Page 1

Data Sheet

Motor operated valves and Actuators

Type ICM and ICAD

ICM motor valve equipped with ICAD actuator provides a higher

suction pressure, and a much better COP, ultimately leading

to signicant energy savings

ICM motor operated valves belong to the ICV

family and are one of two product groups.

ICV types

• ICS - Pilot operated servo valve

• ICM - Motor operated vave

The motor operated valve comprises four main

components: Valve body, top cover, function

module and Actuator. On ICM 20 – 65 the top

cover and function module will be combined.

ICM are motor operated valves driven by

actuator type ICAD.

ICM valves are designed to regulate an

expansion process in liquid lines with or

without phase change or control pressure or

temperature in dry and wet suction lines and

hot gas lines. ICM valves are designed so that

the opening and closing forces are balanced,

therefore, only two sizes of ICAD actuators are

needed for the complete range of ICM from DN

20 to DN 150. The ICM motor operated valve

and ICAD actuator assembly oers a very

compact unit with small dimensions.

ICAD

Actuator types ICAD 600A and 1200A are

dedicated for use with ICM motor operated

valves. There are only two sizes of ICAD

actuators that cover the range of valves from

ICM 20 to ICM 150.

The ICAD is controlled via a modulating

analogue signal (e.g. 4 – 20 mA / 2 – 10 V) or a

digital ON / OFF signal. ICAD incorporates an

advanced MMI (Man Machine Interface),

including continuous display of Opening

Degree, which gives the user a very advanced

and exible setup procedure that can meet

many dierent applications.

AI236186442940en-001201

Page 2

Motor operated valves and Actuators, type ICM and ICAD

Features

ICM valve

• Designed for Industrial Refrigeration applications for a maximum working pressure of 52 bar / 754 psig

• Applicable to HCFC, HFC, R717 (Ammonia) and R744 (CO2)

• Direct coupled connections

• Connection types include butt weld, socket weld, solder and threaded connections

• Low temperature steel body

• Low weight and compact design

• V-port regulating cone ensures optimum regulating accuracy particularly at part load

• Cavitation resistant valve seat on A cones

• Modular Concept

◦ Each valve body is available with several dierent connection types and sizes

◦ Valve overhaul is performed by replacing the function module (ICM 20 – 65)

◦ Possible to convert ICM motor operated valve to ICS pilot operated servo valve

◦ Spare parts available for ICM 100 – 150

• Manual opening possible via ICAD or Multifunction tool

• PTFE seat provides excellent valve tightness

• Magnet coupling - real hermetic sealing

• ICAD 600A / 1200A include encoder function that will provide a true valve position feedback to Danfoss controller

or non-Danfoss control systems

• Classication: DNV, CRN, BV, EAC etc. To get an updated list of certication on the products please contact your

local Danfoss Sales Company

ICAD actuator

• Designed for industrial refrigeration installations

• Advanced and high speed Digital Stepper Motor Technology

• Seven segment LCD display and three programming keys included

• Valve opening degree can be observed continuously

• Can easily be congured to dierent applications on-site (change speed, ON / OFF, Fail Safe operation, modulating

valve, etc..)

• Open – Close time: 3 – 45 seconds depending on valve size

• Modulating, ON / OFF operation or Neutral zone / 3 point control

• Multiple speed selection during operation

• Logging of old alarms

• Password protection

• Control input signal :

◦ 4 – 20 mA, 0 – 20 mA, 0 – 10 V, 2 – 10 V.

◦ One or two digital inputs

• Position feed back : 0 – 20 mA, 4 – 20 mA (ICM)

• 3 Digital ON / OFF feedback

• Resolution: 20 micron / step (0.02 mm stroke pr. step)

• Total steps: 250 – 3650 depending on size

• Auto Calibration, Neutral zone

• In the event of a power failure, multiple fail safe options are possible. During power failure, ICM can be selected to:

◦ Close ICM

◦ Open ICM

◦ Stay in the same position, as when power failure occurs

◦ Go to a specic ICM valve opening degree

• Hermetic magnetic motor

• Enclosure: IP67 ~ NEMA 6

• Approvals: CE, UL, CRN

• Connectors for easy installation and servicing

• ICAD 600A / 1200A ensures an acurate feedback on the valve position

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 2

Page 3

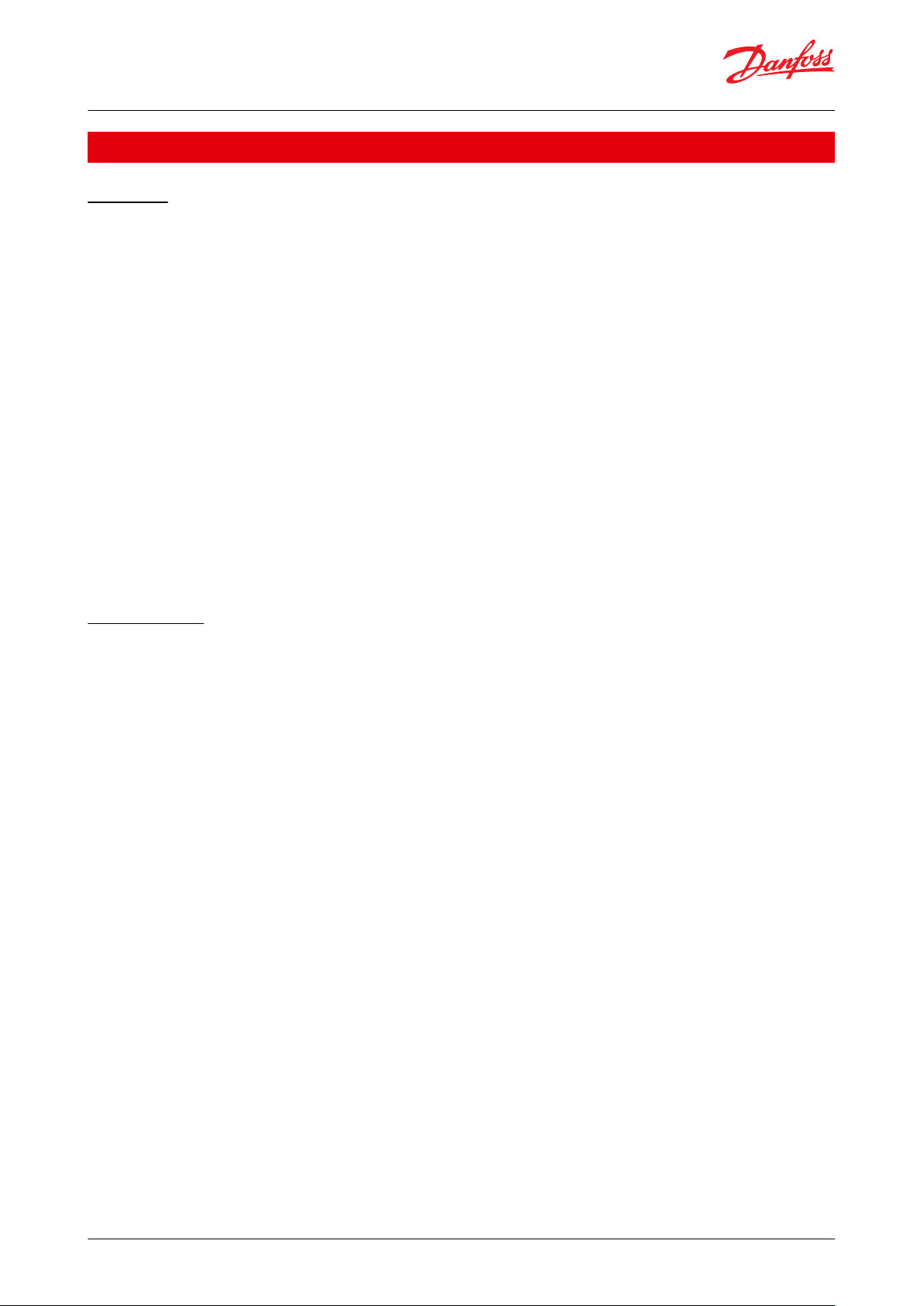

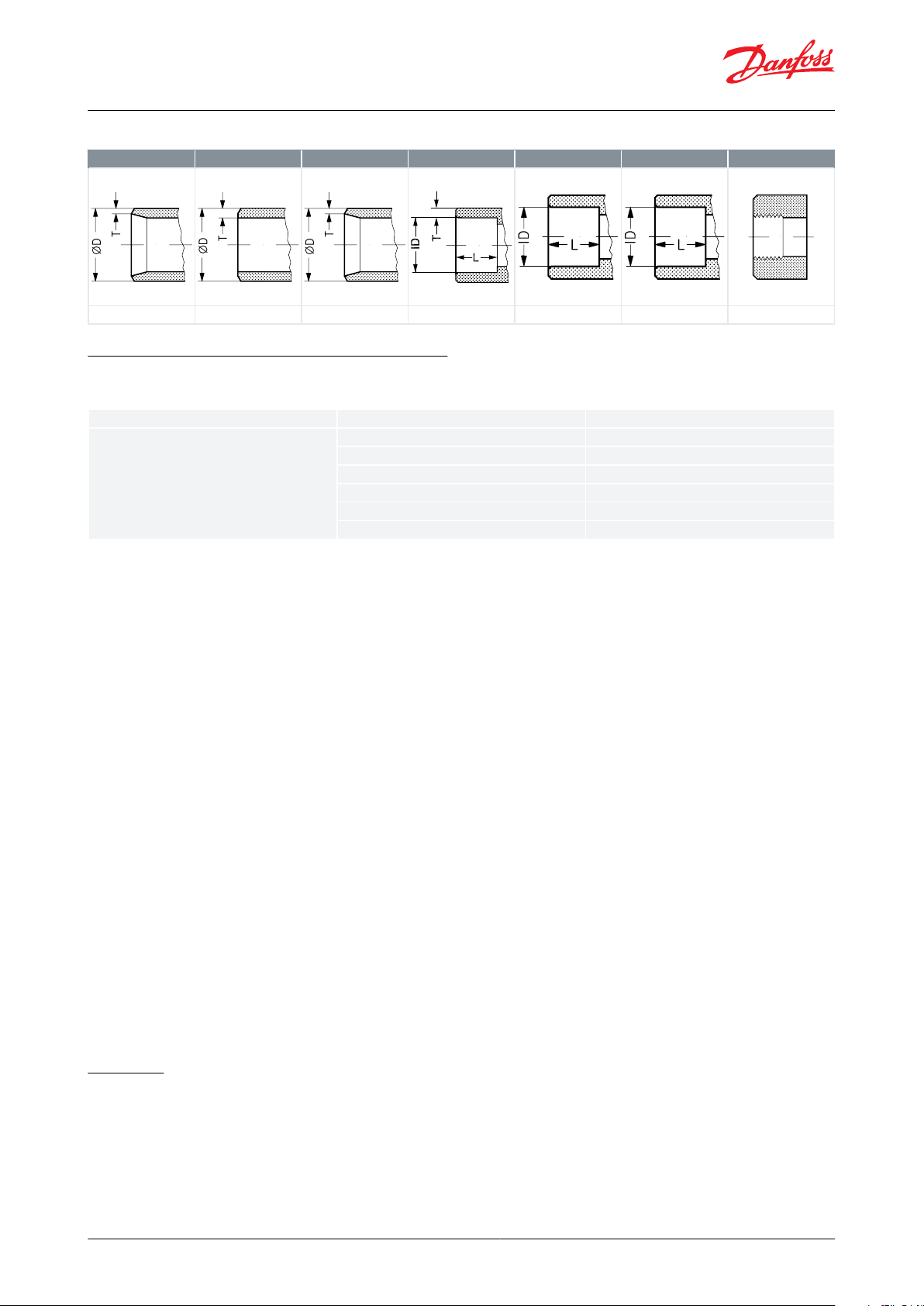

ICM 20

ICM 25-65

ICM 100 – 150

P

2

k

h

i

j

Motor operated valves and Actuators, type ICM and ICAD

Functions

ICM

Table 1: ICM valves

ICM, motor operated valves are designed for use with the ICAD actuator with Display.

The driving force from the actuator is transferred via a magnetic coupling (a) through the stainless steel top housing

(b) and thus eliminates the need for a packing gland. The rotational movement of the magnetic coupling (a) is

transferred to a spindle (c) which in turn provides the vertical movement of the piston (d) and the valve seat (e), to

open and close the valve. The closing force of the actuator, combined with the the valve seat (e) and PTFE valve

plate (f ), provides an eective seal to prevent leakage across the valve port, when the valve is in the closed position.

To prevent damage to the PTFE valve seat (e) and plate (f ) from system debris, it is recommended that a lter is

installed upstream of the valve. Please refer to page 14 for lter sizing and application recommendations.

ICM 20 – 65:

Valve inlet pressure (P1) acting on the underside of the PTFE valve seat (e) also passes through the hollow piston

assembly (d) on to the top of the piston (d) and balances the pressure acting on the piston (d). Any trapped liquid

across the throttle cone (g) is allowed to equalise down to the valve outlet without aecting the valve performance.

ICM 100 – 150:

Valve inlet pressure (P1) acting on the underside of the PTFE valve plate (h) also passes through the equalization

hole (i) and ensures that the servo piston (j) is pressure balanced. This will equalize P1 and P2. During an opening

operation of the valve, the pilot piston (k) will be raised from its valve seat inside the servo piston (j). This allows the

P2 pressure to escape through the servo piston (j) to the outlet of the valve. The pressure P1 will act on the

underside of the servo piston (j) and force it to open. This will close the gap between the pilot piston (k) and the

servo piston (j) until the pressures P1 and P2 are equalized again. When there is no pressure dierence between P1

and the outlet of the valve the pilot piston (k) is attached to the servo piston (j) ensuring it to open up.

