Data Sheet

Valve station

Type ICF SS 20 and ICF SS 25

A complete range of modern, exible stainless steel components

for Industrial refrigeration

Based on advanced technology the ICF SS valve

station incorporates several functions in one

housing, which can replace a series of

conventional mechanical, electro-mechanical

and electronically operated valves.

This valve station not only provides a number

of advantages in the design phase of a

refrigeration plant but also in the installation,

service and maintenance.

The ICF SS valve stations are designed for low

and high pressure refrigerants and can be used

in pumped liquid lines, liquid injection lines

and hot gas lines.

Supplied as a complete assembly, it is fully

tested at high pressure and its functions are

tested under factory controlled conditions.

One code number equals one application

solution.

AI243586442520en-000901

Valve station, Type ICF SS 20 and ICF SS 25

Features

• Designed for industrial refrigeration applications for a maximum working pressure of 52 bar / 754 psig

• Applicable to HCFC, non ammable HFC, R717 (Ammonia) and R744 (CO2). The use of ICF SS valve stations with

ammable hydrocarbons is not recommended

• Direct weld connections (No leaks through anges)

• Stainless steel valve housing and function modules

• Low weight and compact design

• V-port regulating cones on the control modules ensure optimum regulating accuracy particularly at part load

• Modular Concept

◦ Each housing is available with butt-weld DIN connections in several sizes. Valve service is performed by

replacing the function module

• Side ports for the connection of pressure gauges, transmitters, sight glasses, service valve etc

• UL approved

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 2

Application #

Sequence of functions

1

Liquid feed (No hotgas defrost)

Stop

Filter

Solenoid

Man Open

Regul.

Stop2Liquid feed

Stop

Filter

Solenoid

Man Open

Regul.

Stop/Check

3

Liquid feed

Stop

Filter

Solenoid

Check

Regul.

Stop10Liquid feed (No hotgas defrost)

Stop

Filter

Solenoid

Regul.

15

Liquid feed with external connection

Stop

Filter

Solenoid

Check

Welding

Regul.

Application #

Sequence of functions

5

Liquid injection (expansion)

Stop

Filter

Solenoid

Man Open

Motor

Stop14Liquid injection (expansion)

Stop

Filter

Motor

Stop

Application #

Sequence of functions

9

Hot gas defrost

Stop

Filter

Solenoid

Solenoid

Application #

Sequence of functions

90

Multipurpose

congurations

ICFE SS

ICFR SS

ICFF SS

ICFB SS

ICFS SS

ICFS SS

EKC 202

AKS 12

SVA

To liquid

separator

From liquid

separator

Evaporator

Valve station, Type ICF SS 20 and ICF SS 25

Applications

To facilitate selection of the right ICF SS valve station Danfoss has predened and grouped a large number of code

numbers matching common applications:

Liquid feed

Table 1: Liquid feed

Liquid injection

Table 2: Liquid injection

Hot gas defrost

Table 3: Hot gas defrost

Miscellaneous

Table 4: Miscellaneous

NOTE:

For specic identication of the dierent codes and ow capacity (Kv) please refer to ordering section.

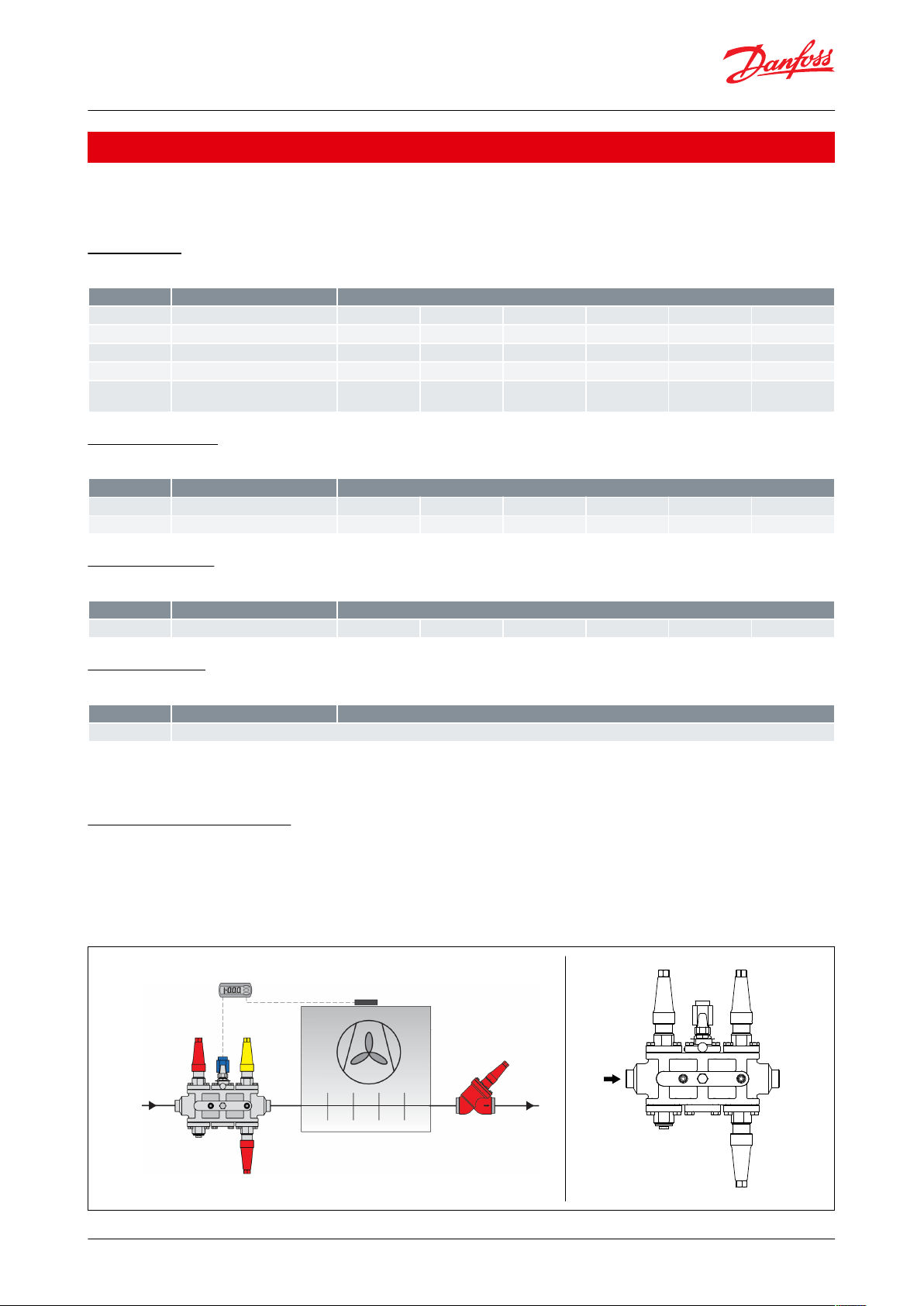

Examples of application:

Liquid feed line

A valve combination for a ooded evaporator operating on/o from a thermostat and with electric defrost is

required. Manual override of the solenoid valve is requested. Common ICF SS congurations for this kind of

application is shown here:

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 3

ICFE SS

ICFR SS

ICFF SS

ICFB SS

ICFS SS

ICFS SS

To liquid separator

From

discharge

line

ICLX/GPLX

CVP

ICS

From liquid separator

ICFS SS

ICFE SS

ICFF SS

ICFF SS

ICFS SS

ICFE SS

ICM

ICFF SS

ICFB SS

ICFS SS

To compressor

suction line

AKS 4100

AKS 38

EKE 347

From

receiver

From

evaporator

SVA

SVA

SNV

SNV

SVASVA

SVA

SVA

SFV SFV

DSV

To evaporator

LLG

Liquid separator

Valve station, Type ICF SS 20 and ICF SS 25

NOTE:

Not all valves are shown. Not to be used for construction purposes.

