Page 1

Design Guidelines

Hydraulic Fan Drive Systems

www.danfoss.com

Page 2

Design Guidelines

Hydraulic Fan Drive Systems

Revision history Table of revisions

Date Changed Rev

January 2020 Updated Appendix H with new graphs for all frame sizes 0401

July 2018 Appendix H - new graphs for some frame sizes 0303

May 2018 add notes: H1 pumps with fan drive control 0302

April 2017 Updated Appendix H chapter 0301

July 2015 Danfoss layout - Add Appendix I - RDM Fan Drives 0201

2006 - 2013 Various changes. AA up to BC

2 | © Danfoss | January 2020 AB00000019en-000401

Page 3

Design Guidelines

Hydraulic Fan Drive Systems

Contents

Introduction

Abstract................................................................................................................................................................................................5

Overview..............................................................................................................................................................................................5

Principles of Operation...................................................................................................................................................................5

Power Savings ...................................................................................................................................................................................6

Modulation Preferred Over on/off Fan Speed Control....................................................................................................... 6

Fan Drive Design

Design Considerations....................................................................................................................................................................7

Fan Drive Components

Fan Drive Element Selection........................................................................................................................................................ 8

Estimate of Maximum Input Torque to the Pump................................................................................................................8

System Design Parameters

Sizing.................................................................................................................................................................................................. 10

Sizing Equations............................................................................................................................................................................. 12

Equations.....................................................................................................................................................................................12

Variables.......................................................................................................................................................................................12

Axial Flow Fan Power Formula..................................................................................................................................................13

System Design Data Form...........................................................................................................................................................14

Engine details.............................................................................................................................................................................14

Power steering...........................................................................................................................................................................14

Fan information.........................................................................................................................................................................15

Control preference...................................................................................................................................................................15

Reservoir...................................................................................................................................................................................... 15

Fluid...............................................................................................................................................................................................16

Filtration.......................................................................................................................................................................................16

Technical Features.........................................................................................................................................................................17

Shaft Loads and Bearing Life......................................................................................................................................................17

Maximum Pump Speed............................................................................................................................................................... 17

Minimum Pump and Motor Speed..........................................................................................................................................17

Motor Starting Pressure (open circuit motors)....................................................................................................................17

Motor Free Run Pressure.............................................................................................................................................................17

Input Torque Ratings....................................................................................................................................................................18

Pump Drive Conditions................................................................................................................................................................18

Tapered Shaft and Hub Connections......................................................................................................................................18

Pump Suction..................................................................................................................................................................................18

Case Drain Pressure.......................................................................................................................................................................19

Filtration............................................................................................................................................................................................ 19

Operating Temperatures.............................................................................................................................................................19

Fluids.................................................................................................................................................................................................. 19

Mounting.......................................................................................................................................................................................... 20

Axial Thrust Motors....................................................................................................................................................................... 20

Piping................................................................................................................................................................................................. 21

Reservoir............................................................................................................................................................................................21

Cavitation and Aeration Damage.............................................................................................................................................21

Cooling...............................................................................................................................................................................................22

Pressure Protection and Ratings...............................................................................................................................................22

Bearing Life Expectancy...............................................................................................................................................................22

Glossary

Terminology.....................................................................................................................................................................................23

Appendix A-Fan Performance

Fans.....................................................................................................................................................................................................24

Fan Performance............................................................................................................................................................................24

Axial Thrust.......................................................................................................................................................................................25

Fan Laws............................................................................................................................................................................................26

Example 1.................................................................................................................................................................................... 28

Example 2.................................................................................................................................................................................... 28

©

Danfoss | January 2020 AB00000019en-000401 | 3

Page 4

Design Guidelines

Hydraulic Fan Drive Systems

Contents

Example 3.................................................................................................................................................................................... 28

Example 4.................................................................................................................................................................................... 29

Appendix B-Fan Drive Sizing Equations

Fan Drive Sizing Equations and Derivations........................................................................................................................ 30

Hydraulic System Comparisons................................................................................................................................................32

Appendix C-Fan Drive Sizing Equations, using Variable Displacement Motors

Hydraulic Systems with 2 Position, Variable Displacement Motors, Equations and Derivations..................... 34

Spreadsheet to Calculate the Optimum Minimum Displacement for 2 Position Variable Motor.................... 35

Appendix D-Pressure change due to transient flow in a passage

Pressure Change due to Transient Flow in a Passage, Equations and Derivations................................................37

Appendix E-Influence of Bypass Valve Pressure Drop in Open Circuit Systems

Appendix F1-Influence of temperature, pressure and relative humidity on specific weight of air

Influence of Temperature, Pressure and Relative Humidity on Specific Weight of Air........................................ 43

Appendix F2-Influence of Altitude on Atmospheric Pressure

Influence of Altitude on Atmospheric Pressure..................................................................................................................45

Appendix F3-Influence of generic altitude on atmospheric pressure

Influence of Generic Altitude on Atmospheric Pressure................................................................................................. 46

Appendix G-Influence of reversed fan rotation on system performance

Appendix H-System considerations for H1 fan drives with reversed fan rotation

System Considerations for H1 Fan Drives with Reversed Fan Rotation.....................................................................54

Pressure Limiter Adjusting Procedure....................................................................................................................................54

Additional Information concerning the H1 Fan Drive Controller Option..................................................................55

FDC Start and End Current..........................................................................................................................................................55

Operating Envelope for H1 Pumps with Fan Drive Control............................................................................................56

Sensitivity to Prime Mover Speed Changes (Load Sensitivity) - (J Frame as example).........................................63

H1 FDC Response Time (with Typical Fan Drive System Loading)...............................................................................66

Application startup method (to account for PL offset).................................................................................................... 66

Appendix I-System Considerations for RDM Fan Drives

System Considerations for RDM Fan Drives.........................................................................................................................68

Reversing Sequence................................................................................................................................................................ 68

Shift Rate Control......................................................................................................................................................................69

System Considerations...........................................................................................................................................................71

Zero RPM Motor Output.........................................................................................................................................................75

Reference Literature

Open Circuit Axial Piston Pumps..............................................................................................................................................76

Open/Closed Circuit Axial Piston Motors..............................................................................................................................76

Controllers........................................................................................................................................................................................ 76

System Guidelines......................................................................................................................................................................... 76

Closed Circuit Axial Piston Pumps........................................................................................................................................... 76

4 | © Danfoss | January 2020 AB00000019en-000401

Page 5

205

0

200

400

600

800

1000

1200

1400

1600

1800

2000

170(F) 175 180 185 190 195 200

F

an speed (rpm)

Engine temperatur e

9580(C) 85 90

P101 276E

Design Guidelines

Hydraulic Fan Drive Systems

Introduction

Abstract

Fan drive system sizing relies heavily on the input received from the customer. All system sizing

calculations are based on the required fan power @ trim speed data given to the hydraulic system design

engineer. This data is a statement of the fan drive motor shaft power that is required to turn a fan at the

required speed to push, or pull, a required volume of air across coolers/radiators. The usual sequence of

events is:

•

•

•

Overview

One goal of this document is to provide the reader with the equations and formulae needed to size a

hydraulic fan drive, given that they are provided with the following information:

•

•

•

•

The engine manufacturer advises the customer, or cooling system designer, of the heat dissipation

required from the cooling system, charge air cooler etc. This information is combined with the heat

rejection data for any accessories and work functions on the machine (such as : transmission cooler,

hydraulic cooler, and A/C condenser) to determine the maximum heat rejection profile for the

system.

The customer’s cooling pack manufacturer uses this data to size the cooling package and generally

recommends a fan to suit this need, providing the rated fan power, rated fan speed, and the fan

speed and static pressure required to satisfy the cooling needs of the system.

With this information, knowing the minimum engine speed at which maximum fan speed needs to

occur, the hydraulic system designer can size the hydraulic fan drive system.

Rated fan power.

Rated fan speed.

Fan speed required to meet the maximum cooling needs of the cooling system.

Engine speed at which maximum system cooling is required.

This document also provides an explanation of the terms and factors used in the derivation of the sizing

equations. In addition, the reader is provided with recommendations of simple system design solutions

that will help provide a viable system with satisfactory performance.

Principles of Operation

The vehicle’s cooling fan is driven by a hydraulic motor, which in turn, is driven by a hydraulic pump. The

hydraulic pump can be driven directly off of the engine supplied PTO (Power Take Off), or with a belt

drive. An electrically controlled proportional pressure control valve modulates the fan speed depending

on a temperature reading. In a cold condition, the fan idles with very low power consumption. During the

hot condition, the maximum fan speed is controlled by a pressure control valve, which adjusts the fan

speed to meet the cooling needs of the total system. Every system has a temperature, which allows for

the most efficient performance. The electronic control system, attempts to maintain the coolant at the

optimum design temperature, which the “system integrator” selects during the design phase of the

project.

