Page 1

Quick Start Guide

ICM/ICAD Motorized Valves

Installation, Programming, and Troubleshooting

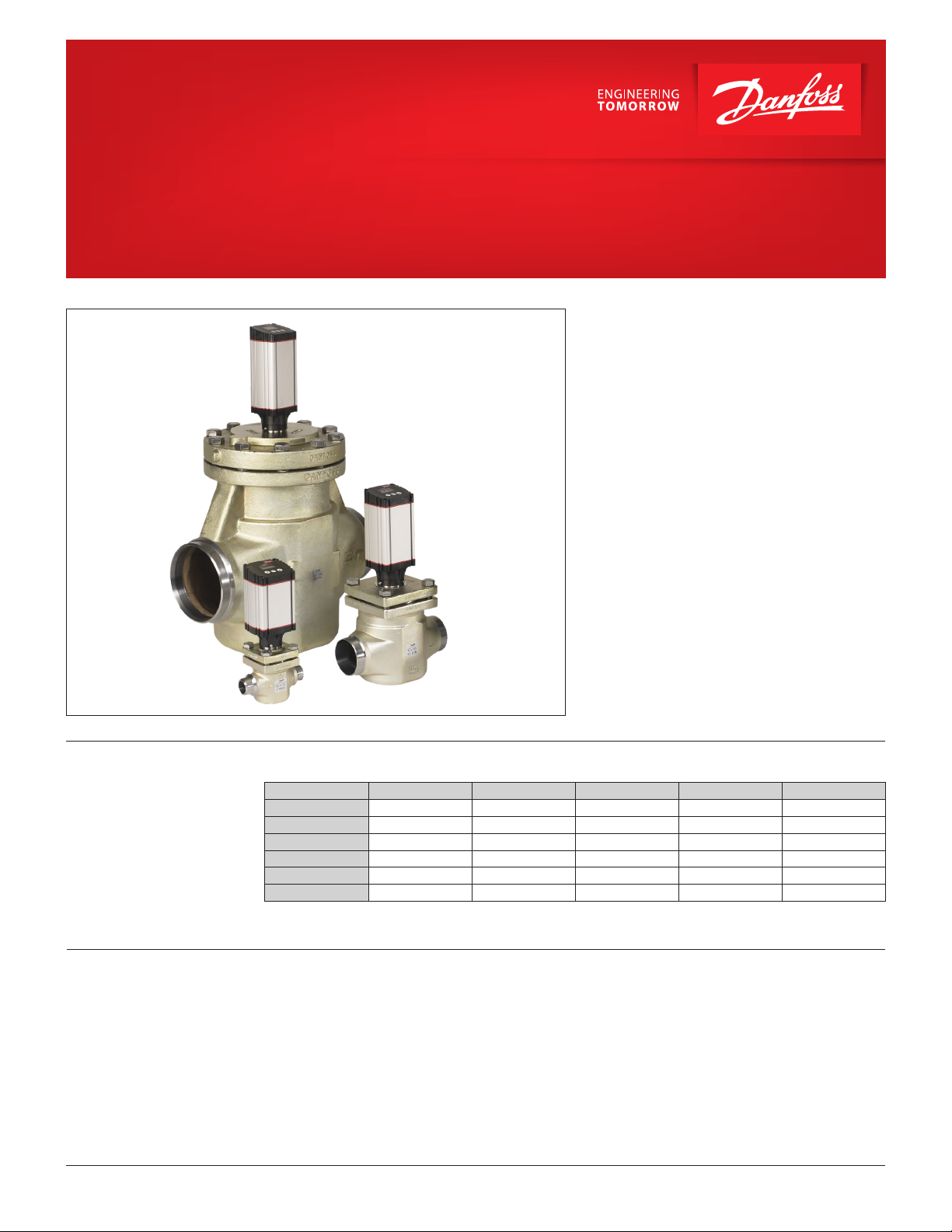

The ICM motorized valve is comprised of up to 4

components:

• the valve body – often referred to as the ICV body

because it is used for ICM motor valves, ICS pilot

operated valves and ICLX solenoid valves.

• the function module – the flow regulating part of

the valve

• the top cover – on the ICM 20 through 65, the

function module and top cover are one part

• the ICAD motor actuator – the “brains” of the

valve

ICM/ICAD overview The combinations of valve and actuator are as follows:

Actuator ICAD 600A ICAD 1200A Old ICAD 600* Old ICAD 900* Old ICAD 1200*

Valve Size ICM 20 ICM 40 ICM 20 ICM 40 ICM 40

Valve Size ICM 25 ICM 50 ICM 25 ICM 50 ICM 50

Valve Size ICM 32 ICM 65 ICM 32 ICM 65 ICM 65

Valve Size ICM 100 ICM 100

Valve Size ICM 125 ICM 125

Valve Size ICM 150 ICM 150

* ICAD 600, 900 and 1200 were discontinued at the end of 2014. ICAD 600A is a direct replacement of ICAD 600 and ICAD 1200A is a

direct replacement of ICAD 900 or ICAD 1200.

© Danfoss | Climate Soutions | 2021.04

AN249186497575en-000402 | 1

Page 2

Quick Start Guide | ICM/ICAD Motorized Valves - Installation, Programming, and Troubleshooting

Contents Page

ICM/ICAD overview .....................................................................................1

Identifying ICM sizes ....................................................................................3

1st and 2nd generation ICAD differences ..................................................................4

Installation .............................................................................................5

Wiring the ICAD actuator ...............................................................................7

Electrical data ..........................................................................................7

ICAD Programming ....................................................................................11

Pre-start up checklist ..................................................................................13

Troubleshooting

Overview ..........................................................................................14

Service parameters ................................................................................14

Alarms.............................................................................................14

Tips ...............................................................................................15

Frequently asked questions ........................................................................16

© Danfoss | Climate Solutions | 2021.04

AN249186497575en-000402 | 2

Page 3

Quick Start Guide | ICM/ICAD Motorized Valves - Installation, Programming, and Troubleshooting