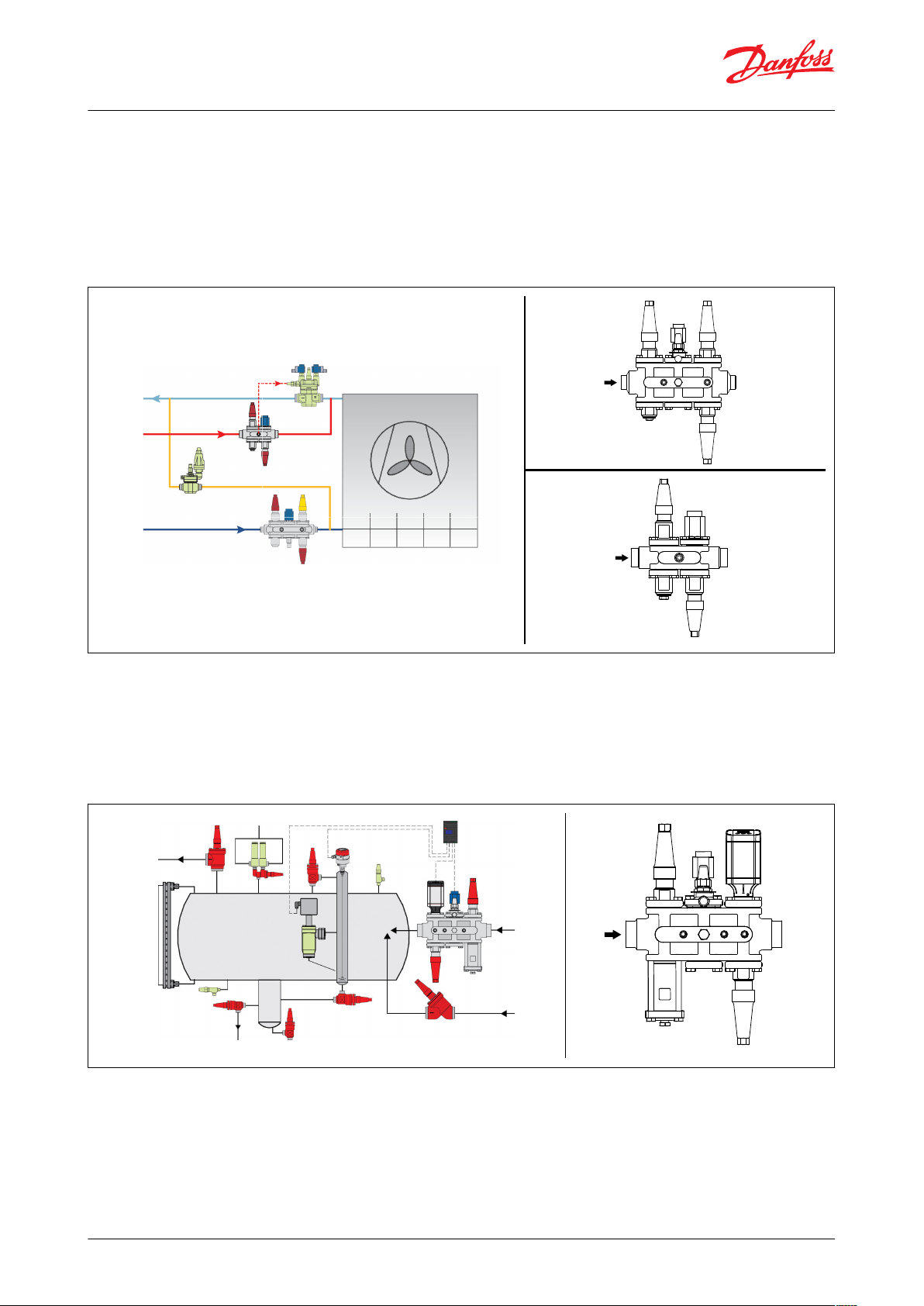

Liquid feed line/Hot gas defrost line

Evaporator with soft opening gas powered valve ICLX in the suction line and hot gas defrost featuring: ICF SS liquid

feed station and ICF SS Hot gas station with side port to power ICLX. ICS+CVP as a defrost regulator (OFV optional

depending on capacity).

Not all valves are shown. Not to be used for construction purposes.

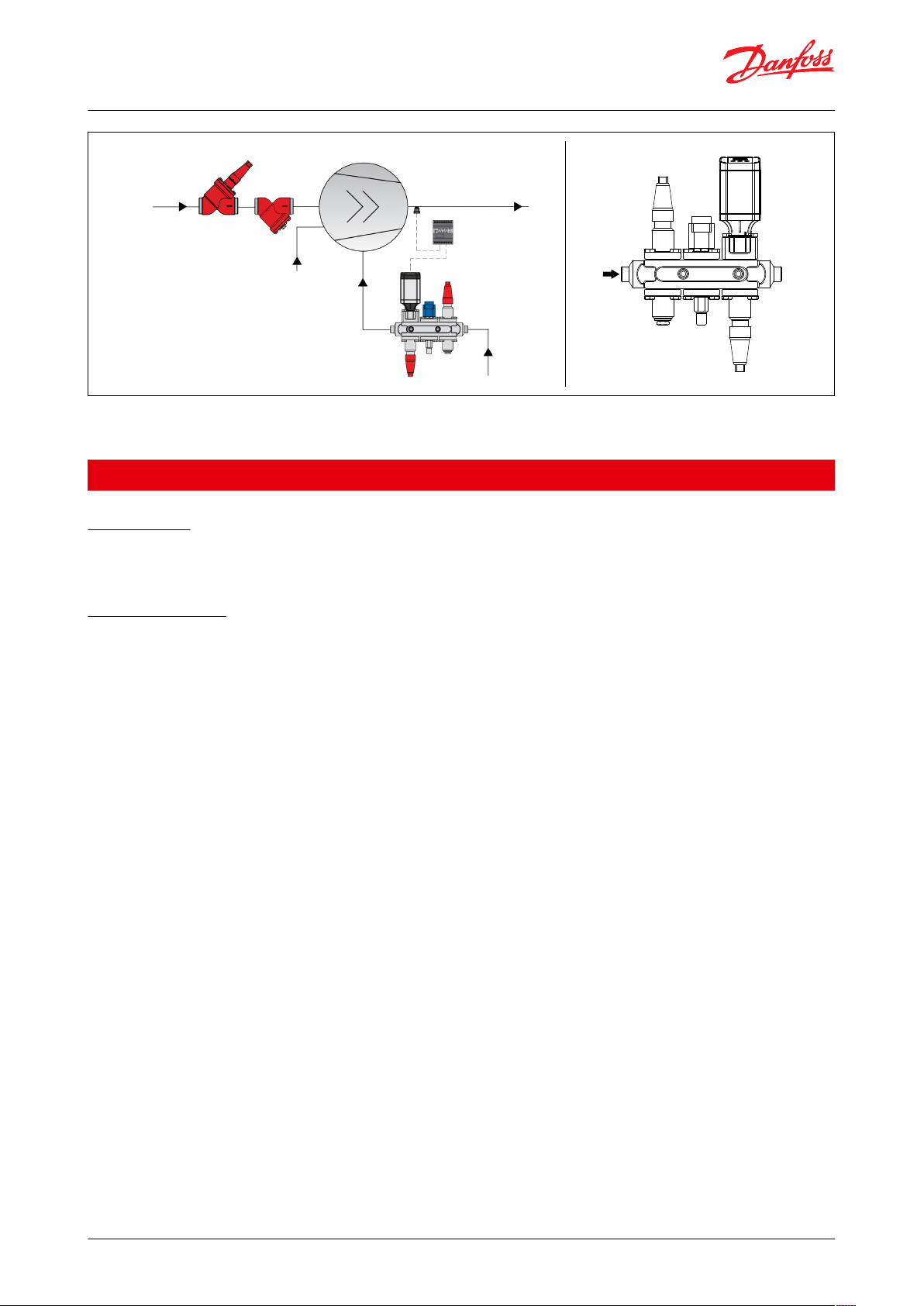

Liquid injection line

A valve combination for liquid injection to separator with electronic injection valve is required. It is requested to

have a solenoid valve in front of the control valve.

NOTE:

Not all valves are shown. Not to be used for construction purposes.

Liquid injection line

A valve combination for compressor liquid injection with electronic injection valve is required. It is a required to

have a solenoid valve in front of the control valve.

NOTE:

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 4

ICFS SS

ICFE SS

ICM

ICFF SS ICFO SS

ICFS SS

Compressor

To oil separator

From

receiver

Oil injection

From separator/

evaporator

AKS 21

EKC 361

FIA

SVA

Valve station, Type ICF SS 20 and ICF SS 25

NOTE:

Not all valves are shown. Not to be used for construction purposes.

Media

Refrigerants

Applicable to HCFC, non ammable HFC, R717 (Ammonia) and R744 (CO2). The use of ICF SS valve stations with

ammable hydrocarbons is not recommended.

New refrigerants

Danfoss products are continually evaluated for use with new refrigerants depending on market requirements.

When a refrigerant is approved for use by Danfoss, it is added to the relevant portfolio, and the R number of the

refrigerant (e.g. R513A) will be added to the technical data of the code number. Therefore, products for specic

refrigerants are best checked at store.danfoss.com/en/, or by contacting your local Danfoss representative.

