Page 1

Parts Manual

H1B 250cc

Bent Axis Motor

www.danfoss.com

Page 2

Parts Manual

H1B 250 Bent Axis Motor

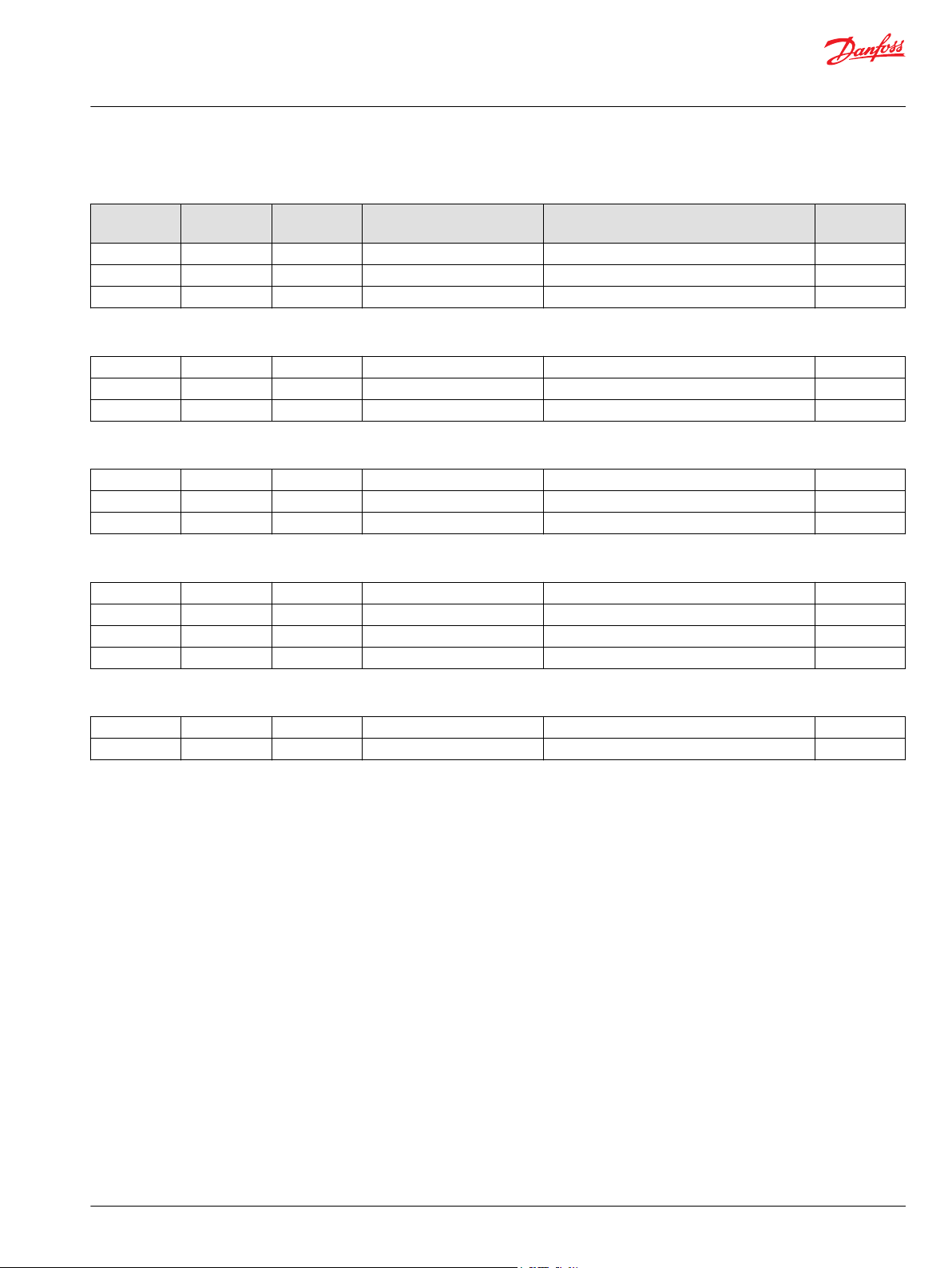

Revision history Table of revisions

Date Changed Rev

December 2021 Corrected loop flushing and endcap part numbers 0611

February 2021 Corrected special hardware NN valve segment assembly part number 0610

January 2021 Updated loop flushing part numbers 0609

June 2020 Changed document number from 'AX00000138' to 'AX152986482121' and changed servo

pressure O-ring part numbers

January 2020 Added new flange options and updated HE/HF servo pressure supply part numbers 0506

August 2019 Updated part numbers and added a caution for servo piston removal 0505

February 2019 Updated servo pressure supply illustrations 0504

November 2018 Updated servo pressure supply option HE 0503

October 2018 Added shaft option LN and corrected End cap A piston assembly number 0502

May 2018 Added SB-2018-028 0501

February 2018 Updated to Engineering Tomorrow design 0402

0608

2 | © Danfoss | December 2021 AX152986482121en-000611

Page 3

Parts Manual

H1B 250 Bent Axis Motor

Contents

General information

Control

Servo pressure supply

Orifice

End cap

Flange/housing

Shaft

Speed sensor

Loop flushing

Service Parts Identification............................................................................................................................................................5

Nameplate...........................................................................................................................................................................................5

Date code............................................................................................................................................................................................ 6

About service bulletins...................................................................................................................................................................6

Procedure to identify a part..........................................................................................................................................................6

Regional part numbers............................................................................................................................................................. 6

Example of a part identification (H1B 250)........................................................................................................................ 6

Adobe Acrobat 2-page viewing..................................................................................................................................................7

Order code.......................................................................................................................................................................................... 8

Notes.....................................................................................................................................................................................................9

Control D1-DH.................................................................................................................................................................................10

Control E1-F2...................................................................................................................................................................................12

Control K1-KH..................................................................................................................................................................................14

Control L1-LH...................................................................................................................................................................................16

Control M1-MH............................................................................................................................................................................... 18

Control P1-T2...................................................................................................................................................................................20

Control TA, TH................................................................................................................................................................................. 22

Servo pressure AA, AD..................................................................................................................................................................24

Servo pressure BA, BB...................................................................................................................................................................26

Servo pressure BC, BD, CA...........................................................................................................................................................28

Servo pressure D1, D1.................................................................................................................................................................. 30

Servo pressure DA, EA.................................................................................................................................................................. 32

Servo pressure G1, G2...................................................................................................................................................................34

Servo pressure HA-HD..................................................................................................................................................................36

Servo pressure HE, HF...................................................................................................................................................................38

Servo pressure K1, K2....................................................................................................................................................................40

Servo pressure KA, KH.................................................................................................................................................................. 42

Servo pressure M1, M2.................................................................................................................................................................44

Servo pressure MA, MF.................................................................................................................................................................46

Servo pressure MH, MW...............................................................................................................................................................48

Servo pressure NP, NR, NT...........................................................................................................................................................50

Orifice A, B, C, D...............................................................................................................................................................................52

End cap PA........................................................................................................................................................................................54

End cap PB........................................................................................................................................................................................56

End cap PF........................................................................................................................................................................................ 58

End cap RA........................................................................................................................................................................................60

End cap RB........................................................................................................................................................................................62

End cap RE........................................................................................................................................................................................ 64

End cap TA........................................................................................................................................................................................66

End cap TB........................................................................................................................................................................................ 68

H1B 250cc flange/housing DN, DS...........................................................................................................................................70

Flange/housing VC, VN................................................................................................................................................................ 72

Flange/housing VS, VT................................................................................................................................................................. 74

Shaft DN-PS......................................................................................................................................................................................76

Speed sensor................................................................................................................................................................................... 78

Loop flushing A-N..........................................................................................................................................................................80

©

Danfoss | December 2021 AX152986482121en-000611 | 3

Page 4

Parts Manual

H1B 250 Bent Axis Motor

Contents

Loop flushing 05-50...................................................................................................................................................................... 84

Loop flushing E2, E3, E4, NN.......................................................................................................................................................86

Special hardware and displacement

H1B 250cc special hardware HN, HP.......................................................................................................................................88

Special hardware NN, NP.............................................................................................................................................................90

H1B 250cc minimum displacement........................................................................................................................................ 92

Maximum displacement..............................................................................................................................................................94

Overhaul seal kit

H1B 250cc seal kit.......................................................................................................................................................................... 98

Service bulletin

SB-2018-028.....................................................................................................................................................................................99

SB-2019-017...................................................................................................................................................................................100

SB-2020-038...................................................................................................................................................................................101

4 | © Danfoss | December 2021 AX152986482121en-000611

Page 5

Made in Germany

Serial No.

N-13-20-23456

Model Code

Model No./Ident No.

