Page 1

Installation guide

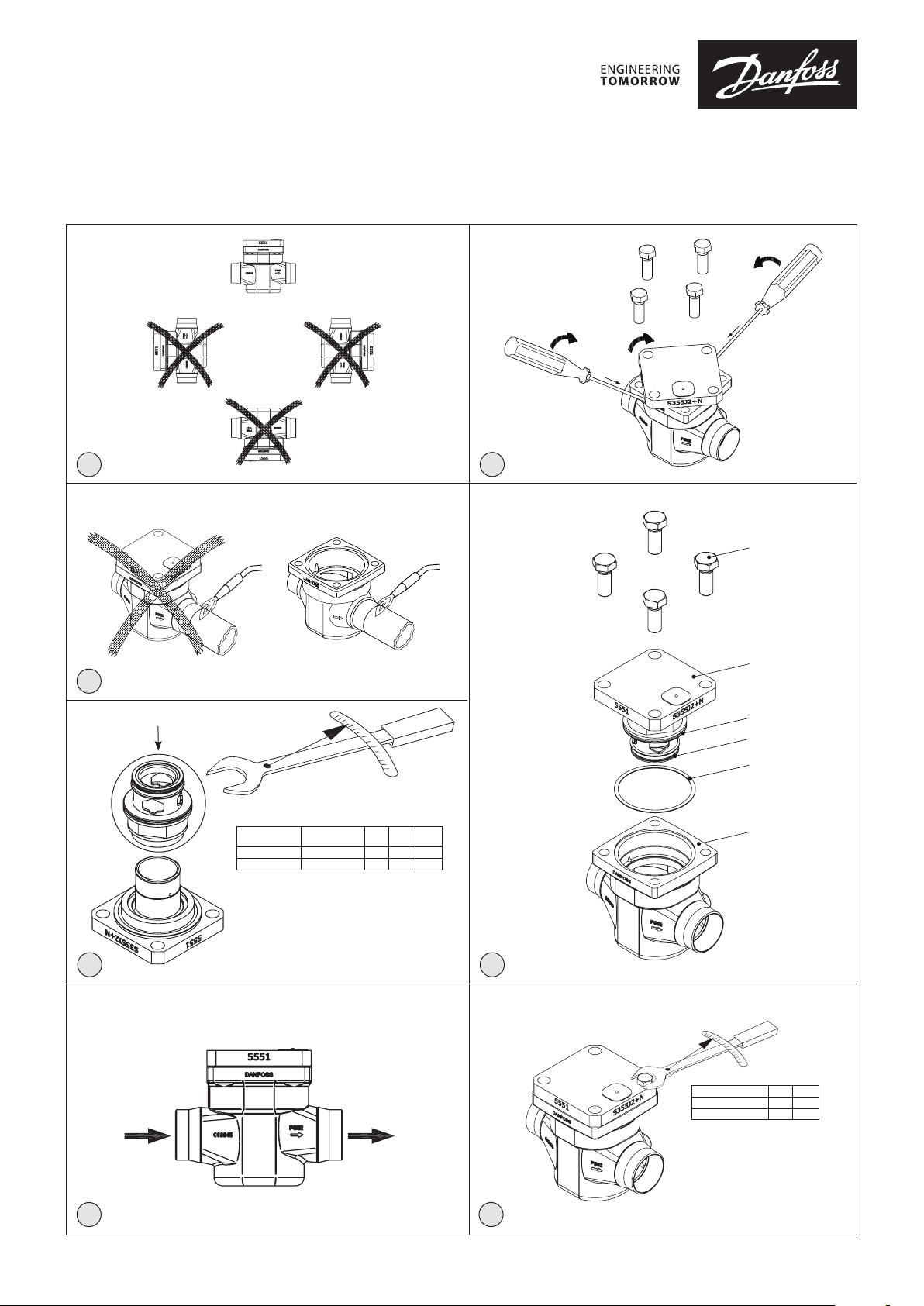

2b

Non-return valve (check valve)

ICC 32 and 50

3

027R9974

1

3

Repair kit

027R9974

3

1

2

2

2

4

2

2a

Type Code number Nm ft lb

ICC 32 027H3039 150 110 46

ICC 50 027H5017 150 110 65

[mm]

3

NV

1

54

Valve body size Nm ft lb

ICC 32 120 88

ICC 50 140 103

6 7

© Danfoss | DCS (ms) | 2019.09

AN318437839947en-000101 | 1

Page 2

ENGLISH

Refrigerants

Applicable to HCFC, HFC, R717(Ammonia) and

R744 (CO₂).

Flammable hydrocarbons are not

recommended.

The valve is only recommended for use in closed

circuits. For further information please contact

Danfoss.

Temperature range

–60/+120 °C (–76/+248 °F)

Pressure range

The valves are designed for a max.

working pressure of 52 barg (754 psig).

