Page 1

Technical Information

Hydraulic Brakes

BK, AB, FB, SB, RP Series

www.danfoss.com

Page 2

Technical Information

Hydraulic Brakes

Revision history Table of revisions

Date Changed Rev

June 2019 Spelling and grammatical updates 0103

Nov 2017 Updated SB 930 max. release pressure rating 0102

Mar 2017 First edition 0101

2 | © Danfoss | June 2019 BC00000383en-000103

Page 3

Technical Information

Hydraulic Brakes

Contents

Technical Information

BK 913 and 915 Series

AB 920 Series

FB 925 Series

SB 930 Series

RP 960 Series

Operating Recommendations..................................................................................................................................................... 4

Oil Type...........................................................................................................................................................................................4

Fluid Viscosity and Filtration...................................................................................................................................................4

Installation and Start-up...........................................................................................................................................................4

Hydraulic Motor Safety Precaution.......................................................................................................................................4

Hydraulic Brake Precaution..................................................................................................................................................... 4

Allowable Bearing and Shaft Loading.......................................................................................................................................5

Vehicle Drive Calculations.............................................................................................................................................................6

Induced Side Load............................................................................................................................................................................9

Hydraulic Equations......................................................................................................................................................................10

Shaft Nut Information...................................................................................................................................................................11

BK 913 and 915 Series Housings...............................................................................................................................................14

BK 913 and 915 Series Technical Information......................................................................................................................14

BK 913 and 915 Series Shafts..................................................................................................................................................... 16

BK 913 and 915 Series Ordering Information...................................................................................................................... 16

AB 920 Series Housings................................................................................................................................................................17

AB 920 Series Technical Information...................................................................................................................................... 18

AB 920 Series Shafts......................................................................................................................................................................19

AB 920 Series Ordering Information....................................................................................................................................... 19

FB 925 Series Housings................................................................................................................................................................ 20

FB 925 Series Technical Information.......................................................................................................................................21

FB 925 Series Shafts.......................................................................................................................................................................22

FB 925 Series Ordering Information........................................................................................................................................22

SB 930 Series Housings................................................................................................................................................................ 24

SB 930 Series Shafts.......................................................................................................................................................................25

SB 930 Series Technical Information.......................................................................................................................................26

SB 930 Series Installation Information....................................................................................................................................26

SB 930 Series Ordering Information........................................................................................................................................27

RP 960 Series Ordering Information........................................................................................................................................29

©

Danfoss | June 2019 BC00000383en-000103 | 3

Page 4

C

Technical Information

Hydraulic Brakes

Technical Information

Operating Recommendations

Oil Type

Hydraulic oils with anti-wear, anti-foam and demulsifiers are recommended for systems incorporating

Danfoss motors. Straight oils can be used but may require VI (viscosity index) improvers depending on

the operating temperature range of the system. Other water based and environmentally friendly oils may

be used, but service life of the motor and other components in the system may be significantly

shortened. Before using any type of fluid, consult the fluid requirements for all components in the system

for compatibility. Testing under actual operating conditions is the only way to determine if acceptable

service life will be achieved.

Fluid Viscosity and Filtration

Fluids with a viscosity between 20 - 43 cSt [100 - 200 S.U.S.] at operating temperature is recommended.

Fluid temperature should also be maintained below 85°C [180° F]. It is also suggested that the type of

pump and its operating specifications be taken into account when choosing a fluid for the system. Fluids

with high viscosity can cause cavitation at the inlet side of the pump. Systems that operate over a wide

range of temperatures may require viscosity improvers to provide acceptable fluid performance.

Danfoss recommends maintaining an oil cleanliness level of ISO 17-14 or better.

Installation and Start-up

When installing a Danfoss motor it is important that the mounting flange of the motor makes full contact

with the mounting surface of the application. Mounting hardware of the appropriate grade and size must

be used. Hubs, pulleys, sprockets and couplings must be properly aligned to avoid inducing excessive

thrust or radial loads. Although the output device must fit the shaft snug, a hammer should never be

used to install any type of output device onto the shaft. The port plugs should only be removed from the

motor when the system connections are ready to be made. To avoid contamination, remove all matter

from around the ports of the motor and the threads of the fittings. Once all system connections are

made, it is recommended that the motor be run-in for 15-30 minutes at no load and half speed to remove

air from the hydraulic system.

Hydraulic Motor Safety Precaution

A hydraulic motor must not be used to hold a suspended load. Due to the necessary internal tolerances,

all hydraulic motors will experience some degree of creep when a load induced torque is applied to a

motor at rest. All applications that require a load to be held must use some form of mechanical brake

designed for that purpose.

Hydraulic Brake Precaution

Caution

Danfoss’ brakes are intended to operate as static or parking brakes. System circuitry must be designed to

bring the load to a stop before applying the brake.

To achieve proper brake release operation, it is necessary to bleed out any trapped air and fill brake

release cavity and hoses before all connections are tightened. To facilitate this operation, all motor/

brakes feature two release ports. One or both of these ports may be used to release the brake in the unit.

Motor/brakes should be configured so that the release ports are near the top of the unit in the installed

position.

Once all system connections are made, one release port must be opened to atmosphere and the brake

release line carefully charged with fluid until all air is removed from the line and motor/brake release

cavity. When this has been accomplished the port plug or secondary release line must be reinstalled. In

the event of a pump or battery failure, an external pressure source may be connected to the brake release

port to release the brake, allowing the machine to be moved.

4 | © Danfoss | June 2019 BC00000383en-000103

Page 5

9000

8000

7000

6000

5000

4000

3000

2000

1000

lb

4000

3500

3000

2500

2000

1500

1000

500

daN

445 daN [1000 lb]

445 daN [1000 lb]

BEARING

SHAFT

-100

-50 -25 0 25 50 75 100

mm

-75

-100

-50 -25 0 25 50 75 100

mm

-75

P109320

Technical Information

Hydraulic Brakes

Technical Information

Allowable Bearing and Shaft Loading

This catalog provides curves showing allowable radial loads at points along the longitudinal axis of the

motor. They are dimensioned from the mounting flange. Two capacity curves for the shaft and bearings

are shown. A vertical line through the centerline of the load drawn to intersect the x-axis intersects the

curves at the load capacity of the shaft and of the bearing.

In the example below, the maximum radial load bearing rating is between the internal roller bearings

illustrated with a solid line. The allowable shaft rating is shown with a dotted line.

The bearing curves for each model are based on laboratory analysis and testing conducted at Danfoss.

The shaft loading is based on a 3:1 safety factor and 330 Kpsi tensile strength. The allowable load is the

lower of the curves at a given point. For instance, one inch in front of the mounting flange the bearing

capacity is lower than the shaft capacity. In this case, the bearing is the limiting load. The motor user

needs to determine which series of motor to use based on their application knowledge.

ISO 281 Ratings vs. Manufacturer's Ratings

Published bearing curves can come from more than one type of analysis. The ISO 281 bearing rating is an

international standard for the dynamic load rating of roller bearings. The rating is for a set load at a speed

of 33 1/3 RPM for 500 hours (1 million revolutions). The standard was established to allow consistent

comparisons of similar bearings between manufacturers. The ISO 281 bearing ratings are based solely on

the physical characteristics of the bearings, removing any manufacturers specific safety factors or

empirical data that influences the ratings.

Manufacturers’ ratings are adjusted by diverse and systematic laboratory investigations, checked

constantly with feedback from practical experience. Factors taken into account that affect bearing life are

material, lubrication, cleanliness of the lubrication, speed, temperature, magnitude of the load and the

bearing type.

The operating life of a bearing is the actual life achieved by the bearing and can be significantly different

from the calculated life. Comparison with similar applications is the most accurate method for bearing life

estimations.

