Page 1

Data sheet

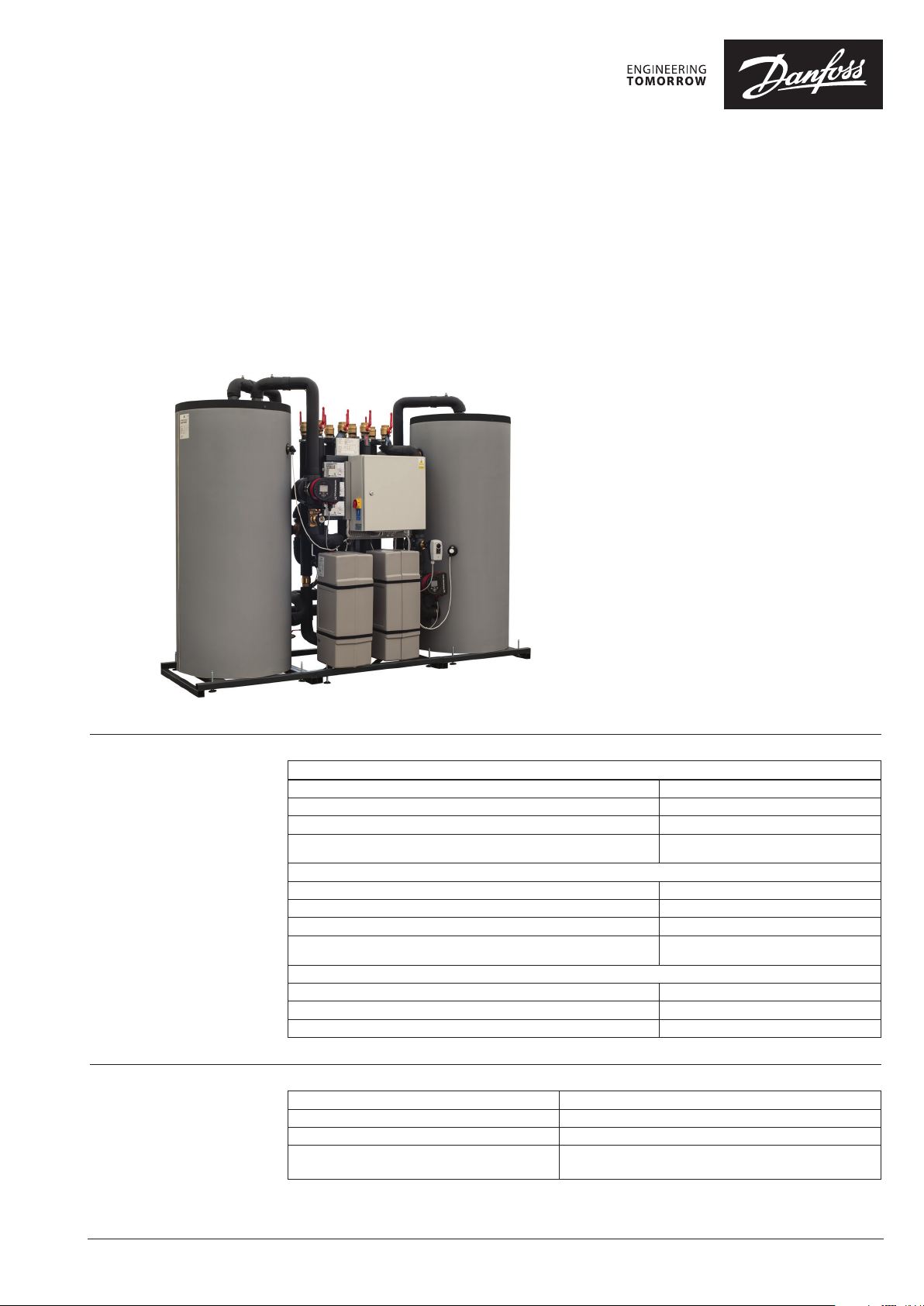

HRU – Heat Recovery Unit

General description

and application

Danfoss Heat Recovery Unit provide the link

between a CO₂ refrigeration systems and the

heating installation. It is developed and designed

for recovery of waste heat from refrigeration

installations, where CO₂ is used as medium, to

heat supermarkets (hot tap water, heating, air

handling units) and enables selling surplus heat

back to the district heating network. Danfoss

HRU can be used in installations with different

external heat supply, such as District energy,

boiler or other heat source.

