Page 1

Data Sheet

Pilot

-operated servo valve

Type ICS

Controlling pressure, temperature and ON/OFF in refrigeration systems

ICS pilot-operated servo valves belong to the

ICV (I

The valve comprises three main components:

valve body, function module and top cover.

ICS pilot-operated servo valves are pilot

operated valves for regulating pressure,

temperature and ON/OFF function in

refrigeration systems. ICS valves are designed

for low and high-pressure refrigerants.

ICS valves can be used on the high and

lowpressure sides, in wet and dry suction lines

and in liquid lines without phase change (i.e.

where no expansion takes place in the valve).

ndustrial Control Valve) family.

The function of ICS valves is dependent on the

pilot pressure applied from either a pilot valve

or external pilot pressure source.

ICS 1 pilot has one pilot pressure connection

and ICS 3 pilot has three pilot pressure

connections.

AI241186442033en-001301

Page 2

Pilot-operated servo valve, type ICS

Features

• Designed for industrial refrigeration applications for a maximum working pressure of 52 bar / 754 psig.

• Applicable to HCFC, HFC, R717 (Ammonia) and R744 (CO2).

• Direct coupled connections.

• Connection types include butt weld, socket weld, solder and threaded connections.

• Low temperature steel body.

• Low weight and compact design.

• V-port regulating cone ensures optimum regulating accuracy particularly at part load.

• Function module has a QPQ surface treated insert and a steel piston ring ensuring precise control accuracy.

• ICV 4 in., 5 in. and 6 in. ANSI with NPT threaded pressure outlet in the outlet of the valve.

• Replaceable Teon valve seat for ICS 25-80.

• Maintenance spare part kit available for ICS 100-150.

• Modular Concept:

◦ Each valve body is available with several

◦ Valve overhaul on ICS 25-80 is done by replacing the function module.

◦ Possible to convert ICS pilot-operated servo valve to ICM motor operated valve.

• Manual opening.

• The ICS valve is a multifunction valve where several pilot valves can be mounted into the pilot ports.

• The standard range of pilot valves can be used on all sizes of ICS valves. Pilot valves can be either screwed directly

into the ICS valve, thus eliminating the need for solder/weld connections or external pilot lines.

• Pressure gauge connection port to measure valve inlet pressure.

• The top cover can be rotated into any possible position without aecting the operation of the valve.

• To get an updated list of certication on the products please contact your local Danfoss Sales Company.

dierent connection types and sizes.

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 2

Page 3

8

p

2

2c

3f

2g

1b

p

3

1a

3c

3g

p

1

p

4

2d 2a 2b

Danfoss

27H436

2g

3b

3a

3d

3e

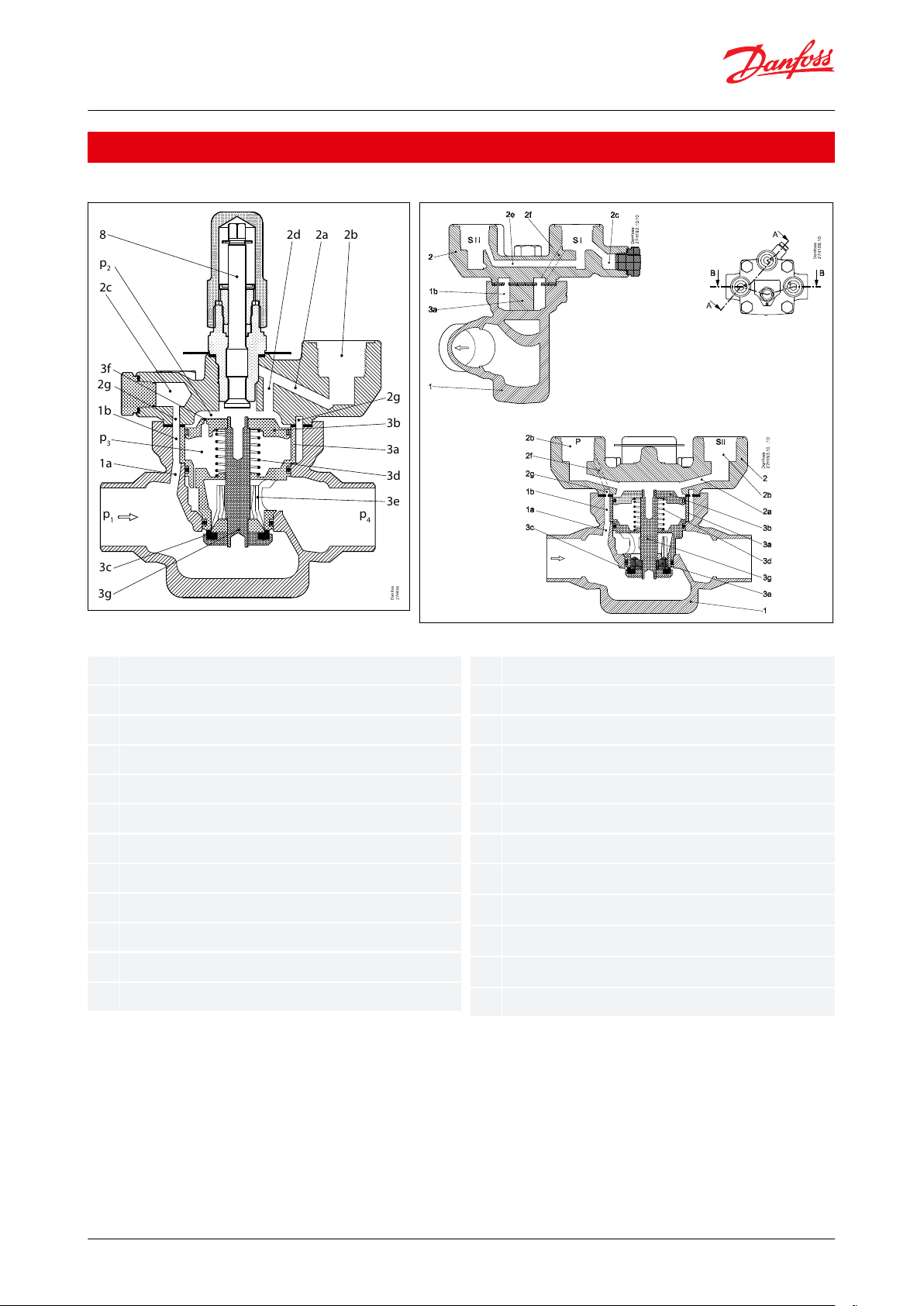

11a1b22a2b2c2d2e2f2g33a3b3c3d3e3f3g

p1p2p3p

4

8

Body

Pilot channel to inlet side

Circular gap between house and module

Top cover

Pilot channels in top cover

Pilot insertion hole

Pressure gauge connection

Piston top inlet channel

Cross channel SI to SII

Inlet channel

Circular groove

Function module

Cylinder

Piston

Valve plate

Spring

Cone

Equalisation orice

Piston rod

Inlet pressure

Pressure on piston

Pressure underneath piston

Outlet pressure

Manual operating spindle

Pilot-operated servo valve, type ICS

Functions

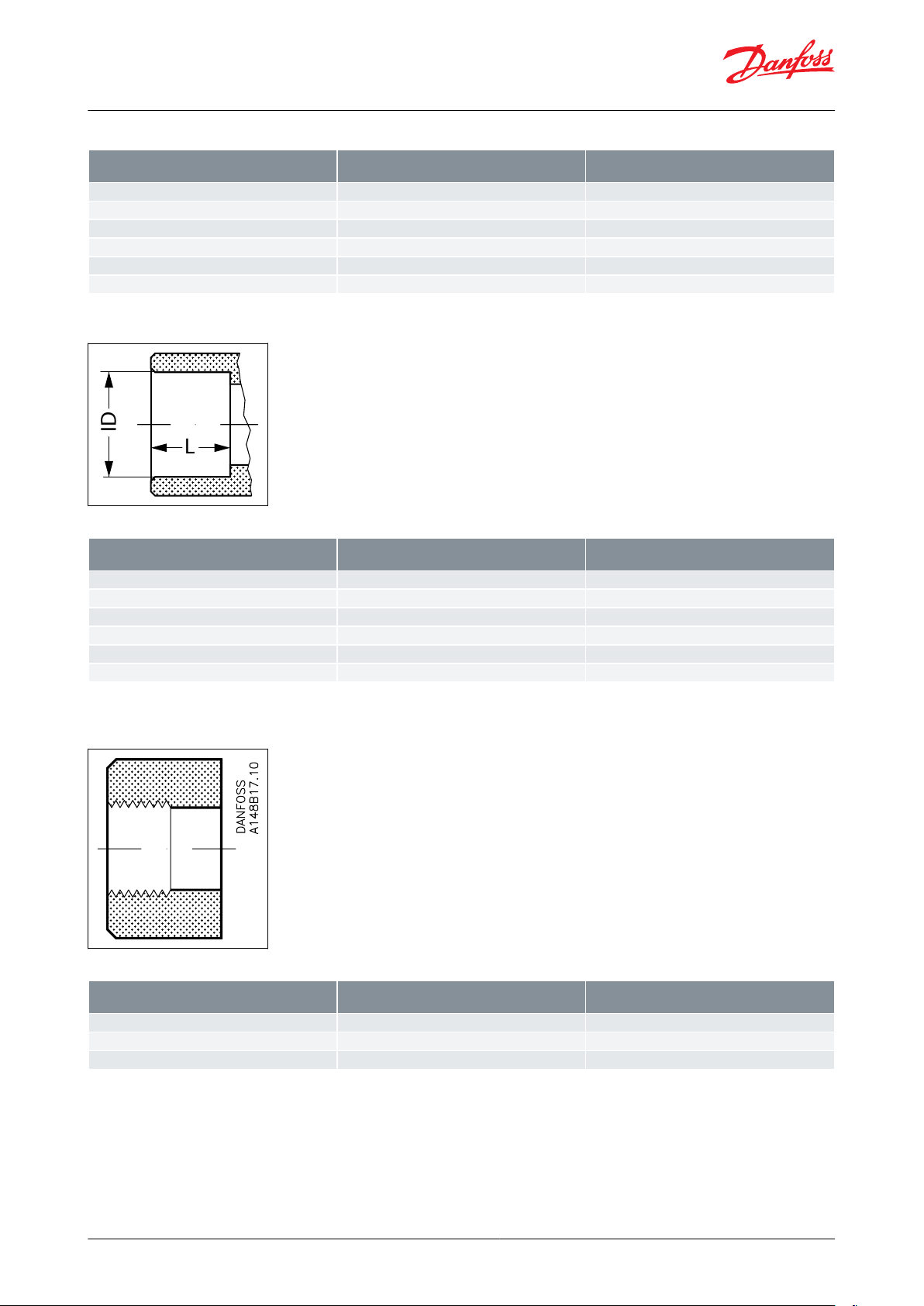

Figure 1: ICS 1 Pilot

Figure 2: ICS 3 Pilots

ICS 1 Pilot and ICS 3 Pilot

The ICS main valve is a pilot operated valve. The types of pilot valves used determine the function. The ICS main

valve with pilot valve(s) controls refrigerant ow

by modulation or on/o in accordance with the pilot valve and

main valve status. The manual spindle can be used to open the valve plate.

The opening degree of the main valve is determined by the pressure dierence (dierential pressure) between

pressure p2, which acts on top of the servo piston (3b), and pressure p3, which acts on the underside of the servo

piston.

If this pressure dierence is 0, the main valve will be fully closed.

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 3

Page 4

Pilot-operated servo valve, type ICS

If the pressure dierence is 0.2 bar (3 psi) or greater, the main valve will be fully open. At pressure

dierences (p2 -

p3) between 0.07 bar (1 psi) and 0.2 bar (3 psi), the degree of opening will be correspondingly proportional.

The port of the throttle cone (3e) is V-shaped, which provide good regulation characteristic to pilot operated main

valves even at low loads. P3 pressure is equal to the valve outlet pressure (P4), due to a clearance between the piston

rod (3g) and the function module. The opening degree of the ICS valve is therefore controlled by the application of

P2 pressure acting on top of the servo piston, which is equal to or greater than valve outlet pressure (P4).

p2 = p4 ~ closed

p2 = p4 + 0.2 bar (3 psi)~ fully open

p4 ≤ p2 ≤ p4 + 0.2 bar (3 psi) ~ proportional degree of opening.

The maximum pressure (p2) can act on the top of the servo piston (3b). p2 normally corresponds to the pressure, p1 ICS main valve inlet pressure. Inlet pressure p1 is led, via the drilled channels (1a, 1b, 2f, 2b (pilot), 2a, 2d) in the valve

body (1) and cover (2) through the individual pilot valves and onto the top of the servo piston (3b).

The degree of opening of the individual pilot valves determines the magnitude of pressure p2 and thus the degree

of opening of the main valve. The equalisation hole (3f) in the servo piston (3b) ensures that pressure p2 is balanced

in accordance with the degree of opening of the pilot valve.

NOTE:

When ICS valves with 3 pilot ports are used with external pressure connector (Figure 2: ICS 3 Pilots, pos. 61), the

valve port inlet pressure will be isolated.

The ICS can be tted with just a single screwed-in pilot valve or external pilot connection. The degree of opening of

the main valve will be in accordance with the control status of the pilot valve or external pilot ow control.

ICS main valve with one pilot connection is fully closed when the pilot valve is fully closed and fully open when the

pilot valve is fully open. Otherwise the degree of opening of the main valve is proportional to the degree of opening

of the pilot valve.

