Page 1

Technical Information

H1P 089/100

Axial Piston Single Pumps

www.danfoss.com

Page 2

Technical Information

H1P 089/100 Axial Piston Single Pumps

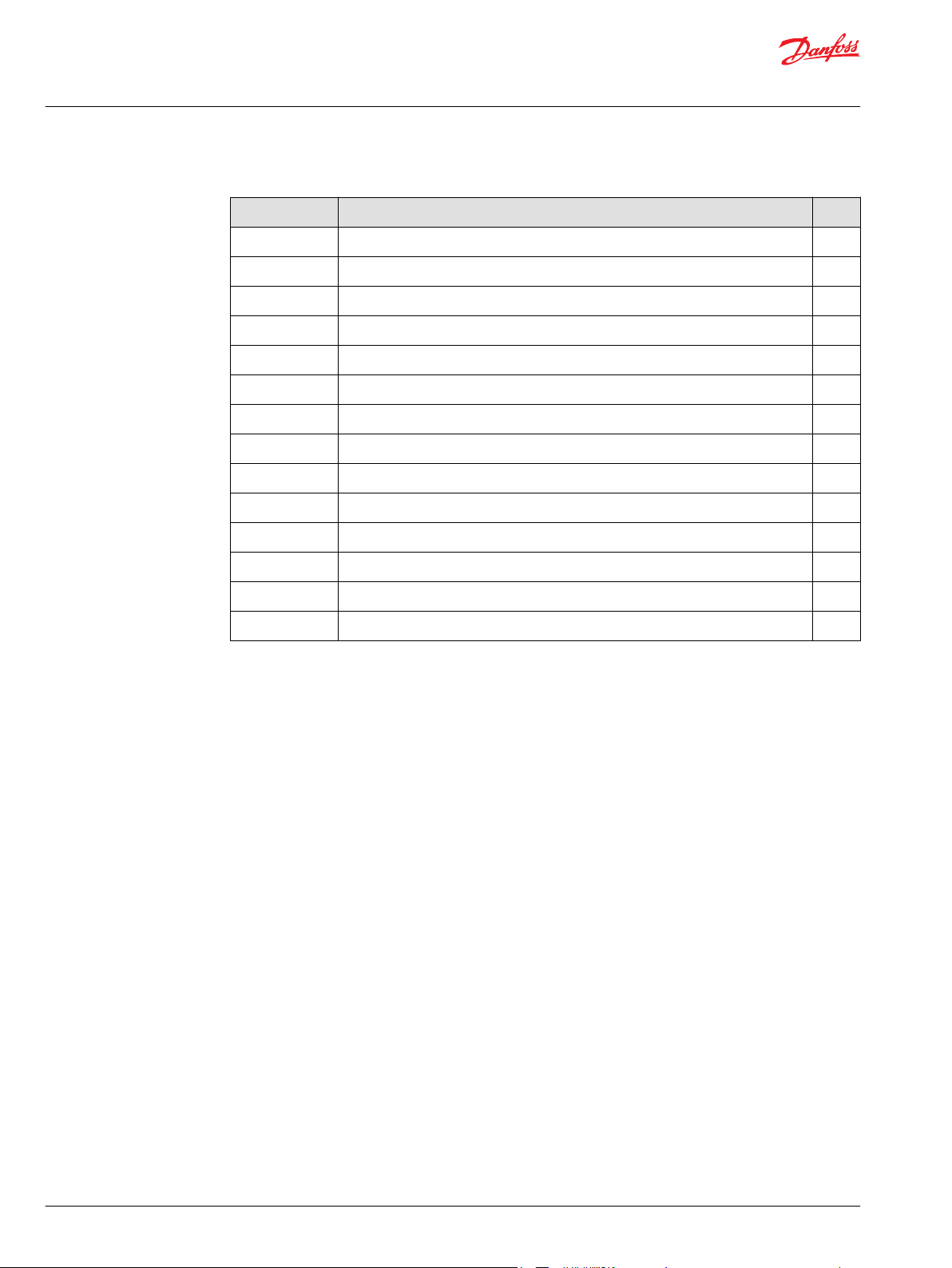

Revision history Table of revisions

Date Changed Rev

December 2021 Added HDC control 1301

April 2021 Corrected interface with ECU (EDC) graphic 1208

January 2021 Corrected unit conversion errors 1207

June 2020 Corrected E/F charge filtration port size 1206

April 2020 Corrected swash plate angle sensor connector and CCO connector descriptions 1205

February 2020 Added NFPE options and changed document number from BC00000067 1204

September 2019 G3 Input shaft option added. 1102

June 2019 Major revision. 1101

May 2018 Angle sensor for EDC; FDC note added. 1001

June 2017 port size changes 0902

May 2017 NFPE gen. 3 changes. 0901

November 2015 Master Model Code changes. 0800

2010-2014 Various changes. BA-GB

Aug 2009 First edition AA

2 | © Danfoss | December 2021 BC152886482765en-001301

Page 3

Technical Information

H1P 089/100 Axial Piston Single Pumps

Contents

Technical Specifications

H1 Pumps General Specification.................................................................................................................................................6

H1P 089/100 Technical Data........................................................................................................................................................ 6

H1P 089/100 Operating Parameters .........................................................................................................................................7

Fluid Specification............................................................................................................................................................................8

H1P 089/100 Mounting Flange Loads ..................................................................................................................................... 8

Bearing Life and External Radial Shaft Loads......................................................................................................................... 9

Charge pump...................................................................................................................................................................................10

Charge Pump Selection..........................................................................................................................................................10

20/24 cm³ Charge Pump – Flow and Power Curves.....................................................................................................10

Master Model Code

Displacement, A—Rotation, B—Product Version, Z—Port Configuration...............................................................11

D—Controls..................................................................................................................................................................................... 12

Electronic Displacement Controls...................................................................................................................................... 12

Fan Drive Controls....................................................................................................................................................................12

Forward-Neutral-Reverse (FNR) Controls.........................................................................................................................12

Non-Feedback Proportional Electric (NFPE) Controls................................................................................................. 12

Automotive Controls...............................................................................................................................................................13

Manual Displacement Control.............................................................................................................................................13

Hydraulic Displacement Control.........................................................................................................................................13

F—Orifices, E—Displacement Limiters..................................................................................................................................14

G—Endcap....................................................................................................................................................................................... 15

H—Mounting Flange, J—Input Shaft, K—Aux Pad...........................................................................................................16

M, N—Overpressure Protection Settings..............................................................................................................................17

S—Charge Pump, T—Filtration, V—Charge Pressure Relief..........................................................................................18

W—Special Hardware, X—Paint, Y—Special Features.................................................................................................... 19

Control Options

Electrical Displacement Control (EDC)................................................................................................................................... 20

EDC Operation...........................................................................................................................................................................20

Control signal requirements, EDC 089/100.....................................................................................................................21

Control Solenoid Data.............................................................................................................................................................21

Single Pump Output Flow Direction..................................................................................................................................21

Connector....................................................................................................................................................................................22

Control response.......................................................................................................................................................................22

Response Time, EDC 089/100...............................................................................................................................................22

Manual Displacement Control (MDC) ....................................................................................................................................23

MDC operation.......................................................................................................................................................................... 24

MDC shaft rotation...................................................................................................................................................................24

MDC Torque................................................................................................................................................................................25

Control response.......................................................................................................................................................................25

Response time, MDC 089/100..............................................................................................................................................25

Neutral start switch (NSS)...................................................................................................................................................... 26

Connector....................................................................................................................................................................................26

Case Gauge Port M14..............................................................................................................................................................26

Lever..............................................................................................................................................................................................26

Hydraulic Displacement Control (HDC)................................................................................................................................. 27

HDC principle.............................................................................................................................................................................27

HDC operation...........................................................................................................................................................................27

Hydraulic signal pressure range..........................................................................................................................................28

Pump output flow direction vs. control pressure.........................................................................................................28

Control response.......................................................................................................................................................................28

Response time, HDC 089/100...............................................................................................................................................29

Forward-Neutral-Reverse Control (FNR)................................................................................................................................30

FNR Solenoid Data....................................................................................................................................................................31

Single Pump Output Flow Direction..................................................................................................................................31

Connector....................................................................................................................................................................................31

Control response.......................................................................................................................................................................32

Response Time, FNR 089/100...............................................................................................................................................32

©

Danfoss | December 2021 BC152886482765en-001301 | 3

Page 4

Technical Information

H1P 089/100 Axial Piston Single Pumps

Contents

Non feedback proportional electric control (NFPE).......................................................................................................... 33

Control Signal Requirements, NFPE 089/100................................................................................................................. 33

Control Solenoid Data.............................................................................................................................................................34

Single Pump Output Flow Direction..................................................................................................................................34

Connector....................................................................................................................................................................................34

Control response.......................................................................................................................................................................35

Response Time, NFPE 089/100.............................................................................................................................................35

Automotive Control (AC).............................................................................................................................................................36

Mode types................................................................................................................................................................................. 36

Basic functions...........................................................................................................................................................................36

Performance functions........................................................................................................................................................... 37

Protection and safety functions.......................................................................................................................................... 37

Engine control and protection.............................................................................................................................................37

Installation features................................................................................................................................................................. 37

Fan Drive Control (FDC)...............................................................................................................................................................38

Control Signal Requirements, FDC 089/100................................................................................................................... 39

Control Solenoid Data.............................................................................................................................................................39

Single Pump Output Flow Direction..................................................................................................................................40

Connector....................................................................................................................................................................................40

Control response.......................................................................................................................................................................40

Response Time, FDC 089/100...............................................................................................................................................40

Manual Override (MOR)............................................................................................................................................................... 41

Swashplate angle sensor for EDC controls........................................................................................................................... 42

Swash plate angle sensor parameters (EDC).................................................................................................................. 42

Swashplate Angle Sensor Connector................................................................................................................................43

Interface with ECU (EDC)........................................................................................................................................................43

Swash Plate Angle Sensor for NFPE and AC2 Controls.....................................................................................................44

Swash Plate Angle Characteristic........................................................................................................................................44

Swash Plate Angle Sensor Parameters (NFPE/AC)........................................................................................................45

Swash Plate Angle Sensor Connector (NFPE).................................................................................................................45

Interface with ECU (NFPE)......................................................................................................................................................46

Control Cut Off Valve (CCO)....................................................................................................................................................... 46

Brake gauge port with MDC................................................................................................................................................. 47

CCO Connector (MDC)............................................................................................................................................................48

H1P CCO Connector (EDC, NFPE)........................................................................................................................................48

CCO solenoid data....................................................................................................................................................................48

Displacement Limiter................................................................................................................................................................... 49

H1P 089/100 Displacement Change (approximately).................................................................................................49

Dimensions and Data

H1P 089/100 Input Shaft Option G1 (SAE C, 14 teeth)......................................................................................................50

H1P Input Shaft Option G3 (SAE C, 13 teeth).......................................................................................................................51

H1P 089/100 Input Shaft Option G9 (SAE C-C, 23 teeth)................................................................................................. 52

H1P 089/100 Input Shaft Option F1 (SAE C, 21 teeth)...................................................................................................... 53

H1P 089/100 Input Shaft Option F4, Code 38–3 ................................................................................................................54

Tapered shaft customer acknowledgement...................................................................................................................54

H1P Auxiliary Mounting, Option H1 (SAE A, 11 teeth) .....................................................................................................55

H1P Auxiliary Mounting, Option H2 (SAE A, 9 teeth)........................................................................................................ 56

H1P Auxiliary Mounting, Option H3 (SAE B, 13 teeth) .....................................................................................................57

H1P Auxiliary Mounting, Option H5 (SAE B-B, 15 teeth) .................................................................................................58

H1P Auxiliary Mounting, Option H6 (SAE C, 14 teeth) .....................................................................................................59

H1P 089/100 Auxiliary Mounting, Option S1 (SAE B-B, 14 teeth).................................................................................60

H1P Displacement Limiter, Option B ..................................................................................................................................... 61

Single Pump Ports..........................................................................................................................................................................62

H1P Dimensions............................................................................................................................................................................. 63

Controls............................................................................................................................................................................................. 66

EDC Options A2 and A3 (12/24 V).......................................................................................................................................66

EDC with MOR, Options A4 and A5 (12/24 V).................................................................................................................67

EDC with CCO (key C), Options E7 and E8 (12/24 V).................................................................................................... 68

EDC with ASNSR, Options: H2 and H3 (12/24 V)............................................................................................................69

4 | © Danfoss | December 2021 BC152886482765en-001301

Page 5

Technical Information

H1P 089/100 Axial Piston Single Pumps

Contents

EDC with MOR and ASNSR, Options H6 and H7 (12/24 V)......................................................................................... 70

EDC with CCO and ASNSR, Options H8 and H9 (12/24 V).......................................................................................... 71

MDC Option: M1........................................................................................................................................................................72

MDC with Neutral Start Switch Option: M2.....................................................................................................................73

MDC with CCO, Options: M3, M4........................................................................................................................................ 74

MDC with NSS and CCO Options: M5, M6........................................................................................................................75

HDC, Options: T1, T2................................................................................................................................................................76

NFPE with MOR, Options: N1, N2 (12/24 V)..................................................................................................................... 77

NFPE with MOR, CCO, ASNSR, Options: N3, N4 (12/24 V)...........................................................................................78

NFPE with MOR and ASNSR, Options: N5, N6 (12/24 V)..............................................................................................79

NFPE with MOR and CCO, Options: N7, N8 (12/24 V).................................................................................................. 80

FDC Options: F1, F2 (12/24V)................................................................................................................................................81

Automotive control (AC)........................................................................................................................................................82

AC connectors dimensions..............................................................................................................................................83

Filtration............................................................................................................................................................................................ 84

Suction Filtration Option L....................................................................................................................................................84

Remote Full Flow Charge Pressure Filtration Option P...............................................................................................85

Integral Full Flow Charge Pressure Filtration, Option M............................................................................................ 86

External Full Flow Charge Pressure Filtration, Option S............................................................................................. 87

©

Danfoss | December 2021 BC152886482765en-001301 | 5

Page 6

Technical Information

H1P 089/100 Axial Piston Single Pumps

Technical Specifications

H1 Pumps General Specification

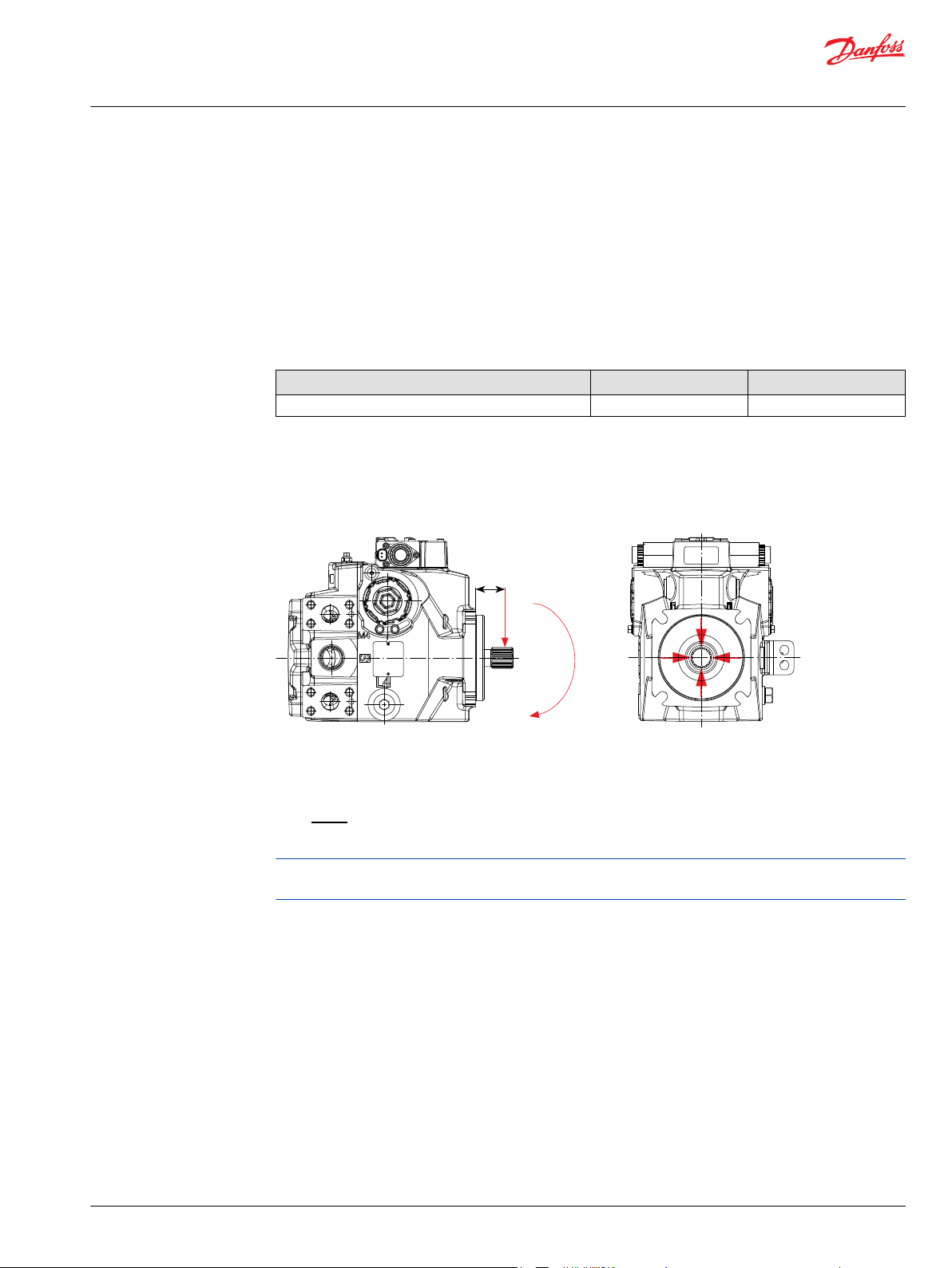

Axial piston closed circuit variable displacement pumps of cradle swash-plate design with clockwise or

counterclockwise direction of rotation.

Pipe connections

•

Main pressure ports: ISO split flange boss

•

Remaining ports: SAE straight thread O-ring boss

Recommended installation position

Pump installation position is discretionary, however the recommended control position is on the top or

at the side with the top position preferred. If the pump is installed with the control at the bottom,

flushing flow must be provided through port M14 located on the EDC, FNR and NFPE control.