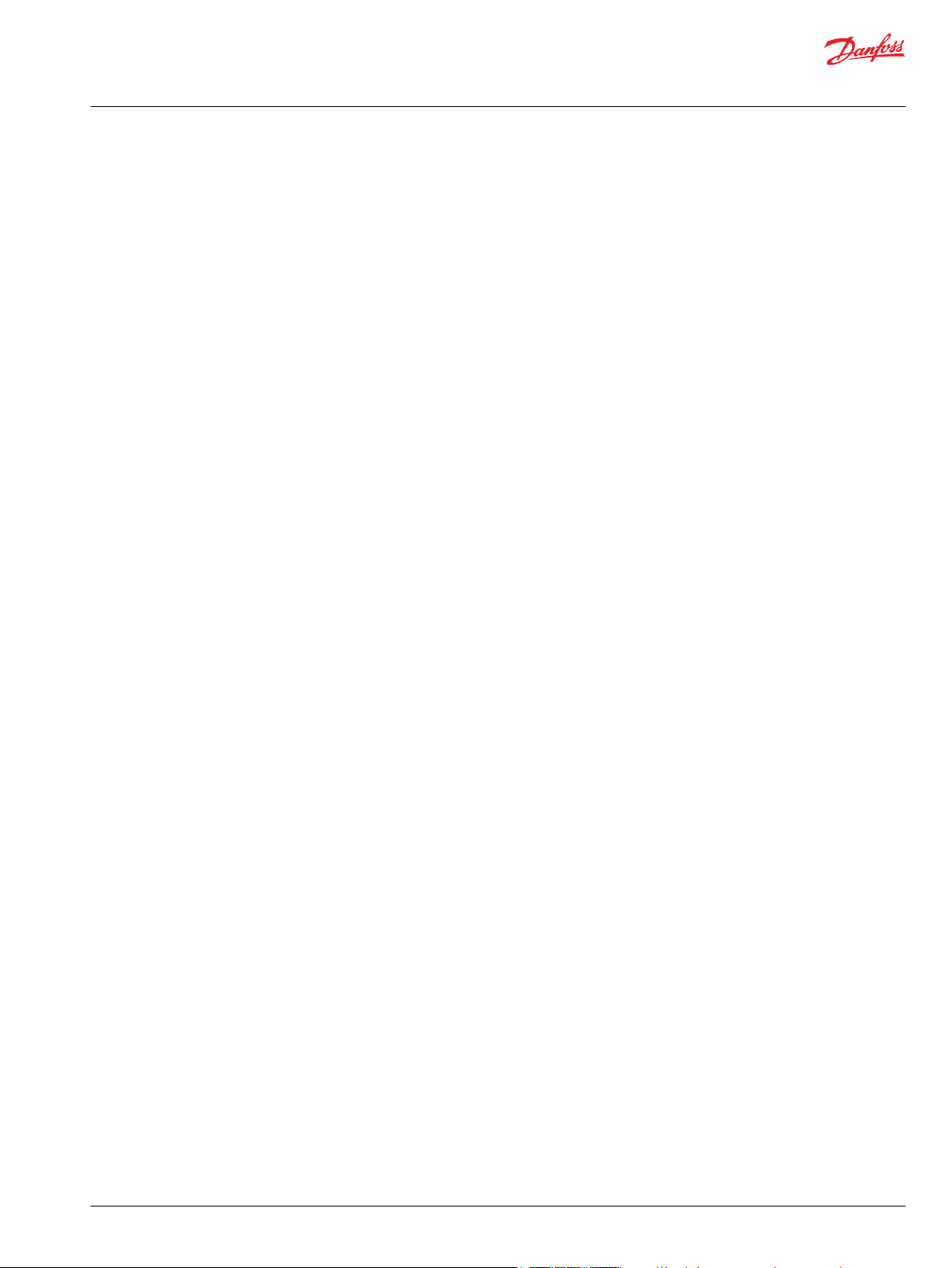

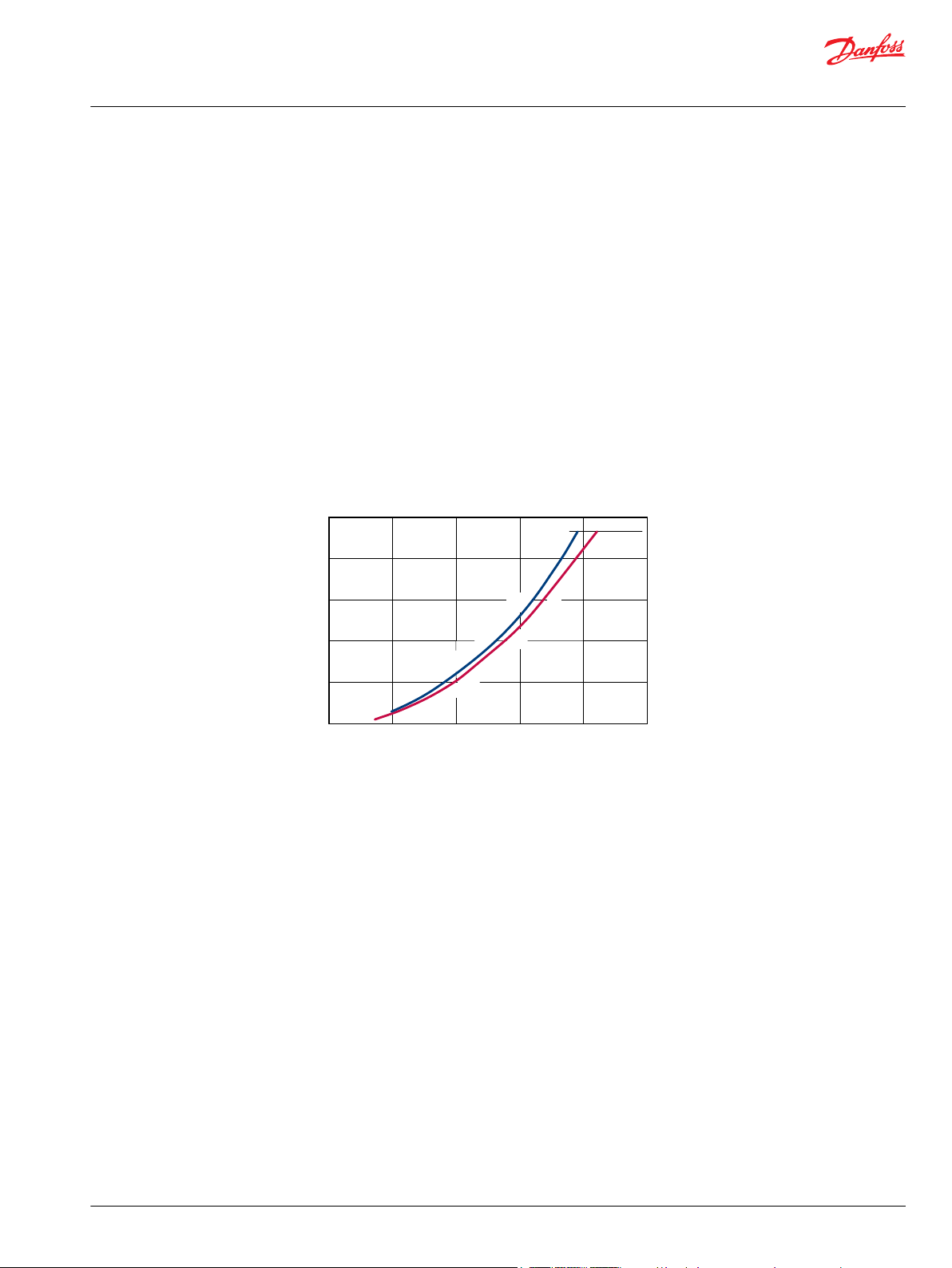

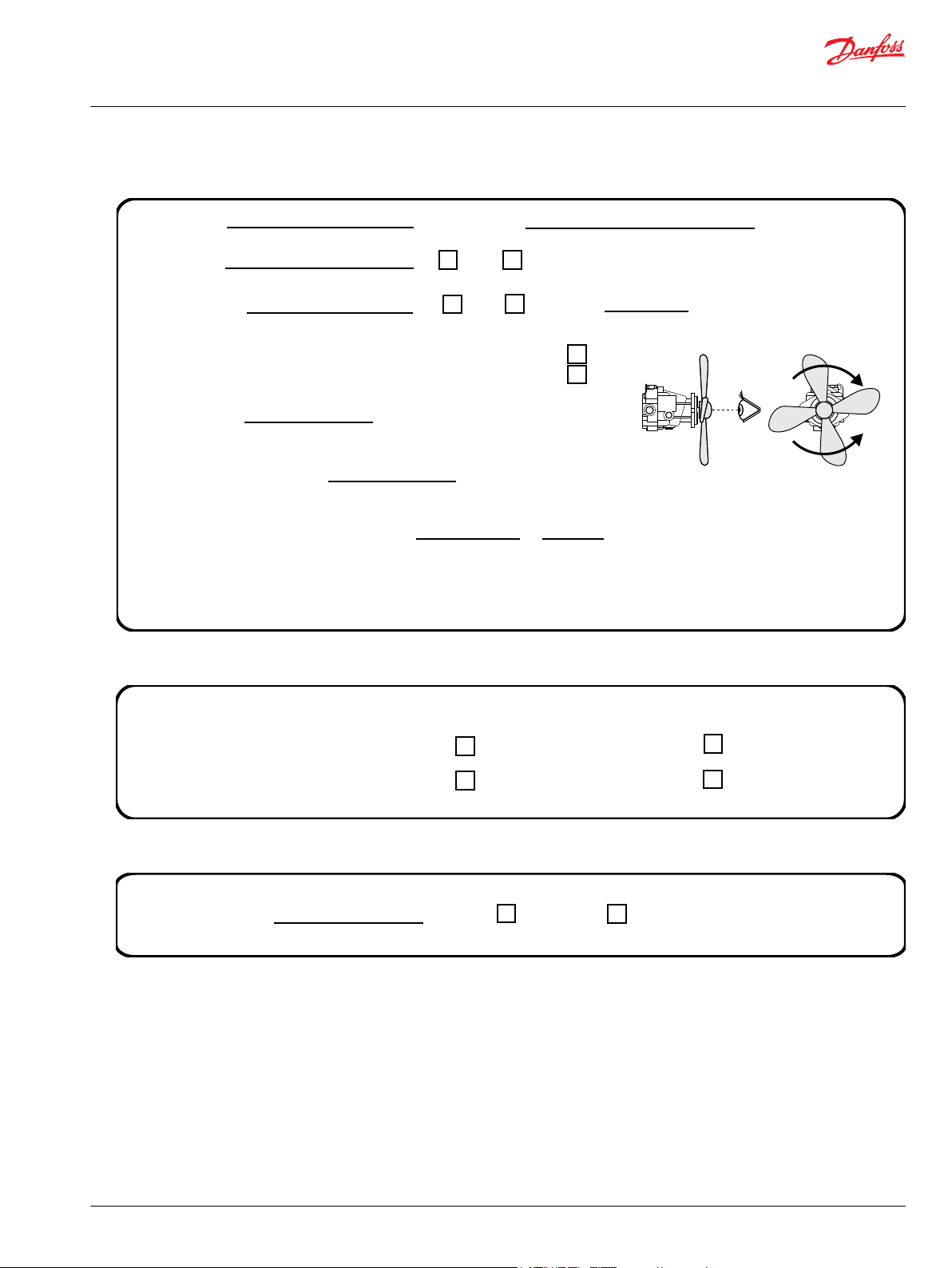

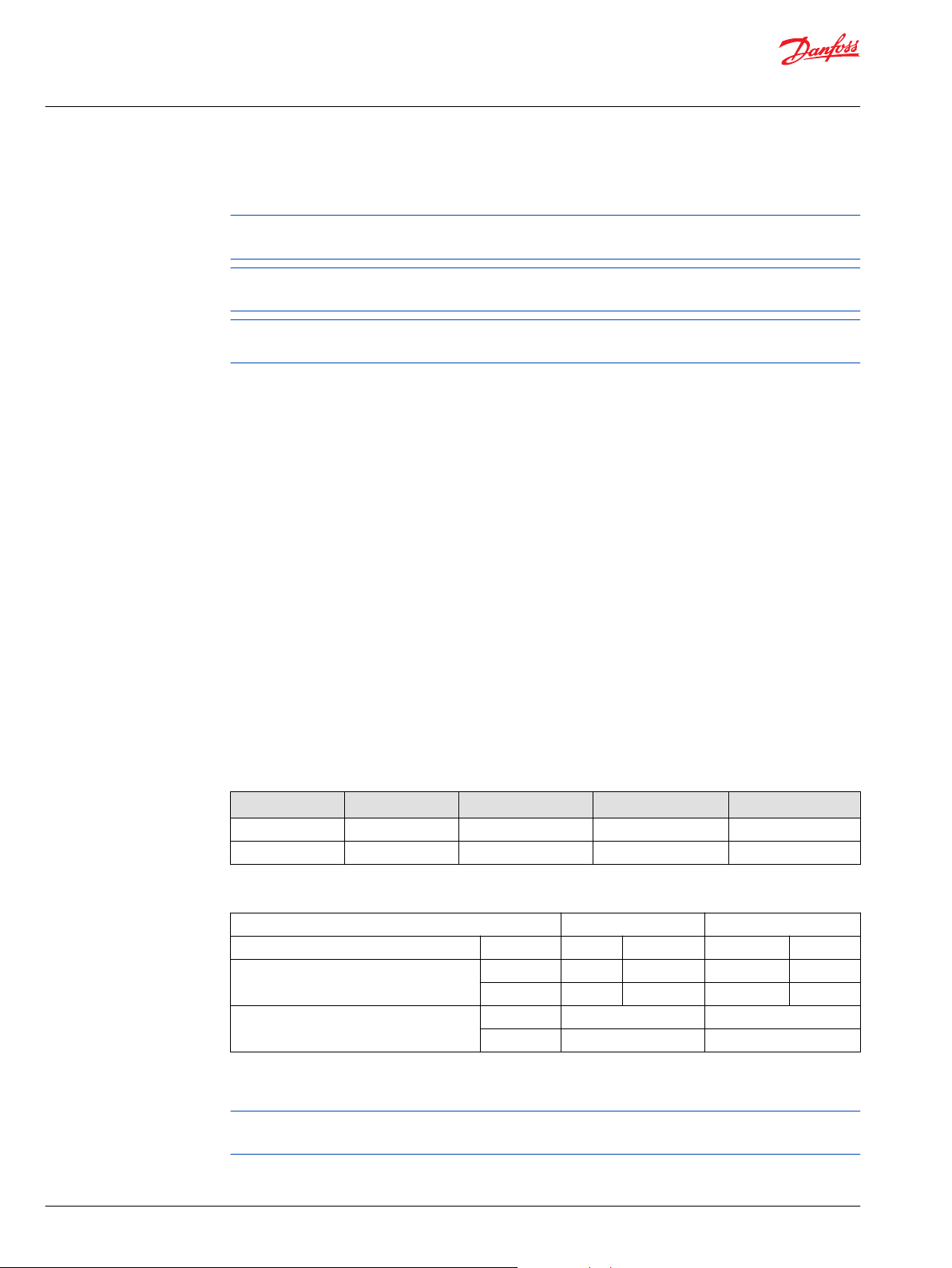

Fan speed vs engine temperature

To optimize the cooling system operation in various environmental conditions and to minimize parasitic

losses, the Danfoss modulating fan drive system enables the fan cycle to be designed to specific heat

©

Danfoss | January 2020 AB00000019en-000401 | 5

Page 6

Design Guidelines

Hydraulic Fan Drive Systems

Introduction

rejection requirements for a wide range of environmental conditions. Vehicle manufacturers have

complete control of the fan cycle by choosing the appropriate temperature limits.

The Danfoss modulating fan drive system remains at idle speed until conditions require increased fan

speeds. By regulating the pressure drop across the hydraulic motor, modulation of fan speed occurs, and

over-cooling is prevented.

Power Savings

In the fan off condition, the fan may idle at approximately 30% of rated speed, but it will only consume

about 3% of rated power. The Danfoss modulating fan drive system allows the system designer to size

the fan for the engine speed at which maximum heat rejection occurs. The fan speed will remain

essentially constant at all higher engine speeds. Consequently, the fan will not require excessive parasitic

losses as engine speed increases. In systems where the engine speed at maximum heat rejection is 80%

of the governed speed, the power savings compared to over-speeding a mechanically driven fan can be

as high as 95%.

Modulation Preferred Over on/off Fan Speed Control

Fan speed modulation occurs over a temperature range chosen by the system’s designer. This eliminates

the sudden changes in speed that cause dramatic changes in noise levels. Similarly, large accelerations of

components, which may limit the reliability for long-term operation, are eliminated. Modulation also

allows intermediate levels of cooling without unnecessary cycling of the fan between minimum and

maximum speed. The calibration temperature, operating range, and ramp times can be varied

independently by the system designer to achieve the desired level of temperature control.

6 | © Danfoss | January 2020 AB00000019en-000401

Page 7

Design Guidelines

Hydraulic Fan Drive Systems

Fan Drive Design

Design Considerations

•

•

•

•

•

•

Hydraulic fan drive system designers select components for unique combinations of engine, fan, and

application parameters. Do not exchange/change fan system components indiscriminately. Design

factors which determine the selection of the fan drive system for a particular engine, or vehicle, include:

•

•

•

•

•

•

•

Parasitic losses from excessive fan speed are high. Power consumed by a fan is proportional to fan

speed cubed (speed3).

Heat rejection to the atmosphere does not increase linearly with engine speed.

Overheating and/or over cooling the system will result in loss of efficiency and productivity.

Overheating, and/or over cooling the engine can result in increased emissions to the environment.

The proportion of operating time during which full fan speed (maximum fan power) is needed is

typically about 20% and can be as low as 5%.

Mounting the fan directly to the engine requires large fan blade tip clearances due to normal engine

vibration and movement. This leads to loss of fan performance. Mounting the fan directly to a

hydraulic motor can minimize tip clearance and boost fan performance significantly.