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 5

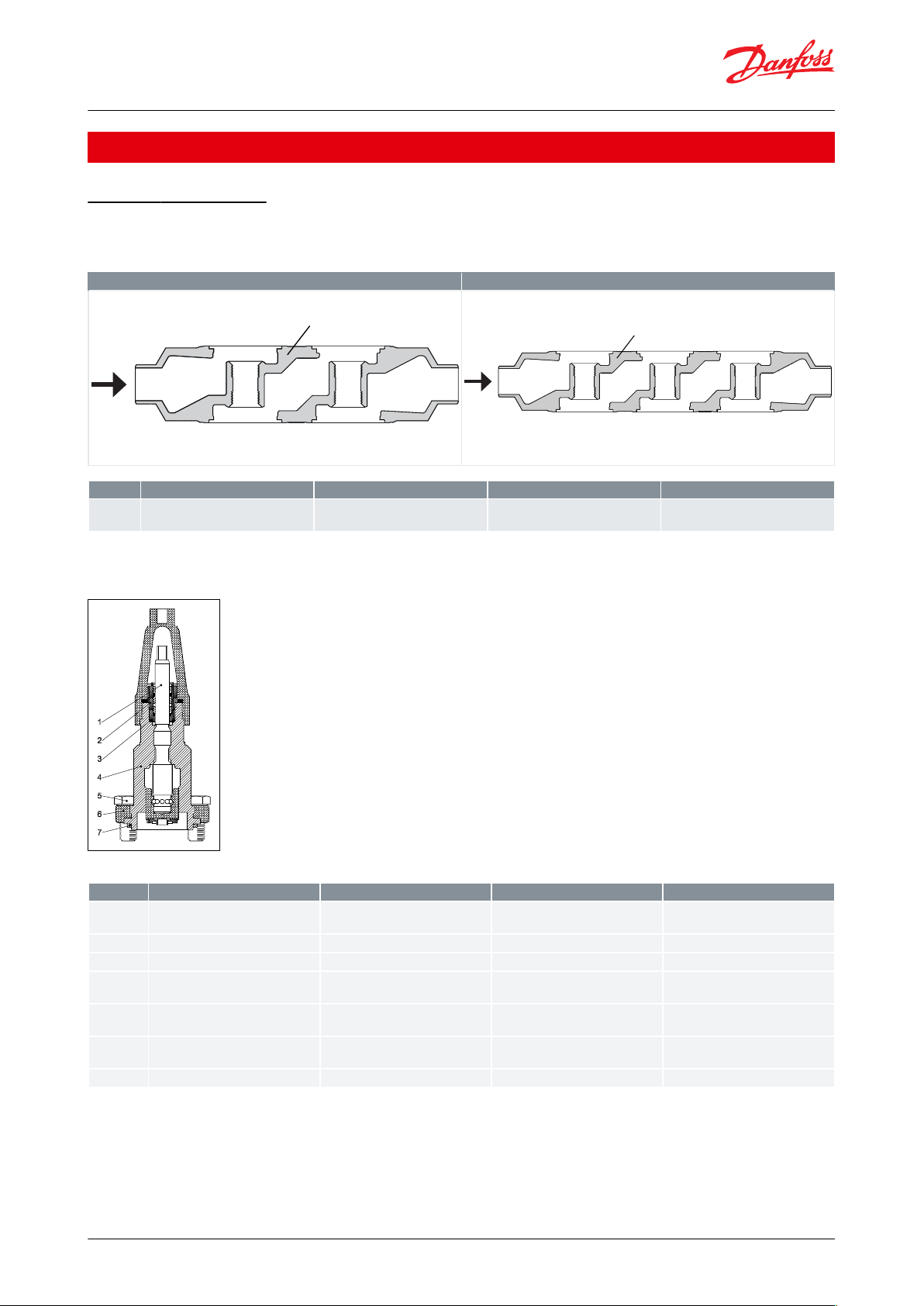

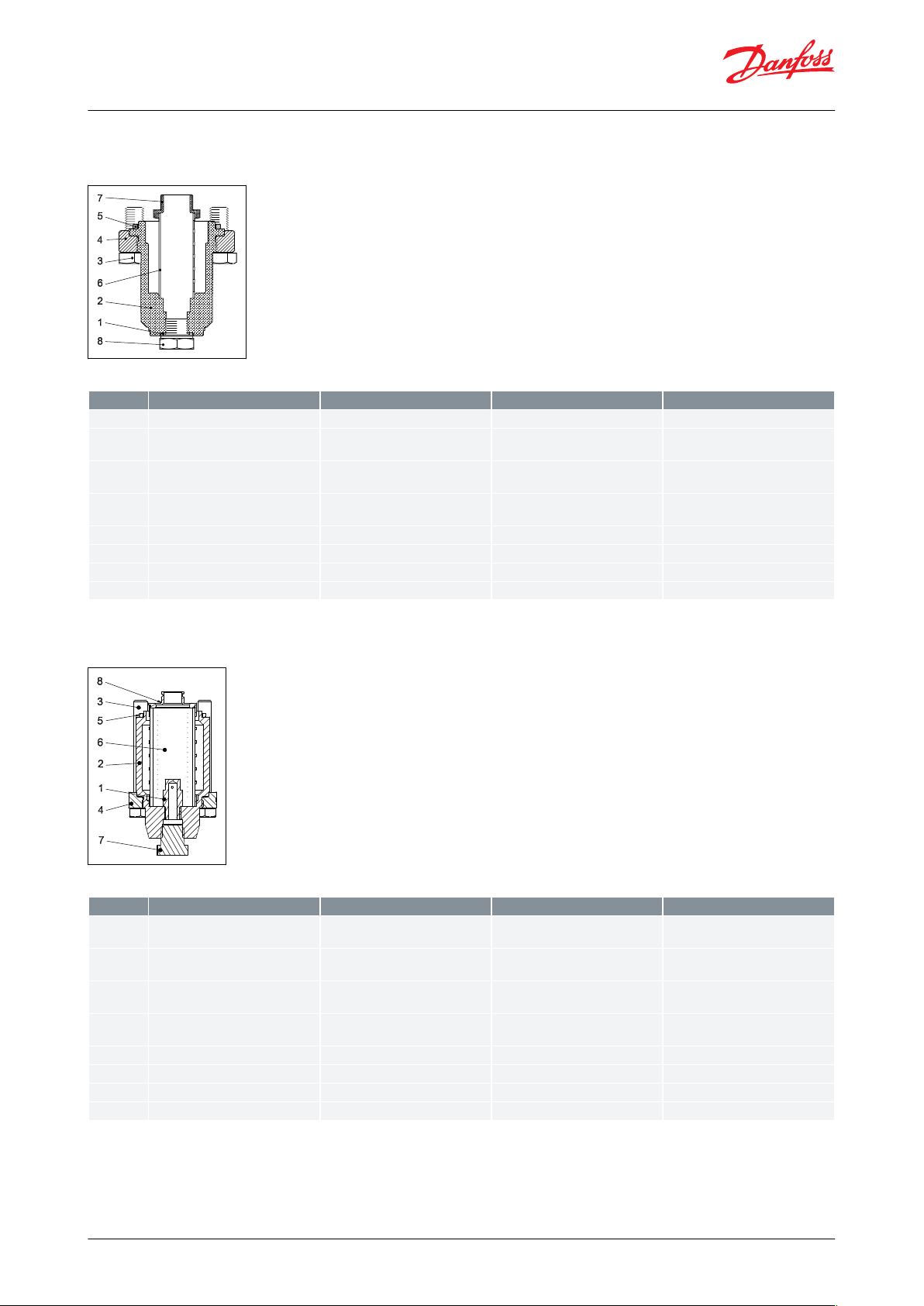

ICF SS 20-4, 25-4

ICF SS 20-6, 25-6

1

1

Pos.

Part

Material

EN

ASTM

1

Housing

Stainless steel

GX5CrNi19-10

EN10213-4

A304

Pos.

Part

Material

EN

ASTM

1

Spindle

Stainless steel

X8CrNiS 18-9

EN 10088

A303

2

Thread part

Stainless steel

3

AL-gasket/Refrig. gasket

4

Bonnet

Stainless steel

X5CrNi 18-10

EN 10272

A304

5

Hex-head bolt

M10 × 25

Stainless steel

A2-70

Type 308

6

Flange

Stainless steel

X5CrNi18-10

EN10088

A304

7

Gasket

Fiber non asbestos

Valve station, Type ICF SS 20 and ICF SS 25

Product specication

Material specication

ICF SS housing

Table 5: ICF SS housing

ICFS SS 20 shut-o valve module

Figure 1: ICFS SS 20 shut-o valve module

Table 6: ICFS SS 20 shut-o valve module

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 6

Pos.

Part

Material

EN

ASTM

1

Gasket

AL 99 F11

2

Bonnet

Stainless steel

X5CrNi 18-10

EN 10272

A304

3

Hex-head bolt

M10 × 25

Stainless steel

A2-70

Type 308

4

Flange

Stainless steel

X5CrNi18-10

EN10088

A304

5

Gasket

Fiber non asbestos

6

Filter element

Stainless steel 74μ and 150μ

7

Plug

Steel8Plug 1/4” RG for butt-weld

Stainless steel

Pos.

