Page 1

Technical Information

Hydraulic Fan Drive Systems

www.danfoss.com

Page 2

Technical Information

Hydraulic Fan Drive Systems

Revision history Table of revisions

Date Changed Rev

Sept 2018 Rebrand to Engineering Tomorrow 0403

June 2015 Danfoss layout - update product information DA

November 2010 new back page CC

February 2010 Fix Osaka address CB

July 2009 updated manual adding new products CA

June 2008 deletions and illustration modifications BA

April 2008 added special tools part numbers AC

March 2008 minor edits and corrections AB

First edition AA

2 | © Danfoss | Sept 2018 520L0824 | BC00000115en-000403

Page 3

Technical Information

Hydraulic Fan Drive Systems

Contents

General Information

Market Leading Experience.......................................................................................................................................................... 5

Typical Applications........................................................................................................................................................................ 5

Reduced Power Consumption.....................................................................................................................................................6

Trimmed and Standby Fan Speed..............................................................................................................................................7

Flexible Mounting............................................................................................................................................................................ 7

Wide Range of Components........................................................................................................................................................ 7

Basic Operation................................................................................................................................................................................. 7

Intelligent Control............................................................................................................................................................................7

Balanced Fan Speed and Heat Generation............................................................................................................................. 8

Fan Drive Systems

Modulating Fan Drive Systems....................................................................................................................................................9

Gear Pump with Gear Motor and PLUS+1TM Fan Drive Controller.................................................................................9

Gear Pump with PLUS+1TM Controller......................................................................................................................................9

Variable Displacement Pump with Fan Drive Control......................................................................................................10

Variable Displacement Pump and HIC Cartridge Valve................................................................................................... 10

Closed Circuit System with Microcontroller.........................................................................................................................11

System Components

Gear Pumps......................................................................................................................................................................................12

Model Sizes and Capacities...................................................................................................................................................12

Configurations...........................................................................................................................................................................12

Series 45 Variable Displacement Axial Piston Pumps.......................................................................................................14

Series 45 Fan Drive Control........................................................................................................................................................ 15

D Series Motor.................................................................................................................................................................................16

SGM2Y Motor...................................................................................................................................................................................18

SGM3Y Motor...................................................................................................................................................................................18

L/K Frame Axial Piston Motors.................................................................................................................................................. 19

PLUS+1TM Controllers...................................................................................................................................................................21

Temperature Sensors....................................................................................................................................................................22

Models.......................................................................................................................................................................................... 23

Features........................................................................................................................................................................................23

PLUS+1 TM Compliance.......................................................................................................................................................... 23

System Design Parameters

Sizing Equations............................................................................................................................................................................. 25

Equations.....................................................................................................................................................................................25

Variables.......................................................................................................................................................................................25

System Design Data Form...........................................................................................................................................................26

Engine details.............................................................................................................................................................................26

Power steering...........................................................................................................................................................................26

Fan information.........................................................................................................................................................................27

Control preference...................................................................................................................................................................27

Reservoir...................................................................................................................................................................................... 27

Fluid...............................................................................................................................................................................................28

Filtration.......................................................................................................................................................................................28

Installation Guidelines

Pumps................................................................................................................................................................................................ 29

Pump Drives............................................................................................................................................................................... 29

Motors................................................................................................................................................................................................29

SGM2YN and SGM3YN Fan Drive Motors.........................................................................................................................29

D Series Fan Drive Motors......................................................................................................................................................29

L and K Variable Motors..........................................................................................................................................................30

Reverse Displacement Motors............................................................................................................................................. 30

Series 40 Fixed Displacement Motors............................................................................................................................... 30

Series 90 Fixed Displacement Motors............................................................................................................................... 30

Controls............................................................................................................................................................................................. 31

Pump Inlet..............................................................................................................................................................................29

Pump Outlet..........................................................................................................................................................................29

©

Danfoss | Sept 2018 520L0824 | BC00000115en-000403 | 3

Page 4

Technical Information

Hydraulic Fan Drive Systems

Contents

PLUS+1TM controller................................................................................................................................................................31

Series 45 Fan Drive Controls.................................................................................................................................................31

H1 Pump with Fan Drive Control........................................................................................................................................31

System................................................................................................................................................................................................32

Filtration.......................................................................................................................................................................................32

Operating Temperatures....................................................................................................................................................... 32

Fluids.............................................................................................................................................................................................32

Installation Drawings

D Series Pumps............................................................................................................................................................................... 34

D Series Gear Motor...................................................................................................................................................................... 38

SGM2YN Gear Motor ....................................................................................................................................................................39

PRV10-IS2 Valve for SGM2Y........................................................................................................................................................48

PRV12-IS2 Valve for SGM3Y........................................................................................................................................................49

Reverse Displacement Motors (RDM).....................................................................................................................................50

Cartridge Motor.........................................................................................................................................................................50

Port locations and gauge installation............................................................................................................................... 51

L and K Frame Variable Motor................................................................................................................................................... 52

Motor Rotation.......................................................................................................................................................................... 53

Schematics ................................................................................................................................................................................. 53

Series 40 Fixed Motors................................................................................................................................................................. 53

M35/M44 MF: mounting flange...........................................................................................................................................54

M35/M44 MF: axial ports, twin ports, loop flushing, speed sensor........................................................................ 54

Series 90 Fixed Motors................................................................................................................................................................. 55

90K55 Fixed Motor Cartridge Mount.................................................................................................................................56

Fan Drive Control Schematic..................................................................................................................................................... 58

Schematics

Fan Drive System Schematics....................................................................................................................................................59

Fan Drive System Related Literature

Overview........................................................................................................................................................................................... 60

Gear Pumps.................................................................................................................................................................................60

Open Circuit Piston Pumps................................................................................................................................................... 60

Closed Circuit Piston Pumps.................................................................................................................................................60

Gear Motors................................................................................................................................................................................ 60

Open Circuit Piston Motors...................................................................................................................................................60

Controllers...................................................................................................................................................................................60

System Guidelines....................................................................................................................................................................60

4 | © Danfoss | Sept 2018 520L0824 | BC00000115en-000403

Page 5

Technical Information

Hydraulic Fan Drive Systems

General Information

Market Leading Experience

Over a number of years, Danfoss has built up a wealth of experience with fan drive applications for

vehicles and machines operating on and off the highway. This knowledge has been gained by providing

system solutions which integrate our market leading hydraulic pumps, motors, valves and electrohydraulic controllers.

Danfoss Hydraulic Fan Drive Systems Provide:

•

•

•

•

•

•

•

•

•

•

On-Off and fully modulating controls

Increased engine reliability

Decreased fan noise

Flexible cooling pack positioning

Vehicle fuel savings

Design flexibility with multiple inputs for the electro-hydraulic controllers plus CAN bus per SAEJ

1939

Integrated systems

Lower operating costs

Ability to downsize the engine while maintaining system productivity

Ability to provide engine anti-stall and overspeed protection

Typical Applications

Due to the versatility, flexibility and reliability of Danfoss fan drive systems, they may be applied in

numerous applications, including the following.

Agriculture Machinery

•

On-Off and fully modulating controls

•

Increased engine reliability

•

Automatic or On-demand reversing

Construction Machinery

•

Backhoe loaders

•

Crawler dozer - Crawler loader

•

Wheel loaders

•

Dump trucks - Haulers

•

Excavators

•

Skid steer loaders

Material Handling Vehicles

•

Fork lift trucks

•

Rough terrain trucks

•

Telehandlers

Road Building Vehicles

•

Pavers

•

Graders

•

Road rollers

•

Crawlers

©

Danfoss | Sept 2018 520L0824 | BC00000115en-000403 | 5

Page 6

Engine speed

Idle

Max

P101 274E

A

v

a

i

l

a

b

l

e

e

n

g

i

n

e

p

o

w

e

r

D

i

r

e

c

t

-

d

r

i

v

e

f

a

n

p

o

w

e

r

Tri

mm

e

d f

an

po

we

r

E

n

g

i

n

e

c

o

o

l

i

n

g

d

e

m

a

n

d

Power

savings!