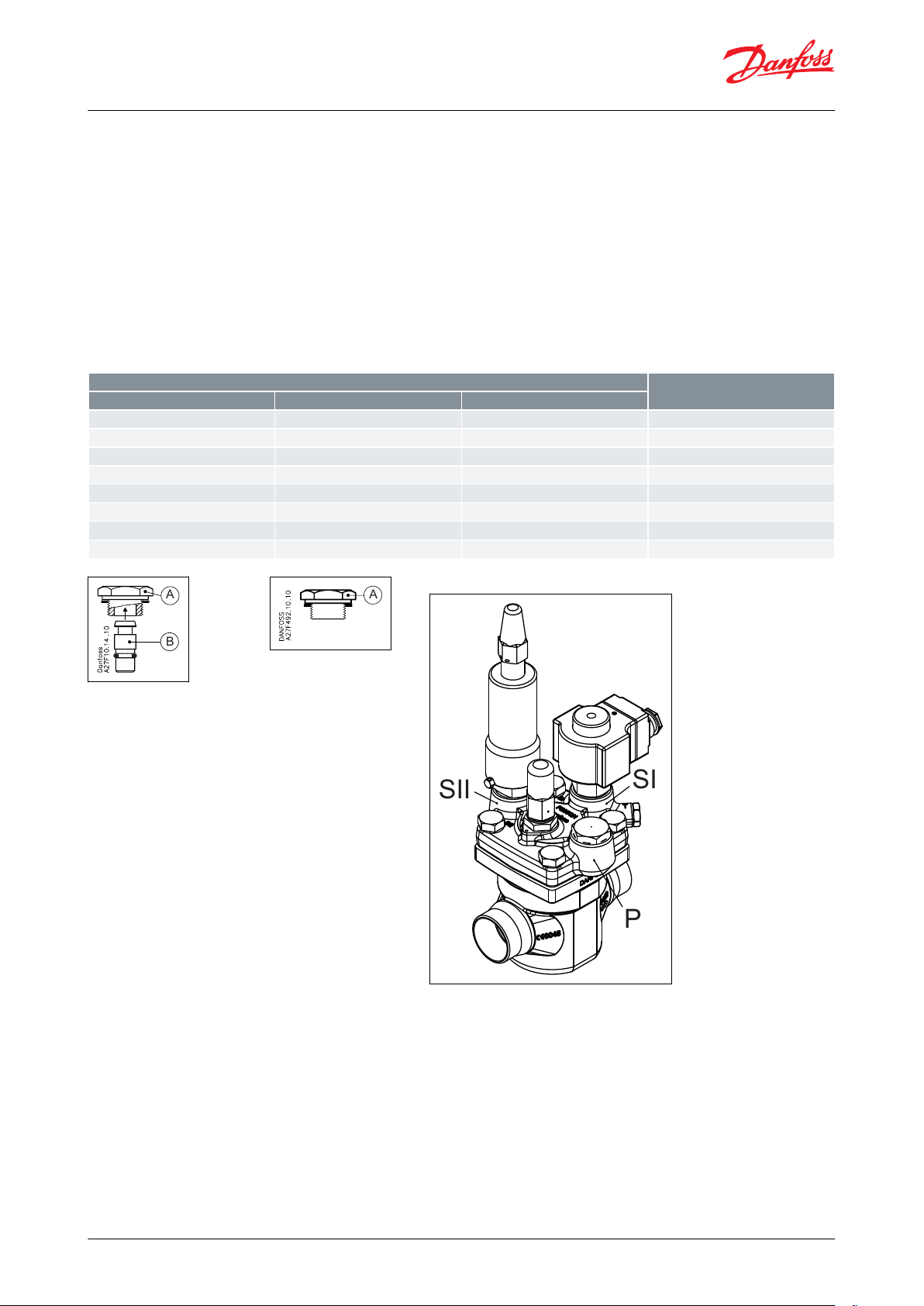

The ICS 3 pilot version can be tted with one, two, or three pilot valves so that up to three regulating functions are

possible. If the external pilot connection is used, more functions can be added.

In the ICS three pilot version, the pilot ports are related as follows:

• The pilot valves tted in ports SI and SII are connected in series.

• The ICS 3 pilot operated main valve will be fully closed if just one of the series-connected pilot valves is closed. The

main valve can only open if both pilot valves are open at the same time.

• The pilot valve tted in port P is connected in parallel to the pilot valves in ports SI and SII.

The ICS valve will be fully open if the pilot valve in P is fully open, irrespective of the degree of opening of pilot

valves SI and SII.

The ICS valve will be fully closed if the pilot valve in P is fully closed and at least one of the valves in SI or SII is fully

closed at the same time. The relation between the pilot valves in ports SI, SII and P is shown in the table on the next

page.

If the ICS is not tted with three pilot valves, the unused port(s) must be sealed with a blanking plug. If the blanking

plug is tted as an assembled unit, A + B, the channels from the specic port will be closed. (See illustration below)

If only the top part, A, of the plug is tted, the channels from the ports in question will be open. If the degree of

opening of the ICS main valve is not to be a function of the main valve inlet pressure, or if more than three

regulating functions are required, ports SI, SII or P can be tted with a nipple for the connection of external pilot

pressure. This applies to all ICS versions.

The pressure to which the external pilot line is connected will then determine pressure p2 on top of the servo

piston. The pilot valves tted in that external pilot line will determine the main valve function. Pilot valves installed

in external lines must be mounted in a type CVH housing.

Depending on the function of the pilot valves, the ICS regulating characteristic becomes:

© Danfoss | Climate Solutions | 2022.04

AI241186442033en-001301 | 4

Page 5

A

B

P

SI

SII

Pilot valve port

ICS valve

SI

SII

P

Open

Open

Closed

Open

Open

Open

Open

Open

Open

Closed

Closed

Closed

Open

Closed

Open

Open

Closed

Open

Closed

Closed

Closed

Open

Open

Open

Closed

Closed

Closed

Closed

Closed

Closed

Open

Open

Pilot-operated servo valve, type ICS

• on/o

• proportional

• integral or

• cascade.

ICS main valves ar

e therefore especially suitable for all forms of temperature and pressure regulating systems.

An overview of the types of pilot valves available can be found in the literature “Pilot valves for operated main

valves” (AI248786497190).

On the following pages, a number of conguration examples can be found. These are only for explanatory purpose.

However, by using the literature regarding pilot valves these examples are easier to comprehend.

Table 1: Pilot valve port

Figure 3: Blanking plug A + B

Figure 4: Blanking plug AAFigure 5: Example (ICS with 3 pilot

valves)

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 5

Page 6

Pilot-operated servo valve, type ICS

Media

Refrigerants

Applicable to HCFC, HFC, R717(

Use with ammable hydrocarbons cannot be recommended; please contact Danfoss.

Surface protection ICS 25-150: The external surface is zinc-chromated to provide good corrosion protection.

Ammonia) and R744 (CO2).

New refrigerants

Danfoss products are continually evaluated for use with new refrigerants depending on market requirements.

When a refrigerant is approved for use by Danfoss, it is added to the relevant portfolio, and the R number of the

refrigerant (e.g. R513A) will be added to the technical data of the code number. Therefore, products for specic

refrigerants are best checked at store.danfoss.com/en/

, or by contacting your local Danfoss representative.

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 6

Page 7

Pilot-operated servo valve, type ICS

Product specication

Design

ICS valves ar

dierence is 0 bar /0 psi, the ICS valve will be closed. If the pressure dierence is 0.2 bar /3 psi or more, the ICS valve

will be fully open. At pressure dierences between 0.07 bar /1 psi and 0.2 bar /3 psi, the opening degree will be

correspondingly proportional.

The ICS is available for use with either one or three pilot valves.

Two of the three pilot pressure connections (S1 and S2) are connected in series whilst the third (P) is connected in

parallel to S1 and S2. This allows dierent combinations of pilot valves to be used, thus providing numerous

variations in control functions.

Valve body and top cover material Low temperature steel

e designed as pilot operated valves requiring minimal pressure dierential to open. If the pressure

Pressure and temperature range

Temperature range

-60 °C /+120 °C (-76 °F /+248 °F).

Pressure range

The valve is designed for: Max. working pressure: 52 bar (754 psig)

Surface protection

ICS 25-150: The external surface is zinc-chromated to provide good corrosion protection.

Opening

Fully open: Min. 0.2 bar (min. 3 psig); Max. Opening Pressure Dierential (MOPD), solenoid valves only - at nominal

conditions.

dierential pressure:

• 10 W a.c. up to 21 bar (305 psi)

• 20 W a.c. up to 40 bar (580 psi)

© Danfoss | Climate Solutions | 2022.04

AI241186442033en-001301 | 7

Page 8

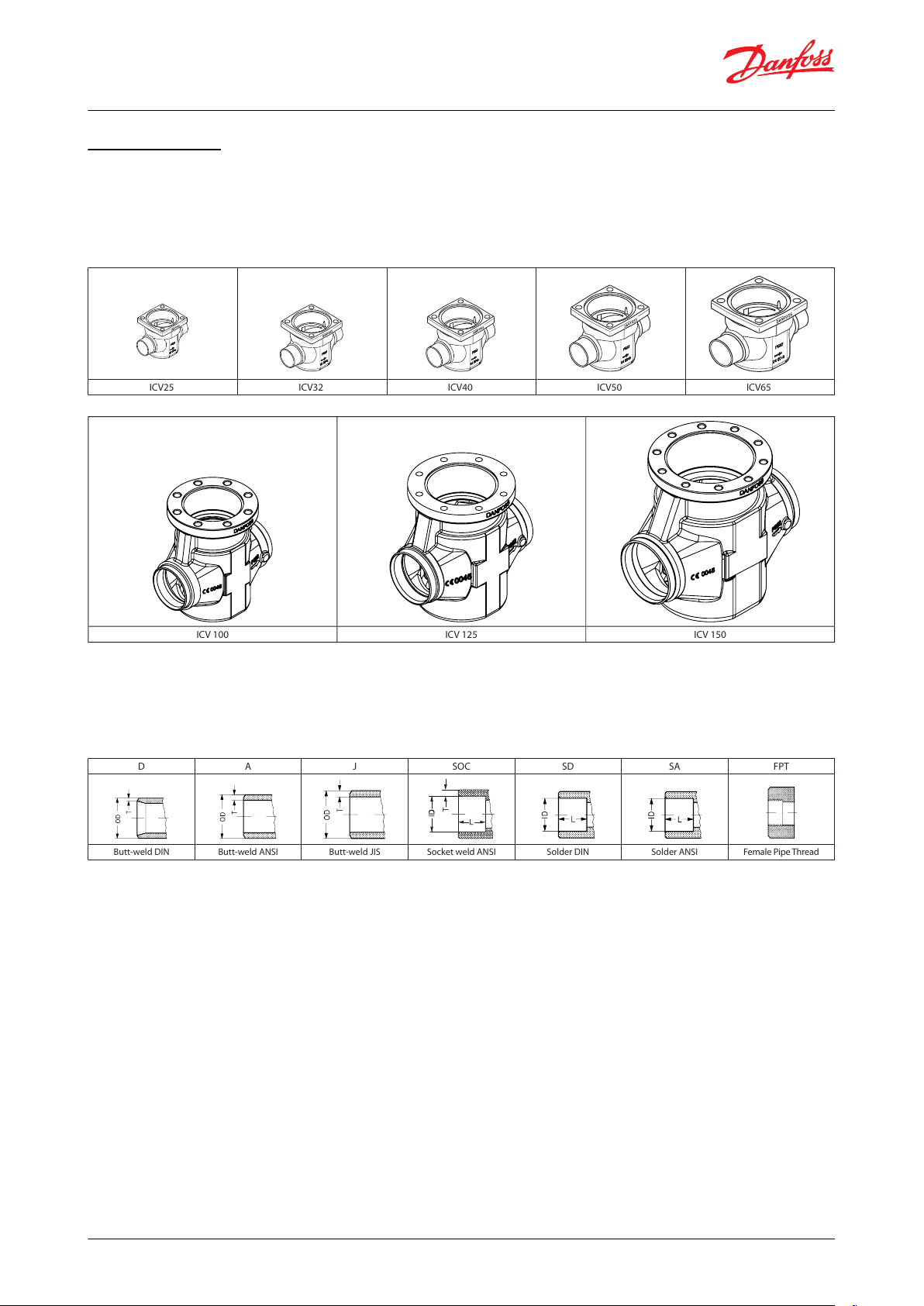

ICV25 ICV32 ICV40 ICV50 ICV65

ICV 100 ICV 125 ICV 150

D A J SOC SD SA FPT

Butt-weld DIN Butt-weld ANSI Butt-weld JIS Socket weld ANSI Solder DIN Solder ANSI Female Pipe Thread

Pilot-operated servo valve, type ICS

The ICS Concept

The ICS conc

ept is developed around a modular principle. This gives the possibility of combining function modules

and top covers with special valve body size that is available in a variety of connection possibilities.

There are eight valve bodies available.

Figure 6: Valve bodies

Valve bodies in the sizes ICV 20-ICV65 are available with a range of undersizes through oversized connection sizes

and types.

V 100 - ICV 150 are available in butt-weld DIN and butt-weld ANSI nominal sizes

IC

Figure 7: Valve body in sizes

Each valve body may be tted with a 1 pilot or 3 pilot top cover.