ICAD

There are two sizes of ICAD actuator that covers the range of valves from ICM 20 to ICM 150. The actuators have a

fully weather protected enclosure with none of the moving parts exposed to the environment.

The fast acting actuators and balanced valve design results in the valve being able to move from the fully closed to

the fully open position in between 3 to 45 seconds depending on valve size and ICAD setup.

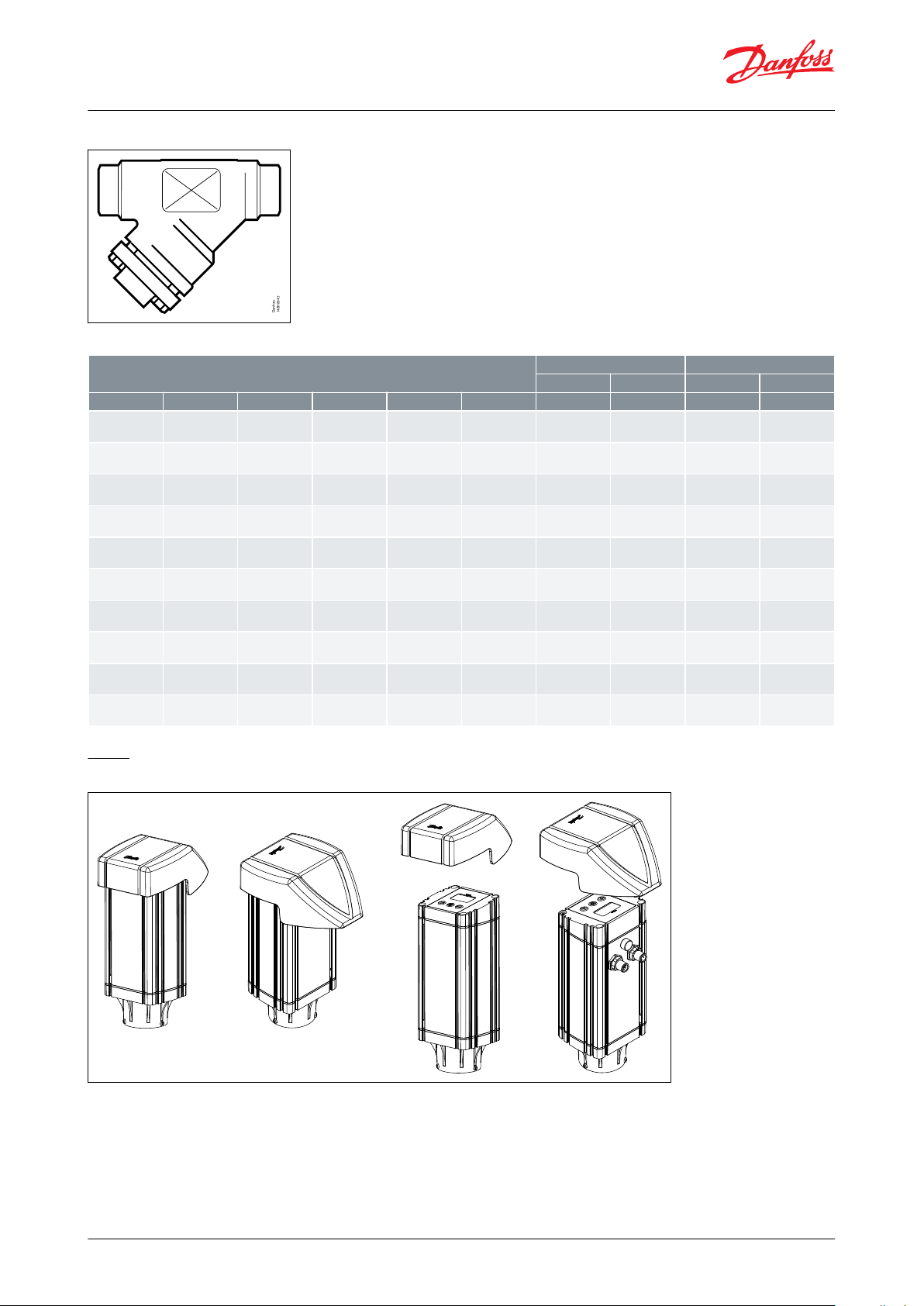

Each body may be tted with multiple function / top cover to give dierent capacities

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 3

Page 4

Type

Valve body size

kv (m3/h)

Cv (US

gal/min

)

ICM 20A-33

20

0.2

0.23

ICM 20-A

0.6

0.7

ICM 20-B66

1.6

1.9

ICM 20-B

2.4

2.8

ICM 20-C

4.6

5.3

ICM 25-A2567ICM 25-A33

2

2.3

ICM 25-B1213.9

ICM 32-A329

10.4

ICM 32-B1720

ICM 40-A401517ICM 40-B2630

ICM 50-A502327ICM 50-B4046

ICM 65-A653541ICM 65-B7081

ICM 100-B

100

142

167

ICM 125-B

125

223

260

ICM 150-B

150

370

430

Motor operated valves and Actuators, type ICM and ICAD

Figure 1: Multiple function / top cover

Table 2: Multiple function / top cover with capacities

ICAD

The design of ICAD is based on a digital stepper motor technology combined with an advanced MMI (Man Machine

Interface), that gives excellent possibilities for having a high degree of exibility with the same type of ICAD

actuator.

At the ICAD display the Opening Degree (0 – 100 %) of the actual ICM valve installed can be continuously observed.

The advanced menu system will allow several parameters to be ajusted to obtain the required function.

Many dierent parameters can be congurated, among these:

• Modulating, ON / OFF operation or Neutral zone / 3 point control

• Analog input

◦ 0 – 20 mA or 4 – 20 mA

◦ 0 – 10 V or 2 – 10 V

• Digital Input

◦ ICAD can be congured to support one or two digital inputs

◦ When using one digital input, 0 – 10 V can not be used at the same time

◦ By using two digital inputs at Neutral zone / 3 point control, the analog input (0/2 – 10 V, 0/4 – 20 mA) and

Analog Output (0/4 – 20 mA) can not be used at the same time

• Analog output

◦ 0 – 20 mA or 4 – 20 mA

• Automatic or manual control

• Change of ICM valve speed

• Automatic calibration

• Multiple Fail Safe set-up options during power cut

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 4

Page 5

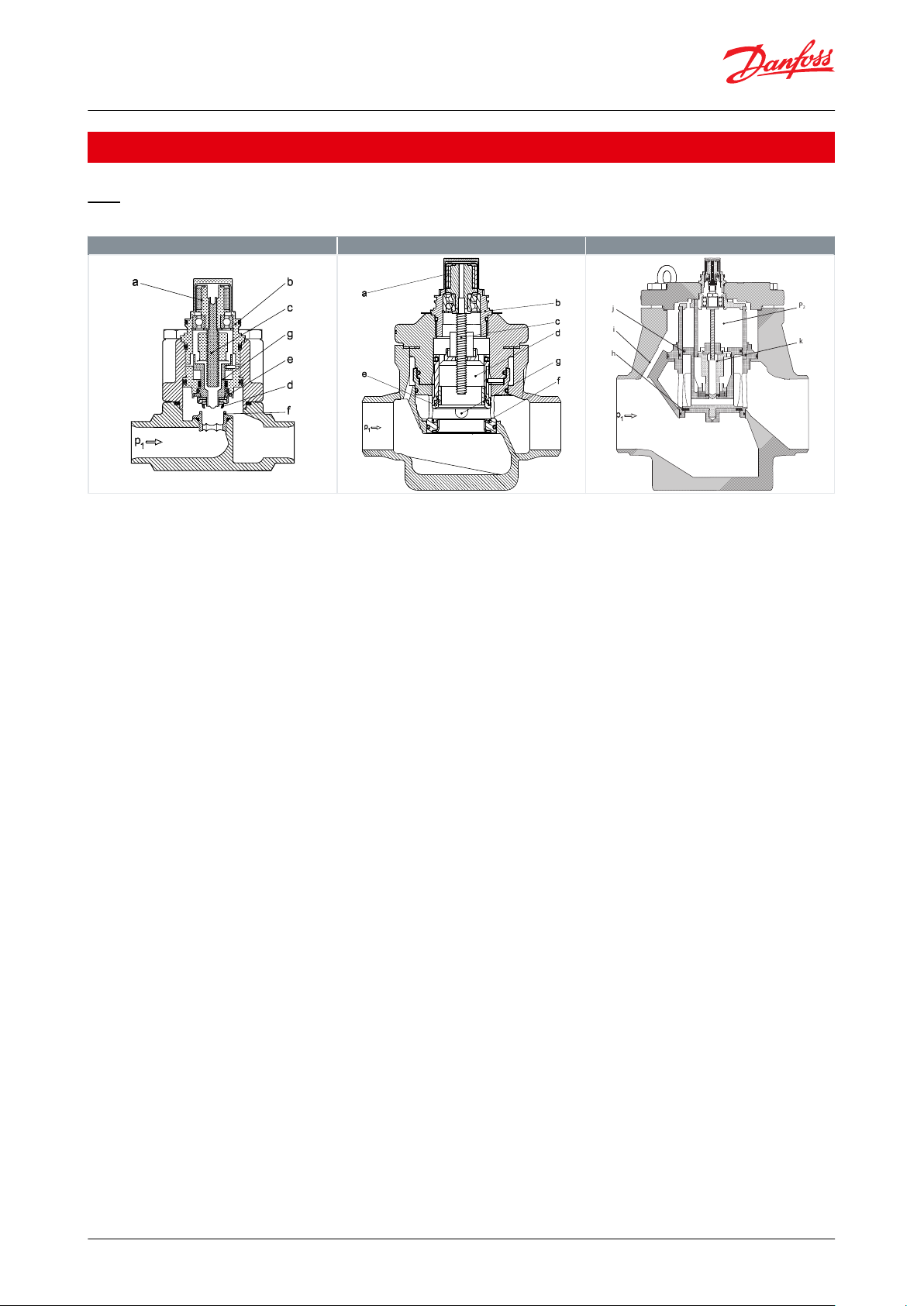

ICAD 600A

ICAD 1200A

Motor operated valves and Actuators, type ICM and ICAD

For service all Input and Output signals can be recalled and observed from the ICAD display.

A password protection has been linked to the parameter of entering the correct ICM valve to avoid unintentional

and non-authorised operation.

ICAD can manage and display dierent alarms. If an alarm has been detected the display will alternate between

showing: Actual alarm present and Opening Degree of ICM valve. If more than one alarm is active at the same time

the alarm with the highest priority will take preference. The alarm with the highest priority is shown on the display.

All alarms will automatically reset when disappearing.

Previous alarms can be recalled for traceability and service purposes.

Any active alarm will activate the common digital alarm output. All alarms will automatically reset when

disappearing.

ICAD provides two digital output signals to 3rd party control equipment (e.g. PLC) indicating if the ICM valve is

completely open or completely closed.

The hermetic magnetic motor coupling makes it easy to dismount the ICAD from ICM valve.

A magnetic coupled actuator is easily installed. Only two actuators are needed to cover the entire ICM