Fan sized to meet

this condition

Po

we

r

Technical Information

Hydraulic Fan Drive Systems

General Information

Forestry Machinery

•

•

•

•

On Highway Vehicles

•

•

•

•

High Power Specialty Vehicles

•

•

•

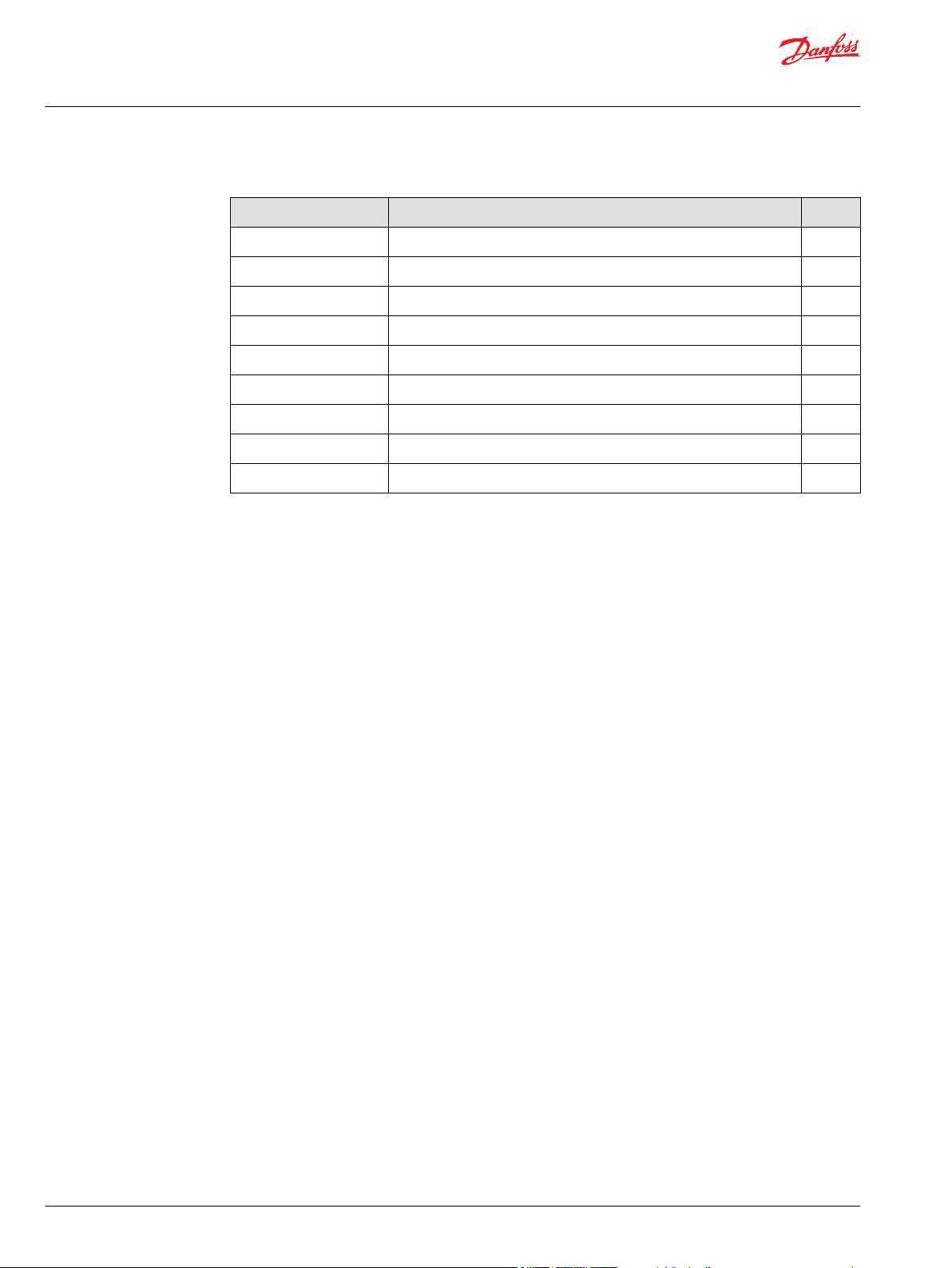

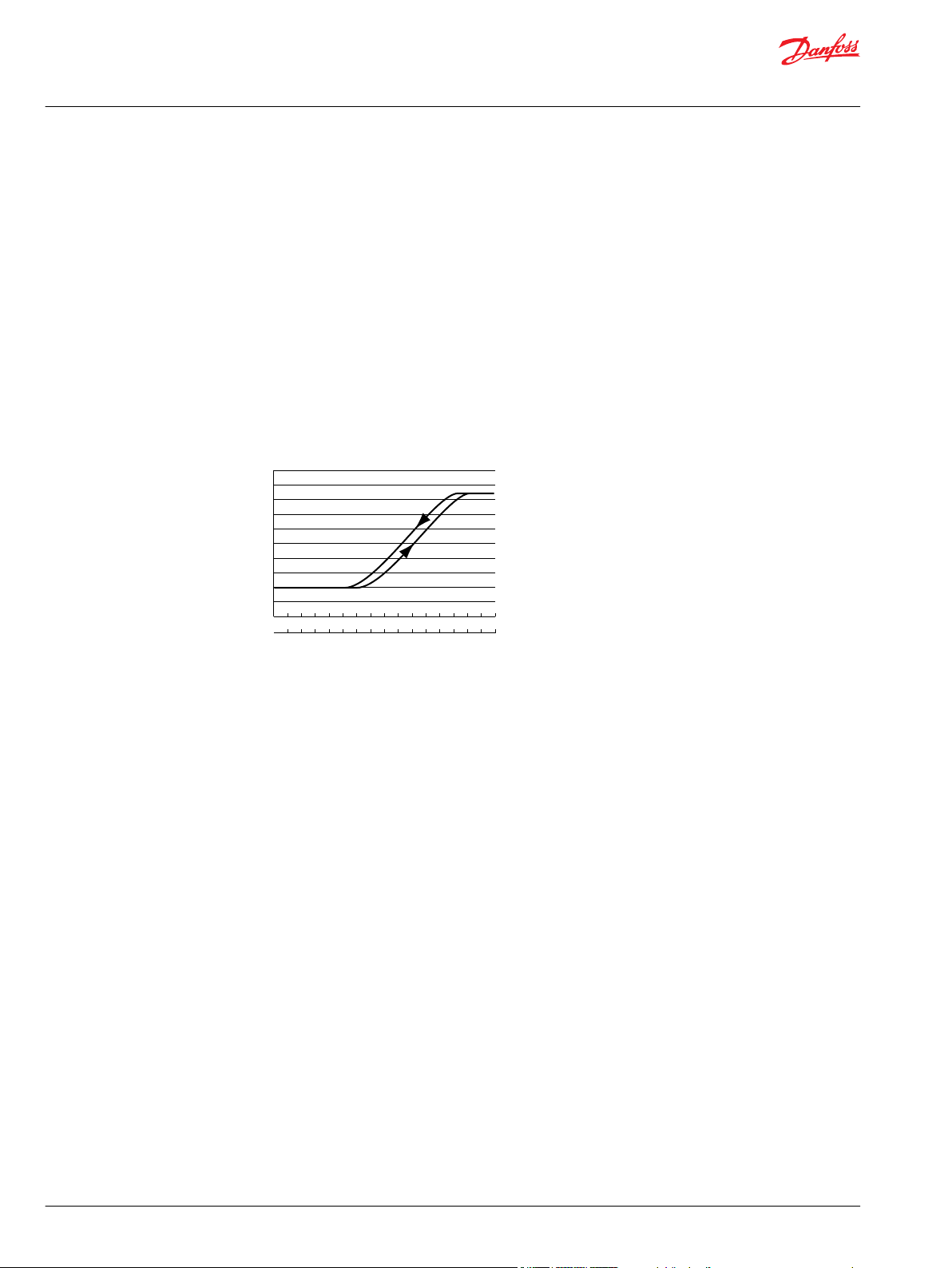

Reduced Power Consumption

Danfoss hydraulic fan drive systems allow cooling fan power consumption to be tailored to cooling

requirements. Our systems provide a precise, modulated cooling flow for a given set of monitored

conditions.

The power to drive a cooling fan rises as a cubic function of fan speed (doubling the fan speed requires

an eight-fold increase of input power). However, engine power and cooling demand decrease at higher

speeds. Because of this inverse relationship, a direct drive cooling fan must be sized to meet cooling

requirement at a relatively low engine speed and is therefore significantly oversized for cooling

requirements at higher speeds. Hydraulic fan drive systems allow fan speed to be trimmed so the fan can

be properly sized at low engine speeds without drawing excessive power at high speeds.

Power vs Engine Speed Curve

Feller bunchers

Forwarders

Harvesters

Log skidders

Buses

RV motorhomes

Garbage trucks

Sweepers

Marine

Oil and Gas drilling/Fracking

Mining

Fan systems are sized to provide required air flow at all engine speeds and operating conditions. Directdrive fans consume a great deal of power at higher engine speeds, without any advantage.

6 | © Danfoss | Sept 2018 520L0824 | BC00000115en-000403

Page 7

F

an speed

Fan standby speed

U

n

t

r

i

m

m

e

d

f

a

n

s

p

e

e

d

Trim at mid-range cooling demand

Set poin t

Trimmed fan speed

Engine speed

P101 275E

Technical Information

Hydraulic Fan Drive Systems

General Information

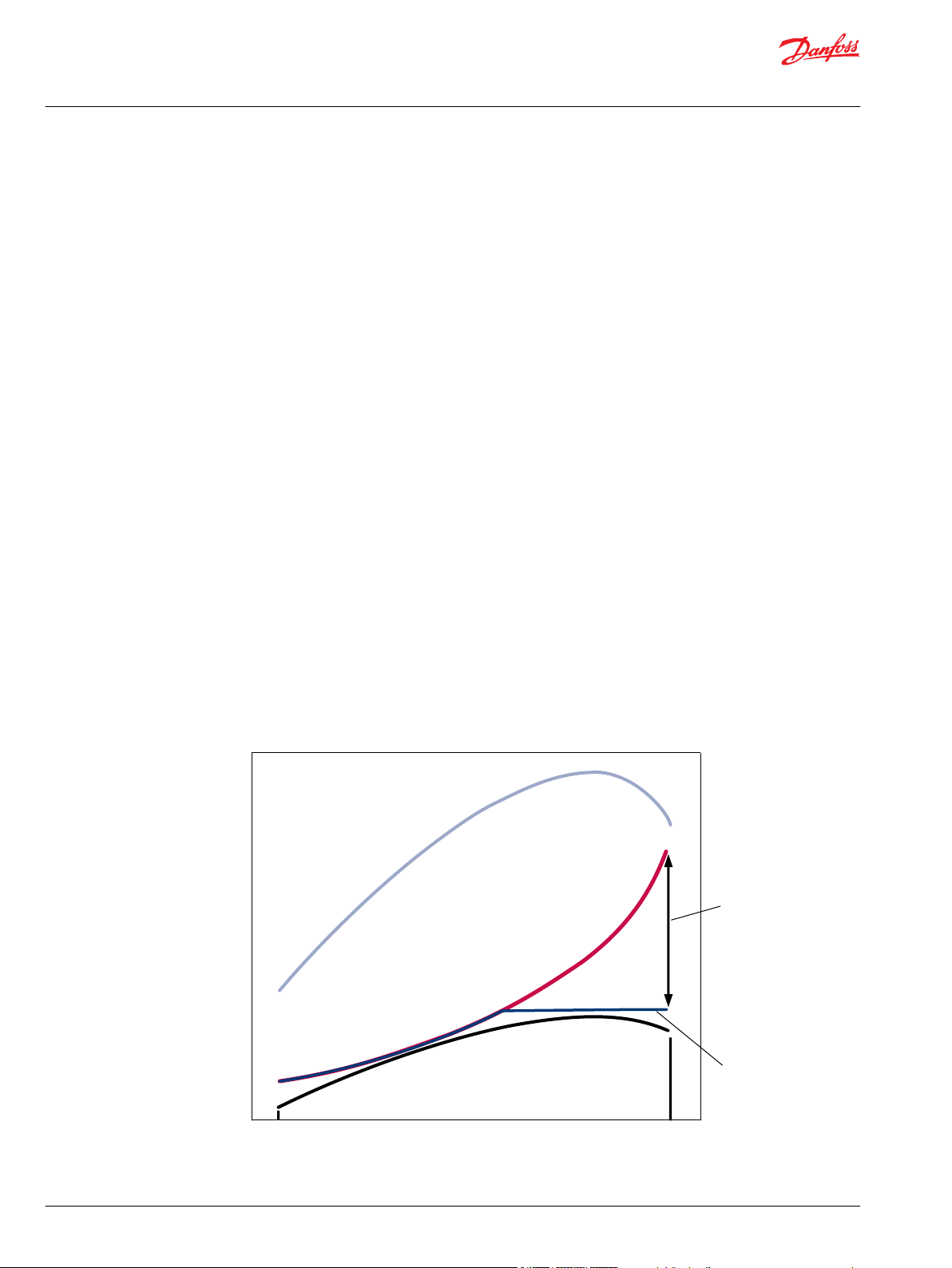

Trimmed and Standby Fan Speed

Under full cooling demand, maximum fan speed increases with engine speed, up to the set point of the

fan drive system (the point where further increase in speed yields no further gain). Beyond this point fan

speed does not increase, allowing greatly reduced power consumption compared to an untrimmed fan.

Under minimum cooling demand, standby fan speed can be set to provide very low, or minimal air flow.

Fan Speed vs Engine Speed

Flexible Mounting

Wide Range of Components

Basic Operation

Intelligent Control

The upper curves represent maximum cooling conditions; maximum fan speed is trimmed at the set

point. The lowest curve represents the standby condition; fan speed is maintained at a minimum value.

Hydraulic fan drives make it is possible to mount the radiator and fan just about anywhere on the vehicle.

This is advantageous in space conscious designs.

A fan drive system is sized to provide the required fan torque and speed. Danfoss has a wide range of

pumps, motors, controls, and sensors to meet your unique fan drive system needs.

In simplest terms, fan speed is controlled by regulating the amount of hydraulic oil passing through the

fan motor. The greater the flow, the greater the fan speed. The amount of flow is regulated based on one

or more inputs from the power system. Typically, engine coolant temperature is the main controlling

factor. Other system inputs may include hydraulic fluid temperature, charge air temperature and various

signals or switches. As inputs indicate a change in cooling demand, the system adjusts flow to the motor.

At the core of the Danfoss Fan Drive System is a controller that monitors relevant cooling parameters and

adjusts fan speed accordingly.

Fan Drive Controller

The Danfoss fan drive control system monitors cooling parameter inputs and provides an electronic

signal to a proportional hydraulic valve. The proportional valve relays a hydraulic signal either to the

©

Danfoss | Sept 2018 520L0824 | BC00000115en-000403 | 7

Page 8

205

0

200

400

600

800

1000

1200

1400

1600

1800

2000

170(F) 175 180 185 190 195 200

F

an speed (rpm)

Engine temperatur e

9580(C) 85 90

P101 276E

Technical Information

Hydraulic Fan Drive Systems

General Information

bypass valve on the motor or the displacement control of a variable displacement pump. Possible inputs

to the fan drive control system include engine coolant temperature, charge air temperature, engine or

transmission oil temperature, compartment temperature, ambient temperature, and various other

signals and switches. Also, many engine control systems provide a fan controlling signal or CAN message

which can serve as a cooling parameter input.

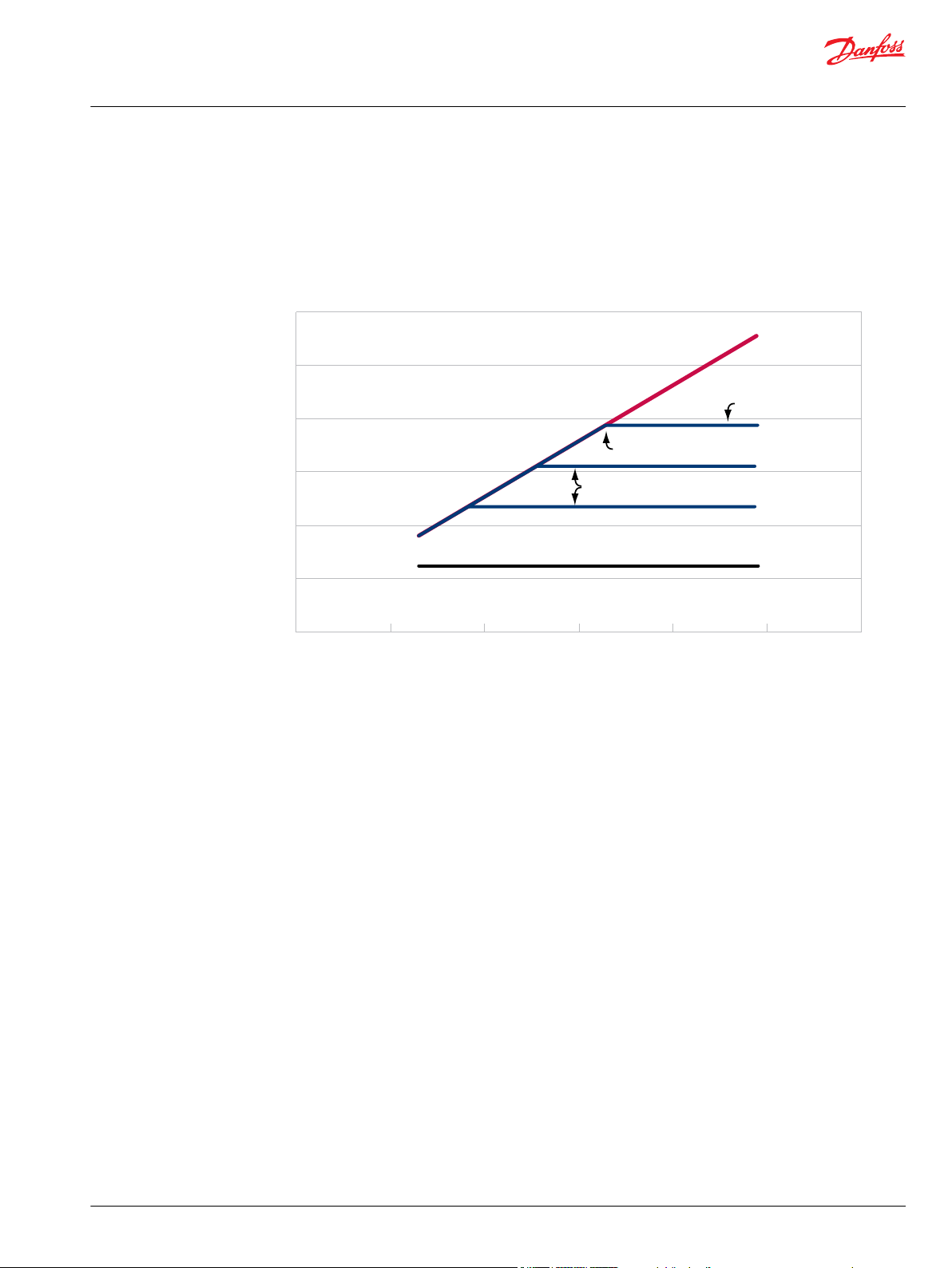

Balanced Fan Speed and Heat Generation

When an input, such as engine coolant temperature, rises above a predetermined level, signalling an

increase in cooling demand; fan speed is gradually increased. Coolant temperature and fan speed

continue to rise until heat generation and cooling are balanced. Under most conditions, this balance

occurs at a level below the maximum capability of the system.

