Page 1

Application Guide

ICFD defrost module

Supplemental application guidelines

Page 2

ICFD defrost module | Contents

Contents

Introduction 3

Liquid drain 4

ICFD liquid drain module (ICFD 20 / ICFD 20-C) 5

ICF liquid drain method 6

ICF valve station with ICFC 20P1 loaded check valve 7

Liquid drain to a separate defrost line 9

Multiple evaporators connected to a common ICF evaporator station 10

Protection of evaporators against excessive pressure caused by trapped liquid 11

Installation 13

Online support 16

© Danfoss | Climate Solutions | 2021.11 AB374240933694en-000101 | 2

Page 3

ICFD defrost module | Introduction

Introduction

This ICFD supplemental application guide describes the special requirements to be taken into account when

designing the liquid drain line with ICFD defrost module.

© Danfoss | Climate Solutions | 2021.11 AB374240933694en-000101 | 3

Page 4

ICFD defrost module | Liquid drain

Liquid drain

Liquid drain method is the most energy ecient method. The method ensures that only liquid condensate is

drained back to the suction accumulator and minimizing the hot gas consumption.

© Danfoss | Climate Solutions | 2021.11 AB374240933694en-000101 | 4

Page 5

Description

Values

Maximum dierential pressure

15 bar/218 psig

Minimum densitet

610 kg/m3 /38,0 lb/ft

3

Max working pressure with oat

28 bar/406 psig

Description

Values

Maximum

dierential pressure

36 Bar/522 psig

Minimum densitet

860 kg/m

3

/53,7 lb/ft

3

Max working pressure with

oat

52 bar/754 psi

ICFD defrost module | ICFD liquid drain module (ICFD 20 / ICFD 20-C)