Technical data

The ICC can be used in Economizer Lines in

combination with ICD and ICS. The ICC prevents

back pressure ow of the medium in the system.

Regulating range

Dependent on the chosen size.

Opening differential pressure (p)

The ICC main valve requires a minimum opening

dierential pressure of 0.04 bar (0,6 psi) to begin

to open and 0.1 bar (1.45 psi) to be completely

open.

Design (fig. 4)

1. Body

2. Top assembly

2a O-ring

2b O-ring

3. Gasket

4. Bolts

Installation

The valve must be installed with the arrow in the

direction of the ow and the top cover upwards

(g. 1 and 6). The top cover can be rotated 4 X

90° in relation to the valve body. The valve is

designed to withstand a high internal pressure.

However, the piping system should be designed

to avoid liquid traps and reduce the risk of

hydraulic pressure caused by thermal expansion.

It must be ensured that the valve is protected

from pressure transients like “liquid hammer” in

the system.

Welding (fig. 3 and 5)

The top assembly (g. 5, pos. 2 and 3) must be

removed before welding to prevent damage to

o-rings and teon (PTFE) in the function module

and to avoid getting welding debris in the

module.

Note: Remove all parts from the valve body

before welding (as shown in g. 3).

In order to maintain the eectiveness

of the anti-corrosion treatment, it is

important to ensure that the valve

is disassembled just prior to the

welding / brazing process being

undertaken.

In the event that the function

modules are to be left disassembled

for any length of time, please

ensure that the function modules

are further protected by placing in

a polyethylene bag or by applying

a rust protection agent (e.g.

refrigeration oil or BRANOROL) on the

surfaces.

Only materials and welding methods,

compatible with the valve body material, must

be welded to the valve body.

The valve should be cleaned internally to

remove welding debris on completion of

welding and before the valve is reassembled.

Avoid welding debris and dirt in thevalve body

and the function module. The valve body must

be free from stresses (external loads) after

installation.

The valves must not be mounted in systems

where the outlet side of the valve is open to

atmosphere. The outlet side of the valve must

always be connected to the system or properly

capped o, for example with a welded-on end

plate.

Assembly

Remove welding debris and any dirt from pipes

and valve body before assembly. Check that the

o-rings are intact before replacing the function

module. If possible, apply some refrigeration

oil to ease the insertion and to protect the

o-rings. Check that the top gasket has not been

damaged. If the surface has been damaged or

the gasket has been bent, it must be replaced.

Tightening (fig. 7)

Tighten the top cover with a torque wrench, to

the values indicated in the table.

Colours and identification

The ICC valves are Zinc-Chromated from factory.

The Zinc-Chromatization does not cover the

welding connections. If further corrosion

protection is required, the valves can be painted.

Precise identication of the valve is made via the

ID plate on the top cover. The external surface

of the valve housing must be protected against

corrosion with a suitable top coating after

installation involving welding and consequent

assembly.Protection of the ID plate when

painting the valve is recommended.

Maintenance

Service

The ICC valves are easy to dismantle.

Do not open the valve while the valve is still

under pressure.

The top assembly module can be lifted out using

two screwdrivers as shown g. 2

Upon opening and removal of the function

module:

- Check that the o-rings on the function

module has not been damaged. A

valve with a damaged o-ring might not

modulate according to the specication.

- Check that the piston and cylinder is

free of scratches and look for wear

marks. If the wear is excessive the

function module should be replaced to

prevent unexpected function issues.

- Check that the movement of the

cylinder and valve seat is free and with

low friction.

- If the teon valve plate is damaged it must

be replaced. A pre-assembled teon valve

plate in cylinder housing is available as repair

kit (see also g. 4):

Type Code number

ICC 32 repair kit 027H3039

ICC 50 repair kit 027H5017

Assembly

Remove any dirt from the body before the valve is

assembled. Check that channel in the valve is not

blocked by particles or similar.If possible, apply

some refrigeration oil to ease the insertion and to

protect the o-rings.

Tightening (fig. 7)

Tighten the top cover with a torque wrench, to

the values indicated in the table.

Use only original Danfoss parts, including

O-rings and gaskets for replacement. Materials

of new parts are certied for the relevant

refrigerant.

In cases of doubt, please contact Danfoss.

Drawings are only for illustration, not for

dimensioning or construction.

Danfoss accepts no responsibility for errors

and omissions. Danfoss Industrial Refrigeration

reserves the right to make changes to products

and specications without prior notice.

The following text is applicable to the UL

listed products ICC 32 and 50

Applicable to all common non-ammable

refrigerants, including R717 and to non-corrosive

gases/liquids dependent on sealing material

compatibility. The design pressure shall not

be less than the value outlined in Sec.9.2 of

ANSI/ASHRAE15 for the refrigerant used in the

system.

© Danfoss | DCS (ms) | 2019.09

AN318437839947en-000101 | 2

Loading...

Loading...