Vertical input shaft installation is acceptable. If input shaft is at the top, 1 bar case pressure must be

maintained during operation. The housing must always be filled with hydraulic fluid. Recommended

mounting for a multiple pump stack is to arrange the highest power flow towards the input source.

Consult Danfoss for nonconformance to these guidelines.

Auxiliary cavity pressure

Auxiliary cavity pressure will be inlet pressure with internal charge pump or case pressure with external

charge supply. For reference see Operating Parameters. Please verify mating pump shaft seal capability.

H1P 089/100 Technical Data

Feature Size 089 Size 100

Displacement

Flow at rated speed (continuous)

Torque at maximum displacement

(theoretical)

Mass moment of inertia of rotating

components

Mass (dry–no charge pump)

Oil volume

89.2 cm3 [5.44 in3] 101.7 cm3 [6.21 in3]

294 l/min [77.7 US gal/min] 335 l/min [88.5 US gal/min]

1.42 N•m/bar

[870 lbf•in/1000 psi]

0.0116 kg•m

[0.0086 slug•ft2]

62 kg [137 lb] 62 kg [137 lb]

2.6 l [0.67 US gal] 2.6 l [0.67 US gal]

2

1.62 N•m/bar

[990 lbf•in/1000 psi]

0.0116 kg•m

[0.0086 slug•ft2]

Shaft, flange and ports description

Input shaft per ISO 3019-1

(outer diameter)

Mounting flange per ISO 3019-1

Auxiliary mounting flange with metric

fasteners, with shaft outer diameter

Suction port per ISO 3019-1

Main configuration port

Case drain ports L2, L4 per ISO 3019-1

Other ports

Customer interface threads

Outer Ø32 mm – 4 (SAE C, 14 teeth)

•

Outer Ø35 mm – 4 (SAE C, 21 teeth)

•

Outer Ø38 mm – 4 (SAE C-C, 23 teeth)

•

Conical keyed shaft end similar to ISO 3019-1 code 38-3, taper 1:8

•

Flange 127-4 (SAE C)

Flange 82-2 (SAE A: 9 teeth and 11 teeth)

•

Flange 101-2 (SAE B, 13 teeth and SAE B-B, 15 teeth)

•

Flange 127-4 (SAE C, 14 teeth)

•

ISO 11926-1 – 1 5∕8 -12 (SAE O-ring boss)

Ø25.4 mm; M12 x 1.75; 20 min. full thread depth

ISO 11926-1 – 15∕16–12

SAE O-ring boss

Metric fasteners

2

6 | © Danfoss | December 2021 BC152886482765en-001301

Page 7

Technical Information

H1P 089/100 Axial Piston Single Pumps

Technical Specifications

H1P 089/100 Operating Parameters

Parameter Unit Size 089/100

Input speed

System pressure

Charge pressure Minimum

Control pressure Minimum (at corner power for EDC,

Charge pump inlet pressure Rated

Case pressure Rated

Lip seal maximum pressure (external)

1)

Performance (displacement and pressure) may be limited due to limited control pressure.

2)

Full performance (displacement and pressure) possible at minimum charge and control pressure supply.

Min. for internal1) and external

2)

charge supply

Min. for full performance, internal

charge supply

Rated

Maximum

Maximum working

Maximum

Max./Min. low loop

Maximum

MDC, FNR)

Minimum (at corner power for NFPE,

FDC, AC)

Maximum

Minimum (cold start)

Maximum

Maximum

min-1 (rpm)

bar [psi]

bar [psi]

bar (absolute) [in

Hg vacuum]

bar [psi]

500

1200

3300

3800

450 [6528 ]

480 [6960]

45/10 [650/145]

18 [261]

34 [493]

17 [247]

25 [363]

40 [580]

0.7 [9.0]

0.2 [24.0]

4.0 [58.0]

3.0 [44.0]

5.0 [73.0]

0.4 [5.8]

Filtration, cleanliness level and βx-ratio (recommended minimum)

Cleanliness per ISO 4406

Efficiency βx (charge pressure filtration)

Efficiency βx (suction and return line filtration)

Recommended inlet screen mesh size

©

Danfoss | December 2021 BC152886482765en-001301 | 7

22/18/13

β

= 75 (β10 ≥ 10)

15-20

β

= 75 (β10 ≥ 2)

35-45

100 – 125 µm

Page 8

M

R

M

S

Technical Information

H1P 089/100 Axial Piston Single Pumps

Technical Specifications

Fluid Specification

Viscosity

Intermittent

Minimum

Recommended range

Maximum

1)

Intermittent = Short term t < 1 min per incident and not exceeding 2 % of duty cycle based load-life.

Temperature

Minimum

Rated

Recommended range

Maximum Intermittent

1)

Cold start = Short term t > 3 min, p ≤ 50 bar [725 psi], n ≤ 1000 min-1 (rpm).

2)

At the hottest point, normally case drain port.

1)

1)

5 mm2/s [42 SUS]

7 mm2/s [49 SUS]

12 – 80 mm2/s [66 – 370 SUS]

1600 mm2/s [7500 SUS]

-40°C [-40°F]

104°C [220°F]

2)

60 – 85°C [140 – 185°F]

115°C [240°F]

H1P 089/100 Mounting Flange Loads

The Rated and Shock load moments apply for top or side orientation of control.

Mounting flange load with control on top

Rated moment MR = 5630 N•m [49 830 lbf•in]

Shock load moment MS = 12 190 N•m [ 107 900 lbf•in]

For more information, see H1 Axial Piston Pumps, Basic Information, BC152886483968, the section

“Mounting flange loads”.

8 | © Danfoss | December 2021 BC152886482765en-001301

Page 9

L

270° R

e

R

e

M

e

180° R

e

90° R

e

0° R

e

Re =

Me

L

Technical Information

H1P 089/100 Axial Piston Single Pumps

Technical Specifications

Bearing Life and External Radial Shaft Loads

All external shaft loads affect bearing life. The pumps are designed with bearings that can accept some

external radial loads. The external radial shaft load limits are a function of the load position and

orientation, and the operating conditions of the unit.

Danfoss recommends clamp-type couplings for applications with radial shaft loads. Contact your Danfoss

representative for an evaluation of unit bearing life if you have continuously applied external loads

exceeding 25 % of the maximum allowable radial load (Re) or the pump swash-plate is positioned on one

side of center all or most of the time.

Maximum external shaft load based on shaft deflection

External radial moment Unit Size 089/100

M

e

External radial shaft loads impact lifetime. For lifetime calculations please contact your Danfoss

representative. In applications with external shaft loads, minimize the impact by positioning the load at

0° or 180° as shown below.

Radial load position

N•m [lbf•in] 118 [1044]

The maximum allowable radial shaft load (Re) is based on the maximum external moment (Me) and the

distance (L) from the mounting flange to the load. It may be determined using the following formula:

Thrust loads should be avoided. Contact your Danfoss representative in the event thrust loads are

anticipated.

©

Danfoss | December 2021 BC152886482765en-001301 | 9

Page 10

100

27

24

21

18

15

12

9

6

3

1

90

80

70

60

50

40

30

20

10

0

l/min

US gal/min

500 1500

1000 2000

Speed min-1(rpm)

3000 4000

2500 3500

24 cm

3

[1.46 in

3

/rev]

20 cm

3

[1.22 in

3

/rev]

P301 206

500 1500

1000 2000

Speed min-1(rpm)

3000 4000

2500 3500

P301 207

14.0

10

9

8

7

6

5

4

3

2

1

0

13.0

12.0

11.0

10.0

9.0

8.0

7.0

6.0

5.0

4.0

3.0

2.0

1.0

HP

Kw

24 cm

3

[1.46 in

3

/rev]

20 cm

3

[1.22 in

3

/rev]

Technical Information

H1P 089/100 Axial Piston Single Pumps

Technical Specifications

Charge pump

Charge Pump Selection

In most applications a general guideline is that the charge pump displacement should be at least 10% of

the total displacement of all components in the system. Unusual application conditions may require a

more detailed review of charge flow requirements. System features and conditions which may invalidate

the 10% guideline include (but are not limited to):

Continuous operation at low input speeds < 1500 min-1 (rpm)

•

High shock loading and/or long loop lines

•

High flushing flow requirements

•

Multiple low speed high torque motors

•

High input shaft speeds

•

Contact your Danfoss representative for application assistance if your application includes any of these

conditions.

For more information, see Selection of Drive line Components, BC157786484430.

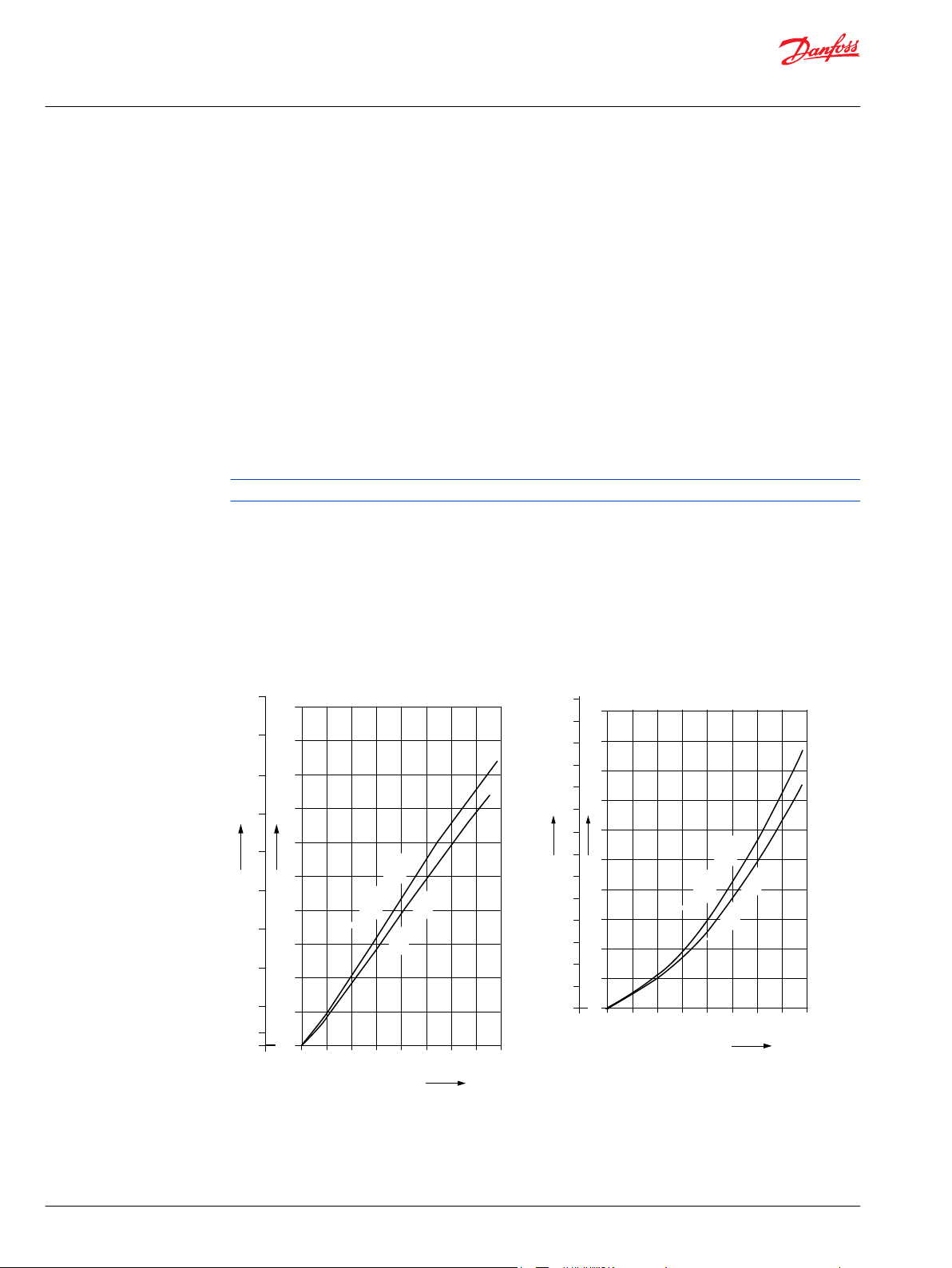

20/24 cm³ Charge Pump – Flow and Power Curves

Charge pump flow and power requirements curves shown below at the following conditions:

Charge pressure = 20 bar [290 psi]

Viscosity = 11 mm²/s [63 SUS]

Temperature = 80°C [176°F]

Charge pump flow

10 | © Danfoss | December 2021 BC152886482765en-001301

Charge pump power requirements

Page 11

G H J K M N S T V W X YZ D EF

H1P

A B

Technical Information

H1P 089/100 Axial Piston Single Pumps

Master Model Code

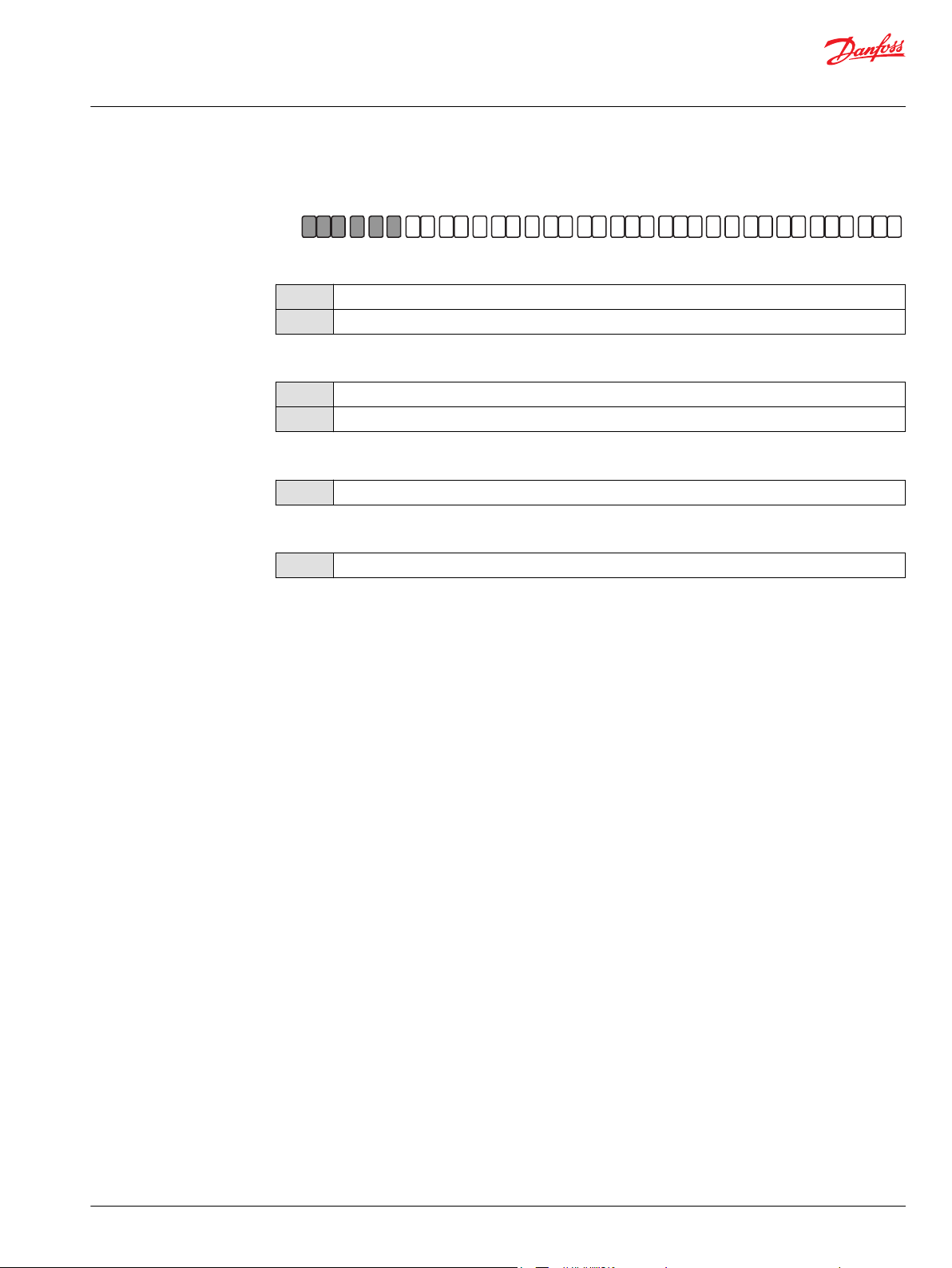

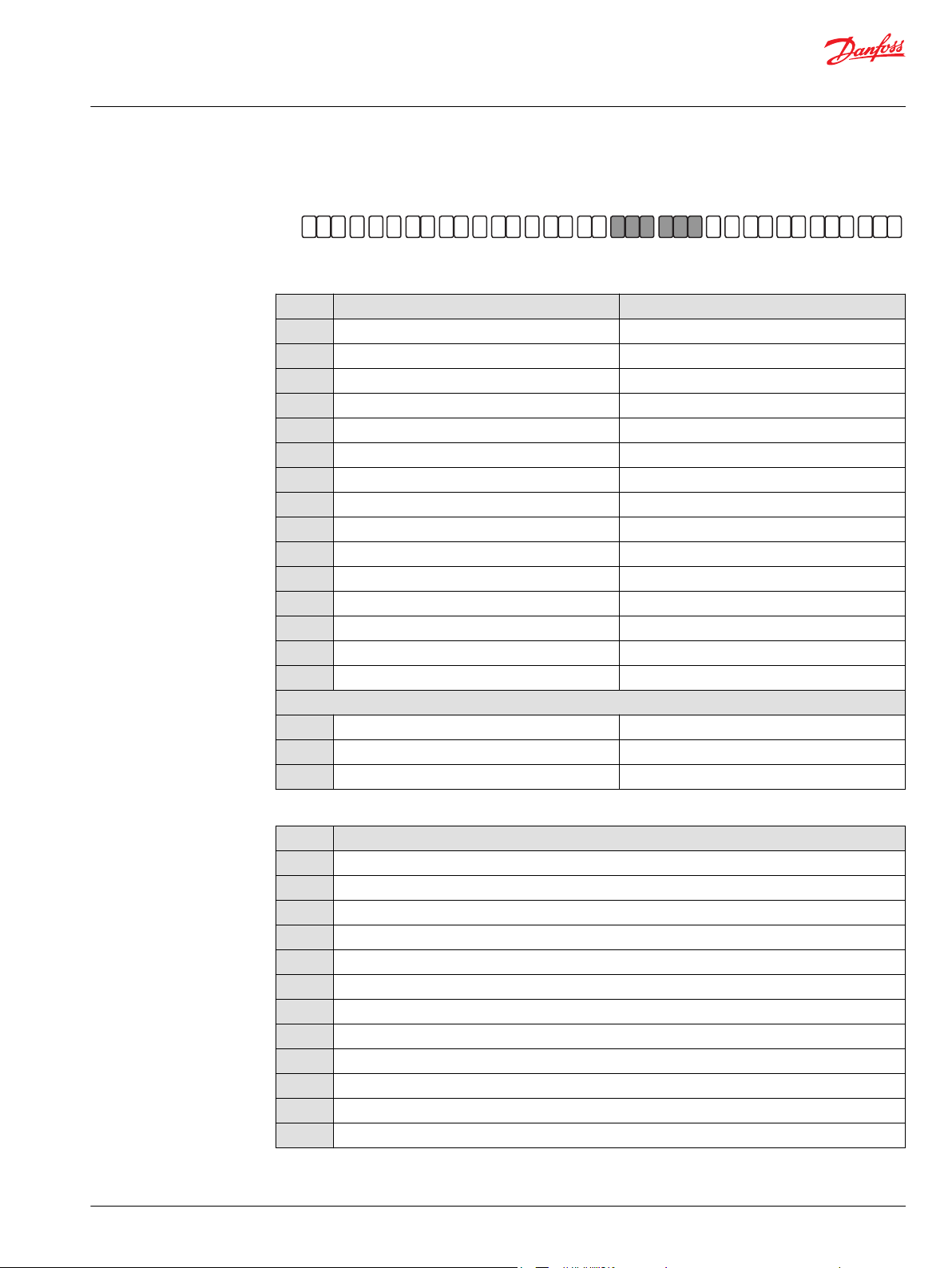

Displacement, A—Rotation, B—Product Version, Z—Port Configuration

Displacement

089

100

A – Direction of Rotation

L

R

B – Product version

B

Z – Port configuration

A

89.2 cm3 [5.44 in3]