H1B250-A-A-L1-BA-NA-PA-VS-FS-S-B-50NN-050-N-00-NNN

83017616

Parts Manual

H1B 250 Bent Axis Motor

General information

Service Parts Identification

Nameplate

The following information and procedure is used to identify the module group, item number,

manufacture date, part number, and part name of the parts included in the .

The parts listed include all parts which may be used when performing either “Minor Repairs”, “Major

Repairs” or “Conversions” on the .

Each unit will have a nameplate affixed to the housing. The nameplate will include the following

information:

Model Code

The Danfoss model code completely defines the specific unit and must be used when ordering parts to

service this product.

Model Number

The Danfoss model number is used by the factory in manufacturing. On repeat orders, a complete unit

can be ordered by the model number.

Serial Number

The Danfoss serial number is used to identify the manufacture date and the unit sequence in the build.

The serial number is also used to identify the units warranty time period.

The letter code indicates the location of original manufacture (assembly).

The first number (2 digits) indicates the year of manufacture. The second number (2 digits) indicates the

calendar week of manufacture.

The third number (5 digits) is a sequential number used to identify a specific unit.

©

Danfoss | December 2021 AX152986482121en-000611 | 5

Page 6

Parts Manual

H1B 250 Bent Axis Motor

General information

Date code

About service bulletins

The date code is defined as the year and week of manufacture. The same item number may list more than

one part number. This indicates that there is more than one configuration for that item number. You will

see that there are different date codes for the different part numbers. Find the date code of your unit

from the nameplate to determine which service part number you need to order.

Example: The service part desired is item G30

Order Code Item Date Begin Date End Part Number Part Name Qty. per

80 G30 89-17 8000243 End cap gasket 1

G30 89-16 8000151 End cap gasket

(SB-1995-006)

Model/Kit

1

All units using this order code with a date code prior to 89-17 must use part number “8000151.” All units

with a date code of 89-17 and newer must use part number “8000243.”

A Service Bulletin Number (SB-_ _ _ _ - _ _ _) may follow the “Part Name” of the part you desire. You must

read that Service Bulletin prior to ordering that part. The information contained in these Service Bulletins,

as of the print date of this bulletin, are included at the end of this manual. Service Bulletins contain more

detailed information such as interchangeability, what additional parts are involved, etc. It is suggested

that you add additional Service Bulletins to this manual as you receive them.

Procedure to identify a part

The modular design of this product results in a simplified service parts list and part number identification

procedure.

The same item numbers are used for same part names on all units within a product type. A part number

that has another number following it in parentheses is done to make this a world wide manual.

Regional part numbers

Some part numbers are region specific and should be ordered accordingly.

As an example, the part number (example: 314583 (9008000-0118) will be used. The first number is sold

in Germany. The number in parentheses is sold in the United States. Customers would order

9008000-0118 if ordering the part in the United States.

Example of a part identification (H1B 250)

The nameplate on an H1 motor has an Order Code of H1B250 A L1 BA N A PA VS FS S B 50 NN 050 N 00

NNN. Use the following procedures to determine the part number of the minimum angle set screw used

on this motor

1. Referring to the minimum displacement module in the Order code on page 8, the minimum angle

set screw option for this motor is identified by the code“050”. (H1B250 A L1 BA N A PA VS FS S B 50

NN

050 N 00 NNN).

2. Referring to the Service Parts List, find the minimum displacement group. Next find the order code

that relates to this unit, which is “050”. The minimum angle set screw is found to be item N1000 and

part number 750646.

6 | © Danfoss | December 2021 AX152986482121en-000611

Page 7

Parts Manual

H1B 250 Bent Axis Motor

General information

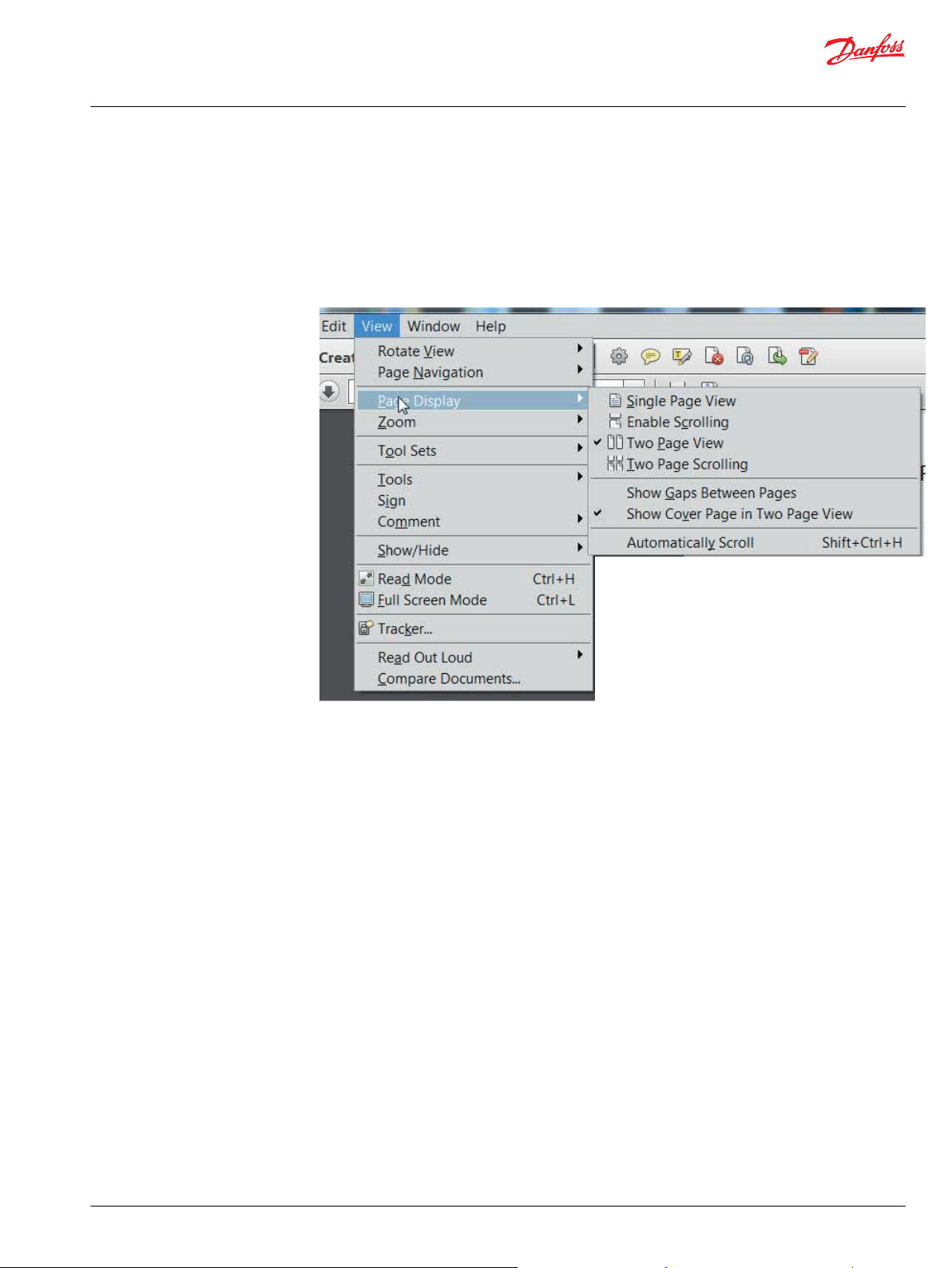

Adobe Acrobat 2-page viewing

While viewing manual in Adobe Acrobat, the following settings need to be applied to ensure proper

page display.