Characteristic:

• Heating demand: 22-540 kW

• Maximum recovered heat from C0₂ pack up

to 50-400kW

Two different solutions based on store size:

1. one- tank solution - for small stores up to 1500 m

2. two-tanks solution - for medium and large stores

Standard layout in 6 versions:

• indirect connection (type A2,A6) or directly

connection (type A4,A7).

• indirect connection (type A1) or connection

to DHU (type A3), designed for areas where it is

possible to sell heat to DHU network.

Maximum operating

parameters

Materials

Primary

Maximum permissible supply temperature, primary* 90 °C

Maximum permissible operating pressure, primary 10 bar

Rated pressure, primary PN 10

Maximum permissible flow primary

Secondary heating

Maximum permissible temperature, secondary* 90 °C

Maximum permissible operating pressure, secondary (A1, A2) – 6 bar, (A3, A4, A6, A7) – 10 bar

Minimum required pressure (static), water supply 1,0 bar

Maximum permissible flow secondary

CO heat supply

Maximum permissible temperature secondary 90 °C

Maximum permissible operating pressure, secondary (A1, A2) – 6 bar, (A3, A4, A6, A7) – 10 bar

Minimum required pressure (static), water supply 1,0 bar

* For higher te mperatures – contac t Danfoss

Pipes, fittings, flanges, valves (Primary side) P235GH, EN-GJL-250 (GG25), CuZn36Pb2As

Pipes, fittings, flanges, valves (Heating side) P235GH, EN-GJL-250 (GG25), CuSn5Pb5Zn5-C (RG-5)

Heat exchanger 1.4404 with Cu solder

Insulation Elstomeric Foam (Nitrile Rubber) – λ = 0.035 W/mK (piping)

PU foam – λ = 0.029 W/mK (heat exchanger)

15 m³/h for v= 1,2 m/s ( A1, A2, A3, A4)

3 m³/h for v= 1,2 m/s ( A6,A7)

15 m³/h for v= 1,2 m/s ( A1, A2, A3, A4)

3 m³/h for v= 1,2 m/s ( A6,A7)