101.7 cm3 [6.21 in3]

Left hand (counter clockwise)

Right hand (clockwise)

Revision code

Inch, Customer O-ring port sealing according to ISO 11926-1

©

Danfoss | December 2021 BC152886482765en-001301 | 11

Page 12

G H J K M N S T V W X YZ D EF

H1P

A B

Technical Information

H1P 089/100 Axial Piston Single Pumps

Master Model Code

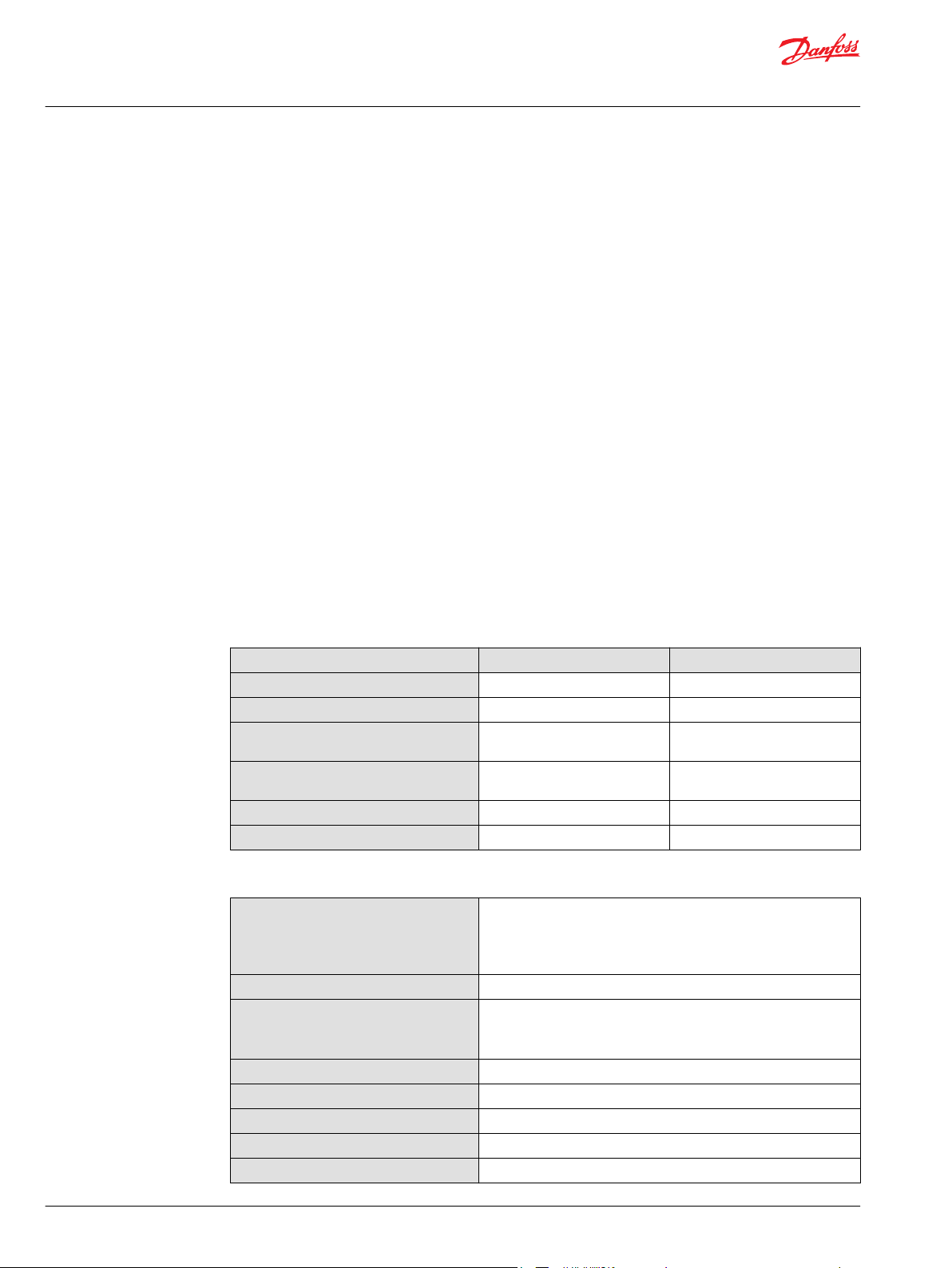

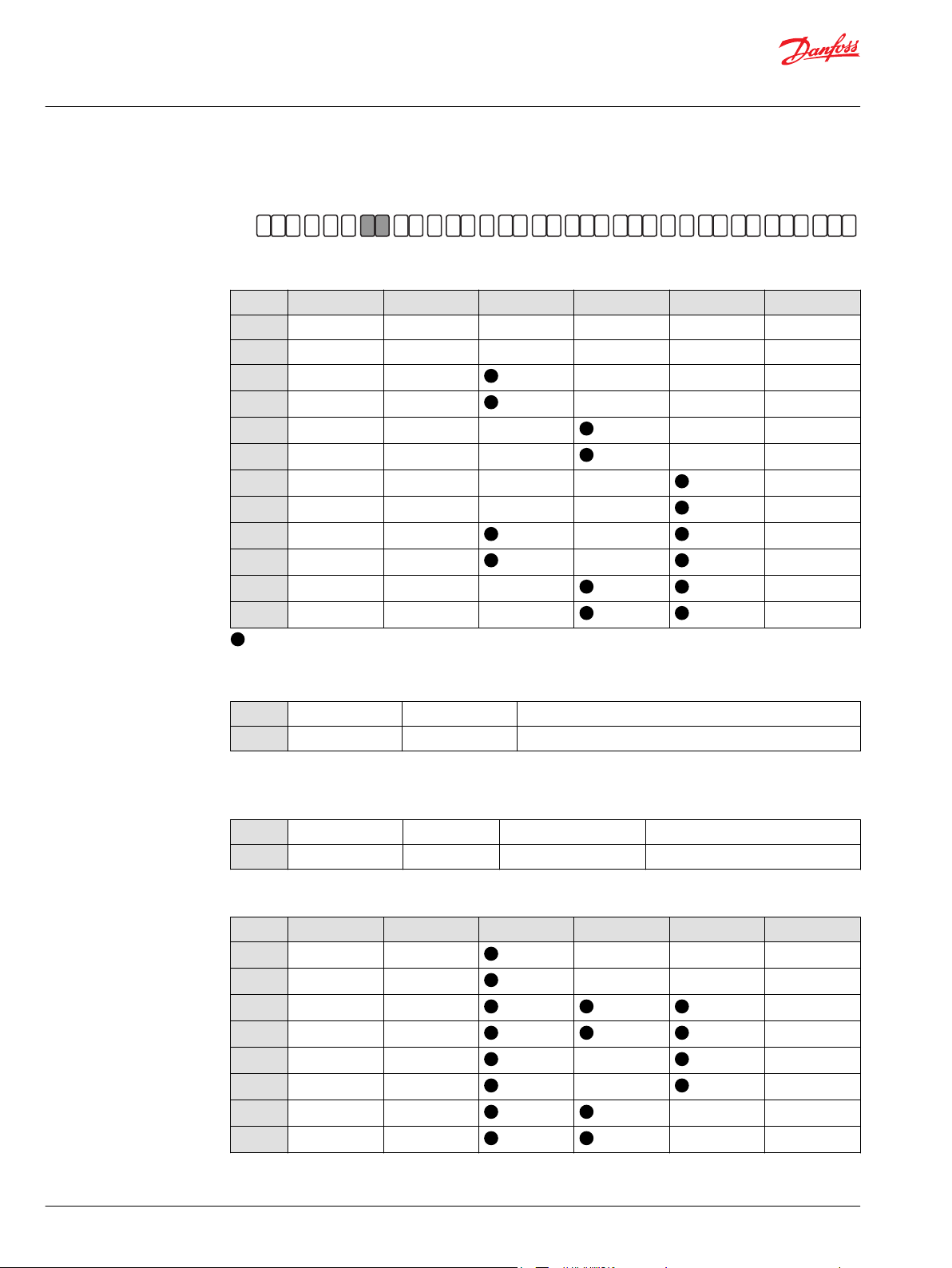

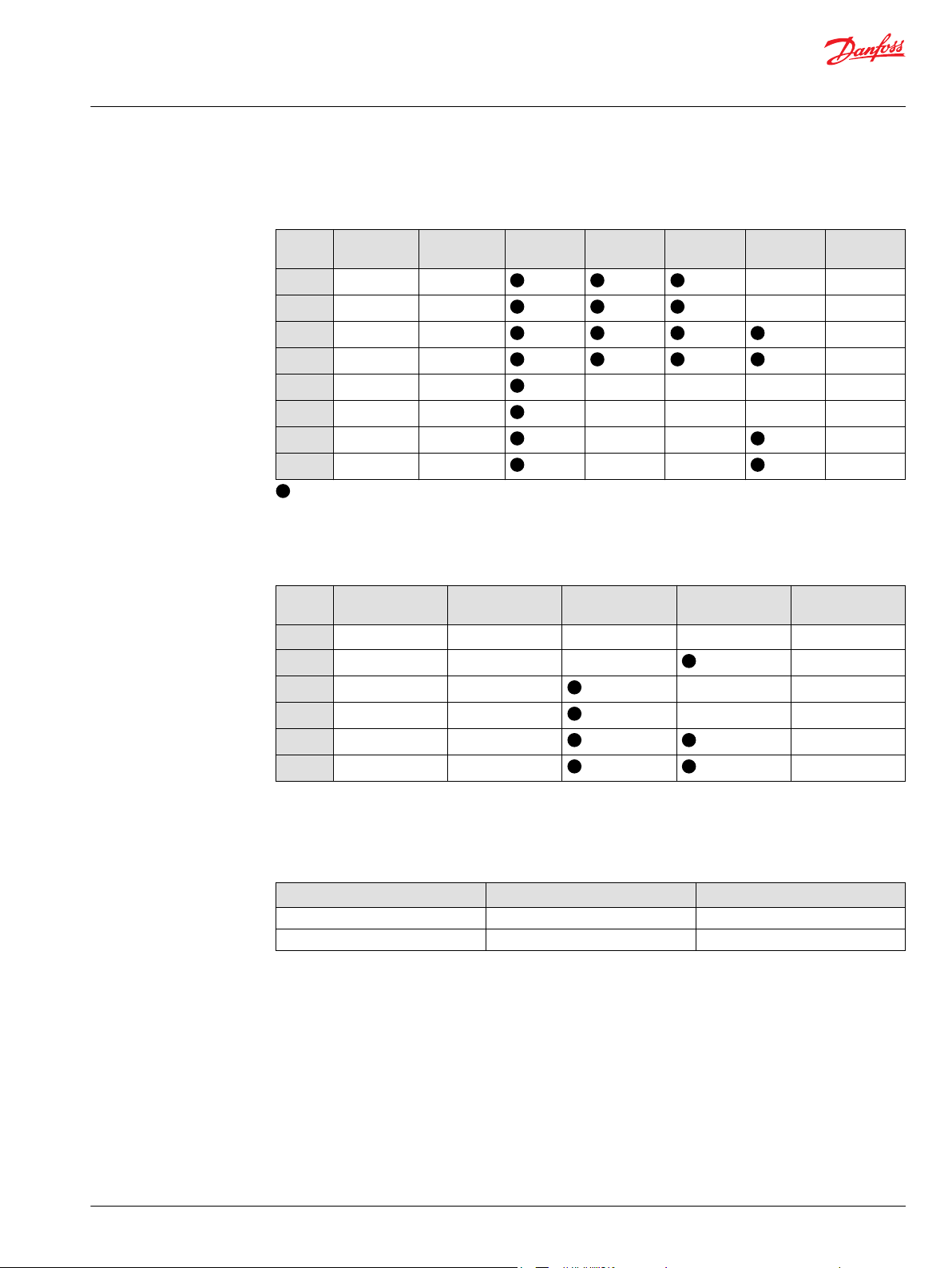

D—Controls

Electronic Displacement Controls

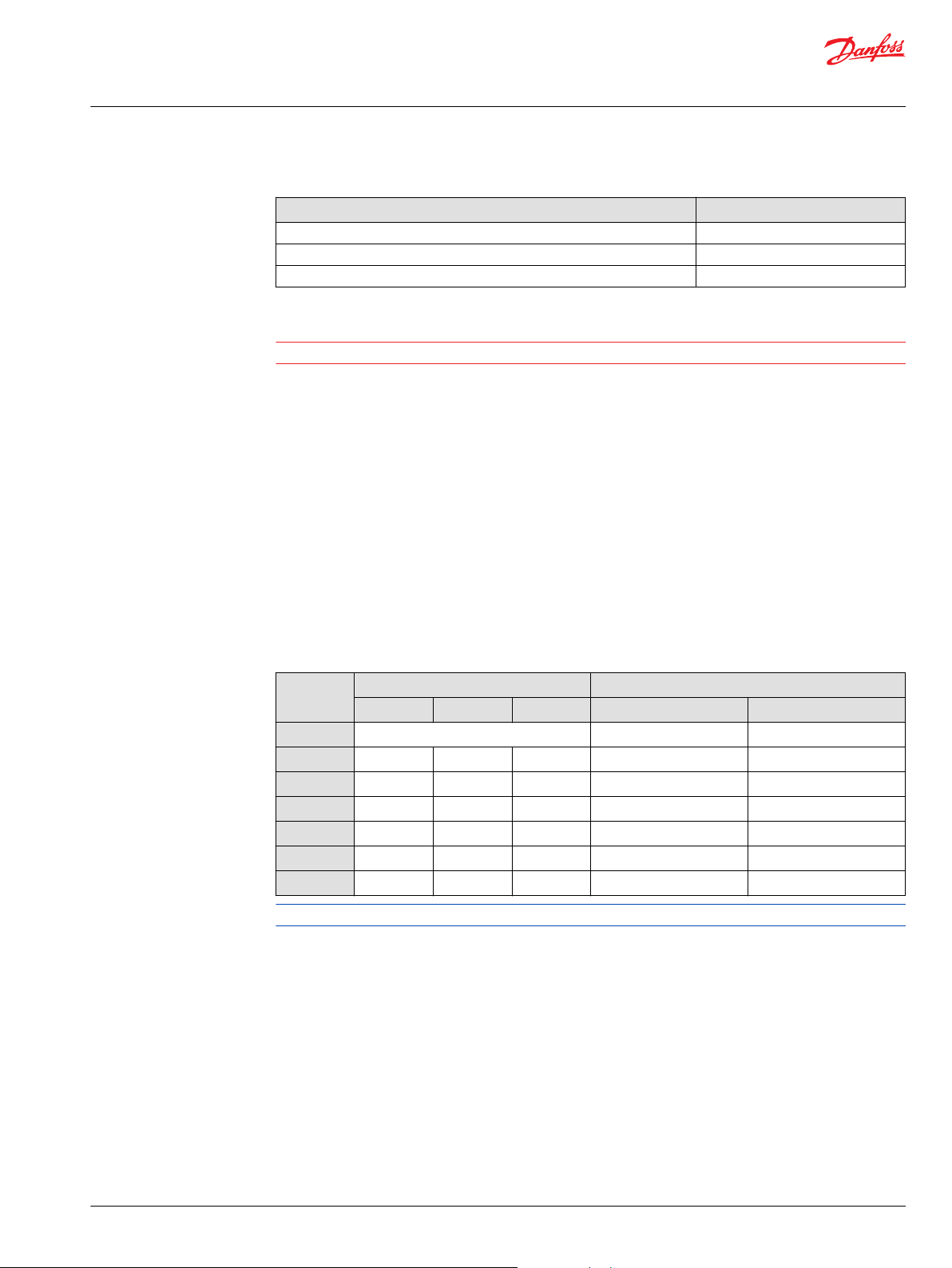

Code Control type Voltage MOR CCO with key C Angle sensor Connector

A2

A3

A4

A5

E7

E8

H2

H3

H6

H7

H8

H9

EDC 12 V — — — DEUTSCH

EDC 24 V — — — DEUTSCH

EDC 12 V — — DEUTSCH

EDC 24 V — — DEUTSCH

EDC 12 V — — DEUTSCH

EDC 24 V — — DEUTSCH

EDC 12 V — — DEUTSCH

EDC 24 V — — DEUTSCH

EDC 12 V — DEUTSCH

EDC 24 V — DEUTSCH

EDC 12 V — DEUTSCH

EDC 24 V — DEUTSCH

– To be used for the control; — Not to be used for the control

Fan Drive Controls

F1 FDC

F2 FDC

Align with options: F: Orifices, E: Displacement limiters, M, N: Overpressure protection, and W: Special hardware.

