Page 1

Application guidelines

Danfoss scrolls, H-Series

Residential and light commercial

R22, R407C, R410A; 50 - 60 Hz

http://cc.danfoss.com

Page 2

Page 3

Contents

GENERAL INFORMATION ........................ 4

PRODUCT INFORMATION ......................... 5

Features ..................................................... 5

Compressor model designation .............. 6

Nomenclature ........................................................................ 6

Technical specifications ........................... 7

50-60 Hz data ......................................................................... 7

Dimensions ............................................. 10

HRM025-032-034-038-040-042 / HRP025-034-038040-042 / HRH029-031-032-034-036-038 / HRM-045-

047 / HRP-045-047 / HRH039-040.................................10

HRM048-051-054-058-060 / HLM068-072-075-078081 / HRP048-051-054-058-060 / HLP068-072-075078-081 / HRH041-044-049-051-054-056 / HLH061-

068 / HLJ072-075-083 .......................................................11

HCM/HCP 094-109-120 ....................................................12

HCJ091-106-121 ..................................................................13

Electrical data, connections and wiring 15

Motor voltage ......................................................................15

Wiring connections ............................................................15

Three phase electrical characteristics .........................16

Single phase electrical characteristics ........................18

IP rating ..................................................................................20

LRA (Locked Rotor Amp) ..................................................20

MCC (Maximum Continuous Current) .........................20

Max Oper. A (Max operating current) ..........................20

Winding resistance.............................................................20

Motor protection ................................................................20

Phase sequence and reverse rotation protection ...20

Electrical connections .......................................................21

Nominal capacitor value and relays .............................21

Approvals and certifications ..................22

Approvals and certificates ...............................................22

Pressure equipment directive 2014/68/EU ...............22

Low voltage directive 2014/35/EU ...............................22

Machines directive 2006/42/EC ....................................22

Internal free volume ..........................................................22

Operating conditions ............................. 23

Refrigerant and lubricants...............................................23

Manage superheat..................................32

Requirement ........................................................................32

System evaluation ..............................................................32

Test, criteria and solutions ...............................................33

Manage off cycle migration ................... 34

Requirement ........................................................................34

Evaluate the risk ..................................................................34

Test, criteria and solutions ...............................................35

On/off cycling (cycle rate limit) .....................................35

Provide power supply and electrical

protection ............................................... 36

Wiring information .............................................................36

Control logic ............................................ 37

Safety control logic requirements ................................37

Cycle rate limit requirements .........................................37

Oil management logic recommendations ................37

Defrost logic recommendations ...................................38

Pump-down logic recommendations .........................38

Reduce moisture in the system .............39

Requirements .......................................................................39

Solutions ................................................................................39

INTEGRATION INTO SYSTEM ..................40

Assembly line procedure .......................40

Compressor storage ..........................................................40

Compressor holding charge ...........................................40

Handling ...............................................................................40

Piping assembly ..................................................................41

System pressure test and leak detection ...................41

Vacuum evacuation and moisture removal .............42

Refrigerant charging .........................................................42

Dielectric strength and insulation resistance tests 42

Commissioning ....................................... 43

Preliminary check ...............................................................43

Initial start-up ......................................................................43

System monitoring ............................................................43

Oil level checking and top-up ........................................43

Dismantle and disposal .......................... 44

SYSTEM DESIGN ...................................... 24

Design piping .......................................... 24

General requirements .......................................................24

Tandem requirements ......................................................25

Design compressor mounting ............... 26

General requirements .......................................................26

Single requirements ..........................................................26

Tandem requirements ......................................................26

Manage sound and vibration ................27

Compressor sound radiation ..........................................27

Mechanical vibrations .......................................................28

Gas pulsation .......................................................................28

Manage operating envelope .................29

Requirement ........................................................................29

R22, R407C Model variation T ........................................29

R410A Model variation T ..................................................29

R22, R410A Model variation U .......................................30

High and low pressure protection................................30

System evaluation ..............................................................31

Test, criteria and solutions ...............................................31

ORDERING INFORMATION .....................45

Ordering information and packaging ...45

Packaging ..............................................................................45

Packaging details ................................................................45

Compressor code numbers.............................................46

R22 Single pack ...................................................................46

R22 Industrial pack .............................................................47

R407C Single pack ..............................................................48

R407C Industrial pack .......................................................49

R410A Single pack ..............................................................50

R410A Industrial pack .......................................................51

Spare parts & accessories ....................... 52

3AB218186428184en-001501

Page 4

General Information

PRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION GENERAL INFORMATION

Danfoss scroll compressors are designed and

manufactured according to the state of the

art and to valid European and US regulations.

Particular emphasis has been placed on

safety and reliability. Related instructions are

highlighted with the following icons:

This icon indicates instructions to avoid

safety risk.

R

This icon indicates instructions to avoid

reliability risk.

You are strongly advise to follow these

instructions. For any deviation from the

guidelines, please contact Danfoss Technical

Support.

4 AB218186428184en-001501

Page 5

PRODUCT INFORMATION

Features

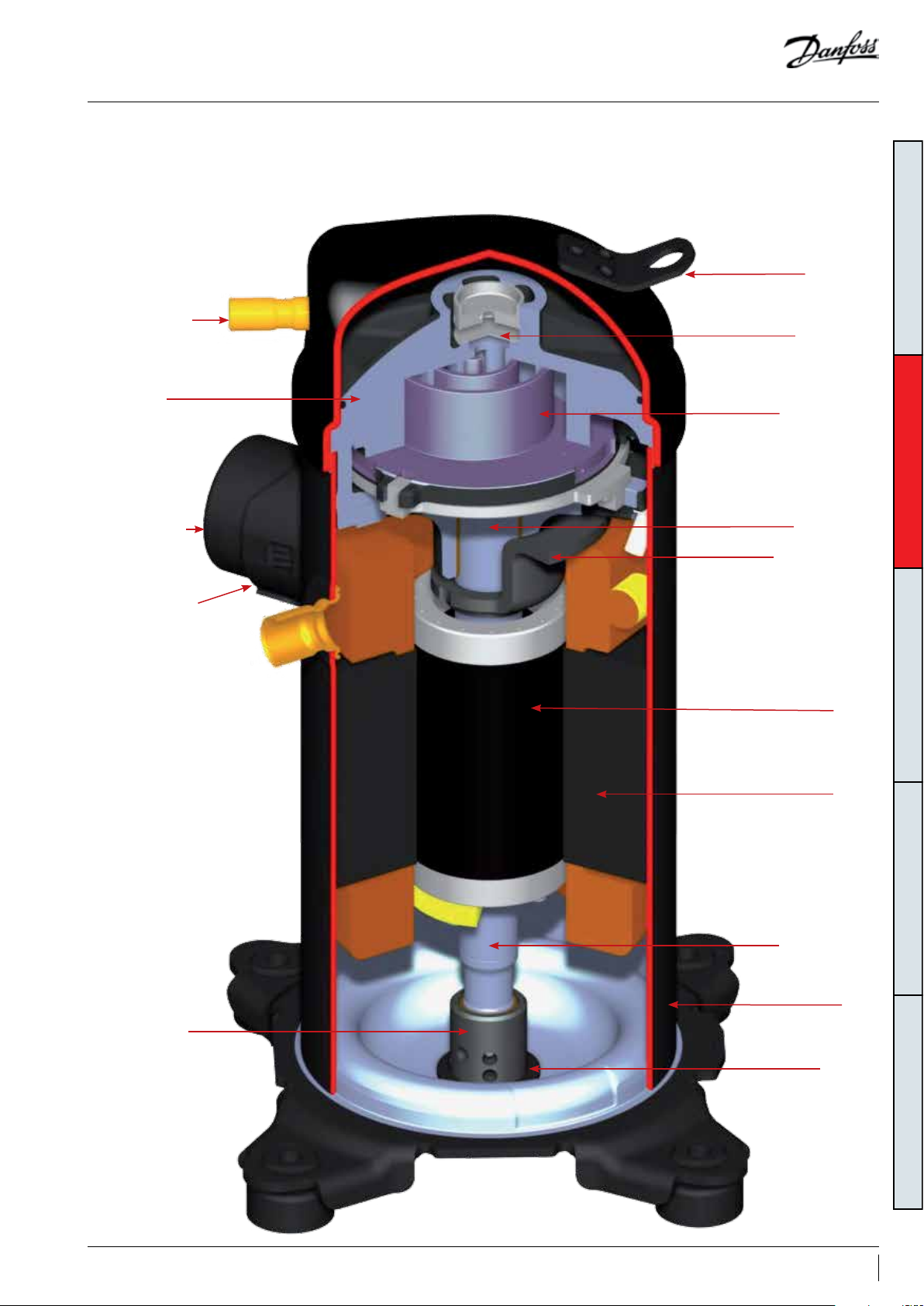

Discharge tube

Fixed scroll

Terminal cover

Danfoss H-series scroll compressors are

manufactured using the most advanced

machining, assembly, and process control

techniques. In design of both the compressor

and the factory, very high standards of reliability

and process control were first priority. The result

is a highly efficient product with the highest

reliability obtainable, and a low sound level.

The H-series compressors can be black or blue

depending on the production site.

Lifting lug

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

Check valve

Orbiting scroll

Slider block

Counterweight

Electric terminal

Lower bearing

Rotor

Stator

Eccentric shaft

Shell

Magnet

5AB218186428184en-001501

Page 6

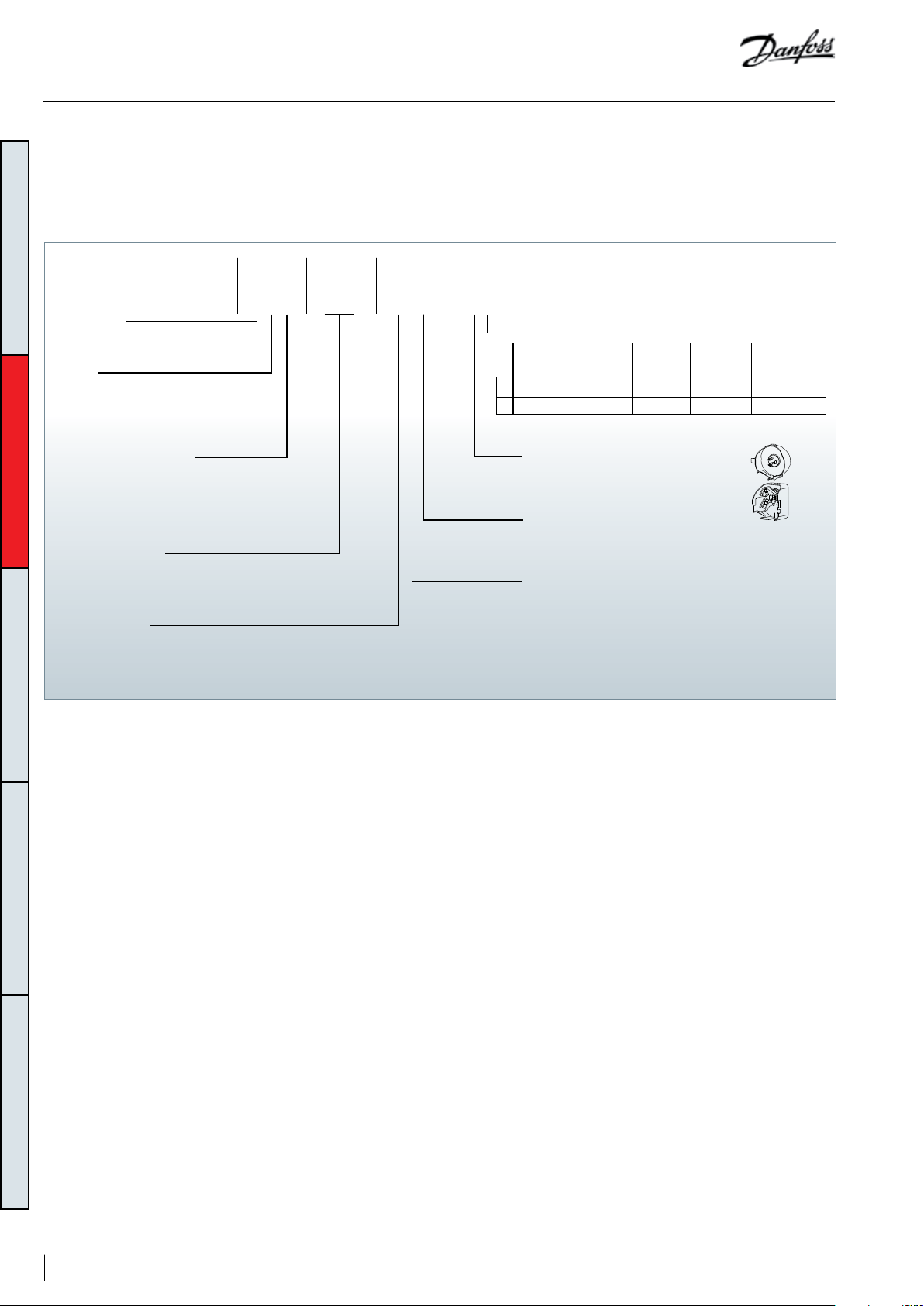

Compressor model designation

Nomenclature

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

Application:

H: high temperature / air conditioning

Family:

C: commercial scroll

R: residential scroll

L: light commercial scroll

Refrigerant & lubricant:

M: R22, alkylbenzene lubricant

P: R407C, PVE lubricant

H: R410A, PVE lubricant

J: R410A, PVE lubricant

Nominal capacity:

In thousand Btu/h at 60 Hz,

ARI conditions

Model variation

T: design optimized for 7.2/54.4°C

U: design optimized for 7.2/37.8°C

Danfoss H-series scroll compressor for R22/

R407C/R410A is available as single compressor

and can be assembled in tandem combinations.

The example below presents the compressor

Type FeaturesMotorSize

HRH P6U1L

036

6

8

nomenclature which equals the technical

reference as shown on the compressor

nameplate. Code numbers for ordering are listed

section “Ordering information and packaging”.