1. Select “View” → “Page Display” → “Two Page View”

2. Select “View” → “Page Display” → “Show Cover Page in Two Page View”

©

Danfoss | December 2021 AX152986482121en-000611 | 7

Page 8

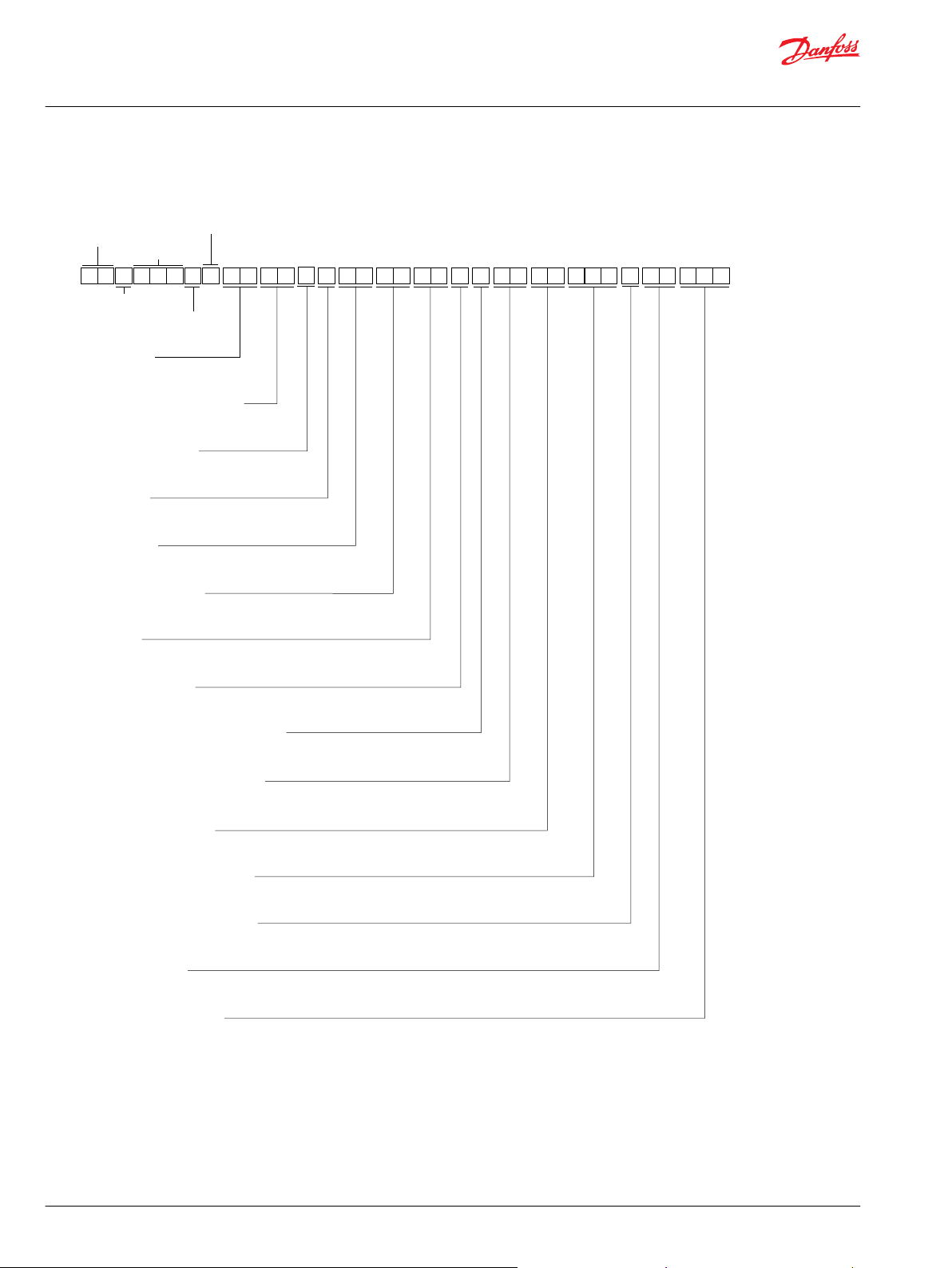

L

1

B

A

A

V S

A

P

N

F S

0

0 NB 5

S

0

0

Servo pressure supply

Not applicable

Orifice

Control

End cap

Flange/housing

Shaft

Speed sensor

Loop flushing shuttle system

B C

E

D

F G L5MH J

N N

0

K

NN N

Q R

P

N

Loop flushing relief valve

Special hardware

PCOR setting

Paint and Nametag

Minimum displacement

Maximum displacement

H1B

0

2

5

Series

Frame

Size

Product Type

A A

Product

Version

Port

Configuration

Parts Manual