©

Danfoss | June 2019 BC00000383en-000103 | 5

Page 6

Technical Information

Hydraulic Brakes

Technical Information

Example Load Rating for Mechanically Retained Needle Roller Bearings

Vehicle Drive Calculations

Bearing Life L

L

10

10

(C/P)p [106 revolutions]

nominal rating life

C dynamic load rating

P equivalent dynamic load

Life Exponent p 10/3 for needle bearings

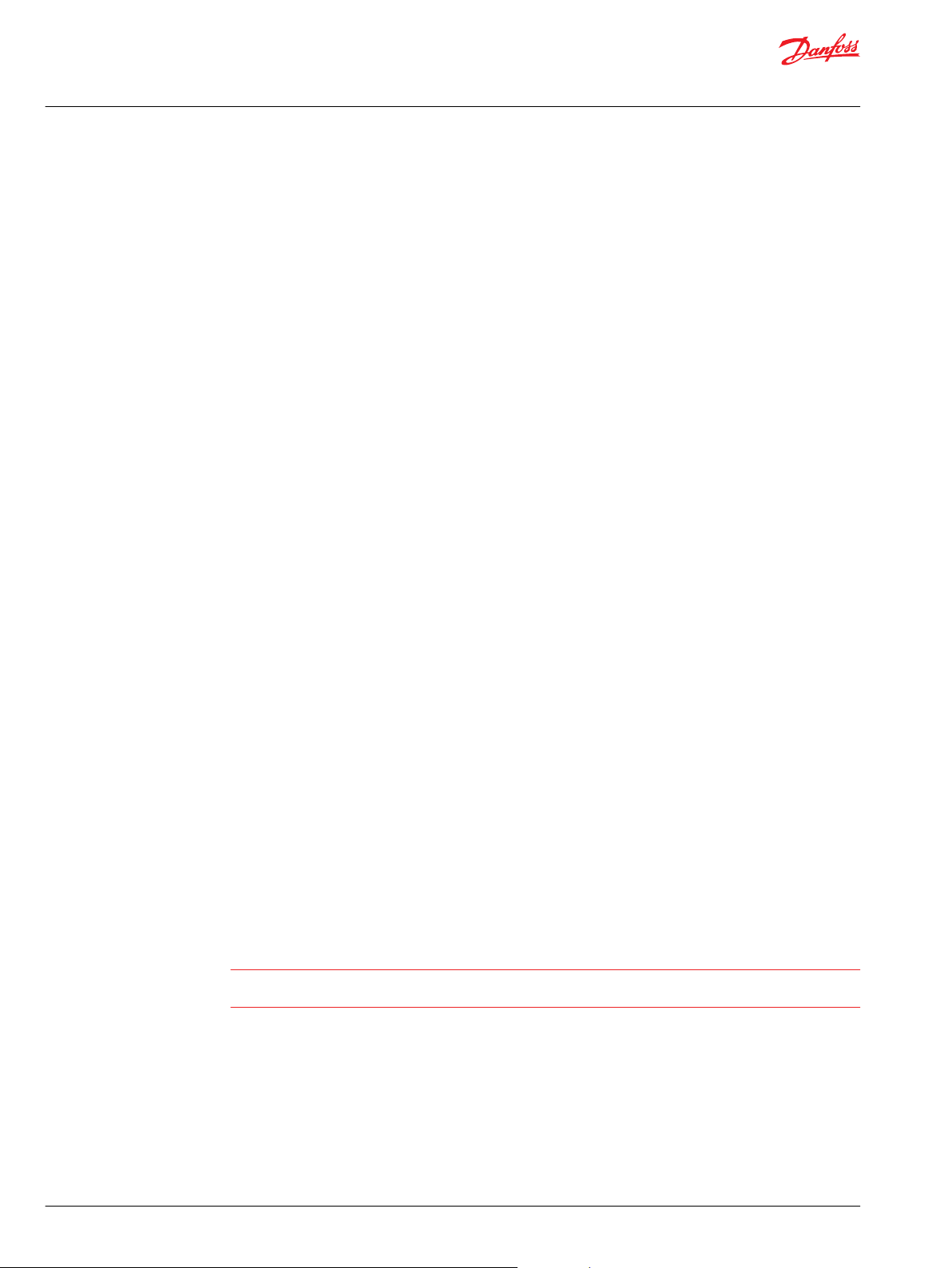

Bearing Load Multiplication Factor Table

RPM Factor

50 1.23

100 1.00

200 0.81

300 0.72

400 0.66

500 0.62

600 0.58

700 0.56

800 0.50

When selecting a wheel drive motor for a mobile vehicle, a number of factors concerning the vehicle

must be taken into consideration to determine the required maximum motor RPM, the maximum torque

required and the maximum load each motor must support. The following sections contain the necessary

equations to determine this criteria. An example is provided to illustrate the process.

Sample application (vehicle design criteria)

vehicle description 4 wheel vehicle

vehicle drive 2 wheel drive

GVW 1,500 lbs.

weight over each drive wheel 425 lbs.

rolling radius of tires 16 in.

desired acceleration 0-5 mph in 10 sec.

top speed 5 mph

gradability 20%

worst working surface poor asphalt

To determine maximum motor speed

RPM = (2.65 x KPH x G) / rm or RPM = (168 x MPH x G) / ri

KPH max. vehicle speed (kilometers/hr)

MPH max. vehicle speed (miles/hr)

6 | © Danfoss | June 2019 BC00000383en-000103

Page 7

Technical Information

Hydraulic Brakes

Technical Information

G gear reduction ratio (if none, G = 1)

rm rolling radius of tire (meters)

ri rolling radius of tire (inches)

RPM = (168 x 5 x 1) / 16 = 52.5

To determine maximum torque requirement of motor

To choose a motor(s) capable of producing enough torque to propel the vehicle, it is necessary to

determine the Total Tractive Effort (TE) requirement for the vehicle. To determine the total tractive effort,

the following equation must be used:

TE = RR + GR + FA + DP (lbs or N)

TE Total tractive effort

RR Force necessary to overcome rolling resistance

GR Force required to climb a grade

FA Force required to accelerate

DP Drawbar pull required

The components for this equation may be determined using the following steps.

Step One: Determine Rolling Resistance

Rolling Resistance (RR) is the force necessary to propel a vehicle over a particular surface. It is

recommended that the worst possible surface type to be encountered by the vehicle be factored into the

equation.

RR = (GVW / 1000) x R (lb or N)

GVW gross (loaded) vehicle weight (lb or kg)

R surface friction (value from Rolling Resistance on page 7)

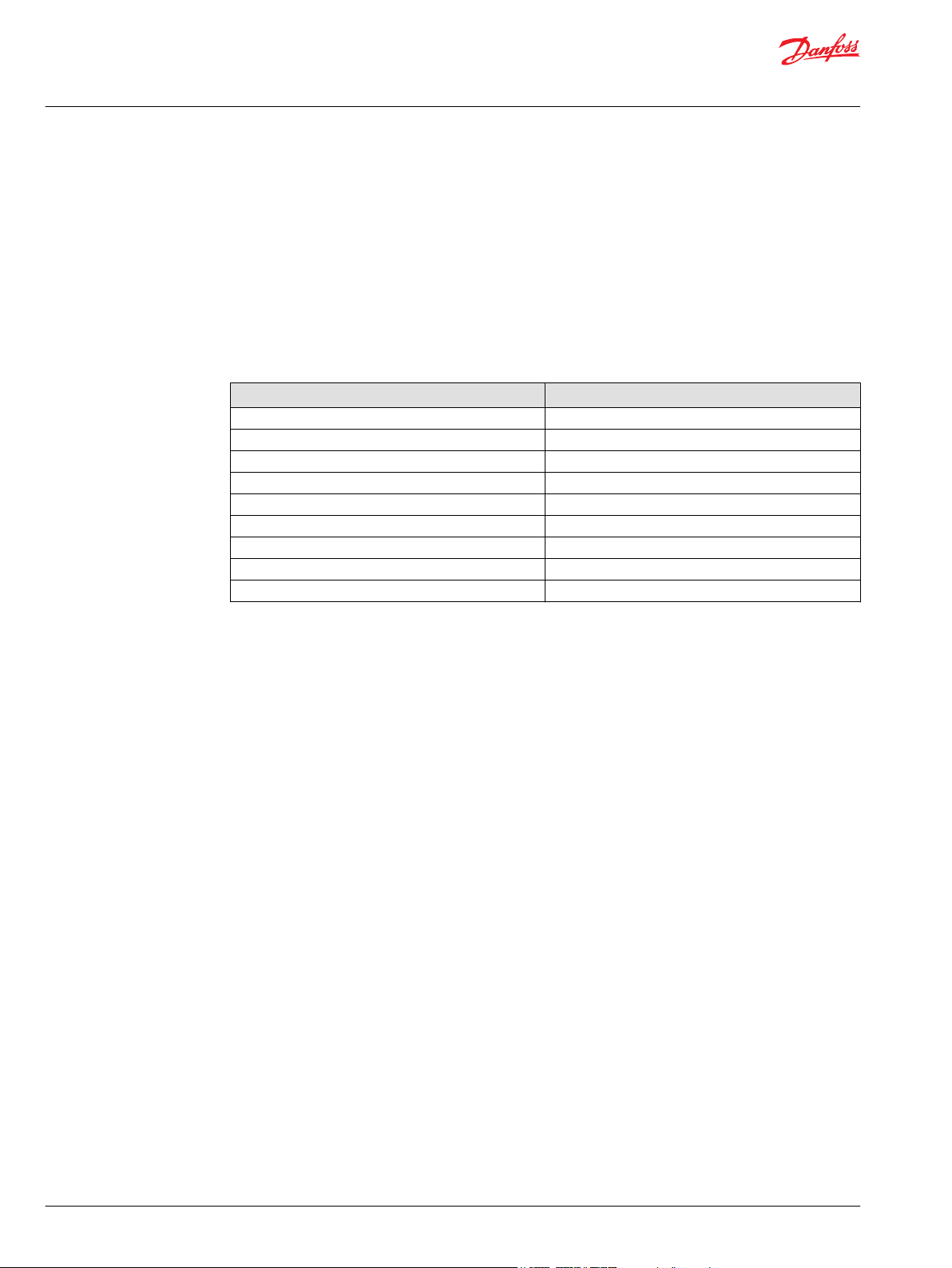

Rolling Resistance

Concrete (excellent) 10

Concrete (good) 15

Concrete (poor) 20

Asphalt (good) 12

Asphalt (fair) 17

Asphalt (poor) 22

Macadam (good) 15

Macadam (fair) 22

Macadam (poor) 37

Cobbles (ordinary) 55

Cobbles (poor) 37

Snow (2 inch) 25

Snow (4 inch) 37

Dirt (smooth) 25

Dirt (sandy) 37

Mud 37 to 150

©

Danfoss | June 2019 BC00000383en-000103 | 7

Page 8

Technical Information

Hydraulic Brakes

Technical Information

Rolling Resistance (continued)

Sand (soft) 60 to 150

Sand (dune) 160 to 300

Step Two: Determine Grade Resistance

Grade Resistance (GR) is the amount of force necessary to move a vehicle up a hill or “grade.” This

calculation must be made using the maximum grade the vehicle will be expected to climb in normal

operation.

