Page 1

Drives and Controls

VLT®is a trademark of Danfoss A/S

Frequency Converter

Danfoss VLT®DrivesDanfoss VLT

Handling aggressive environments

Frequency Converters

Page 2

■ It pays to protect against harsh

environments

Electronic equipment is sensible to the environment,

i.e. moisture, dust and temperature can influence

the reliability of electronics. Reduced reliability

causes downtime in the application with reduced

earnings as a result. Therefore it is important to

choose the right solution for the actual application.

This instruction informs about the possibilities to protect a frequency converter and other electronic devices against influence from an environment where

aggressive gasses and moisture are present.

Basically it is important to protect the electronics

from a harsh environment. The best way to do that,

is to avoid the harsh environment by placing the

electronics outside the harsh environment. Danfoss

offers different solutions:

· Our different drives can control a motor with long

motor cables. This means that the customer can

place the drive far away from the critical environment.

Handling aggressive environments

·

Our small drives are designed for placement di rectly in a typical industrial control cabinet. The

control cabinet can be fitted with air-conditioning

units ensuring that the critical environment does

not get in contact with the drives and other

electronics.

· Some drives are fitted with a cold plate. With this

solution you can place the drive inside a closed

cabinet and via the cold plate the heat is transmitted to the outside. With this solution the drive

is kept away from the critical environment.

· The FCM is fitted with a tight enclosure. The en-

closure protects the electronics from the outside

environment.

· For selected drive series we give the customer

the possibility to buy a frequency converter with

coated electronics as an option. These drives

have a higher reliability in environments where

aggressive gasses and moisture are present.

This instruction will help you choose the right protection.

■ How critical is the environment?

You cannot directly see how critical the environment

is. It depends mainly on 4 factors, the concentration

of pollutants present, dirt, the relative humidity and

temperature.

To find out how critical the environment is, look for

some signs indicating the amount of aggressive gasses, moisture and time of wetness in the environment. This will be described in the following. In many

applications typical conditions are known and for

some of these we have added a table showing typical constituents.

MN.90.I1.02 - VL T is a r egistered Danfoss trademark

1

Page 3

Signs to look for

In existing plants it is possible to see if an aggressive

environment is present. Take a look at a copper

lead having been placed in the installation for a least

some months. If a critical environment is present,

the copper will turn dark.

I.e. unscrew a copperlead in a connector. The part

where the screw presses is nice, but the area

where screw or insulation does not protect is a

good indicator for the environment. If it is black (corroded), the environment can be critical. If the copper is uncorroded, the environment is expected to

be uncritical.

Examples of critical applications

The below table shows typical gasses in some selected applications which can be critical. It can give

you some hints of applications that can be critical.

The information in the table is not necessarily covering all actual constituents in the application.

Application Constituent Symbol

Sewage plants Ammonia NH

3

Hydrogen sulphide H2S

Active organic nitrogen N

2

Paper mills and Hydrogen sulphide H2S

wood pulping Carbon monoxide CO

Chlorine's Cl, Cl

Active organic nitrogen N

Hydrocarbons Cn, H

Water Hydrocarbons Cn, H

2

2

n

n

treatment

Handling aggressive environments

The different constituents attack metals. I.e. sulphur

dioxide attack all metals except noble metals, nitrogen dioxide, ammonia and ammonia salts attack

copper and brass and hydrogen sulphide attack silver and copper.