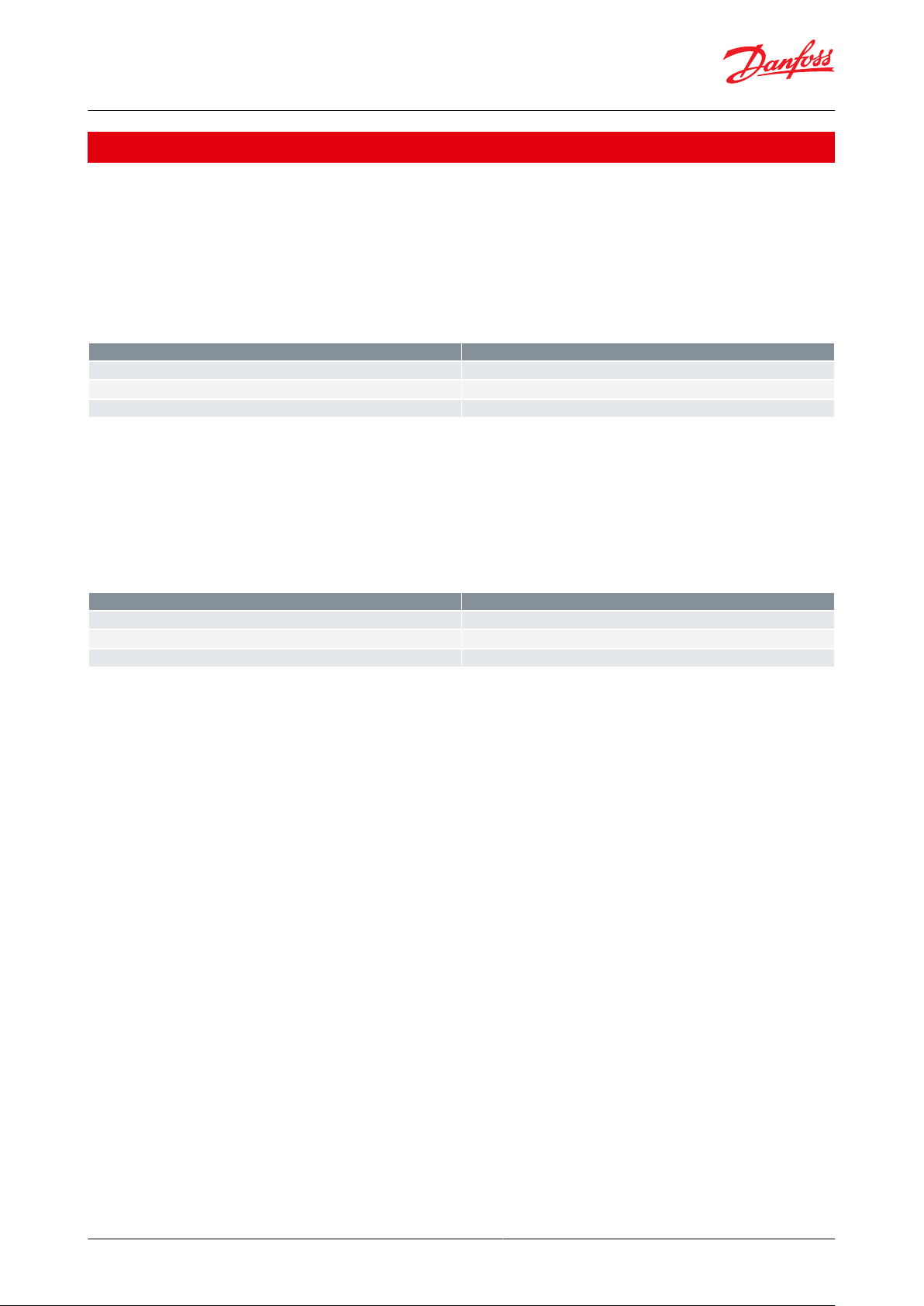

ICFD liquid drain module (ICFD 20 / ICFD 20-C)

Float operated valve module. The module opens for liquid ow when the oat is lifted by the internal liquid level.

The ICFD is a balanced type of oat valve suitable for high dierential pressure. The ICFD is available in two dierent

versions.

ICFD 20 (ammonia)

Is specically designed for ammonia. In order to operate with low density uids, the oat is manufactured with a

very low weight.

Table 1: ICFD 20 (ammonia)

NOTE:

If the refrigeration system includes ICFD 20 module, the test pressure of the system must not exceed 28 bar/406

psig, unless the ICFD oat ball is dis-mounted during the pressure test.

CFD 20-C (CO2)

Is specically designed for CO2. In order to operate with high pressure, the oat is manufactured with a large wall

thickness, and therefor has a higher weight.

Table 2: ICFD 20-C (CO2)

NOTE:

If the refrigeration system includes ICFD 20-C module, the test pressure of the system must not exceed 52 bar/754

psig, unless the ICFD 20C oat ball is dis-mounted during the pressure test.

ICFD liquid drain module is patent pending.

© Danfoss | Climate Solutions | 2021.11 AB374240933694en-000101 | 5

Page 6

A

B

ICFD (drain module) is the main function of the Liquid drain

ICFE (solenoid valve module) ensures that the drain line is closed o during freezing, in order to

avoid any liquid bypassing the evaporator

ICFD defrost module | ICF liquid drain method

ICF liquid drain method

A common solution with “Liquid drain” is equipped with a solenoid valve function and liquid drain function (see the

guration in Figure 1).

Figure 1: Liquid drain "standard conguration"

© Danfoss | Climate Solutions | 2021.11 AB374240933694en-000101 | 6

Page 7

Description

Values

Refrigerants

All

Opening pressure

0,5 bar/73 psi

Max working pressure

52 bar/754 psi

P

1

P

2

Valve

opening

(Capacity)

100%

0%

0,5 0,7 ∆p (P1-P2) [bar]

ICFC

20P1

ICFD defrost module | ICF valve station with ICFC 20P1 loaded check valve

ICF valve station with ICFC 20P1 loaded check valve

The ICFC 20P1 is designed to work together with the ICFD drain module in a pump circulating system, enabling a

defrost solution without using a solenoid valve in the drain line.

The function of the ICFC module, is to prevent that liquid refrigerant from the pump ow through the ICFD drain

module when the evaporator is in freezing mode and at the same time has a high ow capacity when the

evaporator in defrost mode. The ICFC 20P1 valve is designed with a special quick opening feature that ensure that

the valve start to open when the pressure across the check valve module exceeds 0,5 bar and reaches full capacity @

0,7 bar. By this feature it is possible to make a defrost conguration where the traditional solenoid valve is replaced

by an ICFC 20P1 loaded check valve without reducing the capacity.

Table 3: ICFC 20P1

NOTE:

ICFC 20P1 loaded check valve is patent pending.

Figure 2: ”Loaded check valve” - working principle

Evaporators and piping system may be designed dierently, it is therefore important to validate that the total

pressure drop ΔP across the evaporator and connecting pipes is less than 0,5 bar (73 psi) during freezing mode (see

Figure 3).

© Danfoss | Climate Solutions | 2021.11 AB374240933694en-000101 | 7

Page 8

ABΔP1

ΔP2

ΔP3

ICFD (drain module) is the main function of the Liquid drain

ICFC 20-P1 (“Loaded Check Valve”) ensures that there is no liquid ow in the drain line

during freezing mode and has a high capacity during defrosting mode

Pressure drop from valve station in the liquid supply line incl. liquid head pressure

Pressure drop across the evaporator (typically approx. 0,2 bar (29 psi) but can be higher e.g.

for evaporators with distribution nozzles).