Maximum fan speed is reached only under simultaneous conditions of maximum ambient temperature

and maximum engine load. These parameters are set as part of the cooling system design criteria.

Fan Speed Vs. Engine Temperature

Fan speed is increased as monitored temperature increases until balance is reached.

8 | © Danfoss | Sept 2018 520L0824 | BC00000115en-000403

Page 9

Microcontroller

(PLUS+1TM)

Filter

T3

T2

T1

Temperature

sensors

Gear pump

(SNP or D)

Fan drive

gear motor

(D or SGMY)

RESERVOIR

DIESEL ENGINE

P107 983E

Engine

Control

Module

CAN-BUS J1939

Engine Cooling Command

Technical Information

Hydraulic Fan Drive Systems

Fan Drive Systems

Modulating Fan Drive Systems

Monitoring various cooling system parameters enables the Danfoss modulating fan drive systems to

increase fan speed as required. As a modulating system, it ramps fan speed only to the level required,

providing only as much air flow as needed to maintain balance between heat generation and cooling.

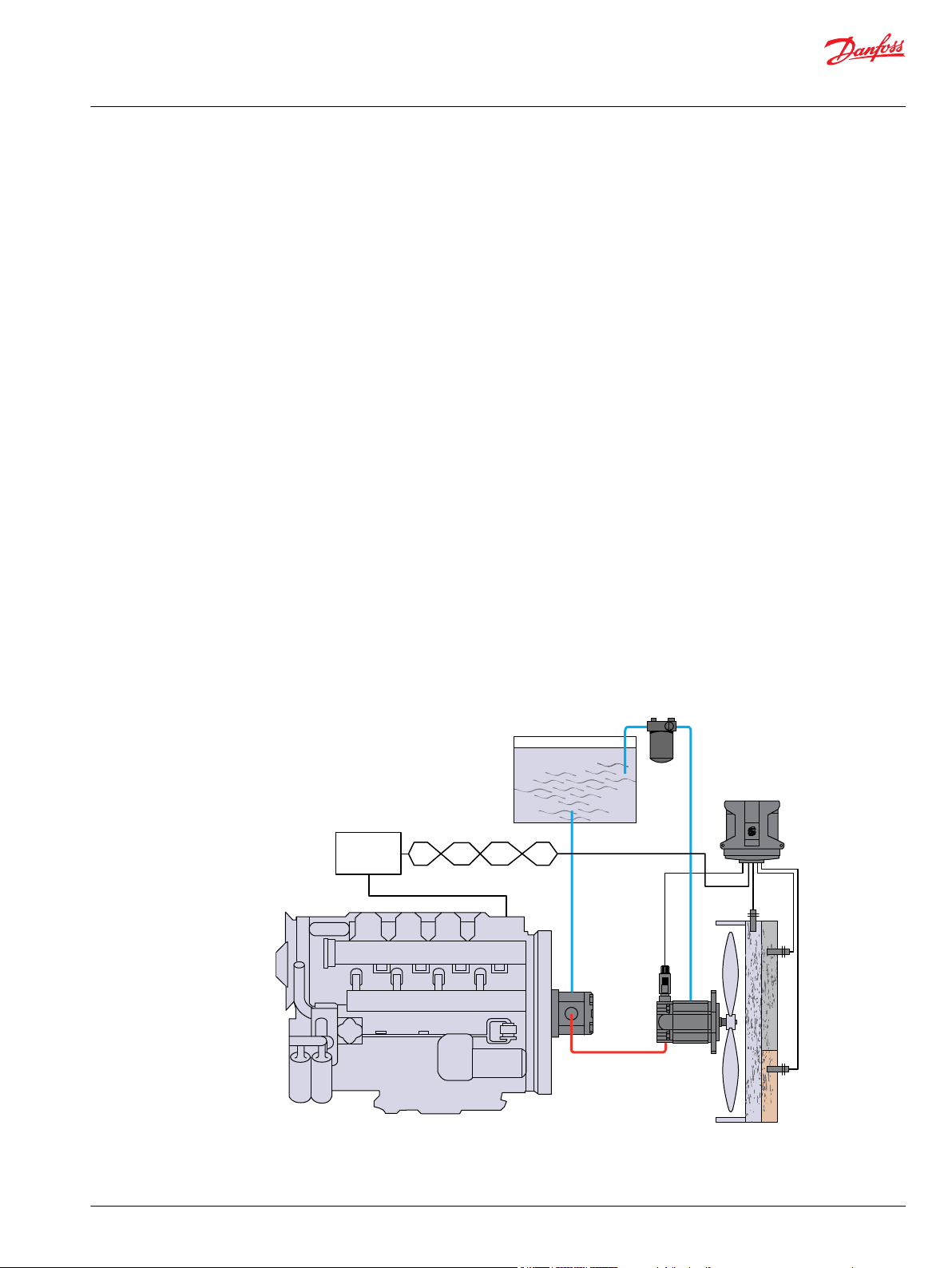

Gear Pump with Gear Motor and PLUS+1TM Fan Drive Controller

The pump receives oil directly from the reservoir through the inlet line. The output of the pump is

directed to a gear motor with an integral proportional relief valve.

The setting of the valve determines the maximum pressure in the system by bypassing oil (around the

motor’s gear set) directly to the return port of the motor. The proportional valve is normally closed and

requires the application of a PWM signal to reduce the bypass pressure. In a hydraulic fan drive system,

the pre-determined maximum pressure setting determines the maximum pressure to the motor, and the

maximum trim speed of the fan.

Applying a PWM signal to the valve allows the fan to run at speeds below its maximum trim speed,

regardless of the flow supplied by the pump.

Oil exiting the motor is directed back to the reservoir through a filter and a heat exchanger. Oil returning

to the reservoir must enter the reservoir well below the fluid level so air will not be entrained in the fluid.

The oil is diffused as it enters the reservoir to decelerate it to an acceptable level, to mix it with the fluid in

the reservoir, and to prevent the oil from flowing immediately back to the pump inlet. The return oil

should remain in the reservoir long enough to allow any entrained air in the fluid to rise to the surface

and dissipate back into the atmosphere. An anti-cavitation check valve prevents damage to the fan

motor in case of overrun. Fan overrun can occur when fan speed exceeds the speed commanded by the

system due to the fan windmilling in the vehicle’s air stream.

Gear Pump with PLUS+1TM Controller

PLUS+1TM System Illustration

©

Danfoss | Sept 2018 520L0824 | BC00000115en-000403 | 9

Page 10

T3

T2

T1

Temperature

sensors

RESERVOIR

Gear motor

(SNM)

Microcontroller

(PLUS+1TM)

Filter

DIESEL ENGINE

Variable pump

(Series 45)

P107 984E

RESERVOIR

Variable pump

(Series 45)

Selector

switch

Signal

lamp

Gear motor

(SNM)

Microcontroller

(PLUS+1TM)

Filter

DIESEL ENGINE

T3

T2

T1

Temperature

sensors

HIC

Cartridge valve

P107 985E

Technical Information

Hydraulic Fan Drive Systems

Fan Drive Systems

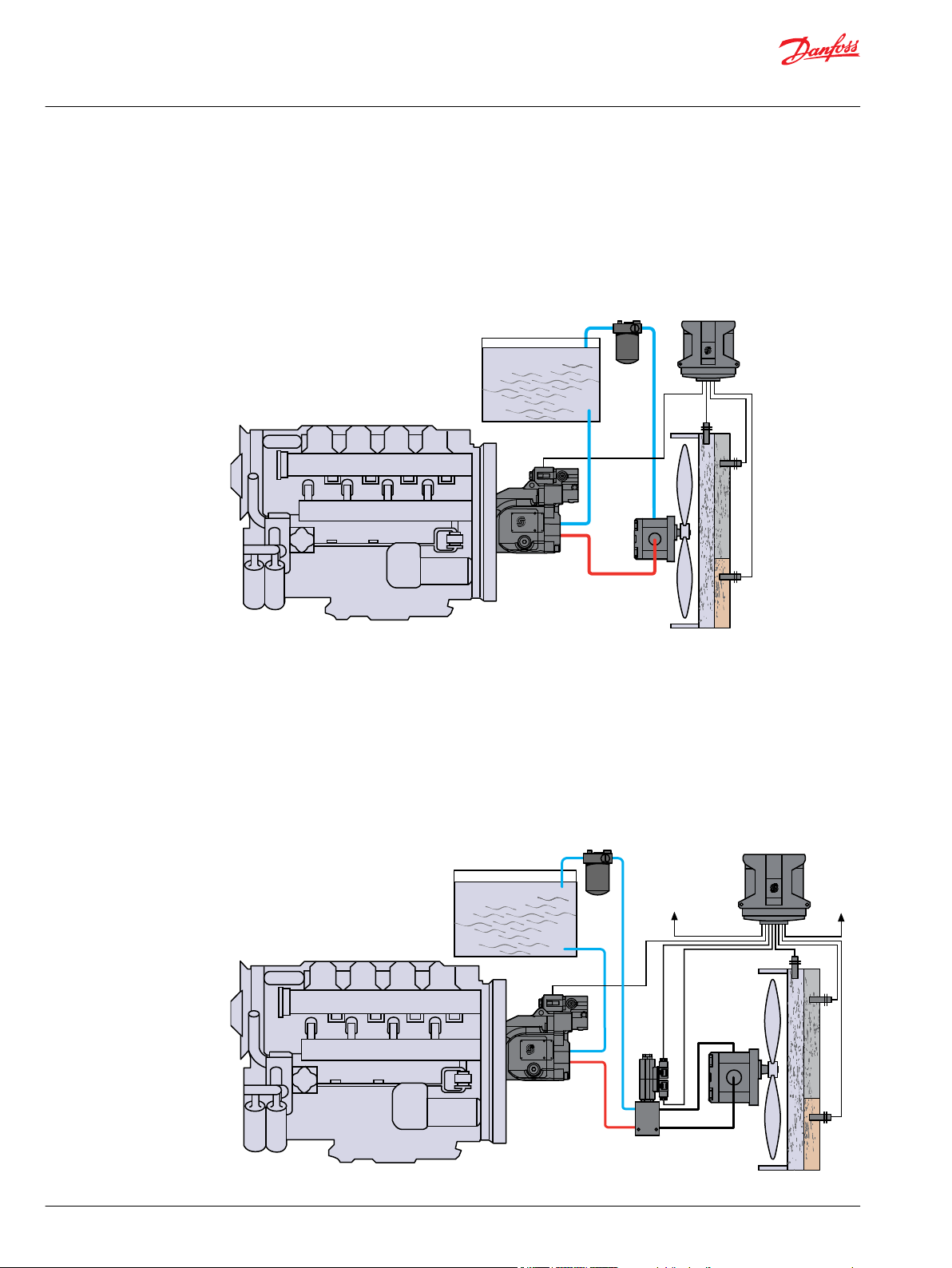

Variable Displacement Pump with Fan Drive Control

The variable displacement pump sends flow to the fan motor. Based on sensor and other inputs, the

microcontroller adjusts the proportional relief valve to regulate the pressure in the pilot port of the

pump’s load sensing control. Higher pressure in the pilot line results in increased flow to the fan motor.

The control has a pressure compensator feature which can be used to limit the fan’s trim speed. Trim

speed can also be set by software in the microcontroller.

Fan Drive Control System Illustration

Variable Displacement Pump and HIC Cartridge Valve

The system shown below is the same as the previous system with the addition of an electronically

controlled HIC cartridge valve between the pump and motor.

The HIC cartridge valve reverses the hydraulic flow to the motor, thus reversing the rotation of the fan.

This feature is commonly used to clean out the radiator if it becomes clogged with debris.