Other features

Oil sight

Tubing and electrical connections

Motor protection

Motor voltage code

Oil equali-

glass

None

None

P: brazed connections, spade terminals

C: brazed connections, screw terminals

L: internal motor protection

1: 208-230V/1~/60 Hz

2: 200-220V/3~/50Hz & 208-230V/3~/60 Hz

4: 380-415V/3~/50 Hz & 460V/3~/60 Hz

5: 220-240V/1~/50 Hz

7: 575V/ 3~/60 Hz

9: 380V/3~/60 Hz

sation

None

Brazed Brazed

None

None

Oil

drain

LP gauge

port

None

None

Gas equa-

li-sation port

None

6 AB218186428184en-001501

Page 7

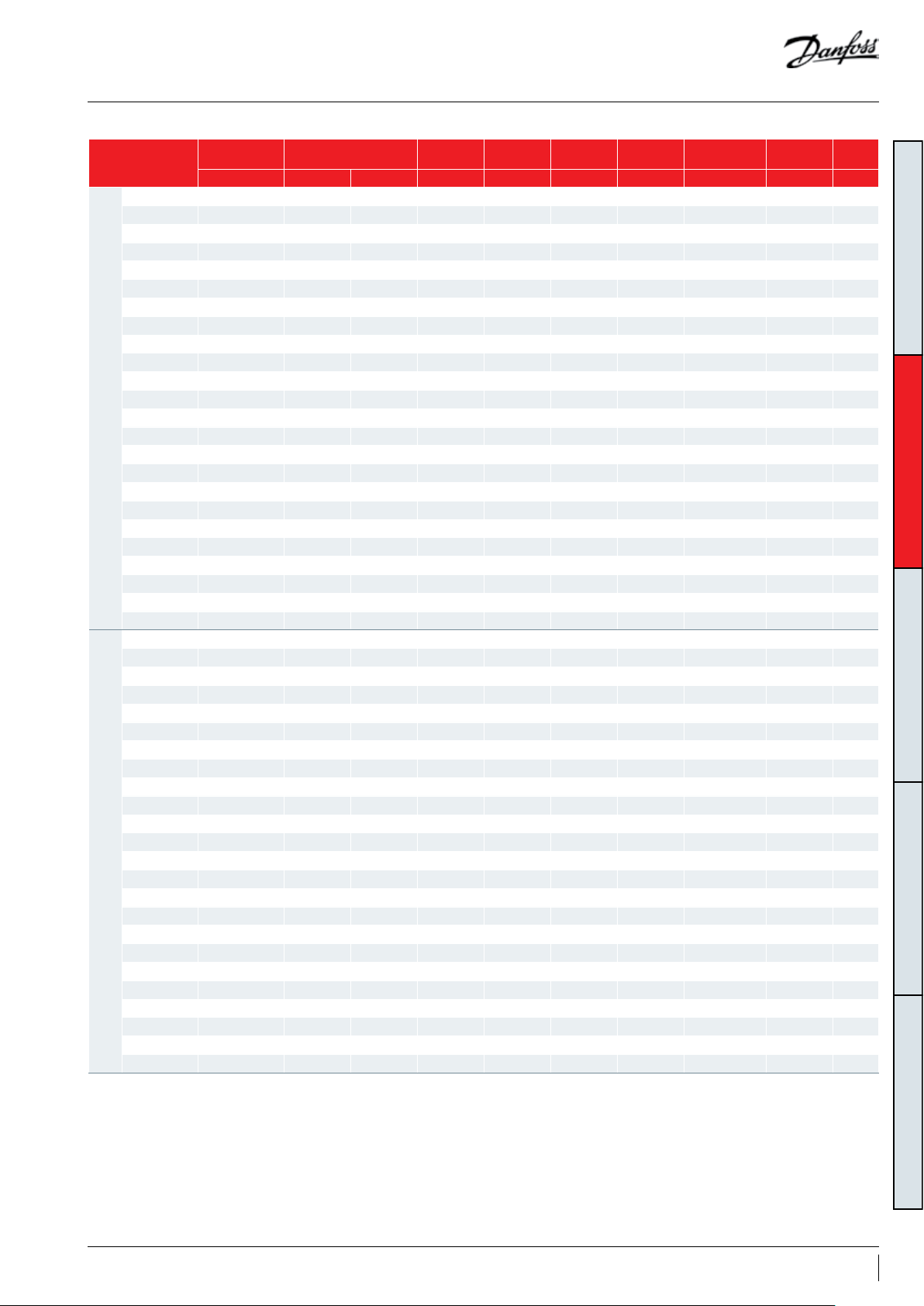

Technical specifications

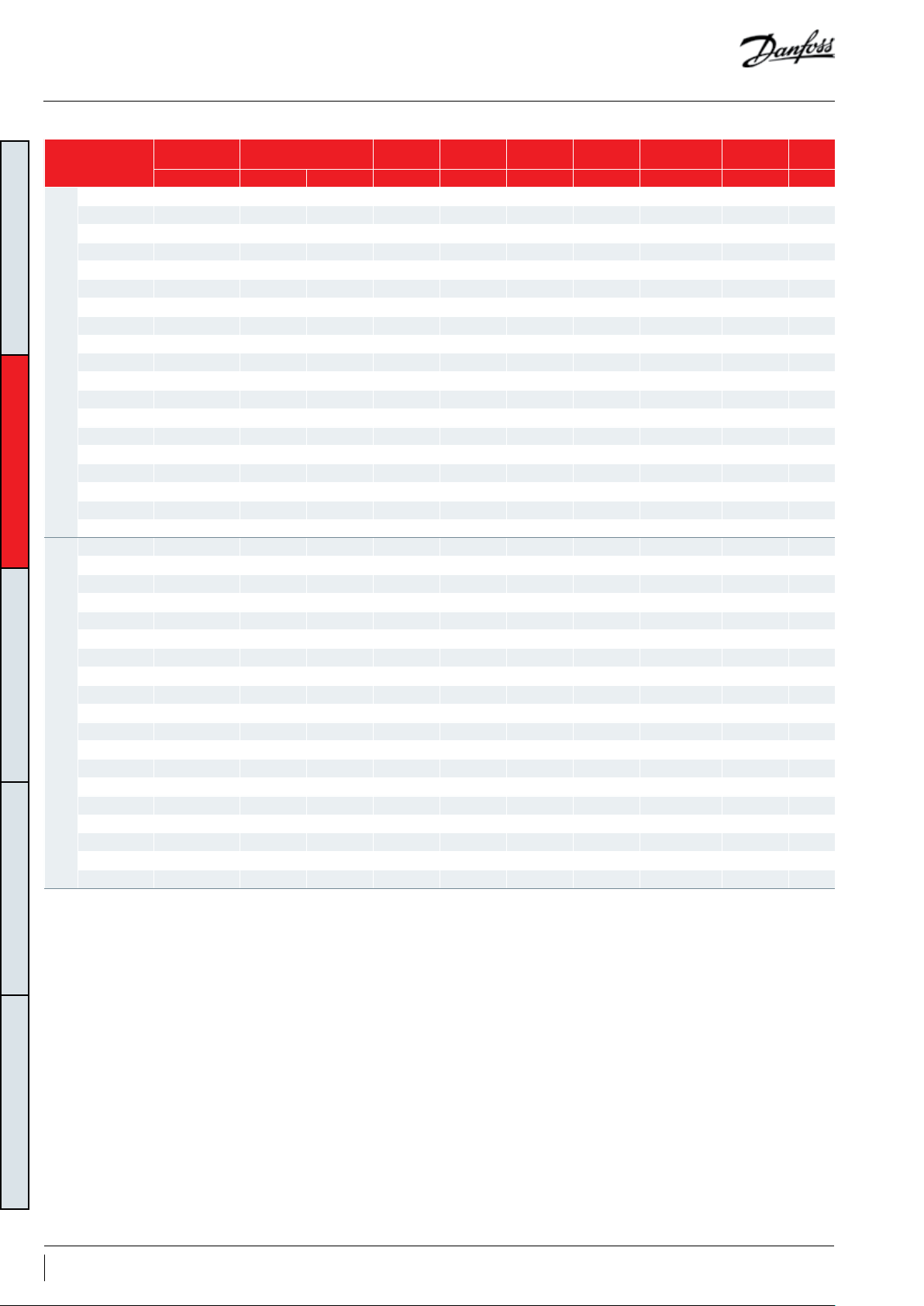

50-60 Hz data

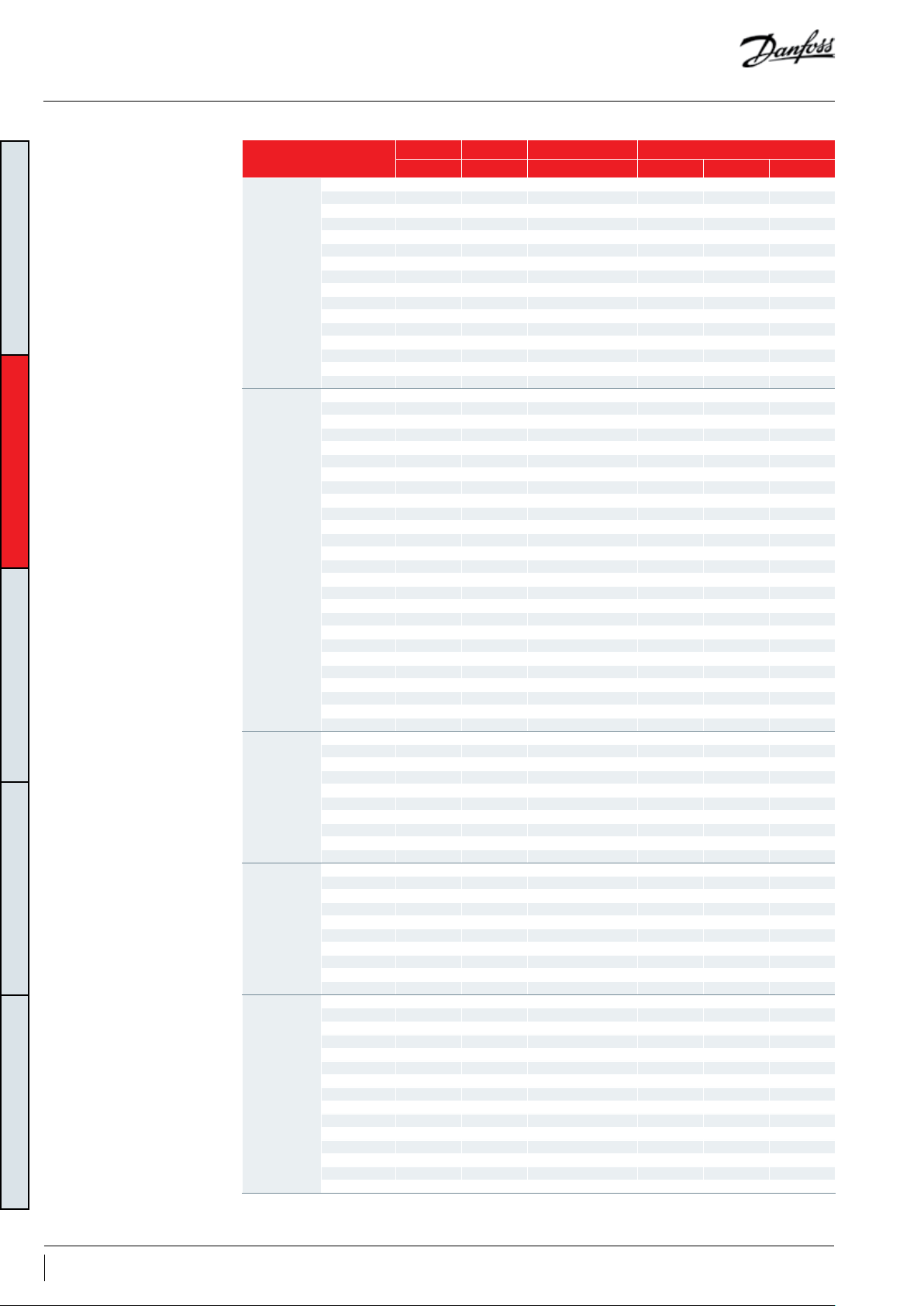

Model

Nominal tons

60 Hz

Nominal cooling capacity Power input COP E.E.R

TR W Btu/h kW W/W Btu/h/W cm

HR M025T4 2 5 950 20 300 1.86 3.2 10.9 34.1 5.9 1.06 32

HRM034U4 2.8 8 350 28 490 2.66 3 .14 10.7 46.2 8.03 1.06 32

HR M034T4 2.8 8 200 28 000 2.66 3.29 11. 2 46.2 8.03 1.06 32

HRM038U4 3.2 9 240 31 520 2.94 3.14 10.7 51.6 8.98 1.06 32

HRM040U4 3.3 9 710 33 120 2.98 3.26 11.1 54.4 9.47 1.06 32

HRM042U4 3.5 10 190 34 770 3.13 3.26 11.1 57. 2 9.95 1.06 32

HR M042T4 3.5 10 110 34 500 3..08 3.28 11. 2 57. 2 9.95 1.0 6 32

HRM045U4 3.8 10 940 37 310 3.45 3 .17 10.8 61. 5 10.69 1.33 32

HRM047U4 3.9 11 50 0 39 250 3.57 3.23 11 64 .1 11.15 1.33 32

HRM048U4 4 11 510 39 270 3.57 3.23 11 64.4 11.21 1.57 39

HR M051T4 4.3 12 390 42 280 3.67 3.37 11 . 5 68.8 11. 98 1. 57 39

HRM0 51U4 4.3 12 800 43 690 3.83 3.34 11. 4 68.8 11. 98 1. 57 39

50Hz

HRM054U4 4.5 13 390 45 680 3.97 3.37 11.5 72.9 12.69 1.57 41

HRM054T4 4.5 13 30 0 45 400 3.84 3.46 11.8 72.9 12.69 1.57 41

HRM058U4 4.8 14 340 48 930 4.25 3.37 11.5 78.2 13.6 1. 57 41

HRM060T4 5 14 570 49 720 4.28 3.4 11. 6 81 14. 09 1.57 41

HRM060U4 5 14 820 50 580 4.4 3.37 11. 5 81 14 .09 1.57 41

HL M06 8T4 5.7 16 880 57 580 5 3. 37 11.5 93.1 16.2 1.57 41

HL M072 T4 6 17 84 0 60 870 5.29 3.37 11. 5 98.7 17.2 1.57 41

HLM075T4 6.3 18 430 62 880 5.37 3.43 11. 7 102.8 17.88 1. 57 41

HL M081T4 6.8 19 890 67 880 5.8 3.43 11 .7 110. 9 19.3 1.57 41

HCM094T4 7. 8 23 060 78 670 6.8 3.39 11.6 126 21.93 2.66 47

HCM109T4 9.1 26 690 91 070 7.77 3.43 11.7 14 8.8 25.89 2.66 47

HC M120T4 10 29 130 99 390 8. 51 3.42 11.7 162.4 28.26 2.66 47

HR M025T4 2 7 090 24 200 2.22 3.2 10.9 3 4.1 7.12 1.06 32

HRM034U4 2.8 9 810 33 480 3.07 3.2 10.9 46.2 9.69 1.06 32

HR M034T4 2.8 9 960 34 010 2.98 3.34 11. 4 46.2 9.69 1.06 32

HRM038U4 3.2 11 13 0 37 980 3.39 3.28 11.2 51.6 10.84 1.06 32

HRM040U4 3.3 11 720 39 980 3.57 3.28 11. 2 54.4 11 .43 1.06 32

HRM042U4 3.5 12 30 0 41 980 3.75 3.28 11.2 57. 2 12.0 1.06 32

HR M042T4 3.5 12 160 41 510 3..64 3.34 11.4 57. 2 12.0 1.06 32

HRM045U4 3.8 13 18 0 44 980 4.01 3.28 11. 2 61.5 12.9 1.33 32

HRM047U4 3.9 13 920 47 490 4.22 3.3 11. 3 6 4.1 13.4 6 1. 33 32

HRM048U4 4 13 8 30 47 180 4.25 3.25 11.1

HR M051T4 4.3 15 030 51 270 4.46 3.37 11 . 5 68.8 14. 46 1.57 39

HRM0 51U4 4.3 15 030 51 280 4.46 3.37 11.5 68.8 14. 46 1.57 39

60Hz

HRM054U4 4.5 15 730 53 680 4.62 3.4 11. 6 72.9 15.32 1.57 41

HRM054T4 4.5 15 820 54 000 4.53 3.49 11.9 72.9 15.32 1.57 41

HRM058U4 4.8 16 930 57 780 5.02 3.37 11. 5 78.2 16.41 1.57 41

HRM060T4 5 17 490 59 670 5.14 3.4 11. 6 81 17.0 1. 57 41

HRM060U4 5 17 490 59 680 5.19 3.37 11.5 81 17. 0 1.57 41

HL M06 8T4 5.7 20 190 68 880 5.94 3.4 11. 6 93.1 19.55 1.57 41

HL M072 T4 6 21 330 72 770 6. 27 3.4 11.6 98.7 20.76 1.57 41

HLM075T4 6.3 2 2 120 75 480 6.45 3.43 11. 7 102.8 21.58 1.57 41

HL M081T4 6.8 23 880 81 470 6.96 3.43 11.7 110 .9 23.29 1.57 41

HCM094T4 7. 8 27 690 94 470 8.07 3.43 11.7 126 26.47 2.66 47

HCM109T4 9.1 32 020 109 270 9.33 3.43 11. 7 14 8.8 31.25 2.66 47

HC M120T4 10 34 950 119 2 60 10.22 3.42 11 .7 162.4 34.11 2.66 47

Displacement at nominal speed: 2900 rpm at 50 Hz, 3500 rpm at 60 Hz

Net weight with oil charge

TR = Ton of Refrigeration Standard rating conditions: ARI standard Evaporating temperature: 7.2 °C

COP = Coefficient Of Performance Refrigerant: R22 Condensing temperature: 54.4 °C

EER = Energy Efficiency Ratio Superheat: 11.1 K Sub-cooling: 8.3 K

All performance test data after run-in 72hr

Subject to modification without prior notification

Data given for motor code 4 compressor, for full data details and capacity tables refer to Online Datasheet Generator: www.danfoss.com/odsg