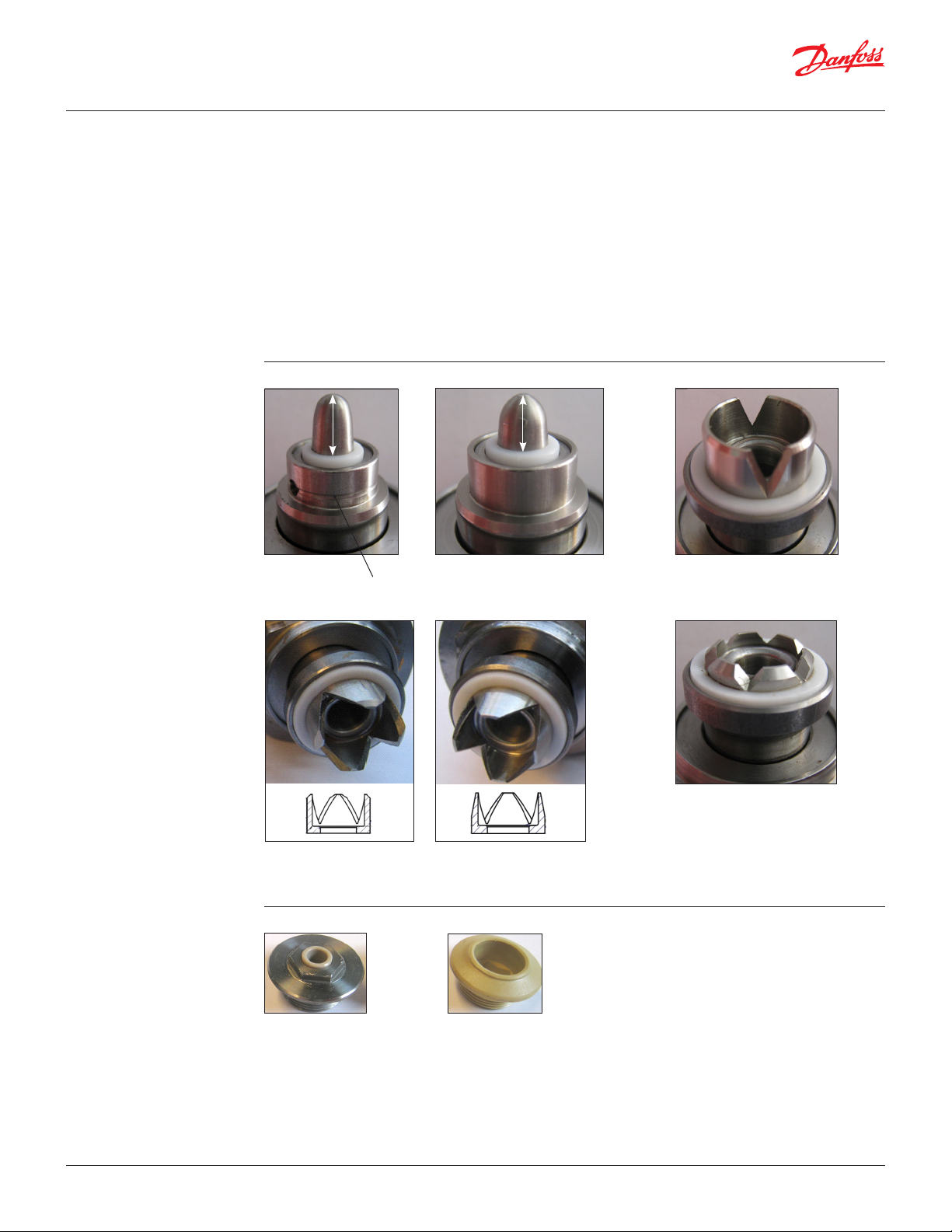

Identifying ICM sizes All ICM sizes except ICM 20 have a stainless steel

ID tag located around the valve stem on the top

cover which the ICAD mounts on. When the ICAD

is mounted it can be difficult to locate this. The

sticker on the valve body of the large valves states

ICV and the valve size because the body is shared

between the ICM motor valves, ICS pilot operated

valves and ICLX solenoid valves.

The ICV size is the same size as the ICM size which

is needed during programming. ICM 20 only has a

sticker on the side of the valve body to identify the

size.

Different ICM 20

cone and orifice

designs

ICM20-A33

A33 has a groove here

for identification

7 mm

ICM20-A (2nd gen.)

Introduced mid 2009

If the sticker is missing the size can be identified by

the shape of the cone. The below figure shows how

to indentify the ICM 20 size by looking at the cone.

5 mm

ICM20-A (1st gen.)

Discontinued mid 2009

Note:

The outside edges of the

B66 cone has more of a

cylindrical shape compared

to the B cone which forms

more of a conical shape.

ICM 20 orifice (valve seat)

© Danfoss | Climate Solutions | 2021.04

ICM20-B66

Introduced Jan. 2011

ICM 20-A33

ICM 20-A (2nd gen.)

ICM20-C

ICM20-B

ICM 20-A (1st gen.), ICM 20-B,

ICM 20-B66, ICM 20-C

AN249186497575en-000402 | 3

Page 4

Quick Start Guide | ICM/ICAD Motorized Valves - Installation, Programming, and Troubleshooting