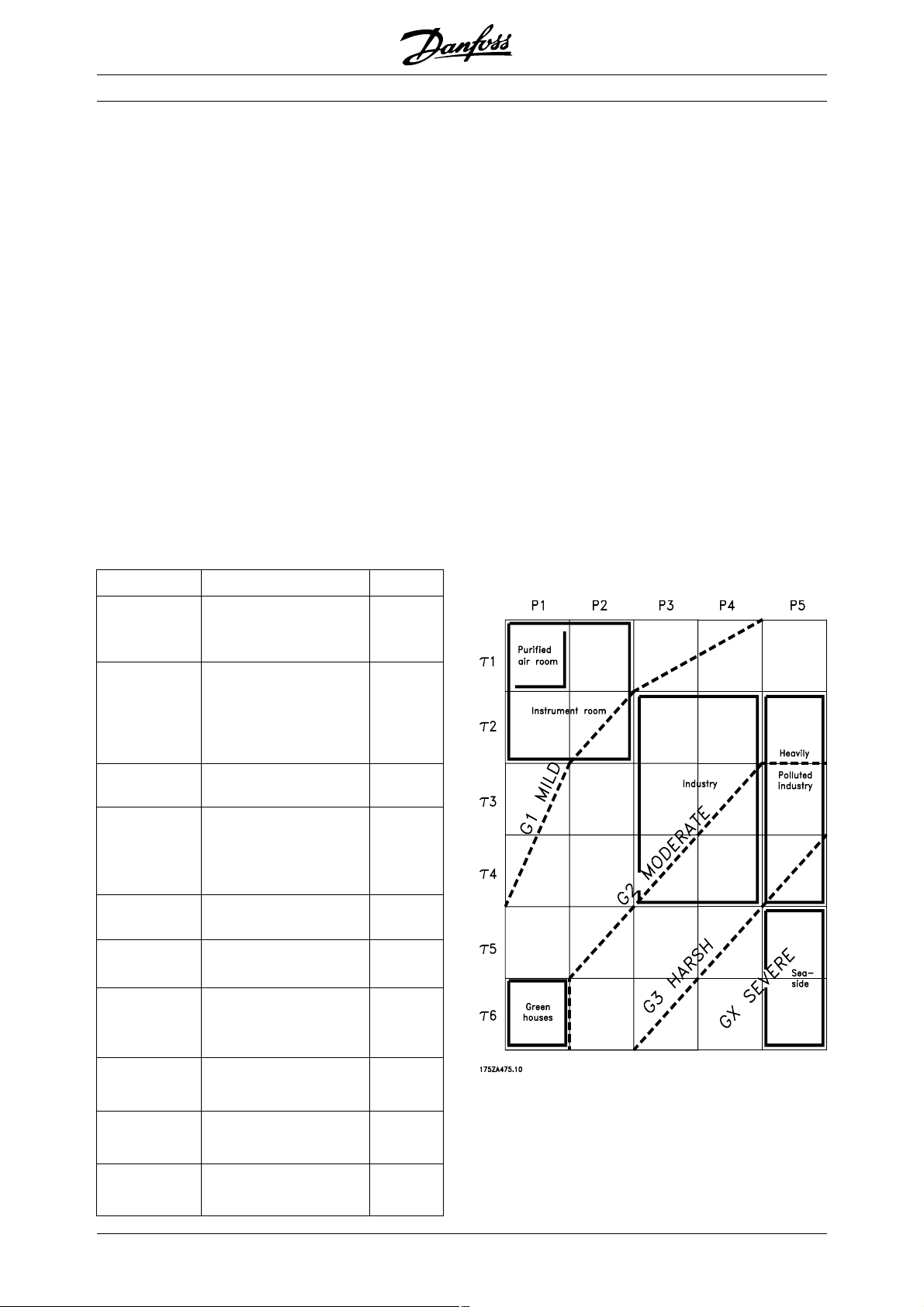

Determining the severity level

Generally the environments can be classified in groups

as defined in IEC721-3-3. The classification is divided into 4 groups, 3C1 to 3C4. ANSI/ISA S71.041985 also divides the environment into 4 groups, G1

- Gx.

Compared with the classification in ANSI/ISA

S71.04-1985, G2 is comparable to 3C2 and G3

comparable to 3C3.

From a Nordic research project the following model

for classification of the environment has been developed.

Use the figure below to make a brief estimate of the

actual application.

Combustion of Hydrogen sulphide H

fossil fuels/ Sulphur dioxide SO

automative Nitrogen oxides NO

S

2

,SO

2

x

emmisions Carbon monoxied CO

Sulphuric acid Hydrogen Chloride HCL

manufacture Hydrocarbons C

n

, H

n

Fertilizer Hydrogen flouride HF

manufacture Ammonia NH

3

Steel manu- Hydrogen flouride HF

facture and Hydrogen sulphide H

ore smelting Sulphur dioxide SO

S

2

,SO

2

Aluminium Hydrogen flouride HF

manufacture Chlorine's Cl, Cl

2

Foundries Mercaptans SB, R-SH

Carbon C

Cleaning of Ammonia NH

products Chlorine's Cl, Cl

3

2

3

3

Reference No. 2

τ1 to τ6 is the time of wetness and P1 to P5 is the

pollution degree. P1 is a low pollution degree, P5 is

a high degree.

Examples of environments have been put in the figure to give an overview.

MN.90.I1.02 - VL T is a registered Danfoss trademark2

Page 4

Handling aggressive environments

For an exact classification it is necessary to test the

environment. A way to do that is by making a

standardised test.

A standard copper coupon is exposed in the actual

environment for 28 days. The corrosion activity is

measured as the amount of corroded copper.

