelle bei

W rite.Request

Die Parameterschnittstelle (PKW) des

®

5000 besitzt insgesamt 4 Worte.

VLT

Hiermit ist es möglich Parameter zu lesen,

zu schreiben, Arrays zu lesen und zu

schreiben usw..

Die Parameterschnittstelle im einzelnen:

1. Wort (Parameter-Kennung-Wert, PKE),

in den unteren 11 Bit (Bit 0..10) tragen Sie

die Parameter nummer ein, in den oberen

vier Bit (Bit 12..15) wählen Sie die Aktion.

2. W ort (Index/Subindex, IND), das Byte

„Index“ wir d nur benutzt, wenn Sie auf

Eigenschaften der PROFIBUS-DP-Seite

Elemente eines Arrays zugreifen wollen. In

diesem Fall tragen Sie hier den Index des

Elementes ein. Bei normalen Parameteraktionen bleibt dieses Byte unbenutzt.

Das Byte Subindex ist für spätere

Erweiterungen vorgesehen und bleibt

unbenutzt.

Gateway InterBus-S

Beispiel:

Es soll am VLT

2 der Parameter 202, maximal Frequenz,

auf 80Hz geändert werden,

PKE: 20CA

IND:0000

PWE: 0000 0320

®

5000 mit der Busadresse

Parameter CA hex = 202

Aktion 2 = Parameterwert änder n

kein Subindex

kein Index

Parameterwert_low =

320 hex = 800 = 80.0 x Faktor 10

Parameterwert_high = 0

3. + 4. Wort (Parameterwert, PWE), hier

w i r d bei Schr eibzugrif fen der Wert für den

angewählten Parameter eingetragen. Das

3. Wort ist das High-W ort, das 4. W or t

das Low-Wort. Das 3.Wort wir d nur

benutzt, wenn Parameterwerte größer

65535 übertragen werden sollen.

Da die zu übertragenden Werte nicht im

Kommaformat Übertragen werden, muß

der jeweilige Parameterwert noch mit

einem Faktor multipliziert werden. Den

jeweiligen Faktor des Parameters

entnehmen Sie dem Handbuch zur

PROFIBUS-Optionskarte.

40

MG.10.G1.51 – VLT is a r egister ed Danfoss trademark

Page 41

Der Auftrag auf dem PCP-Kanal sieht

dann folgendermaßen aus:

Alle Werte in hex.

W rite.Request

Anzahl nachfolgender Werte

invoke_id Kommunkations-

Refer enz

Index

VLT-Adresse Anzahl Bytes

PKE

IND

High_Parameterwert

Low_Parameterwert

Gateway InterBus-S

Eigenschaften der PROFIBUS-DP-Seite

8082

007

00 02

5FA5

02 08

20CA

0000

0000

0320

Die erfolgr eiche Ausführung wird mittels

einer positiven Confirmation angezeigt.

Sollen alle VLT ’s gleichzeitig parametriert

wer den, so ist anstelle der VLT-Adresse

eine Null einzutragen.

■

Parameterschnittstelle bei

Read.Request

Antworten des VLT® auf einen zuvor

mittels Write.Request initiierten Auftrags.

Daten liegen nur bei einer positiven

Confirmation vor, bei einer negativen

Confirmation wir d der Fehlercode

zurückgeliefert.

1. Wort (Parameter-Kennung-Wert, PKE),

in den unter en 11 Bit (Bit 0..10) trägt der

®

die Parameter nummer ein, in den

VLT

oberen vier Bit (Bit 12..15) erscheint der

Typ der Antwort.

2. W ort (Index/Subindex, IND), das Byte

„Index“ wir d nur eingetragen, wenn Sie auf

Elemente eines Arrays zugegriffen haben.

Bei normalen Parameteraktionen bleibt

dieses Byte unbenutzt. Das Byte

Subindex ist für später e Erweiterungen

vorgesehen und bleibt unbenutzt.

MG.10.G1.51 – VLT i s a r egister ed Danfoss trademark

Daran anschließen muß die Länge der

Daten angegeben werden. Da diese aber

nur für den Maximalausbau ausgelegt ist,

muß hier 112Byte Länge eingegeben

werden. Nun folgen die Daten für die VLT ’s,

in der Reihenfolge ihr er Adressierung.

3. + 4. Wort (Parameterwert, PWE), hier

®

trägt der VLT

den Wert für den angewählten Parameter eingetragen. Das 3.

W ort ist das High-Wort, das 4. W ort das

Low-Wort. Das 3.Wort wird nur benutzt,

wenn Parameterwerte größer 65535

übertragen wurden.

Da die zu übertragenden Werte nicht im

Kommaformat Übertragen werden, muß

der jeweilige Parameterwert noch durch

einen Faktor geteilt wer den, um den tatsächlichen Wert zu erhalten. Den jeweiligen Faktor des Parameters entnehmen

Sie dem Handbuch zur PROFIBUSOptionskarte.