Engine set point and maximum heat rejection

Pump rotation

Pump input torque limitations

Maximum applied pressure and speed limits for the individual components

Fit-up and available installation space

Pump support structure requirements for individual engine mounting combinations

Specific engine and accessory temperature control limits

Fan drive element selection

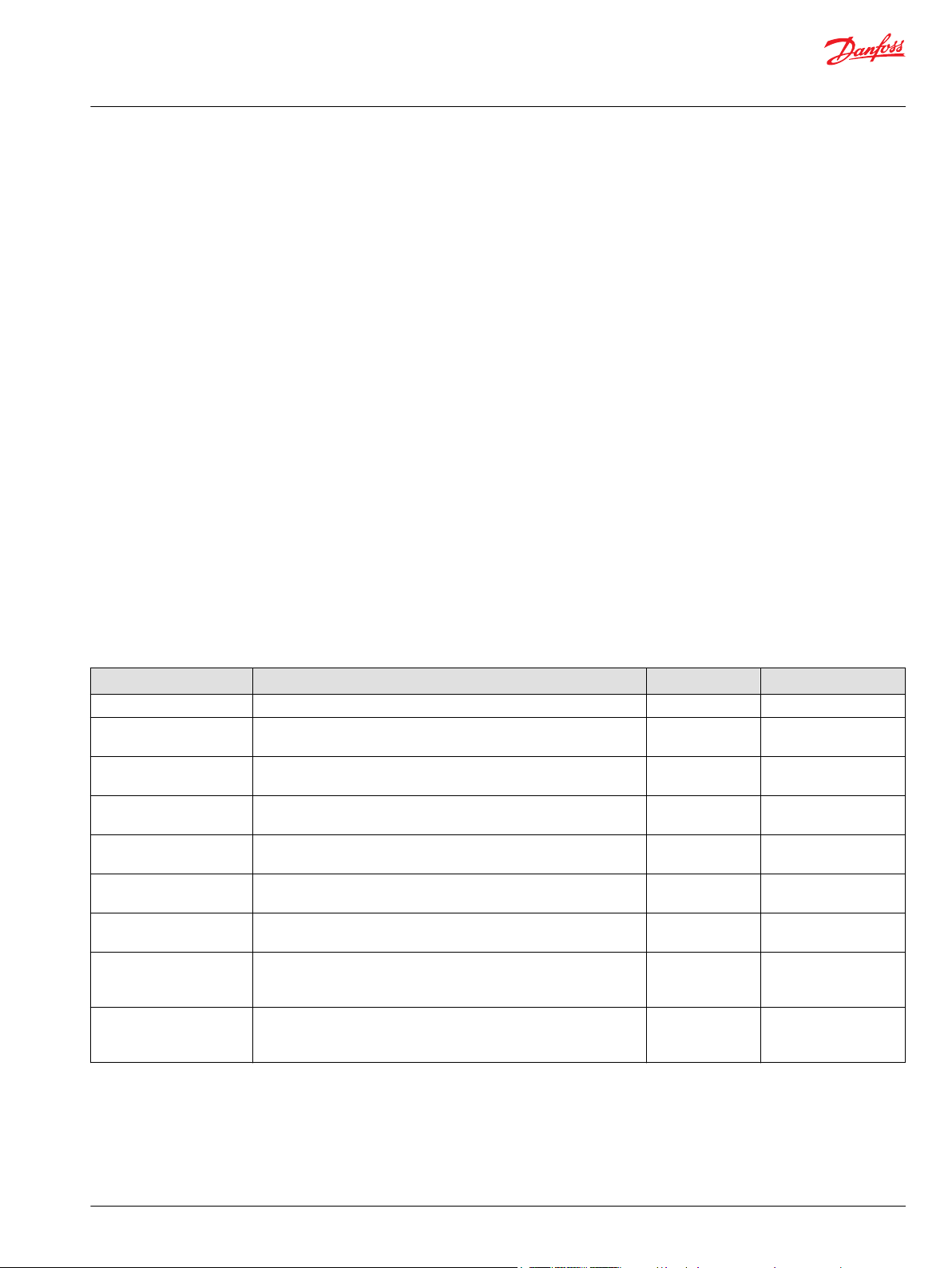

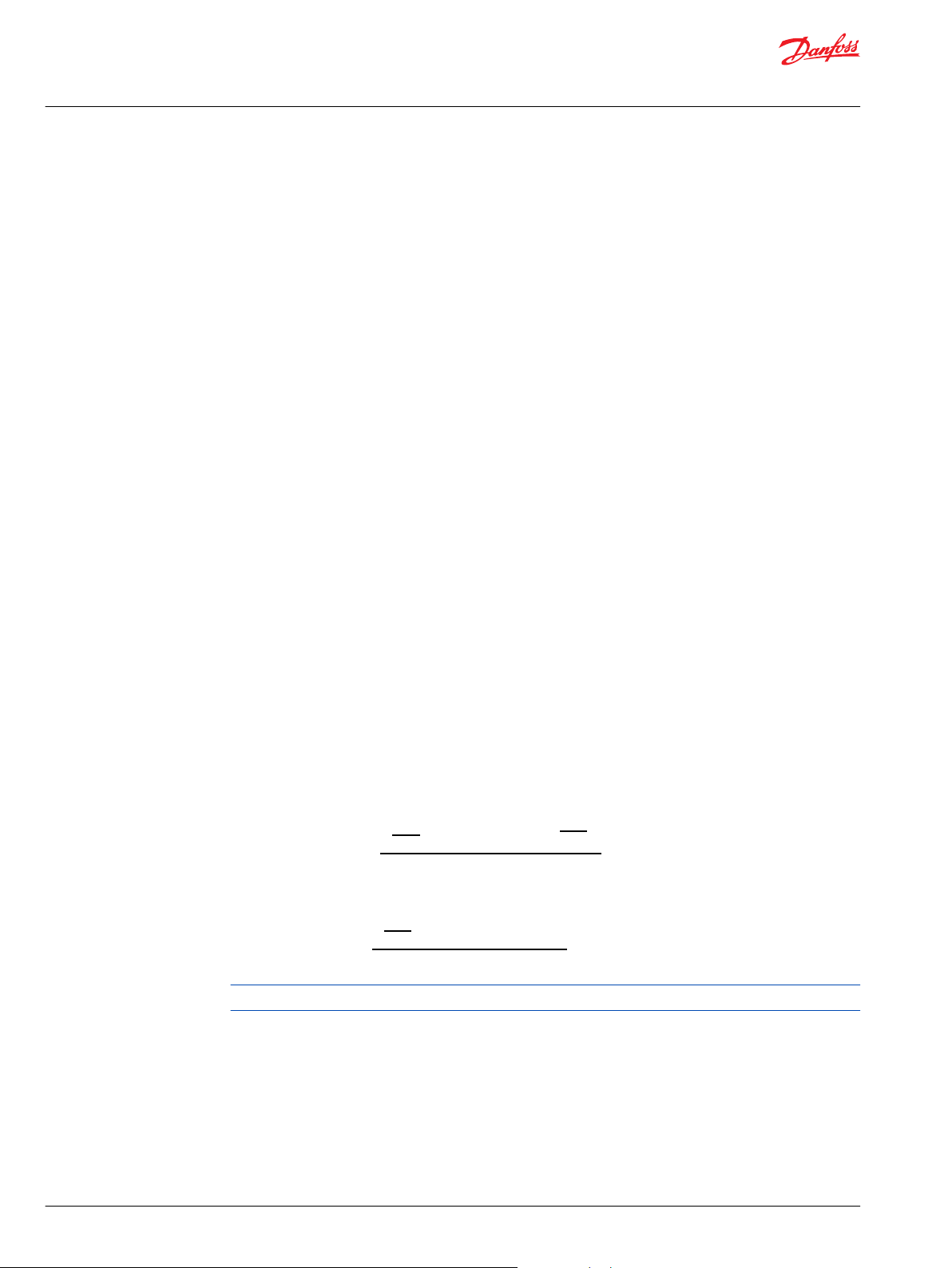

Fan drive Element Design parameter Design flexibility Design champion

Engine & accessories Power, speed, total heat rejection and duty cycle Yes OEM

PTO & Gearing Engine to pump gear ratio Sometimes OEM’s choice of engine

supplier

Pump(s) Displacement, pressure, speed, fixed pump or variable pump, mounting

& drive line

Fan drive control Sensor input(s), control output, number of control elements Yes Danfoss technical

Motor(s) Displacement, pressure, speed, fixed motor or variable motor, mounting

& coupling

Fan(s) Fan rated power @ rated speed, fan diameter, number of blades, blade

pitch, proximity of blades to heat exchanger, direction of air flow

Shroud(s) Type of shroud (flat plate, short duct, venturi), blade axial position in

shroud, tip clearance

Air flow stream(s) Air flow rate & static pressure across heat exchanger(s), maximum

ambient air temperature, minimum atmospheric pressure, hot air

recirculation, baffles, louvres & obstructions

Heat exchangers Physical size, height & width, number of heat exchangers in air flow

stream, side-by-side, axial stack, materials selected, construction,

number and types of tubes, tube configuration, fin density

Yes Danfoss technical

representative, & OEM

representative, & OEM

Yes Danfoss technical

representative, & OEM

Yes OEM & cooling specialists

Yes OEM & cooling specialists

Sometimes OEM & cooling specialists

Yes OEM & cooling specialists

©

Danfoss | January 2020 AB00000019en-000401 | 7

Page 8

Engine speed (rpm )

Fa

n S

peed

(r

pm)

Engine set point

800

1000

1200

1400

1600

1800

2000

2200

600 800 1000 1200 1400 1600 1800 2000 2200

F

a

1

d

n

s

p

e

e

F

a

1

s

p

e

d

n

e

,

h

o

t

o

i

l

Ma

x

.

e

n

g

i

n

e

h

e

a

t

r

e

j

e

c

t

i

o

n

s

pe

e

d

P106 107E

(Fan Trim Speed)

Design Guidelines

Hydraulic Fan Drive Systems

Fan Drive Components

Fan Drive Element Selection

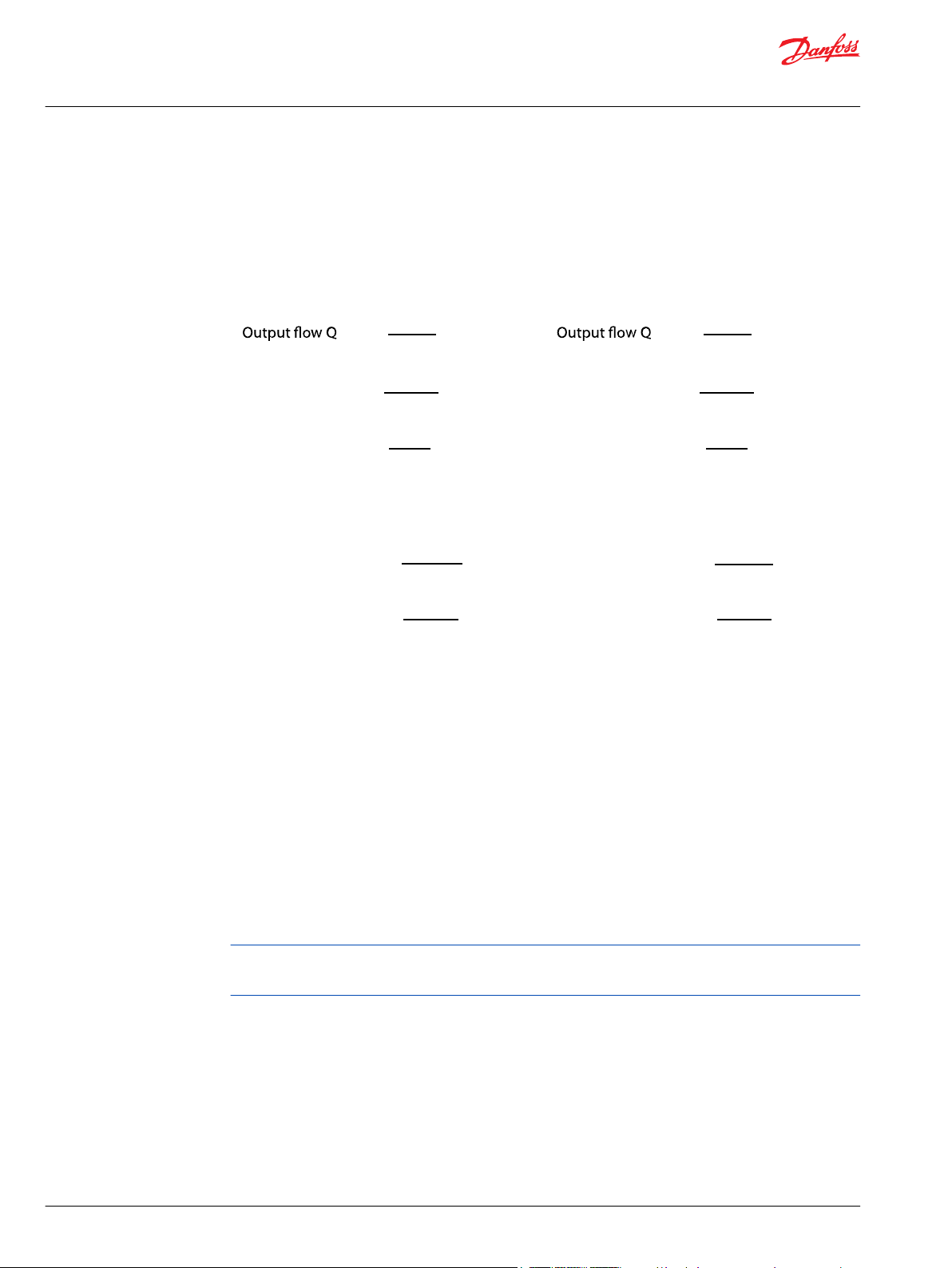

Optimizing the size of fan drive elements depends on selecting the correct components and gear ratios.

By matching these components to the fan power requirements, the required unit sizes can be quickly

determined. The pump and motor displacements, input gear ratios, engine set point, and pressure limits

can be adjusted to provide some optimization of component size. Along with the sizing equations

presented in this article, a Danfoss fan drive sizing computer tool is available to assist with sizing the

hydraulic components.

Many modulating hydraulic fan drives rely on dedicated pumps to provide flow to the fan circuit for

optimum sizing. Other circuits are available that provide additional flow for power assisted steering and

other accessory systems. In these, and many other circuits, the sizing equations and fan drive sizing tool

may still be used to select the required components. Note that the design limits for associated design

elements are not identified in this article. They may be reviewed by referring to the Danfoss technical

information for the components being considered. Machine designers should verify that all design

parameters are met for all drive line components.

While the methods described in this article may be useful, they do not represent the only approach to

sizing hydraulic components. Contact your Danfoss representative if questions of interpretation exist.