To convert incline degrees to % Grade:

% Grade = [tan of angle (degrees)] x 100

GR = (% Grade / 100) x GVW (lb or N)

Example: GR = (20 / 100) x 1500 lbs = 300 lbs

Step Three: Determine Acceleration Force

Acceleration Force (FA) is the force necessary to accelerate from a stop to maximum speed in a desired

time.

FA = (KPH x GVW (N)) / (35.32 x t) or FA = (MPH x GVW (lb)) / (22 x t)

t time to maximum speed (seconds)

Example: FA = (5 x 1500 lbs) / (22 x 10) = 34 lbs

Step Four: Determine Drawbar Pull

Drawbar Pull (DP) is the additional force, if any, the vehicle will be required to generate if it is to be used

to tow other equipment. If additional towing capacity is required for the equipment, repeat steps one

through three for the towable equipment and sum the totals to determine DP.

Step Five: Determine Total Tractive Effort

The Tractive Effort (TE) is the sum of the forces calculated in steps one through three above. On low

speed vehicles, wind resistance can typically be neglected. However, friction in drive components may

warrant the addition of 10% to the total tractive effort to insure acceptable vehicle performance.

TE = RR + GR + FA + DP (lb or N)

Example: TE = 33 + 300 + 34 + 0 (lbs) = 367 lbs

Step Six: Determine Motor Torque

The Motor Torque (T) required per motor is the Total Tractive Effort divided by the number of motors

used on the machine. Gear reduction is also factored into account in this equation.

T = (TE x rm) / (M x G) Nm per motor or T = (TE x ri) / (M x G) lb-in per motor

M number of driving motors

Example: T = (367 x 16) / (2 x 1) lb-in/motor = 2936 lb-in

Step Seven: Determine Wheel Slip

To verify that the vehicle will perform as designed in regards to tractive effort and acceleration, it is

necessary to calculate wheel slip (TS) for the vehicle. In special cases, wheel slip may actually be desirable

to prevent hydraulic system overheating and component breakage should the vehicle become stalled.

TS = (W x f x rm) / G (Nm per motor) or TS = (W x f x ri) / G (lb-in per motor)

8 | © Danfoss | June 2019 BC00000383en-000103

Page 9

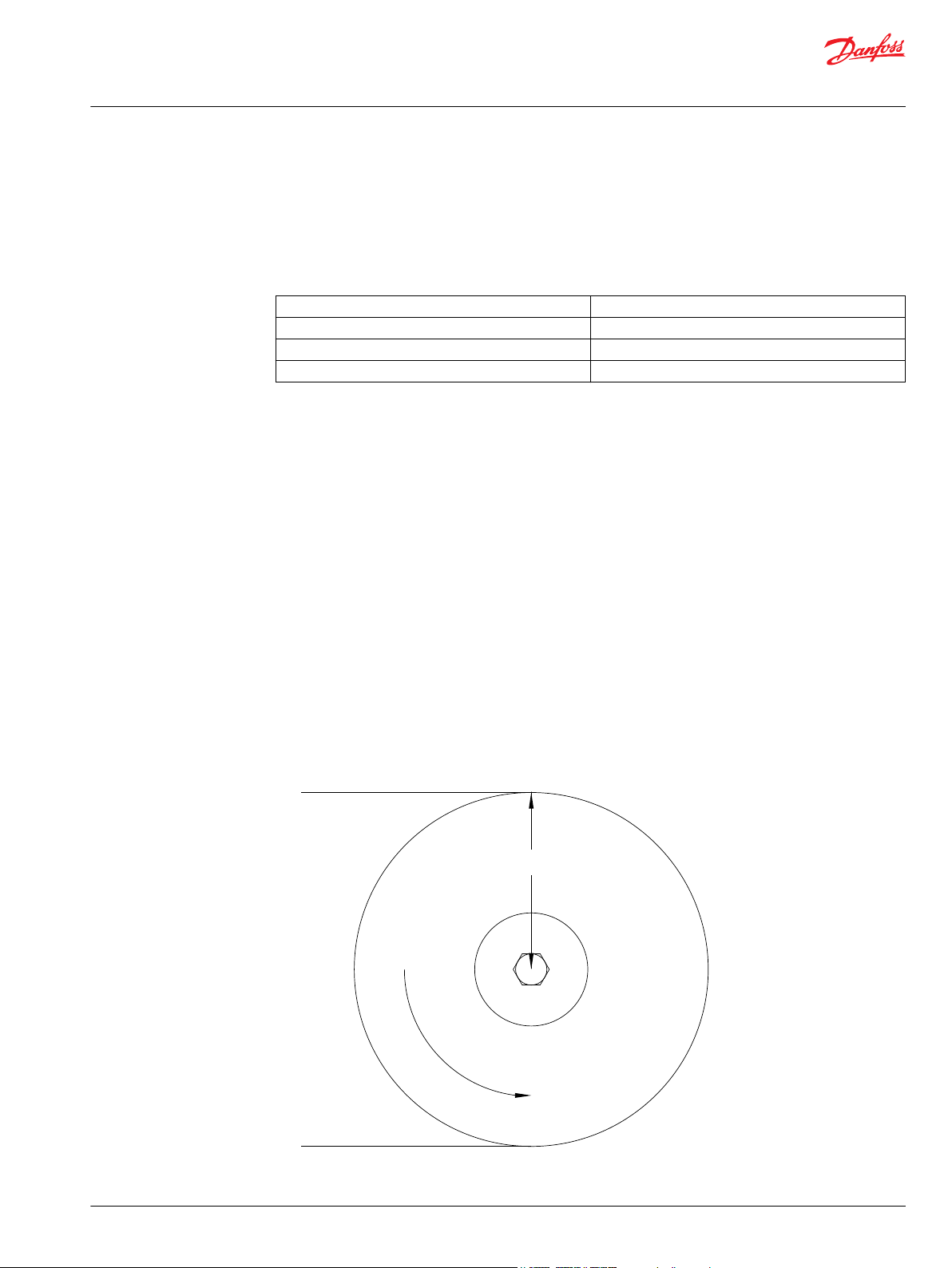

Radius 76 mm [3.00 in]

Torque

1129 Nm

[10000 lb-in]

P109321

Technical Information

Hydraulic Brakes

Technical Information

f coefficient of friction (see Coefficient of friction (f) on page 9)

W loaded vehicle weight over driven wheel (lb or N)