Swept

volume

Displacement Oil charge

3

/rev m3/h dm

3

64.4 13 .53 1.57 39

Net

weight

kg

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

7AB218186428184en-001501

Page 8

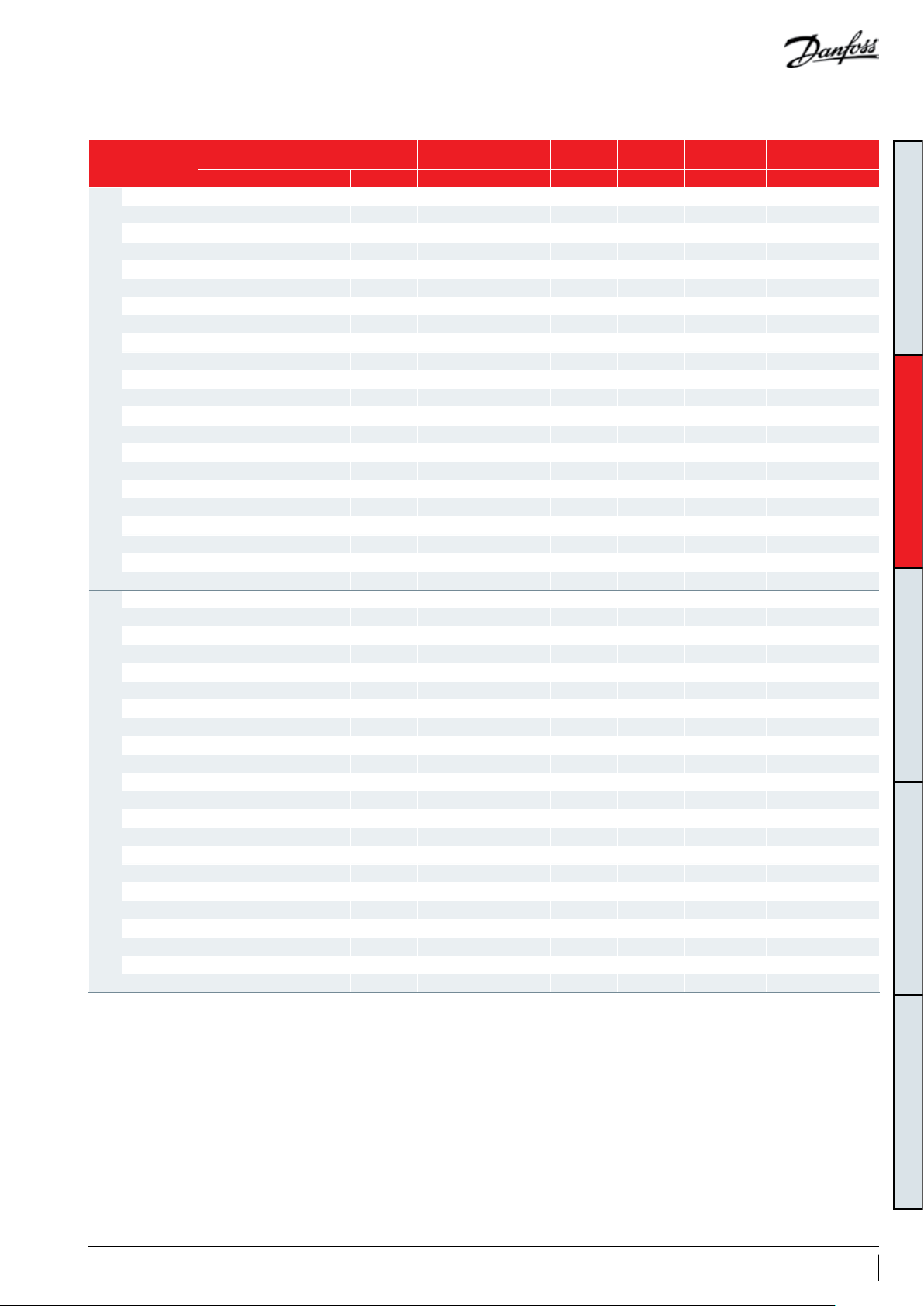

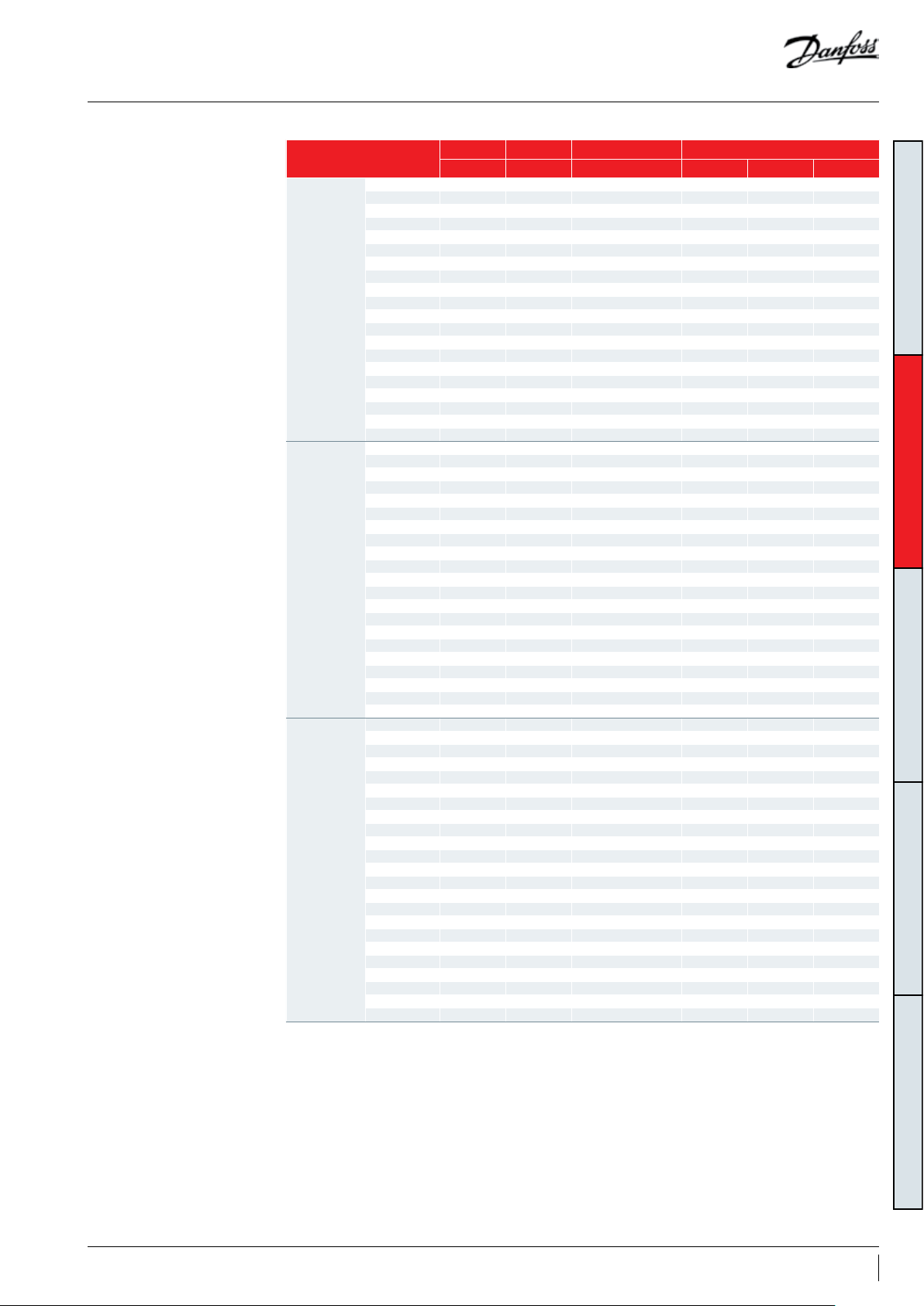

Technical specifications

50-60 Hz data

Model

Nominal tons

60 Hz

Nominal cooling capacity Power input COP E.E.R

TR W Btu/h kW W/W Btu/h/W cm

HR P025 T4 2.0 5730 19 570 1.8 6 3.08 10.5 3 4.1 5.90 1.06 32

HR P034T4 2.8 7 940 27 080 2.68 2.96 10.1 46.2 8.03 1.06 32

HR P038T4 3.2 8 840 30 150 2.82 3.14 10.7 51.6 8.98 1.06 32

HR P04 0T4 3.3 9 11 0 31 0 80 3.14 2.90 9.9 54.4 9.47 1. 06 32

HR P042T4 3.5 9 580 32 680 3.30 2.90 9.9 5 7.2 9.95 1.06 32

HR P045T4 3.8 10 810 36 890 3.58 3.02 10.3 61.5 10.69 1.33 32

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

HR P047T4 3.9 11 13 0 37 980 3.69 3.02 10. 3 6 4.1 11 .15 1.33 32

HR P04 8T4 4.0 11 100 37 880 3.35 3. 31 11. 3 64.4 11. 21 1.57 39

HR P051T4 4.3 12 120 41 370 3.83 3.17 10.8 68.8 11.98 1.57 39

50Hz

HRP054T4 4.5 12 570 42 880 3.97 3.17 10.8 72.8 12.66 1.57 41

HRP058T4 4.8 13 470 45 970 4.25 3 .17 10.8 78.2 13.60 1.57 41

HR P06 0T4 5.0 13 860 47 280 4.26 3.25 11.1 81.0 14.0 9 1.57 41

HLP06 8T4 5.7 15 700 53 560 5.10 3.08 10.5 93.1 16 .20 1. 57 41

HLP072 T4 6.0 16 620 56 740 5.30 3.14 10.7 98.7 17.17 1.57 41

HLP075 T4 6.3 18 040 61 550 5.54 3.26 11 .1 102.8 17.8 8 1.57 41

HLP081T4 6.8 19 4 80 66 510 5.99 3.25 11.1 110 .9 19.30 1.57 41

HCP094T4 7.8 21 590 73 660 6.63 3.26 11 .1 126.0 21.93 2.66 47

HCP109T4 9.1 26 060 88 950 7.9 3 3.28 11.2 148 .8 25.89 2.66 47

HC P120T4 10.0 28 150 96 080 8.88 3.17 10. 8 162.4 28.26 2.66 47

HR P025 T4 2.0 6880 23 490 2.22 3.11 10.6 34 .1 7.12 1.06 32

HR P034T4 2.8 9580 32 700 3.20 3.00 10.2 46.2 9.69 1.06 32

HR P038T4 3.2 10 670 36 410 3.36 3.18 10.8 46.2 10.84 1.0 6 32

HR P04 0T4 3.3 10 990 37 510 3.70 2.97 10.1 54.4 11.43 1.06 32

HR P042T4 3.5 11 560 39 460 3.93 2.94 10.0 57. 2 12 .01 1.06 32

HR P045T4 3.8 13 050 44 540 4.27 3.06 10.4 61. 5 12.9 1.33 32

HR P047T4 3.9 12 690 43 300 4.24 3.00 10.2 64 .1 13 .46 1.33 32

HR P04 8T4 4.0 13 400 45 740 3.99 3.36 11. 5 64.4 13.53 1.57 39

HR P051T4 4.3 14 38 0 49080 4.46 3.23 11.0 68.8 14.46 1. 57 39

60Hz

HRP054T4 4.5 15 120 51 770 4.73 3.21 11.0 72.8 15. 28 1. 57 41

HRP058T4 4.8 16 260 55 510 5.07 3.17 10.8 78.2 16 .41 1. 57 41

HR P06 0T4 5.0 16 720 57 010 5.07 3.30 11. 3 81.0 17.01 1.57 41

HLP06 8T4 5.7 18 950 64 660 6.08 3.12 10.6 93.1 19.55 1.57 41

HLP072 T4 6.0 20 060 68 480 6.32 3.17 10.8 98.7 20.72 1.57 41

HLP075 T4 6.3 21 770 74 330 6.60 3.30 11. 3

HLP081T4 6.8 23 380 79 810 7.14 3.27 11. 2 110.9 23.29 1.57 41

HCP094T4 7.8 26 060 88 950 7.90 3.30 11. 3 12 6.0 26.47 2.66 47

HCP109T4 9.1 31 450 107 350 9.46 3.32 11.3 148 .8 31.25 2.66 47

HC P120T4 10.0 33 970 115 960 10.59 3.21 11.0 162.4 34.11 2.66 47

Displacement at nominal speed: 2900 rpm at 50 Hz, 3500 rpm at 60 Hz

Net weight with oil charge

TR = Ton of Refrigeration Standard rating conditions: ARI standard Evaporating temperature: 7.2 °C

COP = Coefficient Of Performance Refrigerant: R407C Condensing temperature: 54.4 °C

EER = Energy Efficiency Ratio Superheat: 11.1 K Sub-cooling: 8.3 K

Swept

volume

Displacement Oil charge

3

/rev m3/h dm

102. 8 21.58 1.57 41

Net

weight

3

kg

All performance test data after run-in 72hr

Subject to modification without prior notification

Data given for motor code 4 compressor, for full data details and capacity tables refer to Online Datasheet Generator: www.danfoss.com/odsg

8 AB218186428184en-001501

Page 9

Technical specifications

50-60 Hz data

Model

Nominal tons

60 Hz

Nominal cooling capacity Power input COP E.E.R

TR W Btu/h kW W/W Btu/h/W cm

HRH029U4 2.4 7 120 24 310 2.43 2.93 10 2 7. 8 4.84 1.06 32

HRH031U4 2.6 7 530 25 710 2.67 2.82 9.62 29.8 5.19 1.06 32

HRH032U4 2.7 7 670 26 170 2.75 2.79 9. 51 30.6 5.33 1.06 32

HRH034U4 2.8 8 500 29 000 2.9 2.93 10 33.3 5.75 1.06 32

HRH036U4 3 8 820 30 110 3.13 2.82 9.62 34.7 6.04 1.06 32

HRH038U4 3.2 9 250 31 560 3.35 2.76 9.41 36.5 6.36 1.06 39

HRH040U4 3.3 10 20 0 34 810 3.58 2.85 9.72 39.6 6.9 1.33 39

HR H041U 4 3.3 10 050 34 300 3.43 2.93 10 39.3 6.8 1.57 39

HRH044U4 3.7 10 830 36 940 3.92 2.76 9. 41 42.6 7.41 1.57 39

HRH047U4 3.9 11 3 40 38 700 3.87 2.93 10.01 44.4 7.73 1.57 39

HRH049U4 4.1 12 110 41 320 4.04 2.99 10.22 47. 4 8.24 1.57 39

50Hz

HRH051U4 4.3 12 860 43 890 4.21 3.05 10.42 49.3 8.58 1.57 41

HRH054U4 4.5 13 34 0 45 510 4. 41 3.02 10.32 52.1 9.07 1.57 41

HRH056U4 4.7 13 830 47 200 4.58 3.02 10. 31 54.1 9.42 1. 57 41

HLH061T4 5.1 15 210 51 880 4.89 3.11 10.61 57.8 10.1 1.57 41

HLH06 8T4 5.7 16 880 57 610 5.26 3.21 10.96 64.4 11 .21 1.57 41

HL J072T4 6 17 8 40 60 900 5.56 3.21 11 68 11. 82 1.57 41

HL J075 T4 6.3 18 60 0 63 490 5.77 3.22 11 70.8 12.32 1.57 41

HLJ083T4 6.9 20 420 69 690 6.28 3.25 11.1 78.1 13. 59 1.57 41

HCJ091T4 7. 5 22 380 76 360 7. 03 3 .18 10.87 86.9 15.11 2.46 49

HC J106T4 8.8 26 050 88 880 8.07 3.23 11.01 101.6 17.68 2.46 49

HC J121T4 10 29 720 101400 9.22 3.22 11 116.4 20.24 2.46 49

HRH029U4 2.4 8 500 29 000 2.84 2.99 10. 2 2 7.8 5.84 1.06 32

HRH031U4 2.6 9 080 30 990 3.04 2.99 10.2 29.8 6.26 1.0 6 32

HRH032U4 2.7 9 380 31 990 3 .1 3.02 10.3 30.6 6.43 1.06 32

HRH034U4 2.8 10 110 3 4 510 3.38 2.99 10.2 33.3 6.94 1.0 6 32

HRH036U4 3 10 370 35 390 3.47 2.99 10.2 34.7 7. 3 1.0 6 32

HRH038U4 3.2 11 10 0 37 890 3.79 2.93 10 36.5 7. 67 1.06 39

HRH040U4 3.3 12 160 41 49 0 4.03 3.02 10.3 39.6 8.3 1.33 39

HR H041U 4 3.3 12 100 41 3 00 4.05 2.99 10.2 39.3 8.3 1.57 39

HRH044U4 3.7 13 010 44 390 4.31 3.02 10.3 42.6 8.95 1.57 39

HRH047U4 3.9 13 63 0 4 6 510 4.56 2.99 10.2 44.4 9.33 1. 57 39

HRH049U4 4.1 14 36 0 48 990 4.66 3.08 10.5 4 7.4 9.95 1.57 39

60Hz

HRH051U4 4.3 15 180 51 780 4.84 3.14 10.7

HRH054U4 4.5 15 970 54 480 5.14 3 .11 10.6 52 .1 10.9 4 1.57 41

HRH056U4 4.7 16 670 56 880 5.36 3.11 10.6 54.1 11 . 36 1. 57 41

HLH061T4 5.1 18 050 61 580 5.7 3.17 10.8 57.8 12.13 1. 57 41

HLH06 8T4 5.7 20 130 68 670 6.3 3.2 10.9 64.4 13.52 1.57 41

HL J072T4 6 21 240 72 500 6.65 3.19 10.9 68 14. 27 1.57 41

HL J075 T4 6.3 22 320 76 19 0 6.86 3.25 11.1 70.8 14. 87 1.57 41

HLJ083T4 6.9 24 340 83 090 7. 55 3.22 11 78.1 16.4 1. 57 41

HCJ091T4 7. 5 27 140 92 600 8.37 3.24 11.07 86.9 18.24 2.46 49

HC J106T4 8.8 31 670 108 050 9.67 3.28 11.18 101.6 21. 34 2.46 49

HC J121T4 10 35 940 122 62 0 11. 07 3.25 11.08 11 6.4 24.43 2.46 49

Displacement at nominal speed: 2900 rpm at 50 Hz, 3500 rpm at 60 Hz

Net weight with oil charge

TR = Ton of Refrigeration Standard rating conditions: ARI standard Evaporating temperature: 7.2 °C