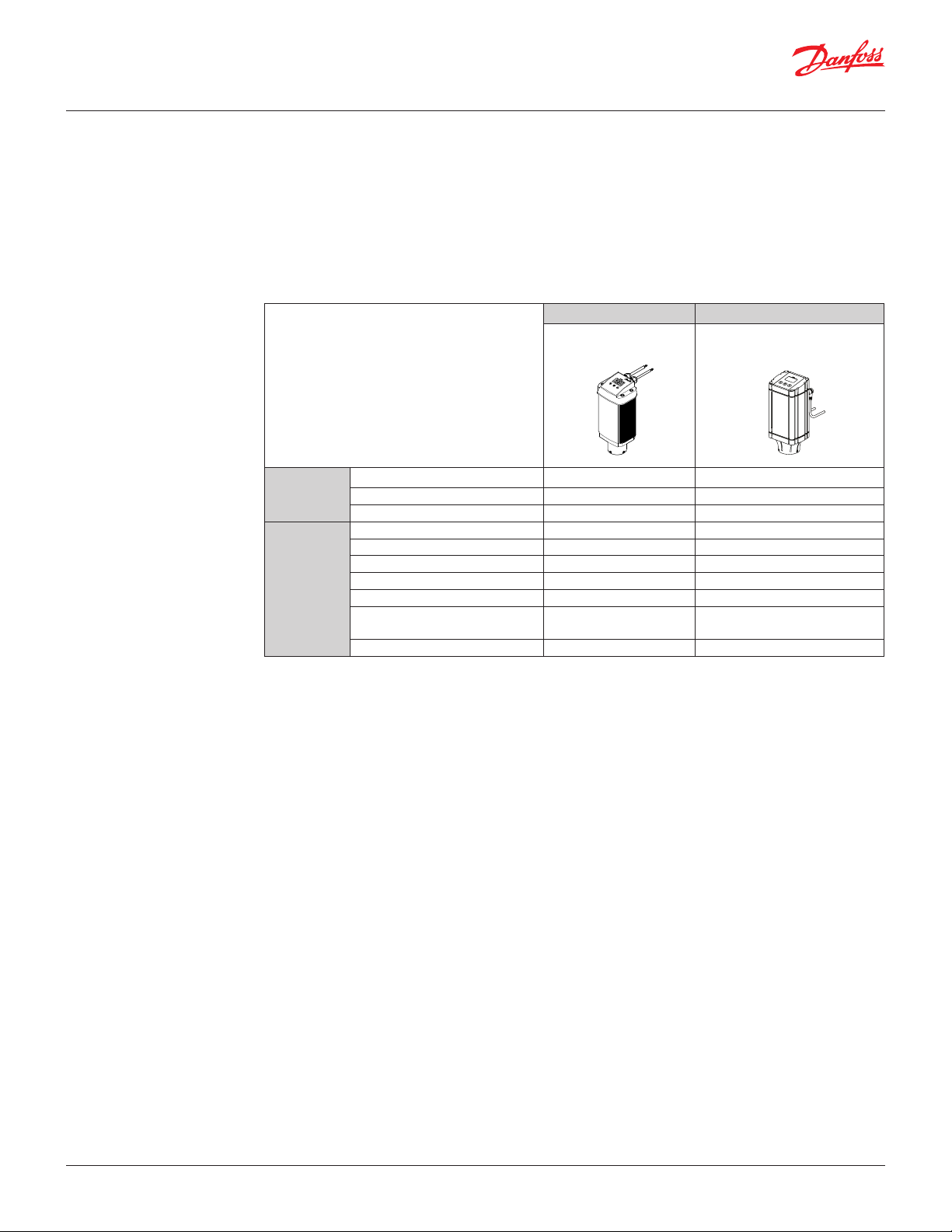

Differences between 1st and

2nd generation ICAD motor

actuators

The 2nd generation ICAD was released in the

beginning of 2010. The part numbers on the

label for the 2nd generation start with 027H9…

and the 1

st

generation part numbers started with

027H12… The cables of the 1st generation were

mounted through cable glands located in the

plastic top whereas the 2nd generation has the

cables mounted on connectors located in the

aluminum body.

Power cable

(3-wire)

Communication

cable (7-wire)

+ 19-24 V d.c. fail safe supply White (+) Black (+)

+ 24 V d.c. Brown (+) White (+)

- 24 C d.c. (GND) Green (-) Brown (-)

Digital output (common alarm) White (-) Black (-)

Digital output (ICM fully open) Brown (-) Brown (-)

Digital output (ICM fully closed) Green (-) Red (-)

GND - ground Yellow (-) Orange (-)

Analog input (0/4-20 mA Grey (+) Yellow (+)

Analog input 0/2-10 V /

Digital ON/OFF input

Analog output 0/4-20 mA Blue (+) Blue (+)

Note: The wire colors are different between the two

generations and the following is a table with the

differences and pictures of old and new generation.

1st Generation ICAD 2nd Generation ICAD

Pink (+) Green (+)

© Danfoss | Climate Solutions | 2021.04

AN249186497575en-000402 | 4

Page 5

Quick Start Guide | ICM/ICAD Motorized Valves - Installation, Programming, and Troubleshooting

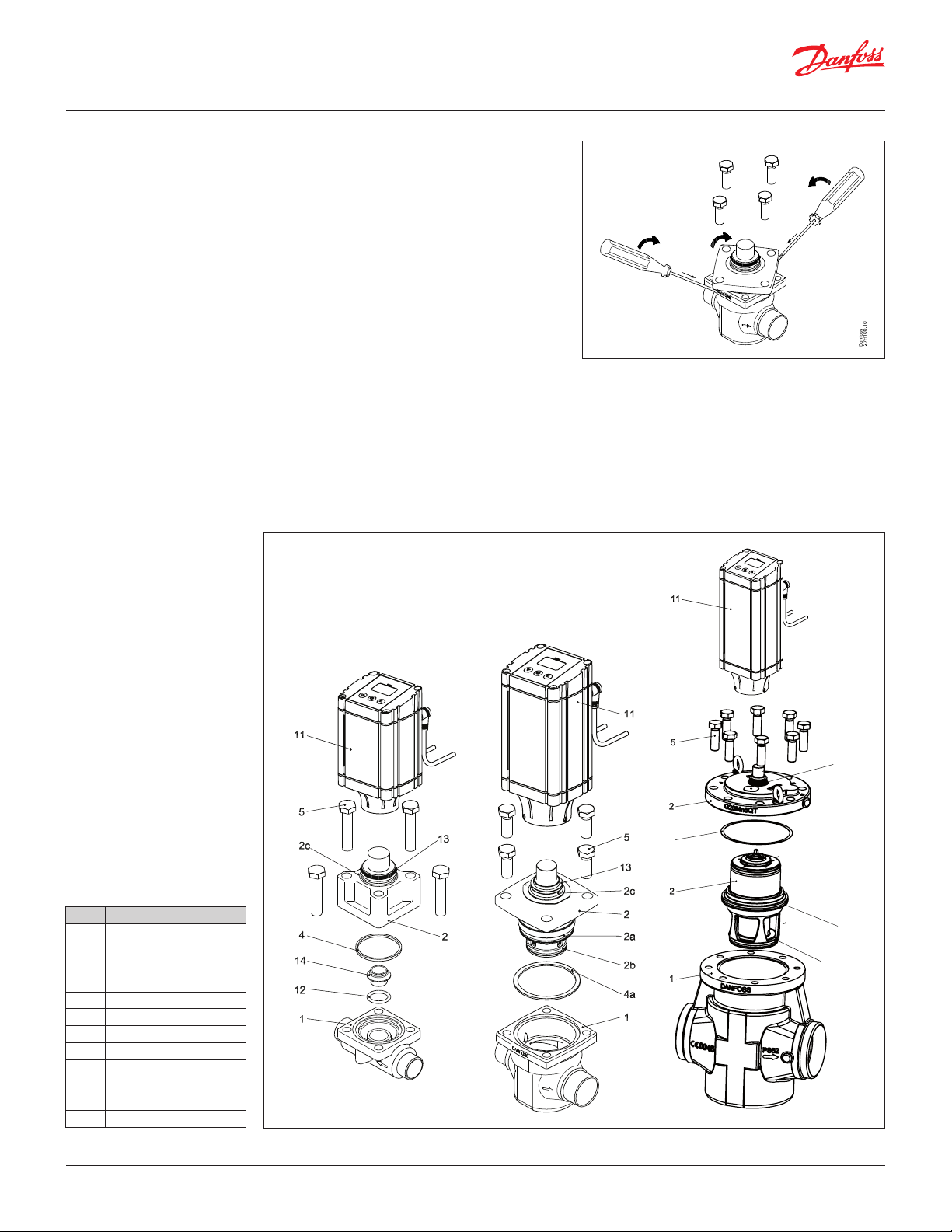

4a

Installation

1. All ICM valves and ICAD motor actuators must

be installed in horizontal pipelines with the

motor actuator in an upright position.

2. Preparation of Valve Body

ICM 20 (3/4”) valves: both the integrated

bonnet/function module and the separate

valve seat must be removed from the valve

body prior to welding. To remove the

ICM20-A33 or ICM20-A valve seat use a 13mm

socket and to remove the ICM20-B66, ICM 20-B

or ICM20-C valve seat, use a 12 mm hex key.

- ICM 25 to 65 (1” to 2-1/2”) valves, the

integrated bonnet and function module

should be removed as shown in the figure.