Part

Material

EN

ASTM

1

Dirt protection plug

Steel

11SMn30

EN 10087

Grade 1213 A29

2

Bonnet

Stainless steel

X5CrNi 18-10

EN 10272

A304

3

Hex-head bolt

M12x80

Stainless steel

A2-70

Type 308

4

Flange

Stainless steel

X5CrNi18-10

EN10088

A304

5

Gasket

Fiber non asbestos

6

Filter element

Stainless steel 250m

7

Plug 3/8” NPT

Stainless steel

8

Filter adaptor

Steel

Valve station, Type ICF SS 20 and ICF SS 25

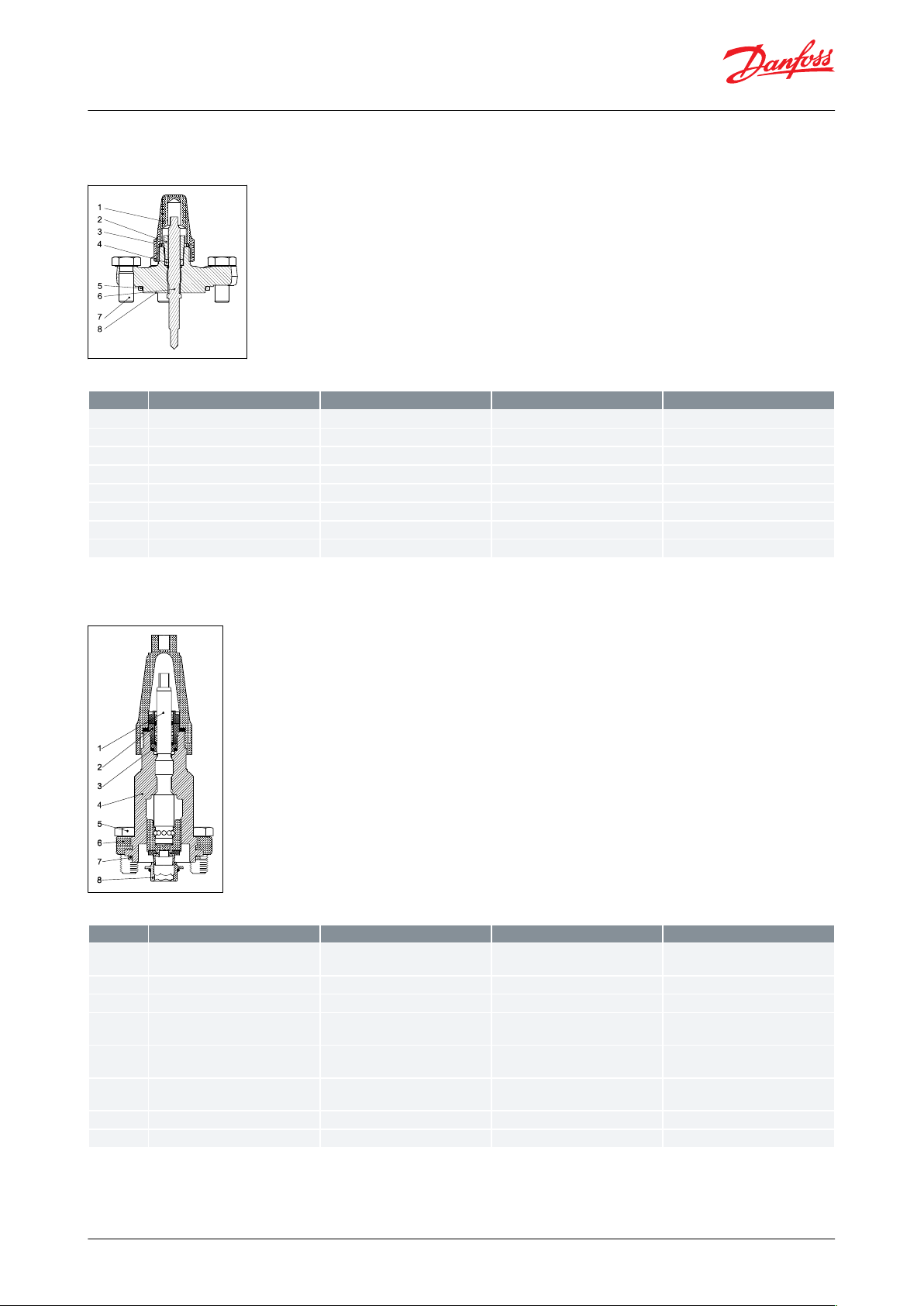

ICFF SS 20 strainer module

Figure 2: ICFF SS 20 strainer module

Table 7: ICFF SS 20 strainer module

ICFF SS 20E extended strainer module

Figure 3: ICFF SS 20E extended strainer module

Table 8: ICFF SS 20E extended strainer module

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 7

Pos.

Part

Material

EN

ASTM

1

Armature tube

Stainless steel

2

Armature tube nut

Stainless steel

X8CrNiS18-9

EN 10088

3

Flange

Stainless steel

X5CrNi18-10

EN10088

A304

4

Gasket

Fiber non asbestos

5

Hex-Head bolt

M10 × 25

Stainless steel

A2-70

Type 308

6

Seat

High density polymer

Pos.

Part

Material

EN

ASTMf

1

Piston

Steel

11SMn30 EN

EN 10025

2

Seat

Teon3Piston ring

4

Bonnet cylinder

Stainless steel

X5CrNi18-10

EN10088

A304

5

Manual opener

Steel6Armature tube

Stainless steel

7

Armature tube nut

Stainless steel

X2CrNi19-11

EN10216

A320

8

Gasket

Fiber non asbestos

Valve station, Type ICF SS 20 and ICF SS 25

ICFE SS 20 solenoid valve module

Figure 4: ICFE SS 20 solenoid valve module

Table 9: ICFE SS 20 solenoid valve module

ICFE SS 20H solenoid valve module

Figure 5: ICFE SS 20H solenoid valve module

Table 10: ICFE SS 20H solenoid valve module

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 8

Pos.

Part

Material

EN

ASTM

1

Seal cap

Stainless steel

2

Gland nut

Steel3Seal cap gasket

Nylon

Polyamid A6

Polyamid PA6

4

Sealing ring

Teon

PTFE

PTFE5Gasket

Fiber non asbestos

CR

CR6Spindle

Stainless steel

X8CrNiS 18-9 EN 10088

A3037Hex-head bolt M10 × 25

Stainless steel

A2-70

Type 308

8

Flange

Stainless steel

X5CrNi18-10 EN10088

A304

Pos.

Part

Material

EN

ASTM

1

Spindle

Stainless steel

X8CrNiS 18-9

EN 10088

A303

2

Thread part

Stainless steel

3

AL-gasket

4

Bonnet

Stainless steel

X5CrNi 18-10

EN 10272

A304

5

Hex-head bolt

M10 × 25

Stainless steel

A2-70

Type 308

6

Flange

Stainless steel

X5CrNi18-10

EN10088

A304

7

Gasket

Fiber non asbestos

8

Seat

High density polymer

Valve station, Type ICF SS 20 and ICF SS 25

ICFO SS 20 manual opening module

Figure 6: ICFO SS 20 manual opening module

Table 11: ICFO SS 20 manual opening module

ICFR SS 20 manual regulating valve module, A or B

Figure 7: ICFR SS 20 manual regulating valve module, A or B

Table 12: ICFR SS 20 manual regulating valve module, A or B

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 9

Pos.

Part

Material

EN

ASTM

1

Armature tube

Stainless steel

2

Armature tube nut

Stainless steel

X8CrNiS18-9

EN 10088

3

Hex-head bolt

M10 × 25

Stainless steel

A2-70

Type 308

4

Flange

Stainless steel

X5CrNi18-10

EN10088

A304

5

Gasket

Fiber non asbestos

6

Adaptor

Stainless steel

Pos.

Part

Material

EN

ASTM

1

Bonnet

Stainless steel

X5CrNi 18-10

EN 10272

A304

2

Hex-head bolt

M10 × 25

Stainless steel

A2-70

Type 308

3

Flange

Stainless steel

X5CrNi18-10

EN10088

A304

4

Gasket

Fiber non asbestos

Valve station, Type ICF SS 20 and ICF SS 25

ICFA SS 20 electronic expansion valve module

Figure 8: ICFA SS 20 electronic expansion valve module

Table 13: ICFA SS 20 electronic expansion valve module

ICFC SS 20 check valve module

Figure 9: ICFC SS 20 check valve module

Table 14: ICFC SS 20 check valve module

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 10

Pos.

Part

Material

EN

ASTM

1

Spindle

Stainless steel

X8CrNiS 18-9

EN 10088

A303

2

Thread part

Stainless steel

3

AL-gasket

4

Bonnet

Stainless steel

X5CrNi 18-10

EN 10272

A304

5

Hex-head bolt

M10 × 25

Stainless steel

A2-70

Type 308

6

Flange

Stainless steel

X5CrNi18-10

EN10088

A304

7

Gasket

Fiber non asbestos

Pos.

Part

Material

EN

ASTM

1

Adapter

Stainless steel

X5CrNi18-10

EN 10088

A240

2

Hex-head bolt

M10 × 55

Stainless steel

A2-70

Type 308

3

O-ring

Chloroprene

4

Bonnet

Stainless steel

X5CrNi 18-10

EN 10088

A304

5

Gasket

Fiber non asbestos

6

Seat

High density polymer

Valve station, Type ICF SS 20 and ICF SS 25

ICFN SS 20 stop & check valve module

Figure 10: ICFN SS 20 stop & check valve module

Table 15: ICFN SS 20 stop & check valve module

ICM SS 20-A, 20-B, 20-C, 20-A33 or 20-B66 motor valve module

Figure 11: ICM SS 20-A, 20-B, 20-C, 20-A33 or 20-B66 motor valve module

Table 16: ICM SS 20-A, 20-B, 20-C, 20-A33 or 20-B66 motor valve module

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 11

Pos.

Part

Material

EN

ASTM

1

Hex-head bolt

M10 × 25

Stainless Steel

A2-70

Type 308

2

Flange

Stainless steel

X5CrNi18-10

EN10088

A304

3

Gasket

Fiber non asbestos

Pos.

Part

Material

EN

ASTM

1

Hex-head bolt

M10 × 25

Stainless Steel

A2-70

Type 308

2

Flange

Stainless steel

X5CrNi18-10

EN10088

A304

3

Gasket

Fiber non asbestos

4

Weld connection

Stainless Steel

Pos.

Part

Material

EN

ASTM

1

Spindle

Stainless steel

X8CrNiS 18-9

EN 10088

A303

2

Thread part

Stainless steel

3

O-ring

Chloroprene

Valve station, Type ICF SS 20 and ICF SS 25

ICFB SS 20 blank top cover

Figure 12: ICFB SS 20 blank top cover

Table 17: ICFB SS 20 blank top cover

ICFW SS 20D welding module, 20 DIN

Figure 13: ICFW SS 20D welding module, 20 DIN

Table 18: ICFW SS 20D welding module, 20 DIN

ICFS SS 25 shut-o valve module

Figure 14: ICFS SS 25 shut-o valve module

Table 19: ICFS SS 25 shut-o valve module

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 12

Pos.

Part

Material

EN

ASTM

4

Bonnet

Stainless steel

X5CrNi 18-10

EN 10272

A304

5

Hex-head bolt M12 × 30

Stainless steel

A2-70

Type 308

6

Flange

Stainless steel

X5CrNi18-10

EN10088

A304

7

Gasket

Fiber non asbestos

Pos.

Part

Material

EN

ASTM

1

Al. Gasket

AL 99 F11

2

Bonnet

Stainless steel

X5CrNi 18-10

EN 10272

A304

3

Hex-head bolt

M12 × 30

Stainless steel

A2-70

Type 308

4

Flange

Stainless steel

X5CrNi18-10

EN10088

A304

5

Gasket

Fiber non asbestos

6

Filter element

Stainless steel 150m

7

Plug

1/4” RG for butt-weld

Stainless steel

Pos.

Part

Material

EN

ASTM

1

Dirt protection plug

Steel

11SMn30

EN 10087

Grade 1213 A29

2

Bonnet

Stainless steel

X5CrNi 18-10

EN 10222

A304

3

Hex-head bolt

M12x140

Stainless steel

A2-70

Type 308

4

Flange

Stainless steel

X5CrNi18-10

EN10088

A304

Valve station, Type ICF SS 20 and ICF SS 25

ICFF SS 25 strainer module

Figure 15: ICFF SS 25 strainer module

Table 20: ICFF SS 25 strainer module

ICFF SS 25E extended strainer module

Figure 16: ICFF SS 25E extended strainer module

Table 21: ICFF SS 25E extended strainer module

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 13

Pos.

Part

Material

EN

ASTM

5

Gasket

Fiber non asbestos

6

Filter element

Stainless steel 250m

7

Plug 3/8” NPT

Stainless steel

Pos.