COP = Coefficient Of Performance Refrigerant: R410A Condensing temperature: 54.4 °C

EER = Energy Efficiency Ratio Superheat: 11.1 K Sub-cooling: 8.3 K

Swept

volume

Displacement Oil charge

3

/rev m3/h dm

49.3 10.36 1.57 41

Net

weight

3

kg

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

All performance test data after run-in 72hr

Subject to modification without prior notification

Data given for motor code 4 compressor, for full data details and capacity tables refer to Online Datasheet Generator: www.danfoss.com/odsg

9AB218186428184en-001501

Page 10

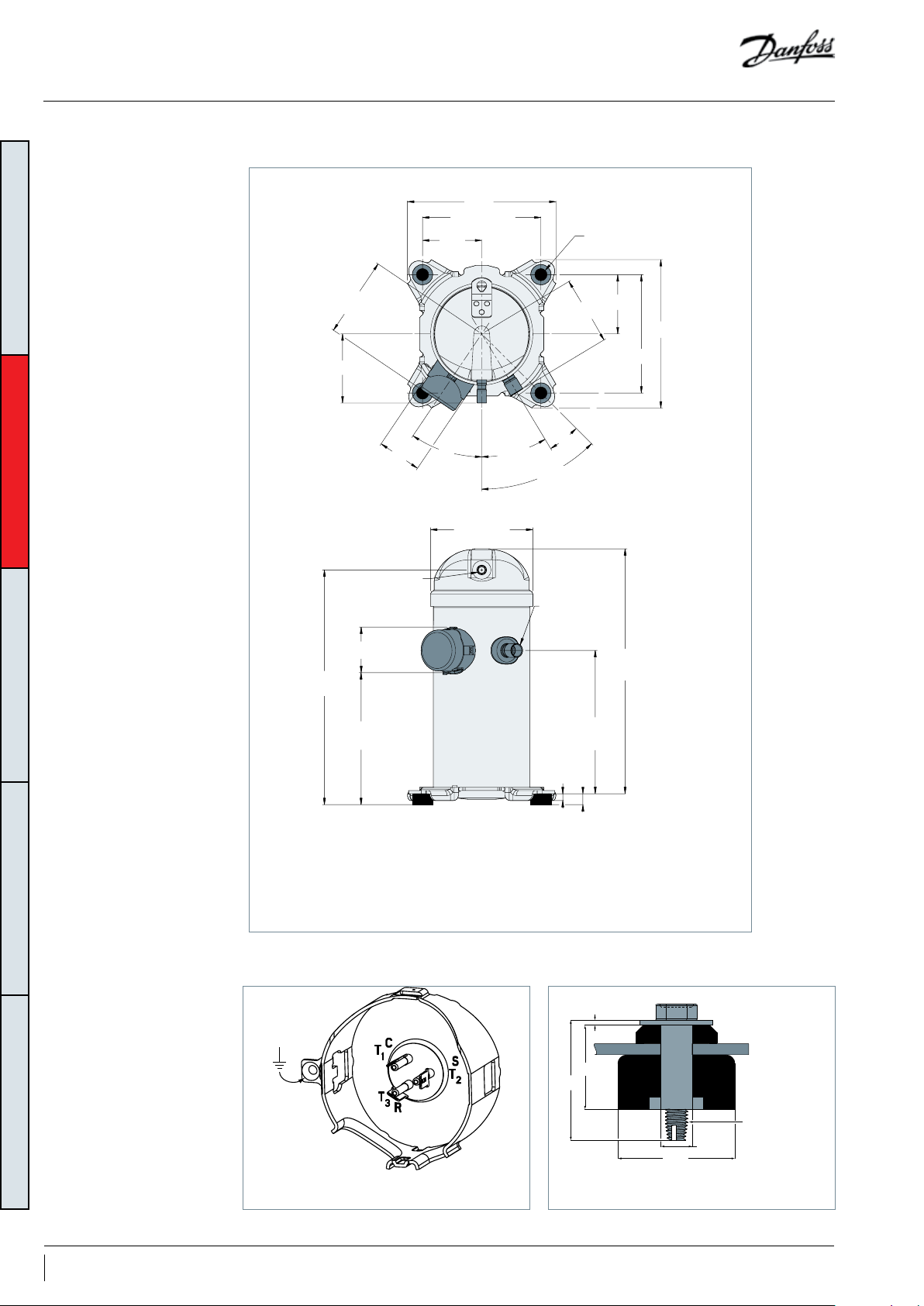

Dimensions

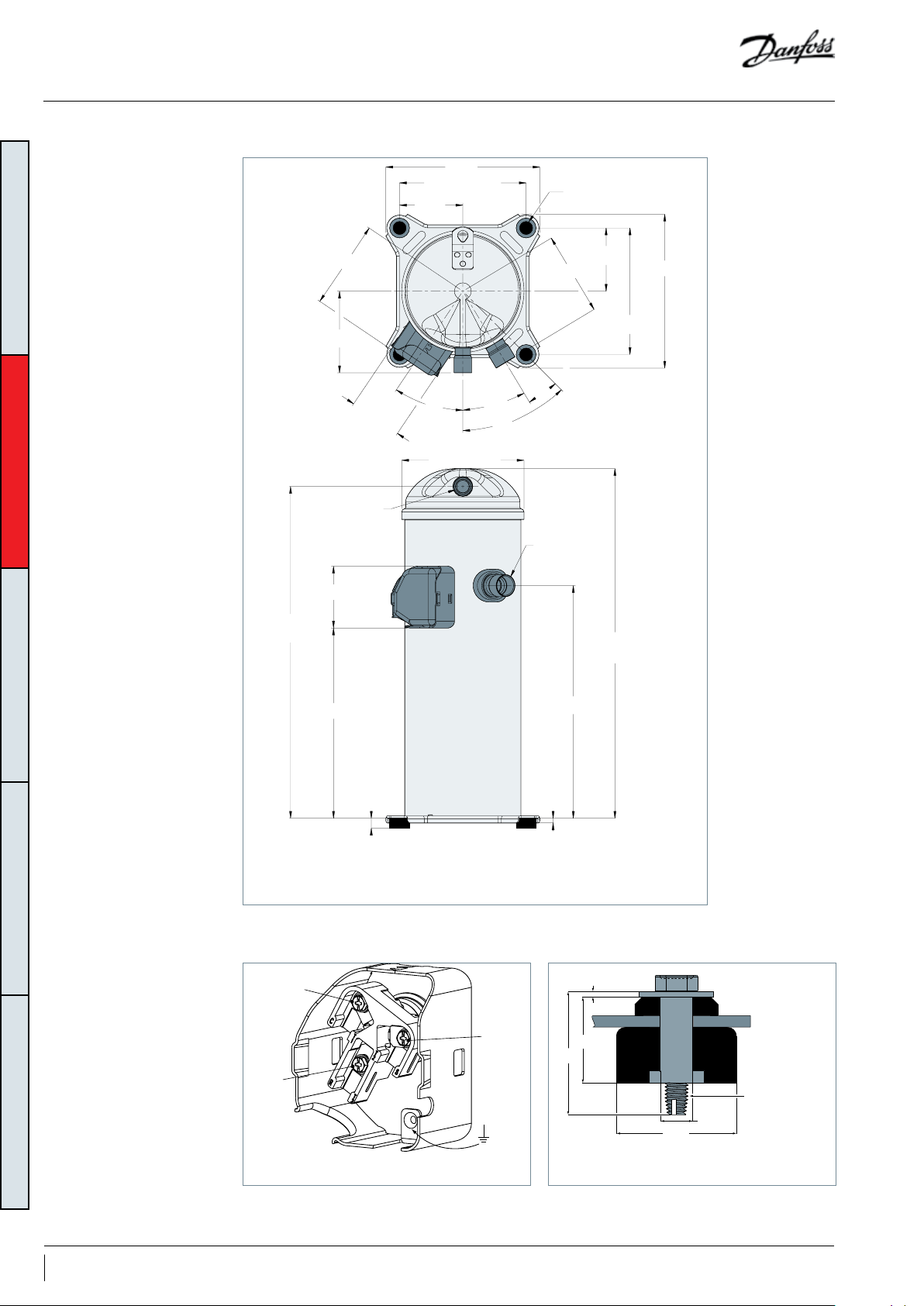

HRM025-032-034-038-040-042 / HRP025-034-038-040-042 / HRH029-031-032-034-036-038 / HRM-045-047 / HRP-045-047 / HRH039-040

238.8

190.25 - 190.75

95.25

4 x Ø 19.0 - 20.0

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

(1) 360.4

(2) 385.8

128.5

111.3

69.4 - 71.4

Discharge line

12.75-12.85

(0.502-0.506 inch)

72.1 - 75.1

(1) 194.9

(2) 220.2

34°

163.5 - 165.5

31°

45°

95.25

109.7

190.25 - 190.50

14°

Suction line

(1) 19.13-19.23

(0.753-0.757 inch)

(2) 22.4 (0.881 inch)

(1) 394.4

(2) 419.9

(1) 230.8

(2) 256.3

238.8

10.7

19

(1) HRM025-032-034-038-040-042 / HRP025-034-038-040-042 / HRH029-031-032-034-036-038

(2) HRM-045-047 / HRP-045-047 / HRH039-040

All dimensions in mm

P6

Mounting grommetTerminal box

1.7

29.5

41

Ø 41

Quick connect spade terminals

P terminal box type

Recommended torque for mounting bolts:

11 Nm (±1 Nm)

Refer to section 44 for overview of shipped mounting

accessories

Ø11

5/16” - 18 UNC

self tapping

10 AB218186428184en-001501

Page 11

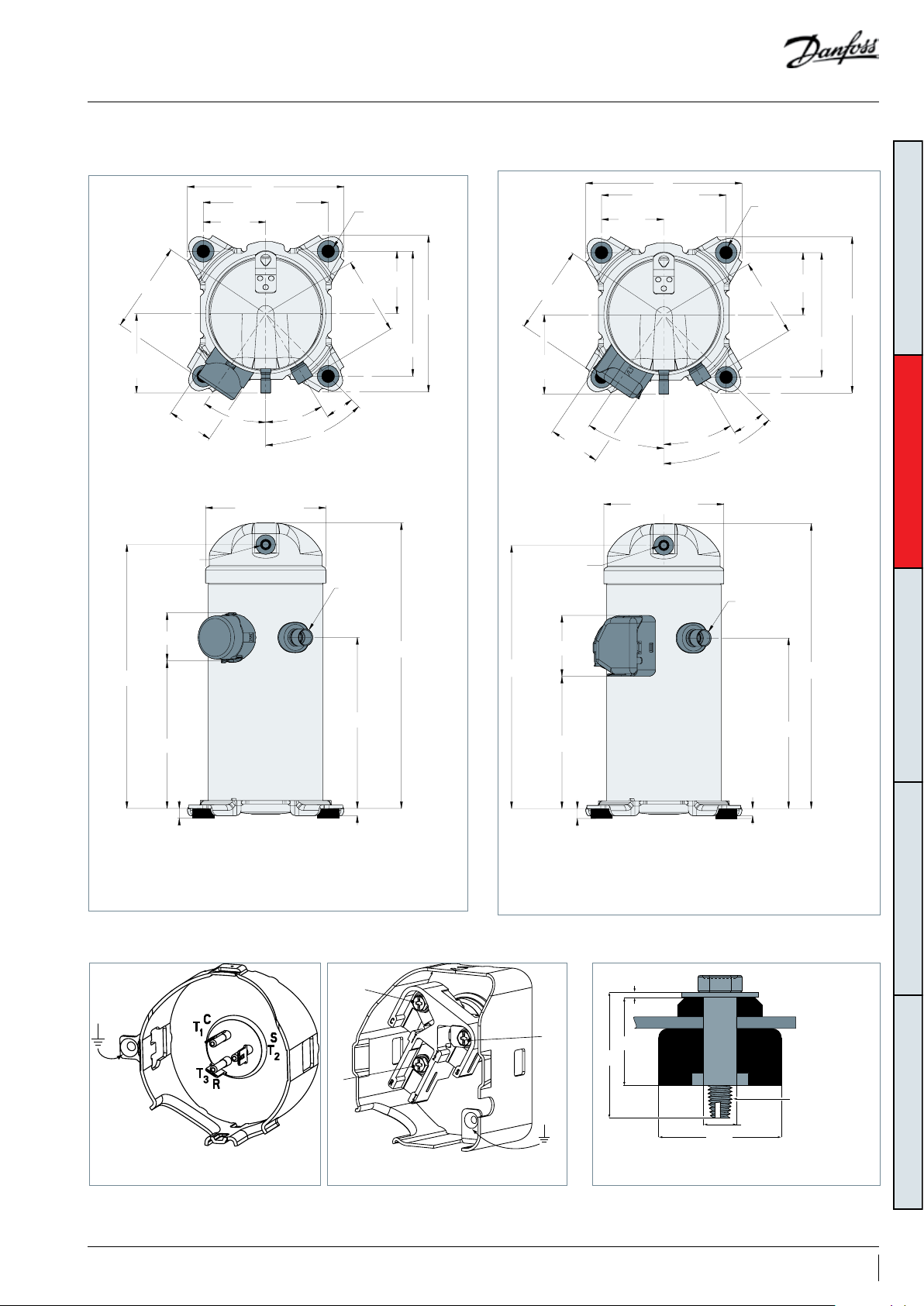

Dimensions

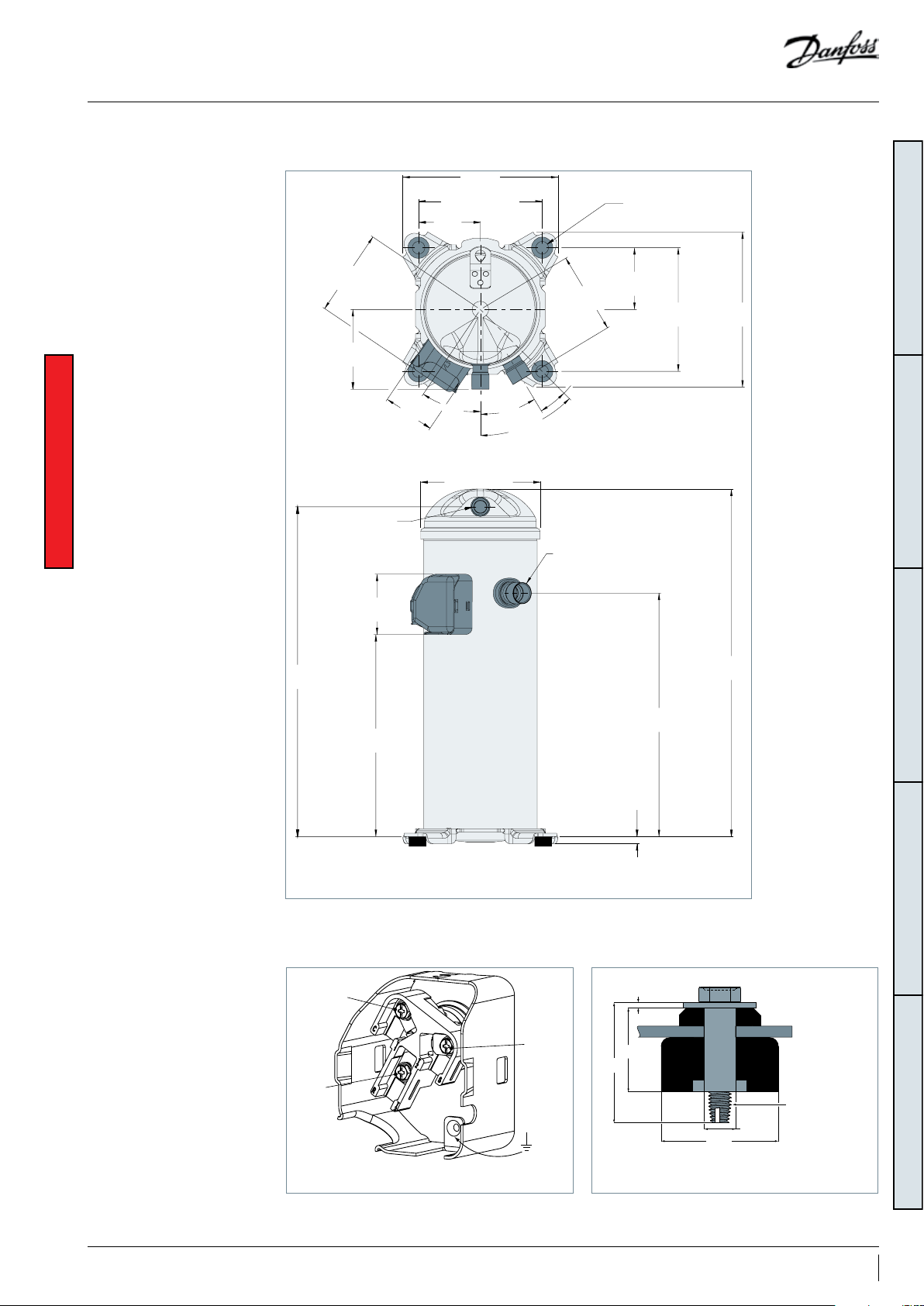

HRM048-051-054-058-060 / HLM068-072-075-078-081 / HRP048-051-054-058-060 / HLP068-072-075-078-081 / HRH041-044-049-051-054-056 / HLH061-068 / HLJ072-075-083

138.2

(1) 121

(2) 121.9

Discharge line

(1) 12.75-12.85

(0.502-0.506)

(2) 19.2 (0.755)

402.7

69.4 - 71.4

72.1 - 75.1

239

190.25-190.75

95.25

34°

182.54 - 184.54

31°

45°

4 x Ø 19.0 - 20.0

118.3

14°

Suction line

22.30-22.48

(0.878 - 0.885)

95.25

190.25-190.75

435.9

239

Discharge line

(1) 12.75-12.85

(0.502-0.506)

(2) 19.2 (0.755)

402.7

133.6

(1) 121

(2) 121.9

78.5 - 80.5

92.0 - 94.0

239

190.25 - 190.75

95.25

34°

182.54 - 184.54

31°

14°

45°

Suction line

22.30-22.48

(0.878-0.885)

4 x Ø 19.0 - 20.0

95.25

119.2

190.25 - 190.75

435.9

239

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

261

225.2

19

(1) HRM048-051-054-058-060 / HLM068-072-075 / HRP048-051-054-058-060 /

HLP068-072-075 / HRH041-044-049-051-054-056 / HLH061-068 / HLJ072-075-083

(2) HLM078-081 / HLP078-081

10.9

P6

All dimensions in mm

C

T₁

R

T₃

Quick connect spade terminals

P terminal box type

Ring connect screw terminals

C terminal box type

261

202.4

10.9

19

(1) HRM048-051-054-058-060 / HLM068-072-075 / HRP048-051-054-058-060 /

HLP068-072-075 / HRH041-044-049-051-054-056 / HLH061-068 / HLJ072-075-083

(2) HLM078-081 / HLP078-081

C6

All dimensions in mm

Mounting grommetTerminal boxes

1.7

S

T₂

29.5

41

5/16” - 18 UNC

Ø11

self tapping

Ø 41

Recommended torque for mounting bolts:

11 Nm (±1 Nm)

Refer to section 44 for overview of shipped mounting

accessories

11AB218186428184en-001501

Page 12

Dimensions

231.9

All dimensions in mm

HCM/HCP 094-109-120

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

(1) 490.1

(2) 499.5

133

122.9

78.5 - 80.5

Discharge line

22.31 - 22.48

(0.878-0.885)

92.0 - 94.0

190.25 - 190.75

95.25

34°

183.14 - 185.14

31°

45°

4 x Ø 19.0 - 20.0

125.1

14°

Suction line

28.65 - 28.83

(1.128-1.135)

95.25

190.25 - 190.75

(1) 516.8

(2) 526.2

231.9

(1) HCM/HCP 094

(2) HCM/HCP 109-120

Terminal box

C

T₁

R

T₃

286.4

19

Ring connect screw terminals

C terminal box type

350.2

7.2

C6

Mounting grommet

1.7

S

T₂

29.5

41

5/16” - 18 UNC

self tapping

Ø 41

Ø11

Recommended torque for mounting bolts:

11 Nm (±1 Nm)

Refer to section 44 for overview of shipped mounting

accessories

12 AB218186428184en-001501

Page 13

Dimensions

239

239

508.3

All dimensions in mm

HCJ091-106-121

PRODUCT INFORMATION

133

122.9

78.5 - 80.5

Discharge line

22.31 - 22.48

92.0 - 94.0

190.25-190.75

95.25

34° 31°

183.14-185.14

45°

125.1

14°

Suction line

28.65 - 28.83

4 x Ø 19.0 - 20.0

95.25

190.25-190.75

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

Terminal box

C

T₁

R

T₃

Ring connect screw terminals

311.4

HCJ091-106-121

C terminal box type

535.5

375.2

10.9

Mounting grommet

1.7

S

T₂

29.5

41

5/16” - 18 UNC

self tapping

Ø 41

Ø11

Recommended torque for mounting bolts:

11 Nm (±1 Nm)

Refer to section 44 for overview of shipped mounting

accessories

13AB218186428184en-001501

Page 14

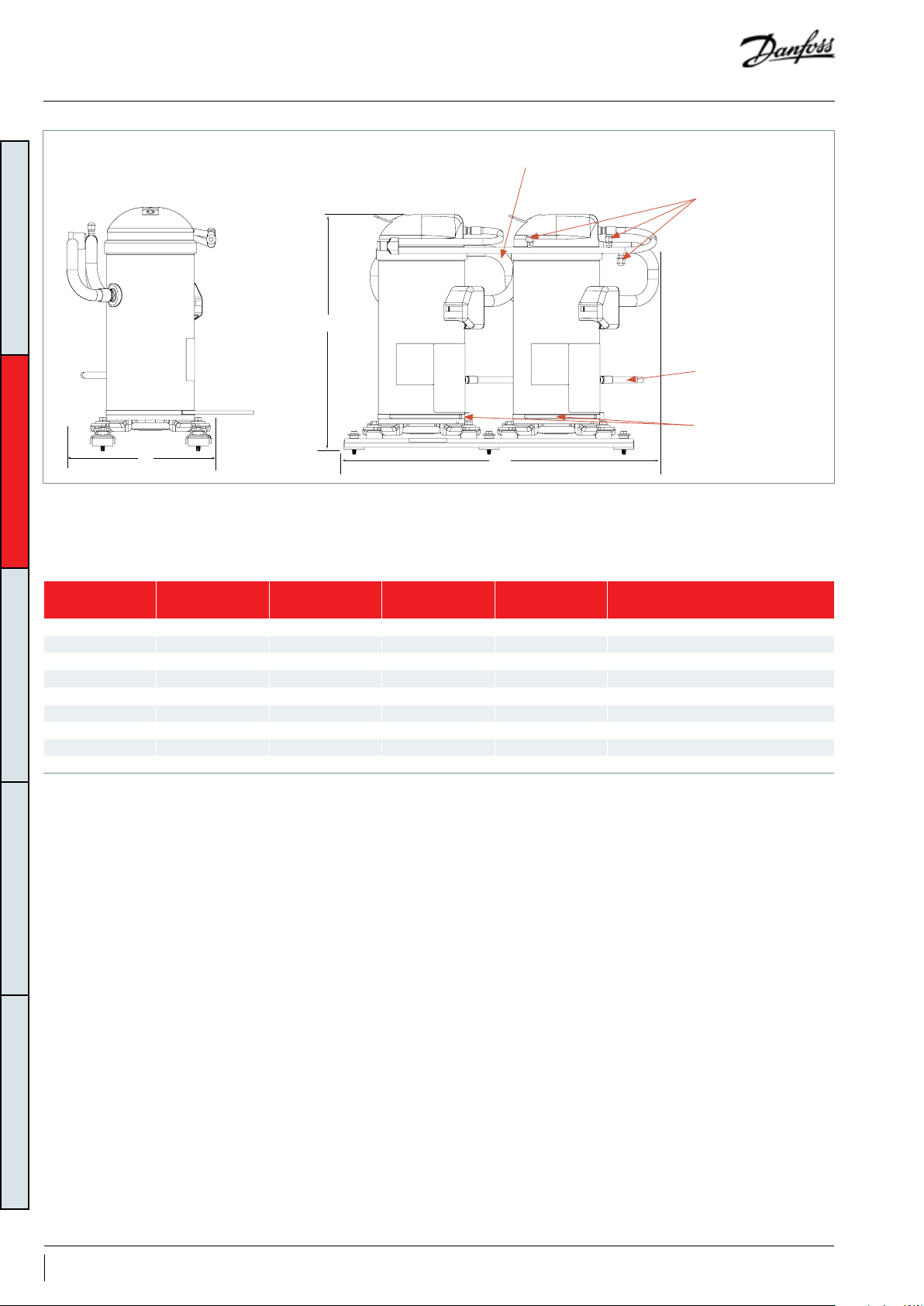

Dimensions

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

Gas equalization line

Schrader ports

for HP/LP switches

and/or access ports

H

Oil equalization line

Crankcase heaters

W

By default, H series tandems are not factorybuilt, just provide tandem version compressors

(feature 8).

L

Tandems to be acheived by assembly of

individual compressors, if they are the feature 8

compressor.

Tandem model Composition L (mm) H(mm) Wmm) Outline drawing number

TLJ082 HR H041 + H RH0 41 636 476 297 8556080

TLJ098 HRH049 + HRH049 636 476 297 8556080

TL J122 HLH061 + HLH0 61 636 476 297 8556080

TL J136 HLH068 + HLH068 636 476 297 8556080

TL J144 HL J072 + HLJ072 636 476 297 8556080

TL J166 HLJ083 + HLJ083 636 476 297 8556080

TCJ181 HCJ091 + HCJ091 676 575 312 8556153

TCJ211 HCJ10 6 + HCJ106 676 575 312 8556153

TCJ241 H CJ121 + HC J121 676 575 312 855 6153

14 AB218186428184en-001501

Page 15

Electrical data, connections and wiring

Danfoss scroll compressors H Series are available in four different motor voltages as listed below.Motor voltage

Motor voltage code Code 1 Code 2 Code 4 Code 5 Code 7 Code 9

Nominal voltage

50 Hz

Voltage range

50 Hz

Nominal voltage

60 Hz

Voltage range

60 Hz

- 200-220 V - 3 ph 380-415V - 3 ph 220-240 V -1 ph - -

- 180 - 242 V 342 - 457 V 198 - 264 V - -

208-230 V - 1ph 208-230 V - 3 ph 460 V - 3 ph - 575 V - 3 ph 380 V - 3 ph

187 - 253 V 187 - 253 V 414 - 506 V - 517 - 632 V 342 - 418 V

Wiring connections

The maximum allowable voltage imbalance is

2%. Voltage imbalance causes high amperage

over one or several phases, which in turn leads

|Vavg - V1-2 |+|Vavg - V1-3 |+|Vavg - V2-3 |

% voltage unbalance:

Vavg = Mean voltage of phases 1, 2 and 3

V1-2 = Voltage between phases 1 and 2

Danfoss Scroll Compressors H-series will only

compress gas while rotating counter-clockwise

(when viewed from the compressor top). Since

single-phase motors will start and run in only

one direction, reverse rotation is not a major

consideration. Three-phase motors, however,

will start and run in either direction, depending

on the phase angles of the supplied power. Care

must be taken during installation to ensure that

the compressor operates in the correct direction

(see “Phase sequence and reverse rotation

protection”).

to overheating and possible motor damage.

Voltage imbalance is given by the formula:

x 100

avg

2 xV

V1-3 = Voltage between phases 1 and 3

V2-3 = Voltage between phases 2 and 3.

Electrical box cover must be fitted and cable

gland or similar protection component must

be used on electrical box’s knockouts before

energizing the compressor to against accidental

contact with electrical parts inside.

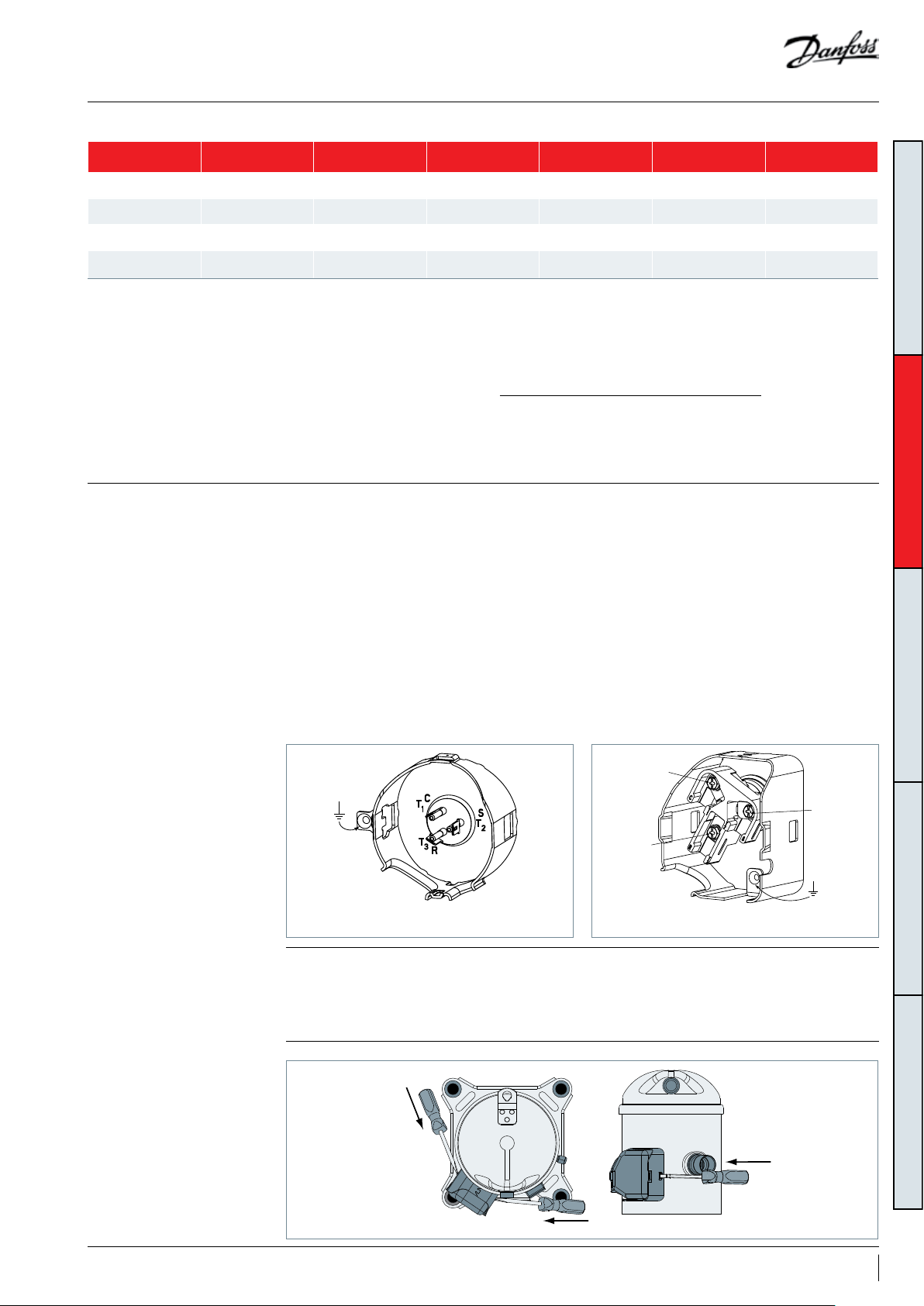

The drawings below show electrical terminal

labelling and should be used as a reference

when wiring the compressor. For three phase

applications, the terminals are labelled T1,

T2, and T3. For single-phase applications the

terminals are labelled C (common), S (start), and

R (run).

