Page 1

Service Kit Instructions

]

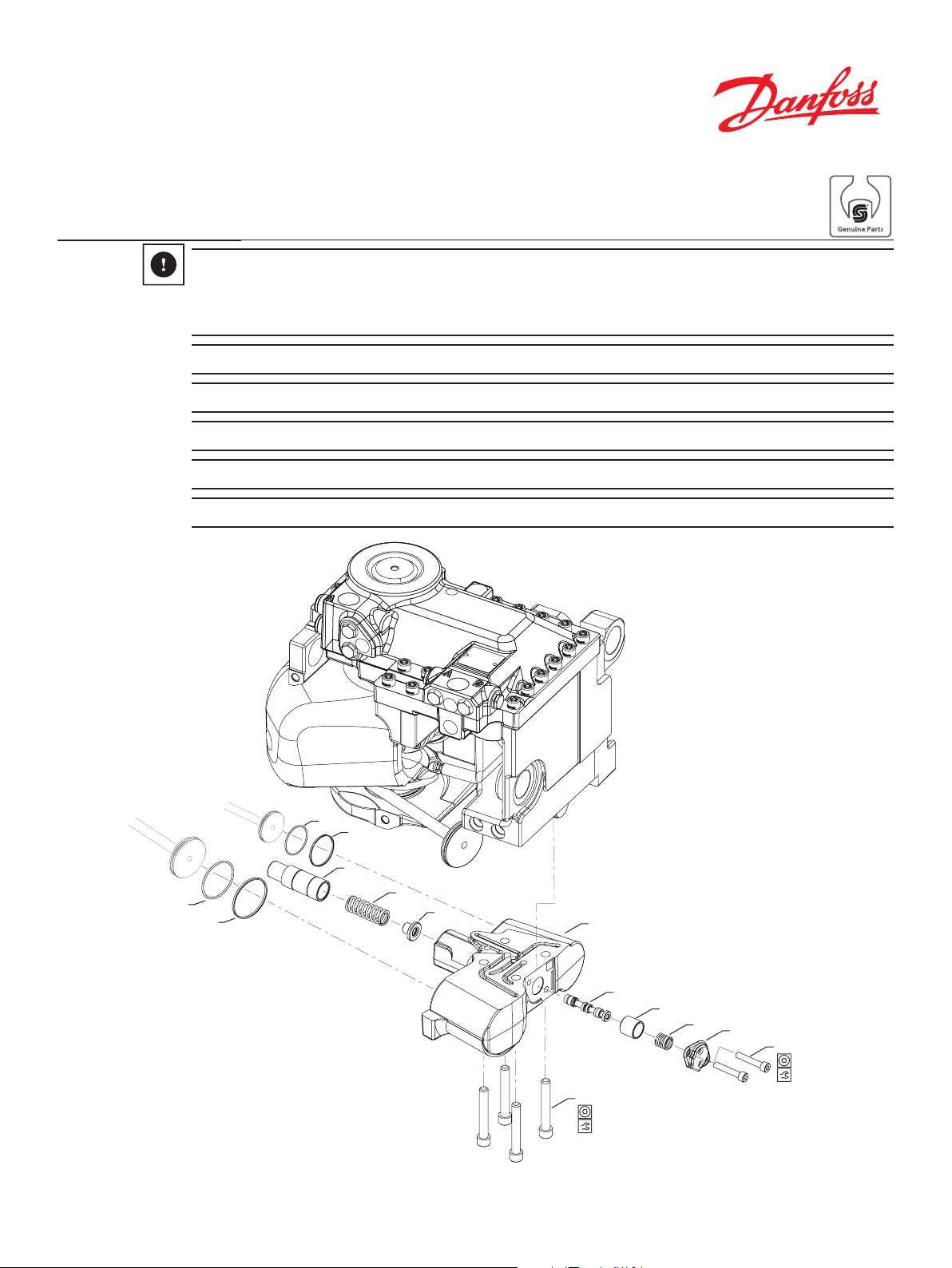

Hydrostatic Module

Control Replacement Instructions

Warning

Older Sphinx controls are not compatible with current Apex control service parts. To determine if the RE592894

Hydrostatic Control Service Kit is needed or if control components can be serviced on an individual basis,

the diameter of the feedback cam guide(#3) needs to be measured . If largest diameter is ~35 mm, the full

RE592894 kit needs to be purchased if any 1 of the following 4 parts need to be replaced:

• Control Housing (#1)

• Feedback Cam Guide (#3)

• Guide Spring [retainer] (#4)

• Spring (#5)

If the feedback cam guide is ~Ø30 mm, parts may be serviced on an individual basis.

26

22

3

25

21

© Danfoss, 2016 AX279272222358en-000101 | 70367696• Rev 0101 • August 2018 1

5

4

1

9

11

10mm

135Nm [100 ft-lb]

7

8

6

2

6mm

34Nm [25 ft-lb

Page 2

Install Control Spool

Ball side

Shallow side

--------->

4

3

into housing

1. Assemble control spool (#9) into control housing (#1)

with the ball side facing into the spool bore. Check for

free movement.

