Page 1

Data Sheet

H1P 210/250/280

Axial Piston Single Pumps

For more than 40 years, Danfoss has been developing

state-of-the-art components and systems for mobile

machinery used in off-highway operations around the

world.

We have become a preferred supplier by offering the

best of what really matters: The hardware inside your

vehicle application.

The H1 range is built around an advanced control and

available in a wide range of displacements. It is

designed for quality and reliability and offers

expanded functionality, greater total efficiency, and

easy installation.

All H1 control and sensor options are PLUS+1

Compliant. PLUS+1® allows you to rapidly develop

and customize electronic machine control. It opens

up the future by combining machine controls and

diagnostics in an integrated operating network.

®

Features

Designed for quality and reliability

•

One design concept

•

Single piece swash plate

Wide range of controls

•

Electro-hydraulic controls:

Electrical Displacement Control

‒

(EDC)

Forward-Neutral-Reverse (FNR)

‒

Non-Feedback Proportional Electric

‒

(NFPE)

•

Automotive Control (AC)

•

Fan Drive Control (FDC)

Comprehensive technical literature is online at www.danfoss.com

•

Manual Displacement Control (MDC)

•

Hydraulic Displacement Control (HDC)

•

Common control across entire family

Greater total efficiency

•

Minimized control losses

•

Improved charge circuit

•

Lower control pressure for less power

consumption

Installation and packaging benefits

•

Length optimized pump

•

Minimum one clean side

•

Higher corner HP / package size ratio

•

Standardized connector interface

Expanded functionality

•

PLUS+1® Compliant control and sensor

options

For more information see the H1P

210/250/280 Axial Piston Single Pumps

Technical Information, BC152986484463.