Variable Pump with HIC Cartridge Valve

10 | © Danfoss | Sept 2018 520L0824 | BC00000115en-000403

Page 11

T3

T2

T1

Temperature

sensors

RESERVOIR

Fixed displacement

piston motor

(S40 or S90)

Microcontroller

(PLUS+1TM)

Filter

DIESEL ENGINE

Piston pump

(H1 w/fan drive control)

P107 983E

Filter

Technical Information

Hydraulic Fan Drive Systems

Fan Drive Systems

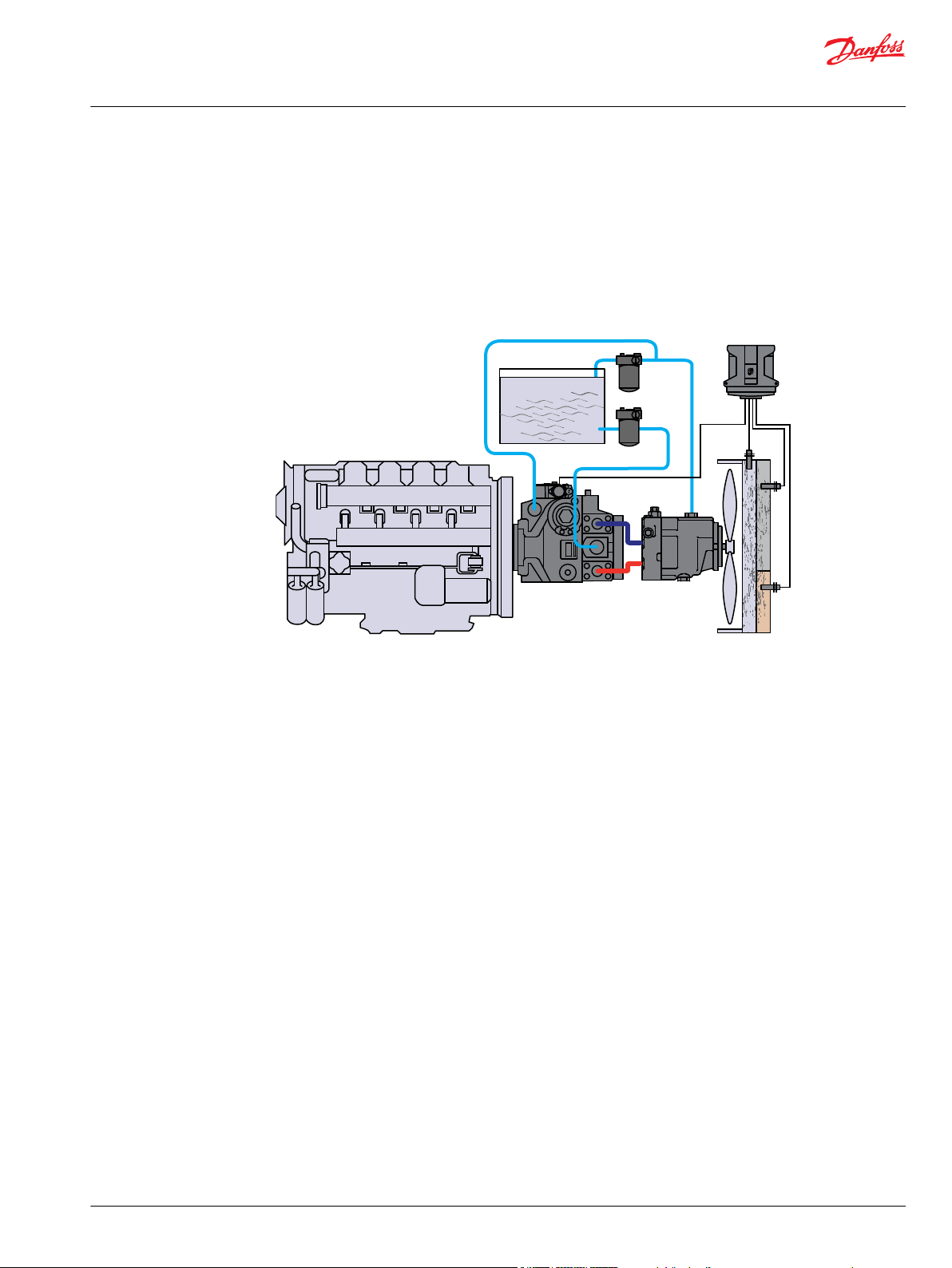

Closed Circuit System with Microcontroller

The variable displacement axial piston pump sends flow to the fixed displacement piston fan motor.

Based on temperature sensor and other inputs, the microcontroller regulates the displacement of the

axial piston pump. Higher coolant temperature results in increased flow to the fan motor. The pumps

displacement control has a pressure compensator feature which can be used to limit the maximum fan

trim speed in either direction. Trim speed can also be set by software in the microcontroller. The nature of

the closed-loop system prevents fan overrun. Zero fan speed is available on demand.

Variable Pump with Fixed Piston Motor

©

Danfoss | Sept 2018 520L0824 | BC00000115en-000403 | 11

Page 12

Technical Information

Hydraulic Fan Drive Systems

System Components

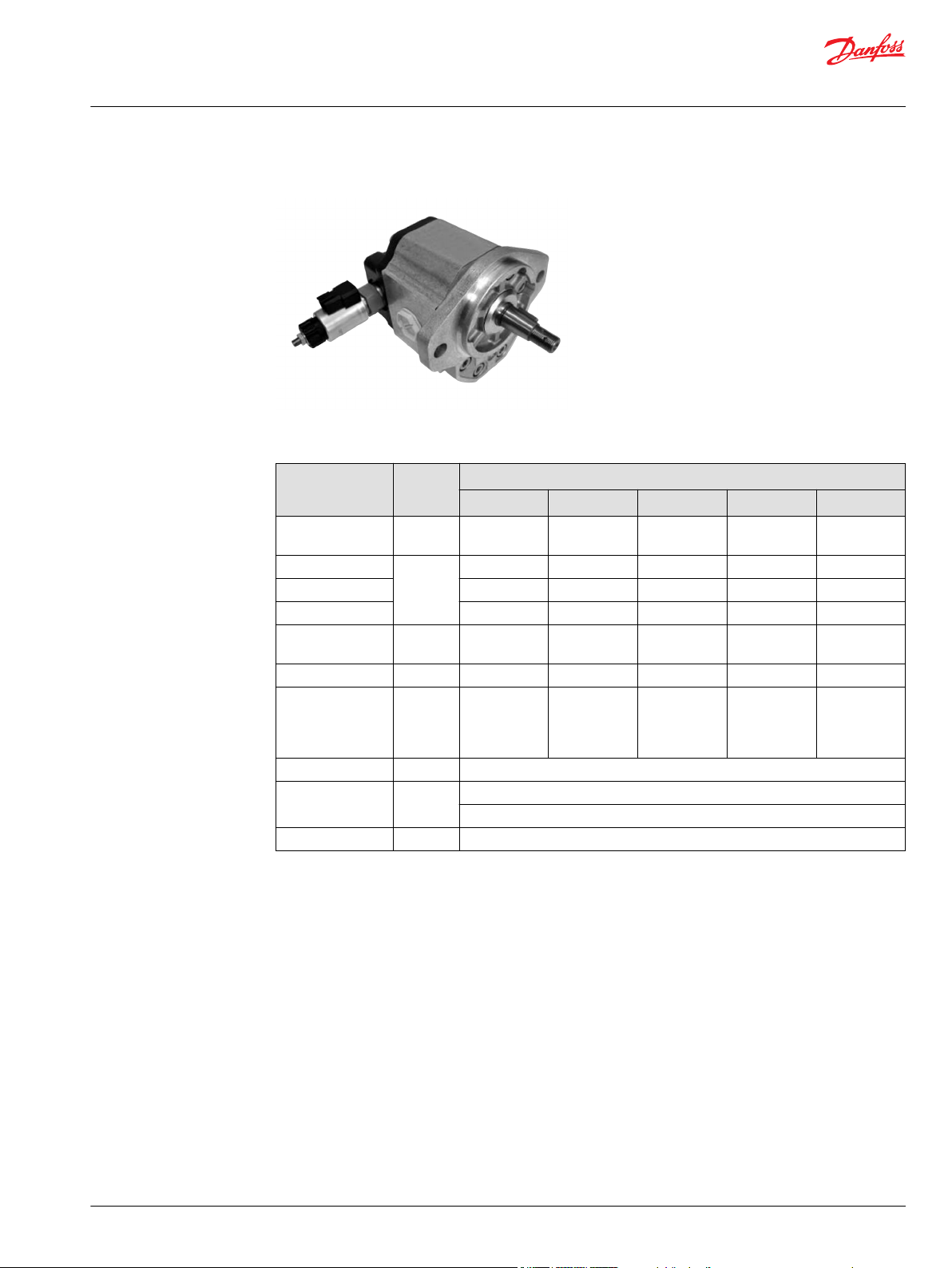

Gear Pumps

Danfoss offers gear pumps in a variety of models, sizes, capacities, and configurations. Integral priority

flow dividers are available which supply a constant flow for power assisted steering with the remainder

driving the fan drive motor.

Model Sizes and Capacities

Danfoss gear pumps are available in the following models and sizes.

Aluminum construction

•

•

Cast iron construction

•

Group 2

4 to 25 cm3/rev [0.24 to 1.53 in3/rev] displacement

Group 3

22 to 90 cm3/rev [1.34 to 5.49 in3/rev]

Group 2.5 (D Series)

7 to 45 cm3/rev [0.43 to 2.75 in3/rev]

Configurations

Single pump

•

Single pump with priority flow divider for power steering assist

•

Tandem pumps

•

Tandem pumps with priority flow divider for power steering assist

•

Multiple pumps (triple, quadruple, etc.)

•

Quadra-Flow pumps (digital displacement)

•

D Series pumps (single and tandem) are available with load sense and discrete flow options.

Group 2 aluminum gear pump

12 | © Danfoss | Sept 2018 520L0824 | BC00000115en-000403

Page 13

Technical Information

Hydraulic Fan Drive Systems

System Components

Group 2.5 D Series gear pump

Quadra-Flow gear pump

©

Danfoss | Sept 2018 520L0824 | BC00000115en-000403 | 13

Page 14

Technical Information

Hydraulic Fan Drive Systems

System Components

Series 45 Variable Displacement Axial Piston Pumps

Danfoss offers a complete family of variable displacement, open circuit, axial piston pumps. The Series 45

family offers a wide range of shafts, flanges, and porting options. Through drives are also available for

auxiliary pump drives. Load sensing (LS), pressure compensating (PC), remote pressure compensating

(RPC) and electro-proportional fan drive controls are available.

Frame K/L

•

25, 30, 38 and 45 cm3/rev [1.53, 1.83, 2.32, 2.75 in3/rev]

•

Operating pressures up to 260 bar [3770 psi]

•

Speeds to 3200 min-1(rpm)

Frame J

•

45, 51, 60, 65 and 75 cm3/rev [2.75 3.11, 3.66, 3.97, and 4.57 in3/rev]

•

Operating pressures to 310 bar [4495 psi]

•

Speeds to 2800 min-1(rpm)

Frame F

•

74 and 90 cm3/rev [4.52 and 5.49 in3/rev]

•

Operating pressures to 310 bar [4495 psi]

•

Speeds to 2400 min-1(rpm)

Frame E

•

100, 130, and 147 cm3/rev [6.10, 7.93 and 8.97 in3/rev]

•

Operating pressures to 310 bar [4495 psi]

•

Speeds to 2450 min-1(rpm)