© Danfoss | 2018.08

VD.MG.D2.02 | 1

Page 2

Data sheet HRU – Heat Recovery Unit

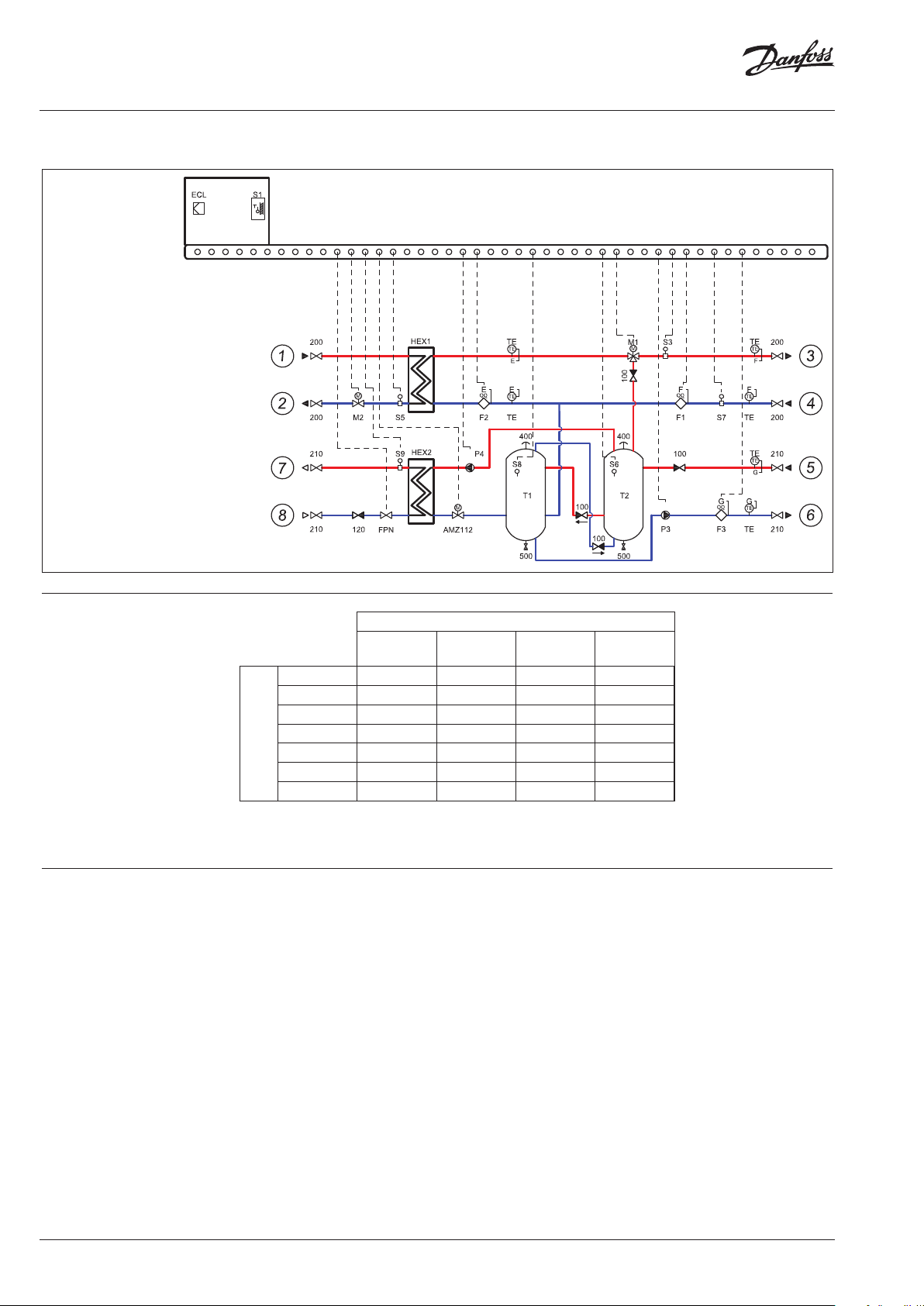

Circuit diagram A1 Indirect connection to DHU network with possibility of transfer heat outside heating system

Twotanks solution

1 DH supply

2 DH return

DN40

*

DN40

3 Heating supply

4 Heating return

5 Supply from

cooling unit

Return to

cooling unit

DN40

DN40

7 DH supply

DH return

* Connections DH⁄HE: up to 216 KWDN 40 up to 337 kWDN50 up to 540 kWDN65

*

A1 selection list

CO2 output [kW] (sales demand)

up to

100

up to

150

up to 22 146B9108 146B9109

up to 54 146B9120 146B9121 146B9122 146B9123

up to 85 146B9126 146B9127 146B9128 146B9129

up to 135 146B9132 146B9133 14 6B9134 146B9135

[kW]

up to 216 146B9138 146B9139 146B9140 146B9141

up to 337 146B9144 146B9145 146B9146 146B9147

Heating demand

up to 540 14 6B9150 146B9151 14 6B9152 14 6B9153

Function Waste heat from CO system is transferred via

CO heat exchanger * using water as medium,

into supply storage tanks T2 and T1.

The temperature sensor (S6) check the

temperature in tank (T2) and send a signal to

a 3-way valve (M1), which will open and heat

accumulated in tanks will be transferred into the

heating circuit.