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

Terminal cover mounting

Terminal cover removal

Quick connect spade terminals

P terminal box type

The terminal cover and gasket should be

installed prior to operation of the compressor.

The terminal cover has two outside tabs, 180

degrees apart, that engage the terminal fence.

push

C

T₁

S

T₂

R

T₃

Ring connect screw terminals

C terminal box type

When installing the cover, check that it is not

pinching the lead wires. Both the inside of the

terminal cover and the gasket have labels for the

terminal pins: C (common), R (run), and S (start).

push

push

15AB218186428184en-001501

Page 16

Electrical data, connections and wiring

Three phase electrical characteristics

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

Compressor model

HRM034U2 95 17. 5 13 .6 1.18 0.87 1.18

HRM038U2 95 19 14. 8 1.18 0.87 1.18

HRM0 40U2 95 20 15. 5 1.18 0.87 1.18

HRM042U2 95 22 16 .6 1.18 0.87 1.18

HRM0 45U2 115 25 18.9 0.98 0.73 0.98

HRM 047U2 115 25 20.1 0.98 0.73 0.98

HRM05 4U2 12 3 27 21.7 0.59 0. 59 0.59

HRM058U2 123 27 22.7 0.59 0 .59 0.59

HRM060U2 123 28 23.5 0.59 0.59 0.59

HLM068T2 170 30 26.6 0.48 0.48 0.46

HLM072T2 170 30 28.2 0.48 0.48 0.46

Motor voltage code 2

Motor voltage code 4

Motor voltage code 7

Motor voltage code 9

Motor voltage code 2

HLM075T2 190 35 31.6 0.42 0 .42 0.42

208-230 V / 3 ph / 6 0 Hz

200-220 V / 3 ph / 50 Hz

HLM081T2 190 39 35.2 0.42 0.42 0.42

HCM094T2 190 40 3 6.1 0. 37 0.37 0.37

HCM109T2 235 46 40.7 0.33 0. 32 0.32

HC M120T 2 250 55 4 7.6 0.30 0.29 0.29

HR M025 T4 30 7 4.9 6.72 4.95 6.72

HR M034T4 45 9.5 6.8 4.66 3.42 4.66

HRM034U4 45 9.5 6.8 4.66 3.42 4.66

HRM038T4 45 9.5 7.6 4.66 3.42 4.66

HRM038U4 45 10 7. 2 4.66 3.42 4.66

HRM040U4 45 10 7.5 4.66 3.42 4.66

HR M042 T4 45 11 8.3 4.66 3. 42 4.66

HRM042U4 45 11 8.3 4.66 3.42 4.66

HRM045U4 50 12 8.9 3.87 2.85 3.87

HR M047 T4 50 12 9.3 3.87 2.85 3.87

HRM 047U4 50 12 9.3 3.87 2.85 3.87

HRM048U4 60 12 .5 9.4 2.65 2.61 2.60

HR M051T4 60 13 9.8 2.65 2.62 2.60

HR M054T4 70 12.5 10.5 2 .37 2.35 2.34

HRM054U4 70 13.1 11 .0 2.37 2.35 2.34

HRM058U4 70 15 11 .3 2.37 2.35 2.34

460 V / 3 ph / 60 H z

HRM060T4 70 15 11. 7 2.37 2.36 2. 35

380- 415 V / 3ph / 50 Hz

HRM060U4 70 15 11. 7 2.37 2. 35 2.34

HL M06 8T4 82 15 12.4 1. 80 1.88 1. 87

HL M072 T4 82 15 14.1 1.82 1.86 1.85

HLM075T4 100 16 15 .0 1.70 1. 68 1.69

HL M078 T4 87 16 15 .6 1. 67 1.69 1.72

HL M081T4 87 17 16. 6 1.82 1.82 1. 83

HCM094T4 95 21 18.1 1.48 1.4 8 1. 48

HCM109T4 110 24 20. 3 1.30 1.28 1. 34

HC M120T4 14 0 25 23.9 1.13 1. 11 1.10

HRM038U7 38 8.5 6.2 7. 34 5.38 7. 34

HRM042U7 38 9 6.6 7. 34 5.38 7. 34

HRM045U7 40 9.5 7.1 6.09 4 .47 6.09

HRM 047U7 40 10 7.4 6.09 4. 47 6.09

HRM054U7 53 11 8.4 4.12 4.06 4.03

HRM058U7 53 11. 5 8.8 4.12 4.06 4.03

HRM060U7 53 11 .5 9.1 4.04 3.97 3.94

HLM072T7 63.6 11.5 11 .3 2.98 2.83 2.87

575 V / 3ph / 60 Hz

HLM075T7 72 13 .5 11.8 2.51 2.48 2. 53

HCM094T7 75 16 14. 4 2.30 2 .31 2.34

HRM034T9 52 12 8.3 3. 01 2.20 3 .01

HRM038T9 52 12 9.3 3.01 2. 20 3.01

HRM042T9

HRM 047T9 59. 6 8.3 11. 3 2. 51 1. 84 2. 51

HRM054T9 81 16.5 12.7 1.49 1.46 1.48

HRM060T9 81 17 14.2 1.0 3 1. 02 1.03

HLM072T9 96 20 17. 0 1.27 1. 25 1.28

HLM081T9 11 0 19 20.4 1.13 1.0 8 1.10

380 V / 3ph / 60 H z

HCM094T9 135 25 21.9 0.93 0.91 0.93

HC M120T 9 13 5 27 23.9 0.87 0.88 0.89

HRP025T2 14.5 9.6 1.67 1.23 1.67

HRP038T2 95 19 14. 8 1.18 0.87 1.18

HRP040T2 95 20 15. 5 1.18 0.87 1.18

HRP 047T2 115 25 20.1 0.98 0.73 0.98

HRP051T 2 120 26 20.1 0.68 0. 67 0.67

HRP058T2 123 27 22.7 0.59 0.59 0.59

HRP060T2 123 28 23.5 0.59 0. 59 0. 59

HLP068T2 170 32 27. 3 0.48 0.48 0.46

HLP072T2 170 33 28.2 0.48 0.48 0.46

HLP075T2 190 35 31.6 0.41 0.40 0 .41

HLP078T2 190 37 33.4 0.43 0.43 0.44

HLP 081T2 190 39 35.2 0.43 0.43 0.44

208-230 V / 3 ph / 6 0 Hz

200-220 V / 3 ph / 50 Hz

HCP094T2 190 40 36.1 0.37 0. 37 0. 37

HCP109T2 235 46 40.7 0.33 0.32 0.32

HC P120T 2 250 55 47.6 0.30 0.29 0.29

LRA MCC Max. operating current Winding resistance (Ohm)

A A A L2-L3 L1- L3 L2 -L1

52 12.5 10.1 3.01 2.20 3.01

16 AB218186428184en-001501

Page 17

Electrical data, connections and wiring

Three phase electrical

characteristics

Compressor model

HR P025 T4 30

HR P034 T4 45

HRP038T4 45

HR P04 0T4 45

HR P042 T4 45

HR P045T4 50

HR P047 T4 50

HRP048T4 60

HR P051T4 60

HR P054T4 70

HRP058T4 70

HRP060T4 70

HL P068T4 82

460 V / 3 ph / 60 H z

Motor voltage code 4

HL P072T4 87

380- 415 V / 3ph / 50 Hz

HL P075T4 100

HL P078T4 87

HL P081T4 87

HCP094T4 95

HCP109T4 110

HC P120T4 14 0

HRH029U2 95 20 14. 8 1.18 0.87 1.18

HRH031U2 95 20 15.8 1.18 0.87 1.18

HRH032U2 95 20 16.3 1.18 0.87 1.18

HRH034U2 95 22 17. 4 1.18 0.87 1.18

HRH036U2 95

HRH038U2 115

HRH0 40U2 115

HR H041U2 120

HRH0 44U2 12 0

HRH 047U2 115

HRH0 48U2 115

HRH049U2 120

HRH050U2 115

Motor voltage code 2

Motor voltage code 4

HRH051U2 121.5

HRH054U2 12 3

208-230 V / 3 ph / 6 0 Hz

200-220 V / 3 ph / 50 Hz

HRH056U2 120

HLH0 61T2 170

HLH068T2 160

HLJ 072T2 180

HLJ075T2 190

HLJ083T 2 190

HRH029U4 45

HRH031U4 45

HRH032U4 45

HRH034U4 45

HRH036U4 45

HRH038U4 50

HRH040U4 50

HR H041U 4 60

HRH044U4 60

HRH 047U4 53

HRH048U4 53

HRH049U4 60

HRH051U4 70

HRH054U4 70

HRH056U4 70

460 V / 3 ph / 60 H z

380- 415 V / 3ph / 50 Hz

HL H061T4 82

HL H06 8T4 87

HL J072T4 87

HL J075 T4 100

HLJ083T4 10 0

HCJ091T4 125

HC J106T4 12 5

HC J121T4 125

LRA MCC Max. operating current Winding resistance (Ohm)

A A A L2-L3 L1- L3 L2 -L1

7

9.5

11

12

11

12

12

12

13

12. 5

14

14

15

15

17

16

17

21

24

25

22

23

25

25

26

27

27

26

30

27. 5

27. 5

27. 5

30

35.6

35

35

39

10

10

10

10

10

12

12

13

13. 5

13

14

13. 5

13

15

15

15

19

19

18

19

25

26

27

4.9 6.72 4.95 6.72

6.8 4.66 3.42 4.66

7.9 4.66 3.42 4.66

8.6 4.66 3.42 4.66

8.3 4.66 3.42 4.66

8.9 3.87 2.85 3.87

9.3 3.87 2.85 3.87

9.0 2.65 2.61 2.60

9.8 2.65 2.62 2.60

10.5 2.37 2.37 2.37

11. 3 2.36 2. 33 2.32

11. 7 2. 37 2.36 2.35

12. 4 1.80 1.88 1. 87

14.1 1.91 1.93 1.94

15.0 1. 62 1.60 1.63

15. 6 1.67 1.69 1.72

16.6 1.9 0 1. 88 1.89

18.1 1.48 1.48 1.48

20.3 1.3 0 1. 28 1. 34

23.9 1.13 1.11 1.10

18.4 1.18 0.87 1.18

18. 8 0.98 0.73 0.98

19.8 0.98 0.73 0.98

16.8 0.68 0.67 0.67

17. 5 0.68 0.67 0.67

22.4 0. 83 0. 61 0.83

23.0 0.83 0. 61 0.83

18.1 0.68 0.67 0. 67

23.3 0.83 0. 61 0.83

20.5 0.59 0.59 0.59

20.5 0.59 0.59 0.59

21.1 0 .61 0.60 0.60

24.9 0.48 0.48 0.46

25.7 0.45 0.45 0.45

30.0 0.42 0 .42 0.42

31.2 0.41 0.40 0 .41

34.0 0.36 0.36 0.37

6.8 4.66 3.42 4.66

7.3 4.66 3.42 4.66

7.5 4.66 3.42 4.66

8.0 4.66 3.42 4.66

8.4 4.66 3.42 4.66

9.4 3.87 2.85 3.87

10.0 3.87 2.85 3.87

8.8 2.65 2.61 2.60

9.1 2.65 2.61 2.60

10.0 3.29 2 .41 3.29

10.5 3.29 2.41 3.29

10.2 2.65 2.61 2.60

8.3 2. 37 2.35 2.34

10.2 2.37 2.36 2.35

10.6 2.37 2. 35 2.34

12. 8 1.83 1.85 1. 84

12. 8 1.93 1.92 1.93

13. 4 1.93 1.92 1.93

15.7 1. 62 1.60 1.63

15.7 1.48 1.44 1.47

19.0 0.98 0.97 1.01

21.5 0.98 0.97 1.01

24.0 0.98 0.97 1.01

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

17AB218186428184en-001501

Page 18

Electrical data, connections and wiring

Three phase electrical

characteristics

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

Single phase electrical characteristics

Compressor model

575 V / 3ph / 60 Hz

Motor voltage code 7

380 V / 3ph / 60 H z

Motor voltage code 9

Compressor model

50 Hz

code 5

Motor voltage

200-220 V / 1 ph /

Motor voltage code 1

208-230 V / 1 ph / 6 0 Hz

LRA MCC Max. operating current Winding resistance (Ohm)

A A A L2-L3 L1- L3 L2 -L1

HRH032U7 38

HRH034U7 38

HRH036U7 38

HRH038U7 40

HRH040U7 40

HR H041U7 42

HRH049U7 42

HRH051U7 53

HRH054U7 53

HRH056U7 53

HLH0 61T7 63.6

HLH068T7 62

HLJ 072T7 62

HLJ083T 7 72

HRH031U9 52

HRH034U9 52

HRH038U9 59.6

HRH054U9 81

HLH061T9 96

HLH068T9 95

HLJ 072T9 95

HLJ083T9 110

LRA MCC Max. operating current Winding resistance (Ohm)

A A A Start Run

HRM032T5 97

HRM034T5 97

HRM038U5 97

HRM042T5 97

HRM042U5 97

HRM 047T5 102. 5

HRM 047U5 102.5

HRM060U5 13 0

HRM025T1 69

HRM 032U1 96.7

HRM 034U1 96.7

HRM 038U1 105

HRM 040U1 115

HRM 042U1 115

HRM 045U1 115

HRM 047U1 12 0

HRM 048U1 15 0

HRM051U1 150

HRM 054U1 15 0

HRM058T1 160

HRM058U1 145

HRM060T1 160

HRM060U1 145

HLM068T1 145

HLM072T1 145

HLM081T1 145

8.5

8.5

8.5

9.5

10

10

10.5

11. 5

11. 7

12. 5

12

13. 5

15

14. 5

12. 5

10

13. 5

16

20

19

19

22.4

23

25

25

27

26

31.2

31.2

45

19

26

26

30

32.9

32.9

35

38

41.5

40

39

45

45

45

45

45

45

45

6.2 7. 34 5.38 7. 34

6.6 7. 34 5.38 7. 34

7.0 7. 34 5.38 7. 34

6.7 6.09 4. 47 6.09

6.7 6.09 4. 47 6.09

6.6 4.47 4.40 4.39

7.4 4.47 4.40 4.39

7.8 4.12 4.06 4.03

8.2 4.12 4.06 4.03

8.5 4.12 4.06 4.03

10.8 2.89 2.83 2.87

10.4 3.26 3.29 3.33

11. 0 3.26 3. 29 3.33

12. 5 2. 51 2.48 2.53

8.3 3.01 2.20 3 .01

9.1 3. 01 2.20 3 .01

9.8 2.51 1.8 4 2.51

13.1 1.49 1.46 1.48

15. 8 1.27 1.25 1.28

13.1 0.58 0.58 0.58

17. 5 0.58 0.58 0.58

20.8 1.13 1.08 1.10

17.9 1.51 0.69

19.5 1.51 0.69

21.2 1.51 0.69

24.2 1.51 0.69

24.2 1.51 0.69

29.0 1.61 0.66

29.0 1.61 0.66

33.9 1.02 0.39

13. 8 1.74 0.85

20.1 1.57 0.67

21.4 1.57 0.67

24.7 1.44 0.54

25.5 1.43 0.54

26.8 1.45 0.54

28.5 0.82 0. 32

29.8 1.32 0.52

32.5 0.86 0.33

31.9 0.86 0.33

33.9 0.86 0.33

36.0 1. 72 0. 27

36.4 0.84 0.29

37. 2 1.76 0.28

37. 7 0.84 0.29

38.2 0.84 0.29

40.5 0.84 0.29

41.2 0.84 0.29

18 AB218186428184en-001501

Page 19

Electrical data, connections and wiring

Single phase electrical

characteristics

Compressor model

HRP032T5 97

HRP034T5 97

HRP038T5 97

HRP040T5 97

HRP042T5 97

HRP045T5 102. 5

HRP 047T5 102.5

HRP054T5 13 0

HRP058T5 13 0

Motor voltage code 5

Motor voltage code 1

Motor voltage code 5

Motor voltage code 1

HRP060T5 130

HLP068T5 130

200-220 V / 1 ph / 50 Hz

HLP072T5 13 0

HLP 081T5 130

HRP025T1 69

HRP034T1 96.7

HRP042T1 11 5

HRP051T 1 150

HRP060T1 160

60 Hz

HLP068T1 145

HLP072T1 145

208-230 V / 1 ph /

HLP 081T1 145

HRH029U5 97

HRH031U5 97

HRH032U5 97

HRH034U5 97

HRH036U5 97

HRH038U5 102 .5

HRH040U5 102 .5

HRH051U5 130

HRH054U5 130

HRH056U5 13 0

HLH0 61T5 130

200-220 V / 1 ph / 50 Hz

HLH068T5 130

HLJ 072T5 130

HLJ083T5 130

HRH029U1 96.7

HRH031U1 96.7

HRH 032U1 87. 5

HRH 034U1 115

HRH036U1 105

HRH 038U1 115

HRH039U1 115

HRH 040U1 115

HR H041U1 15 0

HRH 044U1 150

HRH 047U1 135

HRH 048U1 135

HRH049U1 15 0

HRH 050U1 135

HRH051U1 150

208-230 V / 1 ph / 6 0 Hz

HRH 054U1 145

HRH056U1 145

HLH0 61T1 145

HLH068T1 145

HLJ 072T1 145

HLJ083T1 145

LRA MCC Max. operating current Winding resistance (Ohm)

