Page 1

Data Sheet

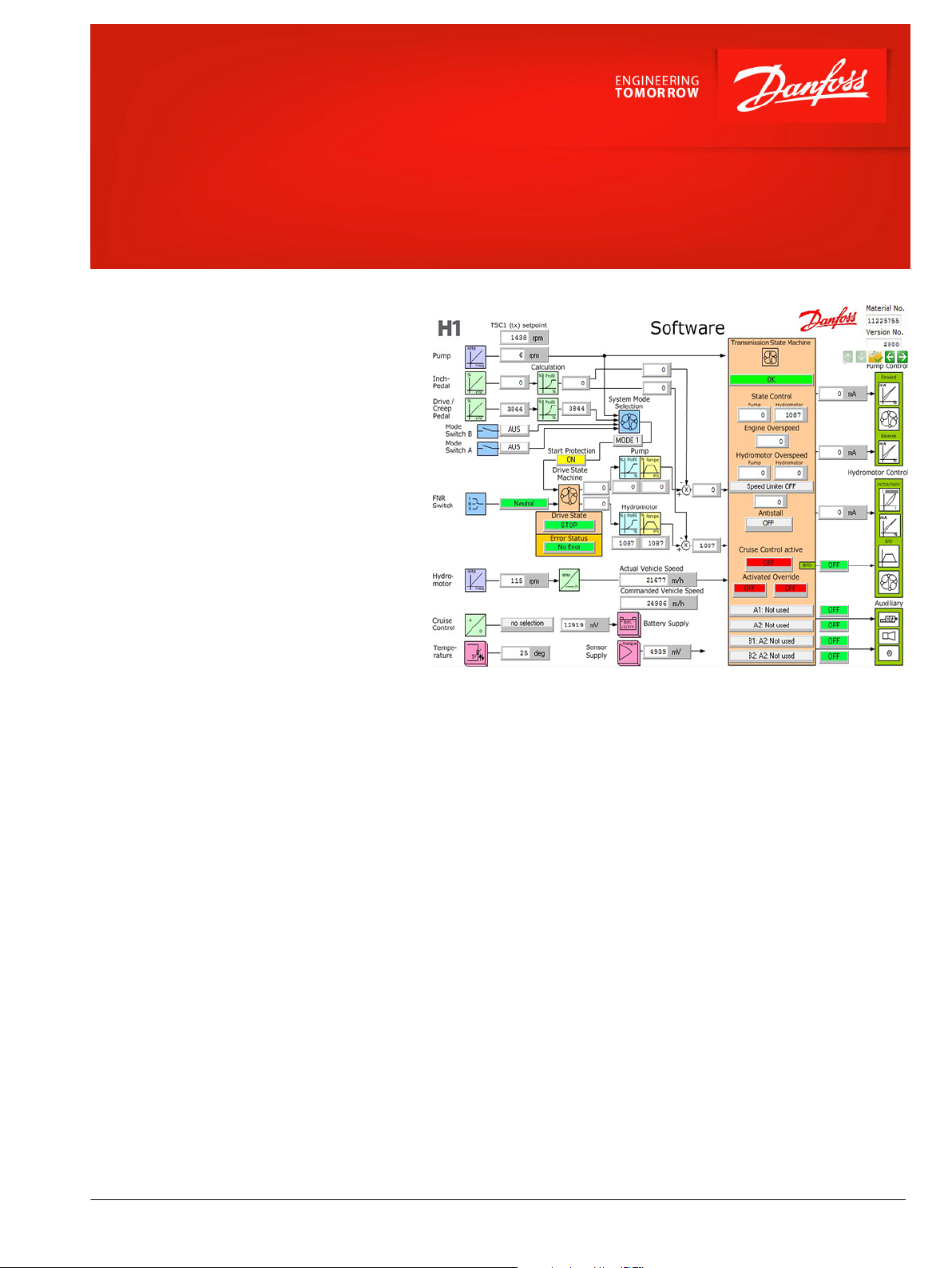

Integrated Automotive Control

for MP1 and H1P single pumps

The Automotive Control (AC) is an electric NFPE

control with an integrated micro-controller, installed

on the pump. The integrated micro-controller

enhances control performance with a flexible,

configurable control scheme for an entire single path

propel transmission. It can be used in combination

with fixed and variable displacement hydraulic

motors. The propel system can be used with

mechanical controlled or CAN controlled engines.

With the pre-installed application software and easily

changeable control parameters, it is possible to tailor

the vehicle‘s driving behavior to the individual

requirements of the customer. Target applications

with a load dependent driving behavior:

•

Wheel loader, telehandler, dumper (torque

controlled)

•

Sweeper, snow blower, forestry machines (speed

controlled)

Features

Basic functions

•

Four system modes, selectable by the

driver for different drive behaviour

•

Independent pump/motor profiling and

ramping for each system mode

•

Electric drive pedal

•

Electric inching

•

Electric creep mode potentiometer

•

Hand throttle for engine speed control

•

Reversing in all possible driving

conditions

•

Load dependent pump displacement

control (automotive)

•

Load independent pump displacement

control with integrated swash-plate

angle sensor (optional)

