Page 1

Data Sheet

Genuine Spare Parts

Hydraulic Filter Cartridge

For more than 45 years, Danfoss has been developing

state-of-the-art components and systems for mobile

machinery used in off-highway operations around the

world.

Danfoss has become a preferred supplier by offering

the best of what really matters: the hardware inside

your vehicle application. Danfoss genuine spare parts

enable longer product life and outstanding system

performance of the hardware.

Genuine Danfoss Filter Cartridges are available in 3

different sizes for flexibility to fit with hydraulic pump

and motor circuits.

Features

•

Filters available in 3 different sizes

(short, medium, long)

•

Robust design

•

High collapse and burst resistance

•

Universal use

Part numbers

•

Short filter: 11004917

•

Medium filter: 11004918

•

Long filter: 11004919

Comprehensive technical literature is

online at www.danfoss.com

©

Danfoss | June 2019 AI308575020149en-000101 | 1

Page 2

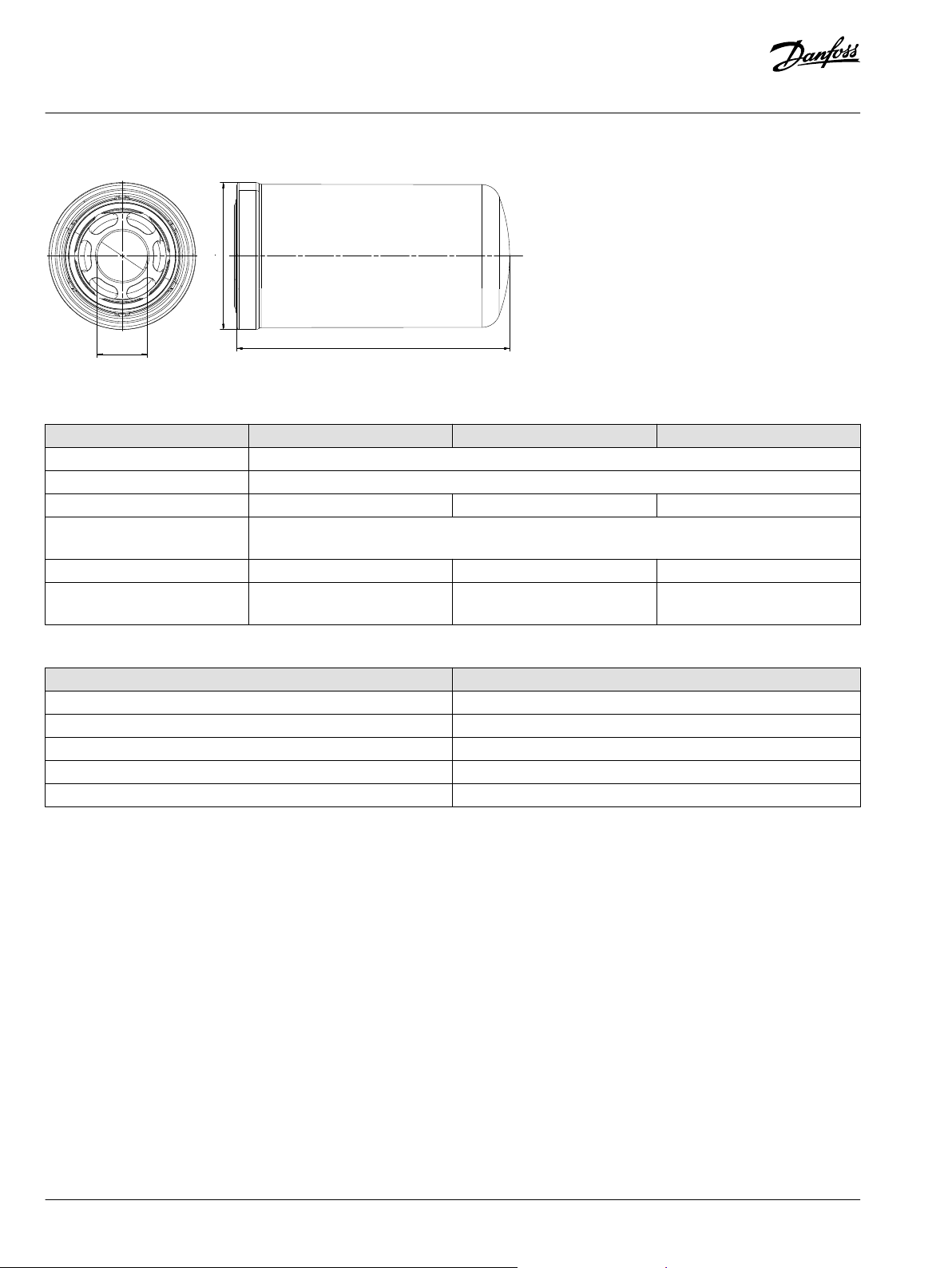

Thread

Length

Outer diameter

Data Sheet

Hydraulic Filter Cartridge

Dimensions

Technical Specifications

Technical data Short filter Medium filter Long filter

Outer diameter (typical) 97 mm

Thread 1.375 - 12 UNF - 2B

Length (typical) 153 mm 181 mm 239.6 mm

Collapse/burst resistance of filter

element per ISO 2941

Max. flow rate 60 l/min (15.6 US gal/min) 80 l/min (21.1 US gal/min) 105 l/min (27.8 US gal/min)

Retained (real) dirt capacity at Δp

max.

≥20 bar collapse resistance at max. flow rate

(Direction of flow: Input - outer ring; output - inner terminal)

30 g at 5.6 bar 40 g at 5.6 bar 60 g at 5.6 bar

β ratio versus maximum particle size

1

β ratio

10 5

75 7.5

100 7.9

200 8.8

1000 11

1

Multi-pass test per ISO 16889. The following flow rate and viscosity apply for determining β ratio and dirt capacity: terminal pressure drop (6 bar [87

psi]); viscosity per ISO 16889 (15mm2/s [78 SUS]); max. flow rate.

Maximum particle size, µm (C)

2 | © Danfoss | June 2019 AI308575020149en-000101

Page 3

Pressure drop [bar]

Flow rate [l/min]

0.5

0.0

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

0 5 10 15 20 25 30 35 40 45 50 55 60

1000 mm²/s

450 mm²/s

130 mm²/s

30 mm²/s

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80

30 mm²/s

130 mm²/s

450 mm²/s

1000 mm²/s

Pressure drop [bar]

Flow rate [l/min]

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105

30 mm²/s

130 mm²/s

450 mm²/s

1000 mm²/s

Pressure drop [bar]

Flow rate [l/min]

Data Sheet

Hydraulic Filter Cartridge

The following graphs show pressure drop versus flow rate according to ISO 3968, class B.

Do not exceed limitations shown in the graph as the border lines.

Short filter

Medium filter

Long filter

©

Danfoss | June 2019 AI308575020149en-000101 | 3

Page 4

Tightening torque

P106 141E

T035

T250 (3X)

8 mm

T350

T045

T015

T150

T010

Generic unit used to show part location only.

1. Lubricate the filter seal and install a new filter (T150).

2. Use a 24mm wrench to hold plug (T015) in place and install

the replacement filter.

3. Hand tighten the filter till it contacts the O-ring, the tighten it

½ turn to achieve proper installation torque.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

4 | © Danfoss | June 2019 AI308575020149en-000101

Loading...

Loading...