© Danfoss | Climate Solutions | 2022.04

AI241186442033en-001301 | 8

Page 9

Danfoss

27H8258

Danfoss

27H8259

Type

Valve body size

K

v

(m3/h)

C

v

(USgal/min)

ICS 25-5

25

1.7

2.0

ICS 25-10

3.5

4.1

ICS 25-15

6.0

7.0

ICS 25-20

8

9.3

ICS 25-25

11.5

13.3

ICS 32

321720

ICS 40

402731

ICS 50

504451

ICS 65

657081

ICS 80

808598

ICS 100

100

142

165

ICS 125

125

207

240

ICS 150

150

354

410

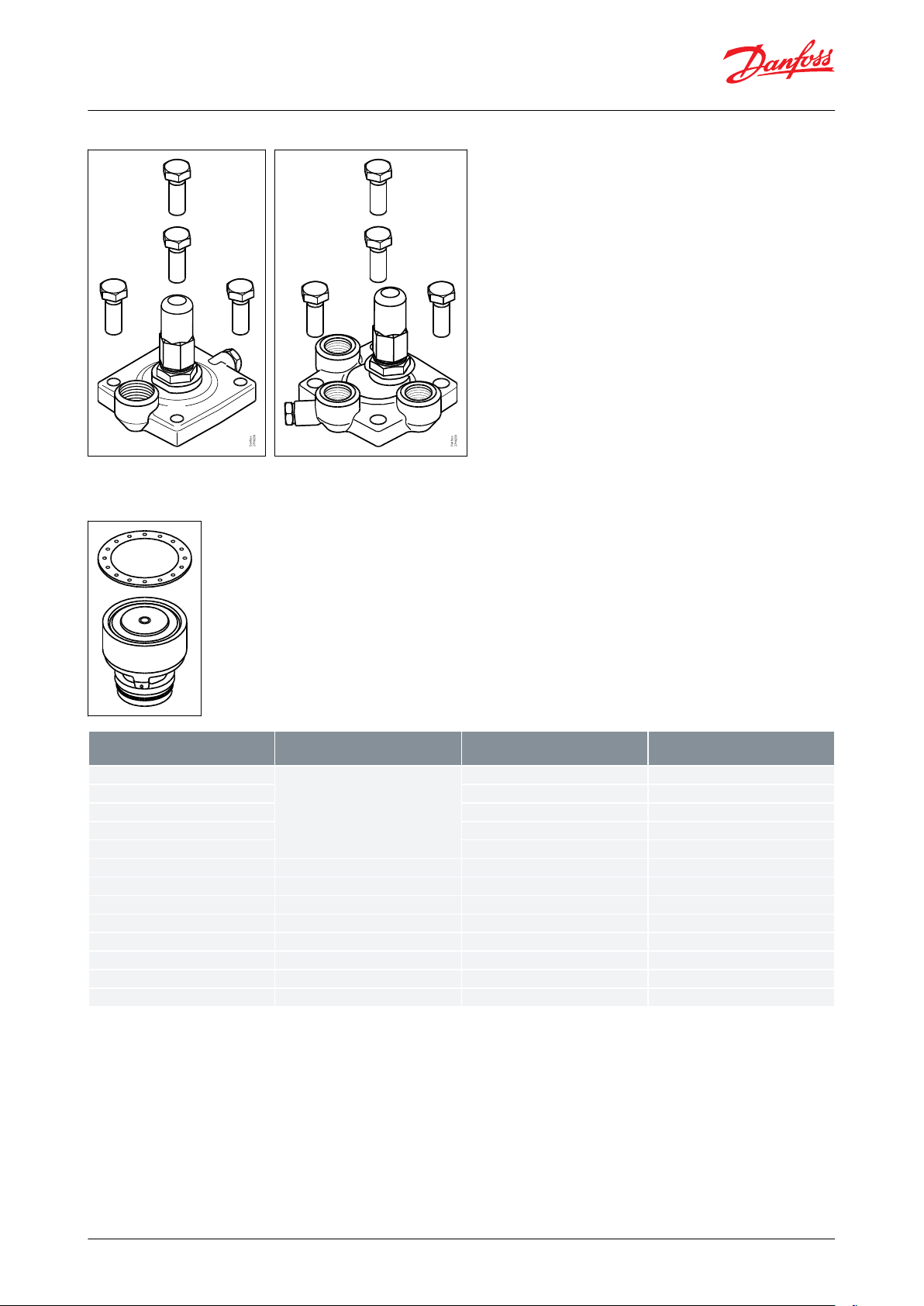

Pilot-operated servo valve, type ICS

Figure 8: 1 pilot top cover

Figure 9: 3 pilot top cover

In ICS, multiple inserts (function modules) are available to give dierent

Figure 10: ICS function modules

capacities.

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 9

Page 10

T

ØD

Danfoss

A148B15.10

SizemmSize

in.ODmmTmmODin.Tin.

20

(¾)

26.9

2.3

1.059

0.09125(1)

33.7

2.6

1.327

0.10332(1¼)

42.4

2.6

1.669

0.10240(1½)

48.3

2.6

1.902

0.103

50

(2)

60.3

2.9

2.37

0.11

65

(2½)

76.1

2.930.1180(3)

88.9

3.2

3.50

0.13

100

(4)

114.3

3.6

4.5

0.14

125

(5)

140.745.5

0.16

150

(6)

168.3

6.3

6.6

0.25

T

ØD

SizemmSize

in.ODmmTmmODin.Tin.

Schedule

(20)¾26.9

4.0

1.059

0.15880(25)133.7

4.6

1.327

0.18180(32)1¼42.4

4.9

1.669

0.19380(40)1½48.3

5.1

1.902

0.201

80

(50)260.3

3.9

2.37

0.15

40

(65)2½73.0

5.2

2.87

0.2040(80)388.9

5.5

3.50

0.22

40

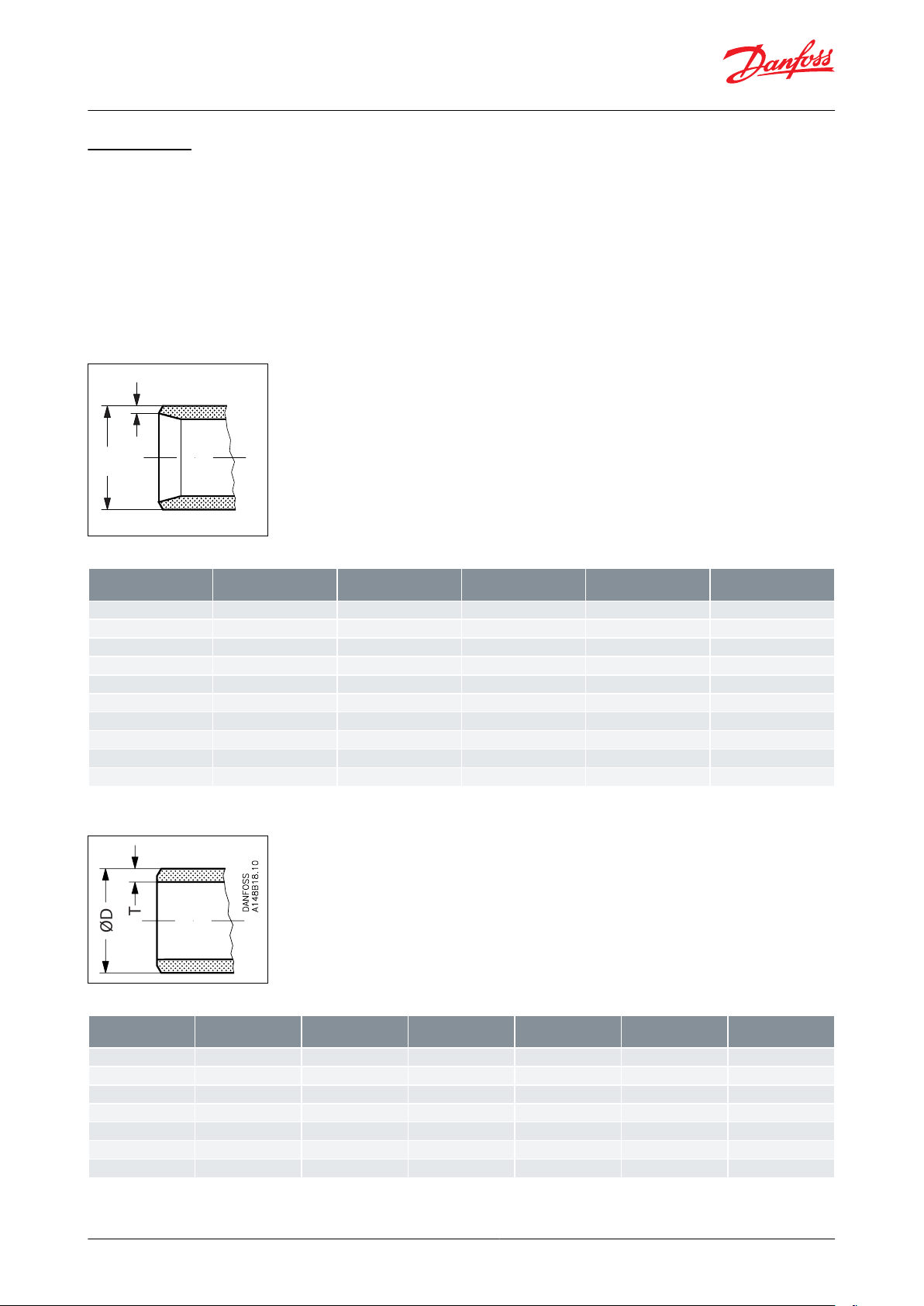

Pilot-operated servo valve, type ICS

Connections

There is a v

ery wide range of connection types available with ICS valves:

• D: Butt weld, DIN (2448)

• A: Butt weld, ANSI (B 36.10)

• J: Butt weld, JIS (B S 602)

• SOC: Socket weld, ANSI (B 16.11)

• SD: Solder connection, DIN (2856)

• SA: Solder connection, ANSI (B 16.22)

• FPT: Female pipe thread (ANSI/ASME B 1.20.1)

Figure 11: D: Butt-weld

DIN (2448)

Table 2: Butt-weld DIN

Figure 12: A: Butt-weld

ANSI (B 36.10)

Table 3: Butt-weld ANSI

© Danfoss | Climate Solutions | 2022.04

AI241186442033en-001301 | 10

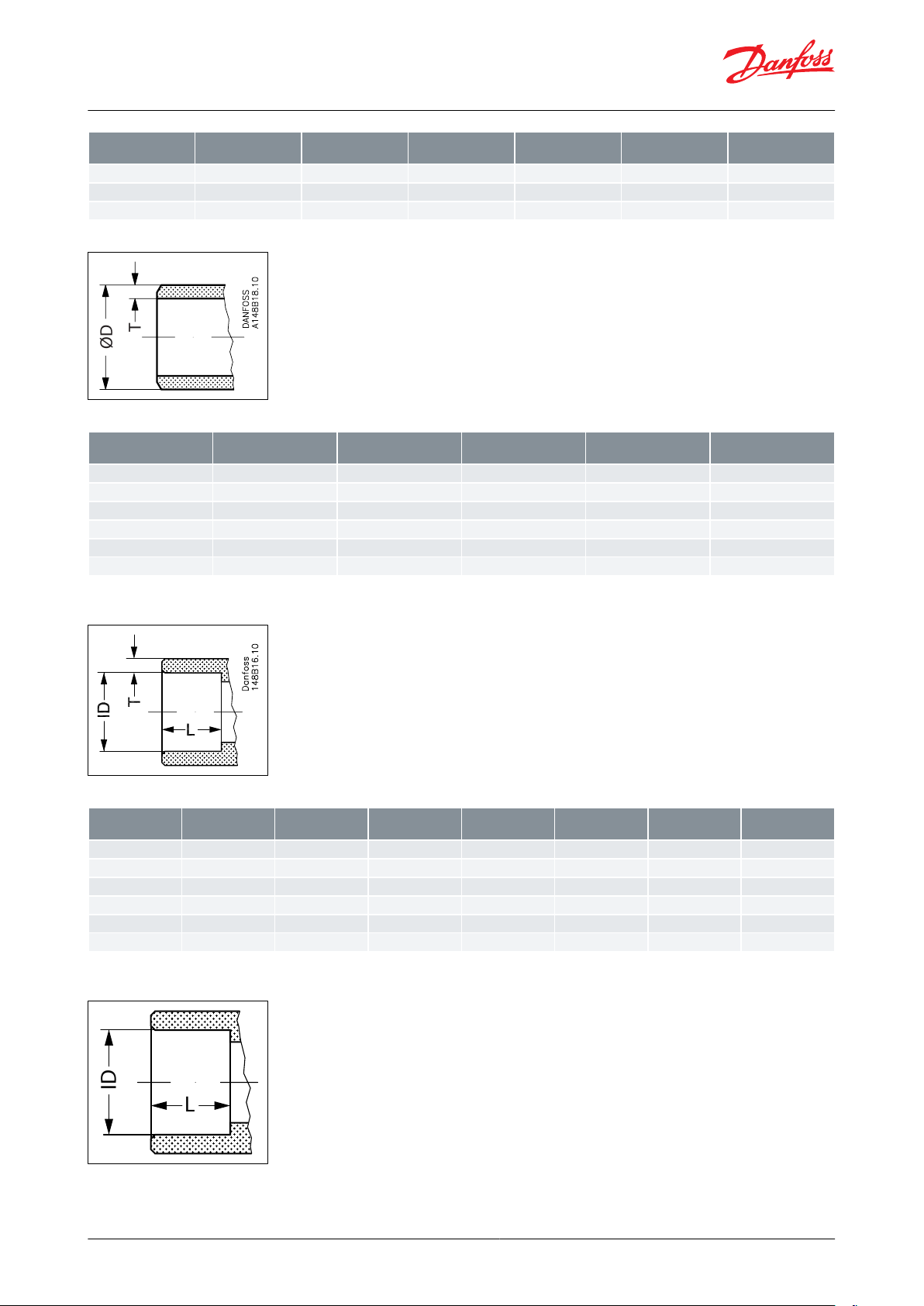

Page 11

SizemmSize

in.ODmmTmmODin.Tin.

Schedule

(100)4114.364.5

0.24

(125)5140.7

6.5

5.5

0.26

(150)6168.3

7.1

6.6

0.28

T

ØD

SizemmSize

in.ODmmTmmODin.Tin.

(20)¾26.9

4.0

1.059

0.158

(25)133.7

4.6

1.327

0.181

(32)1¼42.4

4.9

1.669

0.193

(40)1½48.3

5.1

1.902

0.201

(50)260.3

3.9

2.37

0.15

(65)2½76.3

5.2

3.0

0.20

SizemmSize

in.ODmmTmmODin.Tin.LmmLin.

(20)¾27.2

4.6

1.071

0.181130.51

(25)133.9

7.2

1.335

0.284130.51

(32)1¼42.7

6.1

1.743

0.240130.51

(40)1½48.8

6.6

1.921

0.260130.51

(50)261.2

6.2

2.41

0.24160.63

(65)2½74

8.8

2.91

0.344160.63

L

ID

Pilot-operated servo valve, type ICS

Figure 13: J: Butt-weld JIS

Table 4: Butt-weld JIS

Figure 14: SOC: Socket

welding ANSI (B 16.11)

Table 5: Socket welding ANSI

Figure 15: SD: Soldering

(DIN 2856)

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 11

Page 12

SizemmIDmmL

mm

22

22.08

16.52828.082635

35.072542

42.07

28

54

54.09

33

76

76.1

33

L

ID

Size

in.ODin.Lin.

⅞

0.875

0.6501⅛1.125

1.0241⅜1.375

1.0241⅝1.625

1.102

2⅛

2.125

1.300

2⅝

2.625

1.300

SizemmSize

in.