- ICM 100 to 150 (4” to 6”) valves, the function

module and bonnet are separate pieces and

do not need to be removed prior to welding.

However, some form of arc welding should

be used to weld the valve into the piping and

care should be taken to protect the valve

stem from becoming contaminated.

3

3

1

2

2

Removing the bonnet/function module from the body

of the ICM 25 to 65 valves.

2c

No. Par t

1 Housing

2 Top cover / function module

2a O-ring

2b O-ring

2c O-ring

4 Gasket

4a Gasket

5 Bolts

11 Actuator

12 O-ring

13 O-ring

14 Seat

© Danfoss | Climate Solutions | 2021.04

AN249186497575en-000402 | 5

2a

2b

Page 6

Quick Start Guide | ICM/ICAD Motorized Valves - Installation, Programming, and Troubleshooting

Installation (continued)

Care should be taken to protect the ICM function module when it is removed and stored during

installation of valve body.

3. Weld the valve body in line making sure that the arrow on the valve body is pointing in the direction

of flow.

- For ICM 20 through 65, make sure that all debris is removed from valve body before bonnet/

function module is re-installed.

- For the ICM 20, make sure that the removable orifice seat is re-installed in the valve body with the

small o-ring between the orifice seat and the body. Use a 13mm socket to tighten the ICM20-A33 or

ICM20-A valve seat to a torque of 6.5 ft-lbs (9 N-m). Use a 12 mm hex key to tighten the ICM 20-B66,

ICM20-B or ICM20-C valve seat to a torque of 1.5 ft-lbs (2 Nm).

DO NOT OVERTIGHTEN THE REMOVABLE SEAT.

Make sure that the bonnet gasket is installed and in good condition.

- For the ICM 25 through ICM 65, check that the two o-rings are installed on the function module and

that the gasket located on the top of the valve body is installed and all are in good condition.

A light coating of refrigerant oil on the bonnet o-rings and the cover gasket will facilitate assembly

of the valve.

4. Install the bolts and torque to the following specifications:

Valve Body Nm ft lbs

ICM 20 40 29

ICM 25 100 74

ICM 32 120 88

ICM 40 120 88

ICM 50 140 103

ICM 65 150 110

ICM 100 through 150 220 162

5. Install the ICAD Motor on the ICM valve:

The ICM valve must not be in its full opened position while the ICAD motor is calibrated with the valve

(at a later step). Therefore, if the opening degree of the ICM valve was changed from the factory

setting, it should be set to an opening degree between 0% and 75% using the manual magnet tool.

To easily ensure correct positioning, turn the manual tool counter-clockwise until it is clear that it

cannot be turned any further.

- Make sure that the ICM adapter/valve stem and inner ICAD magnets are completely dry and free

from any debris.

- The ICM adapter O-ring (position 2c in the diagram on page 5)must be removed and Molycote 55

grease (supplied with ICAD motor) needs to be applied in the O-ring groove on the adapter and on

the O-ring before it is re-installed on the ICM adapter.

The Molycote grease ensures a good seal between the ICAD motor and the ICM adapter to prevent

moisture from entering the ICAD magnets.

- Place the ICAD motor on the valve stem.

- Push the ICAD motor completely down to the identification ring on the valve stem. Using a 2.5 mm

hex key, tighten the set screws evenly so the ICAD motor is centered on the ICM valve stem.

Torque the set screws to approximately 3 Nm (2.5 ft-lbs).

© Danfoss | Climate Solutions | 2021.04

AN249186497575en-000402 | 6

Page 7

Quick Start Guide | ICM/ICAD Motorized Valves - Installation, Programming, and Troubleshooting

III

Electrical data

Supply voltage is galvanically isolated from input and output wires

Supply Voltage Fail Safe Supply

24 VDC + 10%/-15% Min. 19 VDC

Load ICAD 600A 1.2 A ICAD 600A 1.2 A

ICAD 1200A 2.0 A ICAD 1200A 2.0 A

Analog Input – Current or Voltage Analog Output

Current 0/4 – 20 mA 0/4 – 20 mA

Load: 200Ώ Load: ≤ 250 Ώ

Voltage 0/2 – 10 VDC

Load: 10k Ώ

Digital Input – Digital On/Off input by means of voltfree contact with gold-plated contacts recommended

Voltage Input Used

ON: contact impedance < 50 Ώ

OFF: contact impedance > 100 k Ώ

Digital Output: 3 pcs. NPN transistor output

External Supply: 5 – 24 VDC (same supply as for ICAD can be used but note that galvanically

isolated system will be spoiled.

Output Load: 50 Ώ

Load Max. 50 mA

Wiring the ICAD actuator There are two cables which are connected to the ICAD motor with M12 connectors:

4 pin male connector 8 pin male connector

II

I

Communication connector / cable

Ref. Color Description

A Black – Common Alarm

B Brown – ICM fully open

C Red – ICM fully closed

D Orange – GND ground

E Yellow + 0/4 - 20 mA Input*

F Green +

G Blue + 0/4 - 20 mA Output*

Power connector/cable (3 wires)

I Black +

II White +

III Brown –

* If using floating 3-point control (parameter i02=3) then wire colors yellow and blue are combined to make the 2nd digital input

0/2 - 10 V Input. Also used with GND (orange wire) as a digital input #1 for

on-off operation or floating 3-point control

Fail safe supply

Battery / UPS (uninterruptable power supply) 19 V d.c.

Supply voltage

24 V d.c.

C

D

E

F

B

A

G

Digital

Ouput

}

© Danfoss | Climate Solutions | 2021.04

AN249186497575en-000402 | 7

Page 8

Quick Start Guide | ICM/ICAD Motorized Valves - Installation, Programming, and Troubleshooting

&86720(56833/,('

Wiring the ICAD actuator Wiring diagram showing ICAD wired to a PLC or other type of third party electronics

Note: The ICAD supplies the power for the 4-20 mA feedback signal.

Terminal box

(customer supplied)

Control cable

PLC

Active 4-20 mA PLC output to control ICAD

+

-

Yellow

Orange

Blue

Black

White

Active 4-20 mA PLC output to control ICAD

-

Passive 4-20 mA PLC input

for valve position feedback

+

Passive 4-20 mA PLC input

for valve position feedback

Optional UPS/battery back up

+

Brown

Power supply cable

+

-

9GF

3RZHU

6XSSO\

Wiring diagram showing ICAD wired to a Danfoss EKC controller

Note: For instructions on completely wiring an EKC controller, please see the relevant EKC controller manual.

Terminal box

(customer supplied)

Control cable

Orange(ground)

(+ 4-20 mA)

Yellow

Blue (+ 4-20 mA)

Power supply cable

Optional position

feedback

Only possible

with EKC 347

Black

White

Brown

Optional UPS/battery back up

+

+

-

24 V d.c

Power

Supply

© Danfoss | Climate Solutions | 2021.04

CUSTOMER SUPPLIED

AN249186497575en-000402 | 8

Page 9

Quick Start Guide | ICM/ICAD Motorized Valves - Installation, Programming, and Troubleshooting

Wiring the ICAD actuator

continued

Connections

upper level

AKS 4100/4100U

+

–

Wiring diagram showing ICAD wired to a Danfoss EKE controller

Note: For instructions on completely wiring an EKE controller, please see the relevant EKE controller manual.