•

Two position and proportional motor

displacement control

•

System status (errors) by LED

Protection and safety functions

•

Safety controlled vehicle start

protection

•

Operator presence detection

•

Hydraulic system overheat and low

temperature protection

•

Hydraulic motor overspeed protection

•

Safety functions according EN1459,

ISO20474, ISO 25119 and ISO 13849 up

to performance level d

Engine control and protection

•

CAN J1939 and Kubota engine protocol

•

Engine speed control via drive pedal or

hand throttle with safety controlled

monitoring function

•

Engine over speed and cold start

protection

•

Engine anti-stall and speed-dependent

retarder control

Performance functions

•

ECO fuel saving mode

•

Cruise control in work mode

•

Vehicle constant speed control by drive

pedal

•

Vehicle speed limitation

•

Digital outputs for:

dynamic brake light

‒

automatic park brake

‒

reverse buzzer

‒

vehicle speed controlled output

‒

functions

•

Temperature compensation for

predictable performance

•

Advanced CAN J1939 interface

©

Danfoss | February 2019 AI289060682770en-000101 | 1

Page 2

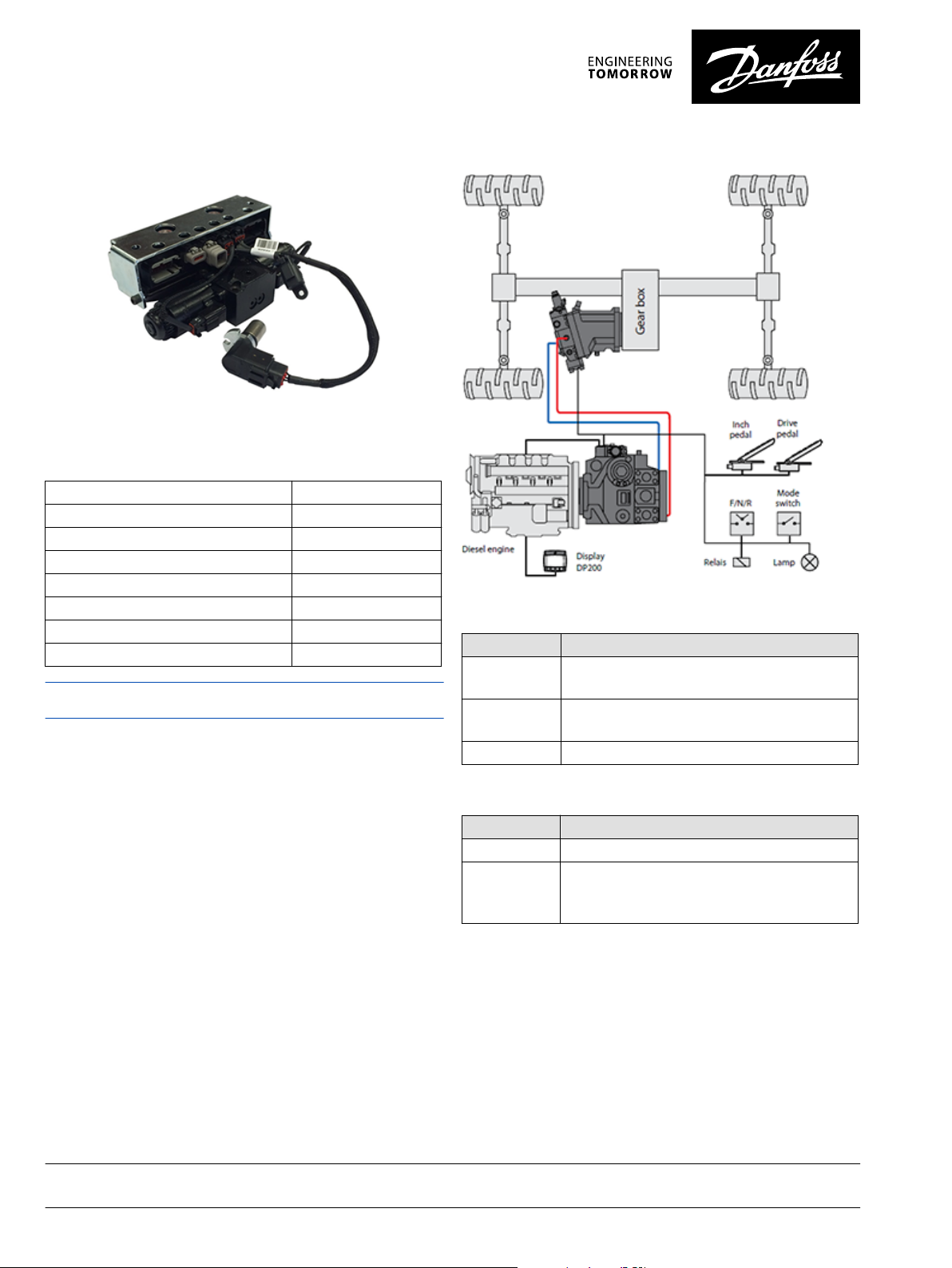

AC controller

Specifications

Controller

Rated supply voltage 12 V system 9 – 16 V

Rated supply voltage 24 V system 18 – 36 V

Digital and PWM outputs 3000 mA

Sensor supply (internal) 5 V / 1 A

Ambient temperature -40 to 104°C

IP rating with attached connectors IP69k

EMC immunity 100 V/m

Vibration and shock tested IEC 60068

Comprehensive technical literature is online at www.danfoss.com

Telehandler system schematic

Input configuration

Input Function

6 x digital FNR (direction selection), seat switch, system mode

switches

7 x analog Inch pedal, drive pedal, creep potentiometer, hand

throttle, engine speed set-up point, pressure sensors

2 x frequency Pump/engine, hydro-motor rpm

Output configuration

Output Function

3 x PWM Pump and hydro-motor displacement control

5 x digital Hydraulic motor brake pressure defeat, dynamic brake

light, hand brake, reverse buzzer, retarder control,

vehicle speed dependent output, status LED

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

2 | © Danfoss | February 2019 AI289060682770en-000101

Loading...

Loading...