Lower demand for heat will cause closing of the

controlling valve (M2) and reduce or cut the need

for energy from the external heat source. The

temperature sensor (S8) control the pump (P3)

and when the temperature reaches the desired

level and no more heat can be accumulated.

Secondary heat meters (F1 and F2) are measuring

flow and heat meter F3 on the charging circuit

calculates the recovered energy.

up to

300

up to

400

The primary function is to recover as much

energy as possible and secondary as high

temperature as possible

We always prioritize usage of heat

recovered from cooling unit before

supplying from external heat source

A1 version offers returning heat back into

the DHU network or other external network

via heat exchanger HEX2

If the recovered energy is more than the

stores can reuse the pump P4 is activated

so this energy can be sold to the district

heating

2 | © Danfoss | 2018.08

* CO₂ HEX is not included in the d elivery of HRU, but is part of the coolin g unit

VD.MG.D2.02

Page 3

Data sheet HRU – Heat Recovery Unit

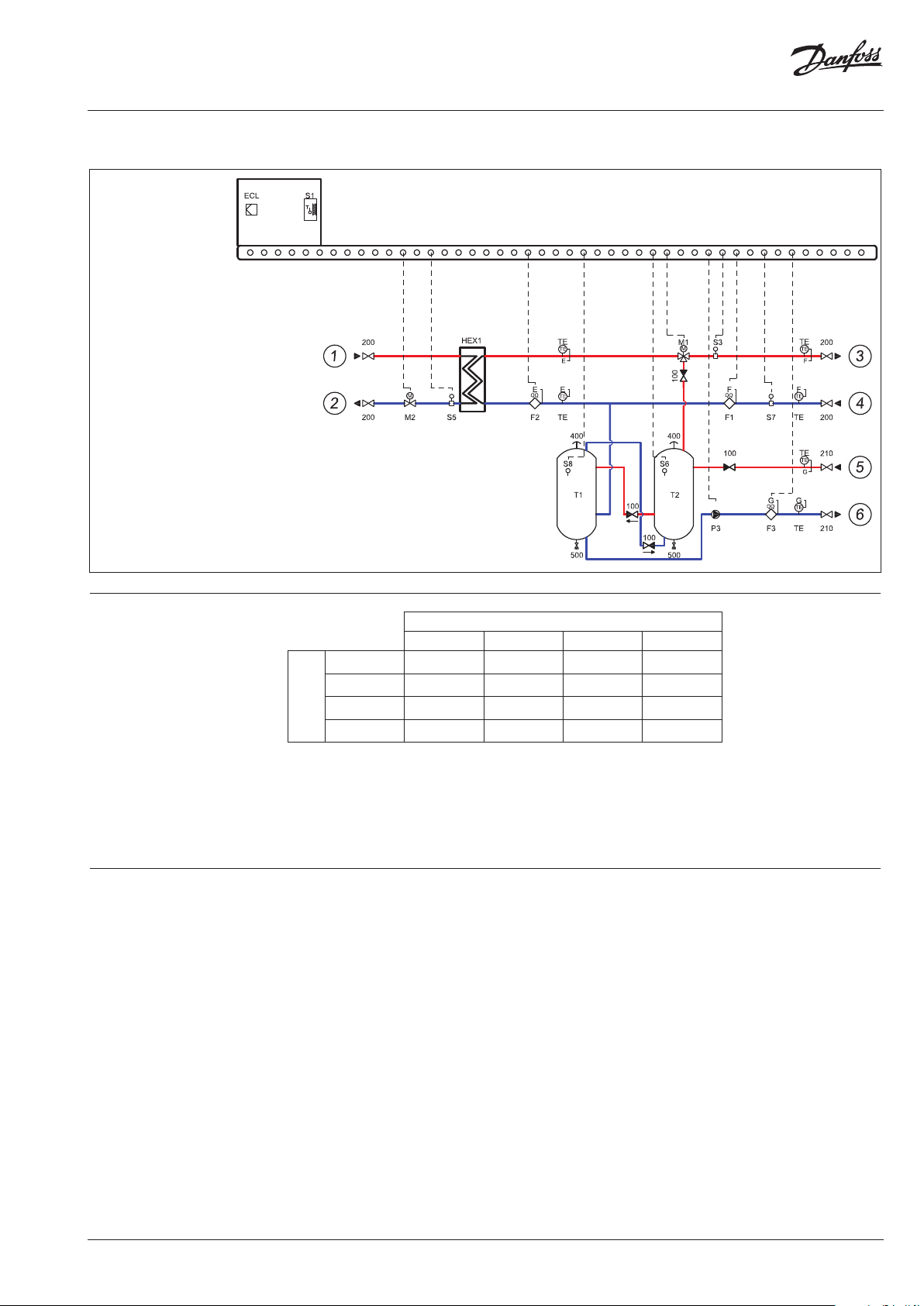

Circuit diagram A2 Indirect connection to DHU network

Twotanks solution

DN40* DN40*

1 DH supply

2 DH return

3 Heating supply

4 Heating return

5 Supply from

cooling unit

Return to

cooling unit

DN40

* Connections DH⁄HE: up to 216 KWDN 40 up to 337 kWDN50 up to 540 kWDN65

A2 selection list

CO2 output [kW]

up to 100 up to 150 up to 300 up to 400

up to 135 146B9164 146B9165

up to 216 146B9168 146B9169 146B9170

up to 337 14 6B9173 146B9174 146B9175 146B9176

Heating

up to 540 146B9179 146B9180 146B9181 146B9182

demand [kW]

Function Waste heat from CO₂ system is transferred via

CO₂ heat exchanger * using water as medium,

into supply storage tanks T2 and T1.

The temperature sensor (S6) check the

temperature in tank (T2) and send a signal to

a 3-way valve (M1), which will open and heat

accumulated in tanks will be transferred into the