Upper level

AKS 41

24 V DC

1

24 V AC

L

N

23

4-20 mA

nd

gen

4-20 mA

orange

blue

ICAD 2

DI1 - main switch

Optional ICAD/ICM

Valve Position

Feedback

24 V+

15 V+

5 V+

COM

AI 5

AI 4

AI 3

AI 2

AI 1

COM

1

2 3 4 5 6 7 8 9 10 11 12 13 14

15 16 17 18 19 20 21 22 23 24

CAN L

GND

plug for

remote display

CAN RJ

R GNDD+D-

R120

CAN H

COM

COM

DI 2

DI 1

COM

AO 1

CANbus connection

to other EKE controllers

© Danfoss | Climate Solutions | 2021.04

ModBUS

orange

yellow

ICAD 2

nd

gen (2010 +)

brown

white

24 V DC

AN249186497575en-000402 | 9

Page 10

Quick Start Guide | ICM/ICAD Motorized Valves - Installation, Programming, and Troubleshooting

+

+

Customer Supplied

Wiring the ICAD actuator

continued

Wiring diagram showing ICAD wired with one digital input for ON/OFF solenoid valve operation

Note: The ICAD motor can be programmed to open or close when the relay is closed. See parameter ¡09 in

programming section.

Green

Relay

Orange

Black

White

Brown

+

Optional UPS/battery

back up

24 V d.c

+

Power

-

Supply

CUSTOMER SUPPLIED

Wiring diagram for floating 3-point control (open-neutral-close)

Default Setting

Par. i13=0 (Direct operation)

DI1=DI2=OFF: maintains

current postion

DI1=DI2=ON: maintains

current postion

DI1=ON, DI2=OFF: opening

degree increases

DI1=ON, DI2=OFF: opening

degree decreases

ICAD Commuication cable

ICAD power cable

Green

Orange

Yellow

Blue

Black

White

Brown

Relay for DI 1 (Digital Input1)

Relay for DI2 (Digital Input2)

+

Optional UPS/battery

+

24 V d.c

Power

supply

back up

Wiring diagram showing ICAD digital outputs wired with customer supplied auxiliary relays

NOTE: The same 24 V d.c. power that powers the ICAD can be used with the ICAD digital outputs to power

auxiliary relays (or other small load devices) but the system will no longer be galvanically isolated.

© Danfoss | Climate Solutions | 2021.04

Auxillary relays

K1K2K

3

Black

Brown

Red

Orange

Black

White

Brown

1

1

Optional UPS/

+

battery back up

K2K

+

5-24 V d.c

Power

-

Supply

K3K2K

K

3

K1 : Common Alarm

K2 : ICM fully open

K3 : ICM fully closed

+

-

CUSTOMER SUPPLIED

24 V d.c

Power

Supply

AN249186497575en-000402 | 10

Page 11

Quick Start Guide | ICM/ICAD Motorized Valves - Installation, Programming, and Troubleshooting

ICAD overview

Operation the ICAD menu

1. All ICAD actuators are digital stepper motors. As the control signal changes ICAD will electronically

count steps up or down from its previous position. The ICAD 600A, ICAD 1200 and 1200A have an

optical encoder which will actually measure the steps to recalibrate while operating if needed. In

all cases, the ICAD actuators will recalibrate every time that power is cut and then reconnected.

Recalibration is also accomplished when the valve is driven closed, the ICAD will take an extra closing

step to make sure it is completely closed and start counting from 0 again.

2. The ICAD actuators can also be put into manual mode by using parameter ¡01. Once the parameter

has been selected and the manual mode entered, the valve can be opened and closed independent

of the control signal. When in the manual mode, the display screen will flash the opening degree and

continue to flash until the parameter is restored to its normal operation setting.

3. The ICAD actuator can be controlled with an analog input for modulating control, 1 digital input for

open/close solenoid function or with 2 digital inputs for floating 3-point control (open-neutral-close).

The speed of the ICAD can be altered (see parameters ¡04 and ¡14).

4. The ICAD display will continuously display the ICM valve opening degree in % unless there is an alarm

or the parameter list is being viewed. The display will also indicate Mod if being controlled by an

analog input signal (modulating mode) or if being controlled by digital inputs the display will indicate

Low, Med or High depending on the speed setting.

5. The ICAD actuator can be connected to a 24 V d.c. UPS (uninterruptable power supply) and can

be programmed for a specific action in the event of a disruption to the normal power supply (see

parameters ¡07, ¡08 and ¡12). Please note that the UPS provides a discrete short term action in the

event of a power failure. It cannot be used for normal operation.

6. The ICAD actuator also has an inverse function (see parameter ¡13). This feature allows the valve to

either open or close on a rising analog signal.

1. To access the ICAD actuator menu, press and hold the middle button (2) until the menu appears.

1. Down arrow push button

2. Enter

3. Up arrow push button

4. Display

2. Once you are in the menu, use the UP (3) and DOWN (1) arrows to move through the list of

3. To display and/or change the value of the parameter, press the middle button (2) to view the current

4. Repeat this procedure for all parameters.

5. Exit from the parameter list by pressing and holding the middle button for 2 seconds or simply wait

© Danfoss | Climate Solutions | 2021.04

parameters.

settings.

a) To change the value of a parameter, use the up or down arrow to establish the new value for

that parameter.

b) Once the new value for the parameter has been selected, press the middle button to save the

change and return to the menu.

for the ICAD to return to the main display (approx. 20 seconds).

AN249186497575en-000402 | 11

Page 12

Quick Start Guide | ICM/ICAD Motorized Valves - Installation, Programming, and Troubleshooting

Programming the ICAD

actuator

When the ICAD actuator is first powered on, the ICAD display will flash an A1 alarm. This alarm is a

reminder that the ICM valve being moved by the ICAD has not been selected in parameter ¡26. Parameter

¡26 is password protected and will not appear in the parameter list until the user enters the password in

parameter ¡10. The password is “11” and will allow the user to access parameter ¡26 where the appropriate

valve size can be selected. Once the ICM valve size is selected (see page 3 on how to identify ICM size), the

ICAD actuator will calibrate itself to that particular size and will then be ready to receive a control signal.