Inside pipe thread

(20)

¾

(¾ × 14 NPT)

(25)

1

(1 × 11.5 NPT)

(32)

1¼

(1¼ × 11.5 NPT)

Pilot-operated servo valve, type ICS

Table 6: SD: Soldering DIN

Figure 16: SA: Soldering

(ANSI B 16.22)

Table 7: Socket welding ANSI

Figure 17: FPT: Female

ead

pipe thr

ANSI/ASME B

, (

1.20.1)

Table 8: Socket welding ANSI

© Danfoss | Climate Solutions | 2022.04

AI241186442033en-001301 | 12

Page 13

B

A

D

3b

E

3a

C

3c

8

7

5

2

9

10

4

6

P

3

C

3c

1

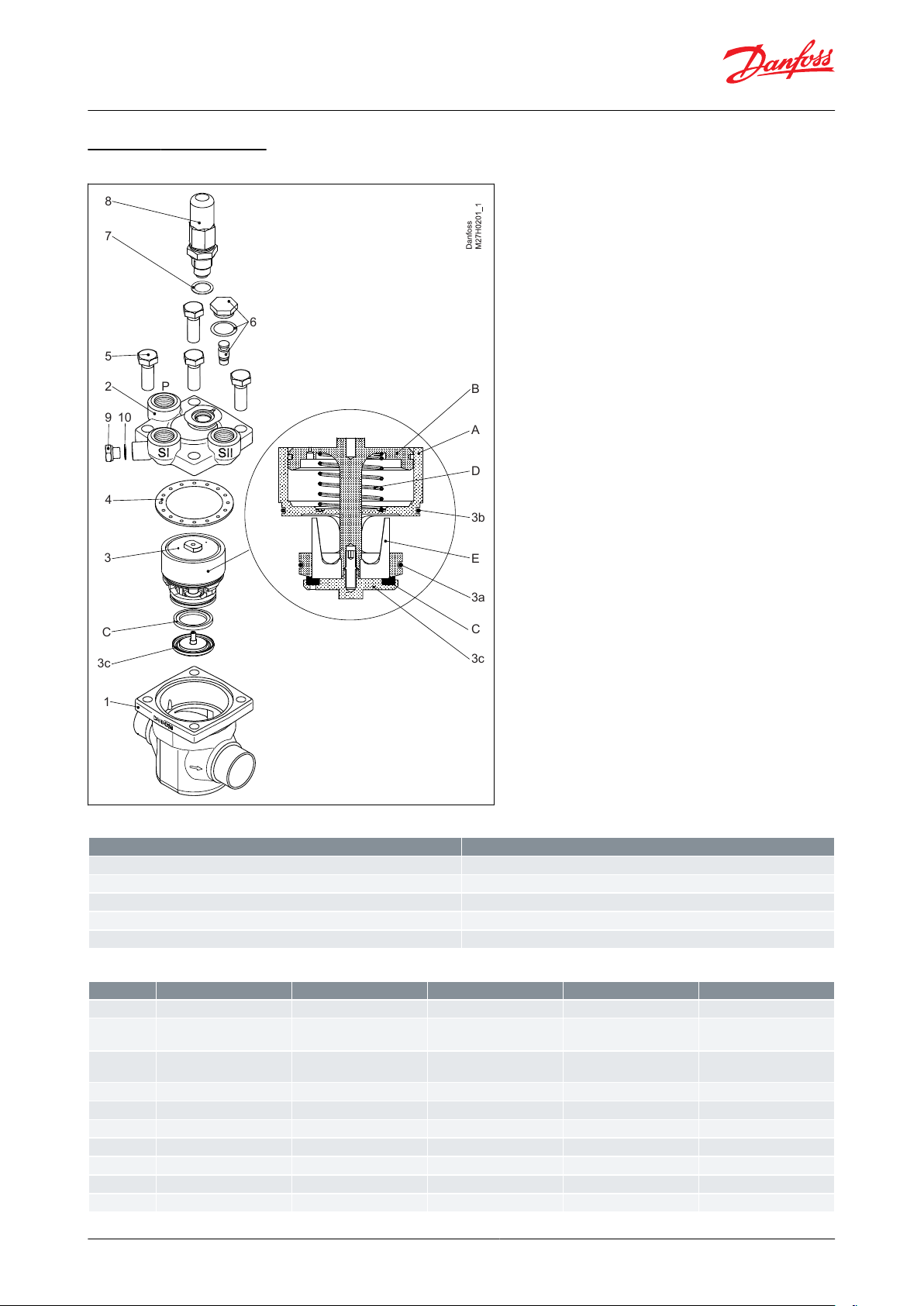

Type

Screw

ICS 25

M12 × 30 A2-70 DIN 933

ICS 32

M14 × 35 A2-70 DIN 933

ICS 40

M14 × 40 A2-70 DIN 933

ICS 50

M16 × 40 A2-70 DIN 933

ICS 65

M16 × 50 A2-70 DIN 933

No.

Part

Material

EN

ASTM

JIS

1

Body

Low temperature steel

G20Mn5QT, EN 10213-3

LCC A352

SCPL1 G5151

2

Top cover

Low temperature steel

G20Mn5QT, EN 10213-3

P285QH+QT 10222-4

LCC A352

LF2, A350

SCPL1 G5151

3

Function module (assembled)3ao-ring

Cloroprene (Neoprene)

3b

o-ring

Cloroprene (Neoprene)

3c

Washer plate

Steel

A

Cylinder

SteelBPiston

SteelCValve plate

PTFE

D

Spring

Steel

Pilot-operated servo valve, type ICS

Material specication

Figure 18: ICS 25, 32, 40, 50, 65

Table 9: Type and size of Bolt (pos. 5)

Table 10: Material and parts list (ICS 25, 32, 40, 50, 65)

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 13

Page 14

No.

Part

Material

EN

ASTM

JIS

E

Cone

Steel4Gasket

Fiber, non-asbestos

5

Bolts

Stainless steel

A2-70, EN 1515-1

Grade B8 A320

A2-70, B 1054

6

Plug

Steel7Gasket

Aluminium

8

Manual operating spindle

Steel

9

Plug

Steel10Gasket

Aluminium

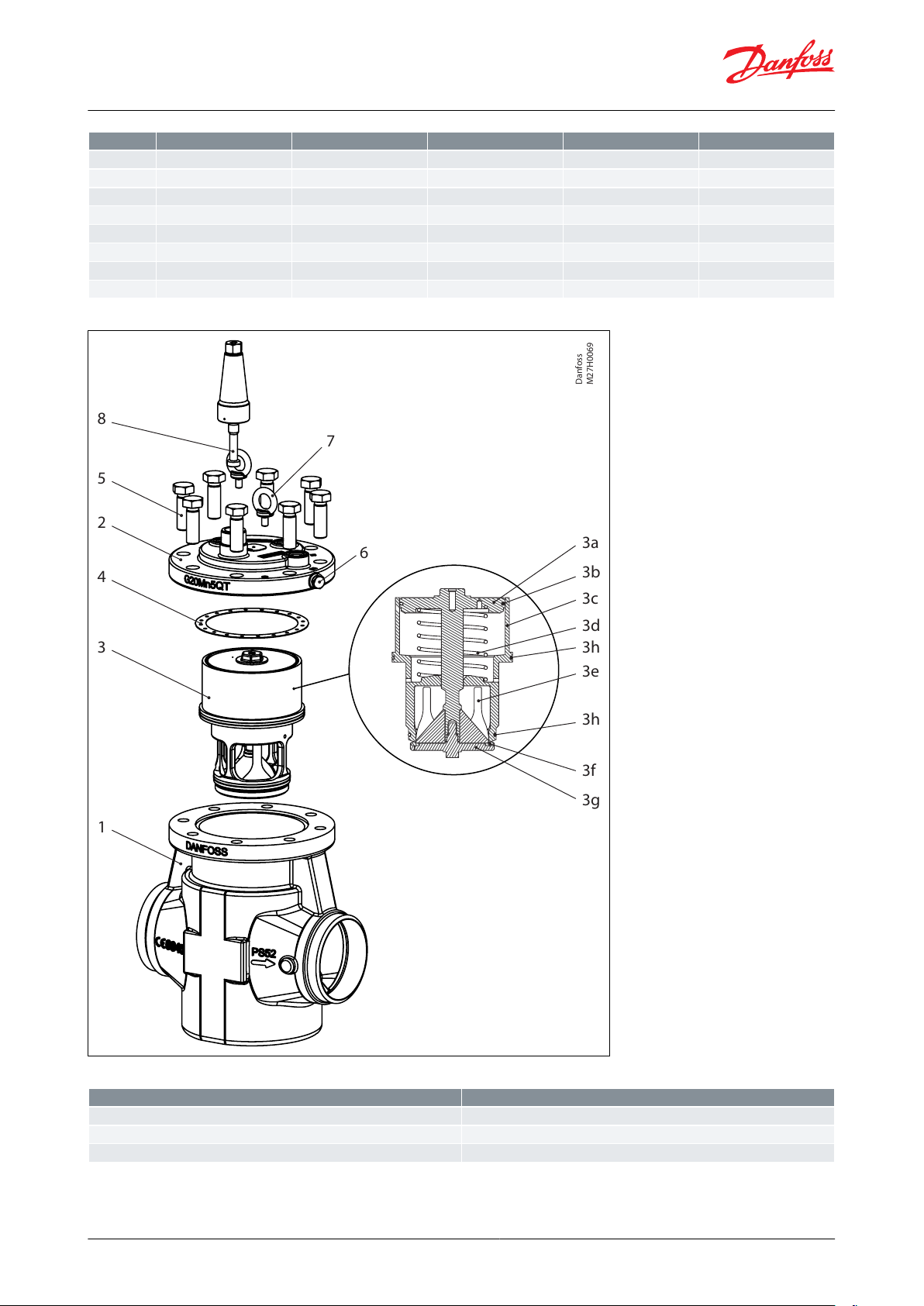

1

2

3

3a

Danfoss

M27H0069

3b

3c

3d

3e

3f

3g

3h

3h

4

5

6

7

8

Type

Screw

ICS 100

M20 × 60 A2-70 DIN 933

ICS 125

M20 × 60 A2-70 DIN 933

ICS 150

M20 × 70 A2-70 DIN 933

Pilot-operated servo valve, type ICS

Figure 19: ICS 100, 125, 150

Table 11: Type and size of Bolt (pos. 5)

© Danfoss | Climate Solutions | 2022.04

AI241186442033en-001301 | 14

Page 15

No.

Part

Material

EN

ASTM

JIS

1

Body

Low temperature steel

G20Mn5QT, EN 10213-3

LCC A352

SCPL1 G5151

2

Top cover

Low temperature steel

G20Mn5QT, EN 10213-3

LCC A352

SCPL1 G5151

3

Function module (assembled)3aPiston/rod

Stainless steel / steel

3b

Piston ring

Steel3cInsert

Steel

3d

Spring

Steel3eCone

Stainless steel / steel

3f

Teon plate

Teon unlled

3g

Washer plate

PTFE3hO-ring

Cloroprene (Neoprene)

4

Gasket

Fiber, non-asbestos

5

Bolts

Stainless steel

A2-70, EN 1515-1

Grade B8 A320

A2-70, B 1054

6

Plug

Steel7Eye bolt

Galvanized steel

8

Manual operating spindle

Steel

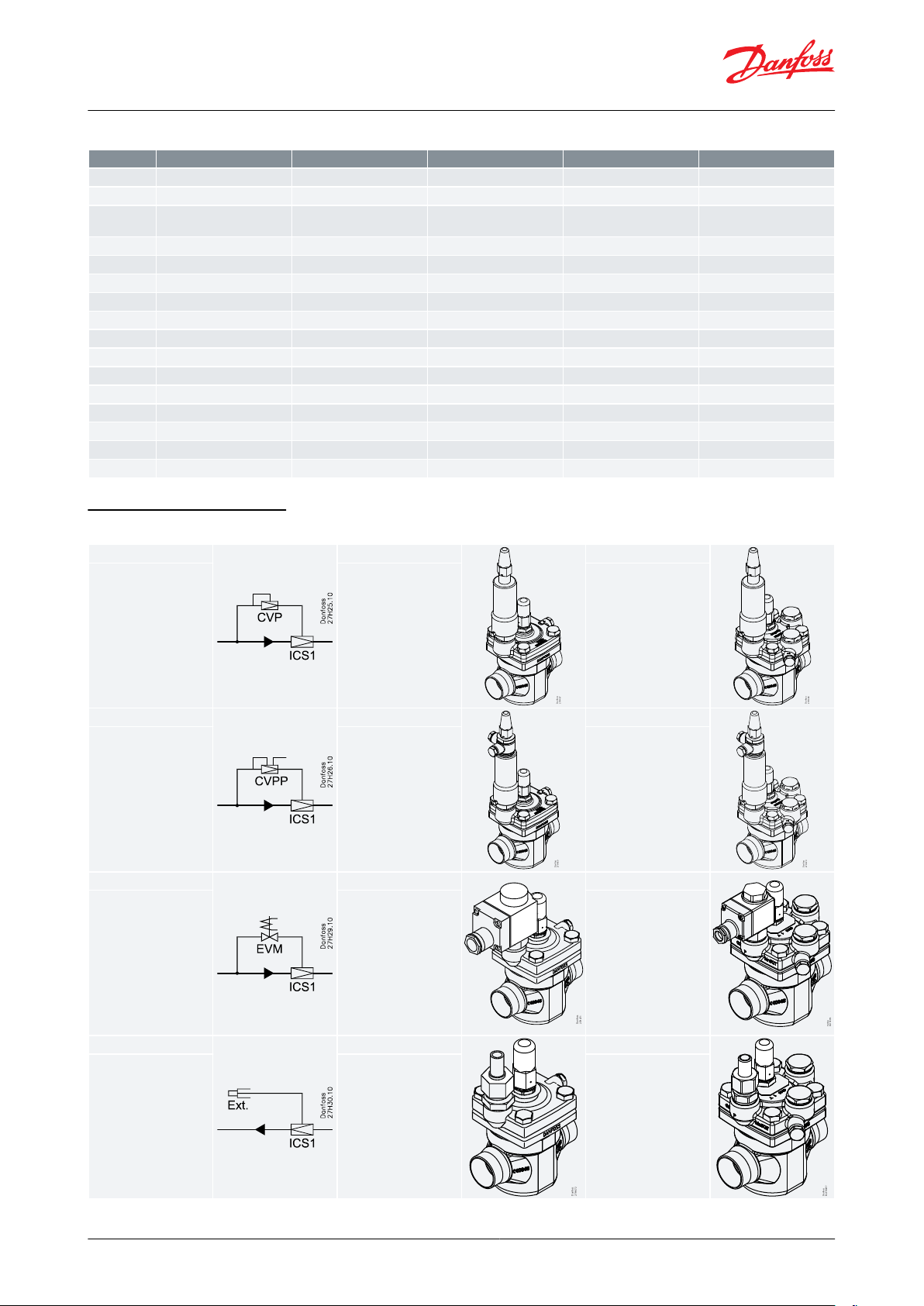

Example no. 1-1

Products

Danfoss

27H467

Products

Danfoss

27H468

Constant pressure

regulation

• CVP

-L (-0.66 to 7 bar g)