program

Table 3: ICAD 600A and ICAD 1200A

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 5

Page 6

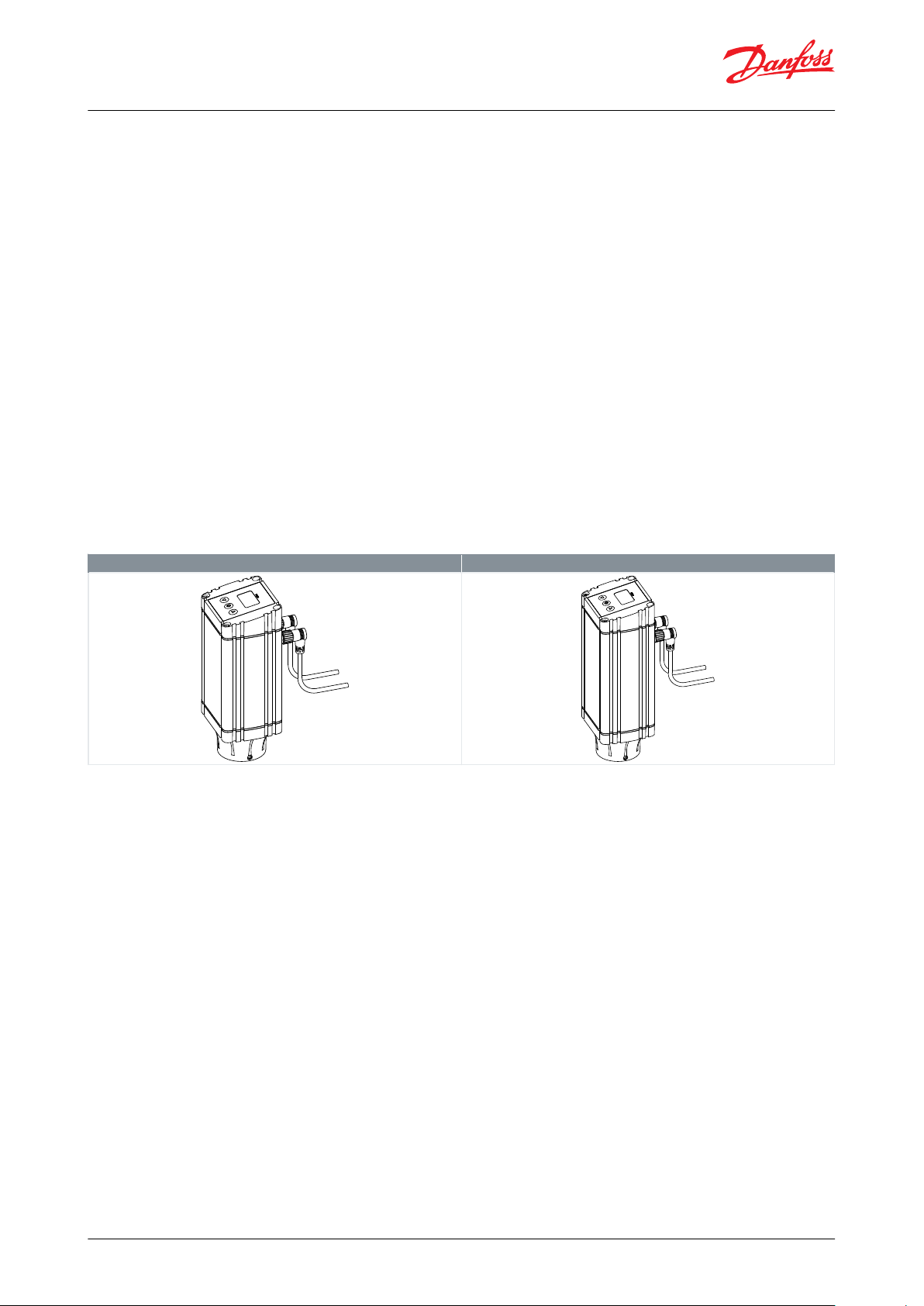

Hot gas bypass or defrost line

Dry suction line

Wet suction line

Liquid line without

phase change

Liquid line with

phase change

Discharge line

Motor operated valves and Actuators, type ICM and ICAD

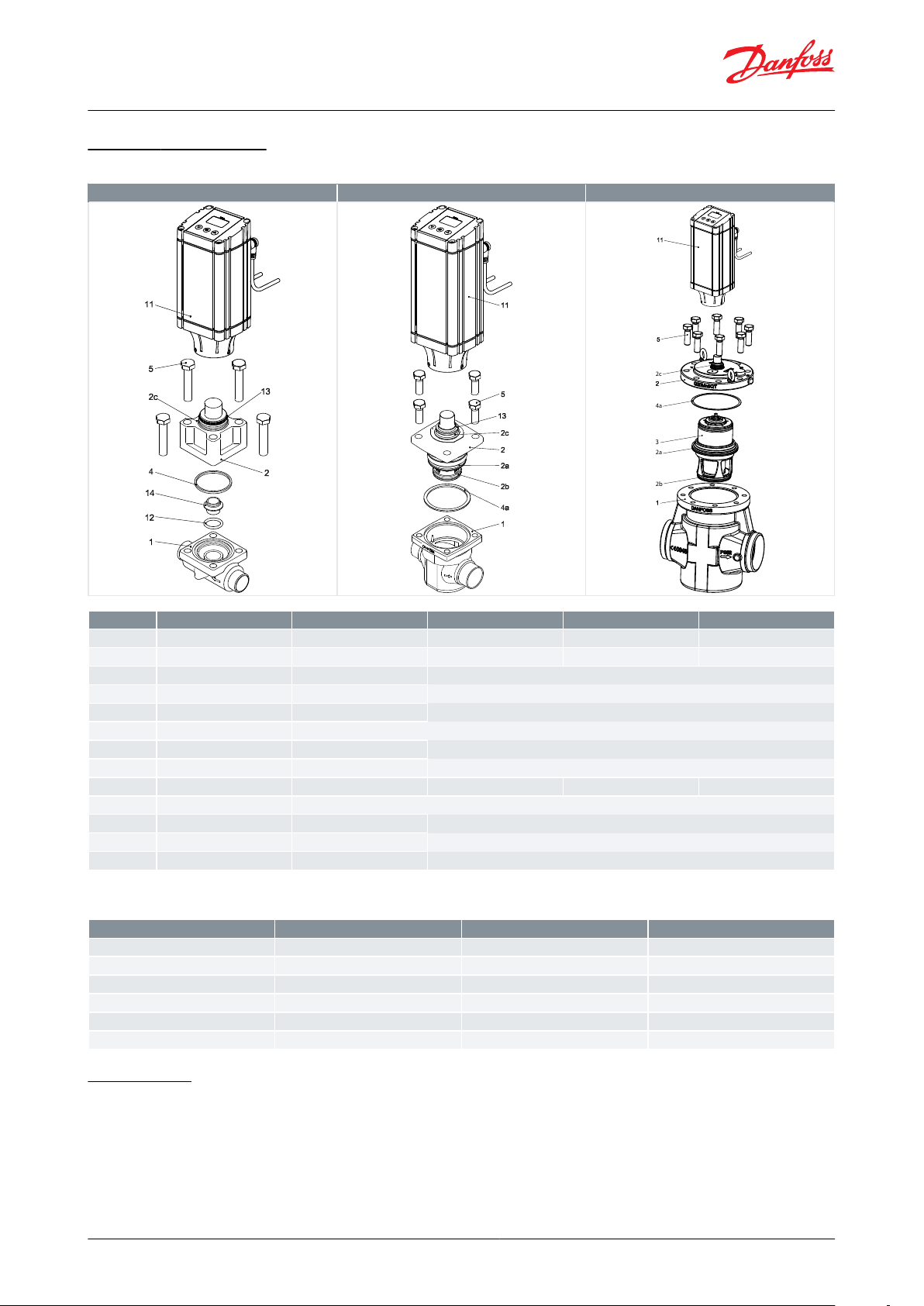

Applications

ICM

Figure 2: ICM Application

NOTE:

ICM can be used for pressure and temperature regulation in dry and wet suction lines, in hot gas lines and in liquid

lines with or without phase change (i.e. where no expansion occurs in the valve).

Valve capacities for dierent refrigerants and applications are given in the following tables. Selection of ICM / ICS

valves will be available with the DIRcalc ver. 1.3 selection program and later. The resultant valve selections will be:ICMEXP for expansion valve functions and where the selection criteria has been predened for expansion valve

application: ICM will be for control valve functions and will include for all available function modules as valve

pressure drop is the main consideration for valve selection.

The process for identifying the ICM valve solution can be determined from the ordering pages. Initially select the

nominal valve size, identify the required valve body and connection types, followed by the module insert and then

the correct actuator to suit the module insert and valve body.

As the ICM and ICS valves use a common body it is possible to install the body without having previously

determined whether a servo or motor function is required. A blank top cover complete with xing screws can be

supplied to allow for pressure testing.

In applications where the ICM is used to control pressure / temperature at diering operating conditions e.g. dual

temperature store, the ICM must be selected so that the full operating conditions (minimum and maximum

capacity / summer and winter conditions) are within the control range of the selected ICM valve.

It is particularly important to ensure that the ICM valve selection is not oversized and as a consequence operates at

a minimum opening degree, which can result in a hunting condition and continuous recalibration of the ICM valve.

NOTE:

ICM valves should be sized to suit required capacity and operating conditions. ICM valves should not be line sized.

For ICM 20 – 65 applications it is recommended that the valve opening degree at the minimum operating

conditions is greater than 5%.

For ICM 100 – 150 applications it is recommended that the valve opening degree at the minimum operating

conditions is greater than 10%.

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 6

Page 7

Danfoss

148H8045

Recommended lters

Filter element for liquid line

Filter element for suction line

150 mesh

100 mesh

72 mesh

38 mesh

Filter Type

SizeDA

FPT

SOC

100 my

150 my

250 my

500 my

FIA Straight-

way

20 (

3

⁄4 in.)

148B5343

148B5347

148B5349

148B5348

148H3122

148H3124

148H3126

148H3128

FIA Straight-

way

25 (1 in.)

148B5443

148B5447

148B5449

148B5448

148H3123

148H3125

148H3127

148H3129

FIA Straight-

way

32 (1

1

⁄4 in.)

148B5544

148B5552

148B5549

148B5548

148H3123

148H3125

148H3127

148H3129

FIA Straight-

way

40 (1

1

⁄2 in.)

148B5625

148B5644

148B5645

148H3123

148H3125

148H3127

148H3129

FIA Straight-

way

50 (2 in.)

148B5713

148B5716

148B5717

148H3157

148H3130

148H3138

148H3144

FIA Straight-

way

65 (2

1

⁄2 in.)

148B5813

148B5815

148H3131

148H3139

148H3145

FIA Straight-

way

80 (3 in.)

148B5906

148B5908

148H3119

148H3120

148H3121

FIA Straight-

way

100 (4 in.)

148B6007

148B6009

148H3132

148H3140

148H3146

FIA Straight-

way

125 (5 in.)

148B6106

148B6108

148H3133

148H3141

148H3147

FIA Straight-

way

150 (6 in.)

148B6203

148B6205

148H3134

148H3142

148H3148

Motor operated valves and Actuators, type ICM and ICAD

Figure 3: Filter

Table 4: Recommended lters

ICAD

Figure 4: ICAD protection cap

ICAD protection cap

For all outdoor applications or where extra protection of the display and keyboard is needed, Danfoss recommends

using the ICAD protection cap.

The protection cap will give the ICAD display and keyboard an extra protection against e.g. sun radiation or other

impacts from the surrounding environment. Furthermore it protects the cable connectors against inappropriate

loads.

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 7

Page 8

Motor operated valves and Actuators, type ICM and ICAD

The special designed protection cap can be mounted on all ICAD 600A / 1200A.

The installation of the protection cap is done by sliding the protection cap down on the top of the ICAD. To secure

the protection cap, tie it to the connector cables using the hole in the protection cap.

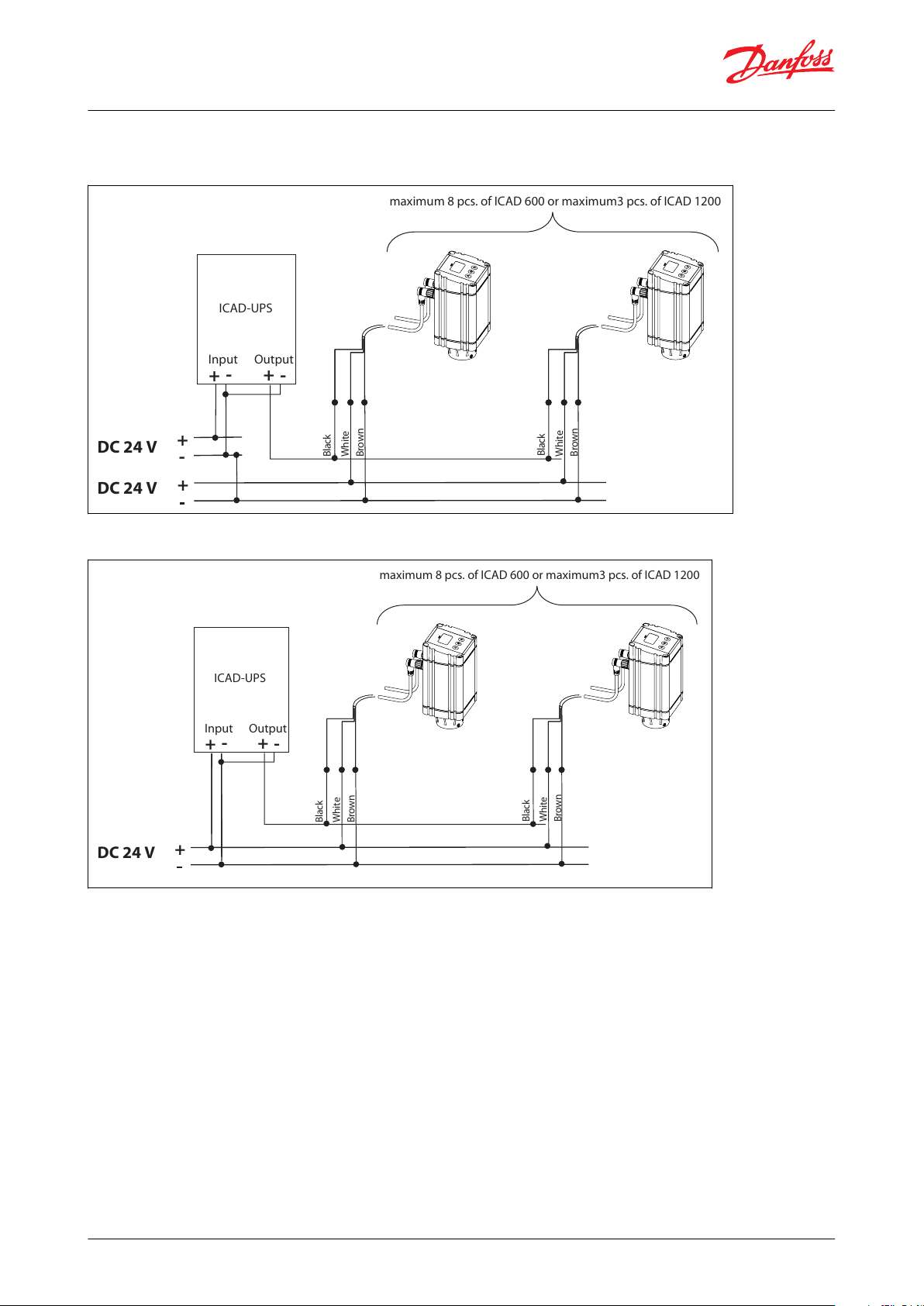

Figure 5: ICAD-UPS for ICM 20 – 150

ICAD-UPS for ICM 20 – 150

ICAD-UPS is dedicated for use along with ICM sizes 20 - 150 installed with ICAD 600A and ICAD 1200A actuators.