Description

OD (Opening degree) - 0 100 % -

Main Switch ¡01 1 2 1

Mode ¡02 1 2 1

AI signal ¡03 1 4 2

Speed

In Modulating Mode

Opening/closing

speed

In ON/OFF Mode

Opening speed

In Neutralzone/

3 point control

Opening speed = 10

Automatic calibration ¡05 0 2 0 - No

AO signal ¡06 0 2 2

Failsafe ¡07 1 4 1

Fail safe supply ¡08 0 1 0

DI function ¡09 1 2 1

Password ¡10 0 199 0 - -

Old Alarms ¡11 A1 A99 - - No

OD at power cut. ¡12 0 100 50

Inverse operation ¡13 0 1 0

ICAD

parameter

Min Max

¡04 1 100 50/ 100

Factory

Setting

Stored Unit Password Comments

- No

- No

- No

- No

- No

- No

ICM/ICMTS valve Opening Degree (CVE pressure setting) is displayed during normal

operation.

Running display value (see ¡01, ¡05).

Internal main switch

1: Normal operation

2: Manual operation. Valve Opening Degree will be flashing. With the down

arrow and the up arrow push buttons the OD can be entered manually.

Operation mode

1: Modulating – ICM, ICMTS & CVE positioning according to Analog Input (see ¡03)

2: ON/OFF - ICM only. Operating the ICM valve like an ON/OFF solenoid valve

controlled via Digital Input. See also ¡09.

3: Neutralzone / 3 point control - ICM only. Increase/Decrease Opening Degree by

Digital Input. See fig. 9

Type of AI signal from external controller

1: 0 – 20 mA

2: 4 – 20 mA

3: 0 – 10 V

4: 2 – 10 V

Speed can be decreased. Max. speed is 100 % - Not active in manual operation (¡01 = 2)

For CVE the speed should not exceed 50 (factory setting)

If ¡26= 1 - 3 then factory setting =100

If ¡26= 4 - 10 then factory setting =50

If the valve is opening and (¡04 < = 33) or the valve is closing and (¡14 < = 33)

=> Low is displayed.

If the valve is opening and (33 < If ¡04 < = 66) or the valve is closing and (33 < If ¡14 < = 66)

=> Med is displayed.

If the valve is opening and (¡04 > = 67) or the valve is closing and (¡14 > = 67)

=> High is displayed"

Not active before ¡26 has been operated.

Always auto reset to 0.

CA will flash in the display during calibration,

if Enter push button has been activated for two seconds

0: No Calibration

1: Normal forced calibration - CA flashing slowly

2: Extended calibration – CA flashing rapidly"

Type of A0 signal for ICM valve position

0: No signal

1: 0 – 20 mA

2: 4 – 20 mA

Define condition at power cut and fail safe supply is installed.

1: Close valve

2: Open Valve

3: Maintain valve position

4: Go to OD given by ¡12"

Fail safe supply connected and enable of A4 alarm:

Yes

0: No

1: Yes

Define function when DI is ON (short circuited DI terminals) when ¡02 = 2

No

1: Open ICM valve (DI = OFF = > Close ICM valve)

2: Close ICM valve (DI = OFF = > Open ICM valve)

Enter number to access password protected parameters: ¡26

Password = 11

Old alarms will be listed with the latest shown first. Alarm list can be reset by means

of activating down arrow and up arrow at the same time for 2 seconds.

Only active if ¡07 = 4

No

If fail safe supply is connected and power cut occurs, the valve will go to the specified OD.

When ¡02 = 1

0: Increasing Analog Input signal => Increasing ICM Opening Degree

1: Increasing Analog Input signal => Decreasing ICM Opening Degree

When ¡02 = 3

0: DI1 = ON, DI2 = OFF => Increasing valve Opening Degree.

DI1 = OFF, DI2 = ON => Decreasing valve Opening Degree

No

DI1 = DI2 = OFF => ICAD/ICM maintain current position

DI1 = DI2 = ON => ICAD/ICM maintain current position

1: DI1 = ON, DI2 = OFF => Decreasing ICM Opening Degree

DI1 = OFF, DI2 = ON => Increasing ICM Opening Degree

DI1 = DI2 = OFF => ICAD/ICM maintain current position

DI1 = DI2 = ON => ICAD/ICM maintain current position

© Danfoss | Climate Solutions | 2021.04

AN249186497575en-000402 | 12

Page 13

Quick Start Guide | ICM/ICAD Motorized Valves - Installation, Programming, and Troubleshooting

Parameter list

(continued)

Description

In ON/OFF Mode

Closing speed

In Neutralzone/

3 point control

Closing speed = 10

Manual set point ¡15 0 100 0 - No When ¡01= 2, ¡15 determine the start up value

Encoder operation ¡16 0 1 1

Forced closing when

ICM valve Opening

Degree < 3%

Action when ICAD is

losing step

See Note 1

Delay after boost,

before A9 alarm

See Note 1

Max offset value

See Note 1

Define how to Reset/

Suppress A9 alarm

See Note 1

Reset delay for A9

See Note 1

Valve configuration ¡26 0 9 0

Running current

factor

Holding current factor ¡31 0 20 10

ICAD

parameter

Min Max

¡14 0 100 50/100

¡17 0 1 0

¡18 0 6 6

¡19 0 30 1

¡20 3 15 3

¡21 0 4 1

¡22 1 20 5

¡30 0 20 10

Factory

Stored Unit Password Comments

Setting

- No

- Ye s

- No

- No

Minutes No Time delay between two boosts. Linked to ¡18 function

% Ye s

- No

Minutes No

- Ye s

- Ye s

- Ye s

See ¡04. Not applicable to CVE

If ¡26= 1 - 3 then factory setting = 100

If ¡26= 4 - 10 then factory setting = 50

NB: Password protected. Password = 7

0: Encoder disabled. Means ICAD operation as ICAD 600A/ICAD 600A-TS/1200A

without encoder.

1: Encoder enabled

Enable/Disable forced closing. Not applicable to CVE

0: When ICM valve Opening Degree < 3% it will be forced to close regardless of

requested ICM valve Opening Degree

1: When ICM valve Opening Degree < 3% no forced to closing will take place

Action when ICAD is losing step.

0: A boost starts if lost step is detected. After 15 sec, the A9 alarm is flashing and

DO A Common Alarm is ON.

A second boost starts after the time in ¡19 has elapsed. If the second boost cyklus

does not bring the valve back in operation a forced calibration is carried out.

3: A9 alarm flashing after 15 sec. DO A Common Alarm ON. ICAD is locked in

actual position.

No boost cyklus, Reset by Power OFF/ON, regardless of setting ¡21

6: Boost cyklus starts if lost step is detected.

After 3 boost cyklus the A9 alarm is flashing and DO A Common Alarm is ON.

Time interval between boost is set in ¡19.

The boost cyklus continues until the valve is back in operation.

Password=13.

Offset value (numeric)=Requested Opening Degree [%] from Analog Input Opening Degree [%] from encoder (Used with ¡21)

Define how to Reset/Suppress A9 alarm. A9 alarm means A9 flashing in display and

DO Common Alarm ON

0: Reset by Power OFF/ON

1: Autoreset when ICAD have succeeded to come back into normal operation.

