Page 1

Fact sheet

H62L-EZU Evaporator

Micro Plate Heat Exchanger

21%

lower hold-up

volume enables

significant reduction

in refrigerant charge

www.danfoss.com

danfoss.com

Page 2

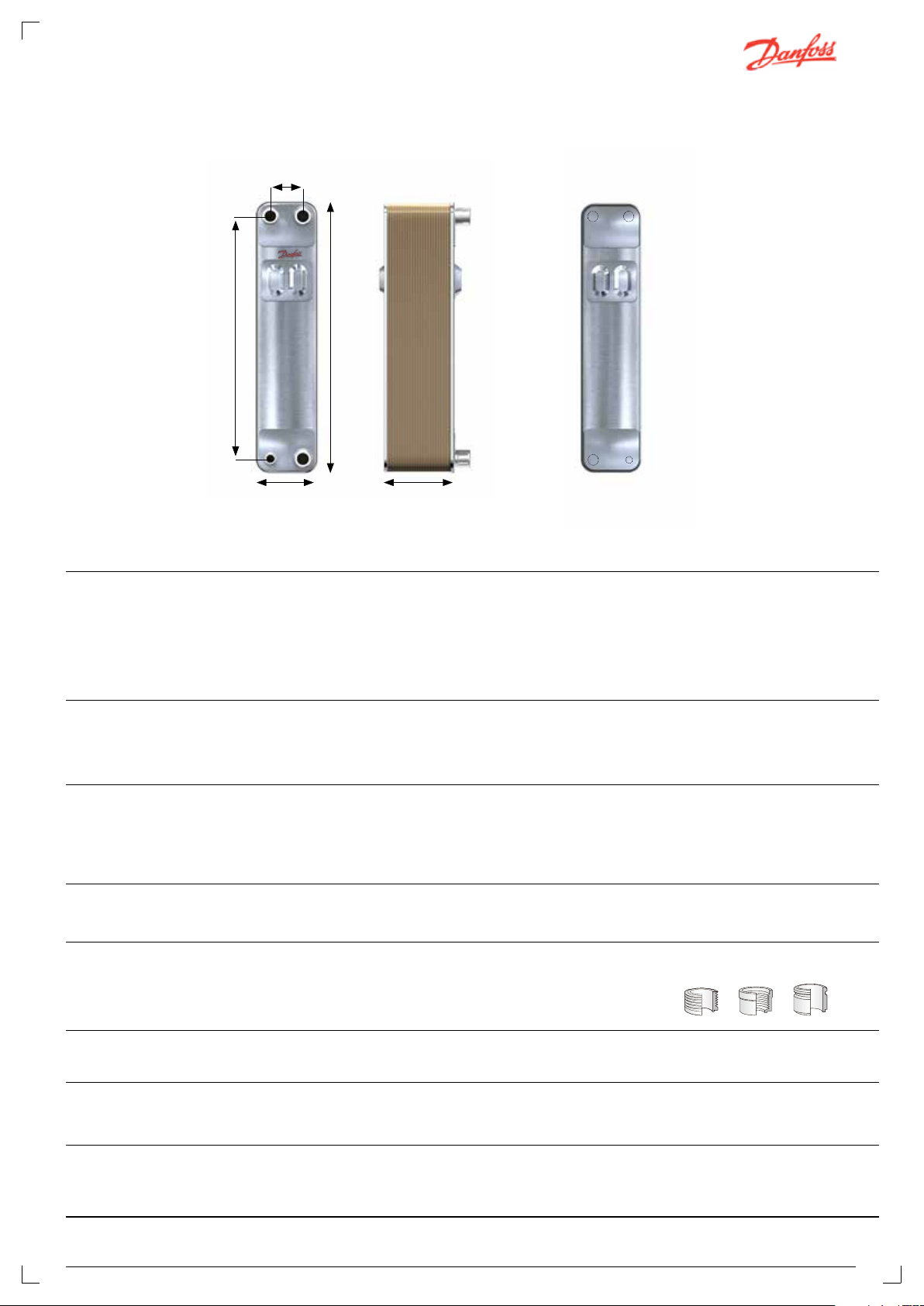

H62L-EZU Evaporator

Micro Plate Heat Exchanger (MPHE)

63

[2.5”]

INTRODUCTION

Q4 Q1

470

[18.5 “]

525

[20.7”]

Q3 Q2

118

[4.6”]

The H62L-EZU is an evaporator optimized for R410A for use in high-efficiency heat pumps with capacities of 5-20 kW.