heating circuit. Lower demand for heat will cause

closing of the controlling valve (M2) and reduce

or cut the need for energy from the external heat

source.

The temperature sensor (S8) controls the pump

with PWM signal (P3) and when the temperature

reaches the desired level and no more heat can

be accumulated.

In two-tanks solution application, secondary

heat meters (F1 and F2) are measuring flow and

heat meter F3 on the charging circuit calculates

the recovered energy.

* CO₂ HEX is not inclu ded in the delivery of H RU, but is part of the cooling uni t)

The primary function is to recover as much

energy as possible, and secondary as high

temperature as possible.

We always prioritize usage of heat recovered

from cooling unit, before supplying from

external heat source.

VD.MG.D2.02

© Danfoss | 2018.08 |PL

Page 4

Data sheet HRU – Heat Recovery Unit

Circuit diagram A3 Direct connection to DHU network with possibility of transfer heat outside heating system

Twotanks solution

1 DH supply

2 DH return

3 Heating supply

DN40* DN40*

4 Heating return

5 Supply from

Cooling unit

Return to

cooling unit

7 DH supply

DN40 DN40

DH return

* Connections DH⁄HE: up to 216 KWDN 40 up to 337 kWDN50 up to 540 kWDN65

A3 selection list

CO2 output [kW] (Sales demand)

up to

100

up to

150

up to 22 146B9191 146B9192

up to 54 146B9203 14 6B9204 146B9205 146B9206

up to 85 146B9209 146B9210 146 B9211 146B9212

up to 135 146B9215 146B9216 146B9217 146B9218

[kW]

up to 216 146B9221 146B9222 146B9223 146B9224

up to 337 146B9227 146B9228 146B9229 146B9230

Heating demand

up to 540 146B9233 146B9234 146B9235 146B9236

Function Waste heat from CO system is transferred via

CO heat exchanger * using water as medium,

into supply storage tanks T2 and T1.

The temperature sensor (S6) check the

temperature in tank (T2) and send a signal to

a 3-way valve (M1), which will open and heat

accumulated in tanks will be transferred into the

heating circuit.