A A A Start Run

23

25

25

25

27

30

31.2

40

42

40

40

40

47

19

24.5

32.9

40

45

45

45

45

24

25

25

25.5

25.5

28

33

38

40

40

42

45

45

50

27

26.5

26

31

34

33

31

32

36.9

38

43

42

45

43

41

45

47

42

42

42

42

18. 3 1.51 0.69

19.5 1.51 0.69

21.2 1.51 0.69

22.3 1. 51 0.69

24.2 1.51 0.69

27. 9 1.61 0.66

29.0 1.61 0.66

30.8 1. 02 0.39

32.8 1.02 0.39

33.9 1.02 0.39

38.4 1. 02 0.39

38.9 1.02 0.39

45.8 1.02 0.39

13. 8 1.74 0.85

21.4 1.57 0.67

26.8 1.47 0.55

31.9 0.86 0.33

37. 2 1.76 0.28

38.2 0.84 0.29

40.5 0.84 0.29

41.2 0.84 0.29

17.9 1.51 0.69

19.2 1.51 0.69

19.8 1.51 0.69

21.0 1.51 0.69

22.3 1. 51 0.69

23.8 1.61 0.66

26.6 1.61 0.66

31.7 1.02 0.39

38.2 1.02 0.39

38.9 1.02 0.39

44 .1 1.02 0.39

41.7 1. 02 0.39

48.9 1.02 0.39

55.7 1.02 0.39

19.5 1.45 0.72

20.8 1. 57 0.67

17.9 1.66 0.67

20.9 1. 40 0.53

23.3 1. 22 0.54

23.6 1. 21 0.54

22.8 1.19 0.53

27. 7 1.31 0.53

28.2 0.86 0.33

29.9 0.86 0.33

35.3 1.06 0.43

35.6 1.06 0.43

32.4 0.84 0.32

39.3 1.06 0.43

33.6 0.84 0. 32

34 .1 0.84 0.29

35.9 0.84 0.29

41.8 0.84 0.29

46 .1 0.84 0.29

48.6 0.84 0.29

57. 6 0.84 0.29

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

19AB218186428184en-001501

Page 20

Electrical data, connections and wiring

IP rating

LRA (Locked Rotor Amp)

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

MCC (Maximum Continuous Current)

Max Oper. A (Max operating current)

The compressor terminal box IP rating according to IEC 529 is IP22 for all models. IP ratings is only

valid when correctly sized cable glands of the IP rating is applied.

• First numeral, level of protection against contact and foreign objects

2 protection against object size over 12.5 mm (fingers of similar)

• Second numeral, level of protection against water

2 protection against dripping water when tilted up to 15°

Locked Rotor Amp value is the higher average

current as measured on mechanically blocked

compressors tested under nominal voltage. The

LRA value can be used as a rough estimation for

The MCC is the current at which the motor

protection trips under maximum load and

low voltage conditions. This MCC value is the

maximum at which the compressor can be

The max. operating current is the current when

the compressors operate at maximum load

conditions and 10% below nominal voltage.

Max Oper. A can be used to select cables and

contactors. In normal operation, the compressor

the starting current. However, in most cases, the

real starting current will be lower.

operated in transient conditions and out of

the application envelope. Above this value,

the external electronic module will cut-out the

compressor to protect the motor.

current consumption is always less than the Max

Oper. A value. When using the Max Operating

Current to define cables and contactors, a

tolerance of +5% need to be taken into account.

Winding resistance Winding resistance is the resistance between

indicated terminal pins at 25°C (resistance value

+/- 7%).

Winding resistance is generally low and it

requires adapted tools for precise measurement.

Use a digital ohm-meter, a ‘4 wires’ method and

measure under stabilised ambient temperature.

Winding resistance varies strongly with winding

temperature ; If the compressor is stabilised

at a different value than 25°C, the measured

resistance must be corrected with following

formula:

Motor protection Danfoss Scroll Compressors H-Series are

equipped with an internal line break protector

mounted on the motor windings. The protector

is an automatic reset device, containing a snap

action bimetal switch.

Internal protectors respond to over-current and

overheating. They are designed to interrupt

Phase sequence and reverse rotation protection

The compressor will only operate properly in a

single direction. Use a phase meter to establish

the phase orders and connect line phases L1, L2

and L3 to terminals T1, T2 and T3, respectively.

For three-phase compressors, the motor will run

equally well in both directions. Reverse rotation

results in excessive noise; no pressure differential

between suction and discharge; and suction line

warming rather than immediate cooling.

A service technician should be present at initial

start-up to verify that supply power is properly

phased and that compressor and auxiliaries are

a + t

R

= R

tamb

a + t

t

25°C

t

amb

R

25°C

R

amb

25°C

: reference temperature = 25°C

: temperature during measurement (°C)

: winding resistance at 25°C

: winding resistance at t

amb

25°C

amb

coefficient a= 234.5

motor current under a variety of fault conditions,

such as lose phase, running overload, and locked

rotor.

If the internal overload protector trips out,

it must cool down to about 60°C to reset.

Depending on ambient temperature, this may

take up to several hours.

rotating in the correct direction.

Danfoss HR* and HL* series scroll compressor are

designed to operate for a maximum of 150 hours

in reverse, but as a reverse rotation situation can

go unnoticed for longer periods, phase monitors

are recommended.

For HC* series compressors, phase monitors are

required. The selected phase monitor should

lock out the compressor from operation in

reverse.

20 AB218186428184en-001501

Page 21

Electrical data, connections and wiring

Electrical connections

PSC wiring

CSR wiring

Nominal capacitor value and relays

Danfoss scroll compressors are designed to

operate without any assistance if running within

The start winding (C-S) of the motor remains in

circuit through a permanent (run) capacitor.

This permanent (run) capacitor is connected

between the start winding (C-S) and the run

winding (C-R).

If start assist is required, in case of operating

below the nominal voltage, a CSR starting device

is required.

During start-up, the start winding (C-S) is

energised through an electromagnetic potential

relay and a start capacitor.

50 Hz, motor voltage code 5

60 Hz, motor voltage code 1

Models

HRM025-032-034-038-040-042 70 μF 145-175 μF 3ARR3*3AL* RVA 9CKL

HRM045-047 60 μF 14 5-175 μF 3ARR3*3AL* RVA 9CKL

R22

HRM054 55 μF 161-193 μF 3ARR3*24AP* RVA 3EKL

HRM058-060 55 μF 88-108 μF 3ARR3*25AS* RVA 4 GK L

HLM068-072-075-081 55 μF 88-108 μF 3ARR3*25AS* RVA 4GKL

HRP025-034-038-040-042 70 μF 145 -175 μ F 3ARR3*3AL* RVA 9CKL

HRP045-047 60 μF 145 -175 μ F 3ARR3*3AL* RVA 9CKL

R407C

HRP054 55 μF 161-193 μF 3ARR3*24AP* RVA 3EKL

HRP058-060 55 μF 88-108 μF 3ARR3*25AS* RVA 4 GKL

HLP068-072-075-081 55 μF 88 -108 μF 3ARR3*25AS* RVA 4GKL

HRH029-031-032-034-036 70 μF 145 -175 μ F 3ARR3*3AL* RVA 9CKL

HRH038-040 60 μF 145 -175 μ F 3ARR3*3AL* RVA 9CKL

R410A

HRH051-054-056 55 μF 88-108 μF 3ARR3*25AS* RVA 4GKL

HLH061-068, HLJ072-083 55 μF 88-10 8 μF 3ARR3*25AS* RVA 4GKL

HRM025-032-034 45 μF 145 -175 μ F 3ARR3*3M* RVA 2ACKL

HRM038 55 μF 88-108 μF 3ARR 3*3L* RVA 2 ABKL

HRM040-042-045-047 60 μF 88 -108 μF 3ARR 3*3L* RVA 2AB KL

HRM048 60 μF 161-193 μF 3ARR 3*3L* RVA 2 ABKL

R22

HRM051-054 70 μF 161-193 μ F 3A RR 3* 3L* RVA 2AB KL

HRM058T1-060T1 55 μF 88-108 μF 3ARR3*25S* RVA A4IKL

HRM058U1-060U1,

HLM068-072-075-081

HRP051 70 μF 161-193 μ F 3A RR 3* 3L* RVA 2AB KL

R407C

HLP068-072-075-081 80 μF 189 -227 μF 3 AR R3 *3 L* RVA 2ABKL

HRH031 45 μF 145 -175 μF 3ARR3*3M* RVA 2ACKL

HRH032-034 50 μF 88 -108 μF 3ARR 3*3L* RVA 2ABKL

HRH036 55 μF 88-108 μF 3ARR3*3AL* RVA 9CKL

R410A

HRH038-039-040 60 μF 88-108 μF 3 AR R3 *3 L* RVA 2ABKL

HRH041-044-048-049-050-051 70 μF 161-193 μF 3 AR R3 *3L* RVA 2ABKL

HRH054-056, HLH061-068,

HLJ072-083

Run capacitor

the defined nominal voltage. PSC wiring is

sufficient (see below).

C

Line

S

Run

Capacitor

R

A permanent (run) capacitor is wired between

the start winding (C-S) and the run winding (C-R).

5

Potential

Relay

C

S

Line

R

PSC wiring

80 μF 189 -227 μF 3 AR R3 *3 L* RVA 2ABKL

80 μF 189 -227 μF 3 AR R3 *3 L* RVA 2ABKL

CSR wiring

Start capacitor

2

Run

Capacitor

Relay

1

Start

Capacitor

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

21AB218186428184en-001501

Page 22

Approvals and certifications

Approvals and certificates

Pressure equipment

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

directive 2014/68/EU

Low voltage directive 2014/35/EU

Machines directive 2006/42/EC

Internal free volume

Danfoss scroll H-series compressors comply with

the following approvals and certificates.

CE

(European Directive)

UL

(Underwriters Laboratories)

Other approvals / certificates Contact Danfoss

Products All models

Refrigerating fluids Group 2

Category PED I

Evaluation module no scope

Products All models

Declaration of conformity

ref. Low voltage Directive 2014/35/EU

Products All models

Manufacturer's declaration of incorporation

ref. Machines Directives 2006/42/EC

Products

HRM/P032-034-038-040-042

HRH029-031-032-034-036-038

HRM/P045-047

HRH040

HRM/P048-051-054-058-060, HLM/P068-072-075-081

HRH044-049-051-054-056, HLH/J061-068-072-075-083

Certificates are listed on the product datasheets:

http://www.danfoss.com/odsg

All models

All models

Contact Danfoss

Contact Danfoss

Internal free volume at LP

side without oil (litre)

2.93 0.49

3.20 0.70

3.44 0.71

Internal free volume at HP

side without oil (litre)

HCM/P094-109-120 5.92 0. 51

HC J091-106-121 5.75 0.51

22 AB218186428184en-001501

Page 23

Operating conditions

Refrigerant and lubricants

General information

When choosing a refrigerant, different aspects

must be taken into consideration:

• Legislation (now and in the future)

• Safety

• Application envelope in relation to expected

running conditions

• Compressor capacity and efficiency

• Compressor manufacturer recommendations &

guidelines

Additional points could influence the final

choice:

• Environmental considerations

• Standardisation of refrigerants and lubricants

• Refrigerant cost

• Refrigerant availability

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

PVE Polyvinyl ether (PVE) is an innovative

refrigeration lubricant for HFC refrigerant

systems. PVE is as hygroscopic as existing

polyolester lubricants (POE), but PVE doesn’t

chemically react with water; no acids are formed

and compressor evacuation is easier.

Alkylbenzene oil

Alkylbenzene oil can be applied in systems

using HCFC refrigerants (R22). Compared to

a mineral oil it provides distinct advantages:

excellent miscibility, excellent thermal stability,

compatibility with mineral oils and constant

quality.

Oil type

Danfoss scroll compressors are charged with

oil at the factory with the oils indicated, in the

following table.

Compressor range Oil type

HRM / HLM / HCM Alkylbenzene

HRP / HLP / HCP PVE

HRH / HLH PVE

HLJ/HCJ PVE

The compressor technology applied in Danfoss

H-series scroll compressors in combination with

PVE lubricant provides the best possible result in

terms of reliability and compressor lifetime.

The PVE lubricant is compatible with R22 which

makes the Danfoss H-series scroll compressors a

very versatile multi- refrigerant solution.

Danfoss Scroll H_M series compressors are

charged with Alkylbenzene oil and herewith

offer an economically interesting alternative to

the Danfoss H series in regions where R22 is still

the predominant refrigerant. Note however that

Danfoss H-series scroll compressors can not be

used with HFC refrigerants.

Effective week 31 of 2009, the HRP/HLP/

HCP & HRH/HLH series of compressors were

changed from POE oil to PVE oil. Compressors

produced prior to this week still had POE,

and may be in stock in the warehouses until

supply is exhausted. This change was made

to standardize to the better oil for reliability.

Replacement PVE 320HV is available for topping

up or replacing oil in the field (see accessory

section). As it is fully miscible with POE, Danfoss

recommends the 320HV regardless of original oil

charge in the compressor.

Residual moisture

Prior to shipment from the factory, every

compressor is dehydrated, evacuated, and

charged with dry nitrogen. Maximum residual

Run-in process Our H product ranges feature a compliance

technology which allows

. an exceptional slugging capability (radial

compliance)

. a very low starting torque (axial compliance)

moisture levels are 0.0082 oz. for models

capacities up to HRM/HRP047 and HRH040 and

0.0120 oz. for larger compressors.

When a compressor with compliance technology

is new, the performance is not immediately at

peak. A run-in period is needed to polish all

surfaces as well as to reduce friction and leakage.

The run-in period eliminates extra power input

23AB218186428184en-001501

Page 24

SYSTEM DESIGN

Design piping

General requirements Proper piping practices should be employed to:

1. Ensure adequate oil return, even under

minimum load conditions (refrigerant speed,

piping slope). For validation tests see section

“Manage oil in the circuit”.

g.1

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

0.5 % slope,

max. 4 m

max. 4 m

4 m/s or more

U-trap, as short as possible

8 to 12 m/s

0.5 % slope,

4 m/s or more

U-trap, as short as possible

U-trap

Evaporator

To condenser

2. Avoid condensed liquid refrigerant from

draining back to the compressor when stopped

(discharge piping upper loop). For validation

tests see section “Manage off cycle migration”.