In the event of power failure, there is a need to make sure that the ICM goes to a safe position.

ICAD-UPS can be connected to the ICAD 600A / 1200A.

The solution ICM with ICAD connected to ICADUPS will give one of the following possibilities in the event of power

failure:

• close ICM

• open ICM

• stay

• go to a specec ICM Opening Degree

When power supply has been re-established the system will automatically return to normal operation.

Facts and features

• Industrial product

• Can support up to

◦ 3 pcs. of ICAD 1200A or

◦ 8 pcs. of ICAD 600A

• Integrated solution - battery and UPS

• Industrial approvals:

◦ CE, UL

DIN rail mounting

•

• LED status indication

• 24 V DC supply → Same transformer as for ICAD can be used

• Continuous monitoring of battery

• Integrated temperature sensor for optimized battery charging

• Adjustable buer time

(1)

. (1, 2, 3, 5, 10, 15, 20 or innity) = Ensures longer life time of the battery

• Forced remote shutdown in buer mode via digital input

• 3 digital volt free relay change over contacts for signals to PLC systems. (Power OK, Buer mode (failsafe supply to

ICAD), Alarm).

Code number: 027H0388

For further information please see the instruction ICAD-UPS

1

Buer time is dened as the period where ICAD is only powered from the ICAD-UPS (i.e. not from main supply). On ICAD-UPS there is an

adjustable buer time setting (1, 2, 3, 5, 10, 15, 20, 30 min. or innity). If set to 3, ICAD-UPS will switch o power to connected ICAD 600A /

1200A, 3 minutes after the power failure occurs. This ensures that the internal battery inside ICAD-UPS do not fully discharge.

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 8

Page 9

+

-

+

-

CAD-U

S

maximum

8 pcs. of ICAD 600 or maximum3 pcs. of ICAD 1200

Input Output

Black

White

Brown

Black

White

Brown

+

+

-

DC 24 V

DC 24 V

ICAD-UPS

+

-

CAD-U S

maximum 8 pcs. of ICAD 600 or maximum3 pcs. of ICAD 1200

Input Output

Black

White

Brown

Black

White

Brown

+

+

-

DC 24 V

ICAD-UPS

Motor operated valves and Actuators, type ICM and ICAD

ICAD-UPS applications

Figure 6: Seperate 24 V DC tranformer for both ICAD-UPS and ICAD 600A / 1200A

Figure 7: One 24 V DC tranformer for ICAD-UPS and ICAD 600A / 1200A

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 9

Page 10

Motor operated valves and Actuators, type ICM and ICAD

Media

Refrigerants

ICM 20, ICM 100, ICM 125 and ICM 150:

Applicable to HCFC, non ammable HFC, R717 (Ammonia) and R744 (CO2).

ICM 25-65:

Applicable to HCFC, non ammable HFC, R717 (Ammonia), R744 (CO2) and R1234ze.

Use with ammable hydrocarbons cannot be recommended. For further information please contact your local

Danfoss sales company.

New refrigerants

Danfoss products are continually evaluated for use with new refrigerants depending on market requirements.

When a refrigerant is approved for use by Danfoss, it is added to the relevant portfolio, and the R number of the

refrigerant (e.g. R513A) will be added to the technical data of the code number. Therefore, products for specic

refrigerants are best checked at store.danfoss.com/en/, or by contacting your local Danfoss representative.

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 10

Page 11

Description

Values

Media temperature range

Media: -60 / +120 °C (-76 / +248 °F)

Max. working pressure

52 bar / 754 psi g

Description

Values

Temperature range (ambient)

-30 / +50 °C (-22 / +122 °F)

Enclosure

IP 67 (~NEMA 6)

ICAD 600A

ICAD 1200A

ICM 20

ICM 40

ICM 25

ICM 50

ICM 32

ICM 65

Motor operated valves and Actuators, type ICM and ICAD

Product specication

Pressure and temperature data

ICM

Table 5: Pressure and temperature data

Max. openening pressure dierential (MOPD)

• ICM 20-32: 52 bar / 750 psi

• ICM 40: 40 bar / 580 psi

• ICM 50: 30 bar / 435 psi

• ICM 65: 20 bar / 290 psi

• ICM 100 20 bar / 290 psi

• ICM 125 20 bar / 290 psi

• ICM 150 20 bar / 290 psi

Time to move from Closed to Open position or in reverse order with maximum selected speed at ICAD

• ICM 20: 3 Sec.

• ICM 25: 7 Sec.

• ICM 32: 8 Sec.

• ICM 40: 10 Sec.

• ICM 50: 13 Sec.

• ICM 65: 13 Sec.

• ICM 100: 25 Sec.

• ICM 125: 35 Sec.

• ICM 150: 45 Sec.

IMPORTANT:

When used in liquid refrigerant above 75 °C / 167 °F, please contact Danfoss.

ICAD

Table 6: Pressure and temperature data

Design

ICM

Valve body and top cover material

Low temperature steel

Surface protection

ICM 20 – 150: The external surface is zinc-chromated to provide good corrosion protection.

ICAD

ICAD 600A and ICAD 1200A can be used together with following Danfoss valves.

Table 7: Valve and actuator combination

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 11

Page 12

ICAD 600A

ICAD 1200A

ICM 100

ICM 125

ICM 150

ICV 20

ICV 25

ICV 32

ICV 40

ICV 50

ICV 65

ICV 100

ICV 125

ICV 150

Motor operated valves and Actuators, type ICM and ICAD

Materials

Housing

Aluminium

Top part of ICAD

PBT thermo plastic

Weight

• ICAD 600A: 1.2 kg / 2.64 lb

• ICAD 1200A: 1.9 kg / 4.19 lb

The ICM Concept

The ICM concept is developed around a modular principle. This gives the possibility of combining function modules

and top covers with special valve body size that is available in a variety of connection possibilities.

There are nine valve bodies available.

Table 8: Valve sizes

Table 9: Valve sizes

Valve bodies in the sizes ICV 20 – ICV 65 are available with a range of undersizes through oversized connection sizes

and types.

ICV 100 – ICV 150 are available in butt-weld DIN and butt-weld ANSI nominal sizes.

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 12

Page 13

DAJ

SOCSDSA

FPT

Butt-weld DIN

Butt-weld ANSI

Butt-weld JIS

Socket weld ANSI

Solder DIN

Solder ANSI

Female Pipe Thread

Actuator

ICAD 600A

ICAD 1200A

Valve size

ICM 20

ICM 40

ICM 25

ICM 50

ICM 32

ICM 65

-

ICM 100

-

ICM 125

-

ICM 150

Motor operated valves and Actuators, type ICM and ICAD

Table 10: Connections

ICM motor and ICAD actuator combinations

The ICM motor operated valve and ICAD actuator combinations are as follows:

Table 11: Valve and actuator combination

ICAD 600A / ICAD 1200A

ICAD actuators can be controlled using the following signals:

• 0 – 20 mA

• 4 – 20 mA (default)

• 0 – 10 V

• 2 – 10 V

• One or two digital Input

ICAD actuators can operate an ICM valve as an On / O function supported by one digital input.

ICAD actuators can operate an ICM valve as Neutral zone / 3 point control supported by two digital inputs.

The ICM valve can be operated manually via the ICAD actuator or the Multi-function tool for ICM (see the ordering

section).

Fail Safe supply options

In the event of a power failure, multiple fail safe options are possible, provided that a ICAD-UPS or similar is used.

During power failure, ICM can be selected to:

• Close ICM

• Open ICM

• Stay in the same position, as when power failure occurs

• Go to a specic ICM valve opening degree

See the section ICAD UPS for further information.

NOTE:

A fail safe supply (battery or UPS) is required.

Electrical

ICAD

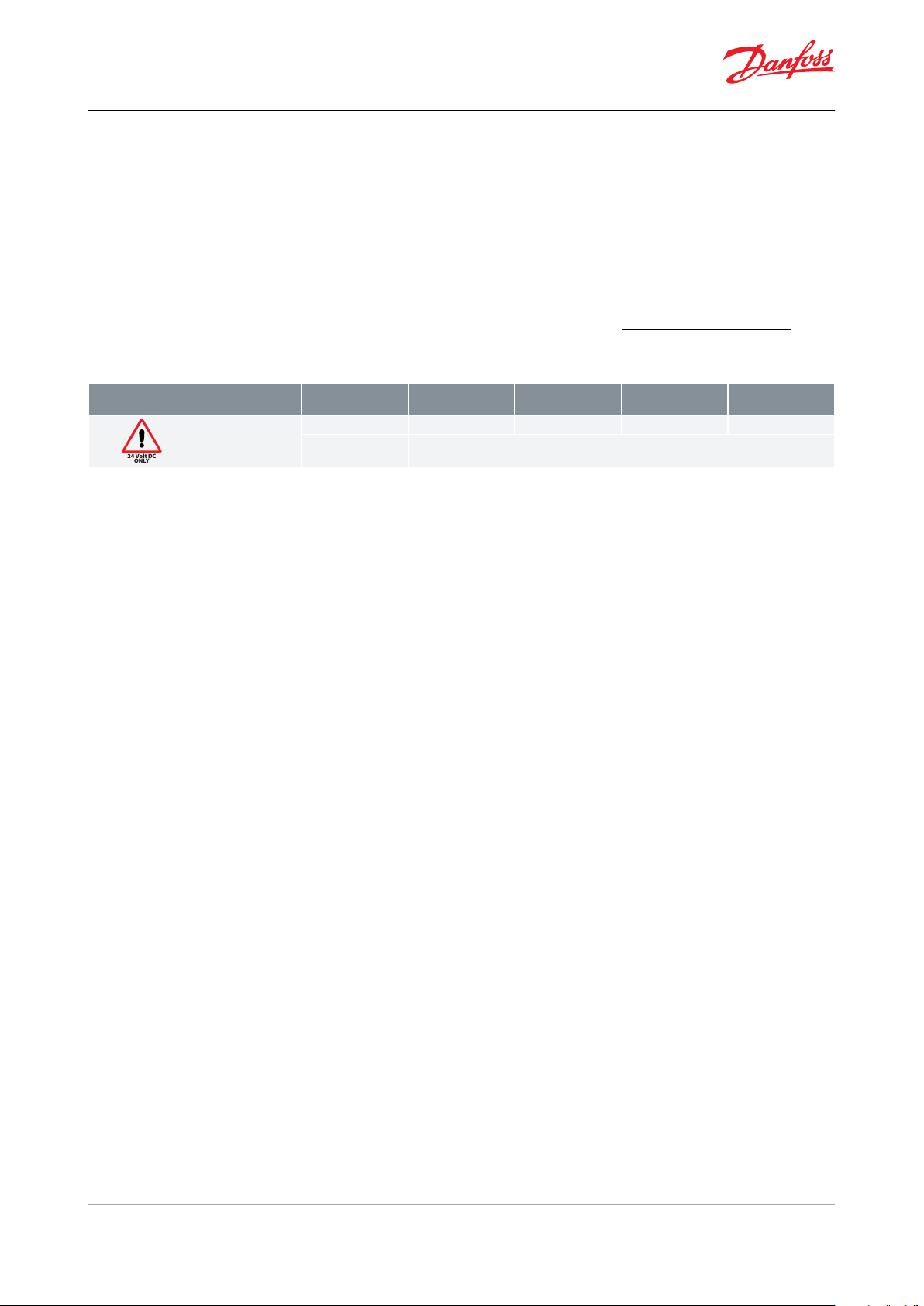

Electrical connection

Connection to ICAD is done via M12 connectors. ICAD has two M12 male connectors build-in:

Power supply:

4 poled M12 male connector

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 13

Page 14

Prefabricated ICAD cable length Code

number

1.5 m

027H0426

3 m

027H0438

10 m

027H0427

15 m

027H0435

24 Volt DC

ONLY

Voltage ICAD terminal

(600A / 1200A) [V DC]

Min.21222324

Max.

26.4

Motor operated valves and Actuators, type ICM and ICAD

Control signals:

8 poled M12 male connector

ICAD can be delivered with (1.5 m. / 60 in.) or without cables with M12 female connectors:

Power Supply cable with 4 poled M12 female connector: 3 x 0.34 mm2 (3 x ~22 AWG)

Control cable with 8 poled M12 female connector: 7 x 0.25 mm2 (7 x ~24 AWG)

Cable set with M12 female connectors in other lengths are available. See the section "Spare parts and accessories".