H1B 250 Bent Axis Motor

General information

Order code

8 | © Danfoss | December 2021 AX152986482121en-000611

Page 9

Parts Manual

H1B 250 Bent Axis Motor

General information

Notes

©

Danfoss | December 2021 AX152986482121en-000611 | 9

Page 10

B0020

*B0035

B0050

B0040

B0010

B0025

B0028

B0027

B0029

B0061

B0060

B0180

B0050

B0190

B0010

Parts Manual

H1B 250 Bent Axis Motor

Control

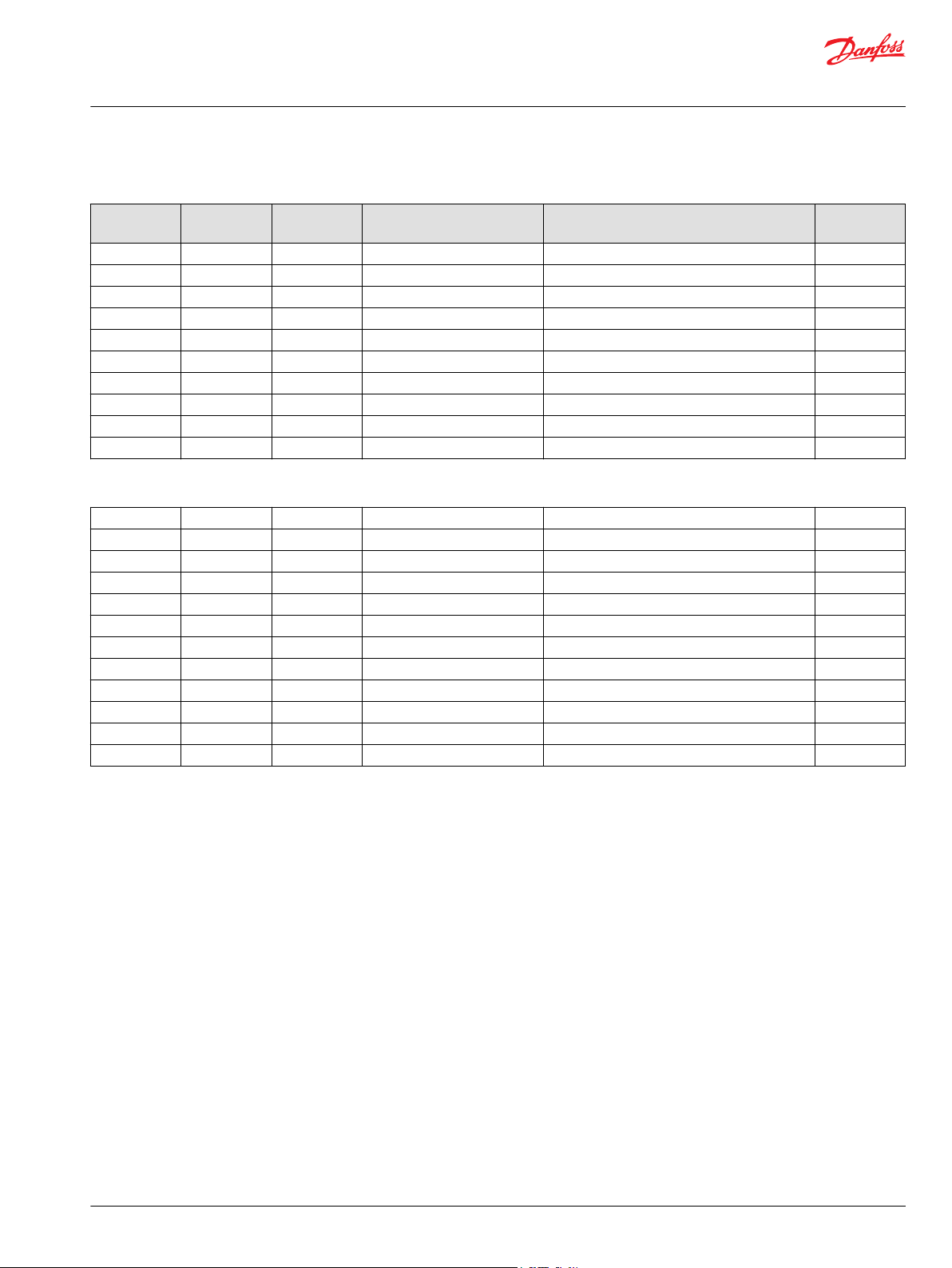

H1B control D1-DH

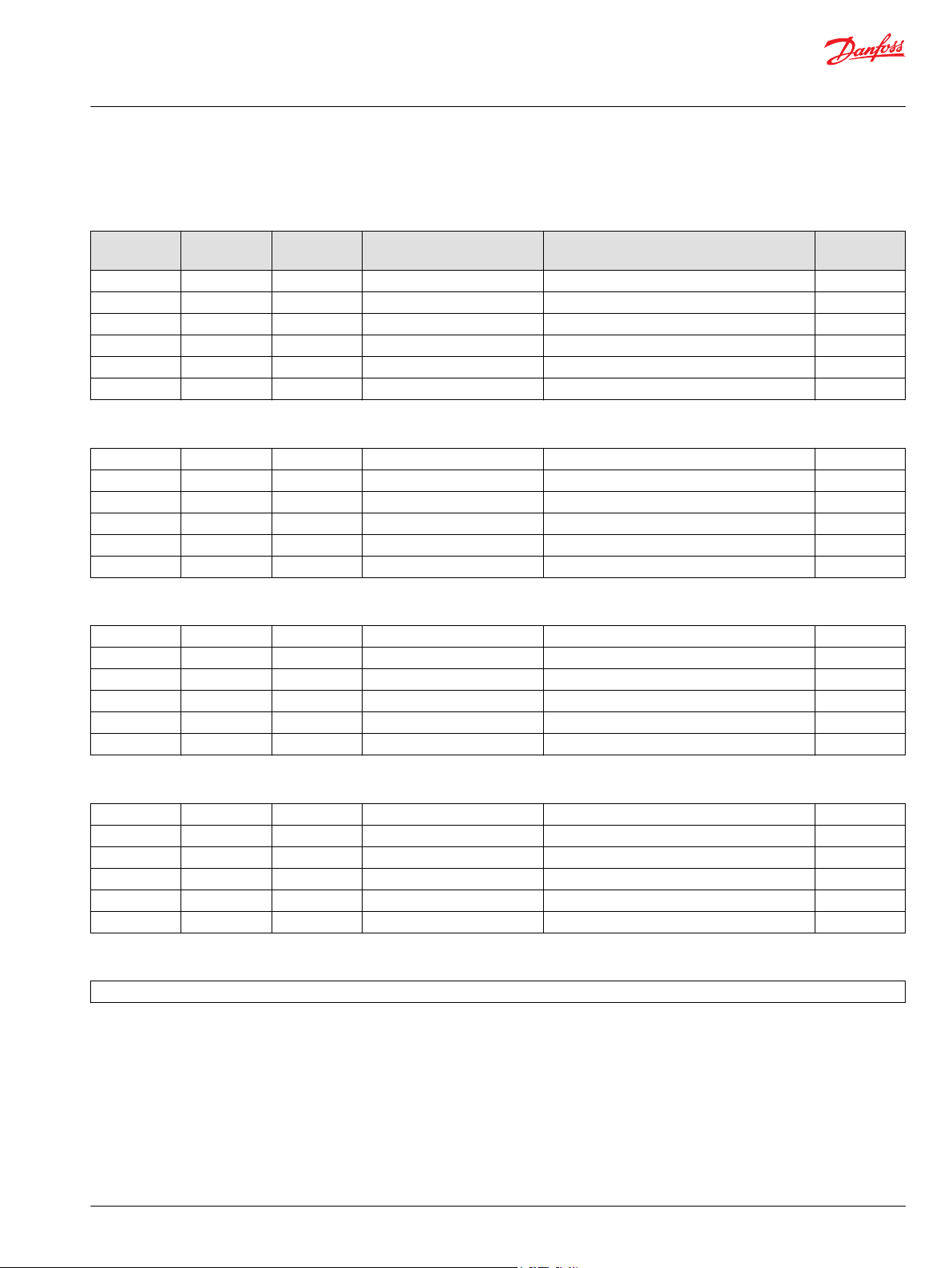

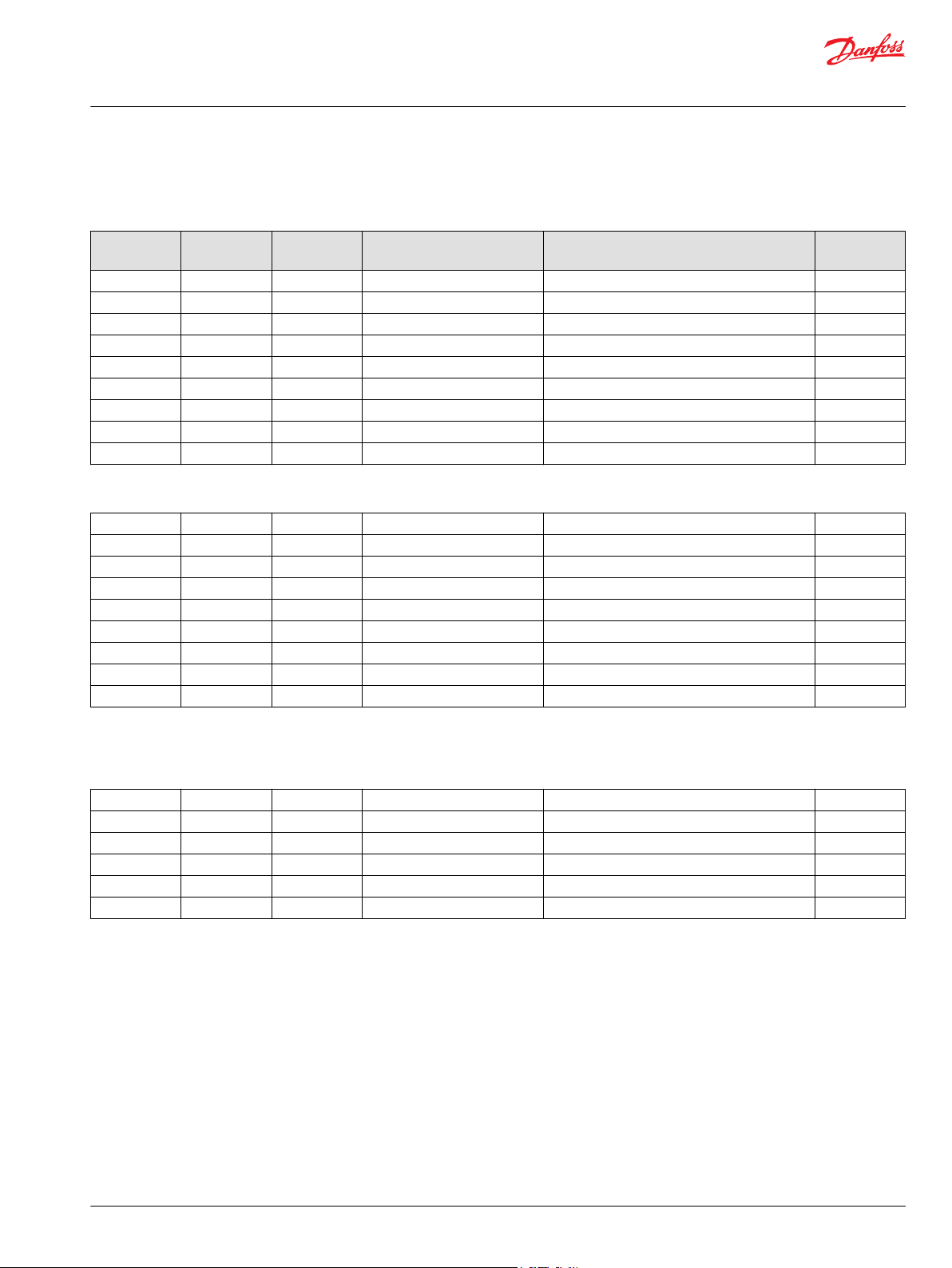

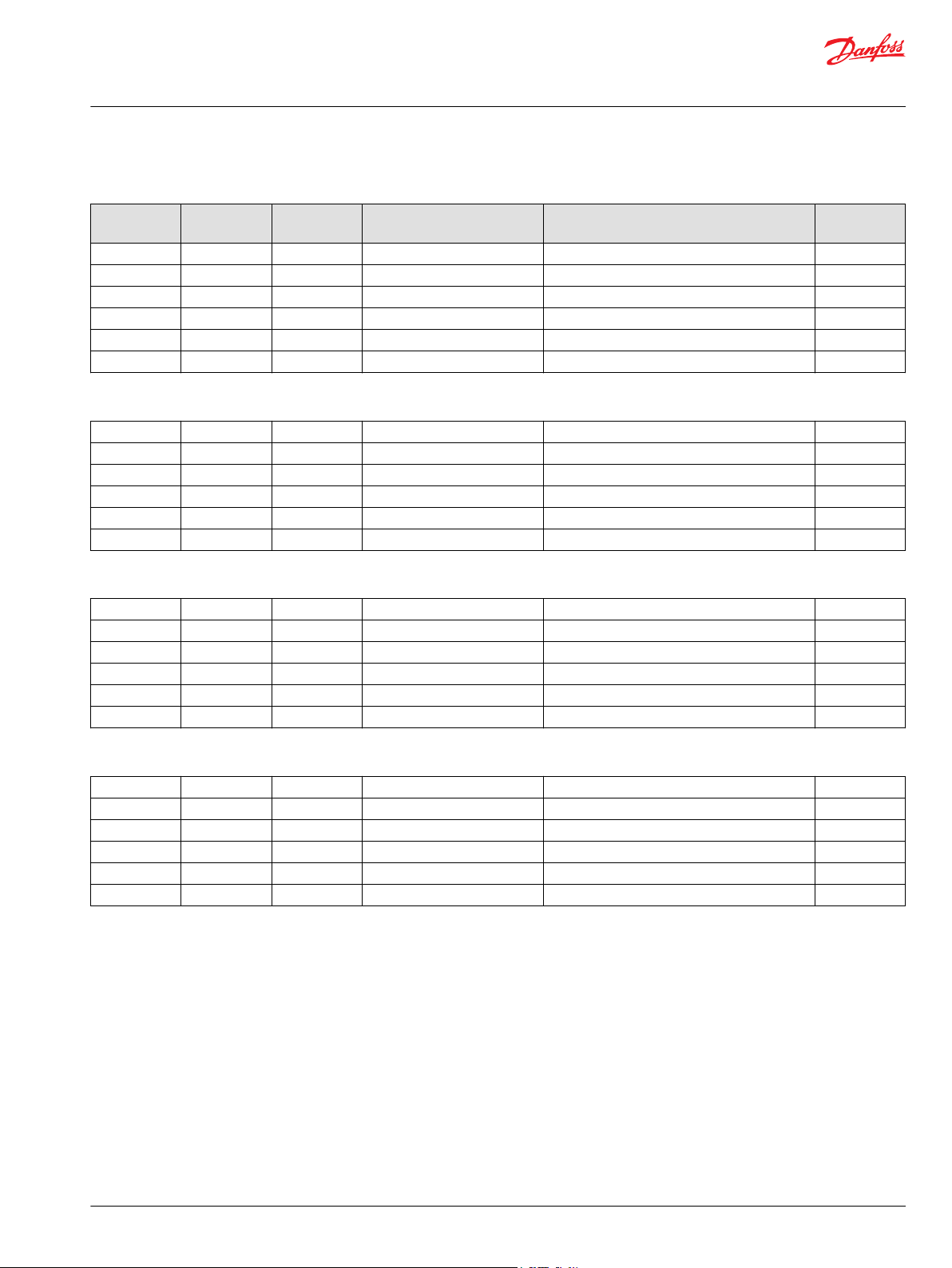

D1 and D2 configuration

DH configuration

Generic housings used to show part locations only.