(19.5 in. Hg to 102

psig)

• CVP-M (4 to 28 bar g)

(58 to 406 psig)

• CVP-H (25 to 52 bar g)

(363 to 754 psig)

1 × ICS 1 Pilot

1 × CVP-L/M/H

1 × ICS 3 Pilots

1 × CVP-L/M/H

2 × Blank

ing plugs

SI: A + B

SII: A

Example no. 1-2

Products

Danfoss

27H469

Products

Danfoss

27H470

Dierential pressure r

egu-

lation

• CVPP-L (0.66 to 7 bar

g) (19.5 in. Hg to 102

psig)

• CVPP-M (4 to 28 bar g)

(58 to 406 psig)

1 × ICS 1 Pilot

1 × CVPP-L/M

1 × ICS 3 Pilots

1 × CVPP-L/M

2 × Blank

ing plugs

SI: A + B

SII: A

Example no. 1-3

Products

Danfoss

27H471

Products

Danfoss

M27H0076

On/o regulation (solenoid valv

e)

1 × ICS 1 Pilot

1 × EVM

1 × coil

1 × ICS 3 Pilots

1 × EVM

1 × coil

2 × Blank

ing plugs

SI: A + B

SII: A

Example no. 1-4

Products

Danfoss

27H472

Products

Danfoss

M27H0077

Regulation with external

contr

ol pressure

1 × ICS 1 Pilot

1 × nipple for ex

ternal

control pressure

1 × ICS 3 Pilots

1 × nipple for ex

ternal

control pressure

2 × Blanking plugs

SI: A + B

SII: A

Pilot-operated servo valve, type ICS

Table 12: Material and parts list (ICS 100, 125, 150)

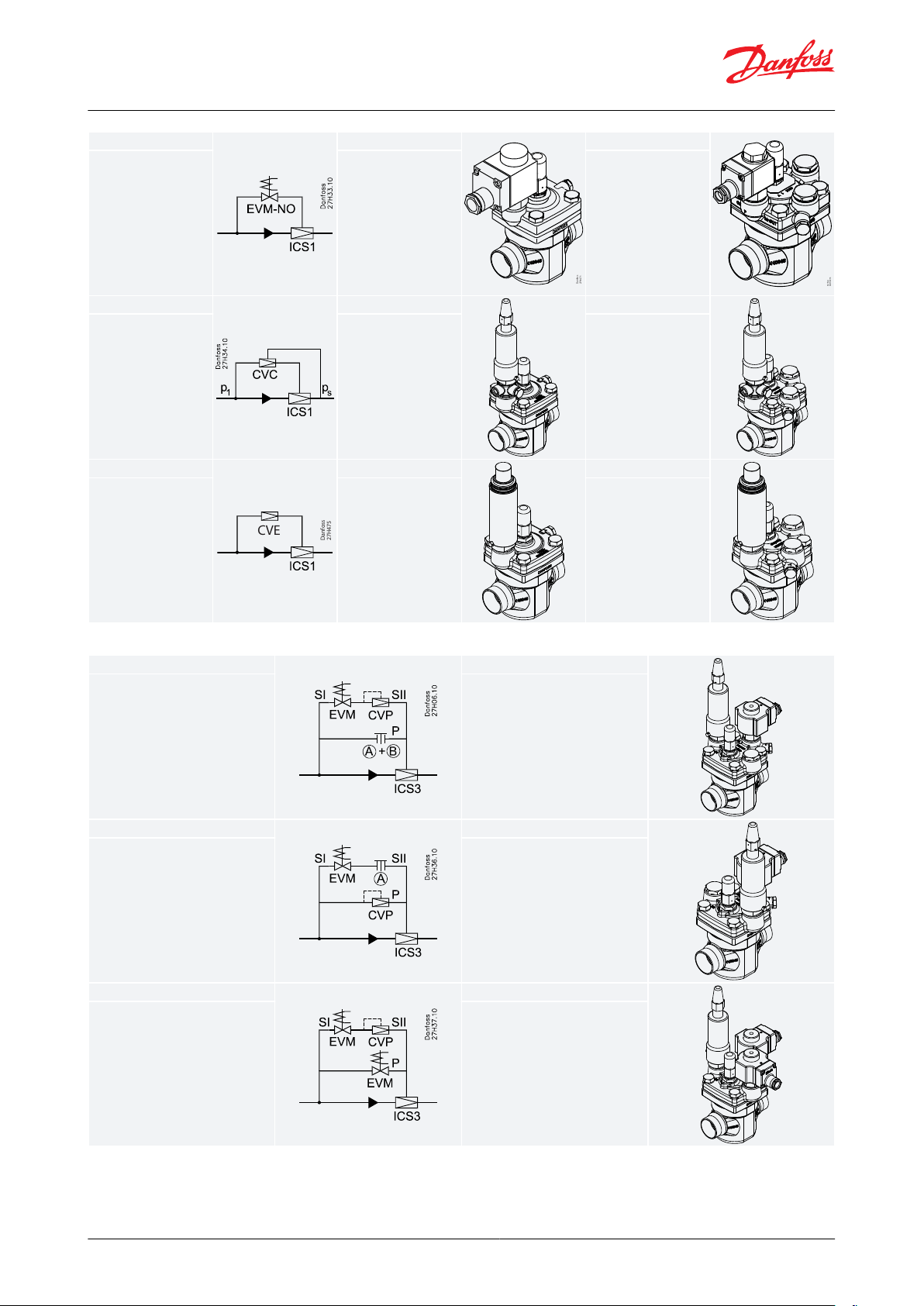

Conguration examples

Table 13: Example no. 1

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 15

Page 16

Example no. 1-5

Products

Danfoss

27H471

Products

Danfoss

M27H0076

On/o regulation (solenoid valv

e)

1 × ICS 1 Pilot

1 × EVM-NO

(12 W c

oil)

1 × ICS 3 Pilots

1 × EVM-NO (12 W c

oil)

2 × Blanking plugs

SI: A + B

SII: A

Example no. 1-6

Products

Products

Crankcase pressure regulation. (Max. suction pr

es-

sure regulation)

• -0.45 to 7 bar g (13.3

in. Hg to 102 psig)

1 × ICS 1 Pilot

1 × CVC-L

1 × ICS 3 Pilots

1 × CVC-L

2 × Blanking plugs

SI: A + B

SII: A

Example no. 1-7

CVE

Danfoss

27H475

Products

Products

Electronically controlled

media temperatur

e regu-

lation

• -0.66 to 8 bar g (19.5

in. Hg to 116 psig)

1 × ICS 1 Pilot

1 × CVE

1 × ICS 3 Pilots

1 × CVE

2 × Blanking plugs

SI: A + B

SII: A

Example no. 2-1

Products

Constant pressure regulation combined

with electrical shut

o

• -0.66 bar to 7 bar (19.5 in. Hg to 102

psig)

1 × ICS 3 Pilots

1 × blanking plug (A + B)

1 × C

VP-L

1 × EVM

1 × coil

Example no. 2-2

Products

Constant pressure regulation combined

with electrical wide open

1 × ICS 3 Pilots

1 × blanking plug (A

)

1 × CVP-L

1 × EVM

Example no. 2-3

Products

Constant pressure regulation combined

with electrical shut

o and wide open

• -0.66 bar to 7 bar (19.5 in. Hg to 102

psig)

1 × ICS 3 Pilots

1 × CVP-L

2 × E

VM

2 × coils

Pilot-operated servo valve, type ICS

Table 14: Example no. 2

© Danfoss | Climate Solutions | 2022.04

AI241186442033en-001301 | 16

Page 17

Example no. 2-4

Products

Constant pressure regulation with

change-o

ver between two preset evap-

orating pressures

• -0.66 bar to 7 bar (19.5 in. Hg to 102

psig)

1 × ICS 3 Pilots

2 × CVP-L

1 × E

VM

1 × coil

Example no. 2-5

Products

External control pressure with electrical

shut o combined with constan

t pres-

sure regulation

• -0.66 bar to 7 bar (19.5 in. Hg to 102

psig)

1 × ICS 3 Pilots

1 × Nipple for e

xternal

control pressure

1 × CVP-L

1 × EVM

1 × Coil

Example no. 2-6

Products

Constant pressure regulation with external c

ontrol pressure combined with

electrical wide open

• -0.66 bar to 7 bar (19.5 in. Hg to 102

psig)

1 × ICS 3 Pilots

1 × Nipple for e

xternal

control pressure

1 × CVP-L

1 × EVM

1 × Coil

Example no. 2-7

Products

Constant pressure regulation with electrical shut o

combined with external

control pressure

• -0.66 bar to 7 bar (19.5 in. Hg to 102

psig)

1 × ICS 3 Pilots

1 × Nipple for e

xternal

control pressure

1 × CVP-L

1 × EVM

1 × Coil

Example no. 2-8

Products

Solenoid valve with external control

pressure f

or small pressure drops

1 × ICS 3

1 × Blanking plug (A + B)

1 × N

ipple for external

control pressure

1 × EVM

1 × Coil

Example no. 2-9

Products

Dierential pressure r

egulation com-

bined with electrical shut o

• CVPP-L (0.66 bar to 7 bar ) (19.5 in.

Hg to 102 psig)

1 × ICS 3

1 × Blanking plug (A + B)

1 × C

VPP-L

1 × EVM

1 × Coil

Pilot-operated servo valve, type ICS

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 17

Page 18

Example no. 2-10

Products

Dierential pressure r

egulation com-

bined with electrical wide open

• CVPP-L (0.66 bar to 7 bar) (19.5 in.

Hg to 102 psig)

1 × ICS 3 Pilots

1 × Blanking plug (A

)

1 × CVPP-L

1 × EVM

1 × Coil

Example no. 2-11

Products

Dierential pressure r

egulation combined with electrical wide open and

shut o

• CVPP-L (0.66 bar to 7 bar) (19.5 in.

Hg to 102 psig)

1 × ICS 3 Pilots

1 × CVPP-L

2 × E

VM

2 × Coils

Example no. 2-12

Danfoss

27H492

Products

Constant pressure regulation combined

with electrical shut

o

• CVP-L (-0.66 bar to 7 bar) (19.5 in. Hg

to 102 psig)

• CVP-M (4 bar to 28 bar) (58 to 406

psig)

• CVP-H (25 bar to 52 bar) (363 to 754

psig)

1 × ICS 3 Pilots

1 × Blanking plug (A + B)

1 × C

VP-L/M/H

1 × EVM

1 × Coil

Example no. 2-13

Danfoss

27H493

Products

Constant pressure regulation combined

with electrical wide open

•

CVP-L (-0.66 bar to 7 bar) (19.5 in. Hg

to 102 psig)

• CVP-M (4 bar to 28 bar) (58 to 406

psig)

• CVP-H (25 bar to 52 bar) (363 to 754

psig)

1 × ICS 3 Pilots

1 × Blanking plug (A

)

1 × CVP-L/M/H

1 × EVM

1 × Coil

Example no. 2-14

Danfoss

27H494

Products

Danfoss

27H491

Constant pressure regulation combined

with electrical shut

o and wide open

• CVP-L (-0.66 bar to 7 bar) (19.5 in. Hg

to 102 psig)

• CVP-M (4 bar to 28 bar) (58 to 406

psig)

• CVP-H (25 bar to 52 bar) (363 to 754

psig)

1 × ICS 3 Pilots

1 × CVP-L/M/H

2 × E

VM

2 × Coils

Example no. 2-15

Danfoss

27H495

Products

Danfoss

27H500

Constant pressure regulation with

change-o

ver between two preset evap-

orating pressures

• CVP-L (-0.66 bar to 7 bar) (19.5 in. Hg

to 102 psig)

• CVP-M (4 bar to 28 bar) (58 to 406

psig)

• CVP-H (25 bar to 52 bar) (363 to 754

psig)

1 × ICS 3 Pilots

2 × CVP-L/M/H

1 × E

VM

1 × Coil

Pilot-operated servo valve, type ICS

© Danfoss | Climate Solutions | 2022.04

AI241186442033en-001301 | 18

Page 19

Example no. 2-16

Danfoss

27H496

Products

Danfoss

27H501

Dierential pressure r

egulation com-

bined with electrical shut o

• CVPP-L (-0.66 bar to 7 bar) (19.5 in.

Hg to 102 psig)

• CVPP-M (4 bar to 28 bar) (58 to 406

psig)

1 × ICS 3 Pilots

1 × Blanking plug (A + B)

1 × C

VPP-L/M

1 × EVM

1 × Coil

Example no. 2-17

Danfoss

27H497

Products

Danfoss

27H502

Dierential pressure r

egulation com-

bined with electrical wide open

• CVPP-L (-0.66 bar to 7 bar) (19.5 in.

Hg to 102 psig)

• CVPP-M (4 bar to 28 bar) (58 to 406

psig)

1 × ICS 3 Pilots

1 × Blanking plug (A

)

1 × CVPP-L/M

1 × EVM

1 × Coil

Example no. 2-18

Danfoss

27H498

Products

Danfoss

27H503

Dierential pressure r

egulation combined with electrical wide open and

shut o

• CVPP-L (-0.66 bar to 7 bar) (19.5 in.

Hg to 102 psig)

• CVPP-M (4 bar to 28 bar) (58 to 406

psig)

1 × ICS 3 Pilots

1 × CVPP-L/M

2 × E

VM

2 × Coils

Example no. 2-19

Danfoss

27H499

Products

Danfoss

27H504

Constant pressure regulation combined

with electrical wide open and shut

o

• CVP-L (-0.66 bar to 7 bar) (19.5 in. Hg

to 102 psig)

• CVP-M (4 bar to 28 bar) (58 to 406

psig)

• CVP-H (25 bar to 52 bar) (363 to 754

psig)

1 × ICS 3 Pilots

1 × CVP-L/M/H

1 × E

VM

1 × EVM-NO (12 W coil)

2 × Coils

Example no. 2-20

Products

Danfoss

27H514

Crankcase pressure regulation (max.

suction pressur

e regulation) combined

with shut o

• -0.45 bar to 7 bar (13.3 in. Hg to 102

psig)

1 × ICS 3 Pilots

1 × Blanking plug (A + B)

1 × C

VC-L

1 × EVM

1 × Coil

Example no. 2-21

Products

Danfoss

27H511

Crankcase pressure regulation (max.

suction pressur

e regulation) combined

with evaporating pressure regulation

• -0.66 bar to 28 bar (19.5 in. Hg to

406 psig).