Please observe cable voltage drop

Distance between the applied DC transformer and the ICAD terminal box may cause a voltage drop. Cross section of

cables and size of DC transformer must be calculated so that the voltage at all time at the ICAD terminal box

(2)

,

both during standstill and during operation of ICAD, is within this range:

Table 12: Voltage at all time at the ICAD terminal box

Supply voltage is galvanic isolated from Input/Output

Supply voltage: see Table 12

Load:

• ICAD 600A: 1.2 A

• ICAD 1200A: 2.0 A

Fail safe supply: See Table 12

Load:

• ICAD 600A: 1.2 A

• ICAD 1200A: 2.0 A

Analogue Input - Current or Voltage

• Current: 0/4 – 20 mA

• Load: 200 W

• Voltage: 0/2 – 10 V DC

• Load : 10 kW

Analogue Output:

• Current: 0/4 – 20 mA

• Load : ≤ 250 W

Digital Input

Digital ON / OFF input by means of volt-free contact (Signal / Telecom relays with goldplated contacts

recommended) – Voltage input used

ON: Contact impedance < 50 W )

OFF: Contact impedance > 100 k W

Digital Output

• 3 pcs. NPN transistor output

• External supply:5 – 24 V DC (Same supply as for ICAD can be used, but please note that the galvanically isolated

system will then be spoiled)

• Output load: 50 W

• Load: Max. 50 mA

2

Do not measure inside the ICAD itself

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 14

Page 15

Type

ICAD 600A

Speed Parameter i04

ICM 20

ICM 25

ICM 32

Max. (i04 = 100)

2 mAh

5 mAh

5 mAh

Min. (i04 = 1)

200 mAh

467 mAh

533 mAh

ICAD 1200A

Speed Parameter i04

ICM 40

ICM 50

ICM 65

Max. (i04 = 100)

17 mAh

22 mAh

22 mAh

Min. (i04 = 1)

1667 mAh

2167 mAh

2167 mAh

ICAD 1200A

Speed Parameter i04

ICM 100

ICM 125

ICM 150

Max. (i04 = 100)

54 mAh

65 mAh

76 mAh

Min. (i04 = 1)

5318 mAh

6351 mAh

7501 mAh

Cable connection - Two 1.5 m / 60 in. cables pre-mounted

Control cable

Supply cable

Terminal box -

not supplied

by Danfoss

III

I

II

C

D

E

B

A

G

F

4 pin male connector

8 pin male connector

Ref.

Colour

Description

A

Black

–

Common Alarm

Digital Ouput

B

Brown

–

ICM fully open

C

Red

–

ICM fully closed

D

Orange

–

GND ground

E

Yellow

+

0/4 – 20 mA Input

(2)

Analogue In/Output

F

Green

+

0/2 – 10 V Input

(3)

G

Blue

+

0/4 – 20 mA Output

(2)

I

Black

+

Fail safe supply Battery / UPS

(4)

19 V DCIIWhite

+

Supply voltage 24 V DC

III

Brown

–

Motor operated valves and Actuators, type ICM and ICAD

Table 13: Battery capacity: For each open / closed cycle

Cable connection

Table 14: Cable connection - Two 1.5 m / 60 in. cables pre-mounted

Table 15: Cable connection

(2)

(2)

If Neutral zone / 3 point control is selected (parameter i02 = 3) then E and G are used as DI2 - Digital ON / OFF input

If Neutral zone / 3 point control is selected (parameter i02 = 3) then E and G are used as DI2 - Digital ON / OFF input

(3)

(3)

Also used with D (GND, ground) for DI1 - Digital ON-OFF operation

Also used with D (GND, ground) for DI1 - Digital ON-OFF operation

(4)

(4)

Uninterruptable Power Supply

Uninterruptable Power Supply

NOTE:

Colour code changed when compared to older colour wiring diagram.

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 15

Page 16

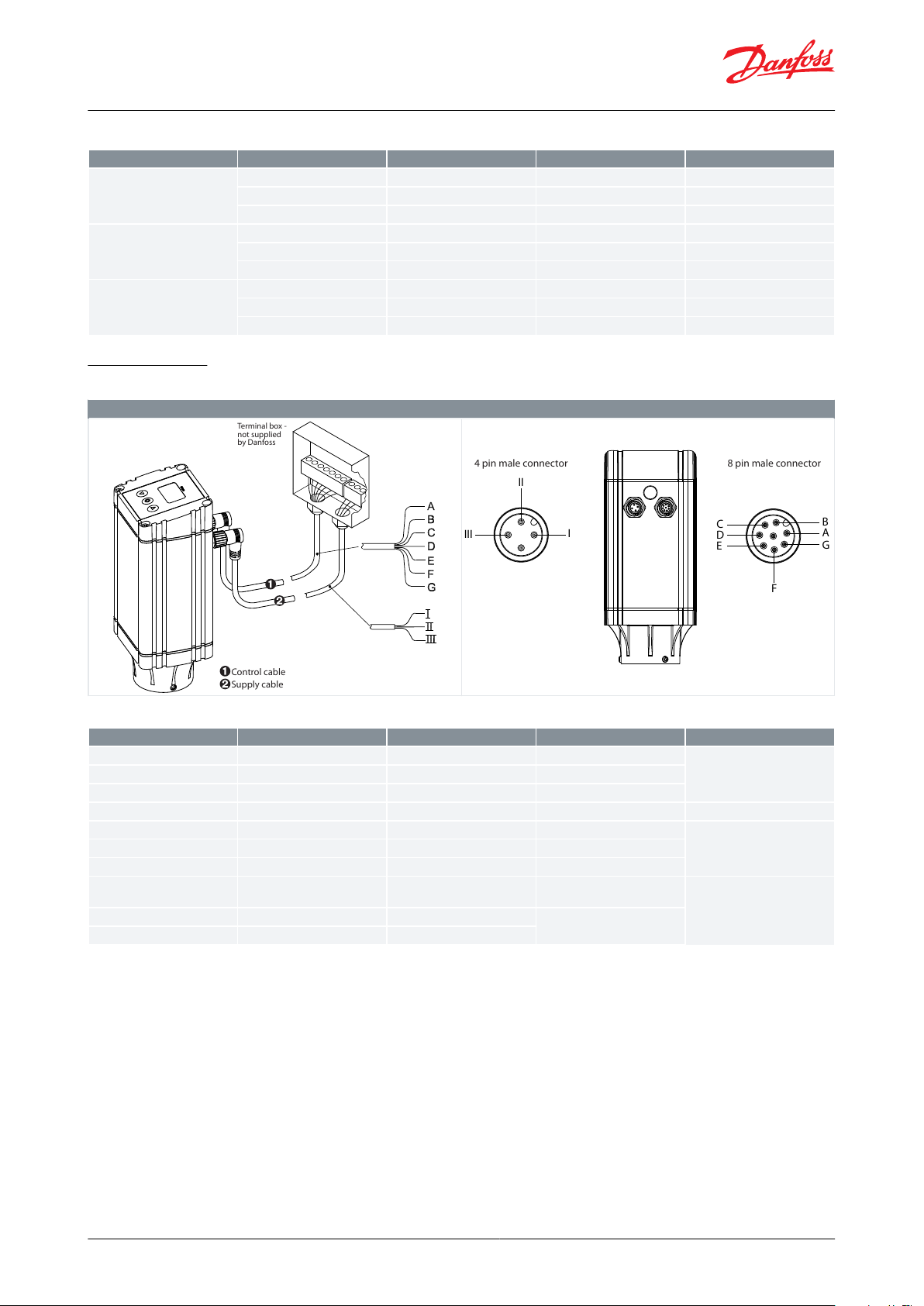

ICM 20

ICM 25-65

ICM 100 – 150

2c

4a

2a

2b

3

No.

Part

Material

EN

ASTM

JIS

1

Housing

Low temperature steel

G20Mn5QT, EN 10213-3

LCC, A352

SCPL1, G5151

2

Top cover

Low temperature steel

G20Mn5QT, EN 10213-3

LCC, A352

SCPL1, G5151

2a

O-ring

Chloroprene (Neoprene)

2b

O-ring

Chloroprene (Neoprene)

2c

O-ring

Chloroprene (Neoprene)

3

Function module

4

Gasket

Chloroprene (Neoprene)

4a

Gasket

Fiber, non-asbestos

5

Bolts

Stainless steel

A2-70, EN 1515-1

Grade B8 A320

A2-70, B 1054

11

Actuator

12

O-ring

Chloroprene (Neoprene)

13

O-ring

Chloroprene (Neoprene)

14

Seat

High density polymer

Type

Screw

Type

Screw

ICM 20

M10 × 55 A2-70 DIN 931

ICM 100

M20 × 60 A2-70 DIN 933

ICM 25

M12 × 30 A2-70 DIN 933

ICM 125

M20 × 60 A2-70 DIN 933

ICM 32

M14 × 35 A2-70 DIN 933

ICM 150

M20 × 70 A2-70 DIN 933

ICM 40

M14 × 35 A2-70 DIN 933

ICM 50

M16 × 40 A2-70 DIN 933

ICM 65

M16 × 40 A2-70 DIN 933

Motor operated valves and Actuators, type ICM and ICAD

Material specication

Table 16: ICM specication

NOTE:

Table 17: Bolt sizes (pos. 5)

Connections

There is a very wide range of connection types available with ICM valves:

• D: Butt weld, EN 10220

• A: Butt weld, ANSI (B 36.10)

• J: Butt weld, JIS (B S 602)

• SOC: Socket weld, ANSI (B 16.11)

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 16

Page 17

DAJ

SOCSDSA

FPT

Butt-weld DIN

Butt-weld ANSI

Butt-weld JIS

Socket weld ANSI

Solder DIN

Solder ANSI

Female Pipe Thread

Size

SizeØDTØDTmmin.mmmm

in.

in.

20

(

3

⁄4)

26.9

2.3

1.059

0.091251

33.7

2.6

1.327

0.103321

1

⁄4

42.4

2.6

1.669

0.102401

1

⁄2

48.3

2.6

1.902

0.103502

60.3

2.9

2.37

0.11652

1

⁄2

76.1

2.930.11803

88.9

3.2

3.5

0.13

1004114.3

3.6

4.5

0.14

1255140.745.5

0.16

1506168.3

6.3

6.6

0.25

Size

SizeØDTØDT

Schedulemmin.mmmm

in.

in.

-20

3

⁄4

26.941.059

0.15880-25133.7

4.6

1.327

0.18180-32

1

1

⁄4

42.4

4.9

1.669

0.19380-40

1

1

⁄2

48.3

5.1

1.902

0.20180-50260.3

3.9

2.37

0.1540-65

2

1

⁄2

73

5.2

2.87

0.240-80388.9

5.5

3.5

0.2240-1004114.364.5

0.24

-1255140.7

6.5

5.5

0.26

-1506168.3

7.1

6.6

0.28

Size

SizeØDTØDTmmin.mmmm

in.

in.

-20

3

⁄4

26.941.059

0.158

-25133.7

4.6

1.327

0.181

-32

1

1

⁄4

42.4

4.9

1.669

0.193

-40

1

1

⁄2

48.3

5.1

1.902

0.201

-50260.3

3.9

2.37

0.15

-65

2

1

⁄2

76.3

5.230.2

-80388.9

5.5

3.5

0.22

Motor operated valves and Actuators, type ICM and ICAD

• SD: Solder connection, EN 1254-1

• SA: Solder connection, ANSI (B 16.22)

• FPT: Female pipe thread (ANSI/ASME B 1.20.1)

Table 18: Connections

Table 19: D: Butt-weld DIN (2448)

Table 20: A: Butt-weld ANSI (B 36.10)

Table 21: J: Butt-weld JIS

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 17

Page 18

Size

SizeIDTIDTLLmmin.mmmm

in.

in.mmin.

-20

3

⁄4

27.2

4.6

1.071

0.181130.51

-25133.9

7.2

1.335

0.284130.51

-32

1

1

⁄4

42.7

6.1

1.743

0.24130.51

-40

1

1

⁄2

48.8

6.6

1.921

0.26130.51

-50261.2

6.2

2.41

0.24160.63

-65

2

1

⁄2

74

8.8

2.91

0.344160.63

SizeIDLmmmm

mm

16

16.071522

22.08

16.52828.082635

35.072542

42.072854

54.093376

76.1

33

SizeIDL

in.

in.

in.

5

⁄8

0.625

0.591

7

⁄8

0.875

0.65

1

1

⁄8

1.125

1.024

1

3

⁄8

1.375

0.984

1

5

⁄8

1.625

1.102

2

1

⁄8

2.125

1.3

2

5

⁄8

2.625

1.3

Size

Size

Inside pipe thread

mm

in.

-20

3

⁄4

(

3

⁄4 x 14 NPT)

-25

1

(1 x 11.5 NPT)

-32

1

1

⁄4

(1

1

⁄4 x 11.5 NPT)

Motor operated valves and Actuators, type ICM and ICAD

Table 22: SOC: Socket welding ANSI (B 16.11)

Table 23: SD: Soldering (DIN 2856)

Table 24: SA: Soldering (ANSI B 16.22)

Table 25: FPT: Female pipe thread, (ANSI/ASME B 1.20.1)

Dimensions and weights

ICM 20 / ICAD 600A

Figure 8: ICM 20 / ICAD 600A

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 18

Page 19

Connection

H

H1H

2

L

L1L

2

Weight ICM

incl. ICAD

20 D (

3

⁄4 in.)

mm4019585107

102653 kg

in.

1.58

7.68

3.35

4.21

4.02

2.56

6.6 lb.

25 D (1 in.)

mm4019585107

102653 kg

in.

1.58

7.68

3.35

4.21

4.02

2.56

6.6 lb.

25 A (1 in.)

mm4019585107

102653 kg

in.

1.58

7.68

3.35

4.21

4.02

2.56

6.6 lb.

20 A (

3

⁄4 in.)

mm4019585107

102653 kg

in.

1.58

7.68

3.35

4.21

4.02

2.56

6.6 lb.

20 SOC (

3

⁄4 in.)

mm4019585107

102653 kg

in.

1.58

7.68

3.35

4.21

4.02

2.56

6.6 lb.

16 SD (

5

⁄8 in.)

mm4019585107

102653 kg

in.

1.58

7.68

3.35

4.21

4.02

2.56

6.6 lb.

22 SD (

7

⁄8 in.)

mm4019585107

102653 kg

in.

1.58

7.68

3.35

4.21

4.02

2.56

6.6 lb.

16 SA (

5

⁄8 in.)

mm4019585107

102653 kg

in.

1.58

7.68

3.35

4.21

4.02

2.56

6.6 lb.

22 SA (

7

⁄8 in.)

mm4019585107

102653 kg

in.

1.58

7.68

3.35

4.21

4.02

2.56

6.6 lb.