Frame J

14 | © Danfoss | Sept 2018 520L0824 | BC00000115en-000403

Page 15

Technical Information

Hydraulic Fan Drive Systems

System Components

Frame K/L

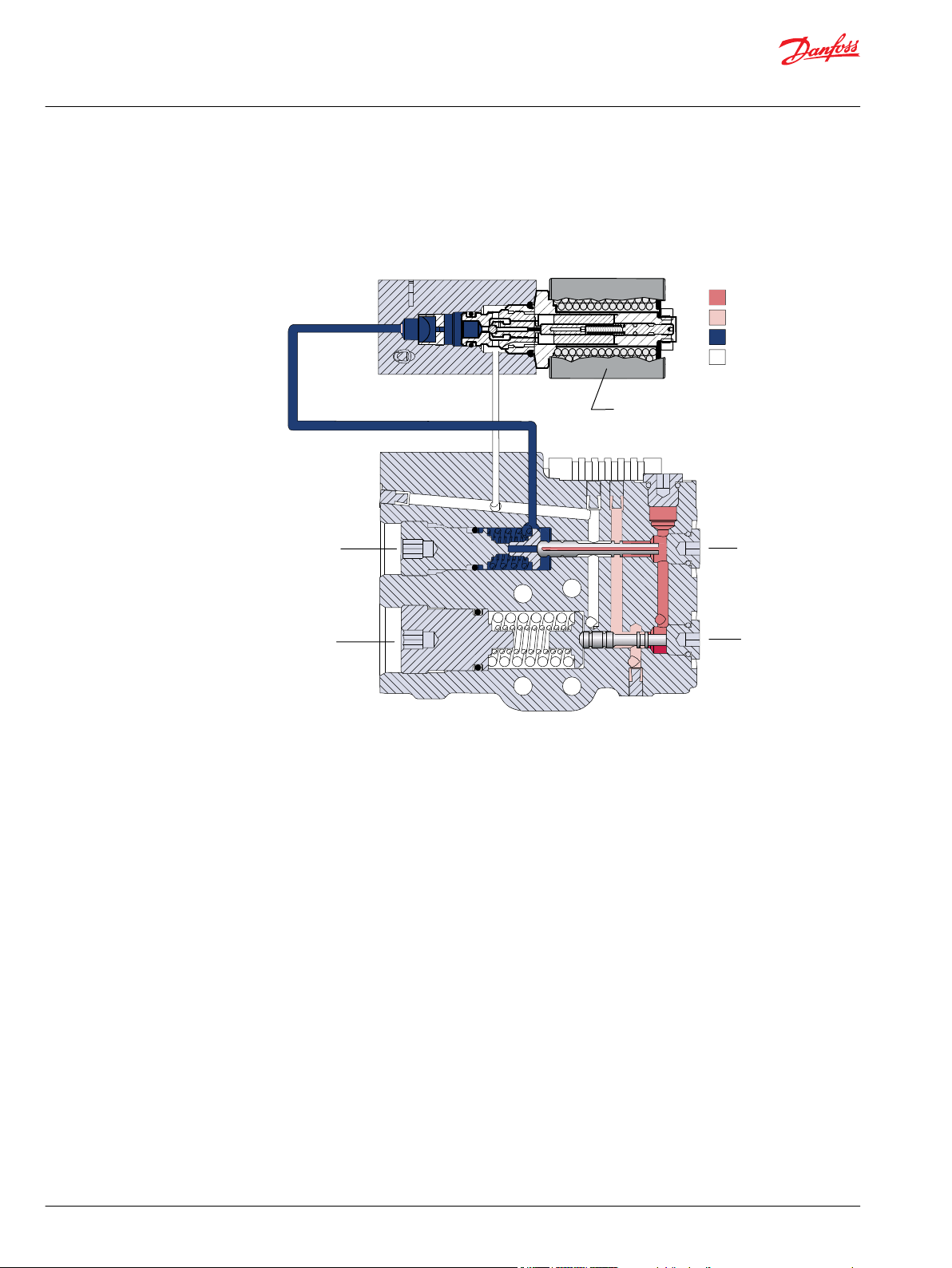

Series 45 Fan Drive Control

The Series 45 fan drive control is an electric proportional control for Series 45 pumps. It controls the

pump based on various machine operating parameters. In a fan drive system, coolant temperature forms

the basis for pump control.

When the solenoid is de-energized, the pump operates in the high pressure standby (pressure

compensation) mode; when the solenoid is fully energized, the pump returns to the low pressure

standby mode of operation. This allows the system to minimize energy loss when the cooling system

does not require cooling fan operation, potentially using existing system control components

(temperature sensor or micro-controller).

The control is proportional. As the current applied to the solenoid increases, the regulated system

pressure gradually decreases until the full current is applied, achieving low standby pressure.

©

Danfoss | Sept 2018 520L0824 | BC00000115en-000403 | 15

Page 16

LS adjustment

PC adjustment

LS spool

PC spool

Proportional solenoid

P106 027E

System pressure

Pilot Pressure

Servo pressure

Drain

Technical Information

Hydraulic Fan Drive Systems

System Components

D Series Motor

D series fan drive motors are available in displacements from 17 cm3/rev [1.04 in3/rev]to 45 cm3/rev [2.75

in3/rev].

D series fan motors are PLUS+1 compliant.

16 | © Danfoss | Sept 2018 520L0824 | BC00000115en-000403

Page 17

Technical Information

Hydraulic Fan Drive Systems

System Components

D Series Motor

D Series Motor Technical Data

Ratings Units 17 19 21 23 25 29 32 36 38 41 45

Displacement cm3/rev 17.0 19.0 20.5 22.5 25.4 29.0 31.8 36.1 38.0 41.0 45.0

in3/rev 1.04 1.16 1.25 1.37 1.55 1.77 1.94 2.20 2.32 2.50 2.75

Rated pressure bar 276 276 276 276 276 276 276 276 276 241 210

psi 4000 4000 4000 4000 4000 4000 4000 4000 4000 3495 3045

Peak pressure bar 303 303 303 303 303 303 303 303 303 265 231

psi 4400 4400 4400 4400 4400 4400 4400 4400 4400 3843 3350

Speed at rated pressure maximum 3400 3400 3400 3400 3400 3400 3400 3400 3400 3000 3000

minimum* 600 600 600 600 600 600 600 600 600 600 600

Minimum shaft speed at 69 bar [1000 PSI] rpm 400 400 400 400 400 400 400 400 400 400 400

Standard Weight kg 8.53 8.66 8.80 8.94 9.07 9.38 9.53 9.84 9.93 10.16 10.43

lb 18.8 19.1 19.4 19.7 20.0 20.7 21.0 21.7 21.9 22.4 23.0

Mass moment of inertia of internal rotating

components

Theoretical torque at rated pressure N•m 65.7 73.4 79.2 87.0 98.2 112.1 122.9 139.6 146.9 138.4 132.4

Theoretical power at rated speed kW 23.4 26.1 28.2 31.0 35.0 39.9 43.8 49.7 46.1 43.5 41.6

x10-6 kg•m² 127 138 146 156 172 191 206 228 239 255 276

-6

x10

slug•ft²

lbf•ft 48.5 54.2 58.4 64.2 72.4 82.7 90.7 102.9 108.3 102.1 97.6

hp 31.2 34.9 37.6 41.3 46.6 53.2 58.4 66.3 61.1 58.0 55.5

94 102 107 115 127 141 152 168 176 188 204

©

Danfoss | Sept 2018 520L0824 | BC00000115en-000403 | 17

Page 18

Technical Information

Hydraulic Fan Drive Systems

System Components

D Series Motor Technical Data (continued)

Ratings Units 17 19 21 23 25 29 32 36 38 41 45

Case drain pressure bar 5.0 5.0 5.0 5.0 5.0 5.0 5.0 5.0 5.0 5.0 5.0

psi 72.5 72.5 72.5 72.5 72.5 72.5 72.5 72.5 72.5 72.5 72.5

* minimum speed at maximum pressure

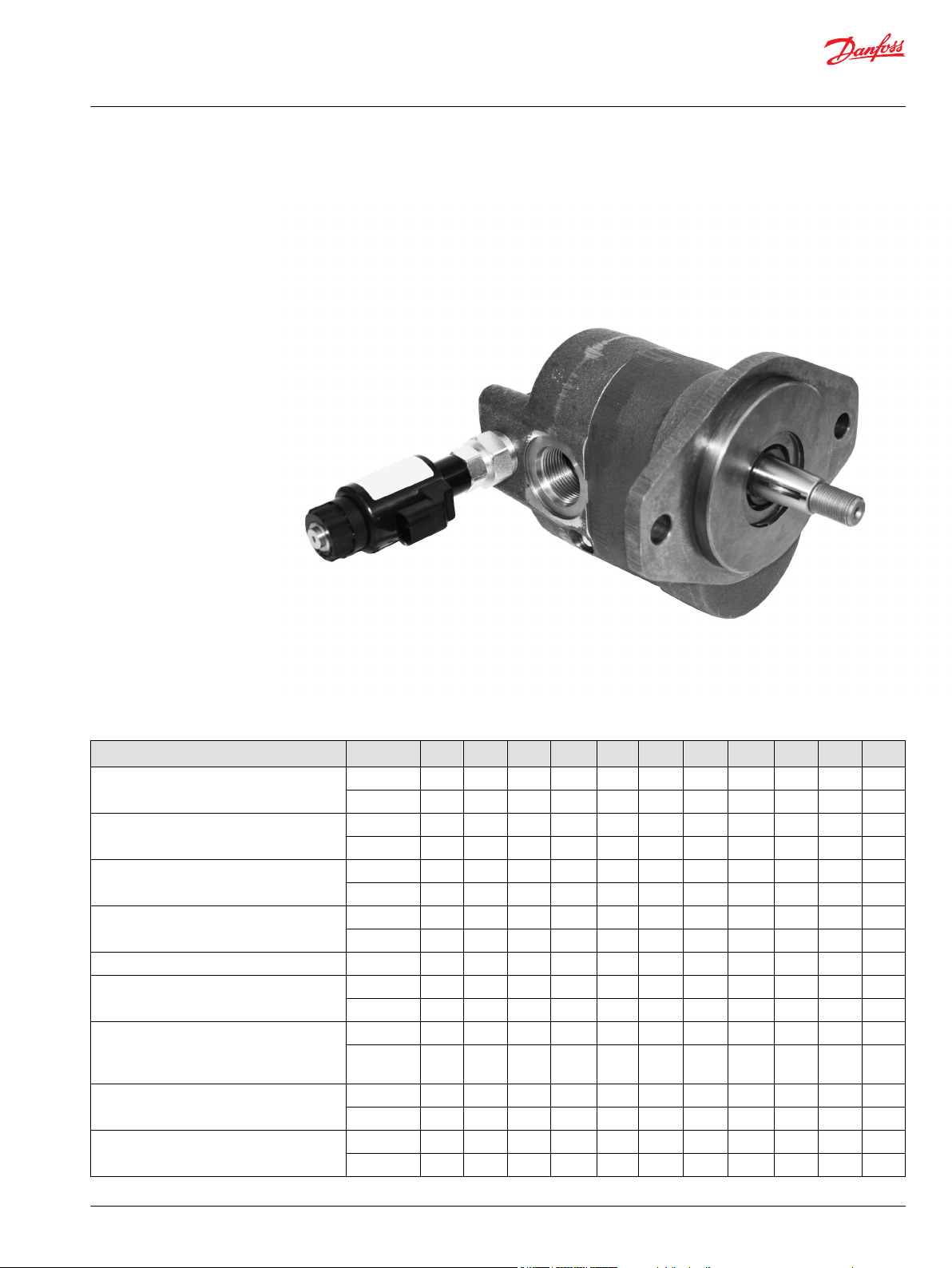

SGM2Y Motor

Group 2 fan drive motors are available in displacements from 8.4 cm3/rev [0.51 in3/rev]to 25 cm3/rev [1.54

in3/rev].

Configurations include European and SAE flanges; taper 1:8, 1:5, and straight shafts Ø15.875 mm [0.62 in].

Group 2 fan drive motors are PLUS+1 compliant.

SGM2Y Motor

SGM2Y technical data

Units Frame size

8.0 011 014 017 019 022 025

Displacement cm3/rev

[in3/rev]

Peak pressure bar [psi] 270 [3916] 270 [3916] 270 [3916] 250 [3626] 230 [3336] 200 [2900] 180 [2610]

Rated pressure 250 [3626] 250 [3626] 250 [3626] 230 [3336] 210 [3046] 180 [2610] 160 [2320]

Back pressure 150 [2176] 150 [2176] 150 [2176] 150 [2176] 130 [1885] 100 [1450] 100 [1450]

Maximum speed min-1 [rpm] 3500 3500 3500 3500 3500 3500 3500

Weight kg [lb] 4.73 [10.43] 4.83 [10.65] 5.03 [11.1] 5.18 [11.42] 5.23 [11.53] 5.33 [11.75] 5.53 [12.2]

Moment of inertia of

rotating components

Electrical connector model Deutsch DT 04-2P connectors (Protection rate IP 69K DIN 400050)

Electrical current signal A 0 to 1.1 A @ 12VDC, with coil resistance of 7.2 ohms @ 20°C [68°F]

PWM frequency Hz from 100 to 200

x 10-6 kg•m

[x 10-6 lbf•ft2]

8.4 [0.51] 10.8 [0.66] 14.4 [0.88] 16.8 [1.03] 19.2 [1.17] 22.8 [1.39] 25.2 [1.54]

2

32.4 [796] 38.4 [911] 47.3 [1122] 53.3 [1265] 59.2 [1405] 68.1 [1616] 74.1 [1758]

0 to 0.55 A @ 24VDC, with coil resistance of 28.8 ohms @ 20°C [68°F]