1 × ICS 3 Pilots

1 × Blanking plug (A + B)

1 × C

VC-L/M

1 × CVP-L/M

Pilot-operated servo valve, type ICS

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 19

Page 20

Example no. 2-22

Products

Danfoss

27H512

Crankcase pressure regulation (max.

suction pressur

e regulation) at low

pressure drops across the valve

• -0.45 bar to 7 bar (13.3 in. Hg to 102

psig)

1 × ICS 3 Pilots

1 × Blanking plug (A + B)

1 × N

ipple for external

control pressure

1 × CVC-L

Example no. 2-23

Products

Danfoss

27H513

Crankcase pressure regulation (max.

suction pressur

e regulation) combined

with constant pressure regulation and

electrical shut o.

• -0.66 bar to 7 bar (19.5 in. Hg to 102

psig).

1 × ICS 3 Pilots

1 × Blanking plug (A + B)

1 × N

ipple for external

control pressure

1 × CVP-L

1 × EVM

1 × Coil

2 × CVH

1 × CVC-L

Example no. 2-24

Products

Danfoss

27H514

Hot gas bypass regulation combined

with electrical shut

o

• -0.45 bar to 7 bar (13.3 in. Hg to 102

psig)

1 × ICS 3 Pilots

1 × Blanking plug (A + B)

1 × C

VC-L

1 × EVM

1 × Coil

Example no. 2-25

Danfoss

27H505

Products

Danfoss

27H515

Constant pressure regulation with electrical shut o

and protection against

high pressure when suction line is

closed

• -0.66 bar to 28 bar (19.5 in. Hg to

406 psig).

1 × ICS 3 Pilots

1 × CVP-L

1 × E

VM

1 × Coil

1 × CVP-M

Example no. 2-26

CVE

Danfoss

27H506

Products

Danfoss

27H516

Electronically controlled media temperature regulation c

ombined with electri-

cal shut o

• -1 bar to 8 bar (0 in. Hg to 116 psig).

1 × ICS 3 Pilots

1 × Blanking plug (A + B)

1 × C

VE

1 × EVM

1 × Coil

Example no. 2-27

CVE

Danfoss

27H506

Products

Electronically controlled media temperatur

e r

egulation c

ombined with electri-

cal shut o and wide open

• -1 bar to 8 bar (0 in. Hg to 116 psig).

1 × ICS 3 Pilots

1 × C

VE

2 × E

VM

2 × C

oils

Pilot-operated servo valve, type ICS

© Danfoss | Climate Solutions | 2022.04

AI241186442033en-001301 | 20

Page 21

Example no. 2-28

CVE

Danfoss

27H507

Products

Danfoss

27H518

Electronically controlled media temperature regulation c

ombined with electrical shut o and changeover to constant

pressure regulation

• -1 bar to 8 bar (0 in. Hg to 116 psig).

1 × ICS 3 Pilots

1 × CVQ

1 × CVP

-L

1 × EVM

1 × Coil

Example no. 2-29

CVE

Danfoss

27H508

Products

Danfoss

27H519

Electronically controlled media temperature regulation with lo

w evaporating

pressure protection combined with

wide open

• -1 bar to 8 bar (0 in. Hg to 116 psig).

1 × ICS 3 Pilots

1 × CVE

1 × CVP

-L

1 × EVM

1 × Coil

Example no. 2-30

CVE

Danfoss

27H509

Products

Danfoss

27H520

Electronically controlled media temperature regulation with lo

w evaporating

pressure protection combined with

changeover to constant pressure regulation

• -1 bar to 8 bar (0 in. Hg to 116 psig).

1 × ICS 3 Pilots

1 × CVE

2 × CVP

-L

Pilot-operated servo valve, type ICS

Valve selection based on capacity calculation

As for extended capacity calculations and valve selection based on capacities and refrigerants, please refer to

Coolselector®2. Rated and extended capacities are calculated with the Coolselector®2 calculation engine to ARI

standards with the ASEREP equations based on laboratory measurements of selected valves.

Download Coolselector®2 for free at coolselector.danfoss.com

.

© Danfoss | Climate Solutions | 2022.04

AI241186442033en-001301 | 21

Page 22

ICS 3 Pilots

ICS 1 pilot

Connection

H1H2H3H

4

L

L1L2B1B

2

Weight

ICS 1 Pilot

Weight

ICS 3

Pilots

20 D (¾ in.)

mm

in.371.46

145

5.71863.39602.36

135

5.31421.65150.59421.65873.43

3 kg

6.6 lb.

3.6 kg

7.92 lb.

25 D (1 in.)

mm

in.371.46

145

5.71863.39602.36

135

5.31421.65150.59421.65873.43

3 kg

6.6 lb.

3.6 kg

7.92 lb.

32 D (1¼ in.)

mm

in.371.46

145

5.71863.39602.36

135

5.31421.65150.59421.65873.43

3 kg

6.6 lb.

3.6 kg

7.92 lb.

40 D (1½ in.)

mm

in.371.46

145

5.71863.39602.36

135

5.31421.65150.59421.65873.43

3 kg

6.6 lb.

3.6 kg

7.92 lb.

20 A (¾ in.)

mm

in.371.46

145

5.71863.39602.36

135

5.31421.65150.59421.65873.43

3 kg

6.6 lb.

3.6 kg

7.92 lb.

25 A (1 in.)

mm

in.371.46

145

5.71863.39602.36

135

5.31421.65150.59421.65873.43

3 kg

6.6 lb.

3.6 kg

7.92 lb.

32 A (1¼ in.)

mm

in.371.46

145

5.71863.39602.36

135

5.31421.65150.59421.65873.43

3 kg

6.6 lb.

3.6 kg

7.92 lb.

20 SOC (¾ in.)

mm

in.371.46

145

5.71863.39602.36

135

5.31421.65150.59421.65873.43

3 kg

6.6 lb.

3.6 kg

7.92 lb.

25 SOC (1 in.)

mm

in.371.46

145

5.71863.39602.36

147

5.79421.65150.59421.65873.43

3 kg

6.6 lb.

3.6 kg

7.92 lb.

22 SD (⅞ in.)

mm

in.371.46

145

5.71863.39602.36

135

5.31421.65150.59421.65873.43

3 kg

6.6 lb.

3.6 kg

7.92 lb.

28 SD (1⅛ in.)

mm

in.371.46

145

5.71863.39602.36

147

5.78421.65150.59421.65873.43

3 kg

6.6 lb.

3.6 kg

7.92 lb.

22 SA (⅞ in.)

mm

in.371.46

145

5.71863.39602.36

135

5.31421.65150.59421.65873.43

3 kg

6.6 lb.

3.6 kg

7.92 lb.

28 SA (1⅛ in.)

mm

in.371.46

145

5.71863.39602.36

147

5.78421.65150.59421.65873.43

3 kg

6.6 lb.

3.6 kg

7.92 lb.

Pilot-operated servo valve, type ICS

Dimensions and weights

ICS 25-5 to ICS 25-25

e 20: Dimensions and weights - ICS 25-5 to ICS 25-25

Figur

Table 15: Connection type and Weight

© Danfoss | Climate Solutions | 2022.04

AI241186442033en-001301 | 22

Page 23

Connection

H1H2H3H

4

L

L1L2B1B

2

Weight

ICS 1 Pilot

Weight

ICS 3

Pilots

35 SA (1⅜ in.)

mm

in.371.46

145

5.71863.39602.36

147

5.78421.65150.59421.65873.43

3 kg

6.6 lb.

3.6 kg

7.92 lb.

20 FPT (¾ in.)

mm

in.371.46

145

5.71863.39602.36

135

5.31421.65150.59421.65873.43

3 kg

6.6 lb.

3.6 kg

7.92 lb.

25 FPT (1 in.)

mm

in.371.46

145

5.71863.39602.36

135

5.31421.65150.59421.65873.43

3 kg

6.6 lb.

3.6 kg

7.92 lb.

ICS 3 Pilots

ICS 1 pilot

Connection

H1H2H3H

4

L

L1L2B1B

2

Weight

ICS 1 Pilot

Weight

ICS 3

Pilots

32 D (1¼ in.)

mm

in.401.57

160

6.30

100

3.93742.91

145

5.71512.00150.59512.00873.43

4.5 kg

9.9 lb.

5 kg

11 lb.

40 D (1½ in.)

mm

in.401.57

160

6.30

100

3.93742.91

145

5.71512.00150.59512.00873.43

4.5 kg

9.9 lb.

5 kg

11 lb.

32 A (1¼ in.)

mm

in.401.57

160

6.30

100

3.93742.91

145

5.71512.00150.59512.00873.43

4.5 kg

9.9 lb.

5 kg

11 lb.

Pilot-operated servo valve, type ICS

NOTE:

Specied weights ar

e approximate values only.

D = Butt-weld DIN

A = Butt-weld ANSI

J = Butt-weld JIS

SOC = Socket weld ANSI

SD = Solder DIN

SA = Solder ANSI

FPT = Female Pipe Thread

ICS 32

Figure 21: ICS 32, Dimensions and weights

Table 16: Connection type and Weight

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 23

Page 24

Connection

H1H2H3H

4

L

L1L2B1B

2

Weight

ICS 1 Pilot

Weight

ICS 3

Pilots

40 A (1½ in.)

mm

in.401.57

160

6.30

100

3.93742.91

145

5.71512.00150.59512.00873.43

4.5 kg

9.9 lb.

5 kg

11 lb.

32 SOC (1¼ in.)

mm

in.401.57

160

6.30

100

3.93742.91

145

5.71512.00150.59512.00873.43

4.5 kg

9.9 lb.

5 kg

11 lb.

35 SD (1⅜ in. SA)

mm

in.401.57

160

6.30

100

3.93742.91

145

5.71512.00150.59512.00873.43

4.5 kg

9.9 lb.

5 kg

11 lb.

42 SD (1⅝ in.)

mm

in.401.57

160

6.30

100

3.93742.91

145

5.71512.00150.59512.00873.43

4.5 kg

9.9 lb.

5 kg

11 lb.

42 SA (1⅝ in.)

mm

in.401.57

160

6.30

100

3.93742.91

145

5.71512.00150.59512.00873.43

4.5 kg

9.9 lb.

5 kg

11 lb.

ICS 3 Pilots

ICS 1 pilot

Pilot-operated servo valve, type ICS

NOTE:

Specied weights ar

e approximate values only.

D = Butt-weld DIN

A = Butt-weld ANSI

J = Butt-weld JIS

SOC = Socket weld ANSI

SD = Solder DIN

SA = Solder ANSI

FPT = Female Pipe Thread

ICS 40

Figure 22: ICS 40, Dimensions and weights

© Danfoss | Climate Solutions | 2022.04

AI241186442033en-001301 | 24

Page 25

Connection

H1H2H3H

4

L

L1L2B1B

2

Weight

ICS 1 Pilot

Weight

ICS 3

Pilots

40 D (1½ in.)

mm

in.491.93

166

6.54

105

4.13783.07

160

6.30512.00150.59542.13873.43

5.9 kg

13.0 lb.

6.3 kg

13.9 lb.

50 D (2 in. )

mm

in.491.93

166

6.54

105

4.13783.07

180

7.09512.00150.59542.13873.43

5.9 kg

13.0 lb.

6.3 kg

13.9 lb.

40 A (1½ in.)

mm

in.491.93

166

6.54

105

4.13783.07

160

6.30512.00150.59542.13873.43

5.9 kg

13.0 lb.

6.3 kg

13.9 lb.

50 A (2 in.)

mm

in.491.93

166

6.54

105

4.13783.07

180

7.09512.00150.59542.13873.43

5.9 kg

13.0 lb.

6.3 kg

13.9 lb.

40 SOC (1½ in.)

mm

in.491.93

166

6.54

105

4.13783.07

180

7.09512.00150.59542.13873.43

5.9 kg

13.0 lb.

6.3 kg

13.9 lb.

42 SD (1⅝ in.)

mm

in.491.93

166

6.54

105

4.13783.07

180

7.09512.00150.59542.13873.43

5.9 kg

13.0 lb.

6.3 kg

13.9 lb.

42 SA (1⅝ in.)

mm

in.491.93

166

6.54

105

4.13783.07

180

7.09512.00150.59542.13873.43

5.9 kg

13.0 lb.

6.3 kg

13.9 lb.

ICS 3 Pilots

ICS 1 pilot

Pilot-operated servo valve, type ICS

Table 17: Connection type and Weight

NOTE:

Specied weights ar

e approximate values only.

D = Butt-weld DIN

A = Butt-weld ANSI

J = Butt-weld JIS

SOC = Socket weld ANSI

SD = Solder DIN

SA = Solder ANSI

FPT = Female Pipe Thread

ICS 50

Figure 23: ICS 50, Dimensions and weights

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 25

Page 26

Connection

H1H2H3H

4

L

L1L2B1B

2

Weight

ICS 1 Pilot

Weight

ICS 3

Pilots

50 D (2 in. )

mm

in.592.32

181

7.13

120

4.72933.66

200

7.87512.00150.59632.48913.58

8.9 kg

19.6 lb.

9.2 kg

20.2 lb.

65 D (2½ in.)

mm

in.592.32

181

7.13

120

4.72933.66

210

8.27512.00150.59632.48913.58

8.9 kg

19.6 lb.

9.2 kg

20.2 lb.

50 A (2 in.)

mm

in.592.32

181

7.13

120

4.72933.66

200

7.87512.00150.59632.48913.58

8.9 kg

19.6 lb.

9.2 kg

20.2 lb.

65 A (2½ in.)

mm

in.592.32

181

7.13

120

4.72933.66

210

8.27512.00150.59632.48913.58

8.9 kg

19.6 lb.

9.2 kg

20.2 lb.

50 SOC (2 in.)

mm

in.592.32

181

7.13

120

4.72933.66

216

8.50512.00150.59632.48913.58

8.9 kg

19.6 lb.

9.2 kg

20.2 lb.

54 SD (2⅛ in. SA)

mm

in.592.32

181

7.13

120

4.72933.66

216

8.50512.00150.59632.48913.58

8.9 kg

19.6 lb.

9.2 kg

20.2 lb.

ICS 3 Pilots

ICS 1 pilot

Pilot-operated servo valve, type ICS

Table 18: Connection type and Weight

NOTE:

Specied weights ar

e approximate values only.