20 FPT (

3

⁄4 in.)

mm4019585107

102653 kg

in.

1.58

7.68

3.35

4.21

4.02

2.56

6.6 lb.

Connection

H

H1H

2

L

L1L

2

Weight ICM

incl. ICAD

20 D (

3

⁄4 in.)

mm4019599135

102844.1 kg

in.

1.58

7.68

3.9

5.31

4.02

3.31

8.8 lb.

25 D (1 in.)

mm4019599135

102844.1 kg

in.

1.58

7.68

3.9

5.31

4.02

3.31

8.8 lb.

32 D (1

1

⁄4 in.)

mm4019599135

102844.1 kg

in.

1.58

7.68

3.9

5.31

4.02

3.31

8.8 lb.

40 D (1

1

⁄2 in.)

mm4019599135

102844.1 kg

in.

1.58

7.68

3.9

5.31

4.02

3.31

8.8 lb.

20 A (

3

⁄4 in.)

mm4019599135

102844.1 kg

in.

1.58

7.68

3.9

5.31

4.02

3.31

8.8 lb.

Motor operated valves and Actuators, type ICM and ICAD

Table 26: ICM 20 / ICAD 600A

NOTE:

D = Butt-weld DIN ; A = Butt-weld ANSI ; SOC = Socket weld ANSI ; SD = Solder DIN ; SA = Solder ANSI ; FPT =

Female Pipe Thread

ICM 25 / ICAD 600A

Figure 9: ICM 25 / ICAD 600A

Table 27: ICM 25 / ICAD 600A

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 19

Page 20

Connection

H

H1H

2

L

L1L

2

Weight ICM

incl. ICAD

25 A (1 in.)

mm4019599135

102844.1 kg

in.

1.58

7.68

3.9

5.31

4.02

3.31

8.8 lb.

32 A (1

1

⁄4 in.)

mm4019599135

102844.1 kg

in.

1.58

7.68

3.9

5.31

4.02

3.31

8.8 lb.

20 SOC (

3

⁄4 in.)

mm4019599135

102844.1 kg

in.

1.58

7.68

3.9

5.31

4.02

3.31

8.8 lb.

25 SOC (1 in.)

mm4019599148

102844.1 kg

in.

1.58

7.68

3.9

5.83

4.02

3.31

8.8 lb.

22 SD (

7

⁄8 in.)

mm4019599135

102844.1 kg

in.

1.58

7.68

3.9

5.31

4.02

3.31

8.8 lb.

28 SD (1

1

⁄8 in.)

mm4019599147

102844.1 kg

in.

1.58

7.68

3.9

5.79

4.02

3.31

8.8 lb.

22 SA (

7

⁄8 in.)

mm4019599135

102844.1 kg

in.

1.58

7.68

3.9

5.31

4.02

3.31

8.8 lb.

28 SA (1

1

⁄8 in.)

mm4019599147

102844.1 kg

in.

1.58

7.68

3.9

5.79

4.02

3.31

8.8 lb.

35 SD (1

3

⁄8 in.

SA)

mm4019599147

102844.1 kg

in.

1.58

7.68

3.9

5.79

4.02

3.31

8.8 lb.

20 FPT (

3

⁄4 in.)

mm4019599135

102844.1 kg

in.

1.58

7.68

3.9

5.31

4.02

3.31

8.8 lb.

25 FPT (1 in.)

mm4019599135

102844.1 kg

in.

1.58

7.68

3.9

5.31

4.02

3.31

8.8 lb.

Connection

H

H1H

2

L

L1L

2

Weight ICM

incl. ICAD

32 D (1

1

⁄4 in.)

mm40195

117

145

102

102

5.8 kg

in.

1.58

7.68

4.61

5.71

4.02

4.02

11.0 lb.

40 D (1

1

⁄2 in.)

mm40195

117

145

102

102

5.8 kg

in.

1.58

7.68

4.61

5.71

4.02

4.02

11.0 lb.

32 A (1

1

⁄4 in.)

mm40195

117

145

102

102

5.8 kg

in.

1.58

7.68

4.61

5.71

4.02

4.02

11.0 lb.

40 A (1

1

⁄2 in.)

mm40195

117

145

102

102

5.8 kg

in.

1.58

7.68

4.61

5.71

4.02

4.02

11.0 lb.

Motor operated valves and Actuators, type ICM and ICAD

NOTE:

D = Butt-weld DIN ; A = Butt-weld ANSI ; SOC = Socket weld ANSI ; SD = Solder DIN ; SA = Solder ANSI ; FPT =

Female Pipe Thread

ICM 32 / ICAD 600A

Figure 10: ICM 32 / ICAD 600A

Table 28: ICM 32 / ICAD 600A

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 20

Page 21

Connection

H

H1H

2

L

L1L

2

Weight ICM

incl. ICAD

32 SOC (1

1

⁄4 in.)

mm40195

117

147

102

102

5.8 kg

in.

1.58

7.68

4.61

5.79

4.02

4.02

11.0 lb.

35 SD (1

3

⁄8 in.

SA)

mm40195

117

148

102

102

5.8 kg

in.

1.58

7.68

4.61

5.83

4.02

4.02

11.0 lb.

42 SD (1

5

⁄8 in.)

mm40195

117

148

102

102

5.8 kg

in.

1.58

7.68

4.61

5.83

4.02

4.02

11.0 lb.

42 SA (1

5

⁄8 in.)

mm40195

117

148

102

102

5.8 kg

in.

1.58

7.68

4.61

5.83

4.02

4.02

11.0 lb.

Connection

H

H1H

2

L

L1L

2

Weight ICM

incl. ICAD

40 D (1

1

⁄2 in.)

mm45219

131

160

102

107

7.8 kg

in.

1.77

8.62

5.16

6.3

4.02

4.21

17.2 lb.

50 D (2 in.)

mm45219

131

180

102

107

7.8 kg

in.

1.77

8.62

5.16

7.09

4.02

4.21

17.2 lb.

40 A (1

1

⁄2 in.)

mm45219

131

160

102

107

7.8 kg

in.

1.77

8.62

5.16

6.3

4.02

4.21

17.2 lb.

50 A (2 in.)

mm45219

131

180

102

107

7.8 kg

in.

1.77

8.62

5.16

7.09

4.02

4.21

17.2 lb.

40 SOC (1

1

⁄2 in.)

mm45219

131

180

102

107

7.8 kg

in.

1.77

8.62

5.16

7.09

4.02

4.21

17.2 lb.

42 SD (1

5

⁄8 in.)

mm45219

131

180

102

107

7.8 kg

in.

1.77

8.62

5.16

7.09

4.02

4.21

17.2 lb.

42 SA (1

5

⁄8 in.)

mm45219

131

180

102

107

7.8 kg

in.

1.77

8.62

5.16

7.09

4.02

4.21

17.2 lb.

Motor operated valves and Actuators, type ICM and ICAD

NOTE:

D = Butt-weld DIN ; A = Butt-weld ANSI ; SOC = Socket weld ANSI ; SD = Solder DIN ; SA = Solder ANSI

ICM 40 / ICAD 1200A

Figure 11: ICM 40 / ICAD 1200A

Table 29: ICM 40 / ICAD 1200A

NOTE:

D = Butt-weld DIN ; A = Butt-weld ANSI ; SOC = Socket weld ANSI ; SD = Solder DIN ; SA = Solder ANSI

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 21

Page 22

Connection

H

H1H

2

L

L1L

2

Weight ICM

incl. ICAD

50 D (2 in.)

mm45219

159

200

102

125

11.1 kg

in.

1.77

8.62

6.26

7.87

4.02

4.92

24.4 lb.

65 D (2

1

⁄2 in.)

mm45219

159

210

102

125

11.1 kg

in.

1.77

8.62

6.26

8.27

4.02

4.92

24.4 lb.

50 A (2 in.)

mm45219

159

200

102

125

11.1 kg

in.

1.77

8.62

6.26

7.87

4.02

4.92

24.4 lb.

65 A (2

1

⁄2 in.)

mm45219

159

210

102

125

11.1 kg

in.

1.77

8.62

6.26

8.27

4.02

4.92

24.4 lb.

50 SOC (2 in.)

mm45219

159

216

102

125

11.1 kg

in.

1.77

8.62

6.26

8.5

4.02

4.92

24.4 lb.

54 SD (2

1

⁄8 in.

SA)

mm45219

159

216

102

125

11.1kg

in.

1.77

8.62

6.26

8.5

4.02

4.92

24.4 lb.

Motor operated valves and Actuators, type ICM and ICAD

ICM 50 / ICAD 1200A

Figure 12: ICM 50 / ICAD 1200A

Table 30: ICM 50 / ICAD 1200A

NOTE:

D = Butt-weld DIN ; A = Butt-weld ANSI ; SOC = Socket weld ANSI ; SD = Solder DIN

ICM 65 / ICAD 1200A

Figure 13: ICM 65 / ICAD 1200A

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 22

Page 23

Connection

H

H1H

2

L

L1L

2

Weight ICM

incl. ICAD

65 D (2

1

⁄2 in.)

mm45219

188

230

102

139

16.6 kg

in.

1.77

8.62

7.4

9.06

4.02

5.47

36.5 lb

80 D (3 in.)

mm45219

188

245

102

139

16.6 kg

in.

1.77

8.62

7.4

9.65

4.02

5.47

36.5 lb

65 A (2

1

⁄2 in.)

mm45219

188

230

102

139

16.6 kg

in.

1.77

8.62

7.4

9.06

4.02

5.47

36.5 lb

80 A (3 in.)

mm45219

188

245

102

139

16.6 kg

in.

1.77

8.62

7.4

9.65

4.02

5.47

36.5 lb

65 J (2

1

⁄2 in.)

mm45219

188

230

102

139

16.6 kg

in.

1.77

8.62

7.4

9.06

4.02

5.47

36.5 lb

65 SOC (2

1

⁄2 in.)

mm45219

188

230

102

139

16.6 kg

in.

1.77

8.62

7.4

9.06

4.02

5.47

36.5 lb

76 SD (3 in.)

mm45219

188

245

102

139

16.6 kg

in.

1.77

8.62

7.4

9.65

4.02

5.47

36.5 lb

67 SA (2

5

⁄8 in.)

mm45219

188

245

102

139

16.6 kg

in.

1.77

8.62

7.4

9.65

4.02

5.47

36.5 lb

H1

H

L

B1

B

H2

Connection

H

H1H

2

L

B

B

2

Weight ICM

incl. ICAD

100 D/A (4 in.)

mm

321

23845295

175

102

44 kg.

in.

12.64

9.37

1.77

11.61

6.89

4.02

97 lb.

Motor operated valves and Actuators, type ICM and ICAD

Table 31: ICM 65 / ICAD 1200A

NOTE:

D = Butt-weld DIN ; A = Butt-weld ANSI ; J = Butt-weld JIS ; SOC = Socket weld ANSI ; SD = Solder DIN ; SA =

Solder ANSI

ICM 100 / ICAD 1200A

Figure 14: ICM 100 / ICAD 1200A

Table 32: ICM 100 / ICAD 1200A

NOTE:

D = Butt-weld DIN ; A = Butt-weld ANSI

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 23

Page 24

B

B1

L

H1

H

H2

Connection

H

H1H

2

L

B

B

2

Weight ICM

incl. ICAD

125 D/A (5 in.)

mm

365

23845350

215

102

55 kg

in.

14.37

9.37

1.77

13.78

8.47

4.02

121 lb.

L

H H1

H2

B

B1

Connection

H

H1H

2

L

B

B

1

Weight ICM

incl. ICAD

150 D/A (6 in.)

mm

443

23845445

255

102

95 kg

in.

17.77

9.37

1.77

17.52

10.04

4.02

209 lb.

Motor operated valves and Actuators, type ICM and ICAD

ICM 125 / ICAD 1200A

Figure 15: ICM 125 / ICAD 1200A

Table 33: ICM 125 / ICAD 1200A

NOTE:

D = Butt-weld DIN ; A = Butt-weld ANSI

ICM 150 / ICAD 1200A

Figure 16: ICM 150 / ICAD 1200A

Table 34: ICM 150 / ICAD 1200A

NOTE:

D = Butt-weld DIN ; A = Butt-weld ANSI

NOTE:

Weight presented in tables 26 to 34 is approximated only

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 24

Page 25

Valve body 22 SD (

7

⁄8 in.)

027H1154

Table 36

Top cover/function mod‐

ule

ICM 20-B

027H1181

Table 37

Actuator

027H9075

Table 38

20 D (

3

⁄4 in.)

25 D (1 in.)

20 A (

3

⁄4 in.)

20 SOC (

3

⁄4 in.)

027H1145

027H1163

027H1148

027H1151

16 SA (

5

⁄8 in.)

22 SA (

7

⁄8 in.)

16 SD (

5

⁄8 in.)

22 SD

7

⁄8 in.)

027H1129

027H1160

027H1132

027H1154

20 FPT (

3

⁄4 in.)

25 A (1 in.)

027H1157

027H1166

Motor operated valves and Actuators, type ICM and ICAD

Ordering

Ordering from the parts programme

ICM 20 / ICAD 600A

Table 35: Example (select from table I, II and III)

Figure 17: ICV 20 valve body

Table 36: ICV 20 valve body w/dierent connections Table I

NOTE:

D = Butt-weld DIN ; A = Butt-weld ANSI ; J = Butt-weld JIS ; SOC = Socket weld ANSI ; SD = Solder DIN ; SA =

Solder ANSI ; FPT = Female Pipe Thread

Figure 18: ICM 20

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 25

Page 26

Description

Code Number

ICM 20-A33

027H1186

(1)

ICM 20-A

027H1180

(1)

ICM 20-B66

027H1194

(1)

ICM 20-B

027H1181

(1)

ICM 20-C

027H1182

(1)

Description

Code Number

ICAD 600A with 1.5 m. / 60 in. cables

027H9075

ICAD 600A without cables

027H9120

Available connections

Type

20 D (

3

⁄4 in.)