Pressure drop in wet return line incl. liquid head pressure

ICFD defrost module | ICF valve station with ICFC 20P1 loaded check valve

Figure 3: Liquid drain conguration with ”loaded check valve”

ΔP1 + ΔP2 + ΔP3 ≤ 0,5 bar (73 psi)

NOTE:

Some systems require more than 0,5 bar dierential pressure = > ICFC 20P1 loaded check valve is

aware of systems with multiple evaporators connected to the same evaporator valve station, which normally

requires additional regulating valves to balance the ow in each evaporator, or single evaporators systems designed

in same way.

The loaded check valve ICFC 20P1 is not recommended to defrost systems draining to a higher pressure than

suction pressure e.g. a low temperature system draining to the intermediate temperature (4-pipe system). In these

systems standard ICFC 20 check valve is recommended.

© Danfoss | Climate Solutions | 2021.11 AB374240933694en-000101 | 8

not suitable. Be

Page 9

A

B

C

ICFD (drain module) is the main function of the Liquid drain

ICFE (solenoid valve module) ensures that the drain line is closed o during freezing mode

ICFC or ICFN (check or stop check valve) ensures that the pressure from the separate defrost drain

line (intermediate pressure) is not pushed backwards into the low temperature liquid line during

freezing mode (backow)

ICFD defrost module | Liquid drain to a separate defrost line

Liquid drain to a separate defrost line

Liquid drain to a separate defrost drain line is designed to drain the condensate to a separate drain system, typical

intermediate pressure. The system is often called a 4-pipe system. The benet with this system is that the

condensate is drained to a higher-pressure level in the system, and thereby slightly improving the eciency of the

system.

Figure 4: Defrost system with separate drain line (4-pipe system)

NOTICE:

Due to low pressure drop in standard check valves, the capacity of the ICFD-liquid drain valve is not aected

signicant compared to the solution with “loaded check valve”.

© Danfoss | Climate Solutions | 2021.11 AB374240933694en-000101 | 9

Page 10

ABC

Adjusting/balancing valves to ensure equal refrigerant ow

Adjusting/balancing valves to ensure equal hot gas ow

Deep liquid trap (P-trap)

ICFD defrost module | Multiple evaporators connected to a common ICF evaporator station

Multiple evaporators connected to a common ICF evaporator station

The defrost system illustrated in gure 5 shows two evaporators connected to one common valve station. In order

to ensure that such a system is operating properly, it is important that the freezers are equally loaded, and the

refrigerant ow is distributed equally. It is furthermore important that the evaporators are installed at equal heights

and are equipped with a good deep liquid trap (P-trap), in order to avoid that gas from one of the evaporators will

block for the liquid ow from the other evaporator.

Figure 5: Multiple evaporators connected to the same evaporator station

© Danfoss | Climate Solutions | 2021.11 AB374240933694en-000101 | 10

Page 11

O

S

"Operation" valve (solenoid valve)

"Service" valve ("locked")

ICFD defrost module | Protection of evaporators against excessive pressure caused by trapped

liquid

Protection of evaporators against excessive pressure caused by trapped liquid

The defrost system shown in Figure 6 has two solenoid valves, one in the liquid feed line, and one in the wet return

line, but none in the liquid drain line. This mean that the ICFD drain module + loaded check valve (ICFC 20P1) are

the pressure barrier between the pressure in the evaporator, and the pressure in the wet return line (liquid

separator).

When designing a defrost system with ICFC 20P1 loaded check valve, and without any solenoid valves modules, the

loaded check valve can be used to protect evaporators against excessive pressure caused by trapped liquid. The

liquid drain valve is connected to the bottom of the evaporator, which will ensure that all liquid in the evaporator

will be drained in the event of continuously heat input into the evaporator and avoid unintended pressure increase.

Figure 6: Evaporator station with ICFC 20P1 loaded check valve and the ICFD drain module preventing

excessive pressure caused by trapped liquid in evaporator

If the pressure in the evaporator exceed more than 0,5 bar higher than the pressure in the liquid separator, the

loaded check valve (ICFC 20P1) starts to open, and the liquid in the evaporator will ow to the ICFD drain module,

which will then open.