Example: TS = (425 x .06 x 16) / 1 = lb-in/motor = 4080 lbs

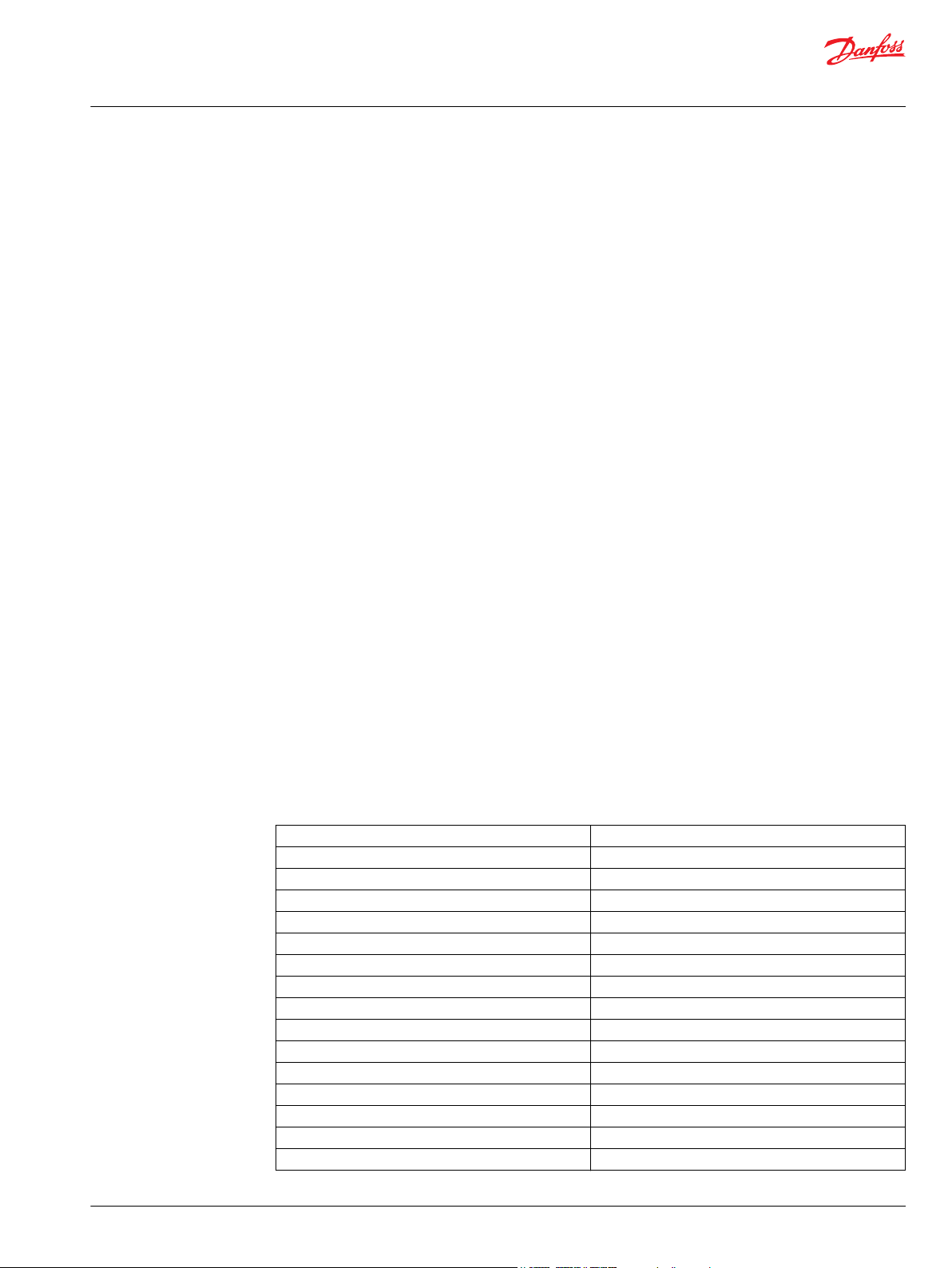

Coefficient of friction (f)

Steel on steel 0.3

Rubber tire on dirt 0.5

Rubber tire on a hard surface 0.6 - 0.8

Rubber tire on cement 0.7

To determine radial load capacity requirement of motor

When a motor used to drive a vehicle has the wheel or hub attached directly to the motor shaft, it is

critical that the radial load capabilities of the motor are sufficient to support the vehicle. After calculating

the Total Radial Load (RL) acting on the motors, the result must be compared to the bearing/shaft load

charts for the chosen motor to determine if the motor will provide acceptable load capacity and life.

RL = sqrt(W2 + (T / ri)2) lb or RL = sqrt(W2 + (T / rm)2) kg

Example: RL = sqrt(4252 + (2936 / 16)2) = 463 lbs

Once the maximum motor RPM, maximum torque requirement, and the maximum load each motor must

support have been determined, these figures may then be compared to the motor performance charts

and to the bearing load curves to choose a series and displacement to fulfill the motor requirements for

the application.

Induced Side Load

In many cases, pulleys or sprockets may be used to transmit the torque produced by the motor. Use of

these components will create a torque induced side load on the motor shaft and bearings. It is important

that this load be taken into consideration when choosing a motor with sufficient bearing and shaft

capacity for the application.

©

Danfoss | June 2019 BC00000383en-000103 | 9

Page 10

Distance

Side Load =

Side Load = 14855 Nm [3333 lbs]

Torque

Radius

P109322

Technical Information

Hydraulic Brakes

Technical Information

To determine the side load, the motor torque and pulley or sprocket radius must be known. Side load

may be calculated using the formula below. The distance from the pulley/sprocket centerline to the

mounting flange of the motor must also be determined. These two figures may then be compared to the

bearing and shaft load curve of the desired motor to determine if the side load falls within acceptable

load ranges.

Hydraulic Equations

Multiplication Factor Abbreviation Prefix

12

10

10

10

10

10

10

10

10

9

6

3

2

1

-1

-2

T tera

G giga

M mega

K kilo

h hecto

da deka

d deci

c centi

Theo. Speed (RPM) (1000 x LPM) / Displacement (cm3/rev)

(231 x GPM) / Displacement (in3/rev)

Theo. Torque (lb-in) (Bar x Disp. (cm3/rev)) / 20 pi

(PSI x Disp. (in3/rev) / 6.28

Power In (HP) (Bar x LPM) / 600

(PSI x GPM) / 1714

Power Out (HP) (Torque (Nm) x RPM) / 9543

10 | © Danfoss | June 2019 BC00000383en-000103

Page 11

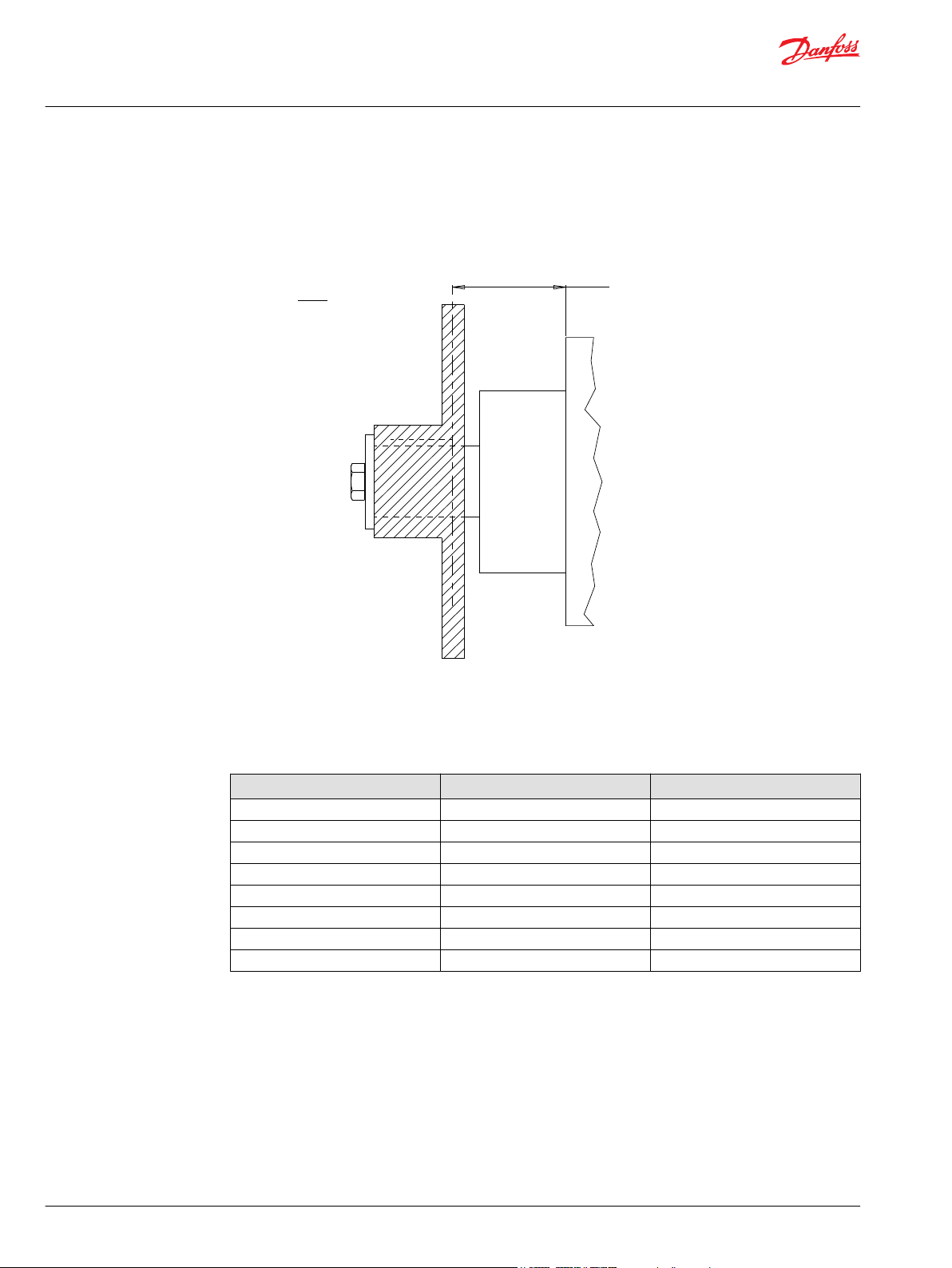

Incorrect

Correct

P109323

Technical Information

Hydraulic Brakes

Technical Information

Shaft Nut Information

(Torque (lb-in) x RPM) / 63024

The tightening torques listed with each nut should only be used as a guideline. Hubs may require higher

or lower tightening torque depending on the material. Consult the hub manufacturer to obtain

recommended tightening torque. To maximize torque transfer from the shaft to the hub, and to

minimize the potential for shaft breakage, a hub with sufficient thickness must fully engage the taper

length of the shaft.