Part

Material

EN

ASTM

1

Armature tube

Stainless steel

2

Armature tube nut

Stainless steel

X8CrNiS18-9

EN 10088

3

Bonnet

Stainless steel

X5CrNi 18-10

EN 10222

A304

4

Gasket

Fiber non asbestos

5

Hex-Head bolt

M10 × 30

Stainless steel

A2-70

Type 308

6

Seat

High density polymer

Pos.

Part

Material

EN

ASTM

1

Spindle

Stainless steel

X8CrNiS 18-9

EN 10088

A303

2

Thread part

Stainless steel

3

O-ring

Chloroprene

4

Bonnet

Stainless steel

X5CrNi 18-10

EN 10272

A304

5

Hex-head bolt

M12 × 30

Stainless steel

A2-70

Type 308

Valve station, Type ICF SS 20 and ICF SS 25

ICFE SS 25 solenoid valve module

Figure 17: ICFE SS 25 solenoid valve module

Table 22: ICFE SS 25 solenoid valve module

ICFR SS 25 manual regulating valve module, A or B

Figure 18: ICFR SS 25 manual regulating valve module, A or B

Table 23: ICFR SS 25 manual regulating valve module, A or B

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 14

Pos.

Part

Material

EN

ASTM

6

Flange

Stainless steel

X5CrNi18-10

EN10088

A304

7

Gasket

Fiber non asbestos

8

Seat

High density polymer

Pos.

Part

Material

EN

ASTM

1

Bonnet

Stainless steel

X5CrNi 18-10

EN 10272

A304

2

Hex-head bolt

M12 × 30

Stainless steel

A2-70

Type 308

3

Flange

Stainless steel

X5CrNi18-10

EN10088

A304

4

Gasket

Fiber non asbestos

Pos.

Part

Material

EN

ASTM

1

Spindle

Stainless steel

X8CrNiS 18-9

EN 10088

A303

2

Thread part

Stainless steel

3

O-ring

Chloroprene

4

Bonnet

Stainless steel

X5CrNi 18-10

EN 10272

A304

5

Hex-head bolt

M12 × 30

Stainless steel

A2-70

Type 308

6

Flange

Stainless steel

X5CrNi18-10

EN10088

A304

7

Gasket

Fiber non asbestos

Valve station, Type ICF SS 20 and ICF SS 25

ICFC SS 25 check valve module

Figure 19: ICFC SS 25 check valve module

Table 24: ICFC SS 25 check valve module

ICFN SS 25 stop & check valve module

Figure 20: ICFN SS 25 stop & check valve module

Table 25: ICFN SS 25 stop & check valve module

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 15

Pos.

Part

Material

EN

ASTM

1

Adapter

Stainless steel

X5CrNi18-10

EN 10088

A240

2

Hex-head bolt

M12 × 30

Stainless steel

A2-70

Type 308

3

O-ring

Chloroprene

4

Bonnet

Stainless steel

X5CrNi18-10

EN10088

A304

5

Gasket

Fiber non asbestos

6

Seat

High density polymer

Pos.

Part

Material

EN

ASTM

1

Hex-head bolt

M10 × 30

Stainless Steel

A2-70

Type 308

2

Flange

Stainless steel

X5CrNi18-10

EN10088

A304

3

Gasket

Fiber non asbestos

Valve station, Type ICF SS 20 and ICF SS 25

ICM SS 25-A or B motor valve module

Figure 21: ICM SS 25-A or B motor valve module

Table 26: ICM SS 25-A or B motor valve module

ICFB SS 25 blank top cover

Figure 22: ICFB SS 25 blank top cover

Table 27: ICFB SS 25 blank top cover

ICFW SS 25 welding module, 25 DIN

Figure 23: ICFW SS 25 welding module, 25 DIN

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 16

Pos.

Part

Material

EN

ASTM

1

Hex-head bolt

M10 × 30

Stainless Steel

A2-70

Type 308

2

Flange

Stainless steel

X5CrNi18-10

EN10088

A304

3

Gasket

Fiber non asbestos

4

Weld connection

Stainless steel

ø

Size

SizeØDTØDTmmin.mmmm

in.

in.

20

(3/4)

26.9

2.3

1.059

0.091251

33.7

2.6

1.327

0.10332(1 1/4)

42.4

2.6

1.669

0.102401 1/2

48.3

2.6

1.902

0.103

Size

SizeØDTØDT

Schedule

mm

in.mmmm

in.

in.

20

(3/4)

26.9

2.9

1.059

0.11

40251

33.7

3.5

1.327

0.14

40321 1/4

42.4

3.6

1.669

0.14

40401 1/2

48.3

3.7

1.902

0.15

40

Valve station, Type ICF SS 20 and ICF SS 25

Table 28: ICFW SS 25 welding module, 25 DIN

Connections

D: Butt-weld DIN (EN 10220)

Figure 24: D: Butt-weld DIN (EN 10220)

Table 29: D: Butt-weld DIN (EN 10220)

A: Butt-weld ANSI (B 36.19)

Figure 25: A: Butt-weld ANSI (B 36.19)

Table 30: A: Butt-weld ANSI (B 36.19)

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 17

260 mm

(10.2 in.)

Valve station, Type ICF SS 20 and ICF SS 25

Dimensions and weights

ICF SS 20-6

Figure 26: ICF SS 20-6

This example indicates the maximum dimensions for the ICF SS valve stations.

ICF SS 20-4

Figure 27: ICF SS 20-4

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 18

252 mm

(9.9 in.)

273 mm

(10.7 in.)

59 mm

(2.3 in.)

70 mm

(2.8 in.)

356 mm

(14.0 in.)

252 mm

(9.9 in.)

273 mm

(10.7 in.)

58 mm

(2.3 in.)

70 mm

(2.8 in.)

266 mm

(10.5 in.)

Valve station, Type ICF SS 20 and ICF SS 25

ICF SS 25-6

Figure 28: ICF SS 25-6

ICF SS 25-4

Figure 29: ICF SS 25-4

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 19

ICF SS 20 - 6 - 3

Type

Number of module ports

Application reference number

(see the below overview)

Housing size

Type

# of

mod‐

ules

Appl.

#

Connec‐

tion size

Connection

type

Module location

Weight

Code

number

[in.]

[mm]M1M2M3M4M5M6kglbs

ICF SS 20

6

1RA

3

⁄4

20

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20

ICFO 20

ICFR 20A

ICFS 20

9.5

20.9

027L4700

ICF SS 20

6

1RA125

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20

ICFO 20

ICFR 20A

ICFS 20

9.7

21.3

027L4701

ICF SS 20

6

1RA

3

⁄4

20

Butt-weld ANSI

(B 36.19)

ICFS 20

ICFF 20

ICFE 20

ICFO 20

ICFR 20A

ICFS 20

10.4

22.9

027L3555

Valve station, Type ICF SS 20 and ICF SS 25

Ordering

Below Nomenclature show the generic conguration and application by identication of housing size, type and

application group.

This designation is often used for discussion on possible solutions and will be the nal identication on the valve

label (see label example).

Figure 30: Label example:

For ordering, connection size and type must be chosen to get the nal identication. The nal identication is

done by code number only. See (Page 20 to Page 25)

Code number selection

To determine the correct ICF SS valve station follow steps 1 through 5.

Step 1 Determine application and function requirements

• Line: Pumped liquid, Liquid Injection, Hot gas defrost, Liquid DX etc

• Control: On/o solenoid valve, motorised valve

• Defrost: Electric or hot gas

NOTE:

From the above determine the application reference number. See (Page 20 to Page 25)

Step 2 Selection criteria - Please use Coolselector®2

Download the software from: http://refrigerationandairconditioning.danfoss.com/support-center/apps-andsoftware/coolselector/

• Refrigerant

• Capacity

• Temperature

• Circulation rate

NOTE:

From the above determine the valve station required, e.g.: ICF SS 20 complete with ICM SS 20-C

Step 3 Establish connection sizes and type

• DIN butt-weld / ANSI butt-weld

• 20 (¾ in.), 25 (1 in.), 32 (1 ¼ in.) or 40 (1 ½ in.)

Step 4 Establish code number. See (Page 20 to Page 25)

Liquid feed

Table 31: Application 1: Liquid feed (no hot gas defrost)

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 20

Type

# of

mod‐

ules

Appl.

#

Connec‐

tion size

Connection

type

Module location

Weight

Code

number

[in.]

[mm]M1M2M3M4M5M6kglbs

ICF SS 20

6

1RA125

Butt-weld ANSI

(B 36.19)

ICFS 20

ICFF 20E

ICFE 20

ICFO 20

ICFR 20A

ICFS 20

9.9

21.8

027L3556

ICF SS 20

6

1HRB125

Butt-weld ANSI

(B 36.19)

ICFS 20

ICFF 20E

ICFE 20H

ICFB 20

ICFR 20B

ICFS 20

10.9

24

027L3578

ICF SS 20

6

1HRB

1

1

⁄4

32

Butt-weld ANSI

(B 36.19)

ICFS 20

ICFF 20E

ICFE 20H

ICFB 20

ICFR 20B

ICFS 20

10.9

24

027L3557

ICF SS 25

6

1RA125

Butt-weld ANSI

(B 36.19)

ICFS 25

ICFF 25E

ICFE 25

ICFB 25

ICFR 25A

ICFS 25

24.1

53

027L3568

ICF SS 25

6

1RA

1

1

⁄4

32

Butt-weld ANSI

(B 36.19)

ICFS 25

ICFF 25E

ICFE 25

ICFB 25

ICFR 25A

ICFS 25

23.8

52.4

027L3569

ICF SS 25

6

1RB

1

1

⁄4

32

Butt-weld ANSI

(B 36.19)

ICFS 25

ICFF 25E

ICFE 25

ICFB 25

ICFR 25B

ICFS 25

24.2

53.2

027L3584

ICF SS 25

6

1RB1½40

Butt-weld ANSI

(B 36.19)

ICFS 25

ICFF 25E

ICFE 25

ICFB 25

ICFR 25B

ICFS 25

23.8

52.4

027L3570

Type

# of

mod‐

ules

Appl.#Connec‐

tion size

Connection

type

Module location

Weight

Code

number

[in.]