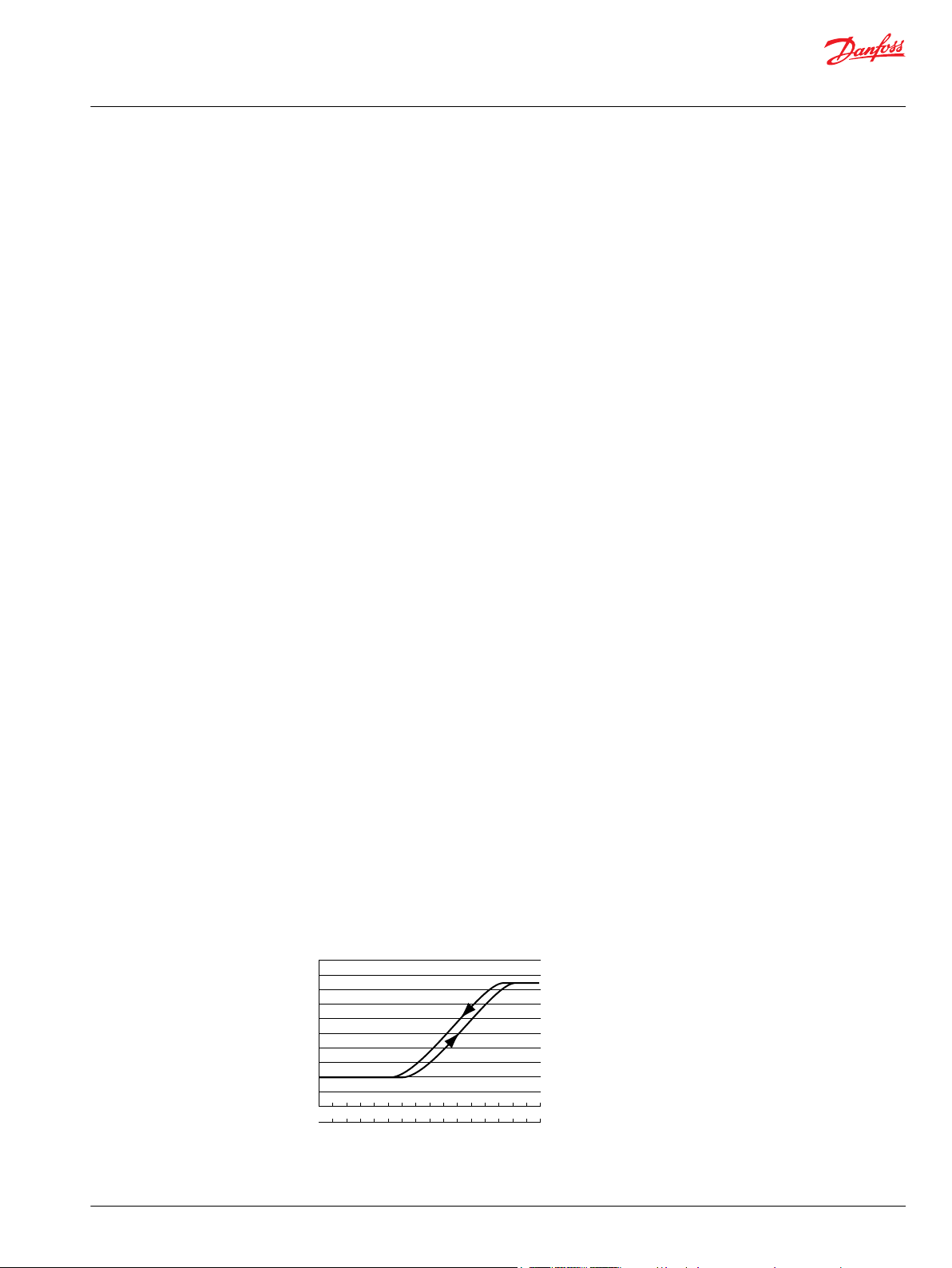

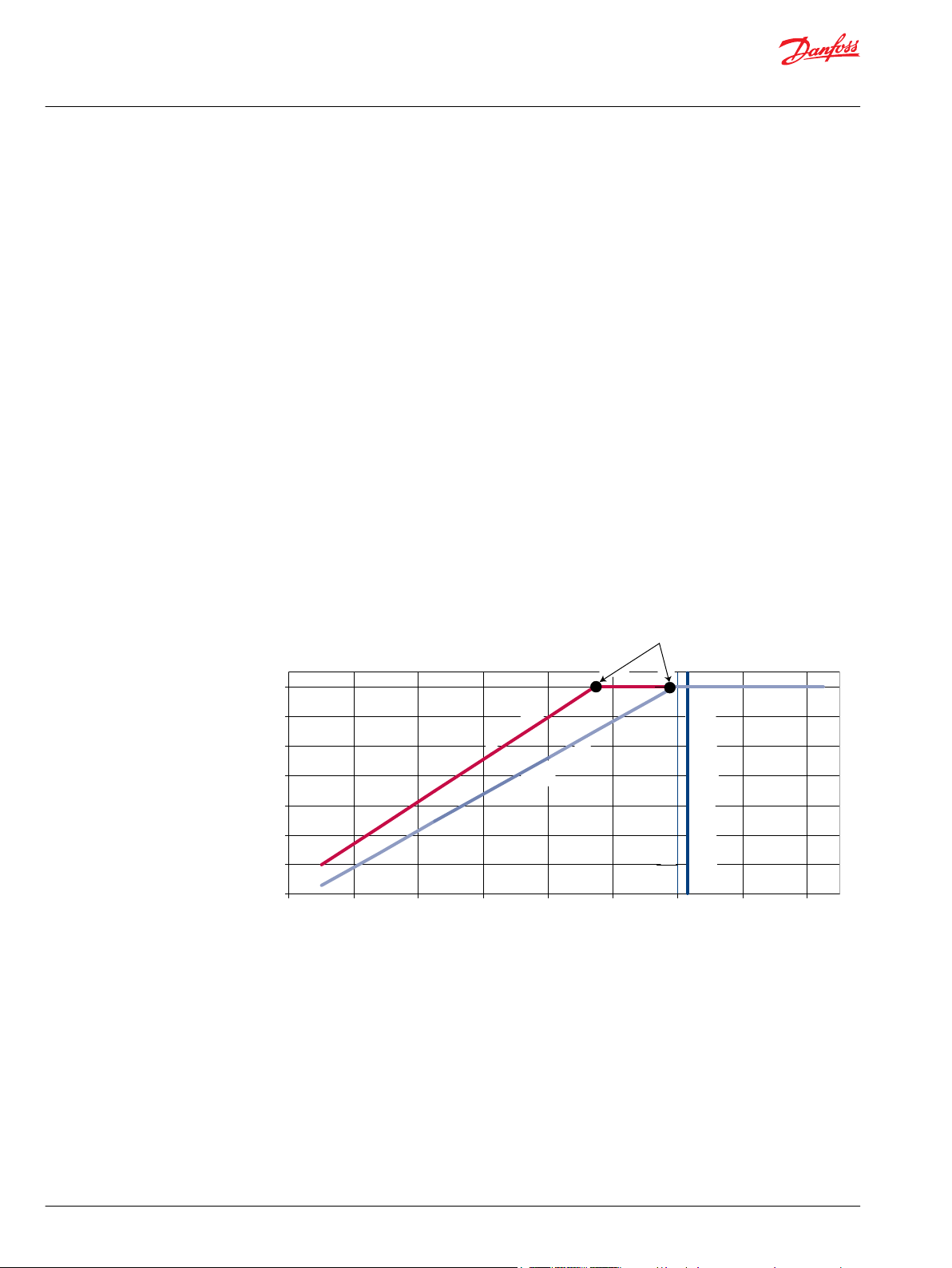

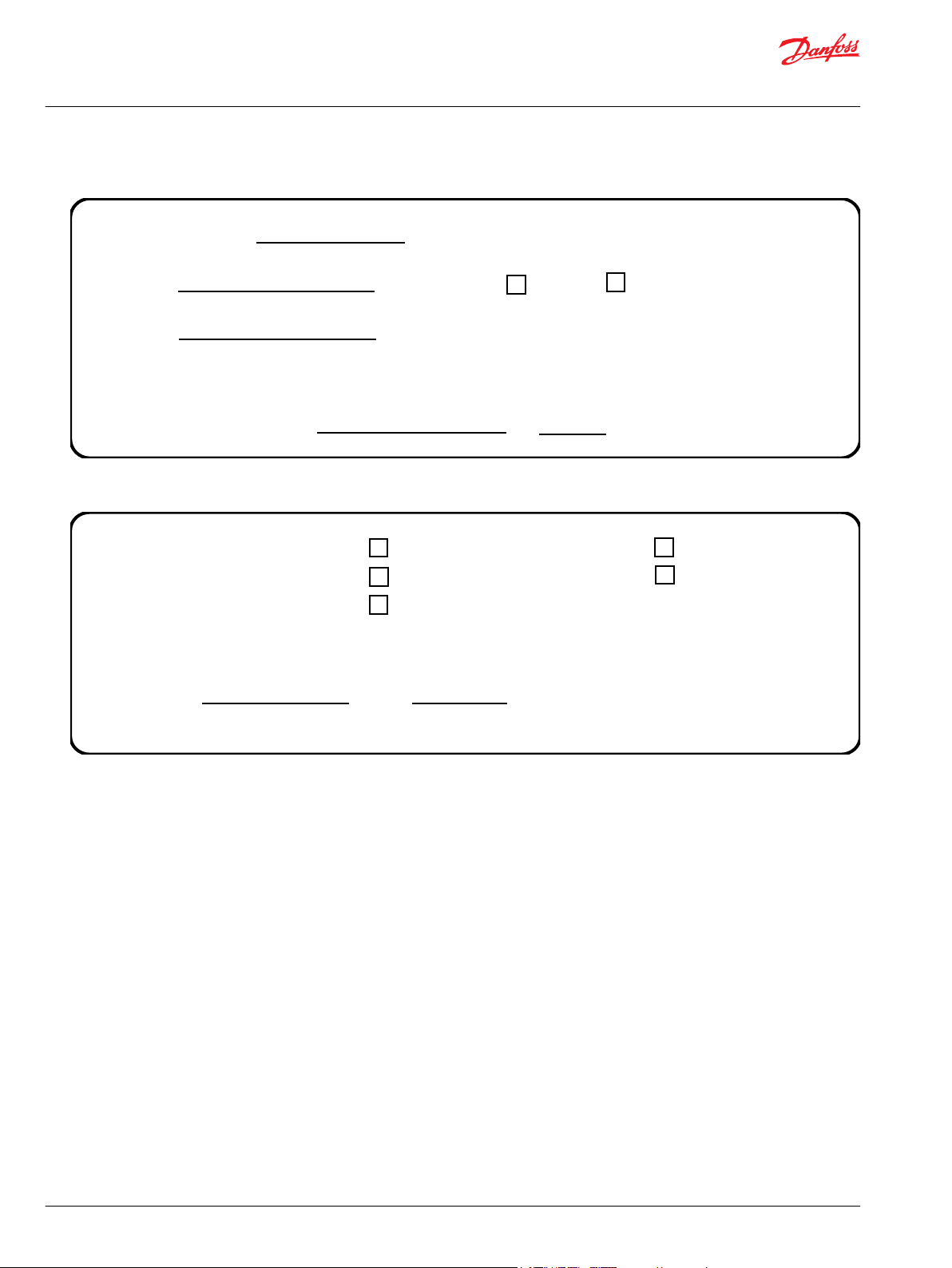

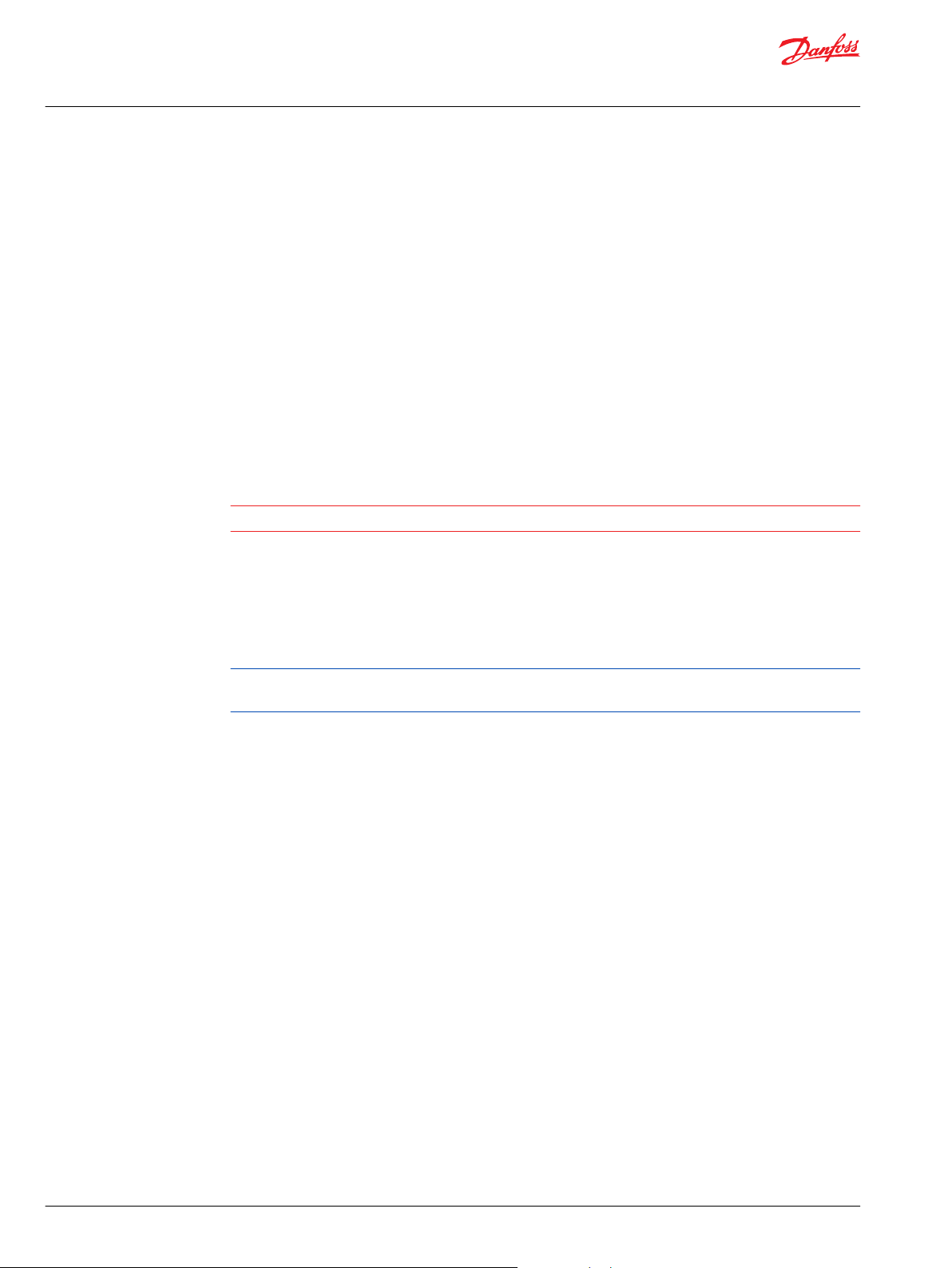

Collect the application sizing parameters as identified in the System Design Parameters chapter of this

document. Pay particular attention to the minimum engine speed at which maximum heat rejection to

the atmosphere is required. When sizing the pump for the application, the system designer should

ensure that the engine set point under hot oil condition is less than the engine speed at which maximum

heat rejection occurs. Failure to do this can result in a condition where the cooling system may not

provide adequate cooling when maximum work loading and maximum ambient conditions occur

simultaneously.

Sample graph, performance prediction will vary depending on choice of input parameters.

Estimate of Maximum Input Torque to the Pump

One of the first things that the systems designer should consider is whether the maximum pump torque

needed will exceed the input torque limitation of the pump drive. One way to calculate this is to divide

the fan power requirement by an estimate of the hydraulic system’s overall efficiency and then determine

the input torque requirement at the pump speed that is equivalent to the maximum heat rejection speed

of the engine.

Compare the estimated maximum input torque to the maximum available input torque at the pump

drive; this will determine the design margin that is available to the designer. The hydraulic system

designer should consult with the vehicle system’s designer, and/or the prime mover’s technical support

staff for assistance, if required.

8 | © Danfoss | January 2020 AB00000019en-000401

Page 9

English system

SI system

Pump torque, Tp

(lbf•in)

≈ (lbf • in)

Pfhp

0.7

•

(Ne • R)

(63025)

( )

]

[

Pump torque, Tp

(N•m)

≈ (N•m)

PfkW

0.7

•

(Ne • R)

(9549.0)

(

)

]

[

Where:

Pf

kW

(Ne • R)

R

Ne

0.7

= Max fan power, kW [hp]

= Pump speed, rpm

= Pump/Engine ratio

= Engine speed, rpm

= ηt for hydraulic system (pump and motor)

Tp

(lbf•in)

8.8507

( )

Pump torque, Tp

(N•m)

= (N•m)

Tp

(lbf•in)

12.0

(

)

Pump torque, Tp

(lbf•ft)

= (lbf•ft)

Tp

(N•m)

0.7376 •

Pump torque, Tp

(lbf•ft)

= (lbf•ft)

Tp

(N•m)

8.8507

•Pump torque, Tp

(lbf•in)

= (lbf•in)

Converting terms

Design Guidelines

Hydraulic Fan Drive Systems

Fan Drive Components

©

Danfoss | January 2020 AB00000019en-000401 | 9

Page 10

P106 108E

F

an power (kW

)

Fan speed (RPM)

40

35

30

25

20

15

10

5

0

0

500

1000

1500

2000

2500

Design Guidelines

Hydraulic Fan Drive Systems

System Design Parameters

Sizing

Fan drive system sizing relies heavily on the input received from the customer. All system sizing

calculations are based on the required fan power @ trim speed data given to the hydraulic system design

engineer. This data is a statement of the fan drive motor shaft power that is required to turn a fan at the

required speed to push, or pull, a required volume of air across coolers/radiators. The usual sequence of

events is:

•

•

•

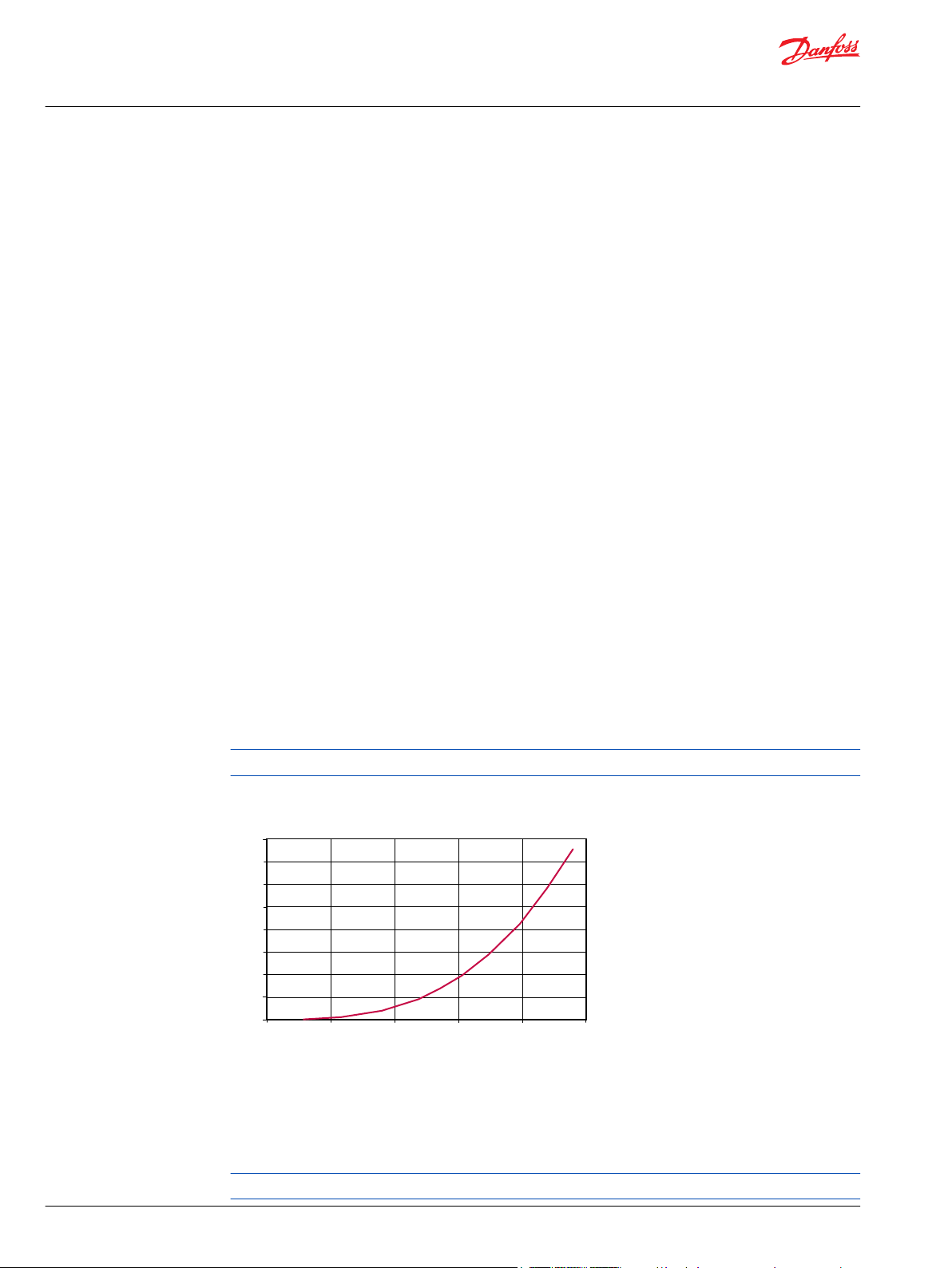

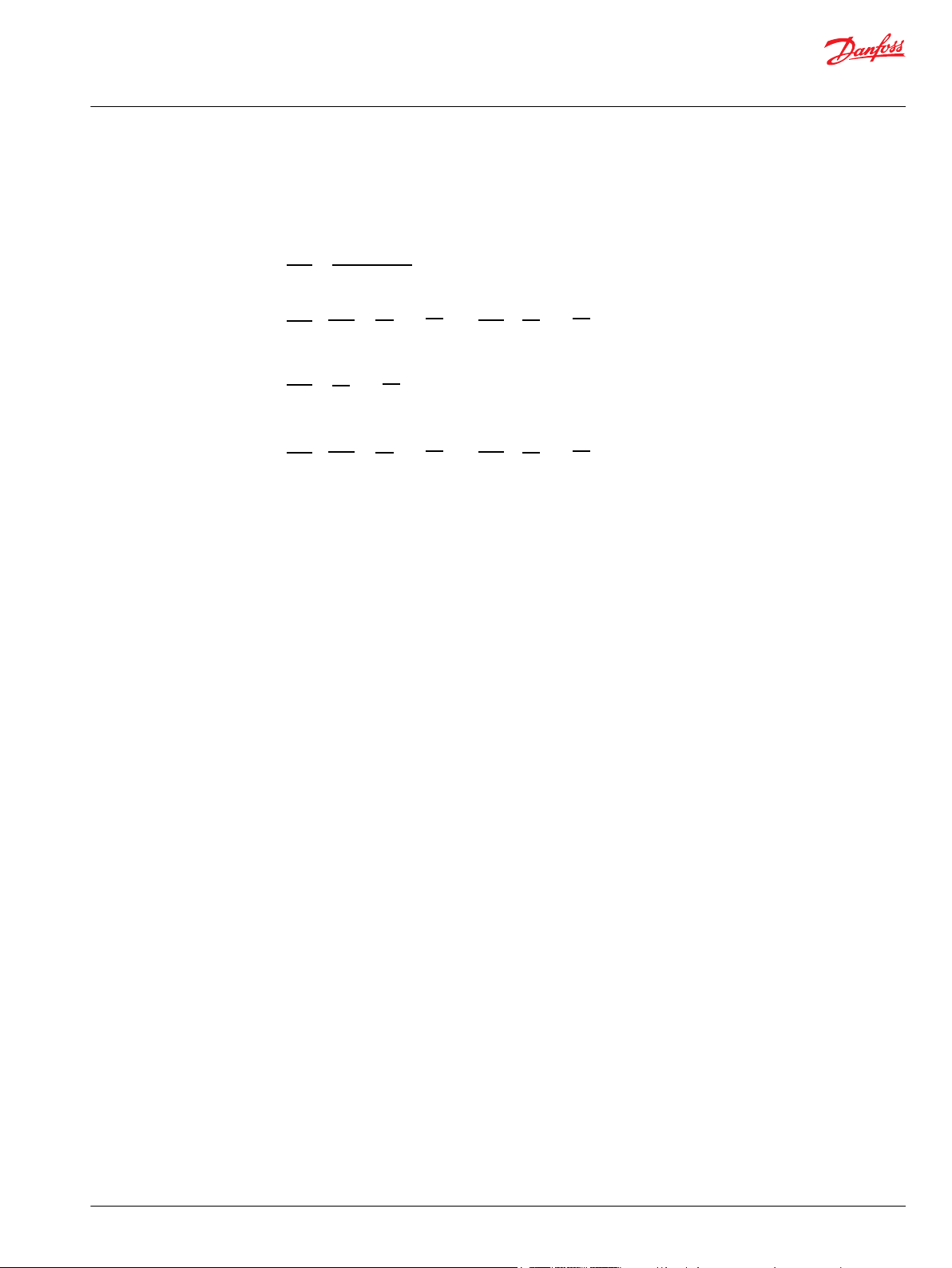

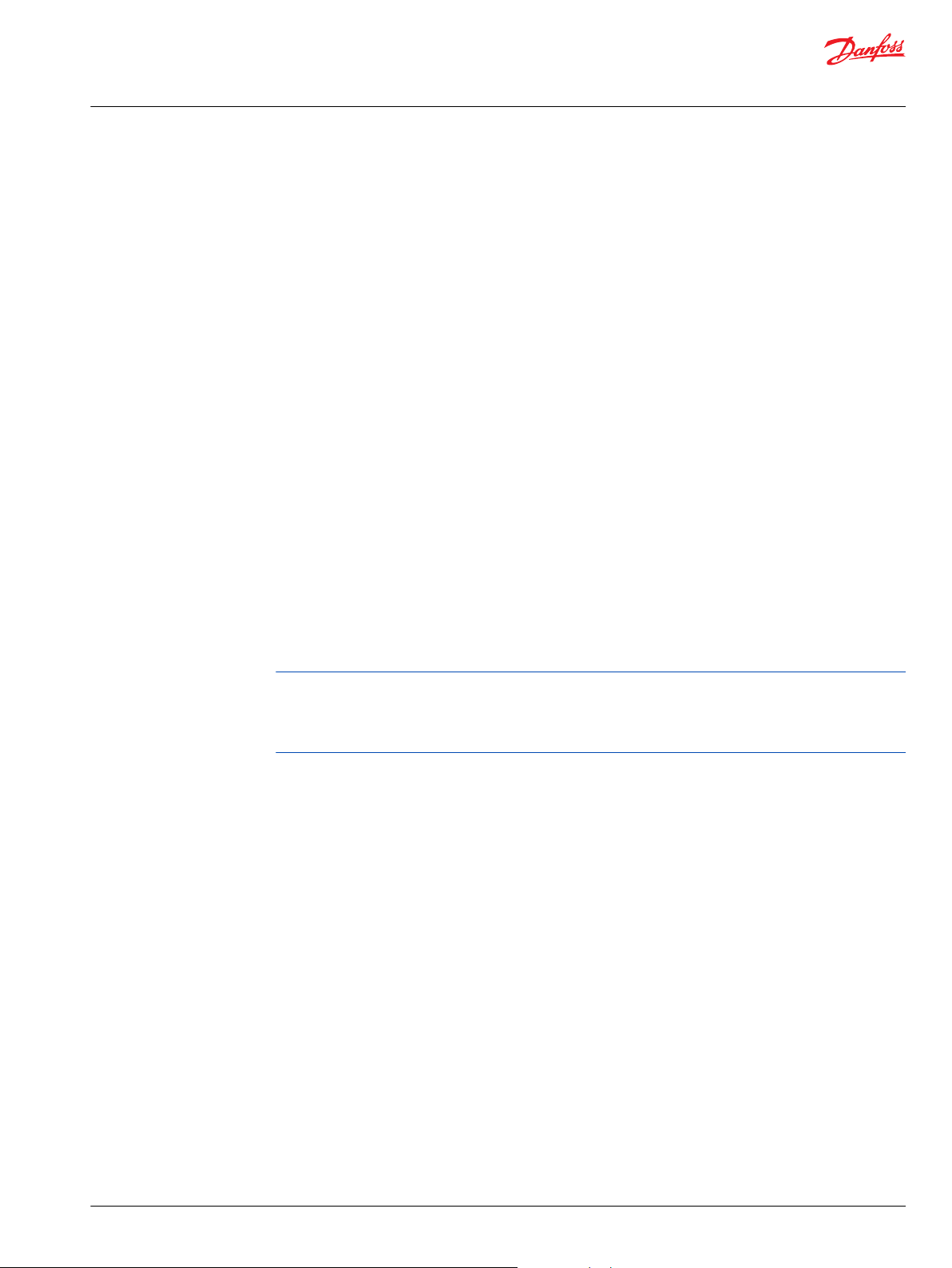

To completely understand any fan drive system is to understand the fan load characteristics. Fans are

unique in that the power to drive the fan changes with the cube of the fan speed, as follows:

Pf=k•(Nf)

Pf1 / Pf2 = (Nf1 / Nf2)

Where:

Pf = fan power (kW, hp)

Nf = fan speed (rpm)

1,2 = subscripts for two different conditions

k = Fan power coefficient

Fan power is defined as the power required to drive the shaft connected to the fan and is equal to the

output power of the motor.

The engine manufacturer advises the customer, or cooling system designer, of the heat dissipation

required from the cooling system, charge air cooler etc. This information is combined with the heat

rejection data for any accessories and work functions on the machine (such as : transmission cooler,

hydraulic cooler, and A/C condenser) to determine the maximum heat rejection profile for the

system.

The customer’s cooling pack manufacturer will then use this data to size the cooling package and will

generally recommend a fan to suit this need, providing the rated fan power, rated fan speed, and the

fan speed required to satisfy the cooling needs of the system.

With this information, knowing the minimum engine speed at which maximum fan speed needs to

occur, the hydraulic system designer can size the hydraulic fan drive system.

3

3

When a given fan speed is doubled; the required power to drive the fan increases by a factor of 8.

Fan power requirements (Example)

Fan rating = 22 kW @ 2000 rpm

10 | © Danfoss | January 2020 AB00000019en-000401

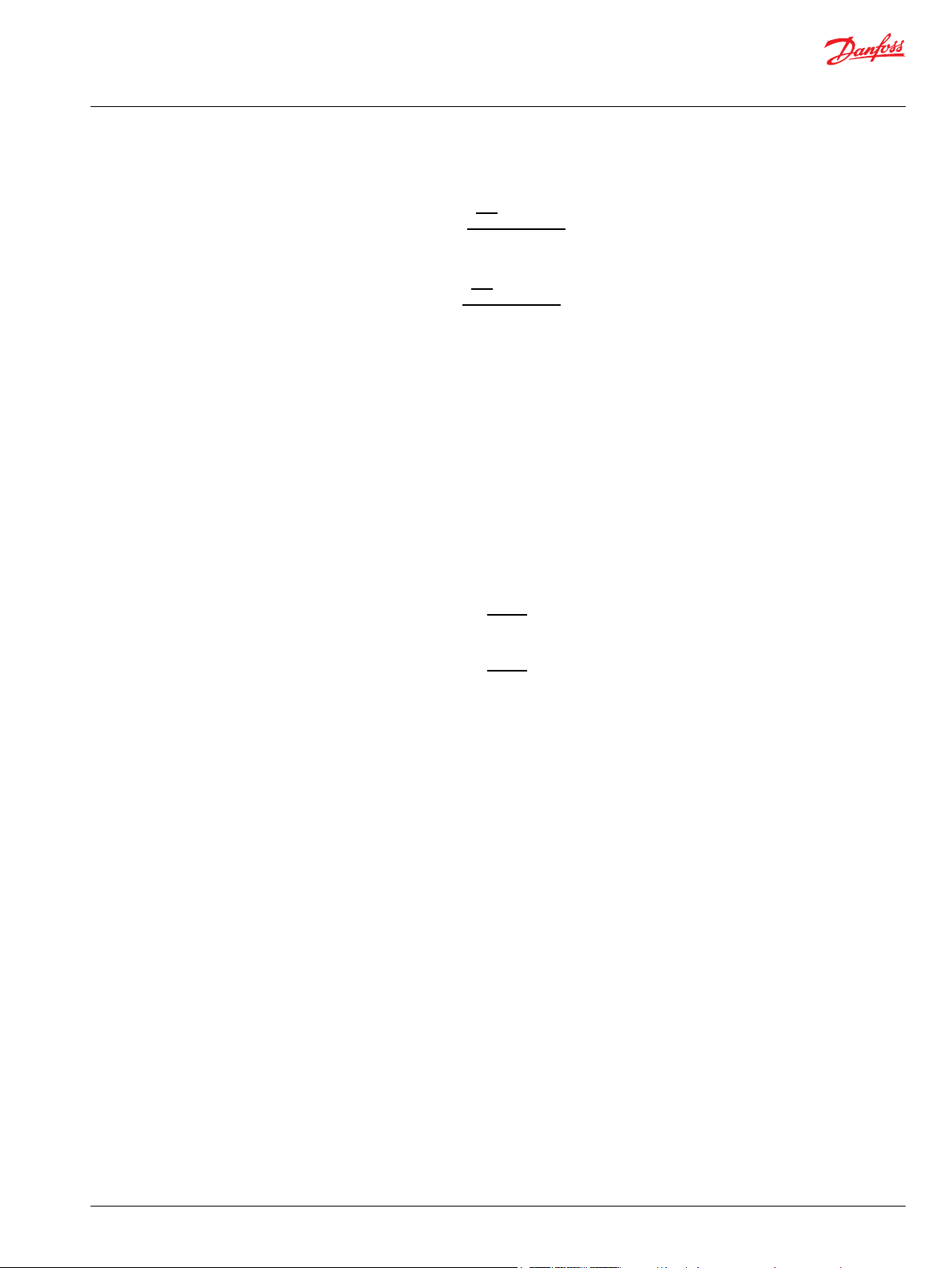

Since fan power is a function of both pressure and flow (fan speed), it follows that the relationship

between fan speed and system pressure is

∆P1 / ∆P2 = (Nf1 / Nf2 )

2

Where: ΔP = delta pressure across the hydraulic motor (bar, psid)

An accurate value of the fan rating is critical to the correct selection of components and their settings.

Page 11

P106 109E

2500

2000

1500

1000

500

0

0

500

1000

1500

2000

2500

System pressure (psi)

System pressure (bar)

Fan speed min-1(rpm)

160 bar

2300 psi

T

h

e

o

r

s

e

t

i

c

a

l

s

y

t

e

m

p

r

e

s

s

u

r

e

E

x

p

e

r

i

m

e

n

t

a

l

s

y

s

t

e

m

p

r

e

s

s

u

e

r

30

60

90

120

150

Design Guidelines

Hydraulic Fan Drive Systems

System Design Parameters

Although the cubic relationship between fan power and fan speed has been consistently verified

experimentally, it is still an approximation of the fan behavior. Therefore, to avoid significant errors in

predicting power requirements, the fan power rating should be taken at a speed representative of typical

fan operation.

For example, for a system in which the fan usually operates in a speed range of 1800-2200 rpm, a fan

rating specified at 2000 rpm will yield more accurate results than a rating specified at, say, 1500 or 2500

rpm.