Hub engagement

©

Danfoss | June 2019 BC00000383en-000103 | 11

Page 12

A Slotted Nut

35MM TAPERED SHAFTS

B Lock Nut

B Lock Nut

B

Lock Nut

C

Solid Nut

C

Solid Nut

C Solid Nut

M24 x 1.5 Thread

A

Slotted Nut

1” TAPERED SHAFTS

3/4-28 Thread

A Slotted Nut

1-1/4” TAPERED SHAFTS

1-20 Thread

A Slotted Nut

1-3/8” & 1-1/2” TAPERED SHAFTS

1 1/8-18 Thread

33 [1.29]

5 [.19]

6 [.24]

12 [.48]

Torque Specifications: 20 - 23 daNm [150 - 170 ft.lb.]

29 [1.13]28 [1.12]

42 [1.64]

6 [.22]

6 [.24]

15 [.59]

Torque Specifications: 32.5 daNm [240 ft.lb.]

36 [1.42]

16 [.63]

3.5 [.14]

33 [1.29]

28 [1.11]

12 [.47]

33 [1.28]

23 [.92]

24 [.95]

28 [1.10]

Torque Specifications: 24 - 27 daNm [180 - 200 ft.lb.]

Torque Specifications: 20 - 23 daNm [150 - 170 ft.lb.]

44 [1.73]

5 [.19]

6 [.25]

14 [.55]

Torque Specifications: 38 daNm [280 ft.lb.] Max.

35 [1.38]38 [1.48]

16 [.63]

4 [.16]

40 [1.57]

38 [1.48]

14 [.55]

44 [1.73]

29 [1.14]

30 [1.18]

34 [1.34]

Torque Specifications: 33 - 42 daNm [240 - 310 ft.lb.] Torque Specifications: 38 daNm [280 ft.lb.] Max.

48 [1.90]

5 [.19]

6 [.22]

15 [.61]

Torque Specifications: 41 - 54 daNm [300 - 400 ft.lb.]

44 [1.73]42 [1.66]

16 [.63]

4 [.16]

51 [2.00]

42 [1.66]

15 [.61]

48 [1.90]

35 [1.38]

36 [1.42]

44 [1.73]

Torque Specifications: 34 - 48 daNm [250 - 350 ft.lb.]

Torque Specifications: 41 - 54 daNm [300 - 400 ft.lb.]

P109324

Technical Information

Hydraulic Brakes

Technical Information

12 | © Danfoss | June 2019 BC00000383en-000103

Page 13

P109449

Technical Information

Hydraulic Brakes

BK 913 and 915 Series

Overview

With safety an increasingly important factor in the design and manufacture of equipment, it has become

necessary to add a brake to many critical machine functions. In response to that concern, Danfoss offers

BK Series brakes. Based on technology proven in Danfoss integrated motor/brakes, this spring-applied,

hydraulically released brake provides up to 1500 Nm [13,300 lb-in] of holding torque for static brake

applications.

Other features contribute to the superior operation and durability of the BK brakes. All internal

components, including roller bearings, brake disks, springs and seals were chosen for maximum

durability. To further extend the life of the unit and reduce noise, all internal components run in an oil

bath. Two brake release ports are also provided to simplify plumbing and bleeding of the brake release

circuit during installation. All of these features combine to make BK Series brakes a top choice for any

static brake application requiring up to 1500 Nm [13,300 lb-in] of holding torque.

Features / Benefits

Heavy-duty roller bearings support high shaft loads and provide long life.

•

Dual release ports allow easier bleeding of brake release cavity.

•

Oil-filled cavity immerses all components providing quiet operation and reduced wear.

•

Typical Applications

Wheel drives, positioners, conveyors, door openers, swing drives, aerial work platforms and more

Specifications

913 Series Holding Torque 1130 Nm [10,000 lb-in]

915 Series Holding Torque 1500 Nm [13,300 lb-in]

Release Pressure 28 bar [400 psi]

Maximum Release Pressure 207 bar [3,000 psi]

Release Volume 11.5 cm3 [0.7 in3]

Max. Speed 250 rpm

Max. Operating Temperature 82 °C [180 °F]

Weight 16.8 kg [37 lb]

Fluid Type Mineral based oil

©

Danfoss | June 2019 BC00000383en-000103 | 13

Page 14

Ø 178 [7.00]

90°

50 [1.95]

25 [1.00]

Ø 200 [7.88]

7/16-20 Fill Hole

Port Plug Installed

(4) Ø 13 [.52]

13 [.50]

59 [2.34]

14.2 [.558]

11.3 [.443]

101.6 [3.999]

101.5 [3.997]

(2) SAE J51 4b

7/16-20 Release Ports,

Min. Depth 11 [.45]

913 Series - 107 [4.21]

915 Series - 117 [4.61]

4-HOLE, BRAKE MOUNT, ALIGNED PORTS

K30

7/16-20 UNF

P109450

Technical Information

Hydraulic Brakes

BK 913 and 915 Series

BK 913 and 915 Series Housings

Dimensions shown are without paint. Paint thickness can be up to 0.13 [.005].

4-Hole, Brake Mount, Aligned Ports

BK 913 and 915 Series Technical Information

Allowable Shaft Load / Bearing Curve

The bearing curve represents allowable bearing loads based on ISO 281 bearing capacity for an L10 life of

2,000 hours at 100 rpm. Radial loads for speeds other than 100 rpm may be calculated using the Bearing

Load Multiplication Factor Table on page 6.

14 | © Danfoss | June 2019 BC00000383en-000103

Page 15

3000

9000

913 SERIES BRAKE - SIDE LOAD CHART

7000

8000

6000

5000

4000

lb

2000

1000

1000

4000

3000

3500

2500

2000

1500

daN

500

8 in90 761 53

200 mm2251751500 25 12575

2 4

50 100

445 daN [1000 lb]

445 daN [1000 lb]

BEARING

SHAFT

P109451

3000

9000

915 SERIES BRAKE - SIDE LOAD CHART

7000

8000

6000

5000

4000

lb

2000

1000

1000

4000

3000

3500

2500

2000

1500

daN

500

8 in90 761 53

200 mm2251751500 25 12575

2 4

50 100

445 daN [1000 lb]

445 daN [1000 lb]

BEARING

SHAFT

P109452

Technical Information

Hydraulic Brakes

BK 913 and 915 Series

BK 913 Series Brake - Side Load Chart

BK 915 Series Brake - Side Load Chart

©

Danfoss | June 2019 BC00000383en-000103 | 15

Page 16

913 Series - 176 [6.92]

915 Series - 185 [7.29]

4 [.15]

8.0 [.314]

8.0 [.313]

45 [1.78]19 [.75]

Ø4 [.17]

5 [.20]

38.1 [1.499]

38.0 [1.498]

1:8 Taper

31.8 [1.250]

30.5 [1.200]

Max. Torque: 2700 Nm [19900 lb-in]

31

1-1/2” Tapered

A slotted hex nut is standard on this

shaft.

P109453

1 2 3 4 5 6 7 8

Standard

Black

No Paint

Standard

Solid Hex Nut

None

4-Hole, Brake Mount, Aligned Ports, 7/16-20 UNF

1-1/2” Tapered

4. SELECT A SHAFT OPTION

31

None

8. SELECT A MISCELLANEOUS OPTION

AA

000

1. CHOOSE SERIES DESIGNATION

2. SELECT A HOLDING TORQUE OPTION

3. SELECT A MOUNT & PORT OPTION

5. SELECT A PAINT OPTION

A

Z

6. SELECT A VALVE CAVITY / CARTRIDGE OPTION

7. SELECT AN ADD-ON OPTION

A

C

A

K30

Hydraulic Brake

Hydraulic Brake

913

915

P109454

Technical Information

Hydraulic Brakes

BK 913 and 915 Series

BK 913 and 915 Series Shafts

BK 913 and 915 Series Ordering Information

16 | © Danfoss | June 2019 BC00000383en-000103

Page 17

P109449

Technical Information

Hydraulic Brakes

AB 920 Series

Overview

The AB series is a multi-wet-disc-brake that provides superior performance; all internal components are

fully immersed in pre-filled fluid and are environmentally sealed to prevent contamination and corrosion

while providing brake durability and maintaining proper holding capacity. Compact design and large

holding torque along with a lower release pressure and lower free turn torque saves your space and

reduces cost. Two brake release ports provide simple plumbing and the bleeding of the brake release

circuit during installation.