[mm]M1M2M3M4M5M6kglbs

ICF SS 20

6

2RA

3

⁄4

20

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20

ICFO 20

ICFR 20A

ICFN 20

10

22.1

027L3428

ICF SS 20

6

2RA125

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20E

ICFE 20

ICFO 20

ICFR 20A

ICFN 20

10

22.1

027L3445

ICF SS 20

6

2RA125

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20

ICFO 20

ICFR 20A

ICFN 20

9.7

21.3

027L4758

ICF SS 20

6

2HRB

1

1

⁄4

32

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20H

ICFB 20

ICFR 20B

ICFN 20

9.2

20.2

027L4759

ICF SS 25

6

2RB

1

1

⁄4

32

Butt-weld DIN-

EN 10220

ICFS 25

ICFF 25

ICFE 25

ICFB 25

ICFR 25B

ICFN 25

23.9

52.6

027L4766

ICF SS 20

6

2RA

3

⁄4

20

Butt-weld ANSI

(B 36.19)

ICFS 20

ICFF 20E

ICFE 20

ICFO 20

ICFR 20A

ICFN 20

10.1

22.2

027L3571

ICF SS 20

6

2RA125

Butt-weld ANSI

(B 36.19)

ICFS 20

ICFF 20E

ICFE 20

ICFO 20

ICFR 20A

ICFN 20

9.9

21.8

027L3572

Type

# of

mod‐

ules

Appl.

#

Connec‐

tion size

Connection

type

Module location

Weight

Code

number

[in.]

[mm]M1M2M3M4M5M6kglbs

ICF SS 20

6

3RA

3

⁄4

20

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20

ICFC 20

ICFR 20A

ICFS 20

9.6

21.1

027L4702

ICF SS 20

6

3RA125

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20

ICFC 20

ICFR 20A

ICFS 20

9.7

21.3

027L4703

ICF SS 20

6

3HRA125

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20H

ICFC 20

ICFR 20A

ICFS 20

10.6

23.3

027L4717

ICF SS 25

6

3RA125

Butt-weld DIN-

EN 10220

ICFS 25

ICFF 25

ICFE 25

ICFC 25

ICFR 25A

ICFS 25

23.4

51.5

027L4724

ICF SS 25

6

3RA

1

1

⁄4

32

Butt-weld DIN-

EN 10220

ICFS 25

ICFF 25

ICFE 25

ICFC 25

ICFR 25A

ICFS 25

23.2

51

027L4760

ICF SS 25

6

3RB

1

1

⁄4

32

Butt-weld DIN-

EN 10220

ICFS 25

ICFF 25

ICFE 25

ICFC 25

ICFR 25B

ICFS 25

23.8

52.4

027L4725

ICF SS 25

6

3RB

1

1

⁄2

40

Butt-weld DIN-

EN 10220

ICFS 25

ICFF 25

ICFE 25

ICFC 25

ICFR 25B

ICFS 25

24

52.8

027L4761

ICF SS 25

6

3RB

1

1

⁄2

40

Butt-weld DIN-

EN 10220

ICFS 25

ICFF 25E

ICFE 25

ICFC 25

ICFR 25B

ICFS 25

24.7

54.3

027L4191

ICF SS 20

6

3HRB

3

⁄4

20

Butt-weld ANSI

(B 36.19)

ICFS 20

ICFF 20E

ICFE 20H

ICFC 20

ICFR 20B

ICFS 20

10.7

23.5

027L3579

ICF SS 20

6

3HRB125

Butt-weld ANSI

(B 36.19)

ICFS 20

ICFF 20E

ICFE 20H

ICFC 20

ICFR 20B

ICFS 20

11.2

24.6

027L3580

ICF SS 20

6

3HRB

1

1

⁄4

32

Butt-weld ANSI

(B 36.19)

ICFS 20

ICFF 20E

ICFE 20H

ICFC 20

ICFR 20B

ICFS 20

11.3

24.9

027L3581

ICF SS 25

6

3RA125

Butt-weld ANSI

(B 36.19)

ICFS 25

ICFF 25E

ICFE 25

ICFC 25

ICFR 25A

ICFS 25

24.2

53.2

027L3585

Valve station, Type ICF SS 20 and ICF SS 25

Table 32: Application 2: Liquid feed

Table 33: Application 3: Liquid feed

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 21

Type

# of

mod‐

ules

Appl.

#

Connec‐

tion size

Connection

type

Module location

Weight

Code

number

[in.]

[mm]M1M2M3M4M5M6kglbs

ICF SS 25

6

3RA

1

1

⁄4

32

Butt-weld ANSI

(B 36.19)

ICFS 25

ICFF 25E

ICFE 25

ICFC 25

ICFR 25A

ICFS 25

24.1

53

027L3586

ICF SS 25

6

3RB

1

1

⁄4

32

Butt-weld ANSI

(B 36.19)

ICFS 25

ICFF 25E

ICFE 25

ICFC 25

ICFR 25B

ICFS 25

24.1

53

027L3587

ICF SS 25

6

3RB1½40

Butt-weld ANSI

(B 36.19)

ICFS 25

ICFF 25E

ICFE 25

ICFC 25

ICFR 25B

ICFS 25

24.2

53.2

027L3588

Type

# of

mod‐

ules

Appl. #

Connection

size

Connection type

Module location

Weight

Code

number

[in.]

[mm]M1M2M3M4kglbs

ICF SS 20

4

10RA

3

⁄4

20

Butt-weld DIN-EN

10220

ICFS 20

ICFF 20

ICFE 20

ICFR 20B

7.4

16.2

027L3440

ICF SS 20

4

10RA125

Butt-weld DIN-EN

10220

ICFS 20

ICFF 20

ICFE 20

ICFR 20A

7.2

15.8

027L4709

ICF SS 25

4

10RA125

Butt-weld DIN-EN

10220

ICFS 25

ICFF 25

ICFE 25

ICFR 25A

15.9

35

027L4731

ICF SS 25

4

10RB

1

1

⁄4

32

Butt-weld DIN-EN

10220

ICFS 25

ICFF 25

ICFE 25

ICFR 25B

15.4

33.9

027L4732

ICF SS 25

4

10RA125

Butt-weld DIN-EN

10220

ICFS 25

ICFF 25E

ICFE 25

ICFR 25A

16.2

35.7

027L4590

ICF SS 20

4

10HRB

3

⁄4

20

Butt-weld ANSI (B

36.19)

ICFS 20

ICFF 20E

ICFE 20H

ICFR 20B

8.4

18.5

027L3582

ICF SS 20

4

10HRB125

Butt-weld ANSI (B

36.19)

ICFS 20

ICFF 20E

ICFE 20H

ICFR 20B

7.8

17.2

027L3583

ICF SS 25

4

10RA125

Butt-weld ANSI (B

36.19)

ICFS 25

ICFF 25E

ICFE 25

ICFR 25A

15.8

34.8

027L3592

ICF SS 25

4

10RB

1

1

⁄4

32

Butt-weld ANSI (B

36.19)

ICFS 25

ICFF 25E

ICFE 25

ICFR 25B

16.2

35.6

027L3593

ICF SS 25

4

10RB1½40

Butt-weld ANSI (B

36.19)

ICFS 25

ICFF 25E

ICFE 25

ICFR 25B

16.2

35.6

027L3594

Type

# of

mod‐

ules

Appl.#Connection

size

Connection type

Module location

Weight

Code

number

[in.]

[mm]M1M2M3M4M5M6kglbs

ICF SS 25

6

15RA125

Butt-weld DIN-EN

10220

ICFS 25

ICFF 25

ICFE 25

ICFC 25

ICFW 25D

ICFR 25A

21.8

48

027L4733

ICF SS 25

6

15RB

1

1

⁄4

32

Butt-weld DIN-EN

10220

ICFS 25

ICFF 25

ICFE 25

ICFC 25

ICFW 25D

ICFR 25B

22.7

49.9

027L4734

Type

# of

mod‐

ules

Appl.

#

Connection

size

Connection

type

Module location

Weight

Code

number

[in.]

[mm]M1M2M3M4M5M6kglbs

ICF SS 20

6

5MA33

3

⁄4

20

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20-74

ICFE 20

ICFO 20

ICM 20-A33

ICFS 20

9.8

21.6

027L4714

ICF SS 20

6

5MB66

3

⁄4

20

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20

ICFO 20

ICM 20-B66

ICFS 20

10.1

22.3

027L3443

ICF SS 20

6

5MA125

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20

ICFO 20

ICM 20-A

ICFS 20

9.8

21.6

027L4704

ICF SS 20

6

5MB125

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20

ICFO 20

ICM 20-B

ICFS 20

9.6

21.1

027L4705

ICF SS 20

6

5HMB125

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20H

ICFB 20

ICM 20-B

ICFS 20

11.4

25.1

027L4718

Valve station, Type ICF SS 20 and ICF SS 25

Table 34: Application 10: Liquid feed (no hot gas defrost)

Table 35: Application 15: Liquid feed with external connection

NOTE:

ICAD and coils are not included and must be ordered separately.

When used in systems with CO2, the o-rings on the ICM module can swell (grow). At service, it is therefore

recommended to install new o-rings, before the ICM function module is re-installed in the ICF SS valve body. ICAD

and coils are not included and must be ordered separately.

Liquid injection

Table 36: Application 5: Liquid injection (expansion)

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 22

Type

# of

mod‐

ules

Appl.

#

Connection

size

Connection

type

Module location

Weight

Code

number

[in.]