25 D (1 in.)

20 A (

3

⁄4 in.)

20 SOC (

3

⁄4

in.)

16 SA (

5

⁄8 in.)

22 SA (

7

⁄8 in.)

16 SD (

5

⁄8 in.)

22 SD (

7

⁄8 in.)

20 FPT (

3

⁄4

in.)

25 A (1 in.)

ICM 20-A

027H1030

027H1020

027H1035

027H1040

(2)

027H1050

(2)

027H1045

(2)

(2)

ICM 20-B

027H1031

027H1021

027H1036

027H1041

(2)

027H1051

(2)

027H1046

(2)

(2)

ICM 20-C

027H1032

027H1022

(2)

(2)

(2)

027H1052

(2)

027H1047

(2)

027H1025

Motor operated valves and Actuators, type ICM and ICAD

Table 37: ICM 20 Function module / top cover Table II

(1)

(1)

Bolts and O-ring (for assembly with ICV valve body) Seat and O-ring (for seat to be mounted in ICV valve body)

Bolts and O-ring (for assembly with ICV valve body) Seat and O-ring (for seat to be mounted in ICV valve body)

Figure 19: Actuator ICAD 600A

Table 38: Actuator ICAD 600A Table III

Ordering complete factory assembled valve without actuator

Figure 20: Valve without actuator

Table 39: Body, function module/top cover Table A

(2)

(2)

Select from parts programme

Select from parts programme

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 26

Page 27

Valve body 32 D (1

1

⁄4 in.)

027H2129

Table 41

Top cover/function mod‐

ule

ICM 25-B

027H2181

Table 42

Actuator

027H9075

Table 43

20 D (

3

⁄4 in.)

25 D (1 in.)

32 D (1

1

⁄4 in.)

40 D (1

1

⁄2 in.)

027H2128

027H2120

027H2129

027H2135

35 SD (1

3

⁄8 in. SA)

28 SA (1

1

⁄8 in.)

22 SA (

7

⁄8 in.)

28 SD (1

1

⁄8 in.)

027H2134

027H2126

027H2125

027H2124

22 SD (

7

⁄8 in.)

20 A (

3

⁄4 in.)

25 A (1 in.)

32 A (1

1

⁄4 in.)

027H2123

027H2131

027H2121

027H2130

20 SOC (

3

⁄4 in.)

25 SOC (1 in.)

20 FPT (

3

⁄4 in.)

25 FPT (1 in.)

027H2132

027H2122

027H2133

027H2127

Description

Code Number

ICM 25-A

027H2180

(1)

ICM 25-A33

027H2190

(1)

ICM 25-B

027H2181

(1)

Motor operated valves and Actuators, type ICM and ICAD

ICM 25 / ICAD 600A

Table 40: Example (select from table I, II and III)

Figure 21: ICV 25 valve body

Table 41: ICV 25 valve body w/dierent connections Table I

NOTE:

D = Butt-weld DIN ; A = Butt-weld ANSI ; J = Butt-weld JIS ; SOC = Socket weld ANSI ; SD = Solder DIN ; SA =

Solder ANSI ; FPT = Female Pipe Thread

Figure 22: ICM 25

Table 42: ICM 25 Function module / top cover Table II

(1)

(1)

Including gasket and O-rings

Including gasket and O-rings

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 27

Page 28

Description

Code Number

ICAD 600A with 1.5 m. / 60 in. cables

027H9075

ICAD 600A without cables

027H9120

Available connections

Type

20 D (

3

⁄4 in.)

25 D (1 in.)

32 D (1

1

⁄4 in.)

40 D (1

1

⁄2 in.)

35 SD (1

3

⁄8 in.

SA)

28 SA (1

1

⁄8 in.)

22 SA (

7

⁄8 in.)

28 SD (1

1

⁄8 in.)

ICM 25-A

(1)

027H2000

(1)

027H2016

027H2014

027H2012

027H2010

027H2008

ICM 25-B

(1)

027H2001

(1)

(1)

027H2015

027H2013

027H2011

027H2009

22 SD (

7

⁄8 in.)

20 A (

3

⁄4 in.)

25 A (1 in.)

32 A (1

1

⁄4 in.)

20 SOC (

3

⁄4 in.)

25 SOC (1 in.)

20 FPT (

3

⁄4 in.)

25 FPT (1 in.)

ICM 25-A

027H2006

(1)

027H2002

(1)

(1)

027H2004

(1)

(1)

ICM 25-B

027H2007

(1)

027H2003

(1)

(1)

027H2005

(1)

(1)

Valve body 40 D (1

1

⁄2 in.)

027H3125

Table 46

Top cover/function mod‐

ule

ICM 32-A

027H3180

Table 47

Actuator

027H9075

Table 48

Motor operated valves and Actuators, type ICM and ICAD

Figure 23: Actuator ICAD 600A

Table 43: Actuator ICAD 600A Table III

Ordering complete factory assembled valve without actuator

Figure 24: Valve without actuator

Table 44: Body, function module / top cover Table A

(1)

(1)

Select from parts programme

Select from parts programme

ICM 32 / ICAD 600A

Table 45: Example (select from table I, II and III)

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 28

Page 29

32 D (1

1

⁄4 in.)

40 D (1

1

⁄2 in.)

42 SA (1

5

⁄8 in.)

42 SD (1

5

⁄8 in.)

027H3120

027H3125

027H3127

027H3128

35 SD (1

3

⁄8 in. SA)

32 A (1

1

⁄4 in.)

32 SOC (1

1

⁄4 in.)

40 A (1

1

⁄2 in.)

027H3123

027H3121

027H3122

027H3126

Description

Code Number

ICM 32-A

027H3180

(1)

ICM 32-B

027H3181

(1)

Description

Code Number

ICAD 600A with 1.5 m. / 60 in. cables

027H9075

ICAD 600A without cables

027H9120

Motor operated valves and Actuators, type ICM and ICAD

Figure 25: ICV 32 valve body

Table 46: ICV 32 valve body w/dierent connections Table I

NOTE:

D = Butt-weld DIN ; A = Butt-weld ANSI ; J = Butt-weld JIS ; SOC = Socket weld ANSI ; SD = Solder DIN ; SA =

Solder ANSI ; FPT = Female Pipe Thread

Figure 26: ICM 32

Table 47: ICM 32 Function module / top cover Table II

(1)

(1)

Including gasket and O-rings

Including gasket and O-rings

Figure 27: Actuator ICAD 600A

Table 48: Actuator ICAD 600A Table III

Ordering complete factory assembled valve without actuator

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 29

Page 30

Available connections

32 D (1

1

⁄4 in.)

40 D (1

1

⁄2 in.)

42 SA (1

5

⁄8 in.)

42 SD (1

5

⁄8 in.)

35 SD (1

3

⁄8 in.

SA)

32 A (1

1

⁄4 in.)

32 SOC (1

1

⁄4 in.)

40 A (1

1

⁄2 in.)

ICM 32-A

027H3000

027H3012

027H3008

(2)

027H3006

027H3002

027H3004

(2)

ICM 32-B

027H3001

(2)

(2)

(2)

027H3007

027H3003

027H3005

(2)

Valve body A 40 (1

1

⁄2 in.)

027H4121

Table 51

Top cover/function mod‐

ule

ICM 40-A

027H4180

Table 52

Actuator

027H9077

Table 53

40 D (1

1

⁄2 in.)

50 D (2 in.)

42 SA (1

5

⁄8 in.)

42 SD (1

5

⁄8 in.)

027H4120

027H4126

027H4124

027H4123

40 A (1

1

⁄2 in.)

40 SOC (1

1

⁄2 in.)

50 A (2 in.)

027H4121

027H4122

027H4127

Motor operated valves and Actuators, type ICM and ICAD

Figure 28: Valve without actuator

Table 49: Body, function module / top cover Table A

(2)

(2)

Select from parts programme

Select from parts programme

ICM 40 / ICAD 1200A

Table 50: Example (select from table I, II and III)

Figure 29: ICV 40 valve body

Table 51: ICV 40 valve body w/dierent connections Table I

NOTE:

D = Butt-weld DIN ; A = Butt-weld ANSI ; J = Butt-weld JIS ; SOC = Socket weld ANSI ; SD = Solder DIN ; SA =

Solder ANSI ; FPT = Female Pipe Thread

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 30

Page 31

Description

Code Number

ICM 32-A

027H3180

(1)

ICM 32-B

027H3181

Description

Code Number

ICAD 1200A with 1.5 m. / 60 in. cables

027H9077

ICAD 1200A without cables

027H9122

Available connections

Type

40 D (1

1

⁄2 in.)

50 D (2 in.)

42 SA (1

5

⁄8 in.)

42 SD (1

5

⁄8 in.)

40 A (1

1

⁄2 in.)

40 SOC (1

1

⁄2 in.)

50 A (2 in.)

ICM 40-A

027H4000

027H4010

027H4006

027H4008

027H4002

027H4004

(2)

ICM 40-B

027H4001

(2)

027H4007

027H4009

027H4003

027H4005

(2)

Motor operated valves and Actuators, type ICM and ICAD

Figure 30: ICM 40

Table 52: ICM 40 Function module / top cover Table II

(1)

(1)

Including gasket and O-rings

Including gasket and O-rings

Figure 31: Actuator ICAD 1200A

Table 53: Actuator ICAD 1200A Table III

Ordering complete factory assembled valve without actuator

Figure 32: Valve without actuator

Table 54: Body, function module/top cover Table A

(2)

(2)

Select from parts programme

Select from parts programme

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 31

Page 32

Valve body 65 D (1

1

⁄2 in.)

027H5124

Table 56

Top cover/function mod‐

ule

ICM 50-A

027H4180

Table 57

Actuator

027H9077

Table 58

50 D (2 in.)

65 D (2

1

⁄2 in.)

54 SD (2

1

⁄8 in. SA)

50 A (2 in.)

027H5120

027H5124

027H5123

027H5121

50 SOC (2 in.)

65 A (2

1

⁄2 in.)

027H5122

027H5125

Description

Code Number

ICM 50-A

027H5180

(1)

ICM 50-B

027H5181

(1)

Motor operated valves and Actuators, type ICM and ICAD

ICM 50 / ICAD 1200A

Table 55: Example (select from table I, II and III)

Figure 33: ICV 50 valve body

Table 56: ICV 50 valve body w/dierent connections Table I

Figure 34: ICM 50

Table 57: ICM 50 Function module / top cover Table II

(1)

(1)

Including gasket and O-rings

Including gasket and O-rings

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 32

Page 33

Description

Code Number

ICAD 1200A with 1.5 m. / 60 in. cables

027H9077

ICAD 1200A without cables

027H9122

Available connections

Type

50 D (2 in.)

65 D (2

1

⁄2 in.)

54 SD (2

1

⁄8 in. SA)

50 A (2 in.)

50 SOC (2 in.)

65 A (2

1

⁄2 in.)

ICM 50-A

027H5000

027H5008

027H5006

027H5002

027H5004

(2)

ICM 50-B

027H5001

(2)

027H5007

027H5003

027H5005

(2)

Valve body 65 J (2

1

⁄2 in.)

027H6122

Table 61

Top cover/function mod‐

ule

ICM 65-B

027H6181

Table 62

Actuator

027H9077

Table 63

Motor operated valves and Actuators, type ICM and ICAD

Figure 35: Actuator ICAD 1200A

Table 58: Actuator ICAD 1200A Table III

Ordering complete factory assembled valve without actuator

Figure 36: Valve without actuator

Table 59: Body, function module / top cover Table A

(2)

(2)

Select from parts programme

Select from parts programme

ICM 65 / ICAD 1200A

Table 60: Example (select from table I, II and III)

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 33

Page 34

65 D (2

1

⁄2 in.)

65 A (2

1

⁄2 in.)

65 J (2

1

⁄2 in.)

80 D (3 in.)

027H6120

027H6121

027H6122

027H6126

80 A (3 in.)

67 SA (2

5

⁄8 in.)

76 SD (3 in.)

65 SOC (2

1

⁄2 in.)

027H6127

027H6125

027H6124

027H6123

Description

Code Number

ICM 65-A

027H6180

(1)

ICM 65-B

027H6181

(1)

Description

Code Number

ICAD 1200A with 1.5 m. / 60 in. cables

027H9077

ICAD 1200A without cables

027H9122

Motor operated valves and Actuators, type ICM and ICAD

Figure 37: ICV 65 valve body

Table 61: ICV 65 valve body w/dierent connections Table I

NOTE:

D = Butt-weld DIN ; A = Butt-weld ANSI ; J = Butt-weld JIS ; SOC = Socket weld ANSI ; SD = Solder DIN ; SA =

Solder ANSI ; FPT = Female Pipe Thread

Figure 38: ICM 65

Table 62: ICM 65 Function module / top cover Table II

(1)

(1)

Including gasket and O-rings

Including gasket and O-rings

Figure 39: Actuator ICAD 1200A

Table 63: Actuator ICAD 1200A Table III

Ordering complete factory assembled valve without actuator

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 34

Page 35

Available connections

Type

65 D (2

1

⁄2 in.)

65 A (2

1

⁄2 in.)

65 J (2

1

⁄2 in.)

