Page 1

Hybridization

– perfectly balancing supply

and demand to meet

carbon goals

POWER

Exactly when

you need it

www.danfossdrives.com

Page 2

Clean energy

revolution transforms

supply comprises a mix of traditional

and renewable power sources, often

including battery storage.

The benefits of hybridization, in this

instance, are fuel savings, performance

improvements and reduced emissions.

performance

Decarbonization is under increasingly urgent global focus as climate change research

and experience increasingly impact societies around the globe. As a result, we develop

the means and measures required to guide the international community towards cleaner

energy sources such as the international Sustainable Development Goals, the Paris

agreement, and International Maritime Organization regulations

The world is steadily, and quite quickly, diversifying its primary sources of energy. As we

transition from fossil fuels such as oil and coal, through natural gases and nuclear power

and further toward solar, wind and hydro, there’s an increasing need to overcome the gaps

produced when the energy demand exceeds energy supply - or when energy supply

exceeds demand.

Energy providers attempt to meet the

ever-changing supply and demand

requirements as closely as possible.

However, external factors, such as

the weather (in relation to renewable

sources of power) and the needs of

industrial customers (with inherent

changes in peak demands), make the

balance of energy supply and demand

quite challenging. This is where

hybridization comes into play.

Hybridization at a glance

A simple and broad

definition of

hybridization is any

system with two

or more sources of

energy acting together to accomplish

a task. A hybrid power supply system

could include a combination of

multiple energy sources, for example

solar power, batteries, and LNG. One

of the most commonly recognized

forms of hybridization today is the

distributed grid, where the mains power

In the world according to Danfoss

Drives, the definition of hybridization

can be summed up by introducing a

means of energy storage into a system.

Hybrid solutions are implemented

primarily for at least one of these

reasons:

Opportunity to sell more energy from

renewable sources to the grid

Reduce total cost of operation (TCO)

over the lifetime of the system by:

- avoiding over-dimensioning a system

- deferring investment in infrastructure

In over-supply situations, the hybrid

system can store the surplus energy.

When demand levels are high,

the stored energy can then be used

again to provide an additional source

of energy

Reduce operating expenses (OPEX)

- improve system efficiency

- increase system availability

Hybrid systems can increase system

efficiency and avoid power outages

caused by grid instability;

Decrease downtime of the system

by increasing robustness in the

case of power-quality issues.