* Included in overhaul seal kit Q210

10 | © Danfoss | December 2021 AX152986482121en-000611

Page 11

Parts Manual

H1B 250 Bent Axis Motor

Control

Electric proportional

Order code: D1

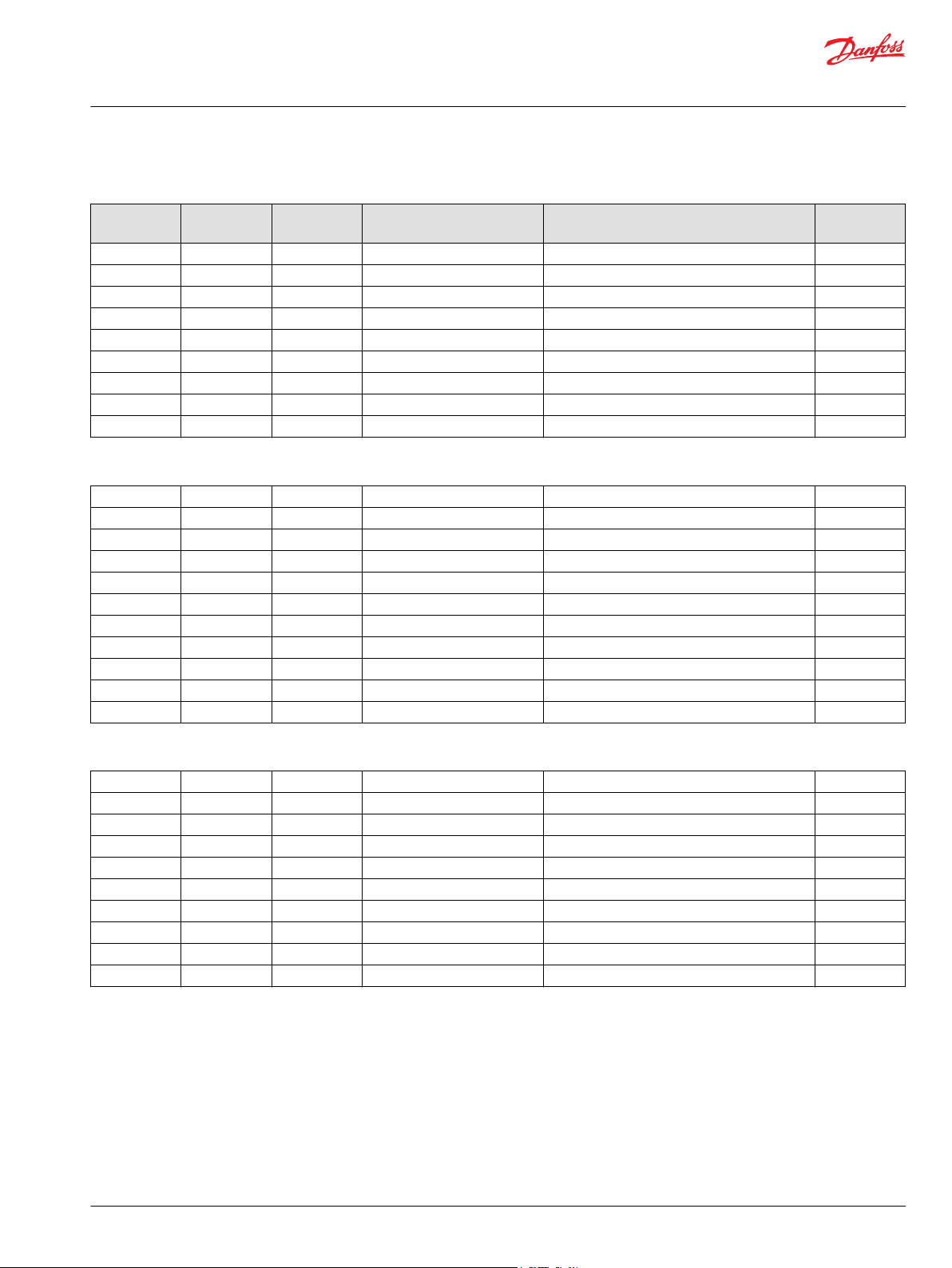

Item Date Begin Date End Part Number Part Name Qty. per

B0010 11-18 149053 Solenoid valve, proportional, 12 volt 1

B0020 11-18 11031746 Coil kit, 12 volt 1

B0025 11-18 11004735 O-ring 1

B0027 11-18 11004749 Coil nut 1

B0028 11-18 063172 O-ring 1

B0029 11-18 11037174 O-ring 1

B0035 11-18 11001952 O-ring 1

B0040 11-18 11014185 Plastic cap 1

B0050 11-18 716860 Screw, M5 x 12 3

Order code: D2

B0010 11-18 11002705 Solenoid valve, proportional, 24 volt 1

B0020 11-18 11031749 Coil kit, 24 volt 1

B0025 11-18 11004735 O-ring 1

B0027 11-18 11004749 Coil nut 1

B0028 11-18 063172 O-ring 1

B0029 11-18 11037174 O-ring 1