D = Butt-weld DIN

A = Butt-weld ANSI

J = Butt-weld JIS

SOC = Socket weld ANSI

SD = Solder DIN

SA = Solder ANSI

FPT = Female Pipe Thread

ICS 65/ ICS 80

Figure 24: ICS 65 / ICS 80, Dimensions and weights

© Danfoss | Climate Solutions | 2022.04

AI241186442033en-001301 | 26

Page 27

Connection

H1H2H3H

4

L

L1L2B1B

2

Weight

ICS 1 Pilot

Weight

ICS 3

Pilots

65 D (2½ in.)

mm

in.652.56

202

7.95

140

5.51

115

4.53

230

9.06512.00150.59702.76913.58

13.4 kg

29.48 lb.

13.5 kg

29.7 lb.

80 D (3 in.)

mm

in.652.56

202

7.95

140

5.51

115

4.53

245

9.65512.00150.59702.76913.58

13.4 kg

29.48 lb.

13.5 kg

29.7 lb.

65 A (2½ in.)

mm

in.652.56

202

7.95

140

5.51

115

4.53

230

9.06512.00150.59702.76913.58

13.4 kg

29.48 lb.

13.5 kg

29.7 lb.

80 A (3 in.)

mm

in.652.56

202

7.95

140

5.51

115

4.53

245

9.65512.00150.59702.76913.58

13.4 kg

29.48 lb.

13.5 kg

29.7 lb.

65 J (2½ in.)

mm

in.652.56

202

7.95

140

5.51

115

4.53

230

9.06512.00150.59702.76913.58

13.4 kg

29.48 lb.

13.5 kg

29.7 lb.

65 SOC (2½ in.)

mm

in.652.56

202

7.95

140

5.51

115

4.53

230

9.06512.00150.59702.76913.58

13.4 kg

29.48 lb.

13.5 kg

29.7 lb.

76 SD (3 in.)

mm

in.652.56

202

7.95

140

5.51

115

4.53

245

9.65512.00150.59702.76913.58

13.4 kg

29.48 lb.

13.5 kg

29.7 lb.

67 SA (2⅝ in.)

mm

in.652.56

202

7.95

140

5.51

115

4.53

245

9.65512.00150.59702.76913.58

13.4 kg

29.48 lb.

13.5 kg

29.7 lb.

Pilot-operated servo valve, type ICS

Table 19: Connection type and Weight

NOTE:

Specied weights are approximate values only.

= Butt-weld DIN

D

A = Butt-weld ANSI

J = Butt-weld JIS

SOC = Socket weld ANSI

SD = Solder DIN

SA = Solder ANSI

FPT = Female Pipe Thread

© Danfoss | Climate Solutions | 2022.04

AI241186442033en-001301 | 27

Page 28

H3

H1

H2

H4

min. 125 mm

min. 4.92 in.

L

B4

L1

L2

B1

B3

B2

L1

L3

P

Sll

Sl

Connection

H1H2H3H

4

L

L1L2L3B1B2B3B

4

Weight

100 D or A (4 in.)

mm

in.

109

4.3

372

14.7

237

9.3

196

7.7

295

11.6602.4512.0502.0

109

4.3381.5522.1331.3

45 kg

99.2 lb

.

Pilot-operated servo valve, type ICS

ICS 100

Figure 25: ICS 100, Dimensions and w

eights

Table 20: Connection type and Weight

NOTE:

Specied weights are approximate values only.

D = Butt-weld DIN ; A = Butt-weld ANSI

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 28

Page 29

L

H1

H4

H2

H3

B3

B4

B1

L1

L2

L3

L4

B2

Sll

Sl

P

min. 125 mm

min. 4.92 in.

Connection

H1H2H3H

4

L

L1L2L3L4B1B2B3B

4

Weight

125 D or A (5 in.)

mm

in.

139

5.5

386

15.2

246

9.7

212

8.4

350

13.8843.3562.2552.2853.4

130

5.1451.8502.0471.9

68 kg

149.9 lb.

Pilot-operated servo valve, type ICS

ICS 125

Figure 26: ICS 125, D

imensions and weights

Table 21: Connection type and Weight

NOTE:

Specied weights are approximate values only.

= Butt-weld DIN ; A = Butt-weld ANSI

D

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 29

Page 30

H1

H2

H4

H3

L

B1

L3 L4

B3

B4

B2

L1

L2

Sll

Sl

P

min. 125 mm

min. 4.92 in.

Connection

H1H2H3H

4

L

L1L2L3L4B1B2B3B

4

Weight

150 D or A (6 in.)

mm

in.

168

6.6

425

16.7

297

11.7

256

10.1

445

17.5

107

4.2582.3692.7963.8

150

5.9481.9522.1502.0

115 kg

253.5 lb.

Pilot-operated servo valve, type ICS

ICS 150

Figure 27: ICS 150, D

imensions and weights

Table 22: Connection type and Weight

NOTE:

Specied weights are approximate values only.

= Butt-weld DIN ; A = Butt-weld ANSI

D

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 30

Page 31

+

+ =

Valve body25 D (1 in.)

027H2120

Function module ICS 25-15

027H2203

Top cover 3 pilots

027H2173

Connection

Code Number

20 D (3/4 in.)

027H2128

25 D (1 in.)

027H2120

32 D (11/4 in.)

027H2129

40 D (11/2 in.)

027H2135

35 SD (13/8 in. SA)

027H2134

28 SA (11/8 in.)

027H2126

22 SA (7/8 in.)

027H2125

28 SD (11/8 in.)

027H2124

22 SD (7/8 in.)

027H2123

20 A (3/4 in.)

027H2131

25 A (1 in.)

027H2121

32 A (11/4 in.)

027H2130

20 SOC (3/4 in.)

027H2132

25 SOC (1 in.)

027H2122

20 FPT (½ in.)

027H2133

25 FPT (1 in.)

027H2127

Pilot-operated servo valve, type ICS

Ordering

ICS 25

Ordering fr

om the parts programme

Figure 28: Example (select from table ICV 25 valve body w/dierent

25 top cover)

Figure 29: ICV 25 valve body

connections, table ICS 25 function module and table ICS

Table 23: ICV 25 valve body w/dierent connections

D = Butt-weld DIN

A = Butt-weld ANSI

J

= Butt-weld JIS

SOC = Socket weld ANSI

SD = Solder DIN

SA = Solder ANSI

FPT = Female Pipe Thread

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 31

Page 32

Danfoss

27H8258

Danfoss

27H8259

Description

Code Number

ICS 25-5

027H2201

(1)

ICS 25-10

027H2202

(1)

ICS 25-15

027H2203

(1)

ICS 25-20

027H2204

(1)

ICS 25-25

027H2200

(1)

Description

Code Number

Top cover 1 Pilot

027H2172

(2)

Top cover 3 Pilots

027H2173

(3)

Pilot-operated servo valve, type ICS

Figure 30: ICS 25 function module

Table 24: ICS 25 function module

(1)

(1)

Including gasket and O-rings

Including gasket and O-rings

Figure 31: ICS 1

Table 25: ICS 25 top cover

(2)

(2)

Including bolts

Including bolts

(3)

(3)

including bolts and one blanking plug

including bolts and one blanking plug

Figure 32: ICS 3

Ordering complete factory assembled valve

(body, function module and top cover)

© Danfoss | Climate Solutions | 2022.04

AI241186442033en-001301 | 32

Page 33

Danfoss

27H8261

Danfoss

27H8260

Available connections

20 D (¾ in.)

25 D (1 in.)

32 D (1¼ in.)

40 D (1½ in.)

35 SD (1⅜ in.

SA)

28 SA (1⅛ in.)

22 SA (⅞ in.)

28 SD (1⅛ in.)

ICS 25-5

1 Pilot

027H2028

027H2020***027H2026

027H2025

027H2024

3 Pilots

(4)

027H2078

027H2070***027H2076

027H2075

027H2074

ICS 25-10

1 Pilot

027H2038

027H2030***027H2036

027H2035

027H2034

3 Pilots

(4)

027H2088

027H2080***027H2086

027H2085

027H2084

ICS 25-15

1 Pilot

027H2048

027H2040***027H2046

027H2045

027H2044

3 Pilots

(4)

027H2098

027H2090***027H2096

027H2095

027H2094

ICS 25-20

1 Pilot

027H2058

027H2050***027H2056

027H2055

027H2054

3 Pilots

(4)

027H2108

027H2100***027H2106

027H2105

027H2104

ICS 25-25

1 Pilot

027H2068

027H2060***027H2066

027H2065

027H2064

3 Pilots

(4)

027H2118

027H2110***027H2116

027H2115

027H2114

Available connections

22 SD (⅞ in.)

20 A (¾ in.)

25 A (1 in.)

32 A (1¼ in. )

20 SOC (¾ in.)

25 SOC (1 in.)

20 FPT (½ in. )

25 FPT (1 in. )

ICS 25-5

1 Pilot

027H2023

027H2029

027H2021

*

027H2140**

*

3 Pilots

(4)

027H2073

027H2079

027H2071

*

027H2145**

*

ICS 25-10

1 Pilot

027H2033

027H2039

027H2031****

*

3 Pilots

(4)

027H2083

027H2089

027H2081

*

027H2146**

*

ICS 25-15

1 Pilot

027H2043

027H2049

027H2041

*

027H2142**

*

3 Pilots

(4)

027H2093

027H2099

027H2091****

*

ICS 25-20

1 Pilot

027H2053

027H2059

027H2051

*

027H2143**

*

3 Pilots

(4)

027H2103

027H2109

027H2101

*

027H2148**

*

ICS 25-25

1 Pilot

027H2063

*

027H2061**

027H2062**

3 Pilots

(4)

027H2113

*

027H2111**

027H2112**

Pilot-operated servo valve, type ICS

Figure 33: 1 pilot

Table 26: Connections

Figure 34: 3 pilots

(4)

(4)

Including one blanking plug (A+B)

Including one blanking plug (A+B)

* Select from parts programme

Table 27: Connections

* Select from parts programme

© Danfoss | Climate Solutions | 2022.04

AI241186442033en-001301 | 33

Page 34

+

+ =

Valve body32 D (11/4in.)

027H3120

Function module ICS 32

027H3200

Top cover 3 pilots

027H3173

Connections

Code Number

32 D (1¼ in.)

027H3120

40 D (1½ in.)

027H3125

42 SA (1⅝ in.)

027H3127

42 SD (1⅝ in.)

027H3128

35 SD (1⅜ in. SA)

027H3123

32 A (1¼ in.)

027H3121

32 SOC (1¼ in.)

027H3122

40 A (1½ in.)

027H3126

Pilot-operated servo valve, type ICS

ICS 32

Ordering fr

Figure 35: Example (select from table ICV 32 valve body w/dierent

32 top cover)

Figure 36: ICV 32 valve body w/dierent

om the parts programme

connections

connections, table ICS 32 function module and table ICS

Table 28: ICV 32 valve body w/dierent

D = Butt-weld DIN

A = Butt

-weld ANSI

J = Butt-weld JIS

SOC = Socket weld ANSI

SD = Solder DIN

SA = Solder ANSI

FPT = Female Pipe Thread

Figure 37: function module

connections

© Danfoss | Climate Solutions | 2022.04

AI241186442033en-001301 | 34

Page 35

Danfoss

27H8258

Danfoss

27H8259

Danfoss

27H8261

Danfoss

27H8260

Description

Code Number

ICS 32

027H3200

(1)

Description

Code Number

Top cover 1 Pilot

027H3172

(2)

Top cover 3 Pilots

027H3173

(3)

Available connections

32 D (1¼ in.)

40 D (1½ in.)

42 SA (1⅝ in.)

42 SD (1⅝ in.)

35 SD (1⅜ in.

SA)

32 A (1¼ in.)

32 SOC (1¼

in.)

40 A (1½ in.)

ICS 32

1 Pilot

027H3020***027H3023

027H3021

027H3022

*

3 Pilots

(4)

027H3030***027H3033

027H3031

027H3032

*

Pilot-operated servo valve, type ICS

Table 29: ICS 32 function module

(1)

(1)

Including gasket and O-rings

Including gasket and O-rings

Figure 38: ICS 1

Table 30: ICS 32 top cover

(2)

(2)

Including bolts

Including bolts

(3)

(3)

Including bolts and one blanking plug

Including bolts and one blanking plug

Figure 39: ICS 3

Ordering complete factory assembled valve

(body, function module and t

Figure 40: 1 pilot

Table 31: Connections

op cover)

Figure 41: 3 pilots

(4)

(4)

Including one blanking plug (A+B)

Including one blanking plug (A+B)

* Select from parts programme

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 35

Page 36

+ + =

Valve body50 D (2 in.)

027H4126

Function module ICS 40

027H4200

Top cover 1 pilot

027H4172

Connections

Code Number

40 D (1½ in.)

027H4120

50 D (2 in.)

027H4126

42 SA (1⅝ in.)

027H4124

42 SD (1⅝ in.)

027H4123

40 A (1½ in.)

027H4121

40 SOC (1½ in.)

027H4122

50 A (2 in.)

027H4127

Pilot-operated servo valve, type ICS

ICS 40

Ordering fr

om the parts programme

Figure 42: Example (select from table ICV 40 valve body w/dierent

40 top cover)

Figure 43: ICV 40 valve body w/dierent

connections

connections, table ICS 40 function module and table ICS

Table 32: ICV 40 valve body w/dierent

D = Butt-weld DIN

A = Butt-weld ANSI

J = Butt-weld JIS

SOC = Socket weld ANSI

SD = Solder DIN

SA = Solder ANSI

FPT = Female Pipe Thread

Figure 44: function module

connections

© Danfoss | Climate Solutions | 2022.04

AI241186442033en-001301 | 36

Page 37

Danfoss

27H8258

Danfoss

27H8259

Danfoss

27H8261

Danfoss

27H8260

Description

Code Number

ICS 40

027H4200

(1)

Description

Code Number

Top cover 1 Pilot

027H4172

(2)

Top cover 3 Pilots

027H4173

(3)

Available connections

40 D (1½ in.)

50 D (2 in.)

42 SA (1⅝ in.)

42 SD (1⅝ in.)

40 A (1½ in.)

40 SOC (1½ in.)

50 A (2 in.)

ICS 32

1 Pilot

027H4020

*

027H4024

027H4023

027H4021

027H4022

*

3 Pilots

(4)

027H4030

*

027H4034

027H4033

027H4031

027H4032

*

Pilot-operated servo valve, type ICS

Table 33: ICS 40 function module

(1)

(1)

Including gasket and O-rings

Including gasket and O-rings

Figure 45: ICS 1

Table 34: ICS 40 top cover

(2)

(2)

Including bolts

Including bolts

(3)

(3)

Including bolts and one blanking plug

Including bolts and one blanking plug

Figure 46: ICS 3

Ordering complete factory assembled valve

(body, function module and t

Figure 47: 1 pilot

Table 35: Connections

(4)

(4)

Including one blanking plug (A+B)

Including one blanking plug (A+B)

op cover)

Figure 48: 3 pilots

* Select from parts programme

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 37

Page 38

+

+ =

Valve body65 D (2

¹

/²in.)