Based on the measured value the environment is

classified in one of four classes. The coupon test is

made by the Swedish Corrosion Institute:

Swedish Corrosion Institute.

Roslagsvägen 101, hus 25

S-104 05 Stockholm

Int. phone: +46 8 674 17 00

Int. fax: +46 8 16 72 70

Homepage: http://www.corr-institute.se

■ How to protect units against corrosion

Basically the best way to avoid problems is to keep

the aggressive environment away from the electrical

installations. This is possible in many applications,

but in some applications not possible. In such cases

other precautions must be taken to reduce the risk

for problems.

Precautions during planning and installation

To avoid problems in an application we recommend

to follow the general guidelines below in the order

stated. If it is not possible to choose the first recommendation, then go for the second and so on.

Beside the point below, You also have to choose

the appropriate enclosure type (IP class) to be used

in the environment, taking dust, water and objects,

such as screwdrivers and fingers, into account.

Alternatively we recommend you to contact an

engineering agency to help you determining the

environments.

1. 1.

1. Plan the installation in such a way that the drives

1. 1.

and other electronics are placed apart from the

harsh environment. Doing that extra costs can

be totally avoided. As the Danfoss frequency

converters are capable of driving motors with

long motor cables, it is possible to place the

drives apart from the machinery.

Examples of such solutions are control rooms in a

factory where the drives are installed or complete

cabinets from OEM’s are placed. These rooms

are sometimes also equipped with climatic

control such as air conditioning.

MN.90.I1.02 - VL T is a r egistered Danfoss trademark

3

Page 5

2.2.

2. If it is not possible to place the drives and other

2.2.

electronics apart from the harsh environment,

then a closed cabinet combined with a heat

exchanger can be used. The harsh environment

is kept away from the electronics and the solu tion is comparable with the first solution, except

for commissioning where you have to open the

cabinet.

Another possibility is to keep the harsh environ ment away from the electronics by supplying the

control cabinet with fresh clean air.

As the speed of the corrosion process is low at

low relative humidity and low temperature, an air conditioning unit can also minimize the corrosion.

In this case it is important that the relative humi dity and the temperature is kept on a low level.

Handling aggressive environments

4. 4.

4. If it is not possible to keep the harsh environment

4. 4.

away from the electronics, a solution can be to

select a coated drive. Coating gives a better pro tection of the drives than an uncoated solution,

but even if you choose a coated drive, precau tions must be taken into account. The harsh en vironment can attack copper in the installation or

other electronics connected to the drives, such

as PLC’s or other control devices which are not

protected. In this case it is important to keep the

relative humidity as low as possible in the environ ment, as a high relative humidity forces corrosion.

In such a case an air-conditioning unit can help

controlling the relative humidity.

3.3.

3. Alternatively choose an integrated frequency con-

3.3.

verter and motor, FCM300, which has a tight

enclosure for the electronics.

General aspectsGeneral aspects

General aspects

General aspectsGeneral aspects

No matter which solution you choose, it is important

that the solution is maintained and the installation is

made according to the requirements. Filters for airconditioning units and fans must be cleaned according to the specifications and the control cabinets

and control rooms must be kept closed to keep the

harsh environment outside.

MN.90.I1.02 - VL T is a registered Danfoss trademark4

Page 6

Select the appropriate VLT frequency converter

®

The VLT

frequency converter is available in different

enclosures. Additionally some of the VLT frequency

converters are available with coated printed circuit

boards for increased protection. See technical literature for your different possibilities to choose between

the different drives and options.

■ Technical information

When referring to aggressive gases and electronics

basically 2 standards are relevant, IEC721-3-3 and

ANSI/ISA-S71.04.

The corrosion process is described briefly in the following.

Handling aggressive environments

What causes corrosion

Corrosion of electronics is determined by several

factors. 4 main factors determine if corrosion

occurs: concentration of aggressive gases, dirt,

moisture and temperature.

· Presence (concentration) of aggressive gases

Different metals are present in electronics such

as copper, tin, lead, silver and aluminum. These

metals react with different aggressive gases

such as sulfur compounds, chlorides, nitrogen

oxides and ammonia.

· Moisture

At a relative humidity below 50% the corrosion

process is very slow. At increasing relative

humidity the corrosion process increases.

· Temperature

If the temperature is below 0 ° C corrosion is

negligible.

· Dirt

Dust can be conductive as well as it can contain

moisture.

A Nordic research project has developed a model

for corrosion classification. This model is described in

short form below. The model has been developed

with the American ANSI/ISA S71-04 standard as

reference.