80 D (3 in.)

80 A (3 in.)

67 SA (2

5

⁄8 in.)

76 SD (3 in.)

65 SOC (2

1

⁄2 in.)

ICM 65-A

027H6010

027H6012

(2)

(2)

(2)

(2)

(2)

(2)

ICM 65-B

027H6001

027H6003

(2)

(2)

(2)

027H6007

027H6009

027H6005

Available connections

Type

100 D (4 in.)

100 A (4 in.)

ICM 100

027H7130

027H7131

Description

Code Number

ICAD 1200A with 1.5 m. / 60 in. cables

027H9077

ICAD 1200A without cable

027H9122

Motor operated valves and Actuators, type ICM and ICAD

Figure 40: Valve without actuator

Table 64: Body, function module / top cover Table A

(2)

(2)

Select from parts programme

Select from parts programme

ICM 100

Complete factory assembled valve without actuator

Figure 41: Body, function module / top cover Figure 42: ICM 100 Valve body

Table 65: Body, function module / top cover

Figure 43: Actuator ICAD 1200A

Table 66: Actuator ICAD 1200A

ICM 125

Complete factory assembled valve without actuator

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 35

Page 36

Available connections

Type

125 D (5 in.)

125 A (5 in.)

ICM 125

027H7150

027H7151

Description

Code Number

ICAD 1200A with 1.5 m. / 60 in. cables

027H9077

ICAD 1200A without cable

027H9122

Available connections

Type

150 D (6 in.)

150 A (6 in.)

ICM 150

027H7170

027H7171

Motor operated valves and Actuators, type ICM and ICAD

Figure 44: Body, function module / top cover Figure 45: ICM 100 Valve body

Table 67: Body, function module / top cover

Figure 46: Actuator ICAD 1200A

Table 68: Actuator ICAD 1200A

ICM 150

Complete factory assembled valve without actuator

Figure 47: Body, function module / top cover Figure 48: ICM 100 Valve body

Table 69: Body, function module / top cover

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 36

Page 37

Description

Code Number

ICAD 1200A with 1.5 m. / 60 in. cables

027H9077

ICAD 1200A without cable

027H9122

Description

Code no.

ICV 25 PM Valve housing

027H2119

(1)

ICV 32 PM Valve housing

027H3129

(1)

ICV 40 PM Valve housing

027H4128

(1)

ICV 50 PM Valve housing

027H5127

(2)

ICV 65 PM Valve housing

027H6128

(2)

Motor operated valves and Actuators, type ICM and ICAD

Figure 49: Actuator ICAD 1200A

Table 70: Actuator ICAD 1200A

Accessories

ICV PM anged valve housings

Figure 50: ICV PM anged valve housings

ICV PM anged valve housings

ICV PM anged valve housings can replace the PM valves on already installed refrigeration systems.

Pressure range

The ICV PM valve housing is designed for a max. working pressure of 28 bar g / 406 psig and therefore a suitable

replacement for PM valves in the service market. They also oer the same drop-in dimensions as the PM valves.

Table 71: ICV PM anged valve housings

(1)

(1)

Includes ICV PM valve housing,

Includes ICV PM valve housing,

(2)

(2)

Includes ICV PM valve housing,

Includes ICV PM valve housing,

ange gaskets and ange bolts

ange gaskets and ange bolts

ange gaskets, ange bolts and ange nuts

ange gaskets, ange bolts and ange nuts

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 37

Page 38

PM

REMOVE

ICV PM

ICV PM

DROP IN

ICM

ICS

ICLX

CUSTOMIZE

Description

Code no.

ICV 25 (H)A4A Valve housing

027H2304

(1)

ICV 32 A4A Valve housing

027H3130

(1)

ICV 32 HA4A Valve housing

027H3131

(1)

ICV 40 (H)A4A Valve housing

027H4129

(1)

ICV 50 (H)A4A Valve housing

027H5128

(2)

ICV 65 (H)A4A Valve housing

027H6129

(2)

Motor operated valves and Actuators, type ICM and ICAD

Figure 51: ICV PM anged valve housings assembly

NOTE:

Function modules and top covers must be ordered separately (see the section Page 25).

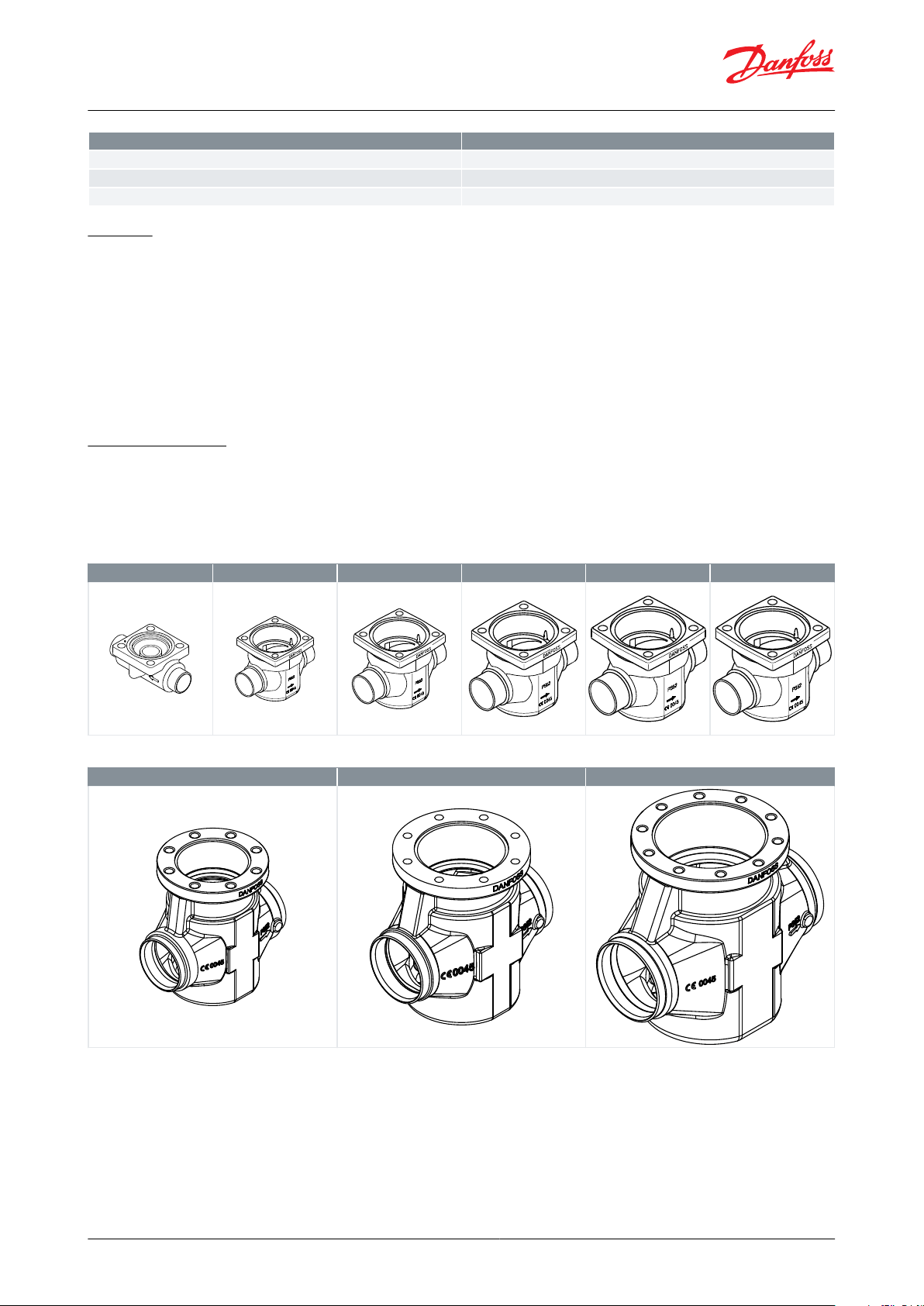

ICV (H)A4A anged valve housings

Figure 52: ICV (H)A4A anged valve housings

ICV (H)A4A anged valve housings

ICV (H)A4A anged valve housings can replace the (H)A4A valves on already installed refrigeration systems.

The ICV (H)A4A anged valve housing provides an upgrade of the old motor valve types HMMR and HMMV to ICM

motorized valve as a drop-in solution.

Pressure range

The ICV (H)A4A valve housing is designed for a max. working pressure of 28 bar g / 406 psig and therefore a suitable

replacement for (H)A4A valves in the service market. They also oer the same drop-in dimensions as the (H)A4A

valves.

Table 72: ICV (H)A4A anged valve housings

(1)

(1)

Includes ICV PM valve housing,

Includes ICV PM valve housing,

(2)

(2)

Includes ICV PM valve housing,

Includes ICV PM valve housing,

ange gaskets and ange bolts

ange gaskets and ange bolts

ange gaskets, ange bolts and ange nuts

ange gaskets, ange bolts and ange nuts

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 38

Page 39

(H)A4A

REMOVE

ICV (H)A4A

ICV (H)A4A

DROP IN

ICM

ICS

ICLX

CUSTOMIZE

Description

Code Number

Repair kit

ICM 20-A / ICM 20-A-33 (Metal with plastic seat)

ICM 20-B / ICM 20-C (Plastic seat)

027H1190

Connectors for ICAD 600A / 1200A

Connector type

Code Number

Two Female Connectors with screw terminals:

• connector for power

• connector for control signals

027H0430

Motor operated valves and Actuators, type ICM and ICAD

Figure 53: ICV (H)A4A anged valve housings assembly

NOTE:

Function modules and top covers must be ordered separately (see the section Page 25).

ICM 20 / ICAD 600A

Figure 54: Repair kit

Table 73: Spare parts

Figure 55: Connectors

Table 74: Accessories

Figure 56: ICAD-UPS

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 39

Page 40

Description

Code Number

ICAD-UPS

027H0388

Description

Code Number

Multi-function tool

027H0180

Connectors for ICAD 600A / 1200A

Cable length

Code Number

Cable set 1.5 m, female

027H0426

Cable set 3 m, female

027H0438

Cable set 10 m, female

027H0427

Cable set 15 m, female

027H0435

Protection cap ICAD 600A / 1200A

Description

Code Number

Protection cap

027H0431

Motor operated valves and Actuators, type ICM and ICAD

Table 75: Accessories

Figure 57: Multi-function tool

Table 76: Accessories

Figure 58: Cable

Table 77: Accessories

Figure 59: Protection cap

Table 78: Accessories

NOTE:

Please observe, when used in CO2, that the o-rings on the ICM module can swell (grow). At service it is recommend

that new o-rings are installed before the ICM functions module again is installed in the ICV valve body.

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 40

Page 41

Description

Code Number

ICM 25 Inspection kit

027H2218

ICM 32 Inspection kit

027H3016

Connectors for ICAD 600A / 1200A

Connector type

Code Number

Two Female Connectors with screw terminals:

• connector for power

• connector for control signals

027H0430

Description

Code Number

ICAD-UPS

027H0388

Description

Code Number

Multi-function tool

027H0180

Motor operated valves and Actuators, type ICM and ICAD

ICM 25 – 32 / ICAD 600A

Figure 60: Inspection kit

Table 79: Spare parts

Figure 61: Connectors

Table 80: Accessories

Figure 62: ICAD-UPS

Table 81: Accessories

Figure 63: Multi-function tool

Table 82: Accessories

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 41

Page 42

Cable for ICAD 600A / 1200A

Cable length

Code Number

Cable set 1.5 m, female

027H0426

Cable set 3 m, female

027H0438

Cable set 10 m, female

027H0427

Cable set 15 m, female

027H0435

Protection cap ICAD 600A / 1200A

Description

Code Number

Protection cap

027H0431

Description

Code Number

ICM 40 Inspection kit

027H4014

ICM 50 Inspection kit

027H5014

ICM 65 Inspection kit

027H6016

Motor operated valves and Actuators, type ICM and ICAD

Figure 64: Cable

Table 83: Accessories

Figure 65: Protection cap

Table 84: Accessories

NOTE:

Please observe, when used in CO2, that the o-rings on the ICM module can swell (grow). At service it is recommend

that new o-rings are installed before the ICM functions module again is installed in the ICV valve body.

ICM 40 – 50 – 65 / ICAD 1200A

Figure 66: Inspection kit

Table 85: Spare parts

Figure 67: Connectors

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 42

Page 43

Connectors for ICAD 600A / 1200A

Connector type

Code Number

Two Female Connectors with screw terminals:

• connector for power

• connector for control signals

027H0430

Description

Code Number

ICAD-UPS

027H0388

Description

Code Number

Multi-function tool

027H0181

Cable for ICAD 600A / 1200A

Cable length

Code Number

Cable set 1.5 m, female

027H0426

Cable set 3 m, female

027H0438

Cable set 10 m, female

027H0427

Cable set 15 m, female

027H0435

Motor operated valves and Actuators, type ICM and ICAD

Table 86: Accessories

Figure 68: ICAD-UPS

Table 87: Accessories

Figure 69: Multi-function tool

Table 88: Accessories

Figure 70: Cable

Table 89: Accessories

Figure 71: Protection cap

© Danfoss | Climate Solutions | 2021.12 AI236186442940en-001201 | 43

Page 44

Protection cap ICAD 600A / 1200A

Description

Code Number

Protection cap

027H0431

Top covers

Size

Code number

ICM 100

027H7133

ICM 125

027H7153

ICM 150

027H7173

Description

Code Number

ICAD-UPS

027H0388

Cable for ICAD 600A / 1200A

Cable length

Code Number

Cable set 1.5 m, female

027H0426

Cable set 3 m, female

027H0438