Features / Benefits

Compact design.

•

Ball bearings support higher shaft loads and provide longer life shaft seal life.

•

Dual release ports allow easier bleeding of brake release cavity.

•

Oil-filled cavity immerses all components providing quiet operation.

•

Large holding torque with lower release pressure and free turn torque.

•

Typical Applications

Wheel drives, positioners, conveyors, door openers, swing drives, aerial work platforms and more

Specifications

Holding Torque 475 Nm [4,200 lb-in]

Release Pressure 20 bar [290 psi]

Maximum Release Pressure 207 bar [3,000 psi]

Release Volume 9.0 cm3 [0.55 in3]

Max. Speed 250 rpm

Max. Operating Temperature 82 °C [180 °F]

Weight 9.25 kg [20.4 lb]

Fluid Type Mineral based oil

AB 920 Series Housings

Dimensions shown are without paint. Paint thickness can be up to 0.13 [.005].

©

Danfoss | June 2019 BC00000383en-000103 | 17

Page 18

Ø149.35 [5.880]

Ø149.10 [5.870]

30°

30°

47 [1.85] Max.

Ø178 [6.99]

Ø82 [3.23]

Max.

Ø110 [4.33]

Max.

Ø95.28 [3.750]

Ø95.12 [3.746]

(2) 7/16-20 UNF Release Port,

Min. Depth 12 [.45]

(2) 1/8-28 Fill Port

82.41 [3.244]

81.39 [3.204]

30° 30°

30°

Ø13.7 [.539]

Ø13.5 [.532]

4-HOLE, BRAKE MOUNT

K30

7/16-20 UNF

P109456

1200

2800

920 SERIES BRAKE - SIDE LOAD CHART

2400

2000

1600

lb

800

400

400

1200

1000

800

600

daN

200

8 in90 761 53

200 mm2251751500 25 12575

2 4

50 100

111 daN [250 lb]

111 daN [250 lb]

BEARING

P109457

Technical Information

Hydraulic Brakes

AB 920 Series

4-Hole, Brake Mount

AB 920 Series Technical Information

Allowable Shaft Load / Bearing Curve

The bearing curve represents allowable bearing loads based on ISO 281 bearing capacity for an L10 life of

2,000 hours at 100 rpm. Radial loads for speeds other than 100 rpm may be calculated using the Bearing

Load Multiplication Factor Table on page 6.

AB 920 Series Brake - Side Load Chart

18 | © Danfoss | June 2019 BC00000383en-000103

Page 19

3/4-16 UNF Slotted Hex Nut

6.35 [.250]

6.30 [.248]

2.65 [.108]

2.63 [.100]

Ø25.425 [1.001]

Ø25.375 [.999]

90.47 [3.562]

87.43 [3.442]

Ø3.96 [.156]

35.18 [1.384]

34.68 [1.366]

35.15 [1.383]

34.65 [1.365]

19 [.75]

4.7 [.185]

19 [.75]

4.7 [.185]

31.75 [1.250]

31.70 [1.248]

Taper 1:8

31.70 [1.248]

31.38 [1.235]

88.64 [3.489]

85.59 [3.369]

31.70 [1.248]

31.38 [1.235]

7.95 [.313]

7.93 [.312]

3.30 [.130]

3.09 [.121]

1-20 UNEF Slotted Hex Nut

Ø4.42 [.174]

Taper 1:8

13 1” Tapered 22 1-1/4” Tapered

P109458

1 2 3 4 5 6 7 8

475 Nm [4200 lb-in]

Black

Black, Unpainted Mounting Surface

Standard

None

4-Hole, Brake Mount, 7/16-20 UNF

1” Tapered

1-1/4” Tapered

4. SELECT A SHAFT OPTION

13

22

1.50 [.060] Pilot Height (Standard)

3.18 [.125] Pilot Height

6.35 [.250] Pilot Height

Single Throttle Valve With Standard Pilot Height

Two Throttle Valves With Standard Pilot Height

8. SELECT A MISCELLANEOUS OPTION

AA

AY

AZ

TC

TD

000

1. CHOOSE SERIES DESIGNATION

2. SELECT A HOLDING TORQUE OPTION

3. SELECT A MOUNT & PORT OPTION

5. SELECT A PAINT OPTION

A

B

6. SELECT A VALVE CAVITY / CARTRIDGE OPTION

7. SELECT AN ADD-ON OPTION

A

A

K30

Hydraulic Brake

920

P109459

Technical Information

Hydraulic Brakes

AB 920 Series

AB 920 Series Shafts

AB 920 Series Ordering Information

©

Danfoss | June 2019 BC00000383en-000103 | 19

Page 20

P109460

Technical Information

Hydraulic Brakes

FB 925 Series

Overview

The FB series is a multi-wet-disc-brake that provides superior performance; all internal components are

fully im- mersed in pre-filled fluid and are environmentally sealed to prevent contamination and

corrosion while providing brake durability and maintaining proper holding capacity. Compact design and

large holding torque along with a lower release pressure and lower free turn torque saves your space and

reduces cost.

Features / Benefits

Compact design.

•

Heavy-duty roller bearings support higher shaft loads and provide longer life shaft seal life.

•

Oil-filled cavity immerses all components providing quiet operation.

•

Large holding torque with lower release pressure and free turn torque.

•

Typical Applications

Wheel drives, positioners, conveyors, door openers, swing drives, aerial work platforms and more

Specifications

Release Pressure 20 bar [290 psi]

Maximum Release Pressure 207 bar [3,000 psi]

Release Volume 9.0 cm3 [0.55 in3]

Max. Speed 250 rpm

Max. Operating Temperature 82 °C [180 °F]

Weight 10.9 kg [24 lb]

Fluid Type Mineral based oil

FB 925 Series Housings

Dimensions shown are without paint. Paint thickness can be up to 0.13 [.005].

20 | © Danfoss | June 2019 BC00000383en-000103

Page 21

Ø159 [6.26]

10.4 [.409]

8.6 [.339]

Ø186 [7.32] Max.

Ø110 [4.33]

Max.

47 [1.85] Max.

Ø114.25 [4.498]

Ø114.20 [4.496]

1/8-28 Fill Port

85.1 [3.350]

84.7 [3.334]

15°

45°

Ø13.8 [.540]

Ø13.2 [.520]

7/16-20 UNF Release Port,

Min. Depth 11.5 [.45]

87.3 [3.44]

86.7 [3.42]

4-HOLE, BRAKE MOUNT

K30

7/16-20 UNF

P109461

925 SERIES BRAKE - SIDE LOAD CHART

lb daN

8 in90 761 53

200 mm2251751500 25 12575

2 4

50 100

5000

9000

8000

7000

6000

3000

4000

2000

1000

1000

4000

3500

2500

3000

2000

1500

500

111 daN [250 lb]

111 daN [250 lb]

BEARING

P109462

Technical Information

Hydraulic Brakes

FB 925 Series

4-Hole, Brake Mount

FB 925 Series Technical Information

Allowable Shaft Load / Bearing Curve

The bearing curve represents allowable bearing loads based on ISO 281 bearing capacity for an L10 life of

2,000 hours at 100 rpm. Radial loads for speeds other than 100 rpm may be calculated using the Bearing

Load Multiplication Factor Table on page 6.

FB 925 Series Brake - Side Load Chart

©

Danfoss | June 2019 BC00000383en-000103 | 21

Page 22

7.95 [.313]

7.93 [.312]

3.30 [.130]

3.09 [.122]

Ø38.10 [1.500]

Ø38.05 [1.498]

150.50 [5.925]

148.78 [5.857]

Ø4.4 [.173]

42.25 [1.663]

41.75 [1.644]

36.25 [1.427]

35.75 [1.408]

5.5 [.217]

21 [.83]

5.5 [.217]

32.00 [1.260]

31.95 [1.258]

Taper 1:8

31.70 [1.248]

31.38 [1.235]

144.50 [5.689]

142.75 [5.621]

31.70 [1.248]

31.38 [1.235]

7.95 [.313]

7.93 [.312]

3.30 [.130]

3.09 [.122]

1-20 UNEF Slotted Hex Nut

Ø4.4 [.173]

Taper 1:8

21 [.83]

1-1/8-18 UNEF Slotted Hex Nut

31 1-1/2” Tapered D7 32mm Tapered

P109463

1 2 3 4 5 6 7 8

350 Nm [3100 lb-in]

550 Nm [4900 lb-in]

650 Nm [5750 lb-in]

Black

Black, Unpainted Mounting Surface

Standard

None

4-Hole, Brake Mount, 7/16-20 UNF

1-1/2” Tapered

32mm Tapered

4. SELECT A SHAFT OPTION

31

D7

None

8. SELECT A MISCELLANEOUS OPTION

AA

350

550

650

1. CHOOSE SERIES DESIGNATION

2. SELECT A HOLDING TORQUE OPTION

3. SELECT A MOUNT & PORT OPTION

5. SELECT A PAINT OPTION

A

B

6. SELECT A VALVE CAVITY / CARTRIDGE OPTION

7. SELECT AN ADD-ON OPTION

A

A

K30

Hydraulic Brake

925

P109464

Technical Information

Hydraulic Brakes

FB 925 Series

FB 925 Series Shafts

FB 925 Series Ordering Information

22 | © Danfoss | June 2019 BC00000383en-000103

Page 23

P109465

Technical Information

Hydraulic Brakes

SB 930 Series

Overview

The SB Series is a multiple-wet-disc-brake that provides superior performance in an extremely compact

package. Unlike conventional brakes offered today, the SB brake is performance-matched to fit the full

range of small-frame SAE A mount motors available today. With an overall diameter of less than 137mm

[5.4 in] the SB has a holding capacity in excess of 620 Nm [5,500 lb-in] and is easily mated to a variety of

global industry standard motor mounting and shaft options. In addition, the SB Series can be used as a

stand-alone brake solution without an input drive motor. This option further opens design flexibility to

meet a wider variety of application needs.