Lower demand for heat will cause closing of the

controlling valve (M2) and reduce or cut the need

for energy from the external heat source. The

temperature sensor (S8) control the pump (P3)

and when the temperature reaches the desired

level and no more heat can be accumulated.

Secondary heat meters (F1 and F2) are measuring

flow and heat meter F3 on the charging circuit

calculates the recovered energy.

up to

300

up to

400

The primary function is to recover as much

energy as possible and secondary as high

temperature as possible

We always prioritize usage of heat recovered

from cooling unit before supplying from

external heat source

A3 version offers returning heat back into the

DHU network or other external network via

heat exchanger HEX2

If the recovered energy is more than the

stores can reuse the pump P4 is activated so

this energy can be sold to the district heating

4 | © Danfoss | 2018.08

* CO₂ HEX is not included in the d elivery of HRU, but is part of the coolin g unit

VD.MG.D2.02

Page 5

Data sheet HRU – Heat Recovery Unit

Circuit diagram A4 Direct connection to DHU network

Twotanks solution

1 DH supply

2 DH return

3 Heating supply

DN40* DN40*

4 Heating return

5 Supply from

Cooling unit

Return to

cooling unit

7 DH supply

DH return

* Connections DH⁄HE: up to 216 KWDN 40 up to 337 kWDN50 up to 540 kWDN65

DN40

A4 selection list

CO2 output [kW]

up to 100 up to 150 up to 300 up to 400

up to 135 14 6B9247 146B924 8

up to 216 146B9251 14 6B9252 146B9253

up to 337 146B9256 146B9257 14 6B9258 146B9259

Heating

up to 540 146B9262 146B9263 146B9264 14 6B9265

demand [kW]

Function Waste heat from CO₂ system is transferred via

CO₂ heat exchanger * using water as medium,

into supply storage tanks T2 and T1.

The temperature sensor (S6) check the

temperature in tank (T2) and send a signal to

a 3-way valve (M1), which will open and heat

accumulated in tanks will be transferred into the

heating circuit. Lower demand for heat will cause

closing of the controlling valve (M2) and reduce

or cut the need for energy from the external heat

source.

The temperature sensor (S8) controls the pump

with PWM signal (P3) and when the temperature

reaches the desired level and no more heat can

be accumulated.

In two-tanks solution application, secondary

heat meters (F1 and F2) are measuring flow and

heat meter F3 on the charging circuit calculates

the recovered.

* CO HEX is not included in the delivery of HRU but is part of the cooling unit

The primary function is to recover as much

energy as possible, and secondary as high

temperature as possible.

We always prioritize usage of heat recovered

from cooling unit, before supplying from

external heat source.

VD.MG.D2.02

© Danfoss | 2018.08 |PL

Page 6

Data sheet HRU – Heat Recovery Unit

Circuit diagram A6 Direct connection to DHU network with possibility of transfer heat outside heating system

Onetank solution

1 DH supply

2 DH return

3 Heating supply

4 Heating return

5 Supply from

Cooling unit

Return to

cooling unit

A6 selection list

CO2 output [kW]

up to 100

up to 22 146B940 0

up to 54 146B9401

Heating

up to 85 146B94 02

demand [kW]

Function Waste heat from CO₂ system is transferred via

CO₂heat exchanger * using water as medium,

into supply storage tank T2. The temperature

sensor (S6) check the temperature in tank (T2)

and send a signal to a 3-way valve (M1), which

will open and heat accumulated in tank will

be transferred into the heating circuit. Lower

demand for heat will cause closing of the

controlling valve (M2) and reduce or cut the

need for energy from the external heat source.

The temperature sensor (S8) control the pump

with PWM signal (P3) and when the temperature

reaches the desired level and no more heat

can be accumulated. In one-tank solution

application, heat meter F3 on the charging circuit

calculates the recovered energy.

The primary function is to recover as much

energy as possible, and secondary as high

temperature as possible.