B0035 11-18 11001952 O-ring 1

B0040 11-18 11014185 Plastic cap 1

B0050 11-18 716860 Screw, M5 x 12 3

Model/Kit

Hydraulic proportional

Order code: DH

B0010 14-37 11146306 Actuator assembly 1

B0050 14-37 716860 Screw, M5 x 12 3

B0060 14-37 140644 Plug assembly 1

B0061 14-37 140644 Plug assembly 1

B0180 14-37 076042 (9003509-0012) Seal nut, M12 1

B0190 14-37 012575 (9004105-1170) O-ring 1

©

Danfoss | December 2021 AX152986482121en-000611 | 11

Page 12

*B0034

C2000

B0010

B0026

B0028

B0024

B0024

B0026

B0028

C2000

*B0034

B0010

Parts Manual

H1B 250 Bent Axis Motor

Control

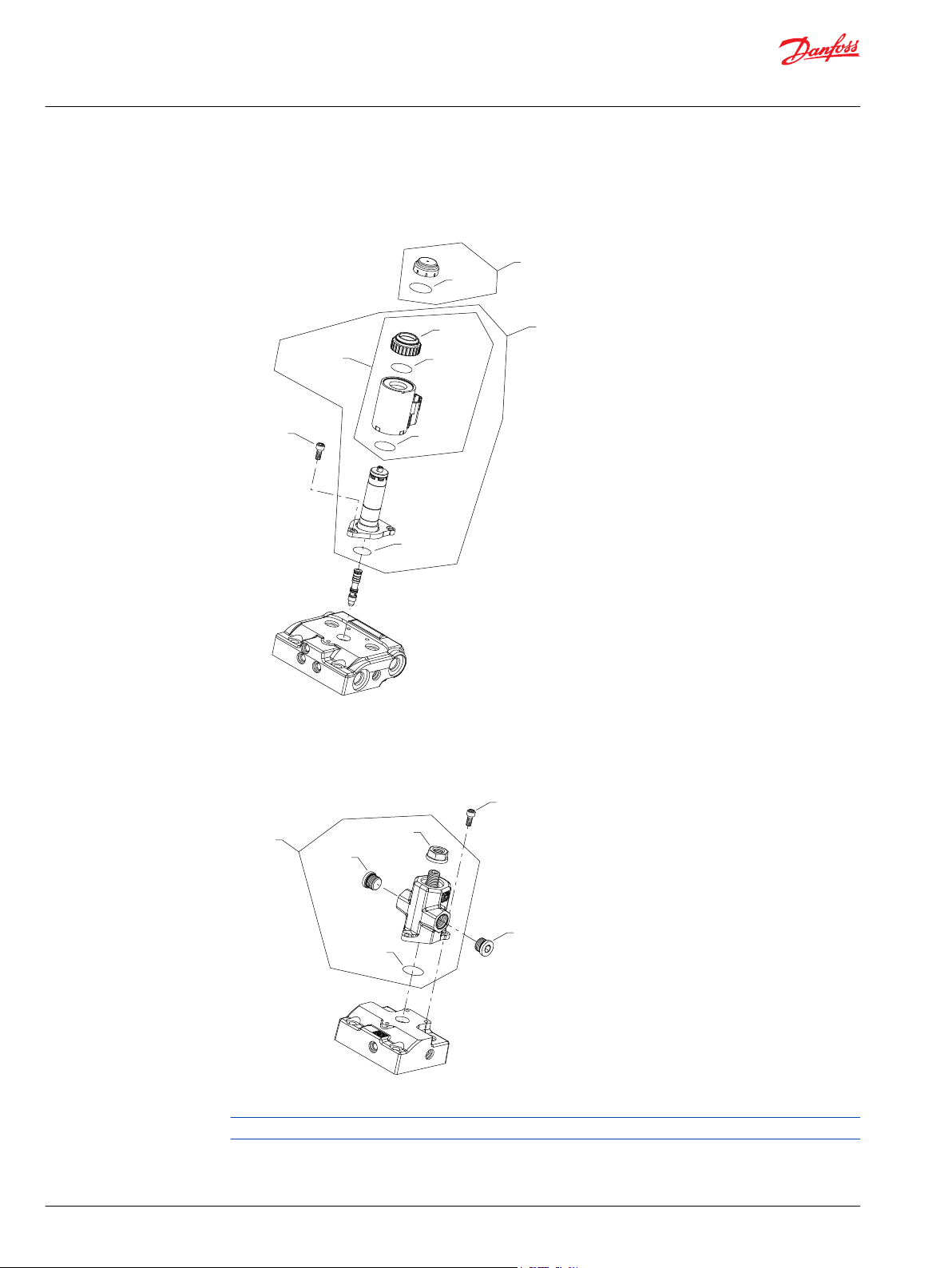

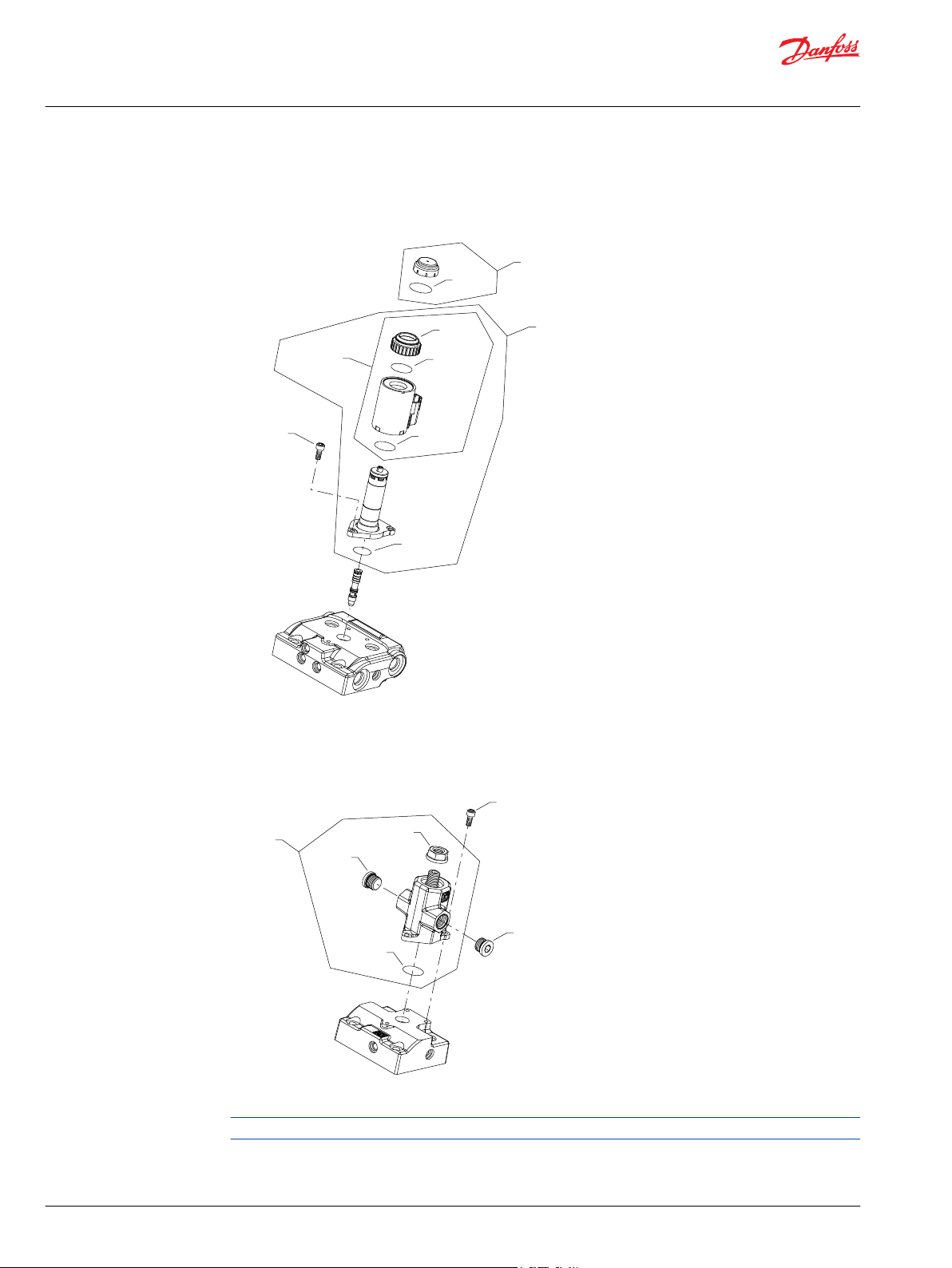

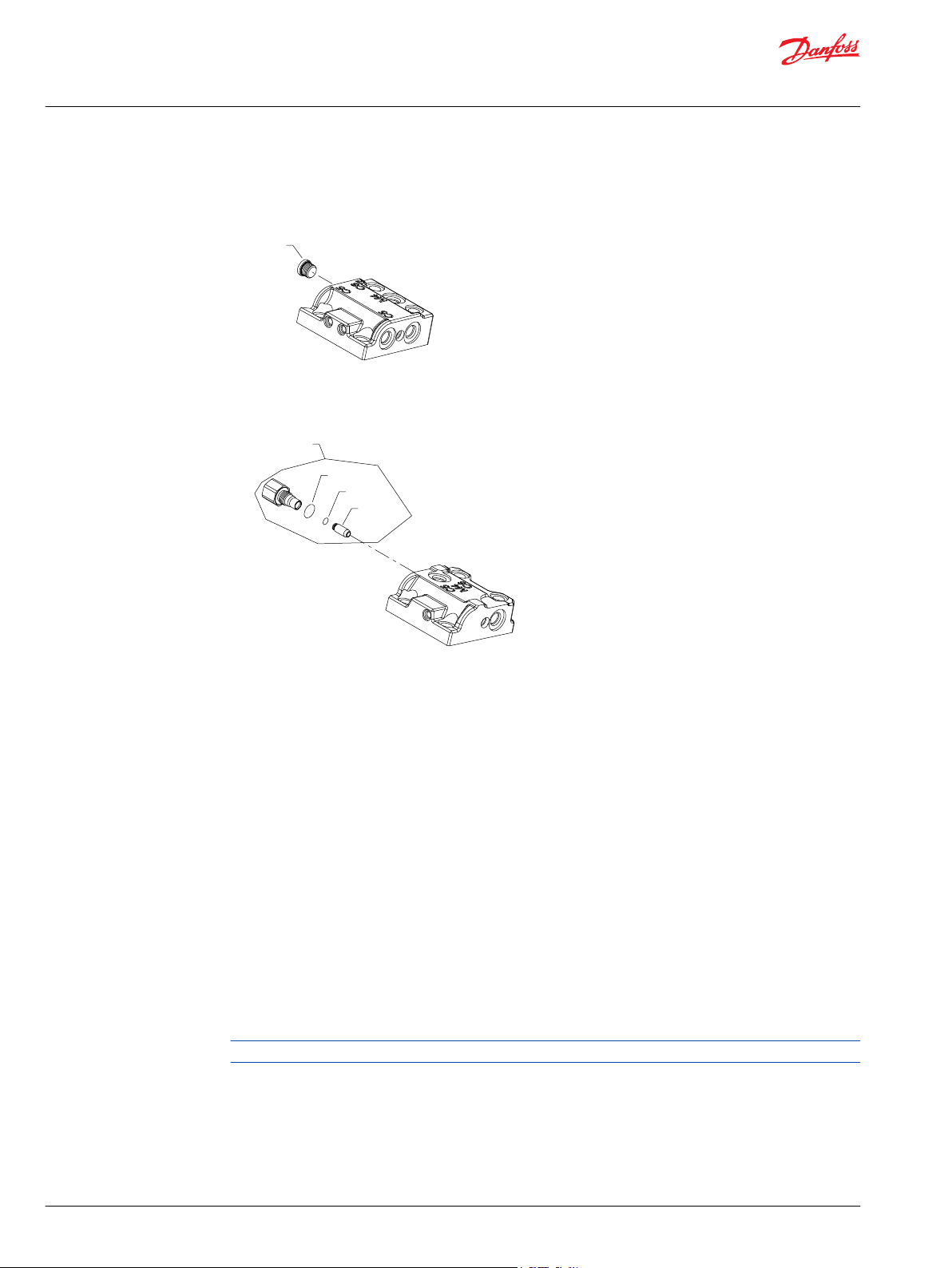

H1B control E1-F2

E1 and E2 configuration

F1 and F2 configuration

Generic housings used to show part location only.