027H5124

Function module ICS 40

027H5200

Top cover 1 pilot

027H5172

Connections

Code Number

50 D (2 in.)

027H5120

65 D (2½ in.)

027H5124

54 SD (2⅛ in. SA)

027H5123

50 A (2 in.)

027H5121

50 SOC (2 in.)

027H5122

65 A (2½ in.)

027H5125

Pilot-operated servo valve, type ICS

ICS 50

Ordering fr

Figure 49: Example (select from table ICV 50 valve body w/dierent

50 top cover)

Figure 50: ICV 50 valve body w/dierent

om the parts programme

connections

connections, table ICS 50 function module and table ICS

Table 36: ICV 50 valve body w/dierent

D = Butt-weld DIN

A = Butt

-weld ANSI

J = Butt-weld JIS

SOC = Socket weld ANSI

SD = Solder DIN

SA = Solder ANSI

FPT = Female Pipe Thread

Figure 51: function module

connections

© Danfoss | Climate Solutions | 2022.04

AI241186442033en-001301 | 38

Page 39

Danfoss

27H8258

Danfoss

27H8259

Danfoss

27H8261

Danfoss

27H8260

Description

Code Number

ICS 50

027H5200

(1)

Description

Code Number

Top cover 1 Pilot

027H5172

(2)

Top cover 3 Pilots

027H5173

(3)

Available connections

50 D (2 in.)

65 D (2½ in.)

54 SD (2⅛ in. SA)

65 A (2½ in.)

50 A (2 in.)

50 SOC (2 in.)

ICS 50

1 Pilot

027H5020

*

027H5023

*

027H5021

027H5022

3 Pilots

(4)

027H5030

*

027H5033

*

027H5031

027H5032

Pilot-operated servo valve, type ICS

Table 37: ICS 50 function module

(1)

(1)

Including gasket and O-rings

Including gasket and O-rings

Figure 52: ICS 1

Table 38: ICS 50 top cover

(2)

(2)

Including bolts

Including bolts

(3)

(3)

Including bolts and one blanking plug

Including bolts and one blanking plug

Figure 53: ICS 3

Ordering complete factory assembled valve

(body, function module and t

Figure 54: 1 pilot

Table 39: Connections

(4)

(4)

Including one blanking plug (A+B)

Including one blanking plug (A+B)

op cover)

Figure 55: 3 pilots

* Select from parts programme

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 39

Page 40

+ +

=

Valve body 76 SD (2

5

/8in.)

027H6124

Function module

ICS 65 027H6200

ICS 80027H8200

Top cover 3 pilots

027H6173

Connections

Code Number

65 D (2½ in.)

027H6120

65 A (2½ in.)

027H6121

65 J (2½ in.)

027H6122

80 D (3 in.)

027H6126

80 A (3 in.)

027H6127

67 SA (2 ⅝ in.)

027H6125

76 SD (3 in.)

027H6124

65 SOC (2½ in.)

027H6123

Pilot-operated servo valve, type ICS

ICS 65 and ICS 80

Ordering fr

Figure 56: Example (select from table ICV 65 valve body w/dierent

and table ICS 65/80 top cover)

Figure 57: ICV 65 valve body w/dierent

om the parts programme

connections

connections, table ICS 65 and ICS 80 function module

Table 40: ICV 65 valve body w/dierent

D = Butt-weld DIN

A = Butt-weld ANSI

J

= Butt-weld JIS

SOC = Socket weld ANSI

SD = Solder DIN

SA = Solder ANSI

FPT = Female Pipe Thread

connections

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 40

Page 41

Danfoss

27H8258

Danfoss

27H8259

Description

Code Number

ICS 65

027H6200

(1)

ICS 80

027H8200

(1)

Description

Code Number

Top cover 1 Pilot (65)

027H6172

(2)

Top cover 3 Pilots (65)

027H6173

(3)

Top cover 1 Pilot (80)

027H8192

(2)

Top cover 3 Pilots (80)

027H8193

(3)

Pilot-operated servo valve, type ICS

Figure 58: function module

Table 41: ICS 65 and ICS 80 function module

(1)

(1)

Including gasket and O-rings

Including gasket and O-rings

Figure 59: ICS 1

Table 42: ICS 65/80 top cover

Figure 60: ICS 3

(2)

(2)

Including bolts

Including bolts

(3)

(3)

Including bolts and one blanking plug

Including bolts and one blanking plug

Ordering complete factory assembled valve

(body, function module and top cover)

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 41

Page 42

Danfoss

27H8261

Danfoss

27H8260

Available connections

65 D (2½ in.)

65 A (2½ in.)

65 SOC (2½

in.)

80 D (3 in.)

80 A (3 in.)

67 SA (2⅝ in.)

76 SD (3 in.)

65 J (2½ in.)

ICS 50

1 Pilot

027H6020

027H6021

027H6023**

027H6025

027H6024

*

3 Pilots

(4)

027H6030

027H6021

027H6033**

027H6035

027H6034

*

ICS 80

1 Pilot***027H8020

027H8021**

*

3 Pilots

(4)

***

027H8030

027H8031**

*

Danfoss

M27H0083

Connections

100 D (4 in.)

100 A (4 in.)

100 A (4 in.) with ⅜ in. NPT pressure

outlet

ICS 100

(1)

027H7120

027H7121

027H7122

Pilot-operated servo valve, type ICS

Figure 61: 1 pilot

Table 43: Connections

(4)

(4)

Including one blanking plug (A+B)

Including one blanking plug (A+B)

Figure 62: 3 pilots

* Select from parts programme

NOTE:

The capacity of the ICS 80 module can only be achiev

ed when using the valve body with 80 D or A (3 in)

connections.

If any other ICV 65 valve body is used the capacity of the complete valve will be reduced by approximately 6%.

ICS 100 - 150

Ordering c

(body, function module and top cover)

Figure 63: ICS 100

omplete factory assembled valve

Table 44: Connections

(1)

(1)

Including two blanking plugs (A) and one sealing plug (B)

Including two blanking plugs (A) and one sealing plug (B)

© Danfoss | Climate Solutions | 2022.04

AI241186442033en-001301 | 42

Page 43

Danfoss

M27H0084

Connections

125 D (5 in.)

125 A (5 in.)

125 A (5 in.) with ⅜ in. NPT pressure

outlet

ICS 125

(1)

027H7140

027H7141

027H7142

Danfoss

M27H0085

Connections

150 D (6 in.)

150 A (6 in.)

150 A (6 in.) with ⅜ in. NPT pressure

outlet

ICS 150

(1)

027H7160

027H7161

027H7162

Pilot-operated servo valve, type ICS

Figure 64: ICS 125

Table 45: Connections

Figure 65: ICS 150

Table 46: Connections

Spare parts:Please see AI245486497115

Accessories

Figure 66: T

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 43

op cover

Page 44

Top covers

Consist of: Top cover complete with manuel spindle,

and gasket

Size

Code number

ICS 100

027H7123

ICS 125

027H7143

ICS 150

027H7163

Danfoss

27H249

Description

Code no.

ICV 25 PM Valve housing

027H2119

(1)

ICV 32 PM Valve housing

027H3129

(1)

ICV 40 PM Valve housing

027H4128

(1)

ICV 50 PM Valve housing

027H5127

(2)

ICV 65 PM Valve housing

027H6128

(2)

PM

REMOVE

ICV PM

ICV PM

DROP IN

ICM

ICS

ICLX

CUSTOMIZE

Pilot-operated servo valve, type ICS

Table 47: Top covers

ICV PM anged v

IC

V PM anged valve housings can replace the PM valves on already installed refrigeration systems.

e housings

alv

Figure 67: ICV PM anged valve housing

Pressure range

The ICV P

M valve housing is designed for a max. working pressure of 28 bar (406 psig) and therefore a suitable

replacement for PM valves in the service market. They also oer the same drop-in dimensions as the PM valves.

Table 48: Top covers

(1)

(1)

Includes ICV PM valve housing, ange gaskets and ange bolts.

Includes ICV PM valve housing, ange gaskets and ange bolts.

(2)

(2)

Includes ICV PM valve housing, ange gaskets, ange bolts and ange nuts.

Includes IC

V PM valve housing, ange gaskets, ange bolts and ange nuts.

Function modules and top covers must be ordered separately (see the section “Ordering”).

Figure 68: ICV PM

ICV (H)A4A anged valve housings

ICV (H)A4A

anged valve housings can replace the (H)A4A valves on already installed refrigeration systems.

© Danfoss | Climate Solutions | 2022.04

AI241186442033en-001301 | 44

Page 45

Danfoss

27H249

Description

Code no.

ICV 25 (H)A4A Valve housing

027H2304

(3)

ICV 32 A4A Valve housing

027H3130

ICV 32 HA4A Valve housing

027H3131

ICV 40 (H)A4A Valve housing

027H4129

ICV 50 (H)A4A Valve housing

027H5128

ICV 65 (H)A4A Valve housing

027H6129

(H)A4A

REMOVE

ICV (H)A4A

ICV (H)A4A

DROP IN

ICM

ICS

ICLX

CUSTOMIZE

Description

Code no.

∅ 6.5 mm / ∅ 10 mm

(∅ 0.26 in. / ∅ 0.39 in.) weld / solder

027B2035

Pilot-operated servo valve, type ICS

Figure 69: ICV (H)A4A anged valve housing

Pressure range

The ICV (H)A4A v

alve housing is designed for a max. working pressure of 28 bar (406 psig) and therefore a suitable

replacement for (H)A4A valves in the service market. They also oer the same drop-in dimensions as the (H)A4A

valves.

Table 49: ICV Valve housing

(3)

(3)

Includes ICV (H)A4A valve housing, ange gaskets, ange

Includes ICV (H)A4A valve housing, ange gaskets, ange bolts and ange nuts.

bolts and ange nuts.

Function modules and top covers must be ordered separately (see the section “Ordering”).

Figure 70: ICV (H)A4A

Pressure gauge connection (weld / solder)

Figure 71: P

connection (weld / solder).

ressure gauge

Table 50: Pressure gauge connection (weld / solder).

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 45

Page 46

Accessories

size

L

L1B1B2B3B4B

5

mm

in.662.60542.13

AF 19

AF 22

G ¼ A

G ⅜ A

∅6.5 / ∅10

Description

Code no.

¼ in. are

027B2041

Accessories

B

B1B

2

¼ in. are

G ¼ A

AF 19

¼ in. are

Pilot-operated servo valve, type ICS

Figure 72: Pressure gauge

connection (w

Table 51: Pressure gauge connection (weld / solder)

eld / solder)

Pressure gauge connection, ¼ in. are (self-

closing)

Pressure gauge connection, ¼ in. are (self-closing) Must not be used in R 717 plant.

Figure 73: ¼ in. are (selfclosing)

Table 52: Connection

Figure 74: ¼ in. are (selfclosing)

Table 53: Pressure gauge connection, ¼ in. are (self-

© Danfoss | Climate Solutions | 2022.04

closing)

AI241186442033en-001301 | 46

Page 47

Description

Code no.

Cutting ring connection, 6 mm

027B2063

Cutting ring connection, 10 mm

027B2064

Accessories

LL1BB1B2

6 mm

mm

in.271.06391.54

G ¼ A

AF 19

AF 14

10 mm

mm

in.291.14401.57

G ¼ A

AF 19

AF 14

Description

Code no.

Multi-function tool for ICS 25-65

027H0180 / 027H0181

Pilot-operated servo valve, type ICS

Pressure gauge connection (cutting ring)

Figure 75: P

ressure gauge

connection (cutting ring).

Table 54: Cutting ring connection

Figure 76: Cutting ring

connection

Table 55: Pressure gauge connection (cutting ring)

Multi-function tool

Table 56: Multi-function tool

Figure 77: Multi-function tool

The multi-funktion tool can be used for:

• Removing the ICS function module

• Operating the manual spindle

For further information please see the instruction PIHU0A.

© Danfoss | Climate Solutions | 2022.04 AI241186442033en-001301 | 47

Page 48

Description

Code no.

¼ FPT

027B2062

Accessories

L

L

1

B

B1B

2

mm

in.230.91

35.5

1.40

G ¼ A

AF 22

¼ FPT

ICS

Description

Code no.

5 - 80

External pilot connection (incl. damping orice

, D: 1.0

mm)

027F1048

5 - 150

Accessory bag with seal and O-ring for pilot valve

027F0666

100 - 150

External pilot connection (incl. damping orice

, D: 1.8

mm)

027F1049

Pilot-operated servo valve, type ICS

Pressure gauge connection

Figure 78: C

onnection

Table 57: Pressure gauge connection

Figure 79: Pressure gauge

connection

Table 58: Pressure gauge connection

External pilot connection

Figure 80: C

Table 59: ICS connections

Figure 81: External pilot

connection

onnection

© Danfoss | Climate Solutions | 2022.04

AI241186442033en-001301 | 48

Page 49

Accessories

H

H

1

OD

B

B1B

2

mm

in.903.54662.60180.71

AF 32

AF 32

M 24 × 1.5

Description

Code no.

Blanking plug

027F1046

Danfoss

148H8045

Recommended lt

ers

Filter element for liquid line

Filter element for suction

line

150 mesh

100 mesh

72 mesh

38 mesh

Filter Type

SizeDA

FPT

SOC

100 my

150 my

250 my

500 my

FIA Straightway

20 (¾ in.)

148B5343

148B5347

148B5349

148B5348

148H3122

148H3124

148H3126

148H3128

FIA Straightway

25 (1 in.)

148B5443

148B5447

148B5449

148B5448

148H3123

148H3125

148H3127

148H3129

FIA Straightway

32 (1¼ in.)