Service Kit Instructions

Charge pressure ranges

*

gauge reading minus the case pressure

po

min

of 50° C (120° F)

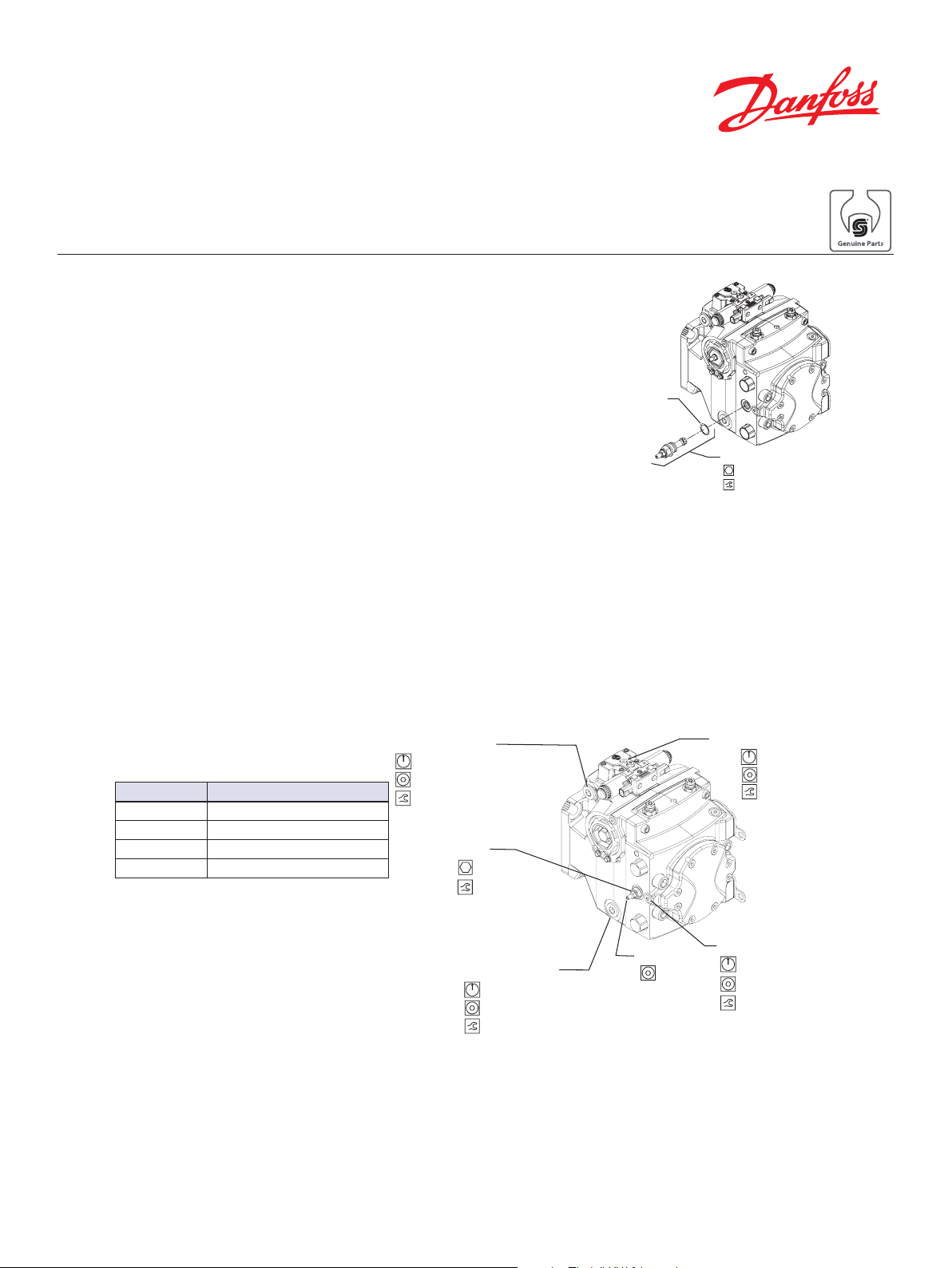

Case drain port L4

Charge pressure gauge port M3

D065 Optional construction port

V024

P106 115E

H1P pumps

Charge pressure relief valve replacement procedure

CHARGE PRESSURE

RELIEF VALVE REMOVAL

CHARGE PRESSURE

RELIEF VALVE

INSTALLATION

CHARGE PRESSURE

RELIEF VALVE

ADJUSTMENT

1. Clean pump externally with clean solvent to

remove debris.

2. Using a 24 mm wrench, remove the charge

pressure relief valve. (V030)

1. Lubricate the external O-ring (V024) using

petroleum jelly.

V030

2. Install the new charge pressure relief valve.

Using a 24 mm socket, torque to 52 N•m [38

24 mm

52 N•m

[38 lbf•ft]

lbf•ft]

1. Install a 50 bar [1000 psi] pressure gage in charge pressure gauge port M3 (next to the adjustment screw). Install a 10 bar [100 psi] gauge at one of the case drain pressure ports L1, L2,

L3, or L4. Operate the system with the pump in neutral (zero displacement) when measuring

charge pressure.

2. The table shows the acceptable pump charge pressure range for some nominal charge relief

valve settings (refer to the model code located on the serial number plate). These pressures

assume 1800 pump rpm and a reservoir temperature of 50°C (120°F), and are referenced to

case pressure.

Model code Measured charge pressure*

20 bar [290 psi] ± 1.5 bar [21.8 psi]

24 bar [348 psi] ± 1.5 bar [21.8 psi]

26 bar [377 psi] ± 1.5 bar [21.8 psi]

30 bar [345 psi] ± 1.5 bar [21.8 psi]

This is the actual charge pressure port

rt gauge reading. Factory set at 1800

-1

Listed pressures assume a

(rpm) with a reservoir temperature

pump speed of 1800 rpm. At

higher pump speeds (with

higher charge flows) the

charge pressure will rise over

the rated settings.

© Danfoss, 2013 AN262753055643en-000102 | 70342065 • Rev 0102 • March 2018 1

0 - 10 bar [0 - 100 psi]

9/16 inch

95-136 N•m [70-100 lbf•ft]

V022

19 mm

40 N•m [30 lbf•ft]

0 - 10 bar [0 - 100 psi]

3/16 inch

11-14 N•m [8-10 lbf•ft]

Case drain port L2

0 - 10 bar [0 - 100 psi]

5/8 inch

95-136 N•m [70-100 lbf•ft]

V020

6 mm

0 - 50 bar [0 - 1000 psi]

1/4 inch

20-27 N•m [15-20 lbf•ft]

3. Adjust valve. Clockwise rotation of the adjusting screw (V020) increases the setting, and

counterclockwise rotation decreases the setting (at a rate of approximately 3.9 bar [56.6 psi]

per turn).

4. Torque locknut (V022) to 40 N•m [30 lbf•ft] using a 19mm socket.

5. When desired charge pressure is achieved, remove the gauges and plug the ports.

P104 466E

Loading...

Loading...