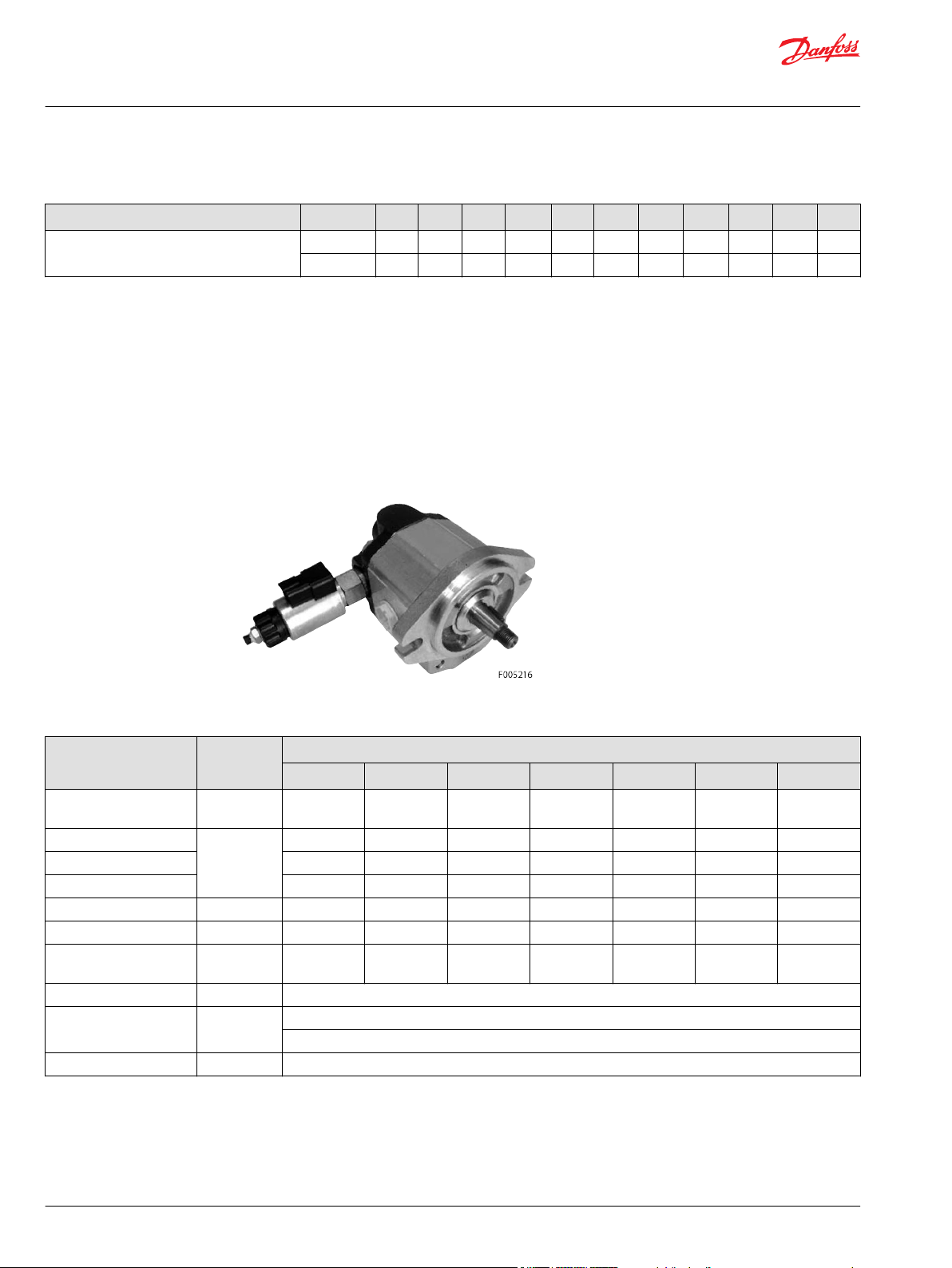

SGM3Y Motor

Group 3 fan drive motor available in displacements from 22.1 cm3/rev [1.34 in3/rev]to 44.1 cm3/rev [2.69

in3/rev].

Group 3 fan drive motors are PLUS+1 compliant.

18 | © Danfoss | Sept 2018 520L0824 | BC00000115en-000403

Page 19

Technical Information

Hydraulic Fan Drive Systems

System Components

SGM3Y Motor

SGM3Y technical data

Displacement cm3/rev

Peak pressure bar [psi] 210 [3046] 210 [3046] 210 [3046] 210 [3046] 210 [3046]

Rated pressure 190 [2756] 190 [2756] 190 [2756] 190 [2756] 190 [2756]

Maximum speed min

Weight kg [lb] 9.12 [20.11] 9.22 [20.33] 9.32 [20.55] 9.38 [20.68] 9.52 [21.0]

Moment of inertia

of rotating

components

Electrical connector model Deutsch DT 04-2P connectors (Protection rate IP 69K DIN 400050)

Electrical current

signal

PWM frequency Hz from 100 to 200

Units Frame size

022 026 033 038 044

22.1 [1.34] 26.2 [1.60] 33.1 [2.02] 37.9 [2.31] 44.1 [2.69]

[in3/rev]

Back pressure 120 [1740] 120 [1740] 120 [1740] 120 [1740] 120 [1740]

-1

[rpm]

-6

x 10

2

kg•m

-6

[x 10

lbf•ft2]

A 0 to 1.1 A @ 12VDC, with coil resistance of 7.2 ohms @ 20°C [68°F]

3500 2500 2500 2500 2500

198 [4699] 216 [5126] 246 [5838] 267.2 [6341] 294.2 [6981]

0 to 0.55 A @ 24VDC, with coil resistance of 28.8 ohms @ 20°C [68°F]

L/K Frame Axial Piston Motors

For higher power applications, Danfoss offers the L and K frame two position, axial piston motor. The KV

and LV motors can operate at two different displacements. Minimum displacement can be used when

high fan speed is required at low engine speed and maximum displacement can be used at high engine

speed. The K and L frame motors can also be used as single displacement motors.

This short, compact motor is configured ideally for installations requiring compact packaging and

optimized plumbing. All hydraulic ports are on one face of the motor. Axial or radial configurations are

available.

Mounting

SAE B-2 bolt and Danfoss cartridge

•

Shaft

SAE 0.875 diameter cylindrical and 1:8 taper keyed shafts

•

System Ports

©

Danfoss | Sept 2018 520L0824 | BC00000115en-000403 | 19

Page 20

Technical Information

Hydraulic Fan Drive Systems

System Components

•

Specifications

•

•

•

Control

•

•

•

Options

•

•

•

LV Motor

SAE O-ring boss, axial or twin radial locations

25, 30, 38 and 45 cm3/rev [1.52, 1.83, 2.14, 2.32 and 2.75 in3/rev] maximum displacements

Operating pressure up to 415 bar [6000 psi]

Speeds up to 5500 min-1(rpm)

Direct acting single line hydraulic displacement control

10 to 241 bar [150 to 3500 psi] shift pressure

Reverse Displacement Control (electric or hydraulic)

Speed sensor

Maximum displacement limiter

Integral over-pressure and anti-cavitation protection

20 | © Danfoss | Sept 2018 520L0824 | BC00000115en-000403

Page 21

Technical Information

Hydraulic Fan Drive Systems

System Components

LC Motor

PLUS+1TM Controllers

12 Pin Microcontroller

©

Danfoss | Sept 2018 520L0824 | BC00000115en-000403 | 21

Page 22

Technical Information

Hydraulic Fan Drive Systems

System Components

24 Pin Microcontroller

PLUS+1TM controllers and input/output expansion modules are designed to provide flexible, expandable,

powerful, and cost effective total machine management systems for off-highway vehicles. These modules

communicate with one another and other intelligent systems over a machine CAN (Controller Area

Network) data bus. PLUS+1TM hardware products are designed to be equally effective in a distributed

CAN network system, with intelligence in every node, or as stand-alone control for smaller machine

systems. PLUS+1TM systems are incrementally expandable: Additional modules can be easily added to the

machine CAN network to increase system capabilities or computational power.

Inputs

Each input pin allows one or more of these functional types. For pins with multiple functions, input

parameters are user programmable using PLUS+1TM GUIDE templates.

Digital (DIN)

•

Digital or Analog (DIN/AIN)

•

Digital or Analog or Frequency (DIN/AIN/FreqIN)

•

Analog or Temperature or Rheostat (AIN/Temp/Rheo)

•

Fixed Range Analog or CAN shield (AIN/CAN shield)

•

Outputs

PLUS+1TM control modules feature user-configurable universal output circuits. Output parameters are

configured using PLUS+1TM GUIDE templates. Refer to product data sheets for maximum current ratings

of individual modules. The following output types are supported:

•

Digital (DOUT)

•

PWM (PWMOUT)

•

Analog voltage suitable for driving Danfoss PVG valves (PVEOUT)

CAN Ports

All PLUS+1TM modules have CAN ports that conform to CAN 2.0b specifications, including CAN shield.

Temperature Sensors

The Danfoss family of analog temperature sensors is designed to operate in conjunction with Danfoss

Fan Drive Controls. The PLUS+1TM compliant sensors are thermistor-type temperature sensors.

22 | © Danfoss | Sept 2018 520L0824 | BC00000115en-000403

Page 23

Technical Information

Hydraulic Fan Drive Systems

System Components

Temperature sensors

Models

Two models are available: An air sensor typically used to measure engine charge air temperature, and a

liquid sensor typically used to measure engine coolant or oil temperature.

Features

Integrated connector and sensor body

•

Brass body construction

•

Anti-fouling air temperature sensor design

•

50° C to 125° C operating temperature

•

range, FDC software configurable

•

For proper operation, the air temperature sensor must be mounted at the top of the manifold pipe with

the sensor tip facing down.

Temperature versus resistance limits

Measured Temp, ° C

[°F]

50 [122] 810.9 ±5%

80 [176] 283.0 ±5%

100 [212] 152.9 ±8%

125 [257] 76.9 ±8%

PLUS+1 TM Compliance

The Danfoss temperature sensors are compliant with the larger microprocessors (for example the

MC050). The MC050 microprocessor has internal resistance in its four temperature inputs.

If you are using the Danfoss temperature sensors with the smaller microprocessors (for example the

MC012 and MC024), you will need to connect the sensors in series with an external resistor (Rv) as shown

in the following illustration.

Nominal Tolerance

Resistance, Ohms

©

Danfoss | Sept 2018 520L0824 | BC00000115en-000403 | 23

Page 24

Technical Information

Hydraulic Fan Drive Systems

System Components

Analog sensor voltage

For assistance in configuring the temperature sensors contact your Danfoss representative.

24 | © Danfoss | Sept 2018 520L0824 | BC00000115en-000403

Page 25

Based on SI units

= (l/min)

Input torque M = (N•m)

Input power P = (kW)

Motors

Based on SI units

Output torque M = (N•m)

Output power P = (kW)

Based on English units

= (US gal/min)

Input torque M = (lbf•in)

Input power P = (hp)

Based on English units

Output torque M = (lbf•in)

Output power P = (hp)

Vg • n • η

v

1000

Vg • ∆p

20 • π • η

m

Vg• n• ∆p

600 000 • η

m

Vg • n • η

v

231

Vg • ∆p

2 • π • η

m

Vg • ∆p • η

m

20 • π

Q • ∆p • ηt

600

Vg • ∆p • η

m

2 • π

Q • ∆p • η

t

1714

Pumps

Vg• n• ∆p

396 000 • η

m

Technical Information

Hydraulic Fan Drive Systems

System Design Parameters

Sizing Equations

Equations

Variables

SI units [English units]

Vg = Displacement per revolution cm3/rev [in3/rev]

pO = Outlet pressure bar [psi]

pi = Inlet pressure bar [psi]

∆p = pO - pi (system pressure) bar [psi]

n = Speed min-1 (rpm)

ηv = Volumetric efficiency

ηm = Mechanical efficiency

ηt = Overall efficiency (ηv • ηm)

SI unit formulas are based on cm3, bar, N, N•m, W.

English formulas are based on in3, psi, lbf•in, hp.

©

Danfoss | Sept 2018 520L0824 | BC00000115en-000403 | 25

Page 26

C

L

O

C

K

W

I

S

E

C

O

U

N

T

E

R

C

L

O

C

K

W

I

S

E

P106110

Model or Series

Belt Drive

(engine to pump)

Clockwise, Right hand

Counterclockwise, Anti-clockwise, Left hand

Manufacturer

Pump Drive

Pump Rotation

Speeds

Engine PTO

Ratio

:1

Low Idle

Governed

High Idle

RPM (rated)

RPM (rated)

RPM (max speed)

Input torque

limit:

P104 376E

US gal/min

bar

(maximum)

Controlled Flow Requirement

Steering Pressure

psi

l/min

Technical Information

Hydraulic Fan Drive Systems

System Design Parameters

System Design Data Form

Print this form. Fill in all the fields and check the appropriate check boxes. Fax the filled out form to your

Danfoss Power Solutions Technical Sales Representative.

Engine details

Power steering

(if applicable)

26 | © Danfoss | Sept 2018 520L0824 | BC00000115en-000403

Page 27

C

l

o

c

k

w

i

s

e

C

o

u

n

t

e

r

c

l

o

c

k

w

i

s

e

P101 344E

Model or Series

mm

Manufacturer

Fan Diameter

in

At speed

kW

Fan Input Power

HP

rpm

Fan Rotation

(viewed on motor shaft, see illustration)

Clockwise

Counterclockwise

Fan Trim Speed

rpm

Set Point at Fan Trim Speed

(engine speed where max heat load occurs)

rpm

Coolant Temperature at Fan Trim Speed

(coolant temp where max fan speed is required)

°F

°C

Note: To properly size and specify a fan drive system, fan power requirements must be stated as accurately as possible. Fan power requirements

can be determined from fan curves supplied by the manufacturer. Radiator and cooler manufacturers will supply air flow requirements based

on heat loads. Air flow information must include accurate air flow and static pressure to determine correct fan power requirements.

P104 377E

Single Input

Electro-Hydraulic Modulating Electro-Hydraulic ON/OFF

Multiple Inputs

P104 378E

US gal

Reservoir Capacity

liter

Technical Information

Hydraulic Fan Drive Systems

System Design Parameters

Fan information

Control preference

Reservoir

©

Danfoss | Sept 2018 520L0824 | BC00000115en-000403 | 27

Page 28

P104 379E

at 40° C [104°F]

Hydraulic Fluid Type

Viscosity

cSt

Maximum Fluid Temperature

°F

°C

SUS

at 100° C [212°F]

P104 380E

Inlet Line

Filter Position

Pressure Line

(recommended)

Return Line

Filter Rating

Full Flow

Filter Flow

Partial Flow

micron

x ratio

Note: Do not locate the filter cartridge inside the reservoir. This reduces the reservoir capacity and reduces the dwell time (the time the oil

spends in the resrevoir). It also increases the potential for damage to the hydraulic components due to aeration of the oil.