Normal operation defined as: Offset value < ¡20 (Max offset value) and ¡22

(delay) has elapsed.

2: A9 alarm is suppressed, meaning no A9 flashing in display and DO Common

Alarm remains OFF

Reset delay for A9. Use when ¡21= 1

OBSERVE: ¡22 is recommended always to be bigger than ¡19 (¡22>¡19)

NB: Password protected. Password = 11

0: No valve selected. Alarm A1 will become active

1: ICM 20 with ICAD 600A / ICMTS 20 with ICAD 600A-TS

2: ICM 25 with ICAD 600A

3: ICM 32 with ICAD 600A

4: ICM 40 with ICAD 1200A

5: ICM 50 with ICAD 1200A

6: ICM 65 with ICAD 1200A

7: ICM 100 with ICAD 1200A

8: ICM 125 with ICAD 1200A

9: ICM 150 with ICAD 1200A

10: CVE pilot with ICAD 1200A

Password=19. Mandatory to set, if ICM/ICADs are installed/serviced, with cold

liquid (-30 °C (-22 °F) or lower) passing through ICM valve.

See also document number AN285243155312

Note 1:

After a parameter change, it is necessary to carry out a Power OFF/ON

© Danfoss | Climate Solutions | 2021.04

AN249186497575en-000402 | 13

Page 14

Quick Start Guide | ICM/ICAD Motorized Valves - Installation, Programming, and Troubleshooting

It is possible to restore the original factory settings to the ICAD by the following procedure:

1. Remove the power supply.

2. Activate the up arrow and the down arrow push buttons at the same time.

3. While pushing the up and down arrows, reconnect the power supply.

4. Release the up and down arrows.

5. When the display on the ICAD is alternating between CA and AI, the factory parameters have been restored.

Pre-startup Checklist

• Valve Assembly

- Bonnet bolts are secure

- Seat has been replaced in body (ICM 20)

- The degree of opening of the valve is 75% or less

- Grease has been applied to o-ring area on valve stem

- Set screws have been uniformly tightened on ICAD Actuator

• Power has been connected to actuator ( 24 V d.c.)

• Back up power (UPS) has been connected to actuator (optional)

• Control Wiring has been connected

- Signal input: digital or analog

- Feedback wiring (optional)

• Programming (mandatory parameters)

- The mode of operation has been set (¡02)

- The input signal type has been set (¡03)

- The ICM valve size has been set (¡26)

Battery back-up (optional) parameters have been established (¡07, ¡08, ¡12)

Troubleshooting

Overview

The ICAD actuator has a number of very useful service parameters which should always be consulted first.

In addition, a manual tool should always be available to manually close the valve completely in the event

the ICAD has failed. When using the manual tool, turn the tool clockwise to open the valve and counterclockwise to close the valve.

NOTE:

When rotating the valve manually you are changing the position of the valve to a value different

than what is in the actuator’s memory. Therefore, a calibration must be performed when ICAD is

remounted to the valve. If power is cut from the actuator prior to using the manual tool or after

the valve has been adjusted, no problem will occur as the valve will automatically recalibrate itself

once power is restored. Power can easily be disconnected and reconnected by unscrewing and then

reconnecting the power cable from the ICAD actuator.

Service parameter (View only)

Service

Description

OD % ¡50 0 100 - % - ICM valve Opening Degree / CVE pressure setting

AI [mA] ¡51 0 100 - mA - AI signal

AI [V] ¡52 0 100 - V - AI signal

AO [mA] ¡53 0 100 - mA - A0 signal

DI ¡54 0 1 - - -

DO Close ¡55 0 1 - - - DO Closed status. ON when OD < 3 %

DO Open ¡56 0 1 - - - DO Open status. ON when OD > 97 %

DO Alarm ¡57 0 1 - - - DO alarm status. ON when a Alarm is detected

Display mP SW ver. ¡58 0 100 - - - Software version for display microprocessor

Motor mP SW ver. ¡59 0 100 - - - Software version for motor microprocessor

ICAD

parameter

Min Max

Factory

Setting

Stored Unit Password Comments

DI signals. Depending of ¡02

If ¡02 = 2, one digits are shown. See fig. 8

0 : DI1 = OFF

1 : DI1 = ON

If ¡02 = 3, two digits are shown. See fig. 9

00 : DI1 = OFF, DI2 = OFF

10 : DI1 = ON, DI2 = OFF

01 : DI1 = OFF, DI2 = ON

11 : DI1 = ON, DI2 = ON

© Danfoss | Climate Solutions | 2021.04

AN249186497575en-000402 | 14

Page 15

Quick Start Guide | ICM/ICAD Motorized Valves - Installation, Programming, and Troubleshooting

Alarms

Description

No Valve type selected A1 Alarm ON

Controller fault A2 Alarm ON

AI input error A3 Alarm ON

Low voltage of fail safe

Supply

Check supply to ICAD A5 Alarm ON If supply voltage < 18 V

Calibration extended

failed

Internal temperature

alarm

POM mode

(Preventive Operational

Mode)

Note: old alarms that may not be active anymore will be saved and listed in paramenter i11

ICAD alarm

text

A4 Alarm ON

A6 Alarm ON

A7 Alarm ON

A8 Alarm ON

A9

Definition of event Comments

See

¡18

and

¡21

At start-up A1 will be displayed

Internal fault inside electronics.

Carry out:

1) Power OFF and Power ON

If A2 still active.

2) Make a Reset to factory setting

If A2 still active. Return ICAD to Danfoss

Not active if ¡01 = 2, or ¡02 = 2

When ¡03 = 1 and AI A > 22 mA

When ¡03 = 2 and AI A > 22 mA

or AI A < 2 mA

When ¡03 = 3 and AI A > 12 V

When ¡03 = 4 and AI A > 12 V

or AI A < 1 V

If 5 V < fail safe supply

<18 V. Enabled by

Check valve type selected.

Check presence of foreign body internally in valve

Temperature for stepper motor component too high.Ventilate/lower ambient ICAD

temperature

Temperature for stepper motor component too high.

Ventilate/lower ambient ICAD temperature.

Only active if

If ICAD meets too high torque from ICM valve

(increased friction/sticking surfaces) ICAD automatic goes into POM mode to overcome

lost step.

(See ¡18 and ¡21)

¡16

¡08

= 1

Troubleshooting continued The alarms and service values work together to allow the user to quickly diagnose the source of operating

issues. The most common alarms are:

A1 The user has not selected the valve type. Each ICAD actuator is capable of driving several

different valve sizes. Upon installation of the valve, it is mandatory that the user select the

valve size from parameter ¡26.

Troubleshooting Tips

A3 The control signal is out of the range of the selected values. The most common causes of

this problem are:

1. Improper wiring

2. Incorrect selection of control signal (parameter ¡03)

3. The source of the control signal is not outputting the correct type of signal.

A9 The valve is locked, disconnect and remove motor. Use magnetic tool to slowly open/close the

valve thru the full range. There should be at no point a sticking/tight spot. You may need to

remove the valve bonnet/module to clean debris or replace the bonnet/module if it is damaged.

