Page 1

Fact sheet

HRU – Heat Recovery Unit

FEATURES AND BENEFITS

• Substations with high quality

components designed for heat recovery

applications fully customized by use

of 3D-tools to fit individual needs

• All control components in the substation

are high quality Danfoss components

like: heat exchanger, control valves,

shut-off valves, energy meter, shutoff valves and automatic controls

• Danfoss prefabricated substations

reduces space demand approximately

30% compared to build-on-site solutions

• Easy to install and use with remote

access via Danfoss free cloud based

ECL portal or via other communication

protocols like MODBUS

• All Danfoss products are manufactured

according PED 97/23/ EC European

Pressure Directive, and Danfoss is

compliant to ISO9001/ISO14001/

iATF 16949 automotive

Designed for heat recovery

The Heat Recovery Unit is designed to

recover the waste heat from refrigeration installations, where CO2 is used. Recovered heat can be used for own heating purposes or returned to District

Heating Utility network. It suits perfectly for supermarkets equipped with

refrigerators. System include heating

substation with accumulation tanks.

Remote controlling and monitoring

Danfoss automatic controller ECL offers

more possibilities for external communication. Traditional SCADA solutions

can communicate with the controller via a Modbus protocol. Further

Danfoss offers a web-based SCADA

solution called ECL portal (ecl. portal.

danfoss.com), which enables remote

controlling, monitoring and alarming

functionalities from the sub- station.

Visualization of the ECL portal gives

you easiness of use, and access via PC

or Smartphone improves the level of

service and reduce costs due to 24/7

access.

Construction / installation

Heat Recovery Unit is designed as

floor station and it is delivered in one

piece, with possibility to be split into

3 parts, which allows to transport station thru narrow corridors. All heat

exchangers are produced in Micro

Plate technology develop by Danfoss,

which significantly increase substation

performance and lifetime. Standard

unit layout allows to prepare connection piping inside the builing before

station is delivered. Piping prepared

with automatic welding machines ensure highest possible welding quality.

Friendly solution for climate

Heat recovery unit is environmental

friendly as it saves globe from unnecessary CO2 emissions. Especially supermarkets can accumulate excess heat

from cooling systems to heat up shop

area. In some areas waste heat via

heating networks can be transferred

to household. System efficiency ensure short “return of investment” time

and allows to save money for heating

in longer term.

Prefabricated substations enable

top quality and shorten installation work on the building site

The Heat Recovery units are produced

based on a 3D models prepared by

our design department. All components like: heat exchangers, control

valves, pumps and measuring equipment are virtually connected with

piping. Based on 3D-drawings pipes

are bent, cut and welded with support of automated machines ensuring

supreme quality and short delivery

time. Units are designed as modular

constructions, which makes transportation and assembly easier. Heating

units includes an electrical wired panel, which is functionally tested and

ready to use after connecting power

supply to the cooling substation on

site. Danfoss substation is a complete product: designed, produced

and tested – ready for use. Danfoss

has more than 40 years of experience

in production of substations, which

guarantees great functionality.

Need a design of substation?

Just send us:

• Heating demand

• CO2 heat capacity

www.danfoss.com

Page 2

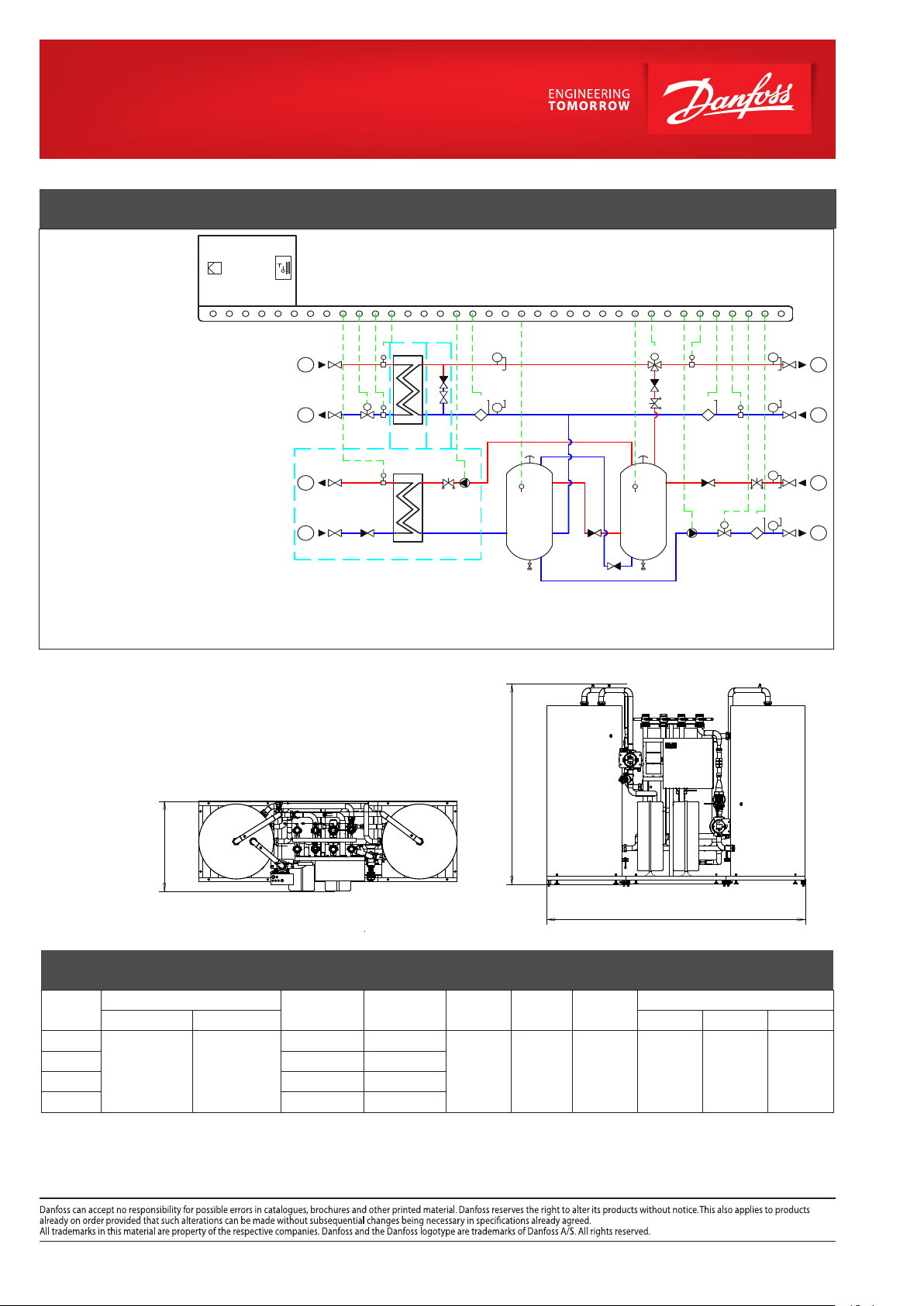

CIRCUIT DIAGRAM - EXAMPLECIRCUIT DIAGRAM

Danfoss Poland Sp. z o.o. · Tuchom, ul. Tęczowa 46 · 80-209 Chwaszczyno · POLAND

Tel.: +48 58 512 91 34 · Fax: +48 58 512 91 05 · serwis@danfoss.pl · www.danfoss.com

200

200

S1

200

200

M

S5M2

200

200

S14

200

200

M

M1

P4

S3

F1

E

S9

120

100

P3MM3 F2

G

300300

TE

E

TE

F

TE

G

ECL

S8

TE

F

TE

G

TE

E

100

100

T1 T2

V2

V1

400

500

400

500

S6

1

2

7

8

3

4

5

6

A1,A3

A1,A2

A3,A4

120

200

F3FS7

110310

100 Check valve

110 Check valve

120 Check valve

200 Ball valve

300 Balancing valve (ver. A1, A3)

310 Balancing valve

400 Air vent

500 Drain

F1, F2, F3 Heat meter

M1 Control valve HE (3-way)

M2 Control valve HE

M3 Control valve

P3 Pump

P4 Pump (ver. A1, A3)

S3, S7 Temperature sensor

S14, S5 Temperature sensor

S9 Temperature sensor (A1, A3)

S6, S8 Temperature sensor

T1, T2 Tanks

V1 Heat exchange r (ver. A1, A2)

120 Check valve (ver. A3, A4)

V2 Heat exchange r (ver. A1, A3)

S1 Outdoor temperature sensor

ECL Electronic controller

1 DH supply

2 DH return

3 Heating supply

4 Heating return

5 Cooling supply

6 Cooling return

7 DH supply

8 DH return

Technical paremeters

Primary side

Maximum temperature: 90 °C

Nominal pressure: PN 10

Diameter (threaded): DN 40

Secondary side

Maximum temperature (A1 / A2): 70 °C

Maximum temperature (A3 / A4): 90 °C

Nominal pressure (A1 / A2): PN 6

Nominal pressure (A3 / A4): PN 10

Diameter (threaded): DN 40

Electrical supply: 230 V AC

Controller: ECL 310

Height

Depth

CAPACITY, WEIGHT AND DIMENSIONS

Type

A1

A2 XB37/XB59 −

A3 DN 40 XB37/XB59

A4 DN 40 −

© Danfoss | DHS-SMCT/PL | 2017.08

Capacity [kW]

Heating CO

14 ÷ 540 50 ÷ 400

2

V1 V2 M1 M2/M3

XB37/XB59 XB37/XB59

VRB3

AMV

+

AHQM

AMV

Width

Weight

[kg]

+

up to

500

External dimensions [mm]

Height Width Depth

2000 2700 120 0

VL.MG.A1.02

Loading...

Loading...