41

English Deutsch

Page 42

Gateway InterBus-S

Beispiel:

®

Es soll die Antwort des VLT

5000 auf

den oben mittels Write.Request gesendeten Auftrag gelesen werden.

Der Auftrag auf dem PCP-Kanal sieht

dann folgender-maßen aus:

Alle Werte in hex.

Read.Request

Anzahl nachfolgender Werte

invoke_id Kommunkations-

Refer enz

Index

VLT-Adr esse Anzahl Bytes

Eigenschaften der PROFIBUS-DP-Seite

Nach dem ausführen des Read.Request,

erhält man folgende Daten:

PKE: 10CA

Parameter CA hex = 202

Aktion 1 = Parameterwert

übertragen

IND: 0000

kein Subindex

kein Index

8081

0003

00 02

5FA5

02 00

PWE: 0000 0320

42

Parameterwert_low =

320 hex = 800 =

80.0 x Faktor 10

Parameterwert_high = 0

MG.10.G1.51 – VLT is a r egister ed Danfoss trademark

Page 43

■

Eigenschaften der InterBus-SSeite

■

ID-Code

Der ID-Code des Gateways : F1hex ; 241dec

32 W orte, davon:

Busbr eite 4 bis 32 Worte

- 4 Worte PCP

- 0 - 28 W orte Pr ozeßdatenkanal

(2 W orte je VLT

®

) Ein / Ausgabe

Längencodes

■

Da beim InterBus-S nicht alle Registerb reiten möglich sind müssen bei bestimmten Konfigurationen des Gateways Füllwörter eingetragen werden. Weiterhin sind

nicht alle InterBus-S-Master in der Lage

einen 4 Wort br eiten PCP-Kanal zu

bedienen (Firmware Version vor 4.0). In

Anzahl InterBus-S Längencode Längencode

VLT® 5000 Busbre i te 1 Wort PCP 4 Worte PCP

0 4 03 hex 00 hex

1 6 05 hex 02 hex

2 8 07 hex 04 hex

3 10 09 hex 06 hex

4 12 0B hex 08 hex

5 14 0D hex 0A hex

6 16 0F hex 0C hex

7 24 17 hex 14 hex

8 24 17 hex 14 hex

9 24 17 hex 14 hex

10 24 17 hex 14 hex

11 32 1F hex 1C hex

12 32 1F hex 1C hex

13 32 1F hex 1C hex

14 32 1F hex 1C hex

Gateway InterBus-S

diesem Fall müssen zur Berechnung der

Längencodes weitere 3 Worte vom PCPKanal berücksichtigt werden. Die

entsprechende Angabe des Längencodes

für Ihr e Konfiguration entnehmen Sie folgender Tabelle:

Eigenschaften der InterBus-S-Seite

English Deutsch

MG.10.G1.51 – VLT i s a r egister ed Danfoss trademark

43

Page 44

Gateway InterBus-S

■

PCP-Kommunikation

■

Kommunikationsobjekte

Anzahl der VLT® 5000

Index: 5F A0 hex

Symbol: inv_count

Datentyp: Unsigned8

Hiermit kann die am Drehschalter

eingestellte Anzahl der am PROFIBUS

erwarteten Frequenzumrichter gelesen

werden. Dies ist nicht immer die Anzahl

Eigenschaften der InterBus-S-Seite

der tatsächlich angeschlossenen

F requenzumrichter.

Zustand der Frequenzumrichter

Index: 5FA2 hex

Symbol: inv_state

Datentyp: Subindex1: Unsigned

8

Subindex2: Unsigned

8

Zugrif f: Nur Lesen

Eingestellter PPO-Typ

Index: 5FA1 hex

Symbol: PPO_type

Datentyp: Unsigned8

Zugrif f: Nur Lesen

PPO-Typ ppo_type

PPO1 0 1 he x

PPO3 0 3 he x

Hiermit kann der am Schiebeschalter

eingestellte PPO-Typ gelesen werden.

inv_state.2 Fehlertyp

01 hex VLT® nicht gefunden

®

02 hex VLT

nicht im Daten-

austausch

03 hex Master nicht aktiv

W enn alle am Drehschalter eingestellten

®

am Bus störungsfre i arbeiten, liefer n

VLT

beide Subindizes eine Null. Beim

a uf t reten einer Kommunikationsstörung

liefert Subindex1 die niedrigste Adr esse,

bei der ein Kommunikationsfehler auftrat,

während der Subindex2 nähere Auskunft

über denn Fehler gibt.