Fan curves provided by the fan manufacturer are often developed under ideal conditions. It is unlikely

that a fan will exhibit exactly the same performance in an actual application (because of: shrouding, heat

exchange airflow characteristics, and air density). Only through test data taken on the actual vehicle can a

fan’s performance characteristics be accurately determined. The curve below illustrates the differences

between predicted performance and actual performance of a fan installed in a vehicle. The system

designer/integrator is encouraged to confirm their performance predictions via test over the entire

operating speed range of the engine, and to refine their prediction model with a revised fan power

coefficient when they rerun the sizing calculations.

Fan power requirements (example)

Fan rating = 22 kW @ 2000 rpm

©

Danfoss | January 2020 AB00000019en-000401 | 11

Page 12

Based on SI units

= (l/min)

Input torque M = (N•m)

Input power P = (kW)

Motors

Based on SI units

Output torque M = (N•m)

Output power P = (kW)

Based on English units

= (US gal/min)

Input torque M = (lbf•in)

Input power P = (hp)

Based on English units

Output torque M = (lbf•in)

Output power P = (hp)

Vg • n • η

v

1000

Vg • ∆p

20 • π • η

m

Vg• n• ∆p

600 000 • η

m

Vg • n • η

v

231

Vg • ∆p

2 • π • η

m

Vg • ∆p • η

m

20 • π

Q • ∆p • ηt

600

Vg • ∆p • η

m

2 • π

Q • ∆p • η

t

1714

Pumps

Vg• n• ∆p

396 000 • η

m

Design Guidelines

Hydraulic Fan Drive Systems

System Design Parameters

Sizing Equations

Equations

Variables

SI units [English units]

Vg = Displacement per revolution cm3/rev [in3/rev]

pO = Outlet pressure bar [psi]

pi = Inlet pressure bar [psi]

∆p = pO - pi (system pressure) bar [psi]

n = Speed min-1 (rpm)

ηv = Volumetric efficiency

ηm = Mechanical efficiency

ηt = Overall efficiency (ηv • ηm)

SI unit formulas are based on cm3, bar, N, N•m, W.

English formulas are based on in3, psi, lbf•in, hp.

12 | © Danfoss | January 2020 AB00000019en-000401

Page 13

(N2)3 • (D2)5 • ν

2

=

(N1)3 • (D1)5 • ν

1

Pf

2

Pf

1

=

Pf

2

Pf

1

r

2

r

1

•

(

N

2

N

1

)

3

•

(

D

2

D

1

)

5

ν

2

ν

1

=

•

(

N

2

N

1

)

3

•

(

D

2

D

1

)

5

V

2

(

D

2

D

1

)

3

•

(

N

2

N

1

)

=

∆P

2

∆P

1

r

2

r

1

•

(

D

2

D

1

)

2

•

(

N

2

N

1

)

2

ν

2

ν

1

=

•

(

D

2

D

1

)

2

•

(

N

2

N

1

)

2

=

•

V

1

•

Design Guidelines

Hydraulic Fan Drive Systems

System Design Parameters

Axial Flow Fan Power Formula

Power to system parameter relationships

Pf1 = Power of fan at known condition #1

Pf2 = Power of fan at condition #2

N1 = Fan speed at condition #1

N2 = Fan speed at condition #2

D1 = Fan diameter at condition #1

D2 = Fan diameter at condition #2

ν1 = Specific weight of air at condition #1

ν2 = Specific weight of air at condition #2

r 1 = Density of air at condition #1

r 2 = Density of air at condition #2

∆P1 = Hydraulic and/or Static Pressure at condition #1

∆P2 = Hydraulic and/or Static Pressure at condition #2

V1 = Flow rate of air at condition #1

V2 = Flow rate of air at condition #2

©

Danfoss | January 2020 AB00000019en-000401 | 13

Page 14

C

L

O

C

K

W

I

S

E

C

O

U

N

T

E

R

C

L

O

C

K

W

I

S

E

P106110

Model or Series

Belt Drive

(engine to pump)

Clockwise, Right hand

Counterclockwise, Anti-clockwise, Left hand

Manufacturer

Pump Drive

Pump Rotation

Speeds

Engine PTO

Ratio

:1

Low Idle

Governed

High Idle

RPM (rated)

RPM (rated)

RPM (max speed)

Input torque

limit:

P104 376E

US gal/min

bar

(maximum)

Controlled Flow Requirement

Steering Pressure

psi

l/min

Design Guidelines

Hydraulic Fan Drive Systems

System Design Parameters

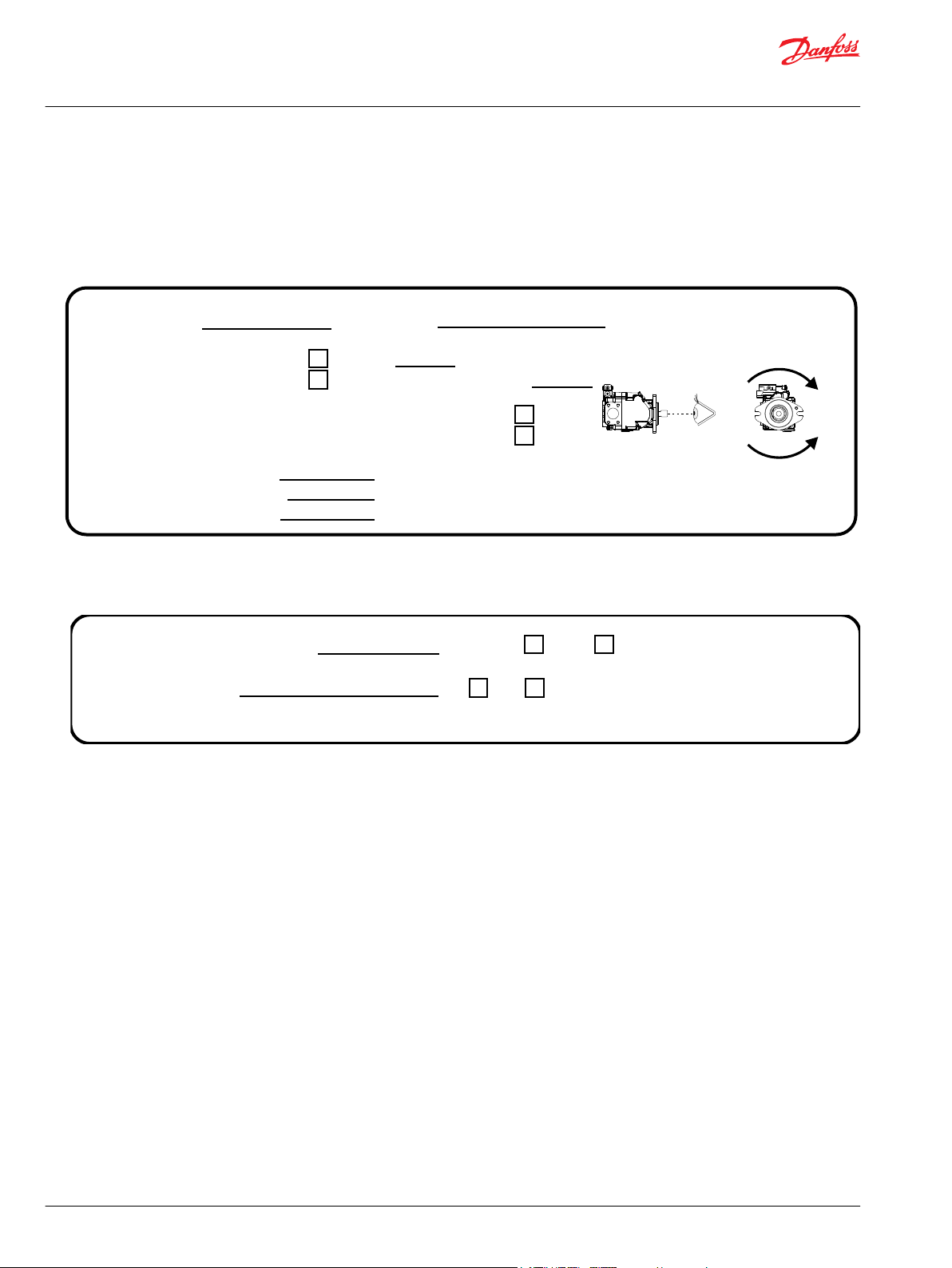

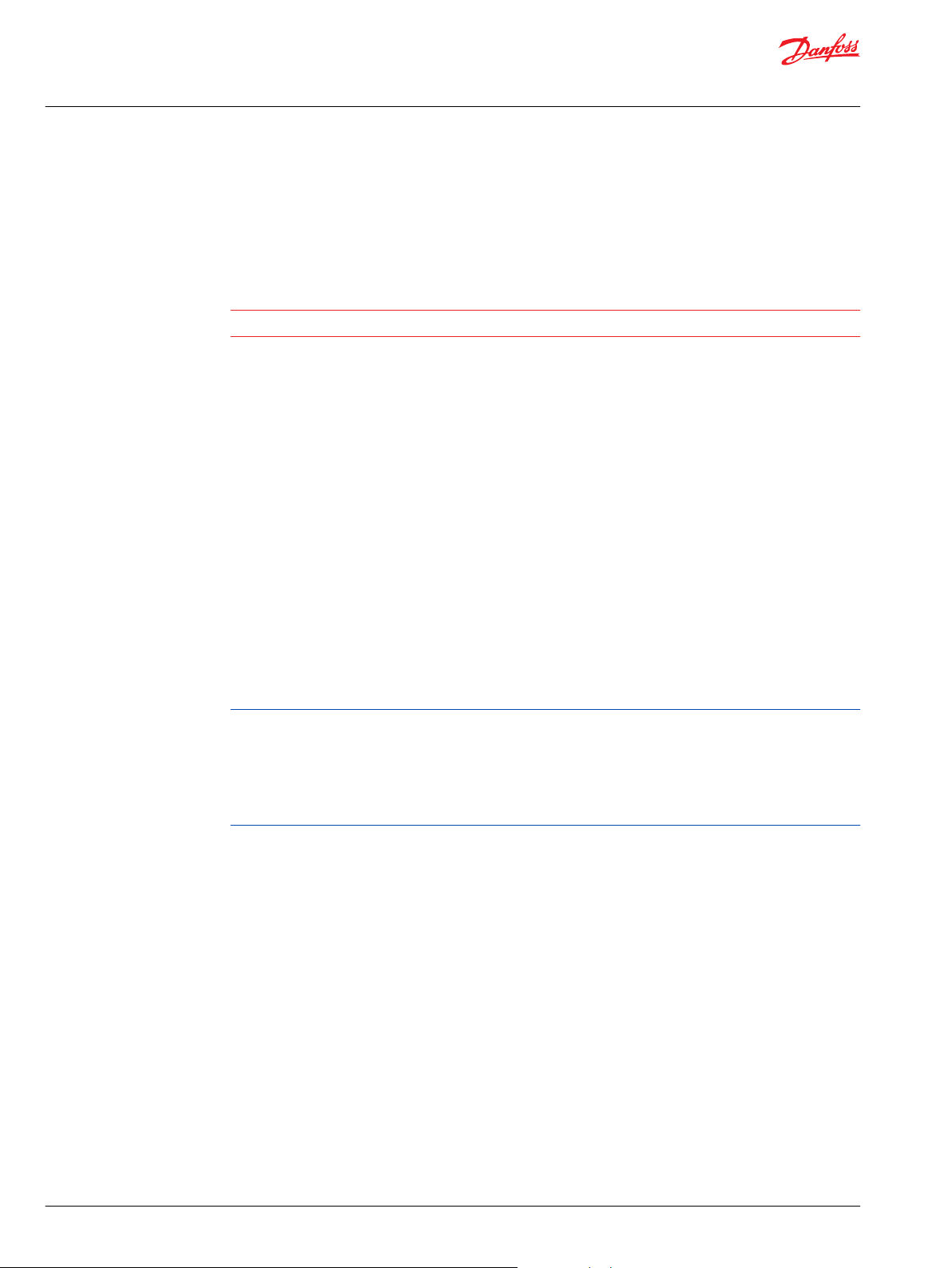

System Design Data Form

Print this form. Fill in all the fields and check the appropriate check boxes. Fax the filled out form to your

Danfoss Power Solutions Technical Sales Representative.

Engine details

Power steering

(if applicable)

14 | © Danfoss | January 2020 AB00000019en-000401

Page 15

C

l

o

c

k

w

i

s

e

C

o

u

n

t

e

r

c

l

o

c

k

w

i

s

e

P101 344E

Model or Series

mm

Manufacturer

Fan Diameter

in

At speed

kW

Fan Input Power

HP

rpm

Fan Rotation

(viewed on motor shaft, see illustration)

Clockwise

Counterclockwise

Fan Trim Speed

rpm

Set Point at Fan Trim Speed

(engine speed where max heat load occurs)

rpm

Coolant Temperature at Fan Trim Speed

(coolant temp where max fan speed is required)

°F

°C

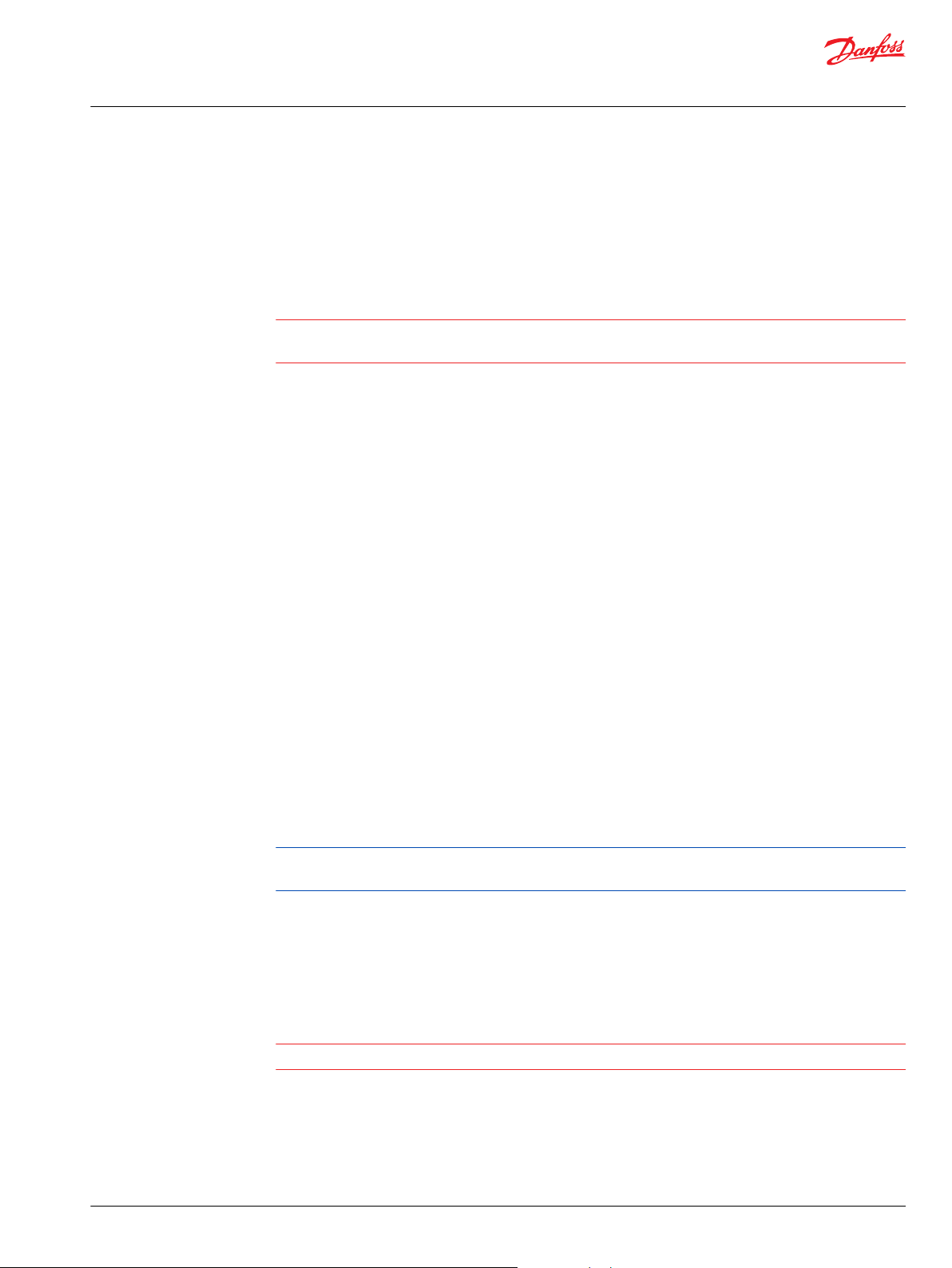

Note: To properly size and specify a fan drive system, fan power requirements must be stated as accurately as possible. Fan power requirements

can be determined from fan curves supplied by the manufacturer. Radiator and cooler manufacturers will supply air flow requirements based

on heat loads. Air flow information must include accurate air flow and static pressure to determine correct fan power requirements.