General recommendations are described in the

figures below:

g. 2

Upper loop

Condenser

HP

U-trap

LP

3D exibility

3. Piping should be designed with adequate

three-dimensional flexibility to avoid excess

vibration. It should not be in contact with the

surrounding structure, unless a proper tubing

mount has been installed. For more information

on noise and vibration, see section on: “Manage

sound and vibration”.

24 AB218186428184en-001501

Page 25

Design piping

Tandem requirements Danfoss scroll compressor H series tandem use

static oil balancing principle to equalize oil level

between the compressors by gravity. This is

ensured by a precise suction and oil equalization

piping designs.

Danfoss scroll H series compressors in C8 version

can be mounted in tandem assemblies.

By default, H series tandems are not factory-built,

just provide tandem version compressors (feature

8).

The discharge line as no impact on oil balancing

and is shown with tees, to indicate that both left

and right side discharge header are possible

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

Such manifolding applications require special

design considerations that go beyond the scope

of this document. Please contact Danfoss for

further information.

For each tandem configuration, specific outline

drawings are available as indicated in following

tables.

Connection Sizes

Tandem model Comp.1 Comp.2

TLJ082 HR H041 HRH 041 1-1/8" 3/4" 1/2" 7/8" 120Z0 636 8556080

TLJ098 HRH049 HRH049 1-1/8" 3/4" 1/2" 7/ 8" 120Z0 636 8556080

TL J122 HL H061 HLH061 1-1/8" 3/4" 1/2" 7/ 8" 120 Z06 36 8556080

TL J136 HLH068 HLH068 1-1/8" 3/4" 1/2" 7/8" 120Z0 636 8556080

TL J144 HLJ072 HLJ072 1-1/8" 3/4" 1/2" 7/8 " 120Z0636 8556080

TL J166 HLJ083 HLJ083 1-1/8" 3/4" 1/2 " 7/8" 12 0Z063 6 8556080

TCJ181 HCJ091 HCJ091 1-5/8" 1-1/8" 1/2" 1-1/8" 120Z0636 855 6153

TCJ211 H CJ106 HCJ106 1-5/8 " 1-1/8" 1/2" 1-1/8 " 120Z0636 855 6153

TCJ241 HC J121 H CJ121 1-5/8" 1-1/8" 1/2" 1-1/8" 120Z0636 8556153

Suction

(in)

Discharge

(in)

Oil equalization

Suction and oil & gas equalization piping

R

drawing must be respected (diameters, minimum

straight lengths)

(in)

Gas equalization

(in)

Kit tandem

Code No

Outline drawing

number

25AB218186428184en-001501

Page 26

Design compressor mounting

General requirements

Single requirements

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

Tandem requirements

Parallel mounting feet

Compressors used in single applications must be

mounted with flexible grommets.

Compressors used in parallel application must be

mounted with rigid mounting spacers onto rails

H-series compressors come delivered with

flexible grommets, accessory Mounting kit

120Z5064.

The grommets must be compressed until contact

between the flat washer and the steel mounting

sleeve is established. The required bolt size for

the H-series compressors is M8*40mm. This bolt

must be tightened to a torque of 11 Nm.

For parallel mounting, the compressor must be

mounted with rigid mounting spacers (included

in the tandem kit 120Z0636) on the rails.

and the manifold assembly must be mounted

with flexible grommets onto frame.

During operation, the maximum inclination from

the vertical plane must not exceed 3 degrees.

1.7

29.5

41

5/16” - 18 UNC

Ø11

Ø 41

Recommended torque for mounting bolts:

11 Nm (±1 Nm)

self tapping

Rubber grommets and sleeves (delivered with

the compressor) must be installed below the rails.

26 AB218186428184en-001501

Supplied with the compressor

Included in tandem

Not supplied

Page 27

Manage sound and vibration

Compressor sound radiation

Typical sounds and vibrations in systems can be

broken down into the following three categories:

• Sound radiation (through air)

The following sections focus on the causes and

methods of mitigation for each of the above

sources.

• Mechanical vibrations (through parts and

structure)

• Gas pulsation (through refrigerant)

For sound radiating from the compressors,

the emission path is air and the sound waves

Sound levels are as follows:

• For compressors running alone:

are travelling directly from the machine in all

directions.

50 Hz 60 Hz

Compressor model

HRM025-038 66 5 69 5 120Z5083

HRM040-047 67 5 70 5 120Z5083

HRM048-054 68 5 71 5 120Z5 084

HRM058-060 69 5 72 5 12 0Z5084

HLM068-0 81 70 5 73 5 120Z 508 4

HCM094 71 5 74 5 120Z5085

HCM109-120 74 5 78 5 120Z5085

HRH029-032 65 5 68 5 120Z5083

HRH034-040 66 5 69 5 120Z5083

HRH041-054 67 5 70 5 12 0Z5084

HLH0 61 70 5 73 5 120Z 508 4

HLH068-HLJ083 71 5 74 5 120Z 508 4

HC J091-106-121 73 5 76 5 120Z5085

Attenuation given with acoustic hood only

Acoustic hood could be applied for both single and tandem version compressors.

Materials are UL approved and RoHS compliant

Sound power and attenuation are given at ARI conditions, measured in free space

H*P series same as H*M series. Compressor’s noise test is after compressor run-in 72hrs. Maximum sound is +5dBA

Sound power

dB(A)

Attenuation

dBA

Sound power

dB(A)

Attenuation

dBA

Acoustic hood

code number

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

Note: During compressor shut down, a short

reverse rotation sound is generated. The duration

of this sound depends on the pressure difference

at shut down and should be less than 3 seconds.

This phenomenon has no impact on compressor

reliability.

Mitigations methods:

We can consider two means to reduce

compressors sound radiations:

1. Acoustic hoods are quick and easy to install

and do not increase the overall size of the

compressors to a great extent. Acoustic hoods

are available from Danfoss as accessories. Refer to

the table above for sound levels, attenuation and

code numbers.

2. Use of sound-insulation materials on the inside

of unit panels is also an effective means to reduce

radiation.

27AB218186428184en-001501

Page 28

Sound and vibration management

Mechanical vibrations Vibration isolation constitutes the primary

method for controlling structural vibration.

H-series scroll compressors are designed to

produce minimal vibration during operations.

The use of rubber isolators on the compressor

base plate or on the frame of a manifolded unit

is very effective in reducing vibration being

transmitted from the compressor(s) to the unit.

Rubber grommets are supplied with all H-series

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

scroll compressors.

Once the supplied rubber grommets have

been properly mounted, vibration transmitted

from the compressor base plate to the unit

Gas pulsation The Danfoss Scroll Compressors H-series has

been designed and tested to ensure that gas

pulsation has been optimised for the most

commonly encountered air conditioning

pressure ratio. Manifolded compressors are

equivalents to lagged sources of gas pulsation.

Therefore pulse level can vary during time.

are held to a strict minimum. In addition, it is

extremely important that the frame supporting

the mounted compressor be of sufficient mass

and stiffness to help dampen any residual

vibration potentially transmitted to the frame.

The tubing should be designed so as to both

reduce the transmission of vibrations to other

structures and withstand vibration without

incurring any damage. Tubing should also be

designed for three-dimensional flexibility. For

more information on piping design, please see

the section entitled “Essential piping design

considerations”.

Mitigations methods:

If an unacceptable level is identified, a discharge

muffler with the appropriate resonant volume

and mass can be installed.

28 AB218186428184en-001501

Page 29

Manage operating envelope

Requirement The operating envelope for H-series scroll

R

compressors is given in the figures below and

guarantees reliable operations of the compressor

for steady-state and transient operation.

R22, R407C

70

Model variation T

65

60

55

50

45

40

35

Condensing temperature (°C)

30

25

20

-30 -25 -20 -15 -10 -5 0 5 10 15

Evaporating temperature (°C)

Steady-state operation envelope is valid for a

suction superheat within 5K to 30K range.

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

SH 11K

R410A Model variation T

70

65

60

55

50

45

40

35

Condensing temperature (°C)

30

25

20

-30 -25 -20 -15 -10 -5 0 5 10 15

SH 5K

SH 11K

Evaporating temperature (°C)

HCJ121 & HCJ 120

condensing temperature boundary

29AB218186428184en-001501

Page 30

Manage operating envelope

Bracket

R22, R410A Model variation U

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

70

65

60

55

50

45

40

35

Condensing temperature (°C)

30

25

20

-30 -25 -20 -15 -10 -5 0 5 10 15

Working pressure range high side bar (g) 10.9 - 27.7 10.5 - 29.1 15.8 - 44.5

Working pressure range low side bar (g) 1.4 - 6.9 1.1 - 6.4 1.9 - 10.8

Maximum high pressure safety switch setting* bar (g) 29 30 45

Minimum low pressure safety switch setting bar (g) 0.5 0.5 1.5

Recommended pump-down switch settings bar (g)

Minimum low pressure pump-down switch setting bar (g) 1.5 1.3 2.3

Evaporating temperature (°C)

SH 11K

R22 R407C R410A

1.5 bar below nominal evap. pressure with

minimum limitation as below

High and low pressure protection

Maximum allowable pressure on high pressure side according to PED regulation.

*

LP and HP safety switches must never

R

be bypassed nor delayed and must stop all the

compressors.

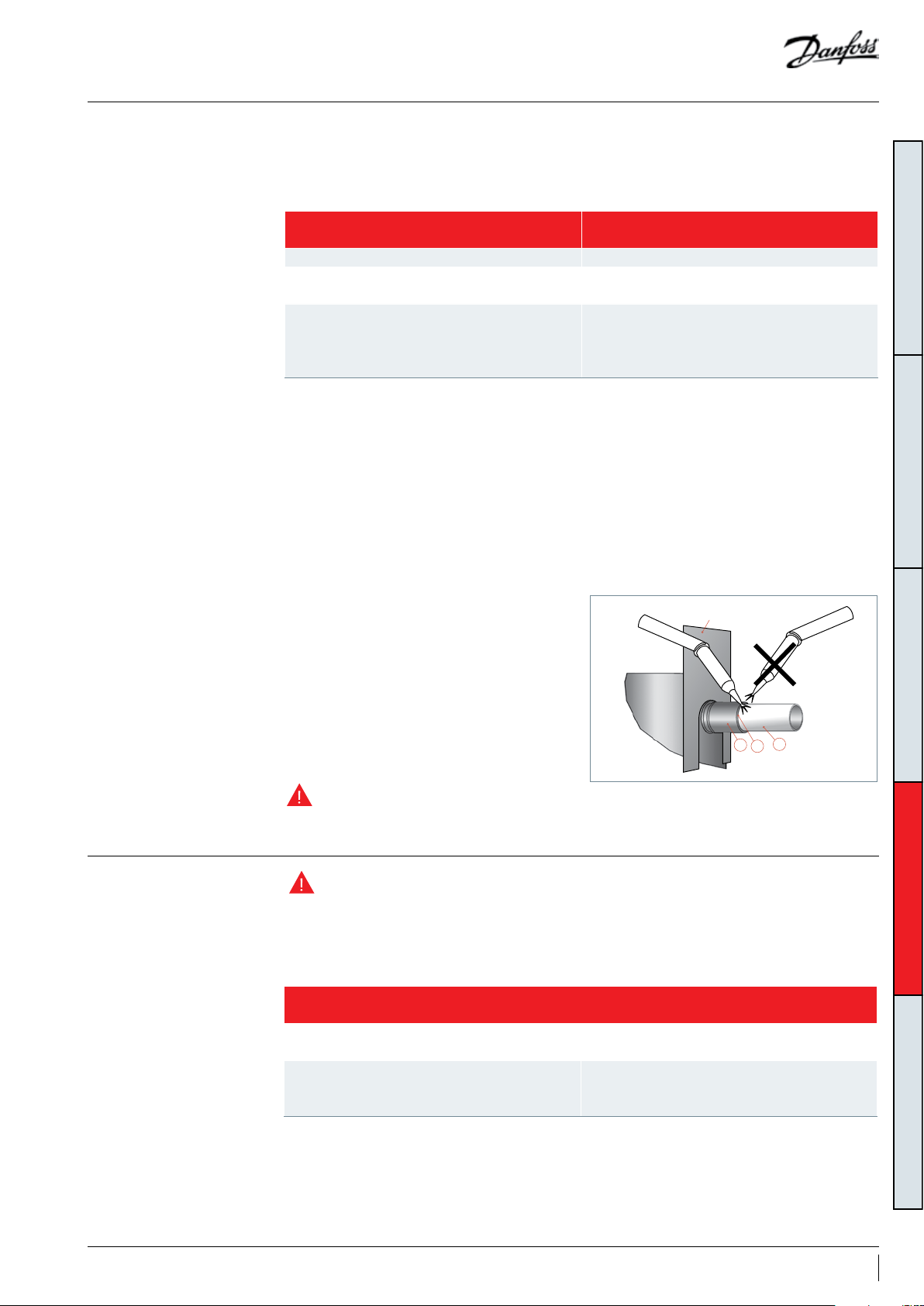

The discharge gas thermostat accessory kit (code

7750009) includes all components required

for installation as shown on the right. DGT

installation must respect below requirements:

When caused low by LP safety switch, limit the

number of auto-restart to maximum 5 times

within 12 hours.

• The thermostat must be attached to the

discharge line within 150 mm from the

compressor discharge port and must be

HP safety switch must be manual reset

Depending on application operating envelope,

you must define HP and LP limits within

thermally insulated and tightly fixed on the pipe.

• The DGT should be set to open at a discharge

gas temperature of 135°C.

operating envelope and pressure setting table

above.

For H-series compressors, the external Discharge

Gas Temperature protection (DGT) is required

if the high and low pressure switch settings do

Discharge line

not protect the compressor against operations

beyond its specific application envelope.

Thermostat

Insulation

30 AB218186428184en-001501

Page 31

Manage operating envelope

System evaluation HP and LP must be monitored to respect operating envelope limitations. We consider two types of

operating envelope management:

Basic:

• HP and LP switch

• MOP (Max Operating Pressure) ensured by expansion

device

• Condensing pressure control

• DGT external

Advanced:

• HP and LP sensor

• Operating envelope limits (permanent and transient)

integrated into control logic

• DGT external

See “Test, criteria and solutions”

DGT

Continuous

Running Area

LP switch setting

Condensing pressure control

HP switch setting

o

1 and 2

tests N

3

o

MOP + test N

Test, criteria and solutions

Tes t N ° Purpose Test condition Pass criteria Solutions

1

Check the

compressor

operation in

2

the “continuous

running area”.

Start test at minimum foreseeable

evaporating temperature (minimum

ambient temerature)

Perform a defrost test if reversible

unit

Confirmed compressor stable

working in the continuous running

area.

Work on compressor staging, fan

staging, water flow etc.

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

31AB218186428184en-001501

Page 32

Manage superheat

Requirement

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

System evaluation

During normal operation, refrigerant enters

the compressor as a superheated vapor. Liquid

flood back occurs when a part of the refrigerant

entering the compressor is still in liquid state.

In steady state conditions,

• Suction superheat must remain within 5K to 30K

• According to the floodback chart

Discharge temperature sensor must be placed

onto the discharge fitting and be insulated.

Oil temperature sensor must be placed on the

mid shell, closed to the lower shell, and be

insulated.

Use the tables below in relation with the system

charge and the application to quickly evaluate

the risk and potential tests to perform.

Liquid flood back can cause oil dilution and, in

extreme situations lead to liquid slugging that

can damage compression parts.

In transient conditions,

• According to the floodback chart

BELOW cHargE Limit aBOVE cHargE Lim it

Non reversible No test or additional safeties required Liquid flood back test

Reversible Defrost test

Liquid flood back test

Defrost test

Charge limit is defined in table below:

Refrigerant charge limit

Single

Tandem

Models

HRM032-034-038-040-042-045-047

HRP034-038-040-042-045-047

HRH029-031-032-034-036-038-039-040-047-048

HRM048-051-054-058-060/HLM068-072-075-078-081

HRP048-051-054-058-060/HLP068-072-075-078-081

HRH041-044-049-051-054-056/

HLH061-068-HLJ072-075-083

HCM094-109-120

HCP094-109-120

HC J091-106-121

TL J082- 098 -122-136 -144-166 6

TCJ181-211-241 8

(kg)

3.6

5.4

7.2

32 AB218186428184en-001501

Page 33

Manage superheat

Test, criteria and solutions