Technical Information

Hydraulic Fan Drive Systems

System Design Parameters

Fluid

Filtration

28 | © Danfoss | Sept 2018 520L0824 | BC00000115en-000403

Page 29

Technical Information

Hydraulic Fan Drive Systems

Installation Guidelines

Pumps

Pump Drives

Where possible, avoid radial and axial loads on the pump drive.

For in-line drives, place a suitable drive coupling between the prime mover (e.g. engine) and the pump

input shaft to remove radial and axial load potential. For belt driven pump applications an outrigger

bearing may be required to relieve the pump of radial loads. Outrigger bearings are available with ball or

roller bearing support for such applications. For Power Take Off (PTO) drives (where an external gear is

assembled to the pump), and for belt driven pump applications, consult your Danfoss representative.

In many applications the limiting factor for driving a pump is available torque. Pump drive shafts have a

torque limit based on material, design and system pressure. Likewise, pump drives such as air

compressors with PTOs also have torque limits. When planning to drive a pump on the back of an air

compressor, first check with the compressor supplier to understand their product torque limitations.

Most compressors do not have a constant torque capability across their speed range. Typically, the

torque capability of a compressor is lower at low engine speeds and increases to a speed where the

capability remains constant.

A number of pump drive shafts are generally available across the Danfoss product range. Consider

driveshaft selection carefully.

Motors

Pump Inlet

When designing the inlet portion of the hydraulic circuit, it is important to keep the pump inlet pressure

within published limits. To reduce the chances of inlet cavitation problems, observe the following

guidelines:

Position reservoir outlet above the pump inlet level whenever possible.

•

Make the inlet line (hose and fittings) as straight and as short as possible without inducing bending or

•

stress loads onto the inlet port.

Size the inlet line to keep fluid velocities and inlet pressure within the limits published in the

•

individual product literature.

To reduce the chances of port fitting leakage, we recommend using SAE split flange or O-ring boss

•

ports whenever possible.

Pump Outlet

•

Make the outlet line (hose and fittings) as straight and as short as possible without inducing bending

or stress loads onto the outlet port.

•

Ensure the outlet line is sized to keep fluid velocities within the limits published in the individual

product literature.

•

To reduce the chances of port-fitting leakage we recommend using SAE split flange or O-ring boss

ports whenever possible.

SGM2YN and SGM3YN Fan Drive Motors

SGM2Y and SGM3Y fan drive motors have the proportional solenoid bypass relief valve built into the rear

cover. Electrical connector is Deutsch DT 04-2P. Mount the motor so the relief valve is below the reservoir

oil level. Keep the relief valve in a horizontal position.

D Series Fan Drive Motors

D series fan drive motors are available with an integrated proportional or standard relief valve. Mount the

motor so the relief valve is below the reservoir oil level. Keep the relief valve in a horizontal position.

©

Danfoss | Sept 2018 520L0824 | BC00000115en-000403 | 29

Page 30

Technical Information

Hydraulic Fan Drive Systems

Installation Guidelines

L and K Variable Motors

L and K variable motors do not have over-pressure protection or an anti-cavitation valve integrated into

the motor. Both valve functions need to be provided externally.

L and K variable motors may be applied in open circuit systems without external back-pressure valves, as

long as the motor case pressure does not exceed the outlet pressure by more than 0.5 bar [7 psi].

Typically the motor's maximum displacement is used when the system is sized for maximum cooling

when the engine is at Full Load High Idle speed. The motor's minimum displacement is selected to

provide improved cooling when the engine is at its low idle speed.

Reverse Displacement Motors

The Reverse Displacement Motor is a unique design variation of the L and K variable motors.

It has been designed to reverse the direction of fan rotation without using an externally mounted four-

way directional control valve.

The motor is switched from maximum displacement in the forward direction to maximum displacement

in the reverse direction with an integrated solenoid valve.

Over-pressure protection and an anti-cavitation valve are integrated into the motors endcap.

Series 40 Fixed Displacement Motors

Series 40 motors are available with over-pressure protection and an anti-cavitation valve in a

unidirectional open circuit configuration.

They may be applied in open circuit systems without external back-pressure valves as long as the motor

case pressure does not exceed the outlet port pressure by more than 0.5 bar [7.0 psi].

Bi-directional open circuit operation is available, provided that a four-way directional control valve is

located between the pump and the motor.

Series 90 Fixed Displacement Motors

Series 90 fixed displacement motors are available without over-pressure protection or an anti-cavitation

valve in an open circuit configuration.

They may be applied in open circuit systems without external back-pressure valves, but

thrust, case pressure, and maximum shaft speed limits must be respected. (Consult your Danfoss

Technical Sales Representative for assistance when specifying a Series 90 fixed displacement motor in an

open circuit application.

specific axial

30 | © Danfoss | Sept 2018 520L0824 | BC00000115en-000403

Page 31

Technical Information

Hydraulic Fan Drive Systems

Installation Guidelines

Controls

PLUS+1TM controller

The Plus+1TM controller is designed to control many different hydraulic devices. Mount the Plus+1

TM

controller in a convenient, out of the way, location. A diagnostic connector is required to connect to the

Plus+1TM controller. Mount the connector in an easily accessible location in the operators cabin. Follow

the wiring guidelines found in Plus+1TM module technical literature.

Series 45 Fan Drive Controls

In Danfoss open circuit fan drives, fan speed is regulated by controlling the system pressure differential

across the fan motor. In Series 45 pumps, this is provided by using the Electric Proportional Control

variation. The Electric Proportional Control consists of a proportional solenoid integrated into the Remote

Pressure Compensated control housing. This control provides an output pressure proportional to the

current supplied to the solenoid and allows the pump to be operated at any pressure limit between the

load sense and pressure compensation settings by varying the current sent to the solenoid. Both

Normally Closed and Normally Open control configurations are available. The Normally Closed

configuration is usually applied in system cooling fan installations. It is desireable that the fan

fail to full

speed if there is an interruption of the electrical command to the solenoid, for any reason.

H1 Pump with Fan Drive Control

A fan drive control option is available for the H1 family of high power, closed circuit, variable

displacement pumps. The H1 Fan Drive Control is compatible with the PLUS+1TM controller and the fan

drive application block. The Fan Drive Control is designed with a single solenoid and uses a single control

input to regulate both the fan speed and direction of rotation.

When the pump speed is at the design set point, fan speed required for the desired cooling capacity is

determined by the pump's displacement. In many systems, the fan's speed at this condition may be close

to its maximum design speed. If the pump speed increases beyond the set point and the pump is

commanded to maximum displacement; then the fan speed will increase in proportion to the pump

speed ratio and the pressure drop across the fan motor will increase in proportion to the square of the

pump speed ratio. To prevent this from happening, the system designer is encouraged to limit the

maximum fan speed in each direction of rotation by adjusting the set pressure of the Pressure Limiters

for both directions of rotation.

The Fan Drive Control (FDC) has limitations on the maximum servo delta pressure developed, compared

to other types of controls, and so there are limitations to the operating conditions which can be achieved

in the various frame size H1 pumps. Typical fan drive systems are unusual in that they achieve peak

pressure only at high flows, so it is important that FDC equipped pumps not be applied beyond the

specified limits. (Refer to Fan Drive Design Guidelines 520L0926, Appendix H, for additional information,

or contact your Danfoss Technical Sales Representative for assistance.)

Fan drives are sized with reserve pump capacity so that peak fan speed can be maintained even when

engine speed is reduced, as illustrated below. This is a feature that is unique to the Danfoss H1 Fan Drive

Control; it allows the system to maintain a nearly constant fan speed without the need for additional

control algorithms in the fan drive controller. In this example, representing an engine lugging condition

(engine speed change of 20%), there was no significant reduction in fan speed.

©

Danfoss | Sept 2018 520L0824 | BC00000115en-000403 | 31

Page 32

3.0

RPM

x 10

Input speed

2.9

2.8

2.7

2.6

2.5

2.4

2.3

2.2

2.1

2.0

1.9

1.8

1.7

1.6

1.5

1.4

1.3

1.2

1.1

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

0

40

80

120

160

200

240

280

320

360

400

-40

-80

-120

-160

-200

-240

-280

-320

-360

-400

Bar

3

Degrees

0

2

4

6

8

10

12

14

16

18

20

-2

-4

-6

-8

-10

-12

-14

-16

-18

-20

0

1

2

3 4 5

7

8

9

10

11

12 13

14

15

16

17

18

19 20

6

Fan drive speed

Swashplate Angle

MA_MB_System_Press

M4_M5_Servo_Press

P108679

Bar

30

26

22

18

14

10

2

-14

-18

6

0

-2

-6

-10

-22

-26

-30

28

24

20

16

12

8

4

-4

-8

-12

-16

-20

-24

-28

Seconds

C

Technical Information

Hydraulic Fan Drive Systems

Installation Guidelines

Prime Mover Speed Change (2500 - 2000 - 2500 rpm)

System

Filtration

To prevent premature wear, it is imperative that only clean fluid enters the pump and hydraulic circuit. A

filter capable of controlling the fluid cleanliness to class 22/18/13 (per ISO 4406-1999) or better, under

normal operating conditions, is recommended. At initial start up, the system can be at Class 25/22/17 but

should not be run at high speed or pressure until the Class 22/18/13 is achieved through filtration. Since

the filter must be changed at regular intervals, the filter housing should be located in an accessible area.

32 | © Danfoss | Sept 2018 520L0824 | BC00000115en-000403

Appropriate filter change intervals may be determined by test or by gauges indicating excessive pressure

drop across the filter element.

For more information refer to Design Guideline for Hydraulic Fluid Cleanliness, Technical Information

520L0467.

Operating Temperatures

With Buna seals and normal operating conditions, the system temperature should not exceed 82 °C [180

°F] except for short periods to 93 °C [200 °F]. With optional Viton elastomer, the system may be operated

at continuous temperatures up to 107°C [225°F] without damage to the hydraulic components.

Caution

Operation in excess of 107 °C [225 °F] may cause external leakage or premature unit failure.

Fluids

A mineral based fluid is recommended that includes additives to resist corrosion, oxidation and foaming.

The oil should have a maximum viscosity commensurate with system pressure drop and pump suction

pressures. Since the fluid serves as a system lubricant, as well as transmitting power, careful selection of

the fluid is important for proper operation and satisfactory life of the hydraulic components. Hydraulic

Page 33

Technical Information

Hydraulic Fan Drive Systems

Installation Guidelines

fluids should be changed at appropriate intervals determined by test, supplier, or by change in color, or

odor, of the fluid.

Every 10°C [18°F] rise in continuous reservoir temperature over 80°C [176 °F] decreases the life of the oil

by ½.

For additional technical information on hydraulic fluids refer to Hydraulic Fluids and Lubricants 520L0463

Technical Information Bulletin and specific product technical bulletins.

For information relating to biodegradable fluids, see Danfoss publication Experience with Biodegradable

Hydraulic Fluids 520L0465 or consult the Danfoss Technical Services Department.

©

Danfoss | Sept 2018 520L0824 | BC00000115en-000403 | 33

Page 34

P106 103E

74.20

[2.92]

63.39

[2.50]

45.47

[1.79]

Illustration of left-hand (CCW) rotation

(SAE B mount available)

Priority flow port (CF)

3/4-16 UNF-2B SAE Str. thd.

for 1/2 in. O.D. tube

D

C

B

SAE B 13T:

*Except as noted

13 Tooth spline, 16/32 pitch

30° Pressure angle

Flat root side fit

Per ANSI B92.1-1970. Class 7

22.07

21.82

Ø

[0.869]

[0.859]

29.97

[1.18]

Eff. spline

39.91

[1.57]

Excess flow port (EF)

7/8-14 UNF-2B SAE Str. thd.

for 5/8 in. O.D. tube

47.75

[1.88]

133.87

[5.27]

20.32

[0.80]

Inlet port

1 5/16-12 UN-2B SAE Str. thd.

for 1 in. O.D. tube

12.45

[0.49]

10.41

[0.41]

6.1

[0.24]

82.55

82.50

[3.250]

[3.248]

Ø

A

106.38

[4.19]

95.5

[3.76]

Ø

53.17

[2.09]

11.18

[0.44]

2X R

20.63

[0.81]

22.55

[0.89]

61.76

[2.43]

41.15

[1.62]

11.68

[0.46]

2X Ø

Dimensions in mm [in]

*

Technical Information

Hydraulic Fan Drive Systems

Installation Drawings

D Series Pumps

D Series pump counterclockwise (CCW) rotation

For specifications and measurements for A, B, C, and D, refer to the folowing table.