©

Danfoss | December 2021 AI152986482988en-000601 | 1

Page 2

Technical Specifications

P003 422

S

C1

C2

M4

M5

M14

M3 L2 MA

A

CW

MB

B

L4

M5

M3

Z

244.96 ±2.5

154.99 ±2.5

136 ±1.5

X

Z

Y

172.2 ±2.5

CCW

Rotation

CW

Rotation

Ø40 ±0.25

4x Ø20.6

+0.3

-0.1

4x 112.25 ±0.25

4x 112.25 ±0.25

418.846 ±2.5

2

2

1

L2

2

L4

M14

A

E

F

B

M4

MB

S

15.65 ±0.25

X

Y

Ø165.1

+0

-0.05

2

1

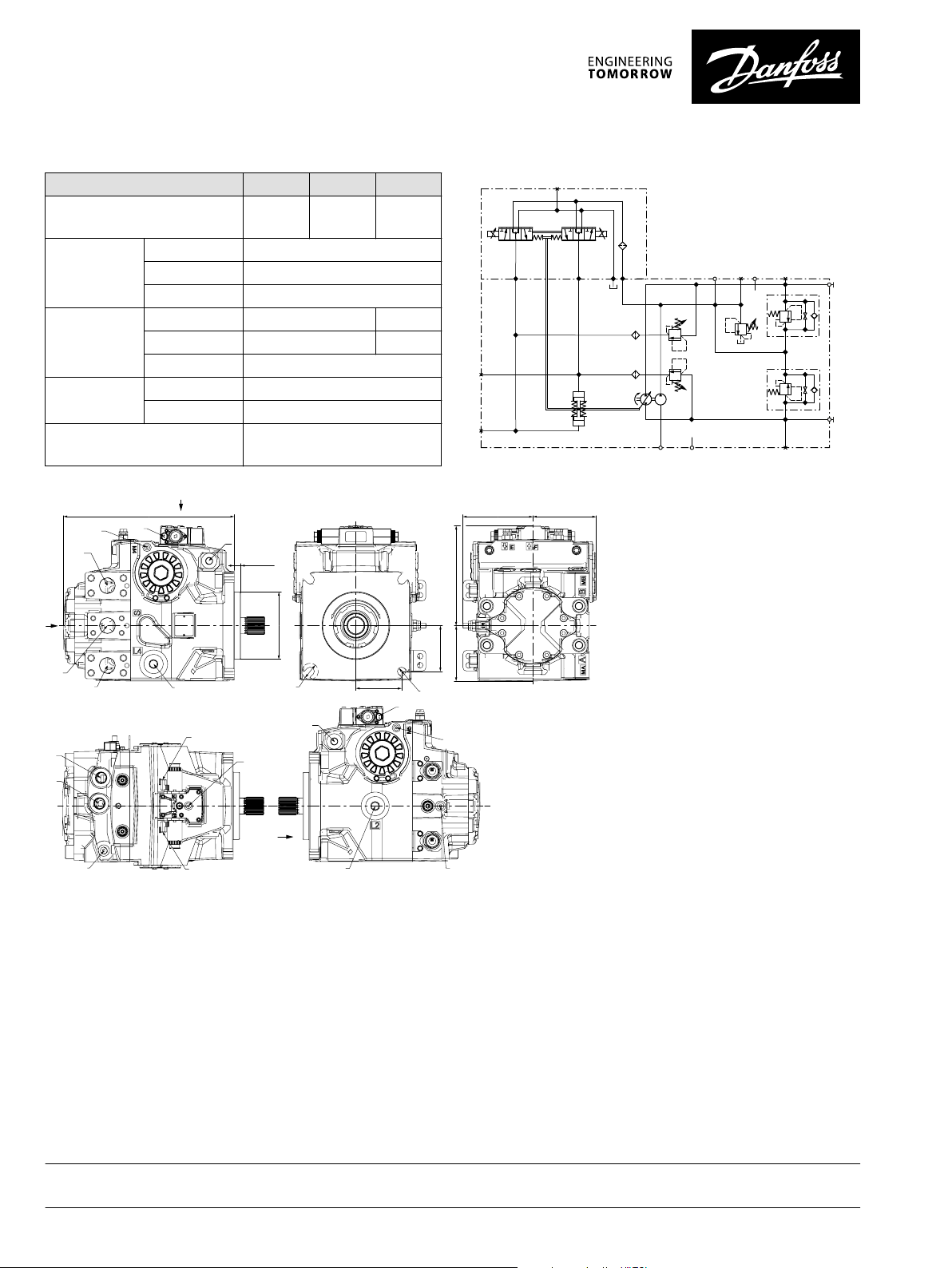

Parameters Size 210 Size 250 Size 280

Displacement

cm3 [in3]

Input speed

min-1 (rpm)

Minimum 500

Rated 2600

Maximum 2800

System pressure

bar [psi]

Max. working

Maximum 480 [6962] 450 [6527]

Min. low loop 10 [145]

Case pressure

bar [psi]

Rated 3.0 [44.0]

Maximum 5.0 [73.0]

Weight (without PTO and filter), kg

[lb]

*

Pressures above max. working pressure requires Danfoss approval.

211.5

[12.91]

*

251.7

[15.36]

280.2

[17.10]

450 [6527] 420 [6091]

163 [359.4]

Schematic

A/B system ports: Ø38 mm, 450 bar split flange boss per ISO 6162, M16 x 2;

27 min. full thread depth

MA/MB (system), M3 (charge) gauge ports per ISO 11926-1: 9∕16–18

M4, M5 (servo), M14 (case) gauge ports per ISO 11926-1: 7∕16–20

L2, L4 – Case drain ports per ISO 11926-1: 15∕8–12

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

2 | © Danfoss | December 2021 AI152986482988en-000601

E/F – Charge filtration ports per ISO 11926-1: 11∕16–12

S – Charge inlet port per ISO 11926-1: Ø38 mm, 350 bar split

flange boss per ISO 6162, M12 x 1.75; 21 min. full thread depth

1 – Case pressure port per ISO 11926-1: 1 5∕16–12

2 – Connector DEUTSCH DT04-2P, to be paint free

Loading...

Loading...