12 V DEUTSCH Connector

24 V DEUTSCH Connector

Forward-Neutral-Reverse (FNR) Controls

A9 FNR

B1 FNR

12 V with MOR DEUTSCH Connector

24 V with MOR DEUTSCH Connector

Non-Feedback Proportional Electric (NFPE) Controls

Code Control type Voltage MOR CCO with key C Angle sensor Connector

N1

N2

N3

N4

N5

N6

N7

N8

Align with options: E: Displacement limiters and W: Special hardware.

NFPE 12 V — — DEUTSCH

NFPE 24 V — — DEUTSCH

NFPE 12 V DEUTSCH

NFPE 24 V DEUTSCH

NFPE 12 V — DEUTSCH

NFPE 24 V — DEUTSCH

NFPE 12 V — DEUTSCH

NFPE 24 V — DEUTSCH

12 | © Danfoss | December 2021 BC152886482765en-001301

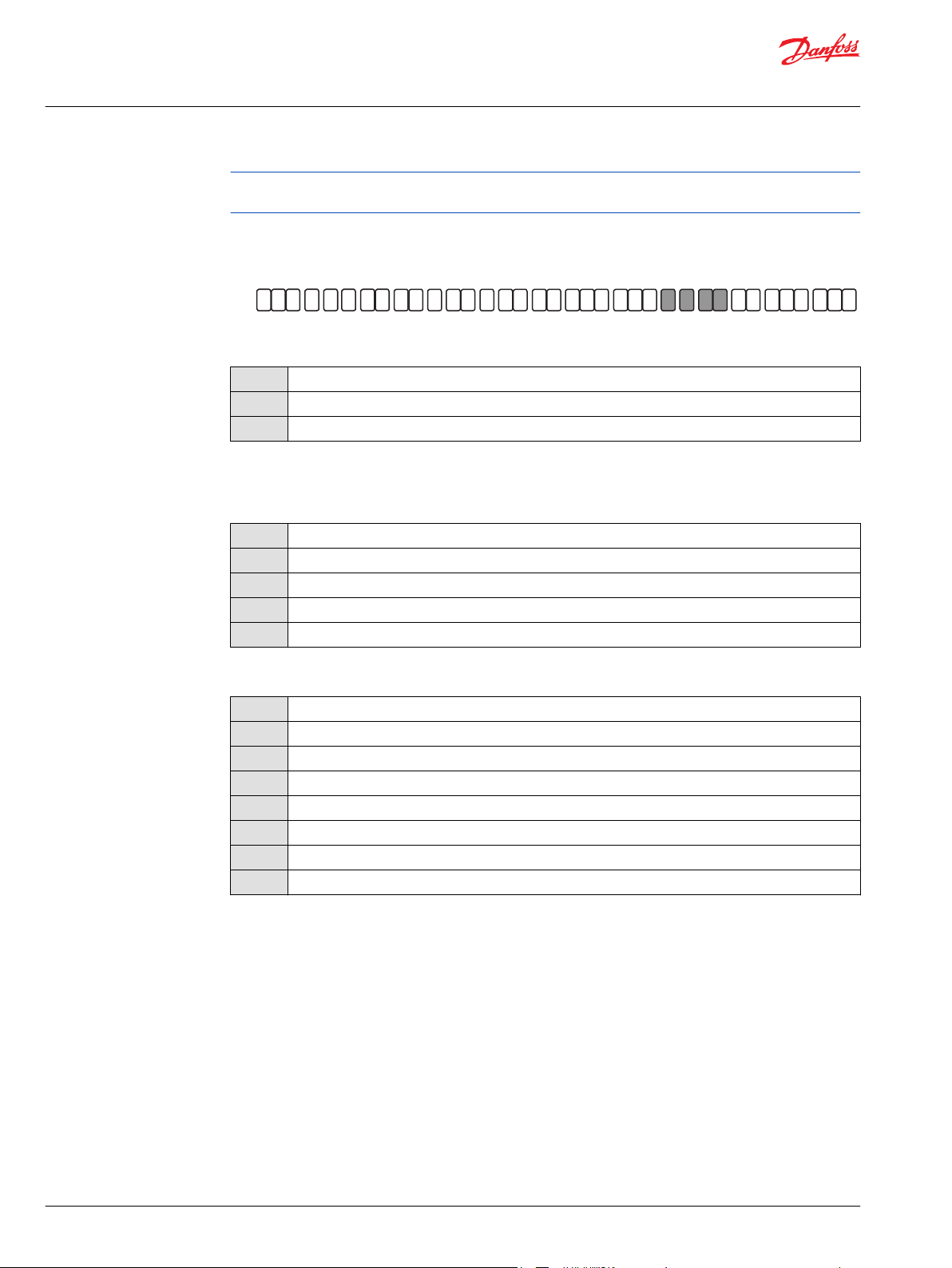

Page 13

Technical Information

H1P 089/100 Axial Piston Single Pumps

Master Model Code

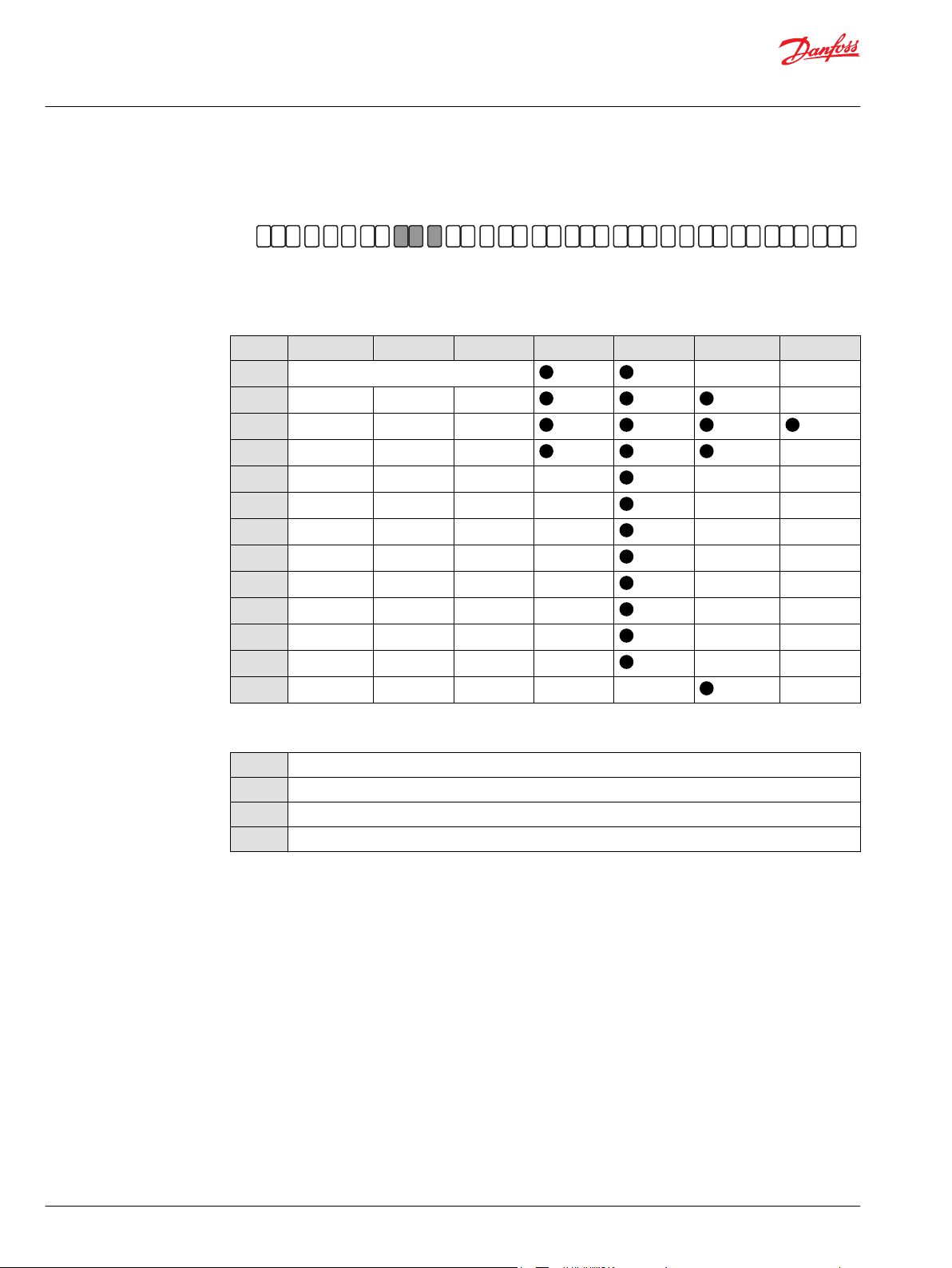

Automotive Controls

Automotive Control (AC)

Code AC type Voltage MOR Speed

P6

P7

P8

P9

P5

R3

R4

R5

Manual Displacement Control

AC–1 12 V — DEUTSCH

AC–1 24 V — DEUTSCH

AC–2 12 V DEUTSCH

AC–2 24 V DEUTSCH

AC–1 12 V — — — DEUTSCH

AC–1 24 V — — — DEUTSCH

AC–2 12 V — — DEUTSCH

AC–2 24 V — — DEUTSCH

– To be used for the control; — Not to be used for the control

sensor

Wire

harness

Angle

sensor

Connector

Manual Displacement Control (MDC)

Code Control type CCO Voltage CCO Neutral Start

M1

M2

M3

M4

M5

M6

Align with options F: Orifices and Y: Settings for adjustment (if applicable).

MDC — — — —

MDC — — DEUTSCH

MDC 12 V — DEUTSCH

MDC 24 V — DEUTSCH

MDC 12 V DEUTSCH

MDC 24 V DEUTSCH

Switch

Hydraulic Displacement Control

Hydraulic Displacement Control (HDC)