[mm]M1M2M3M4M5M6kglbs

ICF SS 20

6

5MA33125

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20

ICFO 20

ICM 20-A33

ICFS 20

9.6

21.1

027L4755

ICF SS 25

6

5MA125

Butt-weld DIN-

EN 10220

ICFS 25

ICFF 25

ICFE 25

ICFB 25

ICM 25-A

ICFS 25

22.8

50.2

027L4726

ICF SS 20

6

5MB66

1

1

⁄4

32

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20

ICFO 20

ICM 20-B66

ICFS 20

9.6

21.1

027L4754

ICF SS 20

6

5HMB

1

1

⁄4

32

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20H

ICFB 20

ICM 20-B

ICFS 20

10.2

22.4

027L4756

ICF SS 20

6

5MC1½32

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20

ICFO 20

ICM 20-C

ICFS 20

9.8

21.6

027L4706

ICF SS 20

6

5HMC

1

1

⁄4

32

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20H

ICFB 20

ICM 20-C

ICFS 20

10.3

22.7

027L4719

ICF SS 25

6

5MB

1

1

⁄4

32

Butt-weld DIN-

EN 10220

ICFS 25

ICFF 25

ICFE 25

ICFB 25

ICM 25-B

ICFS 25

22.3

49

027L4727

ICF SS 25

6

5MB1½40

Butt-weld DIN-

EN 10220

ICFS 25

ICFF 25

ICFE 25

ICFB 25

ICM 25-B

ICFS 25

22.3

49

027L4728

ICF SS 25

6

5MA1½40

Butt-weld DIN-

EN 10220

ICFS 25

ICFF 25

ICFE 25

ICFB 25

ICM 25-A

ICFS 25

22.3

49

027L4735

ICF SS 20

6

5MA33

3

⁄4

20

Butt-weld ANSI

(B 36.19)

ICFS 20

ICFF 20E

ICFE 20

ICFO 20

ICM 20-A33

ICFS 20

10.1

22.2

027L3573

ICF SS 20

6

5MA

3

⁄4

20

Butt-weld ANSI

(B 36.19)

ICFS 20

ICFF 20E

ICFE 20

ICFO 20

ICM 20-A

ICFS 20

10

22

027L3574

ICF SS 20

6

5MA125

Butt-weld ANSI

(B 36.19)

ICFS 20

ICFF 20E

ICFE 20

ICFO 20

ICM 20-A

ICFS 20

10.1

22.2

027L3575

ICF SS 20

6

5MB

3

⁄4

20

Butt-weld ANSI

(B 36.19)

ICFS 20

ICFF 20E

ICFE 20

ICFO 20

ICM 20-B

ICFS 20

9.8

21.6

027L3576

ICF SS 20

6

5MB125

Butt-weld ANSI

(B 36.19)

ICFS 20

ICFF 20E

ICFE 20

ICFO 20

ICM 20-B

ICFS 20

10

22

027L3577

ICF SS 25

6

5MA125

Butt-weld ANSI

(B 36.19)

ICFS 25

ICFF 25E

ICFE 25

ICFB 25

ICM 25-A

ICFS 25

23.1

50.8

027L3589

ICF SS 25

6

5MA

1

1

⁄4

32

Butt-weld ANSI

(B 36.19)

ICFS 25

ICFF 25E

ICFE 25

ICFB 25

ICM 25-A

ICFS 25

23.2

51

027L3590

ICF SS 25

6

5MA331½40

Butt-weld ANSI

(B 36.19)

ICFS 25

ICFF 25-E

ICFE 25

ICFB 25

ICM 25-A33

ICFS 25

23.1

50.8

027L3591

Type

# of

mod‐

ules

Appl. #

Connec‐

tion size

Connection type

Module location

Weight

Code number

[in.]

[mm]M1M2M3M4kglbs

ICF SS 20

4

14MA

3

⁄4

20

Butt-weld DIN-EN

10220

ICFS 20

ICFF 20

ICM 20-A

ICFS 20

7.3

16.1

027L4710

ICF SS 20

4

14MA

3

⁄4

20

Butt-weld DIN-EN

10220

ICFS 20

ICFF 20E

ICM 20-A

ICFS 20

6.9

15.1

027L3444

ICF SS 20

4

14MB125

Butt-weld DIN-EN

10220

ICFS 20

ICFF 20

ICM 20-B

ICFS 20

7.2

15.8

027L4711

ICF SS 20

4

14MB66

1

25

Butt-weld DIN-EN

10220

ICFS 20

ICFF 20

ICM 20-B66

ICFS 20

7

15.4

027L4722

ICF SS 20

4

14MC

1

1

⁄4

32

Butt-weld DIN-EN

10220

ICFS 20

ICFF 20

ICM 20-C

ICFS 20

7.3

16.1

027L4712

ICF SS 25

4

14MB125

Butt-weld DIN-EN

10220

ICFS 25

ICFF 25

ICM 25-B

ICFS 25

14.8

32.5

027L4765

ICF SS 25

4

14MB

1

1

⁄4

32

Butt-weld DIN-EN

10220

ICFS 25

ICFF 25

ICM 25-B

ICFS 25

14.8

32.5

027L4764

Valve station, Type ICF SS 20 and ICF SS 25

Table 37: Application 14: Liquid injection (expansion)

NOTE:

ICAD and coils are not included and must be ordered separately.

When used in systems with CO2, the o-rings on the ICM module can swell (grow). At service, it is therefore

recommended to install new o-rings, before the ICM function module is re-installed in the ICF SS valve body. ICAD

and coils are not included and must be ordered separately.

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 23

Type

# of

mod‐

ules

Appl. #

Connection

size

Connection type

Module location

Weight

Code

number

[in.]

[mm]M1M2M3M4kglbs

ICF SS 20

491

25

Butt-weld DIN-EN

10220

ICFS 20

ICFF 20

ICFE 20

ICFS 20

7.2

15.8

027L4707

ICF SS 20

49H1

25

Butt-weld DIN-EN

10220

ICFS 20

ICFF 20

ICFE 20H

ICFS 20

8.2

18

027L4720

ICF SS 20

491

1

⁄4

32

Butt-weld DIN-EN

10220

ICFS 20

ICFF 20

ICFE 20

ICFS 20

6.8

15

027L4708

ICF SS 20

49H1

1

⁄4

32

Butt-weld DIN-EN

10220

ICFS 20

ICFF 20

ICFE 20H

ICFS 20

7.6

16.7

027L4721

ICF SS 25

491

25

Butt-weld DIN-EN

10220

ICFS 25

ICFF 25

ICFE 25

ICFS 25

16.2

35.7

027L3429

ICF SS 25

491

1

⁄4

32

Butt-weld DIN-EN

10220

ICFS 25

ICFF 25

ICFE 25

ICFS 25

15.7

34.5

027L4729

ICF SS 25

491

1

⁄2

40

Butt-weld DIN-EN

10220

ICFS 25

ICFF 25

ICFE 25

ICFS 25

15.7

34.5

027L4730

ICF SS 25

491

1

⁄2

40

Butt-weld DIN-EN

10220

ICFS 25

ICFW 25D

ICM 25-B

ICFS 25

16.6

36.6

027L4190

ICF SS 20

4

9H

3

⁄4

20

Butt-weld ANSI (B

36.19)

ICFS 20

ICFF 20E

ICFE 20H

ICFS 20

8

17.6

027L3552

ICF SS 20

49H1

25

Butt-weld ANSI (B

36.19)

ICFS 20

ICFF 20E

ICFE 20H

ICFS 20

8.1

17.8

027L3553

ICF SS 20

49H1

1

⁄4

32

Butt-weld ANSI (B

36.19)

ICFS 20

ICFF 20E

ICFE 20H

ICFS 20

7.9

17.4

027L3554

ICF SS 25

491

25

Butt-weld ANSI (B

36.19)

ICFS 25

ICFF 25E

ICFE 25

ICFS 25

16

35.2

027L3565

ICF SS 25

491

1

⁄4

32

Butt-weld ANSI (B

36.19)

ICFS 25

ICFF 25E

ICFE 25

ICFS 25

16

35.2

027L3566

ICF SS 25

491½

40

Butt-weld ANSI (B

36.19)½

ICFS 25

ICFF 25E

ICFE 25

ICFS 25

16.1

35.4

027L3567

Type

# of

mod‐

ules

Appl.

#

Connec‐

tion size

Connection

type

Module location

Weight

Code

number

[in.]

[mm]M1M2M3M4M5M6kglbs

ICF SS 20

4

90

3

⁄4

20

Butt-weld DIN-

EN 10220

ICFR 20A

ICFF 20

ICFA 20

ICFN 20

6.4

14.1

027L4716

ICF SS 20

6

90

3

⁄4

20

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20

ICFB 20

ICFR 20-A

ICFN 20

9.7

21.3

027L4713

ICF SS 20

6

90

3

⁄4

20

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20

ICFC 20

ICM 20-C

ICFS 20

9.7

21.3

027L4715

ICF SS 20

6

90

3

⁄4

20

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20

ICFC 20

ICFR 20A

ICFW 20D

8.9

17.8

027L4740

ICF SS 20

6

90

3

⁄4

20

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20

ICFC 20

ICFR 20B

ICFW 20D

8.9

17.8

027L4741

ICF SS 20

6

90

3

⁄4

20

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20H

ICFC 20

ICFR 20A

ICFW 20D

9.8

21.5

027L4748

ICF SS 20

6

90

3

⁄4

20

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20H

ICFC 20

ICFR 20B

ICFW 20D

9.8

21.5

027L4749

ICF SS 20

6

90

3

⁄4

20

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20

ICFC 20

ICFW 20D

ICFS 20

9.3

20.6

027L4768

ICF SS 20

6

90

3

⁄4

20

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20

ICFB 20

ICFR 20A

ICFS 20

9.9

21.8

027L3427

ICF SS 20

6901

25

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20E

ICFE 20H

ICFC 20

ICFR 20B

ICFW 20D

11.5

25.3

027L4723

ICF SS 20

6901

25

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20

ICFC 20

ICFR 20A

ICFW 20D

8.9

17.8

027L4742

ICF SS 20

6901

25

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20

ICFC 20

ICFR 20B

ICFW 20D

8.9

17.8

027L4743

ICF SS 20

6901

25

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20H

ICFC 20

ICFR 20A

ICFW 20D

9.8

21.5

027L4750

Valve station, Type ICF SS 20 and ICF SS 25

Hot gas defrost

Table 38: Application 9: Hot gas defrost

Miscellaneous

Table 39: Application 90: Miscellaneous

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 24

Type

# of

mod‐

ules

Appl.