Features / Benefits

All wear components are fully immersed in fluid (wet multi-disc design)

•

Performance-matched to fit small-frame motors with SAE A mounts

•

Release pressure independent of motor pressure

•

Brake directly coupled to the output shaft

•

Wide-variety of input and output shaft options

•

Environmentally sealed / factory prefilled with oil

•

Proven, Quiet, Trouble-Free Operation

•

Compact, Cost-Effective Package

•

Simplifies System Circuits - Eliminates Need for Pressure- Reducing Valve

•

Series Operating Capability

•

Reliable Performance - Fewer Critical Components

•

Design Flexibility

•

Global Interchangeability

•

Suited for “Stand Alone” Brake Applications

•

Ease of Installation

•

Typical Applications

Wheel drives, positioners, conveyors, door openers, swing drives, aerial work platforms and more

©

Danfoss | June 2019 BC00000383en-000103 | 23

Page 24

Cast Dimensions are ± 0.8 mm [.030 in.] *Fill and drain ports for filling and draining the brake only.

No system connections are to be made to the fill and drain ports. These ports are not suitable for use in a cooling loop.

13.7 [.54]

71.8 [2.83]

95.3 [3.75]

17°

106.4 [4.19]

Brake Release Port

130.8 [5.15]

129.3 [5.09]

82.6 [3.250]

82.5 [3.248]

6 [.24]

115.1 [4.53] Max.

82.7 [3.255]

82.6 [3.253]

130.8 [5.15]

129.3 [5.09]

(2) M12 x 1.75

Mounting Holes

(2) M12 x 1.75

Mounting Holes

22.6 [.89]

9.5 [.374]

*(4) Fill and Drain Ports

A10 - 42.3 [1.67]

A11 - 41.6 [1.64]

13.7 [.54]

71.8 [2.83]

130.1 [5.12]

17°

106.4 [4.19]

Brake Release Port

82.6 [3.250]

82.5 [3.248]

6 [.24]

115.1 [4.53] Max.

82.7 [3.255]

82.6 [3.253]

130.8 [5.15]

129.3 [5.09]

22.6 [.89]

9.5 [.374]

*(4) Fill and Drain Ports

A30 - 42.3 [1.67]

A31 - 41.6 [1.64]

A11 G 1/4

2-HOLE, SAE A BRAKE MOUNT

A10

7/16-20 UNF

A31

G 1/4

A30

7/16-20 UNF

4-HOLE, SAE A BRAKE MOUNT

P109466

Technical Information

Hydraulic Brakes

SB 930 Series

SB 930 Series Housings

Specifications

Code 225 315 415 520 620

Holding Torque 225 Nm [2,000 lb-

in]

Max. Release

Pressure

Full Release

207 bar [3,000

psi]

23 bar [330 psi] 23 bar [330 psi] 23 bar [330 psi] 36 bar [520 psi] 36 bar [520 psi]

315 Nm [2,800 lbin]

207 bar [3,000

psi]

415 Nm [3,700 lbin]

207 bar [3,000

psi]

520 Nm [4,600 lbin]

207 bar [3,000

psi]

620 Nm [5,500 lbin]

207 bar [3,000

psi]

Pressure

Release Volume 8.3 cm3 [.51 in3] 8.3 cm3 [.51 in3] 8.3 cm3 [.51 in3] 8.3 cm3 [.51 in3] 8.3 cm3 [.51 in3]

Max. Speed 250 rpm 250 rpm 250 rpm 250 rpm 250 rpm

Unit Weight 8 kg [17.6 lb] 8 kg [17.6 lb] 8 kg [17.6 lb] 8 kg [17.6 lb] 8 kg [17.6 lb]

Dimensions shown are without paint. Paint thickness can be up to 0.13 [.005].

24 | © Danfoss | June 2019 BC00000383en-000103

Page 25

12 [.46]

32.6 [1.285]

31.4 [1.235]

10.0 [.394]

9.9 [.392]

25.4 [.999]

25.4 [.998]

20 [.78] Min.

5/16-18 UNC,

Min. Depth 18 [.70]

34.8 [1.372]

34.5 [1.359]

Ø32.0 [1.260]

Ø31.9 [1.259]

Ø25.3 [.996]

Ø25.2 [.992]

43 [1.68]

52 [2.03]

52 [2.03]

43 [1.68]

67 [2.62]

M8 x 1.25, Min. Depth 18 [.70]

56 [2.22]

6B Spline

SAE J499 Standard

6.4 [.251]

6.4 [.250]

28.2 [1.110]

28.0 [1.101]

5 [.18]

25.9 [1.02]

24.6 [.970]

5/16-18 UNC,

Min. Depth 18 [.70]

5 [.21]

30.9 [1.218]

29.7 [1.168]

8.0 [.315]

8.0 [.313]

28.0 [1.102]

27.7 [1.091]

Ø25.0 [.984]

Ø25.0 [.983]

52 [2.03]

M8 x 1.25, Min. Depth 18 [.70]

43 [1.68]

58.6 [2.3]

6.3 [2.5]

Ø 25.4 [1.00]

58.6 [2.3]

28.4 [1.12]

Ø 25.1 [.99]

8.1 [.319]

26.6 [1.047]

10.1 [.398]

Mounting

Surface

26.6 [1.047]

10.1 [.398]

Mounting

Surface

Ø29.9 [1.177]

Ø29.9 [1.177]

ZZ 6B Spline, 6B Input

ZW

1” Straight, 6B Input

ZX

32mm Straight, 25mm Input

ZU

32mm Straight, 6B Input

ZY 25mm Straight, 25mm Input ZT 25mm Straight, 6B Input

6B INPUT DIMENSIONS 25MM INPUT DIMENSIONS

P109468

Technical Information

Hydraulic Brakes

SB 930 Series

SB 930 Series Shafts

Cast Dimensions are ± 0.8 mm [.030 in.] *Fill and drain ports for filling and draining the brake only.

No system connections are to be made to the fill and drain ports. These ports are not suitable for use in a

cooling loop.

©

Danfoss | June 2019 BC00000383en-000103 | 25

Page 26

3000

8000

930 SERIES BRAKE - SIDE LOAD CHART

7000

6000

5000

4000

lb

2000

1000

1000

3500

3000

2500

2000

1500

daN

500

2 in3-4 10-3 -1-2

50 mm75-100 250-75 -25-50

145 daN [320 lb]

145 daN [320 lb]

BEARING

P109467

Technical Information

Hydraulic Brakes

SB 930 Series

SB 930 Series Technical Information

Allowable Shaft Load / Bearing Curve

The bearing curve represents allowable bearing loads based on ISO 281 bearing capacity for an L10 life of

2,000 hours at 100 rpm. Radial loads for speeds other than 100 rpm may be calculated using the Bearing

Load Multiplication Factor Table on page 6.

SB 930 Series Brake - Side Load Chart

SB 930 Series Installation Information

The SB Brake is a wet multi-disc type static brake and is shipped factory filled with fluid. The fluid used is a

standard SAE 20 hydraulic fluid. A hydraulic motor can be mounted to the SB Brake to provide a complete

motor/brake package. A shipping cover protects and seals the input interface until it is ready for

installation. The shipping cover is removed by removing the two cap screws and following the motor

installation procedure below. Mounting pilot surfaces need to be free of paint or other substances for

proper assembly and leak-free performance. Standard SB brakes are sold unpainted with an easy to

remove shipping cover. Stand-alone SB brakes come standard painted and factory installed cover.

The input interface must be sealed to keep the brake environmentally protected and bearings fully

26 | © Danfoss | June 2019 BC00000383en-000103

immersed in fluid for proper lubrication and long life. Standard SAE 20 hydraulic oil is used in the brake

cavity as well as typically used in hydraulic systems.