Code Pressure range Ports

T1 4.2 - 16.2 bar Inch ports 9/16-18

T2 3.0 - 11.6 bar Inch ports 9/16-18

Connector

©

Danfoss | December 2021 BC152886482765en-001301 | 13

Page 14

G H J K M N S T V W X YZ D EF

H1P

A B

Technical Information

H1P 089/100 Axial Piston Single Pumps

Master Model Code

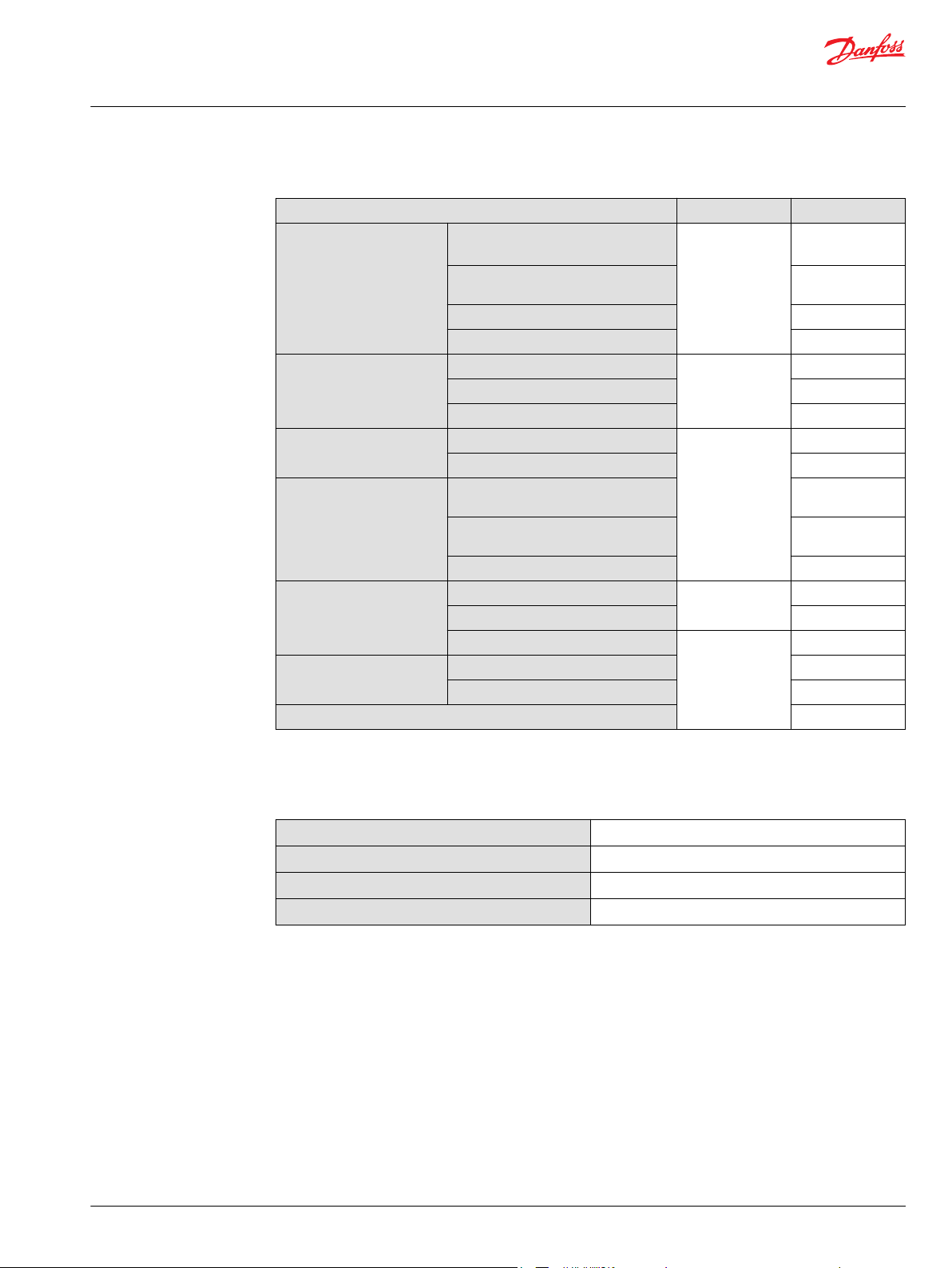

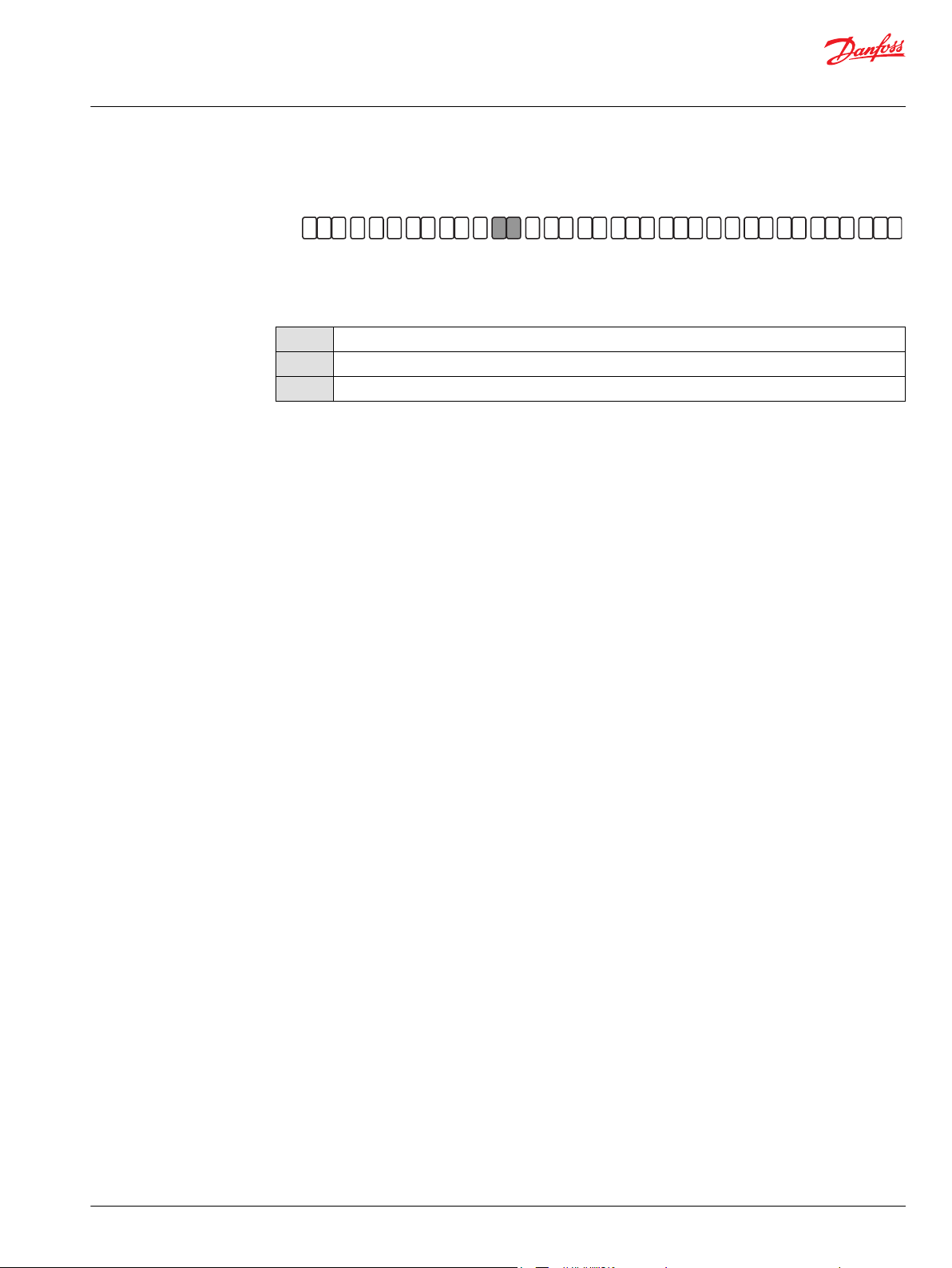

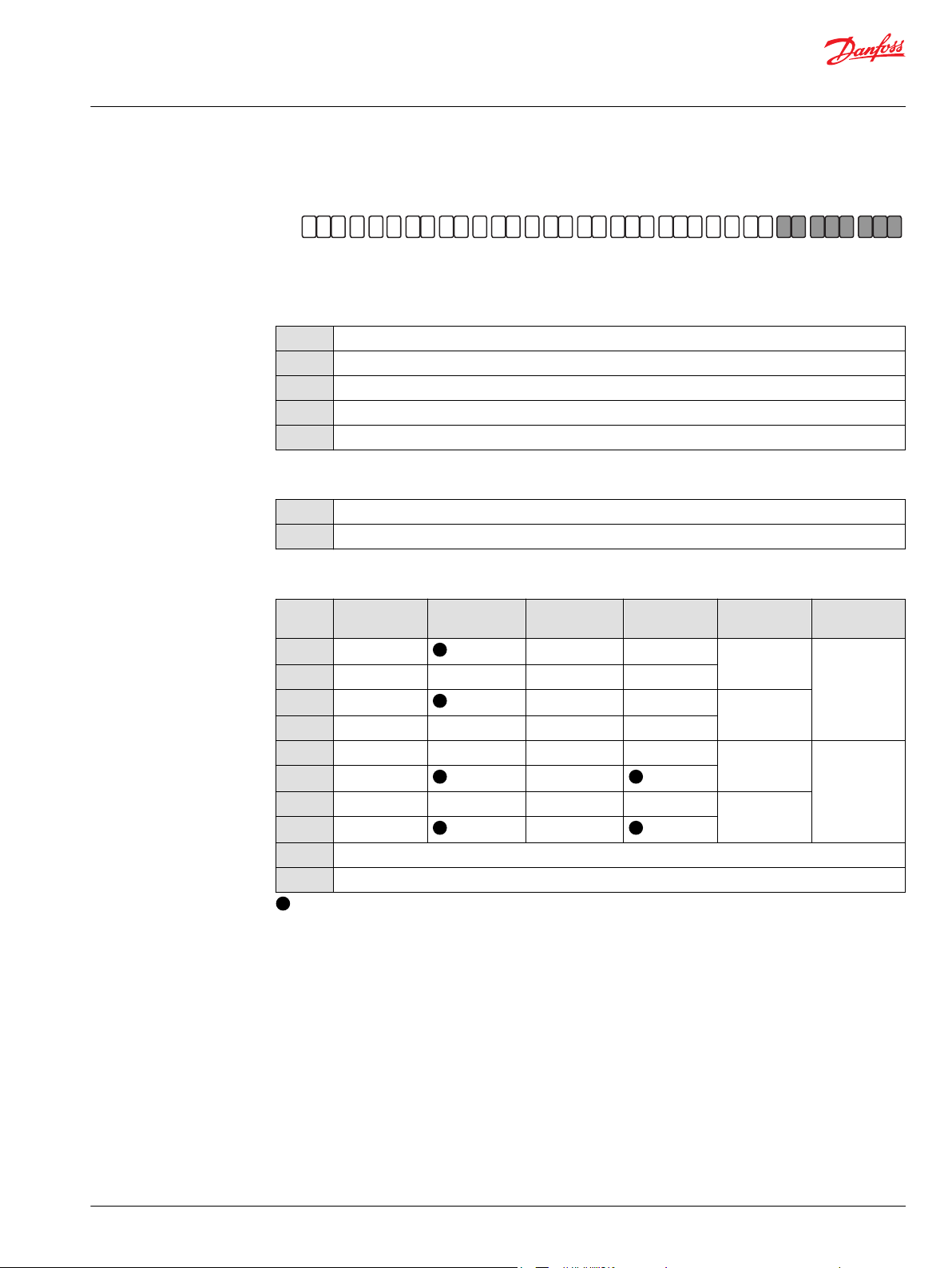

F—Orifices, E—Displacement Limiters

F – Orifices Options

Orifices options related to control type

Code Tank (A+B) P orifice A/B orifices EDC, FNR MDC NFPE, AC FDC

C3

C1

C2

C4

C6

C7

D1

D2

D3

D4

D5

D6

D7

– – 0.8 mm –

– – 1.3 mm

– – 1.8 mm –

1.0 mm – – – –

1.3 mm – – – – –

0.8 mm 1.0 mm – – – –

0.8 mm 1.3 mm – – – –

1.0 mm 1.3 mm – – – –

1.0 mm 1.3 mm 1.3 mm – – –

0.6 mm 0.6 mm 0.8 mm – – –

1.3 mm 1.3 mm – – – –

– – 3.0 mm – – –

No orifice – –

E – Displacement Limiter Options

N

B

C

D

*

Align with option Y: Settings for adjustment (if applicable).

None

Adjustable externally

No limiters, with nested springs, required for NFPE, AC, FDC

Adjustable externally with nested springs, required for NFPE, AC, FDC

*

*

14 | © Danfoss | December 2021 BC152886482765en-001301

Page 15

G H J K M N S T V W X YZ D EF

H1P

A B

Technical Information

H1P 089/100 Axial Piston Single Pumps

Master Model Code

G—Endcap

G – End-cap Options

Twin port, ISO 6162 split flange ports; Align with T: Filtration

D3 Integral pressure filtration

D6 Suction filtration

D8 Remote filtration or external charge supply

©

Danfoss | December 2021 BC152886482765en-001301 | 15

Page 16

G H J K M N S T V W X YZ D EF

H1P

A B

Technical Information

H1P 089/100 Axial Piston Single Pumps

Master Model Code

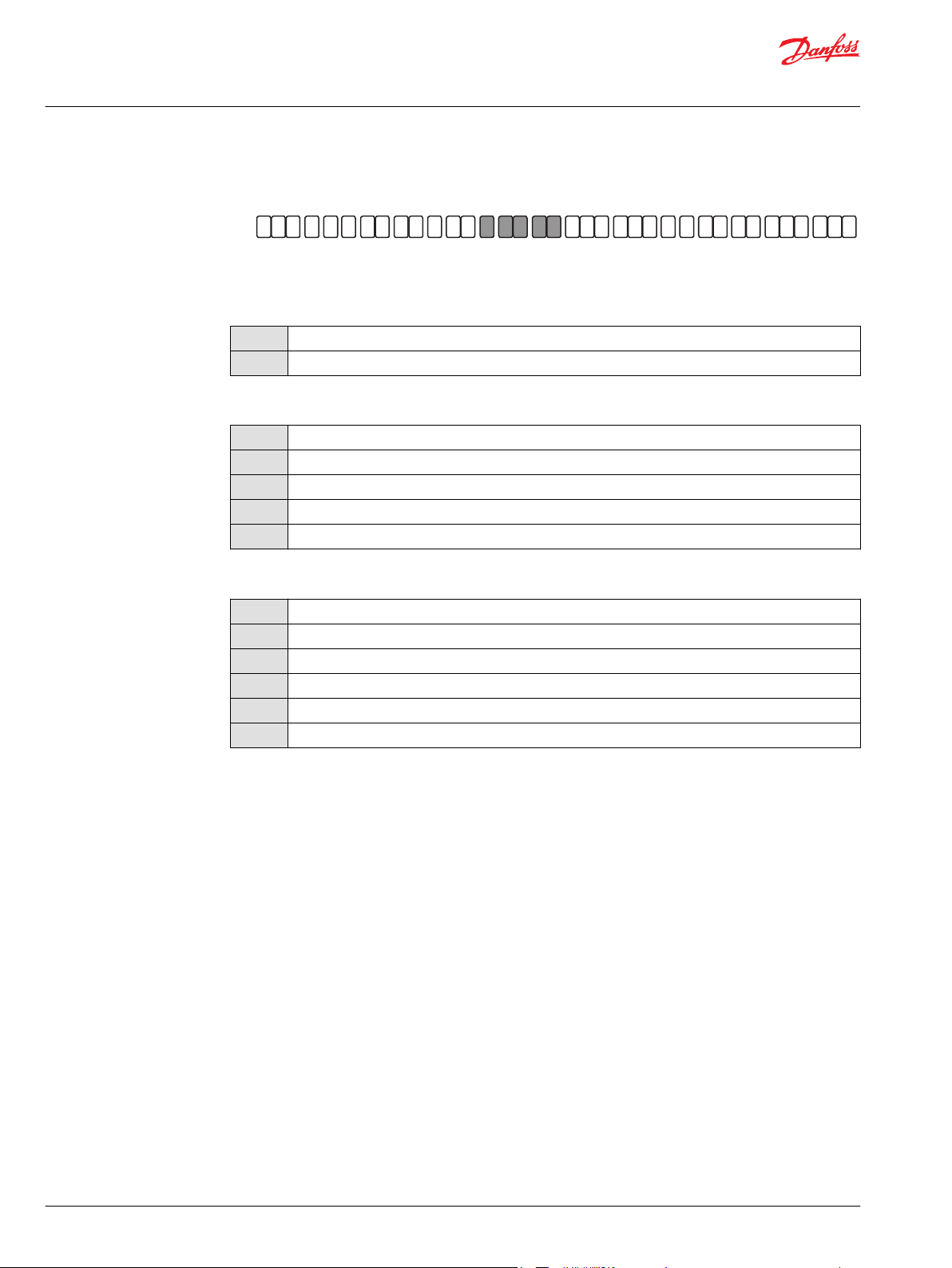

H—Mounting Flange, J—Input Shaft, K—Aux Pad

H – Mounting options

Mounting to be aligned with option W: Special hardware

H

K

J – Input Shaft options

ISO 3019-1 flange 127–4 (SAE C)

ISO 3019-1 flange 127–4 (SAE C), 4-bolt, with speed sensor

G1

G3

G9

F1

F4

ISO 3019-1, outer Ø32 mm - 4 (14 teeth splined shaft 12/24 pitch)

ISO 3019-1, outer Ø44 mm - 4 (13 teeth splined shaft 8/16 pitch)

ISO 3019-1, outer Ø38 mm - 4 (23 teeth splined shaft 16/32 pitch

ISO 3019-1, outer Ø35 mm - 4 (21 teeth splined shaft 16/32 pitch)

Conical keyed shaft end, code 38-3 (similar to ISO 3019-1), taper 1:8 (key not supplied with pump)

K – Auxiliary Mounting Pad options (ISO 3019-1)

NN

H1

H2

H3

H5

H6

None

Flange 82–2 (SAE A, 11 teeth, 16/32 coupling); shipping cover

Flange 82–2 (SAE A, 9 teeth, 16/32 coupling); shipping cover

Flange 101–2 (SAE B, 13 teeth, 16/32 coupling); shipping cover

Flange 101–2 (SAE B-B, 15 teeth, 16/32 coupling); shipping cover

Flange 127–4 (SAE C, 14 teeth, 12/24 coupling); shipping cover

16 | © Danfoss | December 2021 BC152886482765en-001301

Page 17

G H J K M N S T V W X YZ D EF

H1P

A B

Technical Information

H1P 089/100 Axial Piston Single Pumps

Master Model Code

M, N—Overpressure Protection Settings

M and N – Overpressure protection options

L Pressure limiter setting HPRV with bypass setting

L15

L18

L20

L23

L25

L28

L30

L33

L35

L38

L40

L42

L43

L44

L45

Overpressure protection type and setting for FDC

F01

F02

F03

1)

Pressure limiter and HPRV with bypass, over-pressure protection type must be the same for both sides “A” and “B”.

150 bar [2900 psi] 230 bar [3336 psi]

180 bar [2610 psi] 230 bar [3336 psi]

200 bar [2900 psi] 250 bar [3630 psi]

230 bar [3336 psi] 280 bar [4061 psi]

250 bar [3630 psi] 300 bar [4350 psi]

280 bar [4061 psi] 330 bar [4786 psi]

300 bar [4350 psi] 350 bar [5076 psi]

330 bar [4786 psi] 380 bar [5510 psi]

350 bar [5080 psi] 400 bar [5800 psi]

380 bar [5510 psi] 420 bar [6090 psi]

400 bar [5800 psi] 450 bar [6526 psi]

420 bar [6090 psi] 450 bar [6526 psi]

430 bar [6237 psi] 480 bar [6962 psi]

440 bar [6382 psi] 480 bar [6962 psi]

450 bar [6526 psi] 480 bar [6962 psi]

150 bar [2175 psi] 250 bar [3630 psi]

150 bar [2175 psi] 300 bar [4350 psi]

150 bar [2175 psi] 350 bar [5076 psi]

1)

K Pressure setting

K18

K20

K23

K25

K28

K30

K33

K35

K38

K40

K42

K45

1)

Pressure limiter and HPRV with bypass, over-pressure protection type must be the same for both sides “A” and “B”.

©

Danfoss | December 2021 BC152886482765en-001301 | 17

180 bar [2610 psi]

200 bar [2900 psi]

230 bar [3336 psi]

250 bar [3630 psi]

280 bar [4061 psi]

300 bar [4350 psi]

330 bar [4786 psi]

350 bar [5076 psi]

380 bar [5510 psi]

400 bar [5800 psi]

420 bar [6090 psi]

450 bar [6526 psi]

1)

Page 18

G H J K M N S T V W X YZ D EF

H1P

A B

Technical Information

H1P 089/100 Axial Piston Single Pumps

Master Model Code

Please contact Danfoss Power Solutions for pressures not shown or for applied pressure above max.

working pressure.

S—Charge Pump, T—Filtration, V—Charge Pressure Relief

S – Charge pump options

D

M

N

20 cm³/rev [1.22 in³/rev]

24 cm³/rev [1.46 in³/rev]

No charge pump, external charge supply (Align with options: E, T)

T – Filtration options

Filtration to be aligned with G: End cap selection

L

M

N

P

E

Suction filtration

Integral full charge flow filtration with bypass sensor, medium filter length 11004918

Integral full charge flow filtration with bypass sensor, without filter

Remote full charge flow filtration

External full charge flow filtration (Align with options N, S)

V – Charge pressure relief valve (CPRV) setting

*

*

*

20 bar [290 psi]

22 bar [319 psi]

24 bar [348 psi]

26 bar [377 psi]

28 bar [406 psi]

30 bar [435 psi]

32 bar [464 psi]

34 bar [493 psi]

20

22

24

26

28

30

32

34

*

Not to be used for NFPE, AC and FDC controls.

18 | © Danfoss | December 2021 BC152886482765en-001301

Page 19

G H J K M N S T V W X YZ D EF

H1P

A B

Technical Information

H1P 089/100 Axial Piston Single Pumps

Master Model Code

W—Special Hardware, X—Paint, Y—Special Features

W – Special Hardware features

Hardware features to be aligned with options D, E

P1

P2

P4

PN

H1

X – Paint and Name-tag

NFPE/FDC valve plate

NFPE/FDC/AC valve plate and speed ring on the cylinder block

EDC/FNR/MDC valve plate and speed ring on the cylinder block

EDC/FNR/MDC valve plate

MDC/EDC/FNR valve plate with MDC handle

NNN

C08

Black paint and Danfoss name-tag

Paint none and Danfoss name-tag

Y – Special settings (SIL-2 non-certifiable, without customer files)

Code CAN J1939 ECO fuel saving

D3E

D3F

D4E

D4F

D5F

D5J

D6F

D6J

M00

NNN

in/out E –

in/out – F –

in/out E –

in/out – F –

in/out – F –

in/out J

in/out – F –

in/out J

MDC handle standard position

None

– To be used for the control; — Not to be used for the control

mode

Functional

option

Cruise control Control AC type

N1

(12 VDC)

N2

(24 VDC)

P8

(12 VDC)

P9

(24 VDC)

AC–1

AC–2

(with swash

plate angle

sensor)

©

Danfoss | December 2021 BC152886482765en-001301 | 19

Page 20

P003 191

Feedback from

Swash plate

PTF00B

M14

C1 C2

F00A

P003 478E

Technical Information

H1P 089/100 Axial Piston Single Pumps

Control Options

Electrical Displacement Control (EDC)

An EDC is a displacement (flow) control. Pump swash plate position is proportional to the input

command and therefore vehicle or load speed (excluding influence of efficiency), is dependent only on

the prime mover speed or motor displacement.

The Electrical Displacement Control (EDC) consists of a pair of proportional solenoids on each side of a

three-position, four-way porting spool. The proportional solenoid applies a force input to the spool,

which ports hydraulic pressure to either side of a double acting servo piston. Differential pressure across

the servo piston rotates the swash plate, changing the pump‘s displacement from full displacement in

one direction to full displacement in the opposite direction.

A serviceable 170 μm screen is located in the supply line immediately before the control porting spool.

Under some circumstances, such as contamination, the control spool could stick and cause the pump to

stay at some displacement.

Electrical Displacement Control

EDC schematic, feedback from swash plate

EDC Operation

H1 EDC’s are current driven controls requiring a Pulse Width Modulated (PWM) signal. Pulse width

modulation allows more precise control of current to the solenoids.

The PWM signal causes the solenoid pin to push against the porting spool, which pressurizes one end of

the servo piston, while draining the other. Pressure differential across the servo piston moves the

swashplate.

A swashplate feedback link, opposing control links, and a linear spring provide swashplate position force

feedback to the solenoid. The control system reaches equilibrium when the position of the swashplate

spring feedback force exactly balances the input command solenoid force from the operator. As

hydraulic pressures in the operating loop change with load, the control assembly and servo/swashplate

system work constantly to maintain the commanded position of the swashplate.

The EDC incorporates a positive neutral deadband as a result of the control spool porting, preloads from

the servo piston assembly, and the linear control spring. Once the neutral threshold current is reached,

the swashplate is positioned directly proportional to the control current. To minimize the effect of the

control neutral deadband, we recommend the transmission controller or operator input device

incorporate a jump up current to offset a portion of the neutral deadband.

The neutral position of the control spool does provide a positive preload pressure to each end of the

servo piston assembly.

When the control input signal is either lost or removed, or if there is a loss of charge pressure, the springloaded servo piston will automatically return the pump to the neutral position.