P104 377E

Single Input

Electro-Hydraulic Modulating Electro-Hydraulic ON/OFF

Multiple Inputs

P104 378E

US gal

Reservoir Capacity

liter

Design Guidelines

Hydraulic Fan Drive Systems

System Design Parameters

Fan information

Control preference

Reservoir

©

Danfoss | January 2020 AB00000019en-000401 | 15

Page 16

P104 379E

at 40° C [104°F]

Hydraulic Fluid Type

Viscosity

cSt

Maximum Fluid Temperature

°F

°C

SUS

at 100° C [212°F]

P104 380E

Inlet Line

Filter Position

Pressure Line

(recommended)

Return Line

Filter Rating

Full Flow

Filter Flow

Partial Flow

micron

x ratio

Note: Do not locate the filter cartridge inside the reservoir. This reduces the reservoir capacity and reduces the dwell time (the time the oil

spends in the resrevoir). It also increases the potential for damage to the hydraulic components due to aeration of the oil.

Design Guidelines

Hydraulic Fan Drive Systems

System Design Parameters

Fluid

Filtration

16 | © Danfoss | January 2020 AB00000019en-000401

Page 17

Design Guidelines

Hydraulic Fan Drive Systems

System Design Parameters

Technical Features

In this document, we introduce the equations that are used to size the components of a modulating fan

drive system. In addition to these principles, there are several other factors to consider to ensure that the

hydraulic system performs to expectations. Following are some considerations you are encouraged to

address during the design phase.

Shaft Loads and Bearing Life

For information on shaft loads and bearing life, refer to:

•

•

•

•

Maximum Pump Speed

Pump displacement, and centrifugal filling of the pumping chambers, limit maximum pump speed.

Unless otherwise specified, maximum rated pump speeds are based on operation at sea level with

hydraulic fluids having a specific gravity of 0.9 and a viscosity of 58 SUS (9 cSt) at 180° F (80° C). Speed

limits for a particular application depend on the absolute pressure and oil viscosity. Speed limits for

individual products may be found in their respective technical information bulletins. Consult a Danfoss

representative for operation outside of these published limits.

Series 45 Technical Information 520L0519

Series 40 Motors Technical Information 520L0636

Series 42 Pumps Technical Information 11022637

H1 Pumps Technical Information Manuals (see Reference Literature at the back of this manual)

Minimum Pump and Motor Speed

Volumetric efficiency limits minimum pump speed. If lower than recommended starting or operating

speeds are required, contact a Danfoss representative for assistance. Piston motors are designed for

continuous operation at low speed, and at rated pressure. Motors may be started from zero speed on fan

drives, and torque will increase with speed.

Motor Starting Pressure (open circuit motors)

No-load motor start-up pressures may range from 100 to 725 psid (7 to 50 dbar), depending on

displacement. This property of the motor is dependent on motor design parameters, the CSF (Coefficient

of Static Friction), and it is inversely proportional to motor displacement. For example: The starting

torque for any given motor is largely dependent on the pitch diameter of the pistons and the CSF. Since

torque is dependent on the product of pressure and displacement, and starting torque is essentially

constant for any given frame size; starting pressure will be dependent on displacement, in an inverse

relationship. To minimize starting pressure, select the smallest frame size for the required motor

displacement.

Besides displacement, there are several factors which also effect motor starting pressure. They include:

pressure rise rate (pressure gradient), temperature, fluid viscosity, motor return pressure (back pressure),

fan inertia, pump flow rate, and piece-to-piece variation between motors.

Motor Free Run Pressure

Free run pressure is the minimum delta pressure across the motor that is required to keep the motor

turning when there is no cooling demand. Free run pressure is dependent on motor displacement and

shaft speed.

If the delta pressure across the motor is allowed to fall below the free run pressure; the motor will stop,

and it will be necessary for the motor to go through the starting condition (start-up procedure) when

cooling is needed again. In most applications, it is desirable to initiate fan rotation when the engine starts

and prevent the motor from stopping, while the engine is running.

©

Danfoss | January 2020 AB00000019en-000401 | 17

Page 18

C

Design Guidelines

Hydraulic Fan Drive Systems

System Design Parameters

Input Torque Ratings

When applying pumps in multiple configurations, ensure the input torque limitations are met for each

section and for cumulative sections. Refer to individual product technical information bulletins for

specific product torque limits. Always ensure that any individual pump in a multiple unit does not exceed

its respective torque rating.

Torques in excess of recommended values may cause premature input shaft, or unit, failure.

Pump Drive Conditions

Most Danfoss products are available with SAE and metric, standard spline, tapered key, or cylindrical

keyed drive shafts for direct or indirect drive applications. An intermediate coupling is the preferred

method for direct drives, thereby eliminating radial and axial loading. Direct Drive (or plug-in or rigid)

spline drives can impose severe radial loads on the pump shaft when the mating spline is rigidly

supported. Increased spline clearance does not alleviate this condition. Both concentricity and angular

alignment of shafts are important to pump life. Misalignment can induce excessive side loads on bearings

and seals, causing premature failure.

Overhung load drives (chain, belt, or gear) are permissible. Contact Danfoss for assistance. The allowable

radial shaft loads are a function of the load magnitude, the load position, the load orientation, and the

operating pressure of the hydraulic pump. All external shaft loads will have an effect on bearing life and

may affect pump performance. In applications where external shaft loads cannot be avoided; optimizing

the position, orientation, and magnitude of the radial load can minimize their influence on the pump. A

tapered input shaft is recommended for applications where radial shaft loads are present. (Spline shafts

are not recommended for belt or gear drive applications, the clearance between the mating splines will

prevent accurate alignment of the drive elements and will contribute to excessive wear of the spline.) For

belt drive applications, a spring loaded belt-tensioning device is recommended to avoid excessive radial

loads on the input shaft.

Caution

Note for H1 pump with an FDC: Due to the failsafe functionality of the H1P FDC control the pump will

stroke to max. displacement in case the input signal to the pump control and the Diesel engine will be

switched off at the same time. In this situation a low loop event can occur which may damage the pump.

Therefore, it’s strictly recommended to keep the input signal to the pump control alive while switching

off the engine.

For further information please contact your Danfoss representative

Tapered Shaft and Hub Connections

Tapered shaft/hub connections provide excellent control of both axial and radial position of the drive

coupling or fan assembly. When using the tapered connection, additional effort should be used to insure

that there is adequate axial clamping load between the hub and the shaft. The designer is encouraged to

establish that there is:

Adequate clearance under the bolt/nut to insure full axial load may be applied to the taper without

•

bottoming out.

Adequate clearance between the top of the key and the bottom of the keyway in the hub.

•

Interference between the top of the key and the bottom of the keyway will prevent the hub from

seating onto the taper of the shaft. This will compromise the ability of the shaft to transmit its full

torque capacity, and may result in failure of the shaft.

Pump Suction

For maximum pump life, the inlet pressure should not drop below 0.8 bar absolute [6 in. Hg vac.] at the

pump inlet port.

For cold start conditions, inlet pressure down to 0.6 bar absolute [12 in. Hg vac.] is acceptable for short

durations. The possibility of damage due to fluid cavitation and aeration is proportional to decreases in

18 | © Danfoss | January 2020 AB00000019en-000401

Page 19

C

C

Design Guidelines

Hydraulic Fan Drive Systems

System Design Parameters

inlet pressure. In addition, oil film lubrication may be disrupted by low inlet pressure. These factors, either

singularly or combined, may contribute to a decrease in pump life. Multiple changes in either diameter or

direction can have a significant effect on the resistance to flow in inlet passages and can result in a

substantial increase in the effective length of the inlet line. For this reason, Danfoss recommends that the

inlet line contain a minimum number of adaptor fittings, tees, and elbows; as each are a source of

additional restriction and, potentially, a source of leakage.

Continuous operation with inlet pressures below 0.8 bar absolute [6 in. Hg vac.] can cause premature unit

failure. Ensure adequate flow/pressure head at the pump inlet at all times.

Case Drain Pressure

Maximum pressure limitations for both case drain and inlet passages are available by consulting the

appropriate technical information bulletin for the products being applied. Both line length and diameter

influence the pressure drop of the fluid in these passages as it flows to/from the reservoir. In addition,

both steady state flow velocity and transient conditions, which can accelerate the fluid in these passages,

must be considered when determining their correct size. Of the two design parameters: line length and

diameter, diameter has the most influence on the success of the design. Increasing line diameter can

decrease both the steady state and the transient pressure drops exponentially. For additional information

on steady state pressure drops in hydraulic passages, the reader is encouraged to consult any good text

on basic hydraulic design. For additional information on transient pressure drops, refer to Appendix D.

Introducing additional flow from external sources into these return lines can also result in transient

pressure pulses that may exceed the drain, or case pressure limits of these products. Danfoss

recommends that the bearing drain and case drain lines return directly to the reservoir and remain

dedicated to their intended function without connecting them to additional flow sources.

Caution

Filtration

Operating Temperatures

Fluids

To prevent premature wear, it is imperative that only clean fluid enters the pump and hydraulic circuit. A

filter capable of controlling the fluid cleanliness to class 22/18/13 (per ISO 4406-1999) or better, under

normal operating conditions, is recommended. At initial start up, the system can be at Class 25/22/17 but

should not be run at high speed or pressure until the Class 22/18/13 is achieved through filtration. Since

the filter must be changed at regular intervals, the filter housing should be located in an accessible area.

Appropriate filter change intervals may be determined by test or by gauges indicating excessive pressure

drop across the filter element.

For more information refer to Design Guideline for Hydraulic Fluid Cleanliness, Technical Information

520L0467.

With Buna seals and normal operating conditions, the system temperature should not exceed 82 °C [180

°F] except for short periods to 93 °C [200 °F]. With optional Viton elastomer, the system may be operated

at continuous temperatures up to 107°C [225°F] without damage to the hydraulic components.

Caution

Operation in excess of 107 °C [225 °F] may cause external leakage or premature unit failure.

A mineral based fluid is recommended that includes additives to resist corrosion, oxidation and foaming.

The oil should have a maximum viscosity commensurate with system pressure drop and pump suction

pressures. Since the fluid serves as a system lubricant, as well as transmitting power, careful selection of

the fluid is important for proper operation and satisfactory life of the hydraulic components. Hydraulic

©

Danfoss | January 2020 AB00000019en-000401 | 19

Page 20

Design Guidelines

Hydraulic Fan Drive Systems

System Design Parameters

fluids should be changed at appropriate intervals determined by test, supplier, or by change in color, or

odor, of the fluid.

Every 10°C [18°F] rise in continuous reservoir temperature over 80°C [176 °F] decreases the life of the oil

by ½.

For additional technical information on hydraulic fluids refer to Hydraulic Fluids and Lubricants 520L0463

Technical Information Bulletin and specific product technical bulletins.

For information relating to biodegradable fluids, see Danfoss publication Experience with Biodegradable

Hydraulic Fluids 520L0465 or consult the Danfoss Technical Services Department.

Mounting

The pump mount/drive should be designed to minimize axial and radial loads on the shaft. When using

an indirect (chain, belt, or gear) drive, contact Danfoss to determine permissible load limits and

orientation of the installation.

The motor mount should be designed to position the motor/fan assembly within the shroud for

optimum fan performance and to locate the leading edge of the fan blades relative to the adjacent

surface of the heat exchanger. The support structure should be constructed so that it will be robust

against forces and deflections due to shock and vibration as well as the loads applied to it by the fan and

the hydraulic plumbing that will be connected to the motor.

Axial Thrust Motors

When a fan is directly mounted onto the drive shaft of a hydraulic motor, it imparts both a radial and an

axial thrust load onto the shaft. In general, the weight of the fan is insignificant when compared to the

radial load capacity of the bearings in the motor. But, the axial thrust load must be considered carefully.

Under normal operating conditions, Danfoss motors have adequate axial thrust capacity for most fans

that are applied in the industry, but they do have limitations. It is recommended that the system designer

determine the axial thrust force that will be produced by the fan and compare it to the values listed

below:

Series 40 motors external shaft load limits

Unit M25 M35/44 M46

M

e

T N [lbf] 848 [190] 966 [217] 1078 [242]

N•m [lbf•in] 29 [256] 25 [221] 24 [212]

L and K motors external shaft load limits

Frame L K

Mounting configuration SAE Cartridge SAE Cartridge

Maximum allowable external moment (Me) N•m 7.7 21.7 13.3 37.5

[lbf•in] 68 192 118 332

Maximum allowable thrust load (T) N 750 1100

lbf 169 247

Refer to Appendix-A for equations that will assist in calculating the axial thrust loads from the fan.

Calculated loads should be confirmed by test.

For shaft load limit calculations on Series 90 motors and H1B motors, contact your Danfoss

representative.

20 | © Danfoss | January 2020 AB00000019en-000401

Page 21

Design Guidelines

Hydraulic Fan Drive Systems

System Design Parameters

Piping

The choice of piping size and installation should always be consistent with minimizing maximum fluid

velocity. This will reduce system noise, pressure drops and overheating, thereby adding to cost savings

for the operation of the system. Inlet piping should be designed to prevent continuous pump inlet

pressures below 0.8 bar abs. [6 in. Hg vac.] or 0.6 bar abs. [12 in. Hg vac.] during start-up. When selecting

pipe sizing, recognize pressure drops are related to flow velocity. Danfoss recommends limiting the

maximum average mean flow velocity to 5 m/sec [15 ft/sec.] in pressure lines, and 2.5 m/sec [7 ft/sec.] in

suction lines.

In addition to limiting maximum flow velocity, it is recommended that the designer select the hoses,

fittings and integral valve elements to be compatible with the desired working pressure of the hydraulic

system. The following documents may be used to determine the working pressure ratings for the

respective system elements:

•

•

•

•

SAE J514: for working pressure ratings and fitting installation torques for - O-ring boss fittings/ports

and JIC 37º flared tubing connections

SAE J518: for working pressure ratings and bolt installation torques for SAE code 61 4-Bolt flange

fittings/ports,

SAE J517: for working pressure ratings for SAE hydraulic hose

SAE J1453: for working pressure ratings for flat face O-ring fittings.