34 | © Danfoss | Sept 2018 520L0824 | BC00000115en-000403

Page 35

P106 104E

74.60

[2.94]

63.39

[2.50]

45.47

[1.79]

Illustration of right-hand (CW) rotation

(SAE B mount available)

Priority flow port (CF)

3/4-16 UNF-2B SAE Str. thd.

for 1/2 in. O.D. tube

D

C

B

21.12

[0.83]

Excess flow port (EF)

7/8-14 UNF-2B SAE Str. thd.

for 5/8 in. O.D. tube

47.75

[1.88]

133.87

[5.27]

12.45

[0.49]

10.41

[0.41]

6.1

[0.24]

82.55

82.50

[3.250]

[3.248]

Ø

106.38

[4.19]

95.5

[3.76]

Ø

53.19

[2.09]

11.18

[0.44]

2X R

61.27

[2.41]

18.09

[0.71]

80.55

[3.17]

11.68

[0.46]

2X Ø

SAE A 11T:

*Except as noted

11 Tooth spline, 16/32 pitch

30° Pressure angle

Flat root side fit

Per ANSI B92.1-1970. Class 7

or better

18.64

18.52

Ø

[0.734]

[0.729]

26.42

[1.04]

Eff. spline

20.32

[0.80]

Inlet port

1 5/16-12 UN-2B SAE Str. thd.

for 1 in. O.D. tube

38.11

[1.50]

A

Dimensions in mm [in]

*

Technical Information

Hydraulic Fan Drive Systems

Installation Drawings

D Series Pump Clockwise (CW) Rotation

Nominal pump

displacement

cm3/rev

[in3/rev]

7.0 [0.43] 276 [4000] 303 [4400] 3400 80.5 [3.17] 92.0 [3.62] 94.5 [3.72] 116.1 [4.57]

Maximum

continuous

pressure

bar [psi]

9.5 [0.58] 276 [4000] 303 [4400] 3400 82.9 [3.27] 94.4 [3.72] 96.9 [3.82] 118.5 [4.67]

12.6 [0.77] 276 [4000] 303 [4400] 3400 86.1 [3.39] 97.5 [3.84] 100.1 [3.94] 121.7 [4.79]

14.3 [0.87] 276 [4000] 303 [4400] 3400 87.8 [3.46] 99.2 [3.91] 101.7 [4.01] 123.3 [4.86]

17.0 [1.04] 276 [4000] 303 [4400] 3400 90.4 [3.56] 101.9 [4.01] 104.4 [4.11] 126.0 [4.96]

©

Danfoss | Sept 2018 520L0824 | BC00000115en-000403 | 35

Maximum

pressure

bar [psi]

Maximum speed

min-1 (rpm)

A

mm [in]

B

mm [in]

C

mm [in]

D

mm [in]

Page 36

P108899

Inlet port

Outlet port

145.5

[5.73]

132.6

[5.22]

198.6

[7.82]

75.7

[2.98]

151.4

[5.96]

Technical Information

Hydraulic Fan Drive Systems

Installation Drawings

Nominal pump

displacement

cm3/rev

[in3/rev]

Maximum

continuous

pressure

bar [psi]

Maximum

pressure

bar [psi]

Maximum speed

min-1 (rpm)

A

mm [in]

B

mm [in]

C

mm [in]

19.0 [1.16] 276 [4000] 303 [4400] 3400 92.5 [3.64] 103.9 [4.09] 106.4 [4.19] 128.0 [5.04]

20.5 [1.25] 276 [4000] 303 [4400] 3400 94.0 [3.70] 105.4 [4.15] 108.0 [4.25] 129.6 [5.10]

22.5 [1.37] 276 [4000] 303 [4400] 3400 95.8 [3.77] 107.3 [4.22] 109.8 [4.32] 131.4 [5.17]

25.4 [1.55] 276 [4000] 303 [4400] 3400 98.8 [3.89] 110.2 [4.34] 112.8 [4.44] 134.4 [5.29]

29.0 [1.77] 276 [4000] 303 [4400] 3200 102.4 [4.03] 113.8 [4.48] 116.4 [4.58] 138.0 [5.43]

31.8 [1.94] 276 [4000] 303 [4400] 3000 105.2 [4.14] 116.6 [4.59] 119.1 [4.69] 140.7 [5.54]

36.0 [2.20] 241 [3500] 265 [3850] 2750 109.4 [4.31] 120.9 [4.76] 123.4 [4.86] 145.0 [5.71]

38.0 [2.32] 228 [3300] 250 [3630] 2750 111.4 [4.39] 122.8 [4.84] 125.4 [4.94] 147.0 [5.79]

41.0 [2.50] 207 [3000] 228 [3300] 2500 114.4 [4.50] 125.8 [4.95] 128.4 [5.05] 150.0 [5.90]

45.1 [2.75] 190 [2750] 209 [3025] 2500 118.6 [4.67] 130.1 [5.12] 132.6 [5.22] 154.2 [6.07]

Quadra-Flow Pump

D

mm [in]

36 | © Danfoss | Sept 2018 520L0824 | BC00000115en-000403

Page 37

CF

EF

P106105

P107897

CF

EF

LS

Technical Information

Hydraulic Fan Drive Systems

Installation Drawings

D Series Pumps with Priority Flow Schematic

D Series Pump with Load Sensing Schematic

©

Danfoss | Sept 2018 520L0824 | BC00000115en-000403 | 37

Page 38

P108900

P107 882E

CW motor shown. For CCW motor, valve is on the opposite side.

B

44.4

[1.75]

85.1

[3.35]

A

C

Motor is also

available with

cavities only

(no valve)

20.32

[0.8]

170.0

[6.69]

2 pin

Deutsch

connector

14.23

Ø

[0.56]

88.9

[3.50]

44.4

[1.75]

External drain - drive side

Inlet port and outlet port

sized identically

External drain - idler side

Technical Information

Hydraulic Fan Drive Systems

Installation Drawings

Quadra-Flow Schematic

D Series Gear Motor

D Series Motor Dimensions

Dimensions Units 17 19 21 23 25 29 32 36 38 41 45

DimensionAmm 88.9 90.9 92.5 94.2 97.3 100.8 103.6 107.7 109.7 112.8 117.1

in 3.50 3.58 3.64 3.71 3.83 3.97 4.08 4.24 4.32 4.44 4.61

Dimension B mm 91.7 93.8 95.3 97.0 100.1 103.6 106.4 110.7 112.5 115.6 119.9

in 3.61 3.69 3.75 3.82 3.94 4.08 4.19 4.36 4.43 4.55 4.72

Dimension C mm 154.4 156.5 158.0 160.0 162.8 166.4 169.2 173.5 175.5 178.6 182.6

in 6.08 6.18 6.22 6.30 6.41 6.55 6.66 6.83 6.91 7.03 7.19

Dimensions in table are maximum dimensions.

38 | © Danfoss | Sept 2018 520L0824 | BC00000115en-000403

Page 39

Inlet

Outlet

26

F

Drain: 9/16–18UNF–2B

(SAE J1926/1 O-Ring boss)

12.7 [0.5] min. full thread

G M6-6H

12 [0.47] min.

full thread

P005 400E

Connector: Deutsch DT 04-2P

Voltage: 12V DC (Current 1.1 A)

24V DC (Current 0.55 A)

PWM 100-200 Hz

[1.02 ±0.04

]

[0.62

±0.02

]

89 max

[3.504 max.]

92 max

[3.622 max.]

156 max

[6.142 max.]

12.5

[ 0.49 ]

B

A

D

15.7

Ø 80

[

Ø3.15

]

-0.002

-0.004

-0.06

-0.106

X

7.2

±1

±1

±0.039

±0.25

±0.5

±0.5 [±0.02]

E

+0.5

0

±1[±0.04]

B

±1[±0.04]

C

+1.5 [+0.059] max

[0.28 ±0.01]

±0.2 [±0.008]

R 0.8 max.

[0.03 max.]

45

o

[0.62

±0.02

]

15.7

±0.5

Ø 0.75

X

120 [4.72] max.

103 [4.055] max.

(100 [3.94])

65.5

[2.59]

72

[2.83]

34.5

[1.36]

9

+0.5

0

[0.35 ]

+0.02

0

36.2 max.

[1.425 max.

]

67.6 max.

[2.66 max.

]

+0.02

0

][

Valve type: PRV10–IS2

CW motor shown. For CCW motor, valve is on the opposite side.

Technical Information

Hydraulic Fan Drive Systems

Installation Drawings

SGM2YN Gear Motor

02AA

©

Danfoss | Sept 2018 520L0824 | BC00000115en-000403 | 39

SGM2YN - 02AA dimensions

Frame size 8.0 011 [0.67] 014 [0.95] 017 [1.04] 019 [1.16] 022 [1.34] 025 [1.53]

Dimension

mm [in]

Inlet port D 7/8-14 UNF-2B (SAE J1926/1 O-ring boss); 16.7 [0.66] min. full thread

A 47 [1.85] 49 [1.93] 52 [2.05] 54 [2.13] 56 [2.17] 59 [2.32] 61 [2.40]

B 95.5 [3.76] 99.5 [3.91] 105.5

C 118.5

[4.66]

122.5

[4.83]

[4.15]

128.5

[5.05]

109.5 [4.31] 113.5

132.5 [5.22] 136.5

[4.47]

[5.37]

119.5

[4.70]

142.5

[5.61]

123.5

[4.86]

146.5

[5.77]

Page 40

M12x1.25-6g

11.5 [0.453] min.

full thread

13

±0.5

[0.51 ±0.02]

3.7 max

[0.14 max]

5.7

±0.75

[0.22 ±0.029]

16.5

±0.75

[0.65 ±0.029]

A-A

Detail ‘P’

P

Ø 0.35

X

90 ±0.25

[3.54

±0.01]

[0.118 ]

3

0

-0.025

0

-0.001

[0.354 ]

9

+0.3

-0.1

+0.012

-0.004

[Dia 0.687]

Ø 17.46

1: 5

A

H

A

38 ±1

[1.5 ±0.04]

(19.3)

([0.76])

Inlet D

(SAE J1926/1 O-Ring boss)

16.7 [0.66] min. full thread

Detail ‘H’

P005 401E

39.5

±0.25

[1.555

±0.01]

Ø 34 [Dia 1.34]

Depth 5 [0.2] max

Technical Information

Hydraulic Fan Drive Systems

Installation Drawings

SGM2YN - 02AA dimensions (continued)

Outlet port E 15 [0.59] 20 [0.79]

Frame size 8.0 011 [0.67] 014 [0.95] 017 [1.04] 019 [1.16] 022 [1.34] 025 [1.53]

F 35 [1.38] 40 [1.57]

G M6-6H; 12[0.47] min. full thread

Drain port 9/16 18UNF-2B (SAE J1925/1 O-ring boss) 12.7 [0.50] min. full threads

For more information regarding SGM2Y gear motors, refer to SGM2Y and SGM3Y Fan Drive Motors

Technical Information 11040345.

40 | © Danfoss | Sept 2018 520L0824 | BC00000115en-000403

Page 41

Inlet D

26

Outlet E

(SAE J1926/1 O-Ring boss)

F min. full thread

Drain: 9/16–18UNF–2B

(SAE J1926/1 O-Ring boss)

12.7 [0.5] min. full thread

Valve Type: PRV10-IS2

P005 402E

[1.02 ±0.04 ]

[0.62

±0.02

]

89 max

[3.504 max.]

12

[ 0.47 ]

B

A

15.7

6.35

±1

±1

±0.04

-0.5

0

-0.02

0

±0.5

±0.5 [±0.02]

±1 [±0.04]

C

+1.5 [+0.06] max.

[0.25 ]

R 0.8 max.

[0.03 max.]

[0.62

±0.02

]

15.7

±0.5

Ø 0.75

X

36.2 max.

[1.43] max.

19.5 max.

[0.77] max.

R 12.7 max.

[0.5] max.

R 48 max.

[1.89] max.

115.5 max.

[4.55] max.

67.6 max.

[2.66] max.

103 max.

[4.055] max.

11–11.6

[0.43–0.46]

Ø 82.55

[Ø3.25 ]

0

+0.05

0

+0.002

X

132 max

[5.2 max.]

156 max

[6.142 max.]

106.38

[4.19]

Connector: Deutsch DT 04-2P

Voltage: 12V DC (Current: 1.1 A)

24V DC (Current: 0.55 A)

PWM: 100–200 Hz

CW motor shown. For CCW motor, valve is on the opposite side.

Technical Information

Hydraulic Fan Drive Systems

Installation Drawings

06BA

SGM2Y - 06BA dimensions

Frame size 8.0 011 [0.67] 014 [0.95] 017 [1.04] 019 [1.16] 022 [1.34] 025 [1.53]

Dimension

mm [in]

Inlet port D 7/8-14 UNF-2B (SAE J1926/1 O-ring boss); 16.7 [0.66] min. full thread

A 47 [1.85] 49 [1.93] 52 [2.05] 54 [2.13] 56 [2.17] 59 [2.32] 61 [2.40]

B 95.5 [3.76] 99.5 [3.91] 105.5

C 116 [4.57] 120 [4.72] 126 [4.96] 130 [5.11] 134 [5.28] 140 [5.51] 144 [5.67]

Outlet port E 7/8-14 UNF-2B 1 1/16-12 UN-2B

F 16.7 [0.66] min. full thread 19 [0.75] min. full thread