#

Connec‐

tion size

Connection

type

Module location

Weight

Code

number

[in.]

[mm]M1M2M3M4M5M6kglbs

ICF SS 20

6901

25

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20H

ICFC 20

ICFR 20B

ICFW 20D

9.8

21.5

027L4751

ICF SS 20

6901

25

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20

ICFC 20

ICFW 20D

ICFS 20

9.3

20.6

027L4767

ICF SS 20

6901

1

⁄4

32

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20

ICFC 20

ICFR 20A

ICFW 20D

8.9

17.8

027L4746

ICF SS 20

6901

1

⁄4

32

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20

ICFC 20

ICFR 20B

ICFW 20D

8.9

17.8

027L4747

ICF SS 20

6901

1

⁄4

32

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20H

ICFC 20

ICFR 20A

ICFW 20D

9.8

21.5

027L4752

ICF SS 20

6901

1

⁄4r

32

Butt-weld DIN-

EN 10220

ICFS 20

ICFF 20

ICFE 20H

ICFC 20

ICFR 20B

ICFW 20D

9.8

21.5

027L4753

ICF SS 25

6901

25

Butt-weld DIN-

EN 10220

ICFS 25

ICFF 25

ICFE 25

ICFN 25

ICFR 25B

ICFW 25D

24.2

53.2

027L4189

ICF SS 25

6901

25

Butt-weld DIN-

EN 10220

ICFS 25

ICFF 25

ICM 25-A

ICFC 25

ICFB 25

ICFS 25

23.6

51.9

027L4763

ICF SS 25

6901

1

⁄4

32

Butt-weld DIN-

EN 10220

ICFS 25

ICFF 25

ICM 25-B

ICFC 25

ICFB 25

ICFS 25

23.6

51.9

027L4762

Type

Function Module Type

Can be installed in these locations

ICFS SS

Stop valve moduleM1M2M3M4

ICFR SS

Manual regulating valve module

M1M2M3

M4

ICFF SS

Filter (strainer) module

location not possible

M2

location not possible

M4

ICFE SS

Solenoid valve module

location not possible

location not possible

M3

location not possible

ICFC SS

Check valve module

location not possible

location not possible

location not possible

M4

ICFN SS

Stop / check valve module

location not possible

location not possible

location not possible

M4

ICM SS

Motor valve module

M1

location not possible

M3

location not possible

ICFB SS

Blank top coverM1M2M3M4

ICFA SS

Electronic expansion valve module (for ICF SS 20 only)

M1

location not possible

M3

location not possible

ICFE SS 20H

Solenoid valve module (for ICF

SS 20 only)

M1

location not possible

M3

location not possible

ICFO SS

Manual opening module

location not possible

location not possible

location not possible

M4

ICFW SS

Welding moduleM1M2M3M4

Type

Function Module Type

Can be installed in these locations

ICFS SS

Stop valve module

M1M2M3M4M5

M6

ICFR SS

Manual regulating valve module

M1M2M3M4M5

M6

ICFF SS

Filter (strainer) module

location not possi-

ble

M2

location not possi-

ble

M4

location not possi-

ble

M6

ICFE SS

Solenoid valve module

location not possi-

ble

location not possi-

ble

M3

location not possi-

ble

location not possi-

ble

location not possi-

ble

ICFC SS

Check valve module

location not possi-

ble

location not possi-

ble

location not possi-

ble

M4

location not possi-

ble

M6

ICFN SS

Stop/check valve module

location not possi-

ble

location not possi-

ble

location not possi-

ble

M4

location not possi-

ble

M6

ICM SS

Motor valve module

M1

location not possi-

ble

M3

location not possi-

ble

M5

location not possi-

ble

ICFB SS

Blank top cover

M1M2M3M4M5

M6

ICFA SS

Electronic expansion valve module (for ICF SS 20 only)

M1

location not possi-

ble

M3

location not possi-

ble

M5

location not possi-

ble

Valve station, Type ICF SS 20 and ICF SS 25

NOTE:

ICAD and coils are not included and must be ordered separately.

When used in systems with CO2, the o-rings on the ICM module can swell (grow). At service, it is therefore

recommended to install new o-rings, before the ICM function module is re-installed in the ICF SS valve body. ICAD

and coils are not included and must be ordered separately.

Modules

Table 40: ICF SS with four modules

Table 41: ICF SS with six modules

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 25

Type

Function Module Type

Can be installed in these locations

ICFE SS

20H

Solenoid valve module (for ICF

SS 20 only)

M1

location not possi-

ble

M3

location not possi-

ble

M5

location not possi-

ble

ICFO SS

Manual opening module

location not possi-

ble

location not possi-

ble

location not possi-

ble

M4

location not possi-

ble

location not possi-

ble

ICFW SS

Welding module

M1M2M3M4M5

M6

Blind SS plug

Connector SS

1

⁄2 in. - 3⁄8 in.

Sight glass

1

⁄2 in. weld connector SS

Adapter SS G

3

⁄8 - 3⁄8 FPT

Quantity

Code no.

2 pcs.

3

⁄8” RG

027L4811

Quantity

Code no.

2

027L4810

Quantity

Code no.

2 pcs.

3

⁄8” G

027L4812

Quantity

Code no.

2

148B4689

Quantity

Code no.

2

027L4813

ICAD 600A

Cable

Connector

Protection cap

Description

Code no.

ICAD 600A

With 1,5m cable 027H9075

Without cables 027H9120

Cable

Cable set 10 m. 027H0427

Cable set 15 m. 027H0435

Connector

Connector set female 027H0430

Protection cap

Protection cap for ICAD 027H0431

Valve station, Type ICF SS 20 and ICF SS 25

NOTE:

Module locations are indicated by M1, M2, M3, M4, M5 and M6. With respect to refrigerant ow, M1 is closest to

inlet.

Accessories

Table 42: Accessories

Table 43: Blind SS plug

Table 44: Connector SS

1

⁄2 in. - 3⁄8 in.

Table 45: Sight glass

Table 46:

1

⁄2 in. weld connector SS

Table 47: Adapter SS G3/8 - 3/8 FPT

Table 48: ICAD 600A - cable, connector and protection cap

Table 49: ICAD 600A

NOTE:

ICAD details see literature: AI236186442940

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 26

SNV-SS G ½ in.

SNV-SS

3

⁄8 in.

Description

Code no.

SNV-SS for ICF SS 20/SS 25 DIN butt weld connection.

Side connection: G ½ in.

Bottom connection: G ½ in.

Included:

Adapter SS (G ½ in. - G

3

⁄8 in.)

148B6545

SNV SS for ICF SS 20/SS 25 DIN butt weld connection.

Side connection:

3

⁄8 in. FPT

Bottom connection:

3

⁄8 in. MPT

Included:

Adapter SS (

3

⁄8 FPT - G 3⁄8 in.)

148B3750

Coils - Alternating current AC

Valve type

Voltage V

Frequency

Hz

Code no.

Appendix no.*)

Power consump‐

tion

With 1 m 3-core

cable

With terminal box

IP 67

With DIN plugs**)

Alternating current AC

ICFE

12

50

018F6706

15

Holding: 10 W 21

VA

Inrush: 44 VA

24

50

018F6257

018F6707

018F7358

16

220 – 230

50

018F6251

018F6701

018F7351

31

115

60

018F6260

018F6710

20

Direct current DC (can not be used for ICF SS 20 congurations with ICM module) Coil type I

ICFE/ICFA

12

018F6856

1

20 W

24

018F6857

2

Special coils for ICFE (can not be used for ICF SS 20 congurations with ICM module)

Valve type

Voltage V

Frequency Hz

Code no.

Appendix no. Indicates volt‐

age and frequency

Power consumption

With terminal box IP 67

Alternating current AC

ICFE

24

50

018F6807

16

Holding: 12 W 26 VA

Inrush: 55 VA

110

50

018F6811

22

220 – 230

50

018F6801

31

Valve station, Type ICF SS 20 and ICF SS 25

Table 50:

Table 51: SNV-SS

Table 52: Coils - Alternating current AC

Table 53: Coils - Alternating current AC

Table 54: Special coils for ICFE

Table 55: Special coils for ICFE (can not be used for ICF SS 20 congurations with ICM module)

NOTE:

For other coil types please refer to the technical leaets for EVRA or AKVA valves.

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 27

Type

File name

Document type

Document topic

Approval authority

ICF SS

033F0691.AD

Manufacturers Declaration

RoHS

033F0686.AG

Manufacturers Declaration

PED

19.10325.266

Marine - Safety Certicate

RMRS

ICF 20 - 25 SS

0C18678.513467890YTN

Pressure - Safety Certicate

TSSA

CRN

SA7200

Mechanical - Safety Certicate

UL

ICF 20 - 25 SS Body

0C19205.2

Pressure - Safety Certicate

TSSA

CRN

ICF SS valve station

Nominal bore

DN ≤ 25 (1 in.)

DN 32-40 (1 ¼ - 1 ½”)

Classied for

Fluid group I

Category

Article 3, paragraph 3

II

Conformity Approvals

UL approved

Valve station, Type ICF SS 20 and ICF SS 25

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 56: Valid approvals

Table 57: Compliance

Table 58: Compliance table ICF SS 20 and ISF SS 25

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 28

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI243586442520en-000901 | 29

Loading...

Loading...