The influence from the relative humidity is

determined by how long the electronics is exposed

to a critical humidity and temperature, called “Time

Of Wetness”.

The term time of wetness has been defined as:

Hours per year where the temperature is above 0°C

and the relative humidity is above 80%.

Time of wetness is divided into 6 categories, τ 1 to

τ 6.

The critical zones are primarily the last 3 locations,

as the time of wetness is minimum 10% per year.

MN.90.I1.02 - VL T is a r egistered Danfoss trademark

5

Page 7

Handling aggressive environments

Time of wetness

Time of wetness

Category

Category

CategoryCategory

1 <10 <0.1 Indoor air with climatic control.

2 10-250 0.1-3 Indoor air in normal rooms for living or working condition.

3 250-1000 3-10 Indoor air storage rooms.

4 1000-2500 10-30

5 2500-5500 30-60

6 >5500 >60 Outdoor air in tropical zone. Indoor air in greenhouse.

Reference no. 2

The term pollution degreee has been defined based

on different pollutants. P1 is a very low polluted

environment and P5 is a high polluted environment.

See table below.

Time of wetnessTime of wetness

Hours/year

Hours /ye ar % of year

Hours/yearHours/year

% of year

% of year% of year

Example of o ccurrence.

Example of o ccurrence.

Example of o ccurrence.Example of o ccurrence.

Indoor air in some production rooms. Ourdoor air in cold zone,

dry zo ne, par t s of t emperated zone.

Outdoor air in parts of temperated zone, parts of warm zone.

Indoo r ai r i n a nimal h o uses.

Category

Category

CategoryCategory

P1

(very low)

P2

(low)

P3

(medium)

P4

(high)

P5

(very high)

1) Limits if silver is used. 2) Limits for other materials than silver

SO

2

<10 <25 <3 <1 <10 <1 <2

10-30 25-250

30-100 150-500

100-300 500-1000

>300 >1000

NO

2

H2SCI2NH3+NH

1

3-10

)

2

3-20

)

1)

10-50

2)

20-100

50-1001)

2)

100-200

>1001)

>2002)

Reference no. 2

3333

µµµµg/m

Pollutants

Pollutants

Pollutants Pollutants

g/m

g/mg/m

+

1-2 10-250 1-5 2-20

2-5 250-1000 5-10 20-75

5-10

>10 >10000 >50 >150

100010000

-

CI

10-50 75-150

Soot

Remarks

Remarks

RemarksRemarks

Rooms

purified

MN.90.I1.02 - VL T is a registered Danfoss trademark6

Page 8

Handling aggressive environments

In ANSI/ISA S71-04-85 4 severity levels are defined.

The different severity levels are described as follows:

- Severity level G1- Mild

An environment sufficiently well-controlled such

that corrosion is not a factor in determining

equipment reliability.

- Severity level G2 - Moderate

An environment in which the effects of corrosion

are measurable and may be a factor in

determining equipment reliability.

- Severity level G3 - Harsh

An environment in which there is a high

probability that corrosive attack will occur. These

harsh levels should prompt further evaluation

resulting in environmental controls or specially

designed and packaged equipment.

- Severity level GX - Severe

An environment in which only specially designed

and packaged equipment would be expected to

survive. Specifications for equipment in this class

are a matter of negotiation between user and

supplier.

In the figure some examples of application categories have been identified based on the project.

These categories must only be used as guiding examples. In case of doubt, you have to investigate

how the actual application is classified.

References

1. IEC 721-3-3 - Classification of environmental

conditions part 3: Classification of groups of environmental parameters and their severities. Stationary use at weatherprotected locations.

2. Corrosion of Electronics - A Handbook based on

Experiences from a Nordic Research Project.

ISBN 91-87400-02-2 by the Swedish Corrosion

Institute, 1991.

3. ANSI/ISA S71.04-1985 - Environmental Conditions for Process Measurement and Control Systems: Airborne Contaminants.

Time of wetness and polution degree have been

combined with the ANSI/ISA S17-04 standard in the

figure below.

Reference no. 2

MN.90.I1.02 - VL T is a r egistered Danfoss trademark

7

Page 9

Handling aggressive environments

®

Drives

XREF__BC

NOT LOADED ON RIP

© Danfoss Drives A/S (DKDD) 01.2001 - DTP: Reflector A/S

175R0375 MN90I102

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material.

Danfoss reserves the right to alter its products without notice. This applies to products already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed.

*MN90I102*

Loading...

Loading...