The Z-pattern channel plate technology pushes the per formance of heat exchangers to the limits by fully mixing the liquid and gas refrigerant through a “zigzag” flow, which increases the heat transfer coefficient. At the same time, inheriting from dimple plate pattern of the previous generation of MPHE, H62L-EZU reduces the water side pressure drop and the amount of material used. In the reversible mode of the heat

pump as a condenser, H62L-EZU also has outstanding performance.

To meet demands for higher seasonal efficiency, the H62L-EZU is designed to work efficiently and increase comfort in modern residential and

commercial buildings without increasing the carbon footprint. Helping heat pumps perform more efficiently, it reduces both energy costs

and environmental impact. The low hold-up volume reduces the system refrigerant charge and offers valuable savings.

11+1.64*NoP

[0.43+0.065*NoP]

H4H1

H2 H3

KEY FEATURES

TECHNICAL DATA

n = NUMBER O F PLATES

STANDARD

MATERIALS

STANDARD

CONNECTIONS

TH IR D- PART Y

APPROVALS

ACCESSORIES

– STUD BOLTS

CORRESPONDING

CONDENSERS

- Reduced water side pressure drop - equals higher efficiency heat pumps

- Minimal hold-up volume - equals less refrigerant charge

- Smaller footprint - enables more compact heat pumps

- High heat transfer and minimal refrigerant charge - equals a reduced CO2 footprint

Min. working temperature: -196°C

Max. working temperature: 200°C

Max. working pressure: 45 bar (refrigerant side) / 25 bar (water side)*

Hold-up volume: Q1-Q2/ Q3-Q4 (l): 0.089×n/2 / 0.062×(n-2)/2

Weight (kg): 3.2+0.145n Max. no. of plates: 120

* A lower pressure ver sion (30 bar) also available

Cover plates: AISI 304L

Connections: AISI 304L

Other material combinations are available on request. Please contact your Danfoss sales representative for more information.

Standard connections as below are optimzed for this product as an evaporator in heat pump systems. For other connections, please contact

your Danfoss representative, (Internal threaded, R thread (BSPT), and NPT are also available).

Q3 (Refrigerant inlet): soldering 3/8”, 1/2”, 5/8”

Q4 (Refrigerant outlet): soldering 1/2”, 5/8”, 3/4” , 7/8”, 1 1/8”, 1 3/8” or 1 1/2”

Q1-Q2 (Water side): External threaded G 1/2”, G 3/4”, G 1”, G 1 1/4” or G 1 1/2”/soldering 1 1/8

Europe: Pressure Equipment Directive (PED). America: Underwriters Laboratory Inc (UL). The third party approvals stated are standard for all our

products. For details of other existing approvals or to discuss how we can meet your local needs, please contact your Danfoss representative.

Stud bolts and feet on front and/or back cover plates for mounting support are available upon request. Contact your Danfoss sales representative for further information.

A corresponding Micro Plate heat exchanger for condenser duties (H62L-CX) is also available.

- Improved heat transfer - equals higher efficiency heat pumps

Plates: AISI 316L

Brazing filler: Pure copper

Danfoss can accept no responsibility for possible errors in cat alogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to produc ts

already on order provided that such alterations can be made without consequent changes being necessary in specifications already agree d.

All trademarks in this material are the proper ty of the respec tive companies. Danfoss and the Danfoss lo gotype are trademarks of Danfoss A/S. All right s reserved.

520H119 04 | DKQB.PD.300.1C.02

© Danfoss | DSC (im) | 2017.03

Loading...

Loading...