Reservoir

The reservoir should be designed to accommodate expected maximum volume exchange during all

system operating modes and to prevent aeration of the fluid as it passes through the reservoir. Return

and inlet lines should be positioned below the reservoir low oil level and be located as far as possible

from each other. A diffuser and a baffle plate located between the pump inlet and return line is desirable

to reduce turbulence and to allow the oil to de-aerate before it re-enters the pump.

Reservoirs must be sized to ensure de-aeration of the oil before it re-enters the pump. For dwell times of

less than 90 seconds, the system designer is encouraged to verify that entrained air (bubbles) are not

included in the oil that is being transmitted from the reservoir to the pump. This may be accomplished by

placing a sight gage into the inlet line between the reservoir and the pump. Placing a variable frequency

strobe light source behind the sight gage will improve the observer’s ability to see air bubbles present in

the fluid as it passes through the inlet line.

Danfoss encourages system designers to locate the reservoir so that the oil level in the reservoir will

remain above the level of the inlet port of the pump under all conditions. By doing this, a positive head is

produced that can offset the effects of line losses and altitude on the inlet pressure available at the pump.

Danfoss also encourages system designers to consider the potential for air to be introduced into the inlet

line within the reservoir via the introduction of a vortex or whirlpool, between the surface of the oil and

the inlet port. One way to discourage a vortex is to locate a baffle between the inlet passage, or suction

strainer, and the surface of the oil. The system designer should consider the design parameters of size

and position for the baffle to ensure that a vortex cannot form if the reservoir attitude is at its extremes,

the oil level is at or below the minimum recommended capacity, or if sloshing occurs due to operation of

the machine.

Cavitation and Aeration Damage

Hydraulic oil used in the majority of systems contains about 10% dissolved air by volume. This air, under

certain conditions of vacuum within the system, is released from the oil causing air bubbles. These

entrained air bubbles collapse if subjected to pressure, and this collapse creates erosion of the adjacent

metal surfaces and degradation of the oil. Because of this, it becomes obvious that the greater the air

content within the oil, or the greater the vacuum in the inlet line, the more severe will be the resultant

damage. The main causes of over-aeration of the oil are air leaks, particularly on the inlet side of the

pump, and flow line restrictions such as inadequate pipe sizes, elbow fittings and sudden changes in flow

passage cross-sectional area. To avoid cavitation problems when using Danfoss pumps and motors, avoid

defects in plumbing and construction, maintain pump inlet pressure and rated speed requirements, and

ensure reservoir size and follow recommended guidelines.

©

Danfoss | January 2020 AB00000019en-000401 | 21

Page 22

C

Design Guidelines

Hydraulic Fan Drive Systems

System Design Parameters

When entrained air entering the pump is pressurized at the pump outlet, it is forced into solution in the

oil as the bubbles collapse. This super-saturated solution of dissolved air and oil will release its air when

the pressure is released. Symptoms of this condition can be observed by oil / foam escaping from the fill

port of the reservoir when the system is shut down.

Cooling

Depending on duty cycle and reservoir/line construction, an oil-cooler may be required. The oil-cooler

size is based on typical power losses in the hydraulic circuit. The oil cooler is usually placed in the return

line to the reservoir.

Pressure Protection and Ratings

The pump, as well as other system components, has pressure limitations. Thus a relief valve, or pressure

limiting device, must be installed in the system, and its setting must be consistent with the product

ratings. Refer to the relevant Danfoss technical bulletins for this information.

Failure to install a relief valve or over-pressure protection may result in premature unit failure.

Caution

Bearing Life Expectancy

All Danfoss piston pumps and motors utilize anti-friction, rolling element bearings, and journal bearings,

which have an oil film maintained at all times between the bearing surfaces. If this oil film is sufficiently

sustained through proper system maintenance and the product’s operating limits are adhered to, a long

bearing life can be expected.

A B10 type life expectancy number is generally associated with rolling element bearings. Bearing life is a

function of speed, system pressure, and other system parameters such as oil viscosity and oil cleanliness.

22 | © Danfoss | January 2020 AB00000019en-000401

Page 23

Design Guidelines

Hydraulic Fan Drive Systems

Glossary

Terminology

Trim speed is the maximum fan speed required at the full-on condition. This is equal to, or greater than,

the fan speed required to meet the maximum cooling needs of the cooling system.

Engine set point is the engine speed at which trim speed should occur, and is provided by the cooling

system designer. This is equal to, or less than, the engine speed at which maximum system cooling is

required.

Fan power at trim is the power that needs to be generated at the motor shaft to drive the fan at trim

speed.

Fan rating is the value by which different types of fans can be compared. Usually designated as X power

@ Y rpm and equates back to an air volume (mass flow rate) that can be moved per minute at the Y rpm.

To assist with the sizing exercise, Danfoss has developed a sizing tool to perform the necessary

calculations. Within the sizing tool, worksheets are provided for both fixed displacement pump/fixed

displacement motor, and variable displacement pump/fixed displacement motor hydraulic systems. The

sizing tool has been provided to your Danfoss representative.

Refer to the data sheets on pages in the System Design Parameters chapter. When the data on these

sheets is complete, calculations can be made to determine the most suitable pump/motor/controller

combination for the application based on:

•

•

•

•

•

•

Pump drive available (torque, shaft, mounting flange, overall space envelope)

System pressure required

Additional flow/pressure required from the pump, (for example: steering flow)

Control type requested by the customer

Limiting operating parameters of the fan drive family products

Fit (space envelope)

Contact your Danfoss representative for a report of the performance prediction generated by the fan

drive sizing tool.

For systems using axial piston pumps, refer to AE Note 2010-02 for sizing calculations. Contact your

Danfoss representative for access to AE Note 2010-02.

©

Danfoss | January 2020 AB00000019en-000401 | 23

Page 24

English system

Theoretical hp = [hp]

ft3

min

( )

•

(Total pressure, [in H20])

(6356)

Theoretical power = [watts]

m3

sec

( )

•

(Total pressure, [Pa],

(1.0)

N

[

]

m2

)

SI system

Design Guidelines

Hydraulic Fan Drive Systems

Appendix A-Fan Performance

Fans

Fans are generally divided into two classifications:

•

•

The typical axial flow fan is commonly referred to as a propeller fan, and is customarily used for free

delivery, or against low resistance. They are usually mounted within a circular ring or shroud with a

circular opening.

Fan Performance

Fan performance is a measure of volume, total pressure, static pressure, speed, power input, mechanical

efficiency, and static efficiency, at a stated density. Some useful definitions are:

Volume delivered by a fan is the number of cubic feet of air per minute (or, cubic meters per second),

expressed at fan inlet conditions.

Total pressure is the rise of pressure from fan inlet to fan outlet.

Velocity pressure is the pressure corresponding to the average velocity, determined from the volume of

airflow at the fan outlet area.

Static pressure is the total pressure diminished by the fan’s velocity pressure. Static pressure is a

measure of the fan’s performance and is reported by the fan manufacturer in their technical literature.

Static pressure is also a measure of the resistance to the flow of air thru the heat exchanger.

Power output is expressed in horsepower (or, kilowatts) and is based on fan volume and fan total

pressure.

Power input is expressed in horsepower (or, kilowatts) and is the measured power delivered to the fan

shaft.

Mechanical efficiency of a fan is the ratio of power output to power input.

Static efficiency of a fan is the mechanical efficiency multiplied by the ratio of static pressure to the total

pressure.

The theoretical power required to move a quantity of air may be determined by the following formula:

Centrifugal or radial flow - in which the air flows radially thru the impeller within a scroll type of

housing

Axial flow - in which the air flows axially thru the impeller within a cylinder or ring.

Pressure and power both vary with air density.

Fan efficiencies may be determined by the following formulae:

24 | © Danfoss | January 2020 AB00000019en-000401

Page 25

English system

ft3

min

•

(Total pressure, [in H20])

(6356.0)

m3

sec

•

(Total pressure, [Pa],

(Power input, [watts])

N

m2

)

SI system

(Horsepower input)

(

)

[ ]

[

]

(

)

English system

ft3

min

•

(Static pressure, [in H20])

(6356.0)

m3

sec

•

(Static pressure, [Pa],

(Power input, [watts])

N

m2

)

SI system

(Horsepower input)

(

)

[ ]

( )

[ ]

English system

ft3

min

•

(Static pressure, [in H20])

(6356.0)

m3

sec

•

(Static pressure, [Pa],

(Power input, [watts])

N

m2

)

SI system

(Horsepower input)

(

)

[ ]

( )

[ ]

Design Guidelines

Hydraulic Fan Drive Systems

Appendix A-Fan Performance

Mechanical efficiency, based on total pressure is applicable for fans operating with high outlet velocity

pressure relative to the static pressure, typical of centrifugal fans.

Axial Thrust

Static efficiency, based on static pressure is applicable to fans with high static pressure relative to the

velocity pressure. Static pressure and static efficiency are used more often than mechanical efficiency and

total pressure. When a fan operates against no resistance, the static efficiency becomes zero and is

meaningless.

Total pressure = static pressure + velocity pressure

Velocity pressure is proportional to air velocity.

©

Danfoss | January 2020 AB00000019en-000401 | 25

Page 26

English system

Velocity pressure =

V

V =

ft

min

4005

)2,

(

[in H20]

[

]

Velocity pressure =

Pa,

N

(V2 • )

SI system

m2

V =

m

sec

2

,

= Density of air,

Kg

m3

[

]

[

]

[ ]

English system

Axial thrust = , [N]

π • Total pressure • (Fan diameter)

2

SI system

Total pressure,

4

Pa,

N

m2

Fan diameter, [m]

Axial thrust =

π • Total pressure • (Fan diameter)

2

Total pressure,

(27.68)•4

Fan diameter, [inches]

[in H20]

[

]

[

]

[

]

, [lbf ]

Design Guidelines

Hydraulic Fan Drive Systems

Appendix A-Fan Performance

Four inches H2O = 1000 Pa

Fan Laws

The performance characteristics of fans of all types follow certain laws, which are useful in predicting the

effect upon performance of certain changes in the conditions of operation, or the size of the equipment

due to limitations of space, power, and/or speed. In the following categories, Q = air flow, and Pres. =

static, velocity, or total pressure. The categories pertaining to fan size apply only to fans, which are

geometrically similar, i.e., those in which all of the dimensions are proportional to some linear dimension

identified as size.

1.

Variation in fan speed:

26 | © Danfoss | January 2020 AB00000019en-000401

Constant air density – Constant system

a.

Q: Varies as fan speed

b.

Pres: Varies as square of fan speed

c.

Power: Varies as cube of fan speed

2.

Variation in fan size:

Constant tip speed – Constant air density

Constant fan proportions – Fixed point of rating

Page 27

Design Guidelines

Hydraulic Fan Drive Systems

Appendix A-Fan Performance

3.

4.

5.

6.

a.

Q: Varies as square of fan diameter

b.

Pres: Remains constant

c.

rpm: Varies inversely as fan diameter

d.

Power: Varies as square of fan diameter

Variation in fan size:

At constant rpm – Constant air density

Constant fan proportions – fixed Point of rating

a.

Q: Varies as cube of fan diameter

b.

Pres: Varies as square of fan diameter

c.

Tip speed: Varies as fan diameter

d.

Power Varies as fifth power of diameter

Variation in air density: (Refer to Appendix F)

Constant volume – Constant system

Fixed fan size – Constant fan speed

a.

Q: Constant

b.

Pres: Varies as density (SI), specific weight (English)

c.

Power: Varies as density (SI), specific weight (English)

Variation in air density: (Refer to Appendix F)

Constant pressure – Constant system

Fixed fan size – Variable fan speed

a.

Q: Varies inversely as square root of density (SI), specific weight (English)

b.

Pres: Constant

c.

rpm: Varies inversely as square root of density (SI), specific weight (English)

d.

Power: Varies inversely as square root of density (SI), specific weight (English)

Variation in air density: (Refer to Appendix F)

Constant weight of air – Constant system

Fixed fan size – Variable fan speed

a.

Q: Varies inversely as density (SI), specific weight (English)

b.

Pres: Varies inversely as density (SI), specific weight (English)

c.

rpm: Varies inversely as density (SI), specific weight (English)

d.

Power: Varies inversely as square of density (SI), specific weight (English)

Fan laws at a glance

Variation in fan speed Variation in fan size Variation in air density

Fan laws Fan law #1 Fan law #2 Fan law #3 Fan law #4 Fan law #5 Fan law #6

Parameters Constant air density &

constant system

Q, Air volume, (flow rate) Varies as fan speed Varies as square of

©

Danfoss | January 2020 AB00000019en-000401 | 27

Constant tip speed &

constant air density

Constant tip

proportions & fixed

point of rating

fan diameter

Constant rpm &

constant air

density

Constant fan

proportions &

fixed point of

rating

Varies as cube of

fan diameter

Constant

volume &

constant

system

Fixed fan size &

constant fan

speed

Constant Varies

Constant

pressure &

constant

system

Fixed fan

size &

variable fan

speed

inversely as

square root

of density or

specific

weight

Constant weight of

air & constant

system

Fixed fan size &

variable fan speed

Varies inversely as

density or specific

weight

Page 28

Design Guidelines

Hydraulic Fan Drive Systems

Appendix A-Fan Performance

Fan laws at a glance (continued)

Variation in fan speed Variation in fan size Variation in air density

Fan laws Fan law #1 Fan law #2 Fan law #3 Fan law #4 Fan law #5 Fan law #6

Pressure Varies as square of fan

speed

rpm Constant Varies inversely as

Power Varies as cube of fan

speed

Tip Speed N/A N/A Varies as fan

Remains constant Varies as square of

fan diameter

Constant Constant Varies

fan diameter

Varies square of fan

diameter

Varies as 5th

power of diameter

diameter

Varies as

density or

specific weight

Varies as

density or

specific weight

Varies inversely

as 4th power of

diameter

N/A

Constant Varies inversely as

density or specific

weight

Varies inversely as

inversely as

square root

of density or

specific

weight

Varies as

inversely as

square root

of density or

specific

weight

density or specific

weight

Varies as inversely

as square of density

or specific weight

Example 1

A fan delivers 12,000 cfm at a static pressure of 1 in. H2O when operating at a speed of 400 rpm and

requires an input of 4 hp. If in the same installation, 15,000 cfm are required, what will be the speed, static

pressure, and power?

Using fan law 1:

Speed = 400 * {15,000/12,000} = 500 rpm

Static pressure = 1 * {500/400}2 = 1.56 in. H2O

Power = 4 * {500/400}3 = 7.81 hp

Example 2

A fan delivers 12,000 cfm at 70 °F and normal barometric pressure (density = 0.075 lb per cubic foot) at a

static pressure of 1 in. H2O when operating at 400 rpm, and requires 4 hp. If the air temperature is

increased to 200 °F (density = 0.0602 lb per cubic foot) and the speed of the fan remains the same, what

will be the static pressure and power?

Using fan law 4:

Static pressure = 1 * {0.0602/0.075} = 0.80 in. H2O

Power = 4 * {0.0602/0.075} = 3.20 hp

Example 3

If the speed of the fan in example 2 is increased to produce a static pressure of 1 in. H2O at 200 °F, as at 70

°F, what will be the speed, capacity, and static power?

Using fan law 5:

Speed = 400 * SQRT {0.0705/0.0602} = 446 rpm

Capacity = 12,000 * SQRT {0.075/0.0602} = 13,392 cfm (measured at 200°F)

Power = 4 * SQRT {0.075/0.0602} = 4.46 hp

28 | © Danfoss | January 2020 AB00000019en-000401

Page 29

Design Guidelines

Hydraulic Fan Drive Systems

Appendix A-Fan Performance

Example 4

If the speed of the fan in the previous examples is increased to deliver the same weight of air (same