20 | © Danfoss | December 2021 BC152886482765en-001301

Page 21

"0"

-b -a

ba

100 %

100 %

Displacement

Current mA

Technical Information

H1P 089/100 Axial Piston Single Pumps

Control Options

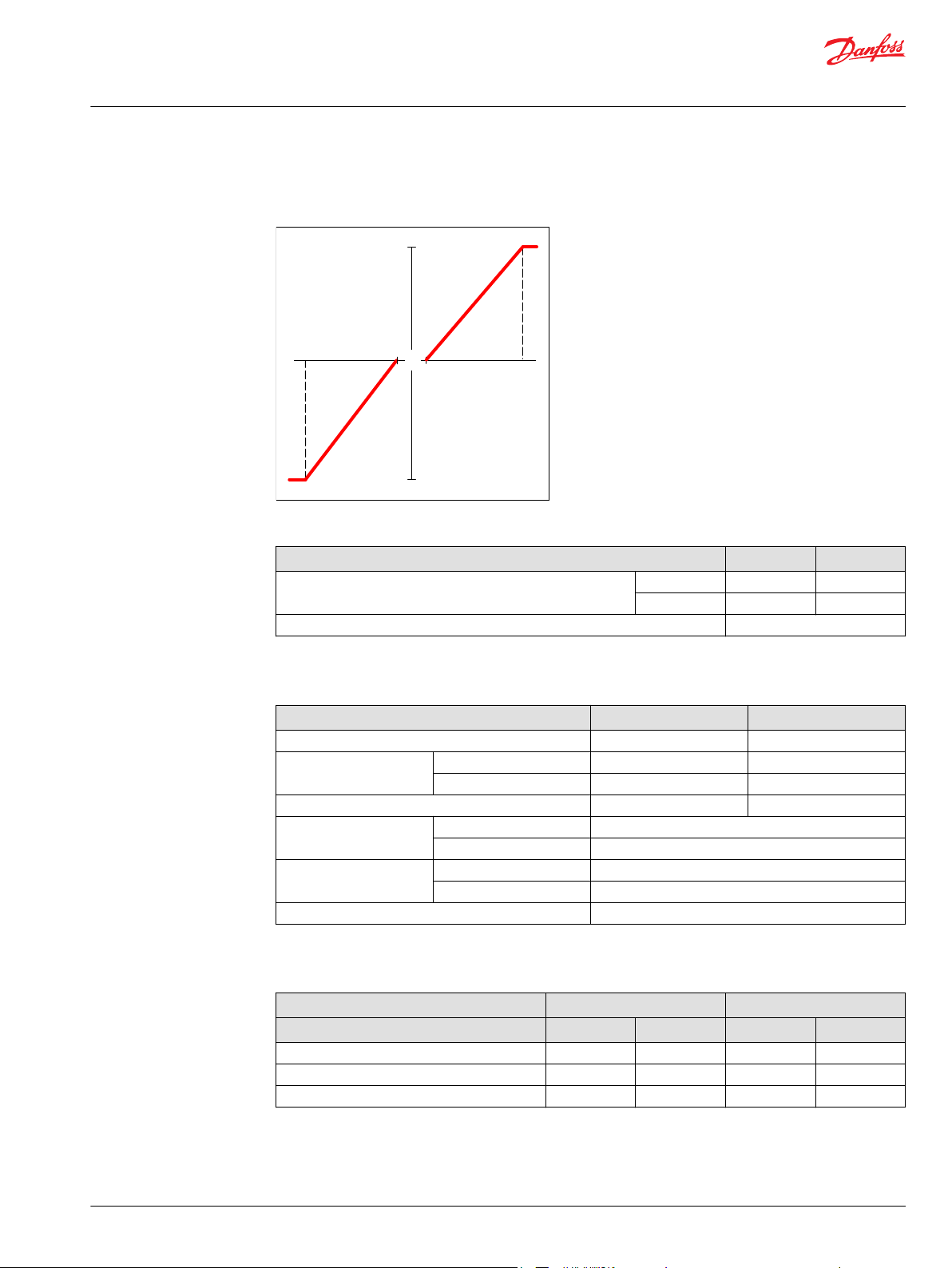

Control signal requirements, EDC 089/100

Pump displacement vs. control current

EDC control current

Voltage 12 V

Minimum current to stroke pump a

Pin connections any order

*

Factory test current, for vehicle movement or application actuation expect higher or lower value.

DC

*

640 mA 330 mA

24 V

DC

b 1640 mA 820 mA

Control Solenoid Data

Description 12 V 24 V

Maximum current 1800 mA 920 mA

Nominal coil resistance @ 20 °C [68 °F] 3.66 Ω 14.20 Ω

@ 80 °C [176 °F] 4.52 Ω 17.52 Ω

Inductance 33 mH 140 mH

PWM signal frequency Range 70 – 200 Hz

Recommended

*

100 Hz

IP Rating IEC 60 529 IP 67

DIN 40 050, part 9 IP 69K with mating connector

Connector color Black

*

PWM signal required for optimum control performance.

Single Pump Output Flow Direction

Shaft rotation Clock-Wise (CW) Counter-Clock-Wise (CCW)

Coil energized

Port A out in in out

Port B in out out in

Servo port pressurized M4 M5 M4 M5

*

For coil location see installation drawings.

*

C1 C2 C1 C2

©

Danfoss | December 2021 BC152886482765en-001301 | 21

Page 22

2

1

Technical Information

H1P 089/100 Axial Piston Single Pumps

Control Options

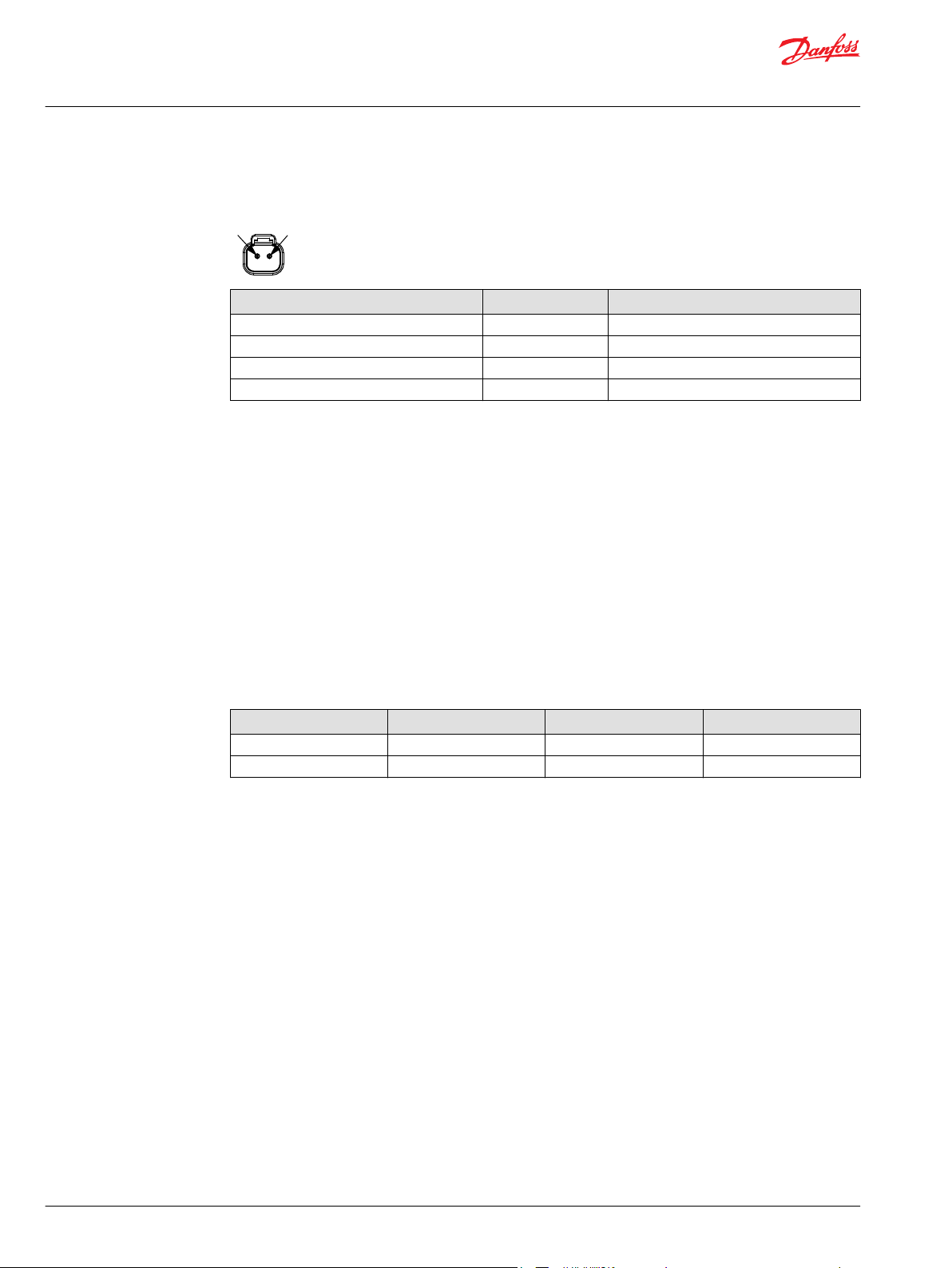

Connector

Connector DEUTSCH, 2-pin

Description Quantity Order data

Mating connector 1 DEUTSCH DT06-2S

Wedge lock 1 DEUTSCH W2S

Socket contact (16–18 AWG) 2 DEUTSCH 0462-201-16141

Danfoss mating connector kit 1 K29657

Control response

H1P controls are available with optional control passage orifices to assist in matching the rate of swashplate response to the application requirements (e.g. in the event of electrical failure).

The time required for the pump output flow to change from zero to full flow (acceleration) or full flow to

zero (deceleration) is a net function of spool porting, orifices, and charge pressure.

A swash-plate response times table is available for each frame size. Testing should be conducted to verify

the proper orifice selection for the desired response. Typical response times at the following conditions:

Δ p = 250 bar [3626 psi]

Charge pressure = 20 bar [290 psi]

Viscosity and temperature = 30 mm²/s [141 SUS] and 50 °C [122 °F]

Speed = 1800 min-1 (rpm)

Response Time, EDC 089/100

Stroking direction 0.8 mm [0.03 in] orifice 1.3 mm [0.05 in] orifice No orifice

Neutral to full flow 3.8 s 1.8 s 1.0 s

Full flow to neutral 2.2 s 1.0 s 0.6 s

22 | © Danfoss | December 2021 BC152886482765en-001301

Page 23

"0"

Lever rotation

"A"

Displacement

100 %

a

-a

100 %

"B"

-b

-d

b

c

d

-c

P301 752

Technical Information

H1P 089/100 Axial Piston Single Pumps

Control Options

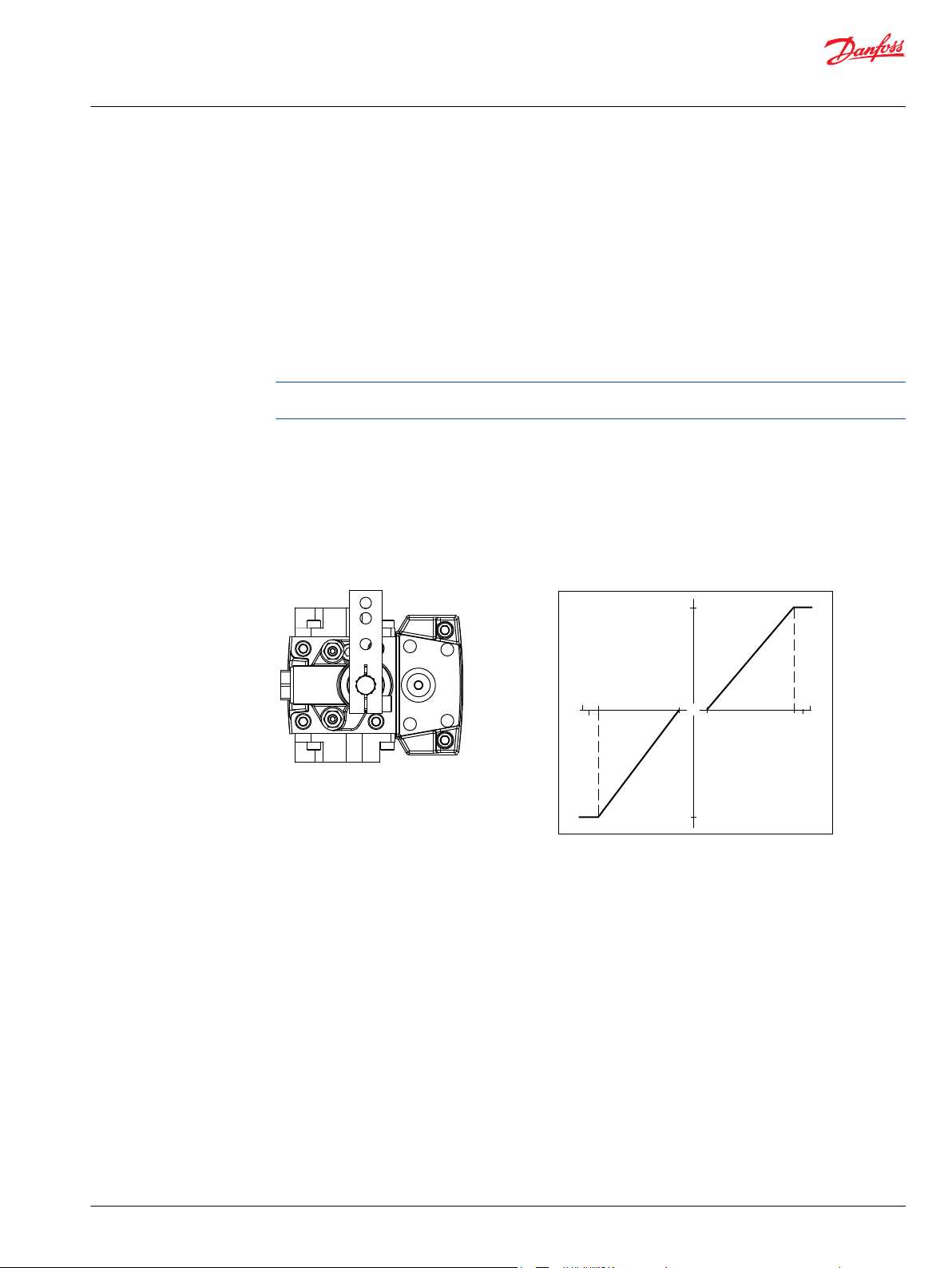

Manual Displacement Control (MDC)

A Manual proportional Displacement Control (MDC) consists of a handle on top of a rotary input shaft.

The shaft provides an eccentric connection to a feedback link. This link is connected on its one end with a

porting spool. On its other end the link is connected the pumps swashplate.

This design provides a travel feedback without spring. When turning the shaft the spool moves thus

providing hydraulic pressure to either side of a double acting servo piston of the pump.

Differential pressure across the servo piston rotates the swash plate, changing the pump’s displacement.

Simultaneously the swashplate movement is fed back to the control spool providing proportionality

between shaft rotation on the control and swash-plate rotation. The MDC changes the pump

displacement between no flow and full flow into opposite directions.

Under some circumstances, such as contamination, the control spool could stick and cause the pump to

stay at some displacement.

For the MDC with CCO option the brake port (X7) provides charge pressure when the coil is energized to

activate static function such as a brake release. The X7 port must not be used for any continuous oil

consumption.

The MDC is sealed by means of a static O-ring between the actuation system and the control block. Its

shaft is sealed by means of a special O-ring which is applied for low friction. The special O-ring is

protected from dust, water and aggressive liquids or gases by means of a special lip seal.

Manual Displacement Control Pump displacement vs. control lever rotation

Deadband on B side: a = 3° ±1°

Maximum pump stroke: b = 30° +2/-1°

Required customer end stop: c = 36° ±3°

Internal end stop: d = 40°

©

Danfoss | December 2021 BC152886482765en-001301 | 23

Page 24

C

CCW

CW

Technical Information

H1P 089/100 Axial Piston Single Pumps

Control Options

MDC operation

The MDC provides a mechanical dead-band required to overcome the tolerances in the mechanical

actuation. The MDC contains an internal end stop to prevent turning the handle into any inappropriate

position.

The MDC provides a permanent restoring moment appropriate for turning the MDC input shaft back to

neutral position only. This is required to take the backlash out of the mechanical connections between

the Bowden cable and the control.

High case pressure may cause excessive wear and the NSS to indicate that the control is not in neutral

position. In addition, if the case pressure exceeds 5 bar there is a risk of an insufficient restoring moment.

The MDC is designed for a maximum case pressure of 5 bar and a rated case pressure of 3 bar.

Customers must install some support to limit the setting range of their Bowden cable to avoid an

•

overload of the MDC.

Customers can apply their own handle design but they must care about a robust clamping

•

connection between their handle and the control shaft and avoid overload of the shaft.

Customers can connect two MDC’s on a tandem unit in such a way that the actuation force will be

•

transferred from the pilot control to the second control. The kinematic of the linkages must ensure

that either control shaft is protected from torque overload.

Caution

Using the internal spring force on the input shaft is not an appropriate way to return the customer

connection linkage to neutral, or to force a Bowden cable or a joystick back to neutral position. It is not

applicable for any limitation of the Bowden cable stroke, except the applied torque to the shaft will never

exceed 20 N•m.

MDC shaft rotation

Pump shaft rotation

MDC shaft rotation CW CCW CW CCW

Port A in (low) out (high) out (high) in (low)

Port B out (high) in (low) in (low) out (high)

Servo port high pressure M5 M4 M5 M4

*

As seen from shaft side.

*

Clockwise (CW) Counter-clockwise (CCW)

24 | © Danfoss | December 2021 BC152886482765en-001301

Page 25

C

Technical Information

H1P 089/100 Axial Piston Single Pumps

Control Options

MDC Torque

Description Value

Torque required to move handle to maximum displacement 1.4 N•m [12.39 lbf•in ]

Torque required to hold handle at given displacement 0.6 N•m [5.31 lbf•in]

Maximum allowable input torque 20 N•m [177 lbf•in]

Caution

Volumetric efficiencies of the system will have impacts on the start and end input commands.

Control response

H1P controls are available with optional control passage orifices to assist in matching the rate of swashplate response to the application requirements (e.g. in the event of electrical failure).