44

MG.10.G1.51 – VLT is a r egister ed Danfoss trademark

Page 45

InterBus-S Modulfehler

Index: 5FA3 hex

Symbol: stat_err

Datentyp: Boolean

Zugrif f: Lesen/Schreiben

Erkennt ein InterBus-S-Slave einen Fehler,

so kann er dem InterBus-S-Master einen

Modulfehler melden. Der Master verwirft

daraufhin den letzten Datenzyklus und

startet einen Identifikationszyklus, mit dem

der Master den Teilnehmer ermittelt,

welcher den Modulfehler gemeldet hat.

Baudrate auf dem PROFIBUS-DP

Gateway InterBus-S

Mit stat_err kann eingestellt wer den, ob

bei einem Fehler auf der PROFIBUS-DPSeite ein Modulfehler ausgelöst werden

s o l l .

stat_err = FF hex Modulfehler wird

ausgelöst

stat_err = 00 hex Modulfehler wird nicht

ausgelöst

Als Vo r einstellung ist FF hex eingestellt,

d.h. der Modulfehler als Fehlermeldung ist

a kt iv i er t .

Eigenschaften der InterBus-S-Seite

Index: 5FA4 hex

Symbol: baud_rate

Datentyp: Unsigned8

Zugrif f: Lesen/Schreiben

Hiermit kann die Baudrate mit welcher auf

der PROFIBUS-Seite gearbeitet wird ,

gelesen und auch eingestellt werden. Um

die Baudrate zu änder n w ird d er

PROFIBUS komplett gestoppt und dann

mit der neuen Übertragungsgeschwindigk e i t n eui nit ialisi ert .

baud_rate Baudrate

00 hex 9.600 Bit/s

01 hex 19.200 Bit/s

02 hex 93.750 Bit/s

03 hex 187.500 Bit/s

04 hex 500.000 Bit/s

05 hex 750.000 Bit/s

06 hex 1.500.000 Bit/s

Zur Zeit ist es nicht möglich, die

Baudrate zu stellen. Die Baudrate ist fest auf 1.5MBaud

eingestellt und das Objekt ist nur

zum Lesen freigegeben.

English Deutsch

MG.10.G1.51 – VLT i s a r egister ed Danfoss trademark

45

Page 46

Gateway InterBus-S

PKW-Teil von PPO1

Index: 5FA5 hex

Symbol: PC V

Datentyp: 14 OCTET_STRING mit je

8 Octet (bytes)

Zugriff: Lesen/Schreiben

Dieses Objekt dient zum Lesen und

Schreiben der ersten 8 Octets (PKW-Teil )

vom PPO-Typ1. Die 14 Elemente des

Objekts 5FA5 hex können einzeln als auch

gemeinsam gelesen und geschrieben

werden.

Eigenschaften der InterBus-S-Seite

Um den PKW-T eil eines der angeschlossenen VLT

®

zu lesen oder zu

schr eiben wir d bei dem Write.Request

zusätzlich zum Index noch die Nummer

des VLT’s als Subindex übergeben. Siehe

auch das Beispiel auf Seite 6.

Schreibzugrif fe :

Schreibversuche werden nur dann mit

einer positiven Confirmation quittiert,

wenn der neu geschriebene Wert an den

oder die Fr equenzumrichter geschrieben

werden kann, also wenn :

1. PPO-Typ1 benutzt wird ,

2 . der PROFIBUS-DP-Master im Zustand

Operate ist,

3 . sich alle am PROFIBUS-DP erwarteten

Frequenzumrichter im Datenaustausch

befinden

4. Mindestens einmal wurden die neuen

Daten auf dem PROFIBUS-DP

gesendet und empfangen.

Lesezugriff e :

Um die Rückgabewerte der VLT’s zu

erhalten, muß die Struktur gelesen

werden.

Die Daten werden als Parameter

interpr etiert und mit dem entsprechenden

W ert des Pr ozeßdatenkanals zu einem

Telegramm zusammengesetzt. Eine

Plausibilitätsprüfung findet nicht statt.

46

Auf die beiden PPO-Objekte kann nur

entsprechend der Schalterstellung auf der

F r ontplatte zugegrif fen wer den, d.h. wenn

der Schalter auf PPO-Typ3 steht, kann

das Objekt PPO-Typ1 nicht gelesen oder

geschrieben werden.

MG.10.G1.51 – VLT is a r egister ed Danfoss trademark

Page 47

e

,

m

r

■

Kommunikationsbeziehungsliste

Folgende Änderungen sind an der KBL

(Kommunikationsbeziehungsliste)

erfor derlich. Dies kann über die SPS

erfolgen oder über das PC-Programm

SYSSWT. Die V orgehensweise für eine

Siemens-SPS, ist aus dem

Beispielpr ogramm ersichtlich.

■

Fehlermeldungen bei PCP-Kommunikation

Error_Class „Access“ (06 hex):

Error CodeAdditional

Error Code

05 hex object -attribut-inconsistent

10 hex bad-subindex

12 hex too-much-data

13 hex too-few-data