An internal seal is provided to seal long-pilot motors. When a short-pilot motor is used, an o-ring face seal

is needed to properly seal the motor/brake interface. Two mounting bolts (M12 x 1.75 thread) and an oring seal with mounting instructions are included in the brake installation kit 930999001 and shipped

with each SB Brake.

Page 27

2.3 [.090]

2.1 [.084]

2.54 [.100]

Face Seal

Factory Installed

Pilot Seal

To remove cover, pierce and

pry with a sharp awl.

When using the 930 Series as a

Stand-Alone unit, this cover is

not to be removed. It retains oil

needed to lubricate the bearings.

930 SERIES BRAKE INSTALLATION

The factory installed pilot seal may be left in place. However, this seal will not provide proper sealing for motors with

short pilot mounts, therefore, the face seal contained in the mounting kit must be used.

P109470

1 2 3 4 5 6 7 8

225 Nm [2000 lb-in]

315 Nm [2800 lb-in]

415 Nm [3700 lb-in]

Hydraulic Brake

520 Nm [4600 lb-in]

620 Nm [5500 lb-in]

2-Hole, SAE A Brake Mount, 7/16-20 UNF

2-Hole, SAE A Brake Mount, G 1/4

4-Hole, SAE A Brake Mount, 7/16-20 UNF

4-Hole, SAE A Brake Mount, G 1/4

25mm Straight, 6B Input

32mm Straight, 6B Input

1” Straight, 6B Input

Black

Black, Unpainted Mounting Surface

No Paint

Standard

Standard

None

32mm Straight, 25mm Input

25mm Straight, 25mm Input

6B Spline, 6B Input

P109469

930

1. CHOOSE SERIES DESIGNATION

2. SELECT A HOLDING TORQUE

225

315

415

520

620

3. SELECT A MOUNT & PORT OPTION

A10

A11

A30

A31

4. SELECT A SHAFT OPTION

ZT

ZU

ZW

ZX

ZY

ZZ

5. SELECT A PAINT OPTION

A

B

Z

6. SELECT A VALVE CAVITY / CARTRIDGE OPTION

7. SELECT AN ADD-ON OPTION

A

8. SELECT A MISCELLANEOUS OPTION

AA

A

Technical Information

Hydraulic Brakes

SB 930 Series

930 Series Brake Installation

SB 930 Series Ordering Information

The factory installed pilot seal may be left in place. However, this seal will not provide proper sealing for

motors with short pilot mounts, therefore, the face seal contained in the mounting kit must be used.

©

Danfoss | June 2019 BC00000383en-000103 | 27

Page 28

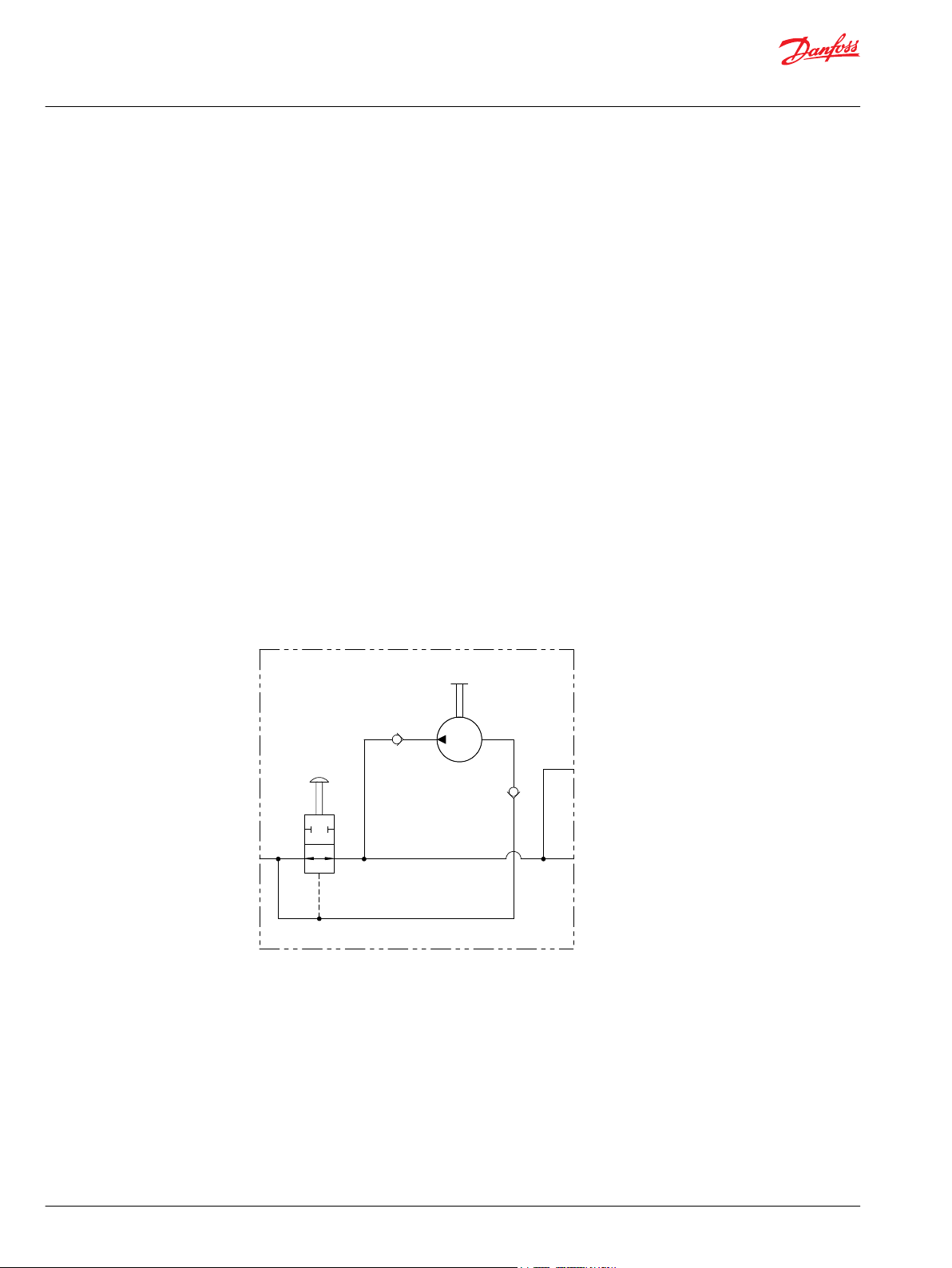

B1

RIGHT BRAKE

LEFT BRAKE

P109471

Technical Information

Hydraulic Brakes

RP 960 Series

Overview

The 960 Series is a device designed to replace existing, costly and complicated hydraulic brake release

hand pumps that are present on various types of mobile equipment. It is typically used to release various

types of spring applied/ hydraulically released brakes. Depending on the brake, typically 1-5 pumps of

the 960 will release the brake. This enables equipment to be moved to a service area or a recharge/refuel

station.

To operate, the equipment operator must depress the valve rod until it is firmly seated. The operator

must then pump the pump rod until the brakes are released. If the hydraulic circuit is pressurized at any

time during or after the 960 has released the brakes, the valve rod will automatically pop out and the

mobile equipment will revert to its normal operation. This serves as a built in safety feature that ensures

the equipment’s normal braking operation is never accidentally disabled.

The 960 is a simplified product compared to competitive brands that are currently available. In addition,

the product is a cost competitve alterative that offers superior performance and design flexibility.

Specifications

Typical output flow 1cm3 [.06 in3] - 2cm3 [.12 in3] per stroke depending upon oil viscosity, speed of

•

stroke, and pressure.

Maximum working pressure of 276 bar [4000 psi].

•

Schematic

28 | © Danfoss | June 2019 BC00000383en-000103

Page 29

45 [1.78]

26 [1.04]

Stroke

35 [1.38]

76 [3.00]

(2) 3/8-16 UNC

Through Mounting Holes

28 [1.10]

24 [.95]

99 [3.90]

25 [1.00]

22 [.85]

Pump Rod

Valve Rod

9 [.36]

9 [.27]

9 [.38]

14 [.55]

41 [1.62]

ORDER CODES 960020A10AAAA 960020A12AAAA960020A11AAAA

The 960020A10AAAA has 7/16-20 UNF Ports. The 960020A11AAAA has #4 JIC fittings pre-installed. The 960020A12AAAA has G 1/4 Ports.

P109472

Technical Information

Hydraulic Brakes

RP 960 Series

RP 960 Series Ordering Information

©

Danfoss | June 2019 BC00000383en-000103 | 29

Page 30

Technical Information

Hydraulic Brakes

30 | © Danfoss | June 2019 BC00000383en-000103

Page 31

Technical Information

Hydraulic Brakes

©

Danfoss | June 2019 BC00000383en-000103 | 31

Page 32

Technical Information

Hydraulic Brakes

32 | © Danfoss | June 2019 BC00000383en-000103

Page 33

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | June 2019 BC00000383en-000103

Loading...

Loading...