* Included in overhaul seal kit Q210

12 | © Danfoss | December 2021 AX152986482121en-000611

Page 13

Parts Manual

H1B 250 Bent Axis Motor

Control

Electric 2-position

Order code: E1

Item Date Begin Date End Part Number Part Name Qty. per

B0010 11-18 11013615 Solenoid, on/off, 12 volt 1

B0024 11-18 11027046 O-ring 1

B0026 11-18 11027046 Coil nut 1

B0028 11-18 063172 O-ring

B0034 11-18 085043 (9004201-3700) O-ring 1

C2000 11-18 11031763 Coil kit, 12 volt 1

Order code: E2

B0010 11-18 11013616 Solenoid, on/off, 24 volt 1

B0024 11-18 11031608 O-ring 1

B0026 11-18 11027046 Coil nut 1

B0028 11-18 063172 O-ring 1

B0034 11-18 085043 (9004201-3700) O-ring 1

C2000 11-18 11031764 Coil kit, 24 volt 1

Model/Kit

Order code: F1

B0010 11-48 11013615 Solenoid, on/off, 12 volt 1

B0024 11-48 11027046 O-ring 1

B0026 11-48 11027046 Coil nut 1

B0028 11-48 063172 O-ring

B0034 11-48 085043 (9004201-3700) O-ring 1

C2000 11-48 11031763 Coil kit, 12 volt 1

Order code: F2

B0010 11-48 11013616 Solenoid, on/off, 24 volt 1

B0024 11-48 11031608 O-ring 1

B0026 11-48 11027046 Coil nut 1

B0028 11-48 063172 O-ring 1

B0034 11-48 085043 (9004201-3700) O-ring 1

C2000 11-48 11031764 Coil kit, 24 volt 1

Order code: HE and HF

No parts

©

Danfoss | December 2021 AX152986482121en-000611 | 13

Page 14

*B0035

B0040

B0010

B0020

B0050

B0025

B0028

B0027

B0029

B0190

B0180

B0050

B0060

B0061

B0010

Parts Manual

H1B 250 Bent Axis Motor

Control

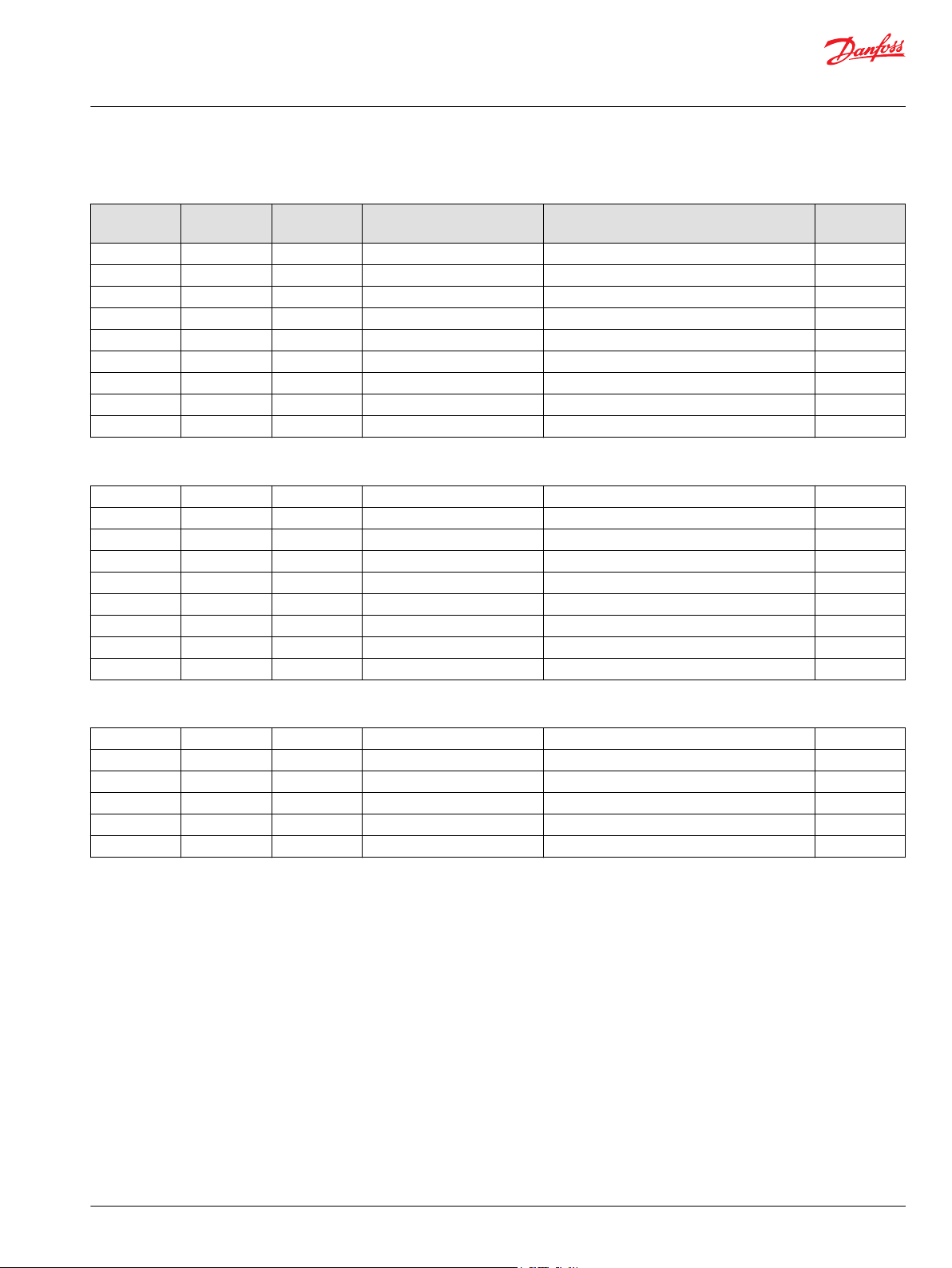

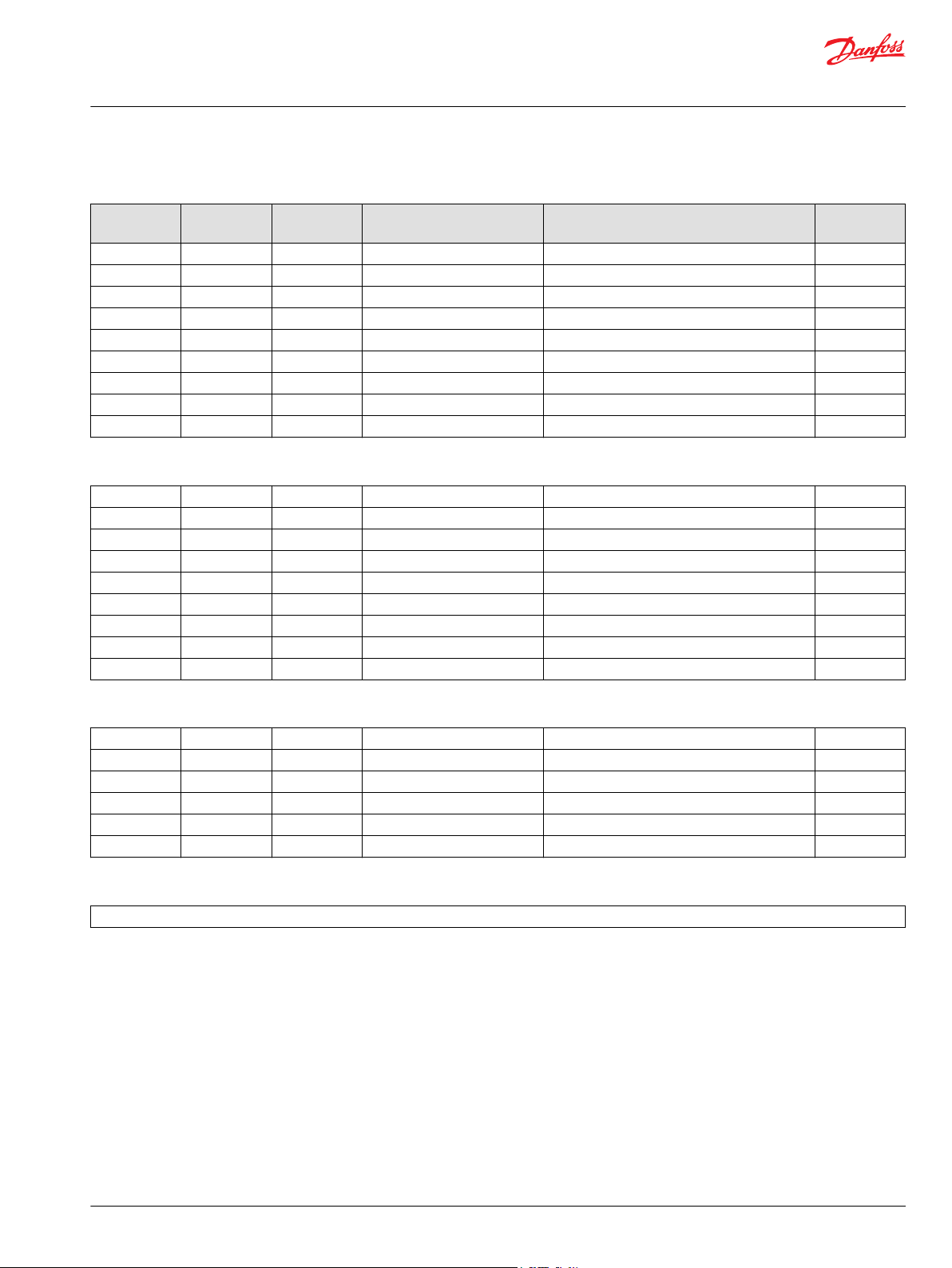