We always prioritize usage of heat recovered

from cooling unit, before supplying from

external heat source.

6 | © Danfoss | 2018.08

* CO₂ HEX is not included in the d elivery of HRU, but is part of the coolin g unit

VD.MG.D2.02

Page 7

Data sheet HRU – Heat Recovery Unit

Circuit diagram A7 Direct connection to DHU network

Onetank solution

1 DH supply

2 DH return

3 Heating supply

4 Heating return

5 Supply from

Cooling unit

Return to

cooling unit

A7 selection list

CO2 output [kW]

up to 100

up to 22 146B9403

up to 54 146B940 4

Heating

up to 85 146B9405

demand [kW]

Function Waste heat from CO₂ system is transferred via

CO₂heat exchanger * using water as medium,

into supply storage tank T2. The temperature

sensor (S6) check the temperature in tank (T2)

and send a signal to a 3-way valve (M1), which

will open and heat accumulated in tank will

be transferred into the heating circuit. Lower

demand for heat will cause closing of the

controlling valve (M2) and reduce or cut the

need for energy from the external heat source.

The temperature sensor (S8) control the pump

with PWM signal (P3) and when the temperature

reaches the desired level and no more heat

can be accumulated. In one-tank solution

application, heat meter F3 on the charging circuit

calculates the recovered energy.

The primary function is to recover as much

energy as possible, and secondary as high

temperature as possible.

We always prioritize usage of heat recovered

from cooling unit, before supplying from

external heat source.temperature as possible.

We always prioritize usage of heat recovered

from cooling unit, before supplying from

external heat source.

VD.MG.D2.02

* CO₂ HEX is not included in the d elivery of HRU, but is part of the coolin g unit

© Danfoss | 2018.08 |PL

Page 8

Data sheet HRU – Heat Recovery Unit

Dimensions

Twotanks solution (A1 A2 A3 A4)

max. 2000 mm

max. 2800 mm

8

23

5

Component overview

max. 1200 mm

4

1

67

Item ( see circuit diagram) Description

100, 120, 125 Check valve

200, 210 Shut-off Ball valve

AMZ112 Motorized ON/OFF ball valve

FPN Flowswitch DN25

400 Air vent

500 Drain

F1F2F3 Heat meter

M1 Motorized Control valve HE 3way VRB+AMV

M2 M3 Motorized Combi valve AHQM + AMV

P3 Pump

P4 Pump ver A1 A3

S1 Outdoor temperature sensor ESMT

S3 S5 S7S9 Surface temperature sensor ESM

S6 S Immersion temperature sensor ESMU 250

T1 T2 Tank 6 bar( ver A1 A2) Tank 10 bar( A A

HEX1 Heat exchanger XB 37⁄XB (ver A1 A2

HEX Heat exchanger XB 37⁄XB59 (ver A1 A3

ECL Electronic controller+ A501

8 | © Danfoss | 2018.08

VD.MG.D2.02

Page 9

Data sheet HRU – Heat Recovery Unit

1

2

3

45

6

max. 2000 mm

max. 1500 mm

max. 800 mm

Dimensions

Onetank solution (A6, A7)

Component overview

Item ( see circuit diagram) Description

100, 120 Check valve

200, 210 Shut-off Ball valve

400 Air vent

500 Drain

F3 Heat meter

M1 Motorized Control valve HE 3way VRB+AMV

M2 Motorized Combi valve AHQM + AMV

P3 Pump

S1 Outdoor temperature sensor ESMT

S3 S5 S7 Surface temperature sensor ESM

S6 S Immersion temperature sensor ESMU 250

T2 Tank 10 bar( ver A6 A7)

HEX Heat exchanger XB 37⁄XB (ver A6

ECL Electronic controller+ P501

VD.MG.D2.02

© Danfoss | 2018.08 |PL

Page 10

Data sheet HRU – Heat Recovery Unit

10 | © Danfoss | DHS-SMCT/PL | 2018.08

VD.MG.D2.02

Loading...

Loading...