The time required for the pump output flow to change from zero to full flow (acceleration) or full flow to

zero (deceleration) is a net function of spool porting, orifices, and charge pressure.

A swash-plate response times table is available for each frame size. Testing should be conducted to verify

the proper orifice selection for the desired response. Typical response times at the following conditions:

Δ p = 250 bar [3626 psi]

Charge pressure = 20 bar [290 psi]

Viscosity and temperature = 30 mm²/s [141 SUS] and 50 °C [122 °F]

Speed = 1800 min-1 (rpm)

Response time, MDC 089/100

Code Orifice description (mm) Stroking direction

Tank (A+B) P A/B Neutral to full flow Full flow to neutral

C3

C6

C7

D1

D2

D3

D4

1 – – 1.7 s 1.5 s

1.3 – – 1.1 s 1.0 s

0.8 1 – 3.1 s 2.4 s

0.8 1.3 – 2.8 s 2.2 s

1 1.3 – 2.0 s 1.6 s

1 1.3 1.3 2.4 s 1.9 s

No orifice 0.5 s 0.6 s

For further data please contact your Danfoss representative.

©

Danfoss | December 2021 BC152886482765en-001301 | 25

Page 26

P005 702

M14

M5

M4

M3

2

1

Technical Information

H1P 089/100 Axial Piston Single Pumps

Control Options

Neutral start switch (NSS)

The Neutral Start Switch (NSS) contains an electrical switch that provides a signal of whether the control

is in neutral. The signal in neutral is Normally Closed (NC).

Neutral start switch schematic

Neutral start switch data

Max. continuous current with switching

Max. continuous current without switching

Max. voltage

Electrical protection class

8.4 A

20 A

36 V

DC

IP67 / IP69K with mating connector

Connector

Connector DEUTSCH, 2-pin

Description Quantity Order data

Mating connector 1 DEUTSCH DT06-2S

Wedge lock 1 DEUTSCH W2S

Socket contact (16–18 AWG) 2 DEUTSCH 0462-201-16141

Danfoss mating connector kit 1 K29657

Case Gauge Port M14

The drain port should be used when the control is mounted on the unit’s bottom side to flush residual

contamination out of the control.

Lever

MDC-controls are available with an integrated lever.

26 | © Danfoss | December 2021 BC152886482765en-001301

Page 27

P400520

P400519

X1

F00B

F00A

Feedback from

Swashplate

T P

X2M14

Technical Information

H1P 089/100 Axial Piston Single Pumps

Control Options

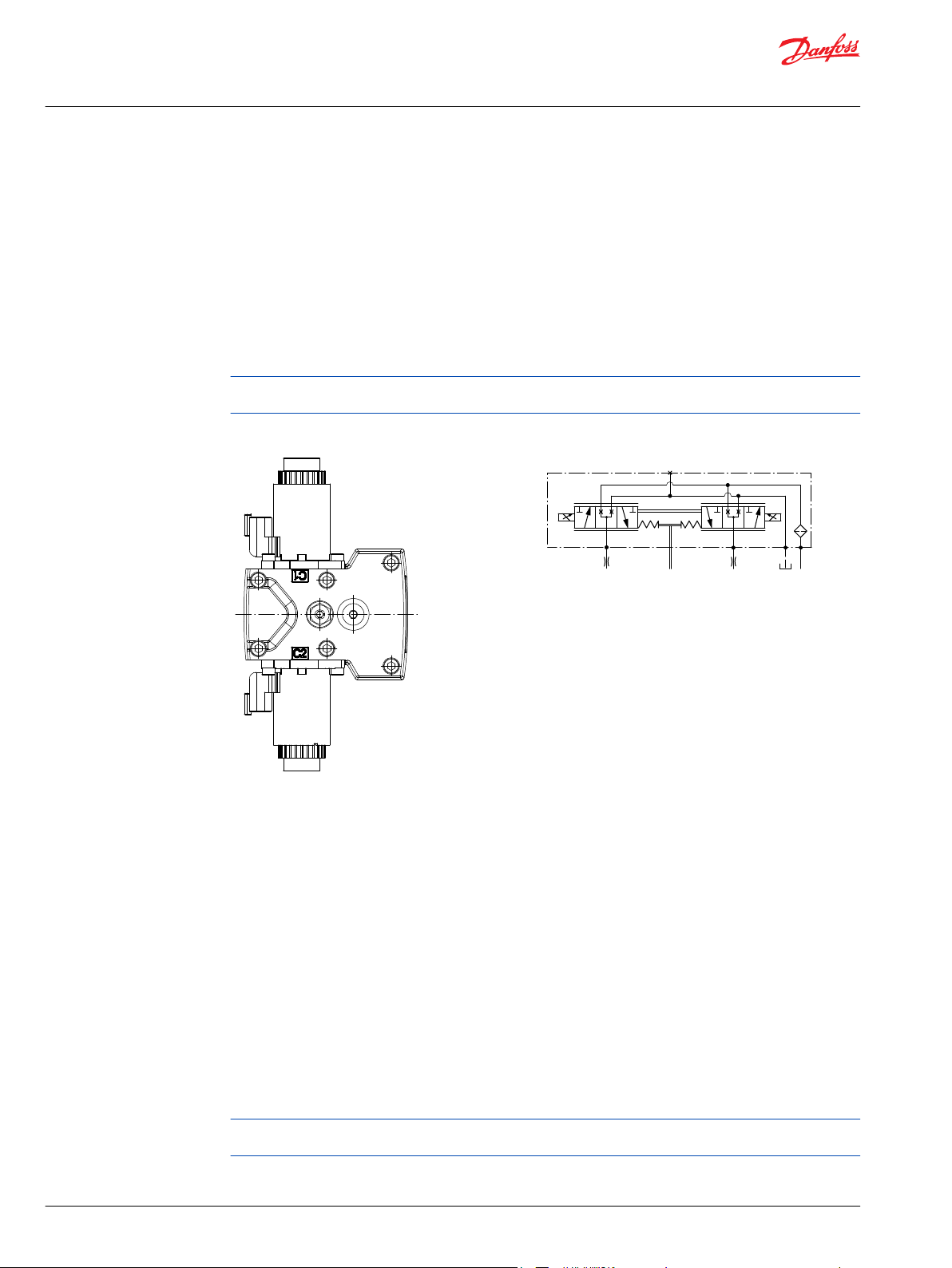

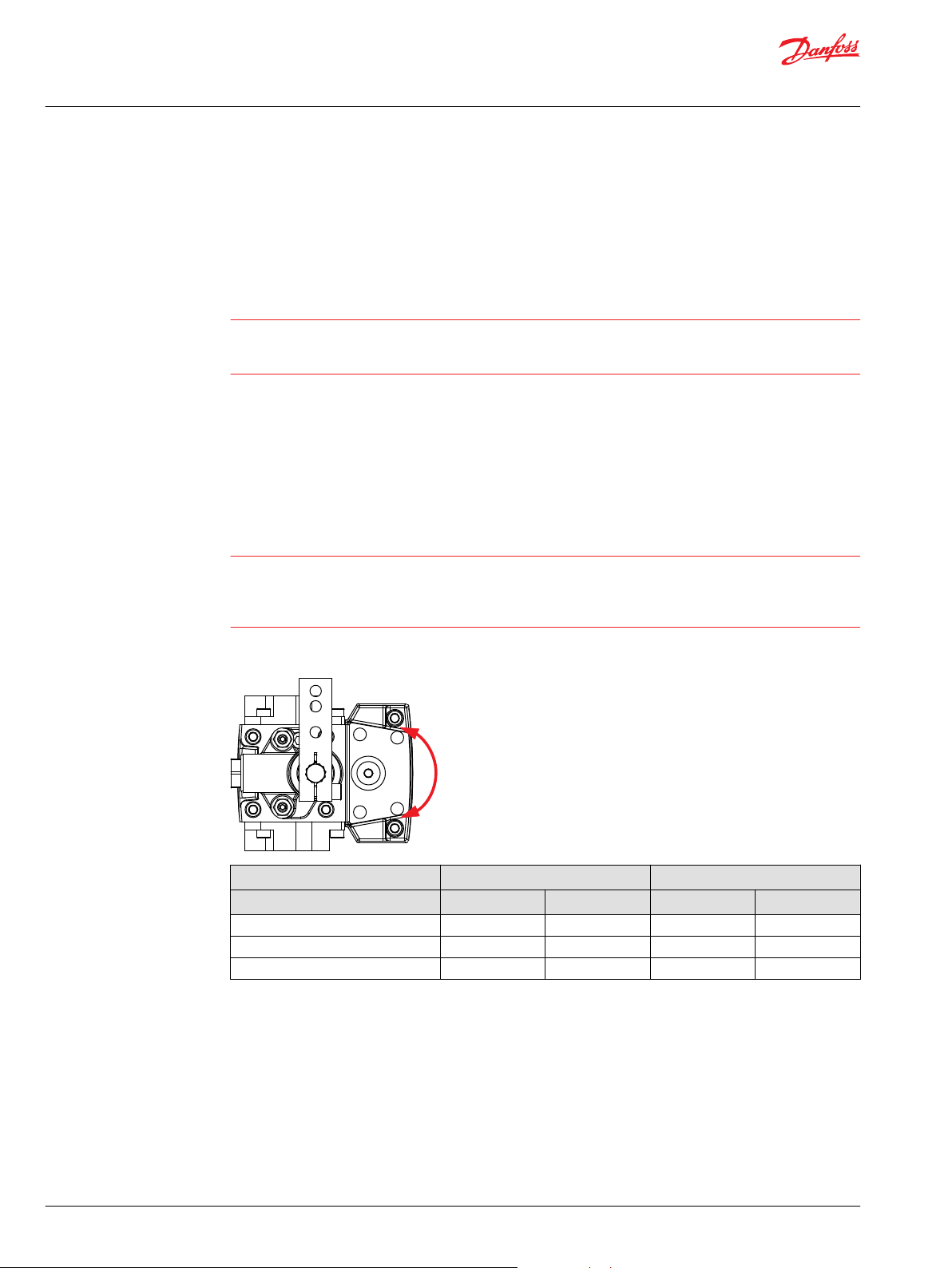

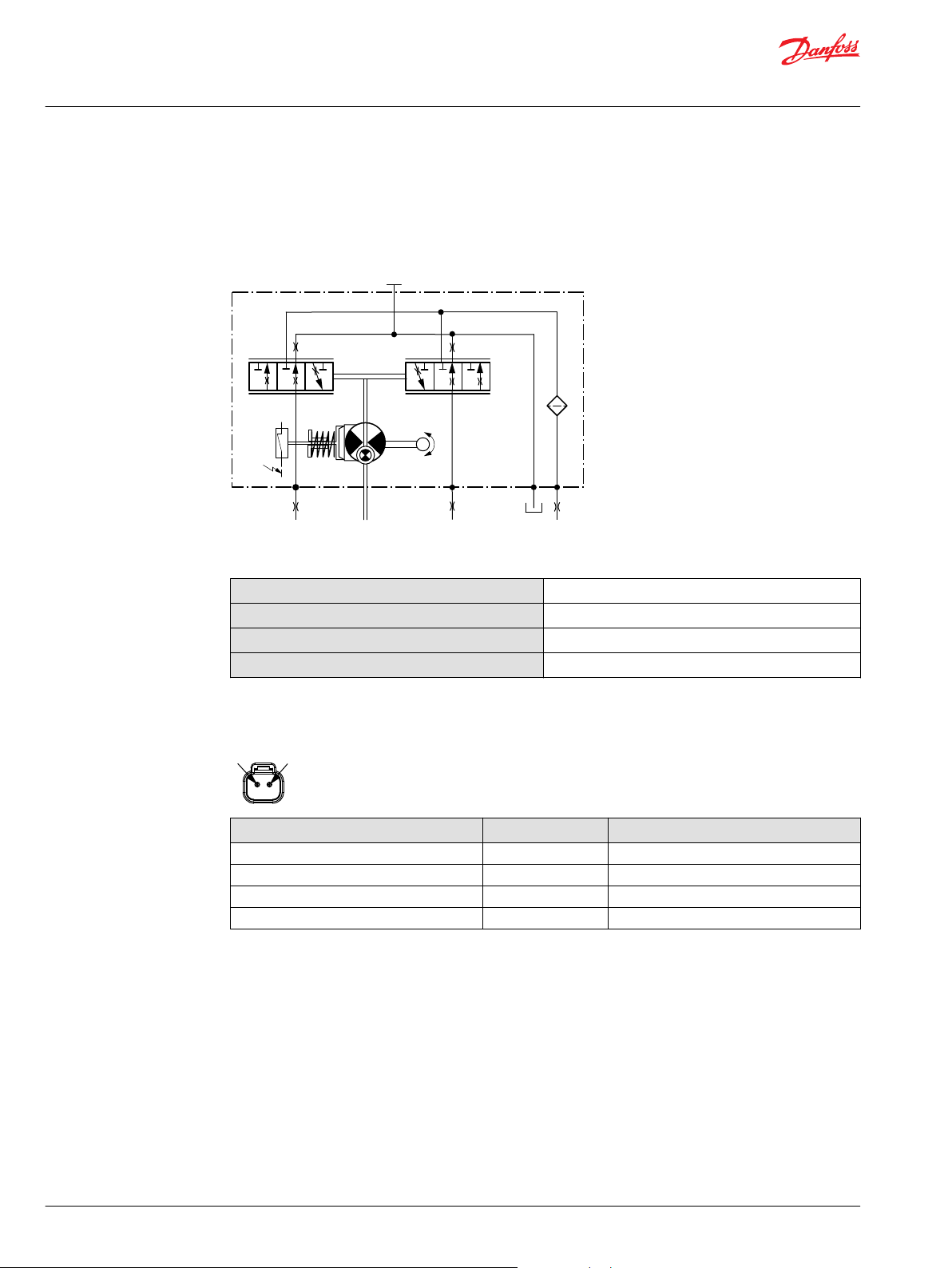

Hydraulic Displacement Control (HDC)

HDC principle

An HDC is a Hydraulic Displacement Control. Pump swashplate position is proportional to the input

command and therefore vehicle speed or load speed (excluding influence of efficiency), is dependent

only on the prime mover speed or motor displacement.

The HDC control uses a hydraulic input signal to operate a porting spool, which ports hydraulic pressure

to either side of a double acting servo piston. The hydraulic signal applies a force input to the spool

which ports hydraulic pressure to either side of a double acting servo piston. Differential pressure across

the servo piston rotates the swashplate, changing the pump’s displacement from full displacement in

one direction to full displacement in the opposite direction. Under some circumstances, such as

contamination, the porting spool could stick and cause the pump to stay at some displacement.

A serviceable 175 μm screen is located in the supply line immediately before the control porting spool.

HDC control

HDC schematic

HDC operation

HDC’s are hydraulically driven control which ports hydraulic pressure to either side of a porting spool,

which pressurizes one end of the servo piston, while draining the other end to case. Pressure differential

across the servo piston moves the swashplate.

A swashplate feedback link, opposing control linkage, and a linear spring provide swashplate position

force feedback to the hydraulic pressure. As hydraulic pressures in the operating loop change with load,

the control assembly and servo/swashplate system work constantly to maintain the commanded position

of the swashplate.

©

Danfoss | December 2021 BC152886482765en-001301 | 27

Page 28

"0"

Signal pressure

Displacement

100 %

a b

-b -a

100 %

P102 031E

Technical Information

H1P 089/100 Axial Piston Single Pumps

Control Options

The HDC incorporates a positive neutral dead band as a result of the control spool porting, preloads from

the servo piston assembly, and the linear control spring. Once the neutral threshold point is reached, the

swashplate is positioned directly proportional to the control pressure.

When the control input is either lost or removed, or if there is a loss of charge pressure, the spring loaded

servo piston will automatically return the pump to the neutral position.

Pump displacement vs signal pressure

Hydraulic signal pressure range

Type Unit Start of control End of control

Option bar 3.0 11.6

Standard 4.2 16.2

Pump output flow direction vs. control pressure

Shaft rotation HDC Clockwise (CW) seen from shaft Counter Clockwise (CCW) seen from shaft

Port energized X1 X2 X1 X2

Port A Out (high) In (low) In (low) Out (high)

Port B In (low) Out (high) Out (high) In (low)

Servo port high

pressure

M4 M5 M4 M5

For appropriate performance of HDC characteristic, keep the drain pressure of pilot valve to be equal or

slightly higher than pump case pressure.

Control response

H1P controls are available with optional control passage orifices to assist in matching the rate of swashplate response to the application requirements (e.g. in the event of electrical failure).

The time required for the pump output flow to change from zero to full flow (acceleration) or full flow to

zero (deceleration) is a net function of spool porting, orifices, and charge pressure.

A swash-plate response times table is available for each frame size. Testing should be conducted to verify

the proper orifice selection for the desired response. Typical response times at the following conditions:

Δ p = 250 bar [3626 psi]

Charge pressure = 20 bar [290 psi]

Viscosity and temperature = 30 mm²/s [141 SUS] and 50 °C [122 °F]

Speed = 1800 min-1 (rpm)

28 | © Danfoss | December 2021 BC152886482765en-001301

Page 29

Technical Information

H1P 089/100 Axial Piston Single Pumps

Control Options

Response time, HDC 089/100

Stroking direction 0.8 mm [0.03 in] orifice 1.3 mm [0.05 in] orifice No orifice

Neutral to full flow 2.8s 1.3s 0.7s

Full flow to neutral 1.9s 0.9s 0.5s

©

Danfoss | December 2021 BC152886482765en-001301 | 29

Page 30

P003 193

P003 189

C2C1

F00A

M14

T PF00B

100 %

“0“

100 %

Voltage V

DC

Displacement

Technical Information

H1P 089/100 Axial Piston Single Pumps

Control Options

Forward-Neutral-Reverse Control (FNR)

The 3-position FNR control options A9 (12 V) and B1 (24 V) uses an electric input signal to switch the

pump to a full stroke position. A serviceable 125 μm screen is located in the supply line immediately

before the control porting spool.

Under some circumstances, such as contamination, the control spool can stick and cause the pump to

stay at some displacement.