Ball side

--------->

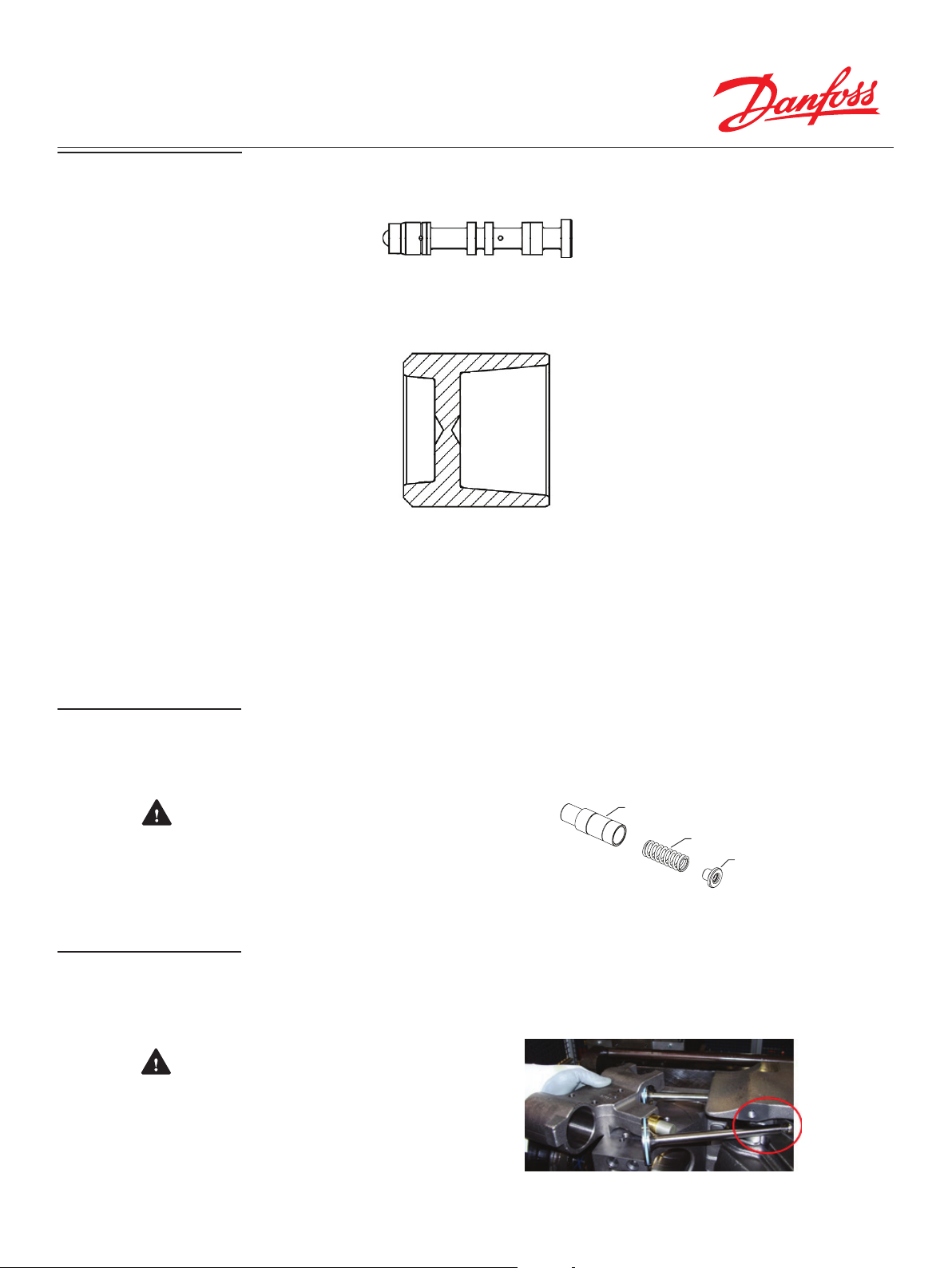

2. Install centering valve plunger (#7) with the shallow

side facing into the spool bore, see cutaway below.

--------->

3. Install cold start valve spring (#8) into the plunger

(#7).

4. Install cap (#6) and hand start the cap screws (#2)

5. Using a 6mm internal hex wrench, torque cap screws

(#2) to 34 Nm [25 ft-lb]

Install Feedback Cam

Install Piston Seal

Rings

6. Install spring guide (#4), control feedback spring (#5),

and feedback cam guide (#3) into the cam bore.

CAUTION - Spring guide (#4) must be

oriented so the control feedback spring (#5) is

seated on guide

7. Install O-rings (#25 & #26) onto pistons before

installing ring-seals (#21 & #22) onto pistons. Oil ringseals and inside of bore before installing into control.

CAUTION - When removing old and

installing new seals, do not stress ball and socket

joint. Piston neck should not contact casting.

5

© Danfoss, 2016 AX279272222358en-000101 | 70367696• Rev 0101 • August 2018 2

Page 3

Assemble control to

unit

8. Start pistons into control bores at an angle and align

control with mounting holes.

9. Hand start control mounting screws (#11) making

sure they move freely.

10. Visually look into the servo piston bores to inspect

the piston ring-seals for cut or protruding material, if

present replace the outer ring-seals (#21 & #22).

11. Check that the Feedback Cam Guide (#3) is on the

Cam surface.

12. Using a 10mm internal hex wrench, torque 4 screws

(#11) to 135 Nm [100 ft-lb] following the below torque

sequence.

1

3

4

© Danfoss, 2016 AX279272222358en-000101 | 70367696• Rev 0101 • August 2018 3

2

Loading...

Loading...