Assuming all stop valve in the evaporator station are treated as “service valve” (S) - (valve only accessed by

competent persons), and only solenoid valves are active “operation valves” (O). If liquid refrigerant is present in the

evaporator there is a risk of trapped liquid (see Figure 6). Systems having a liquid drain valve and loaded check valve

in drain line are protected against trapped liquid. Trapped liquid (100% liquid) => drain valve open and loaded

check valve opens @ Δp = 0,5 bar.

Mtv (max trapped volume for ICFD + ICFC 20 P1):

Mtv = 883.23*Kv100 [l] = 883.23*1.116 = 985 Liter (at Kv of 1.116 m3/h)

NOTE:

The drain valve has a build-in parallel bleed orice (ø 1,25 mm ~ Kv = 0,064 m3/h).

© Danfoss | Climate Solutions | 2021.11 AB374240933694en-000101 | 11

Page 12

ICFD defrost module | Protection of evaporators against excessive pressure caused by trapped

liquid

In defrost system with 3 solenoid valves, one in the liquid feed line, one in the wet return line and one in the liquid

drain line, the evaporator must be protected against excessive pressure caused by trapped liquid in a proper way

(see example in Figure 1).

© Danfoss | Climate Solutions | 2021.11 AB374240933694en-000101 | 12

Page 13

Nozzles

Nozzles

Hot gas inlet

Condensate drain

ICFD defrost module | Installation

Installation

Figures 7 to 9 shows the most common evaporator types.

If the defrost system is designed with the ICFD liquid drain method, all types of evaporators must be connected to

the ICF valve station with the same piping conguration.

• Condensate drain outlet at the lowest pipe of the evaporator

• Hot gas inlet at the top pipe of the evaporator

The ICFD module is designed for drainage of primarily liquid. The gas in the system at the beginning of the defrost

process is drained only through a small parallel bleed orice, built into the ICFD module. For a correct defrost of the

evaporator, it is important that all liquid can be drained from the evaporator during the defrost sequence.

Figure 7: Bottom feed

Figure 8: Top feed with distribution nozzles

Figure 9: Side/bottom feed with distribution nozzles

Drain line

During piping layout, take all precautions to minimize the pressure drop to avoid ash gas. Any pressure loss will

reduce the liquid drain capacity.

© Danfoss | Climate Solutions | 2021.11 AB374240933694en-000101 | 13

Page 14

ICFD defrost module | Installation

For Evaporators with distribution nozzles at the drain outlet (side/bottom feed in Figure 9), the liquid passing the

nozzles during defrost will create a certain pressure drop in the drain line. This pressure drop must be taken into

account To minimize total pressure drop the lifting height of the liquid should not exceed 5 m (16.5 ft) (see Figure 10

and Figure 11).

To calculate the total pressure drop for ICF with ICFD included, the Danfoss selection tool Coolselector®2 is

recommended.

Always install a P-trap at the drain line connection to the evaporator to collect the liquid The optimum piping layout

for the liquid drain line is a separate line for the defrost drain (see Figure 10). By this set-up the dimensions of the

liquid drainpipe can be determined for optimized liquid velocity and liquid volume and thereby reducing pressure

loss. Figure 11 shows alternative piping layouts for the defrost liquid line. An acceptable option is to use the existing

liquid line provided that a P-trap is installed.

During piping layout, take all precautions to minimize the pressure drop in the hot gas line to ensure sucient

defrost pressure (temperature) in the evaporator. Any pressure loss may reduce the defrost capacity.

For evaporators with distribution nozzles at the hot gas entrance (top feed in Figure 8), the gas passing the nozzles

during defrost will create a certain pressure drop in the hot gas line. This pressure drop must be taken into account

when determining the total pressure loss.

For calculation and optimizing of the pressure losses in both liquid drain line and hot gas line the Danfoss selection

tool Coolselector®2 is recommended.

The liquid drain setup with ICFD does not include any control of the pressure during defrost. It is therefore

recommended to consider the following: If the hot gas supply pressure is higher than the pressure required for

defrosting, it is recommended to install a pressure reducing valve like ICS/CVC ahead of the hot gas valve station to

prevent too high hot gas pressure entering and potentially damaging the evaporator. The CVC should be set to the

pressure intended for the defrost process.

Figure 10: Best solution (Optimized liquid velocity and volume). Always install P-trap

© Danfoss | Climate Solutions | 2021.11 AB374240933694en-000101 | 14

Page 15

ICFD defrost module | Installation

Figure 11: Possible solution. Always install P-trap

© Danfoss | Climate Solutions | 2021.11 AB374240933694en-000101 | 15

Page 16

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.11 AB374240933694en-000101 | 16

Loading...

Loading...