Forward-Neutral-Reverse electric control (FNR)

FNR hydraulic schematic

Pump displacement vs. electrical signal

FNR control current

Voltage 12 V

Minimum current to stroke pump 750 mA 380 mA

Pin connections any order

DC

24 V

DC

30 | © Danfoss | December 2021 BC152886482765en-001301

Page 31

2

1

Technical Information

H1P 089/100 Axial Piston Single Pumps

Control Options

FNR Solenoid Data

Solenoid data

Voltage 12 V

Minimum supply voltage

Maximum supply voltage (continuous)

Bi-directional diode cut off voltage

Maximum current

Nominal coil resistance @ 20°C

PWM Range

PWM Frequency (preferred)

*

PWM signal required for optimum control performance.

Electrical Protection Standard Class

IP Rating IEC 60 529 IP 67

24 V

19 V

29 V

53 V

DC

DC

DC

DC

9.5 V

14.6 V

28 V

DC

DC

DC

DC

1050 mA 500 mA

8.4 Ω 34.5 Ω

70 – 200 Hz

*

100 Hz

DIN 40 050, part 9 IP 69K with mating connector

Single Pump Output Flow Direction

Shaft rotation Clock-Wise (CW) Counter-Clock-Wise (CCW)

Coil energized

*

C1 C2 C1 C2

Port A in out out in

Port B out in in out

Servo port pressurized M5 M4 M5 M4

*

For coil location see installation drawings.

Connector

Connector DEUTSCH, 2-pin

Description Quantity Order data

Mating connector 1 DEUTSCH DT06-2S

Wedge lock 1 DEUTSCH W2S

Socket contact (16–18 AWG) 2 DEUTSCH 0462-201-16141

Danfoss mating connector kit 1 K29657

©

Danfoss | December 2021 BC152886482765en-001301 | 31

Page 32

Technical Information

H1P 089/100 Axial Piston Single Pumps

Control Options

Control response

H1P controls are available with optional control passage orifices to assist in matching the rate of swashplate response to the application requirements (e.g. in the event of electrical failure).

The time required for the pump output flow to change from zero to full flow (acceleration) or full flow to

zero (deceleration) is a net function of spool porting, orifices, and charge pressure.

A swash-plate response times table is available for each frame size. Testing should be conducted to verify

the proper orifice selection for the desired response. Typical response times at the following conditions:

Δ p = 250 bar [3626 psi]

Charge pressure = 20 bar [290 psi]

Viscosity and temperature = 30 mm²/s [141 SUS] and 50 °C [122 °F]

Speed = 1800 min-1 (rpm)

Response Time, FNR 089/100

Stroking direction 0.8 [0.03] orifice 1.3 [0.05] orifice No orifice

Neutral to full flow 3.7 s 1.7 s 1.1 s

Full flow to neutral 3.0 s 1.3 s 0.6 s

32 | © Danfoss | December 2021 BC152886482765en-001301

Page 33

P003 192

P003 188

C2C1

F00A

M14

T PF00B

"0"

Signal current (mA)

a b c

abc

Displacement

100 %

100 %

p = 300 bar

p = 300 bar

p = 0 bar

p = 0 bar

Technical Information

H1P 089/100 Axial Piston Single Pumps

Control Options

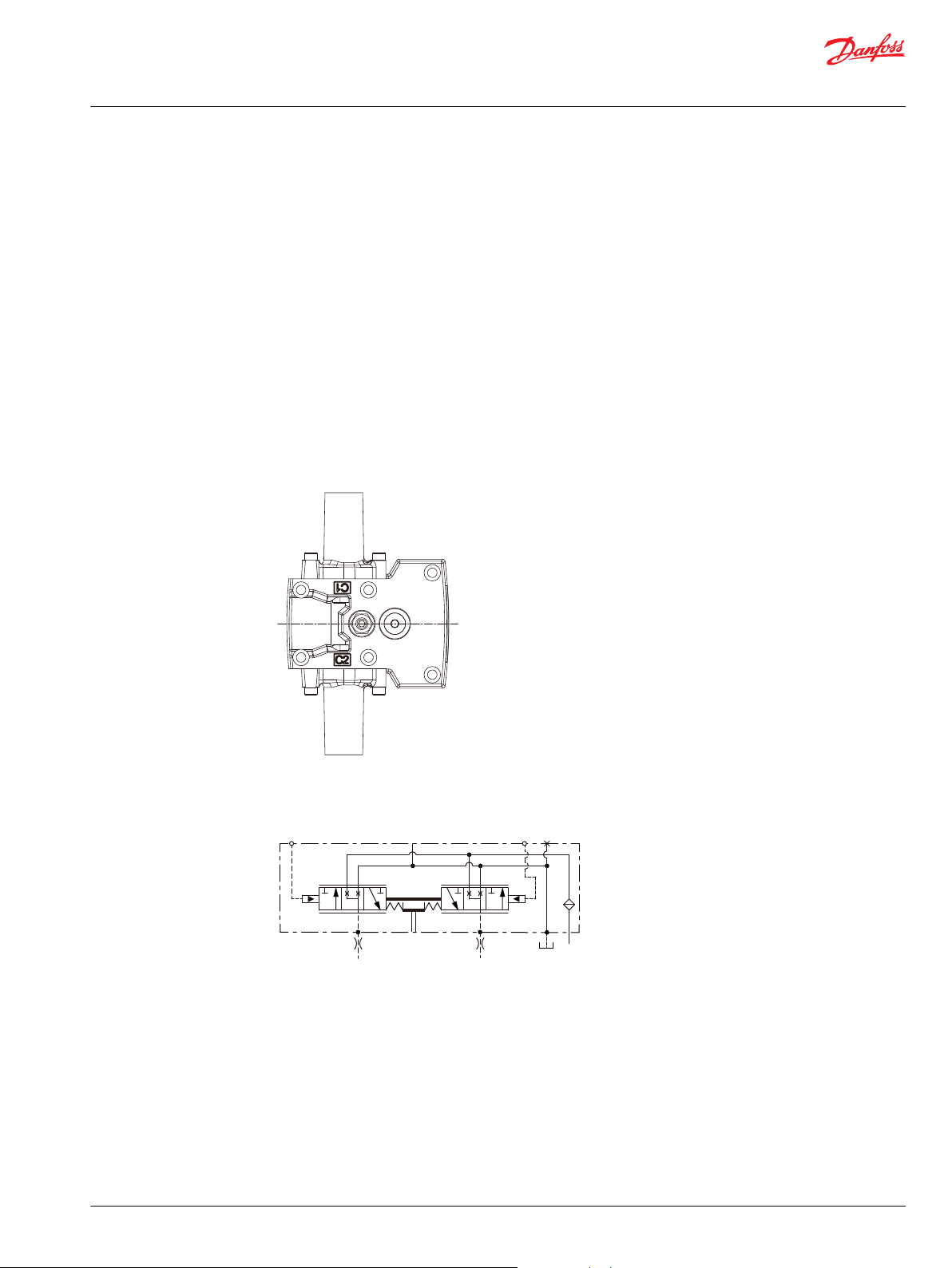

Non feedback proportional electric control (NFPE)

The Non Feedback Proportional Electric (NFPE) control is an electrical automotive control in which an

electrical input signal activates one of two proportional solenoids that port charge pressure to either side

of the pump servo cylinder. The NFPE control has no mechanical feedback mechanism.

A serviceable 170 μm screen is located in the supply line immediately before the control porting spool.

Under some circumstances, such as contamination, the control spool could stick and cause the pump to

stay at some displacement.

NFPE control

NFPE schematic

Control Signal Requirements, NFPE 089/100

The pump displacement is proportional to the solenoid signal current, but it also depends upon pump

input speed and system pressure. This characteristic also provides a power limiting function by reducing

the pump swash-plate angle as system pressure increases.

A typical response characteristic is shown in the accompanying graph below:

Pump displacement vs. input signal

©

Danfoss | December 2021 BC152886482765en-001301 | 33

Page 34

2

1

Technical Information

H1P 089/100 Axial Piston Single Pumps

Control Options

Control current requirements

*

Voltage

12 V

DC

24 V

DC

*

Factory test current, for vehicle movement or application actuation expect higher or lower value.

Control Solenoid Data

Description 12 V 24 V

Maximum current 1800 mA 920 mA

Nominal coil resistance @ 20 °C [68 °F] 3.66 Ω 14.20 Ω

Inductance 33 mH 140 mH

PWM signal frequency Range 70 – 200 Hz

IP Rating IEC 60 529 IP 67

Connector color Black

*

PWM signal required for optimum control performance.

a b c Pin config.

694 mA 1168 mA 1540 mA

347 mA 600 mA 770 mA

any order

@ 80 °C [176 °F] 4.52 Ω 17.52 Ω

Recommended

*

100 Hz

DIN 40 050, part 9 IP 69K with mating connector

Single Pump Output Flow Direction

Shaft rotation Clock-Wise (CW) Counter-Clock-Wise (CCW)

Coil energized

*

C1 C2 C1 C2

Port A in out out in

Port B out in in out

Servo port pressurized M5 M4 M5 M4

*

For coil location see installation drawings.

Connector

Connector DEUTSCH, 2-pin

Description Quantity Order data

Mating connector 1 DEUTSCH DT06-2S

Wedge lock 1 DEUTSCH W2S

Socket contact (16–18 AWG) 2 DEUTSCH 0462-201-16141

Danfoss mating connector kit 1 K29657

34 | © Danfoss | December 2021 BC152886482765en-001301

Page 35

Technical Information

H1P 089/100 Axial Piston Single Pumps

Control Options

Control response

H1P controls are available with optional control passage orifices to assist in matching the rate of swashplate response to the application requirements (e.g. in the event of electrical failure).

The time required for the pump output flow to change from zero to full flow (acceleration) or full flow to

zero (deceleration) is a net function of spool porting, orifices, and charge pressure.

A swash-plate response times table is available for each frame size. Testing should be conducted to verify

the proper orifice selection for the desired response. Typical response times at the following conditions:

Δ p = 250 bar [3626 psi]

Charge pressure = 20 bar [290 psi]

Viscosity and temperature = 30 mm²/s [141 SUS] and 50 °C [122 °F]

Speed = 1800 min-1 (rpm)

Response Time, NFPE 089/100

Stroking direction 0.8 mm [0.03 in] orifice 1.3 mm [0.05 in] orifice 2.3 mm [0.09 in] orifice

Neutral to full flow 4.3 s 1.9 s 0.8 s

Full flow to neutral 2.6 s 1.1 s 0.5 s

©

Danfoss | December 2021 BC152886482765en-001301 | 35

Page 36

P003 544

CAN PPC PSC PPU

CC2

CC1

WARRANTY VOID IF REMOVED

CC3

Technical Information

H1P 089/100 Axial Piston Single Pumps

Control Options

Automotive Control (AC)

The H1 Aautomotive Control (AC) is an electric NFPE Control with an integrated micro-controller,

installed on the pump. The integrated micro-controller enhanced control performance with a flexible,

configurable control scheme for an entire single path propel transmission. It can be used in combination

with fixed and variable displacement hydraulic-motors. With the pre-installed application software and

easily changeable control parameters, it is possible to tailor the vehicle’s driving behavior to the

individual requirements of the customer.

The H1 Automotive Control is divided into 2 systems:

AC-1

•

AC-2

•

AC-2 is an extension of AC-1 that features an integrated pump swash plate angle sensor and software

enabled functions such as Swash Plate Control.

Mode types

The application software provides 3 different hydrostatic propel methods, defined as mode types, which

can be used individually.

Automotive Load dependent (torque controlled) driving behavior. Setpoint for the drive curve is

•

the engine rpm.

Non-Automotive Load independent (speed controlled) driving mode. Setpoint for the drive curve is

•

a Joystick or drive pedal signal, independent of the engine rpm. The best performance will achieved

with an AC-2 Swash Plate Angle Sensor.

Creep-Automotive Load dependent (torque controlled) driving behavior (like Automotive).

•

Setpoint for the drive curve is the engine rpm. The setpoint can be reduced by the creep

potentiometer if a high engine rpm in combination with low vehicle speed is needed.

Basic functions

Four selectable system modes, selectable via switch.

•

Individual settings for forward and reverse driving direction (4 x 2 curves).

•

Independent pump and hydraulic-motor profiling and ramping for each mode.

•

Electric drive pedal connection

•

Electronic inching function without separate control valve

•

Electric creep mode potentiometer

•

36 | © Danfoss | December 2021 BC152886482765en-001301

Page 37

Technical Information

H1P 089/100 Axial Piston Single Pumps

Control Options

Configurable System Mode & Direction change

•

Load independent pump displacement control with integrated Swash Plate Angle Sensor (AC-2)

•

Hydraulic-motor displacement control including brake pressure defeat function

•

Performance functions

ECO fuel saving mode with automatic reduction of the engine speed during transport (Cruise control)

•

Vehicle constant speed drive control

•

Vehicle speed limitation

•

Dynamic brake light, automatic park brake, reverse buzzer and status LED outputs

•

Vehicle speed controlled output function.

•

Temperature compensation for predictable performance

•

Advanced CAN J1939 interface for the information exchange with the vehicle control system

•

Protection and safety functions

Safety controlled vehicle start protection with engine speed check, battery check and FNR must be in

•

neutral, etc..

Operator presence detection

•

Hydraulic system overheat and low-temperature protection

•

Hydraulic motor over speed protection

•

Park brake test mode for roller applications to fulfill SAE J1472 / EN500-4.

•

SIL2 compliant

•

Engine control and protection

CAN J1939 engine interface

•

Engine speed control via drive pedal with safety controlled monitoring function

•

Engine antistall protection

•

Engine over speed protection during inching

•

Engine speed dependent Retarder control

•

Engine cold start protection

•

Installation features

Factory calibration for hysteresis compensation.

•

Starting current adjustment in the factory

•

Pre-installed application software and parameter files

•

For more information, see Automotive Control for H1 Single Pumps Technical Information,

BC152986482596.

©

Danfoss | December 2021 BC152886482765en-001301 | 37

Page 38

P301 441

PT

F00B

M14

C1 C2

F00A

P301 442

W

Technical Information

H1P 089/100 Axial Piston Single Pumps

Control Options

Fan Drive Control (FDC)

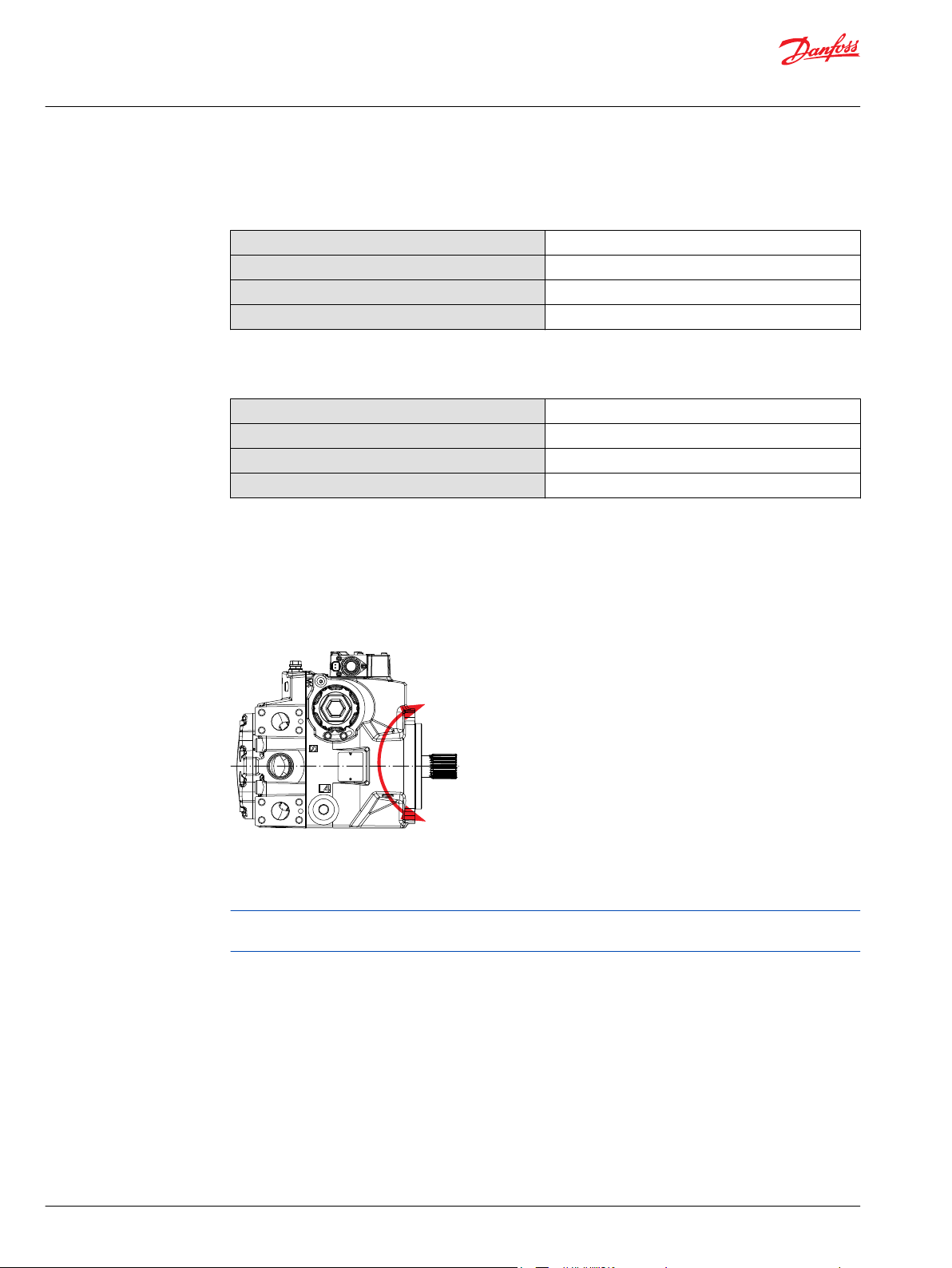

The Fan Drive Control (FDC) is a non-feedback control in which an electrical input signal activates the

proportional solenoid that ports charge pressure to either side of the pump servo cylinder. The single

proportional solenoid is used to control pump displacement in the forward or reverse direction.

The control spool is spring biased to produce maximum forward pump displacement in the absence of

an electrical input signal. Based on the spring bias spool default forward flow for a CW rotation pump is

out of port B while default forward flow for a CCW rotation pump is out of port A.