Page 1

Fact sheet

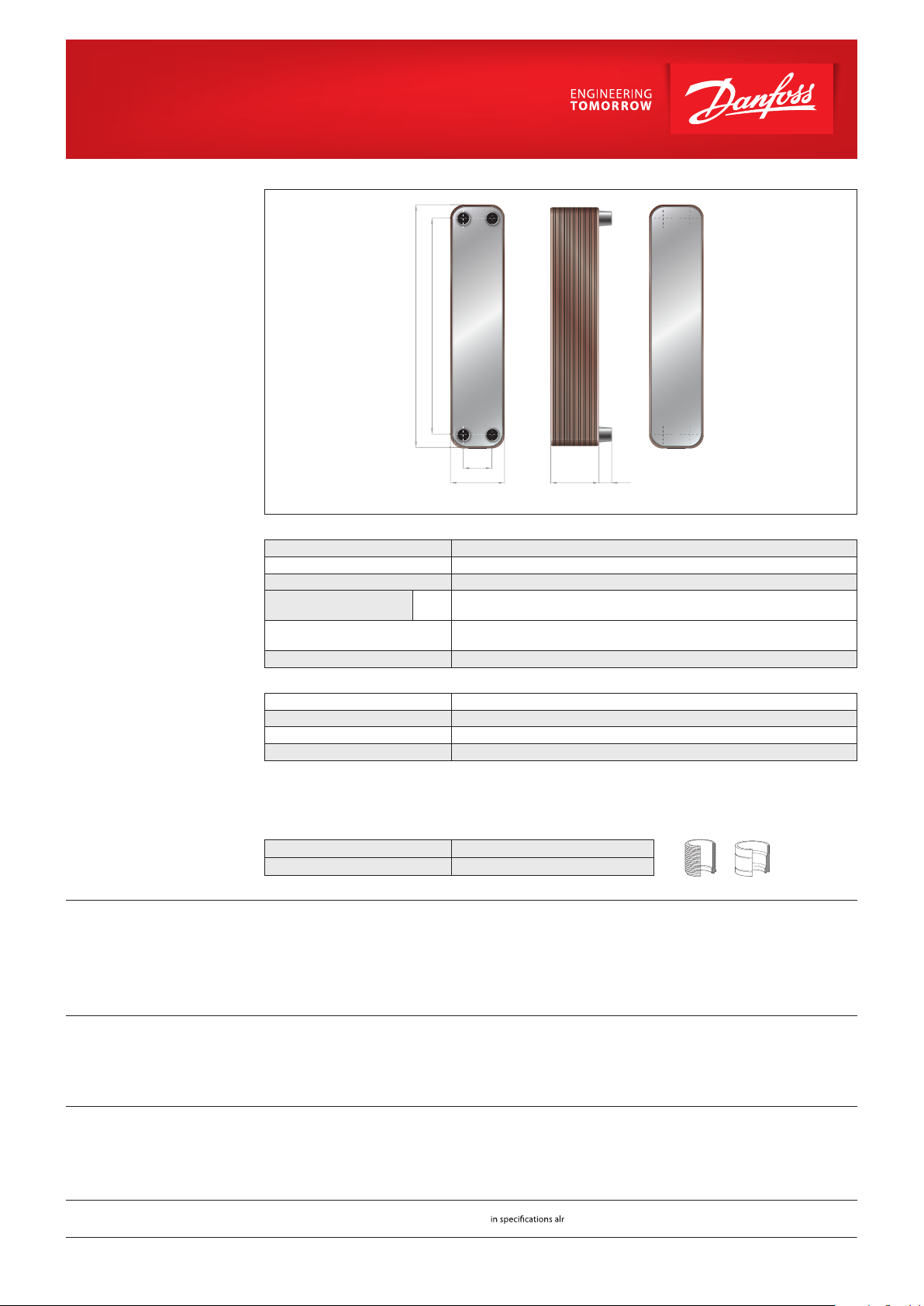

Micro Plate Heat Exchanger

For more efficient system

H34-CL & CM Suction Gas to Liquid Heat exchanger

H34-CL/CM is Microplate Heat Exchanger

optimized for applications in Heat pump systems

specifically for the heat transfer process in

between the suction gas and the liquid line.

Specifically design to operate with refrigerants

characterized by large glide like R454C or R455A,

applied as suction gas heat exchanger it

contributes to keep low the temperature

approach in condensation and evaporation

phase helping to achieve high efficiency for the

heat pump system.

The model is available in two versions covering

capacity systems up to 70 kW:

• CL for low pressure drop

• CM for high heat transfer coefficient

Thanks to the technology flexibility of the

microplate concept, it can be applicable also as

condenser and or desuperheater for capacity up

to 30 kW.

Features • Minimal hold up volume: Less refrigerant

charge

• High heat transfer: For a more efficient system

where heat exchanger is implemented

• Reduced CO₂ footprint: Environmentally

friendly with high heat transfer and minimal

refrigerant charge

• Small footprint enables more compact heat

pumps

40%

charge compared with a traditional BPHE.

The ideal solution to meet the world`s climate

and energy spirations.

© Danfoss | DCS (ms) | 2020.01

AM330826034591en-000101 | 1

Page 2

Danf

already on order pro

All trademarks in this material are property of the respec

Technical data

n = number of plates

Q4 Q1Q4 Q1

234 [19.2’’]

289 [11.4’’]

H1 H4H1 H4

Q3 Q2Q3 Q2

63 [2.5’’]

118 [4.6’’]

Min. working temperature -196 °C (-320 °F)

Max. working temperature 200 °C (390 °F)

Max. working pressure 35 bar

Hold up volume (l)

Weight

Max. no. of plates 110

Standard materials

Cover plates AISI 304

Plates AISI 316

Connections AISI 304L

Brazing filler Pure copper

Other material combinations are available on request.

Please contact your Danfoss sales representative for more information.

Standard connections

Standard connections as per below are optimised for this product as Suction Gas to Liquid Heat exchanger. For other connections,

please contact your Danfoss representative.

Q3-Q4 Soldering ½” or 5/8”

Q1-Q2 Soldering 1” or 3/8”

Q1-Q2/Q3-Q4: CL: 0.047 x n/2 / 0.047 x (n-2)/2

CM: 0.0361 x n/2 / 0.0361 x (n-2)/2

CL: 1.8 kg + 0.08 x n [4 lb + 0.18 x n]

CM: 1.6 + 0.08 x n [3.5 lb + 0.18 x n]

CL: 1.75 x n +10 [0.07’’ x n + 0.4’’]

CM: 1.40 x n +10 [0.06’’ x n + 0.4’’]

H2 H3H2 H3

20 [1.1”]

Third-party

approvals

Accessories

– stud bolts

Accessibility We will help you set up a logistic solution that will meet your needs.

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

© Danfoss | DCS (ms) | 2020.01 AM330826034591en-000101 | 2

Europe: Pressure Equipment Directive (PED).

The third party approvals stated are standard for all our products.

For details of other existing approvals or to discuss how we can meet your local needs,

please contact your Danfoss representative.

Stud bolts on front and/or back plates for mounting support are available upon request.

Please contact your Danfoss sales representative for further information.

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Loading...

Loading...