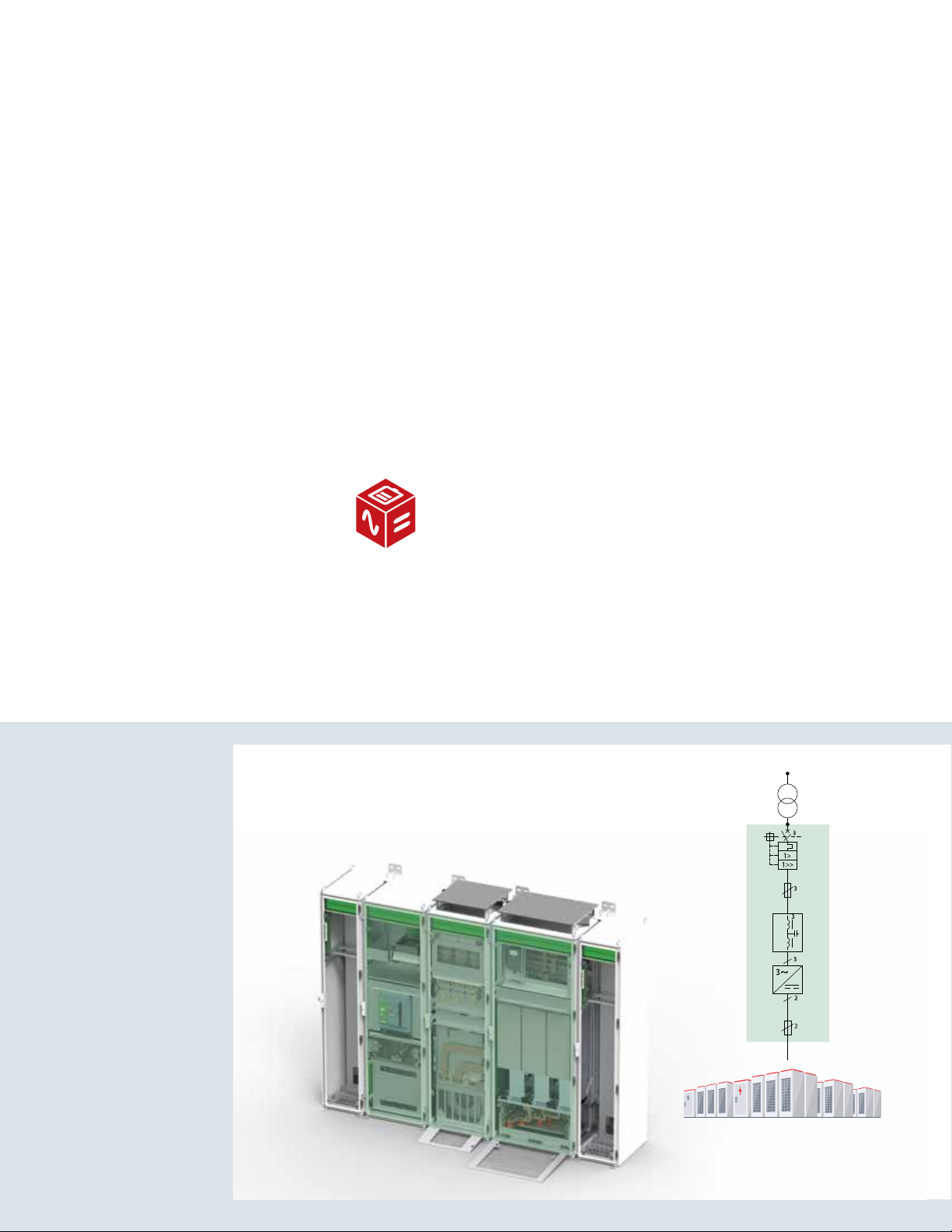

Hybrid

configurations

The illustration

shows how some of

these systems can

be arranged. The size

and layout of each

hybrid system varies

greatly depending

on the application.

Multiple sources

can supply energy

to the application,

for example mains

supply, local

renewable energy

source, and energy

storage in the form

of batteries, super

caps or other form

of energy storage.

2

Energy storage directly connected to the AC grid using

a grid converter

This reduces the component count and size of the system and improves efficiency.

Page 3

Danfoss Drives products for hybridization can

be utilized in many applications

Hybrid lifts efficiency ambitions

Energy storage is a prerequisite for

integrating renewable energy into

power generation. However, Danfoss is

widening the scope of energy storage

and developing solutions that also

focus on the optimization of energy

consumption. By equipping residential

and industrial consumers, as well as

renewable energy sources with

energy storage systems, it is possible to

significantly improve power quality and

upgrade performance and overall

efficiency.

Key benefits of energy

storage

Energy storage provides greater stability

in power production systems by

providing peak shaving to the incoming

power, time shifting for production and

back-up power in emergency situations.

LVDC

Feeder Station

LVDC

Maximum Power

Point Tracking

LVDC

Substation

Battery

Management

LVDC

Substation

Substation

LVDC

Electric Vehicle

Charging

LVDC

Substation

Challenge Benefit

Integration of renewable energy sources • Energy production forecasting

Grid stability – ancillary services • Frequency regulation/inertia emulation

µGrids • Peak power compensation on a substation-level

Efficiency • Energy production optimization in co-operation

Ecology • Clean energy in harbors

Availability of electrical power • Uninterrupted power supply to, for example,

Land construction and mining • Local energy production, typically diesel gensets,

• Peak shaving

• Time shifting of production

• Spinning reserves

• Overload ability/boosting

• Fast starting/reacting

• Back-up power in disturbance situations

with diesel and LNG generators

• Consumption optimization of loads in marine

environment

• Avoid transmission losses

• Time shifting, integration of renewable power supplies

telecommunications, airports and hospitals

operation optimization with batteries

• Machine hybridization

DC/DC converter connected between the DC link and the energy storage

This brings the load power/energy support close to the consumption, provides different storage

voltage/technology adaptations, increases expandability and enables the battery stack to be replaced

as needed.

M

3

Page 4

Peak shaving

Peak shaving involves optimizing the energy flow between the incoming supply and local storage to meet spikes in

demand. Excess energy can be stored when demand and costs are low.

Time shifting

Time shifting involves storing energy during times when energy costs from the grid are low, and supplying energy from

the storage medium when energy costs from the grid are high

Back-up power

Energy storage can be used to provide back-up power during outages maintaining the ability to operate for a period of

time.

Hybrid system utilization is expected to

continue to increase significantly across

a wide cross section of land- and seabased industry and commercial sectors,

especially due to the reduction of battery

costs and the drive to decarbonization.

As well as these financial incentives,

intensifying regulation to enforce

decarbonization means hybrid solutions

are more relevant today than ever before.

Energy storage in wind and

solar applications

Traditional energy production with

ancillary services

Grid support

Marine and Offshore industry

Harbors

Machinery-level energy storage

Land construction and mining

Remote locations

Read more about sustainable power

networks here.

Features and benefits of the Danfoss hybrid solutions

Feature Benefit

One-stop power conversion shop Reduce procurement costs – Air- and liquid-cooled

drives, AFE, NFE, DC/DC, Grid Converter, DC Modules

and components are available from one source

Wide power range Reduce variants – solutions are available for applications

in a kW to MW range

Modular solution Based on the VACON® NXP platform power modules,

the DC bus system can be easily configured

Wide voltage range Increase flexibility – Ability to integrate a wide variety

of common battery bank voltages using a DC/DC

converter

Flexibility Easy to upgrade – The simple-to-extend VACON® NXP

platform provides great system flexibility with a low

additional investment

Scalability Solutions can be scaled up to meet future energy

requirements in terms of new energy sources, additional

storage or to meet increasing demand

Serviceability Lower investments – Utilizing the same VACON® NXP

hardware configurations, service teams require little to

no additional training

Industry and application knowledge Made to last – Liquid- and air-cooled solutions based

on in-depth application knowledge for the most

demanding industries

Open approach Faster Go-To-Market – Wide range of applications made

available as foundation for building tailored solutions

Partnership Stronger together – System integrators collaborate with

a vendor who has a vested interest in their success

DKDD.PFM.406.A2.22 © Copyright Danfoss Drives | 2019.11

Loading...

Loading...