If A9 alarm continues please contact Danfoss with application details.

Of course, there are numerous other alarm messages designed to protect the equipment and help to

diagnose problems as pro-actively as possible. Most of these alarms are fairly self-explanatory.

The valve does not appear to close or stay closed completely.

• The display shows 0% opening degree but the valve can be driven further closed with the manual

tool.

Solution: Recalibrate the valve. In addition, if the manual tool has been used to open or close the

valve, the valve should turn very easily. If there appears to be resistance in opening or closing the

valve, replace the module.

• The display shows 0% opening degree and the valve cannot be driven closed any further with the

manual tool.

Solution: Pull the function module and check to ensure that there are 2 o-rings on the module for ICM

25 and larger. For size ICM 20, make sure valve seat is installed.

© Danfoss | Climate Solutions | 2021.04

AN249186497575en-000402 | 15

Page 16

Quick Start Guide | ICM/ICAD Motorized Valves - Installation, Programming, and Troubleshooting

Troubleshooting Tips

The valve does not appear to be moving to the correct position.

• Check service value ¡51. This is the mA input from the control system. The degree of opening is

linearly proportional to the mA input. (For example, if 4-20 mA was chosen as the input range and

the service value shows 12mA, the valve should be 50% open.)

Solution: Check parameter ¡03 to make sure that the correct scale was selected.

• Compare service value ¡51 to the value reported to be the output from the control system. If

necessary, measure the actual current into the ICAD.

Solution: If the two values do not equate, check wiring, paying special attention to wire polarity. If

measured mA does not equate to the stated controllers output, the problem is likely to be in the

control system. If measured mA does not equate to the value seen in ¡51 and everything is wired

properly, the problem is likely with the ICAD actuator.

• The ICAD was not mounted properly on the valve stem.

Solution: Check to make sure that the ICAD set screws are evenly torqued around the base of the ICAD.

The valve does not appear to be opening fast enough or seems too fast

• The speed of the ICM valves are preset at the factory:

• For ICM valves 20, 25, and 32, the preset speed is 100%

• For ICM valves 40, 50, 65, 100, 125, and 150, the preset speed is 50%

Solution: Check parameter ¡04 to note the actual setting and adjust accordingly

The valve position feedback signal is not working with the customer supplied controller/PLC.

• A power supply was installed in the 4-20mA/0-20 mA feedback loop. The ICAD motor actuator

supplies power for the 4-20mA/0-20 mA feedback loop.

Solution: Remove any power source that may be supplied to the feedback loop.

• Wiring problem.

Solution: Check the service value of ¡53 (the analog output signal) to see what the ICAD is outputting.

If nothing is revealed, check the output wire (blue) with an ammeter to verify the actual output value.

• The feedback output signal was not turned on in parameter ¡06.

Solution: Change this parameter to the appropriate signal.

Frequently Asked Questions

What happens in the event of a power failure?

The ICAD actuator will remain in the position it is in when power is lost. There are two approaches to

solving the issue:

• Add a UPS (Uninterruptible Power Supply) device to the power wiring. This is easily accomplished

with the brown (-) and black (+) wires in the power cable bundle. A UPS device is available from

Danfoss and can provide up to 10 amps of power for up to 90 seconds in order to move the valve to

the desired position. Because of the high amperage, the UPS is capable of providing power to several

ICAD actuators depending on the size of the actuator. NOTE: The UPS is not a continuous power

supply. It is only meant to change the valve position once in the event of a power failure.

• Add a solenoid valve in front of the ICM in order to stop refrigerant flow. This is a simple solution

provided that there is no issue associated with the additional pressure drop through the solenoid

valve.

How much power do I need to supply to the ICAD?

The total power required depends on the ICAD size and the number of ICAD’s powered by the dc power

supply. The power for each ICAD is:

• ICAD 600 (ICM 20, 25, and 32), the requirement per valve is approximately 30 watts.

• ICAD 900 (ICM 40, 50, and 65), the requirement per valve is approximately 50 watts.

• ICAD 1200 (ICM 100, 125, and 150) the requirement per valve is approximately 75 watts.

• ICAD 600A (ICM 20, 25, and 32), the requirement per valve is approximately 30 watts.

• ICAD 1200A (ICM 40, 50, 65, 100, 125, and 150) the requirement per valve is approximately 50 watts.

How can I monitor the valve position remotely?

The control wiring bundle provides for a 4 to 20 mA or 0 to 20 mA signal output with the blue (+) and

orange (-) wires. The signal can be sent to:

• A remote display

• A PLC or PC

• Another ICAD actuator to provide the same input signal (daisy chain)

At what minimum OD%/mA will the ICAD automatically close and calibrate?

The ICAD will automatically close or be closed when the opening degree is below 3% which corresponds

to 4.48 mA. After it is closed it will give a few extra steps to calibrate the valve.

If the 4-20mA signal is lost while the valve is open, will the ICAD close the valve?

Yes, if the input signal is lost while the valve is open, the ICAD will close the valve and flash an A3 alarm

which is for an input error.

© Danfoss | Climate Solutions | 2021.04

AN249186497575en-000402 | 16

Page 17

Quick Start Guide | ICM/ICAD Motorized Valves - Installation, Programming, and Troubleshooting

How many turns/revolutions with the manual tool will fully open/close ICM valve?

• ICM 20: 1.25 turns

• ICM 25: 2.5 turns

• ICM 32: 3 turns

• ICM 40: 4 turns

• ICM 50: 5 turns

• ICM 65: 5 turns

• ICM 100: 12.75 turns

• ICM 125: 15.25 turns

• ICM 150: 18.25 turns

Does the ICAD make a high frequency noise?

Yes, when the ICAD is at standstill, it will generate a high frequency noise which is normal.

What size wire gauge is recommended to run to the ICADs?

The typical wire gauge is 22 AWG. For power wiring, the recommended maximum lengths (for 22 AWG)

are:

• ICAD 600 90 feet

• ICAD 900 50 feet

• ICAD 1200 30 feet

• ICAD 600A 90 feet

• ICAD 1200A 50 feet

Heavier wire gauge will allow for longer lengths of power wiring. For example with 17 AWG, maximum

lengths are:

• ICAD 600 285 feet

• ICAD 900 170 feet

• ICAD 1200 115 feet

• ICAD 600A 285 feet

• ICAD 1200A 170 feet

Control wire lengths can be as long as 1500 feet.

When running wire to the ICADs, does the wire need to be shielded?

There is no need for shielded cable; however, if used, the EMC capabilities of the ICAD will be improved.

© Danfoss | Climate Solutions | 2021.04

AN249186497575en-000402 | 17

Page 18

www.danfoss.us/Industrial_Refrigeration

© Danfoss | Climate Solutions | 2021.04

AN249186497575en-000402 | 18

Loading...

Loading...