H1B control K1-KH

K1, K2 configuration

KH configuration

Generic housing used to show part location only.

* Included in overhaul seal kit Q210

14 | © Danfoss | December 2021 AX152986482121en-000611

Page 15

Parts Manual

H1B 250 Bent Axis Motor

Control

Order code: K1

Item Date Begin Date End Part Number Part Name Qty. per

B0010 11-18 149053 Solenoid valve, proportional, 12 volt 1

B0020 11-18 11031746 Coil kit, 12 volt 1

B0025 11-18 11004735 O-ring 1

B0027 11-18 11004749 Coil nut 1

B0028 11-18 063172 O-ring 1

B0029 11-18 11037174 O-ring 1

B0035 11-18 11001952 O-ring 1

B0040 11-18 11014185 Plastic cap 1

B0050 11-18 716860 Screw, M5 x 12 3

Order code: K2

B0010 11-18 11002705 Solenoid valve, proportional, 24 volt 1

B0020 11-18 11031749 Coil kit, 24 volt 1

B0025 11-18 11004735 O-ring 1

B0027 11-18 11004749 Coil nut 1

B0028 11-18 063172 O-ring 1

B0029 11-18 11037174 O-ring 1

B0035 11-18 11001952 O-ring 1

B0040 11-18 11014185 Plastic cap 1

B0050 11-18 716860 Screw, M5 x 12 3

Model/Kit

Order code: KH

B0010 15-48 11146306 Actuator assembly 1

B0050 15-48 716860 Screw, M5 x 12 3

B0060 15-48 140644 Plug assembly 1

B0061 15-48 140644 Plug assembly 1

B0180 15-48 076042 (9003509-0012) Seal nut, M12 1

B0190 15-48 012575 (9004105-1170) O-ring 1

©

Danfoss | December 2021 AX152986482121en-000611 | 15

Page 16

B0020

*B0035

B0050

B0040

B0010

B0025

B0028

B0027

B0029

B0061

B0060

B0180

B0050

B0190

B0010

Parts Manual

H1B 250 Bent Axis Motor

Control

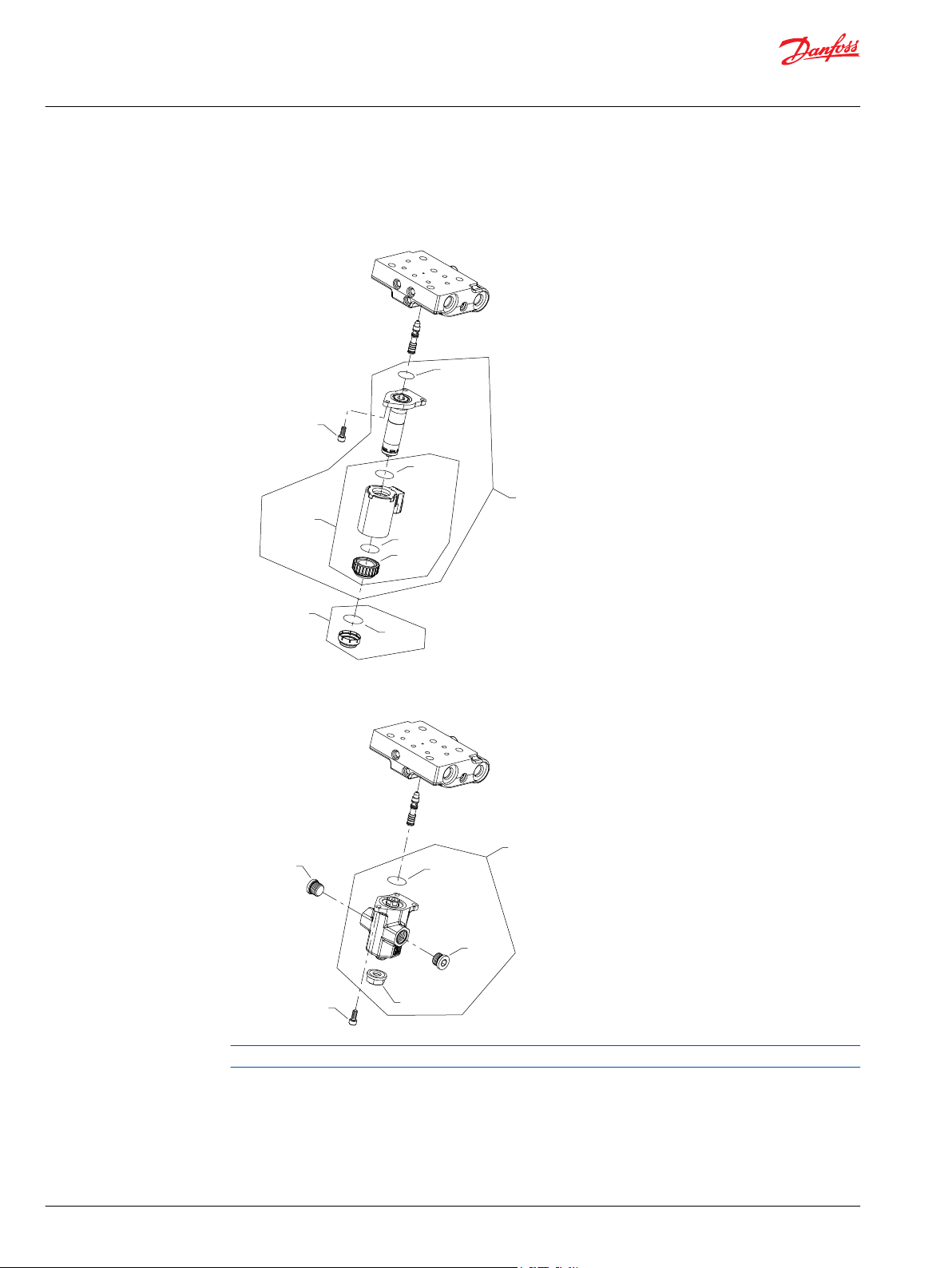

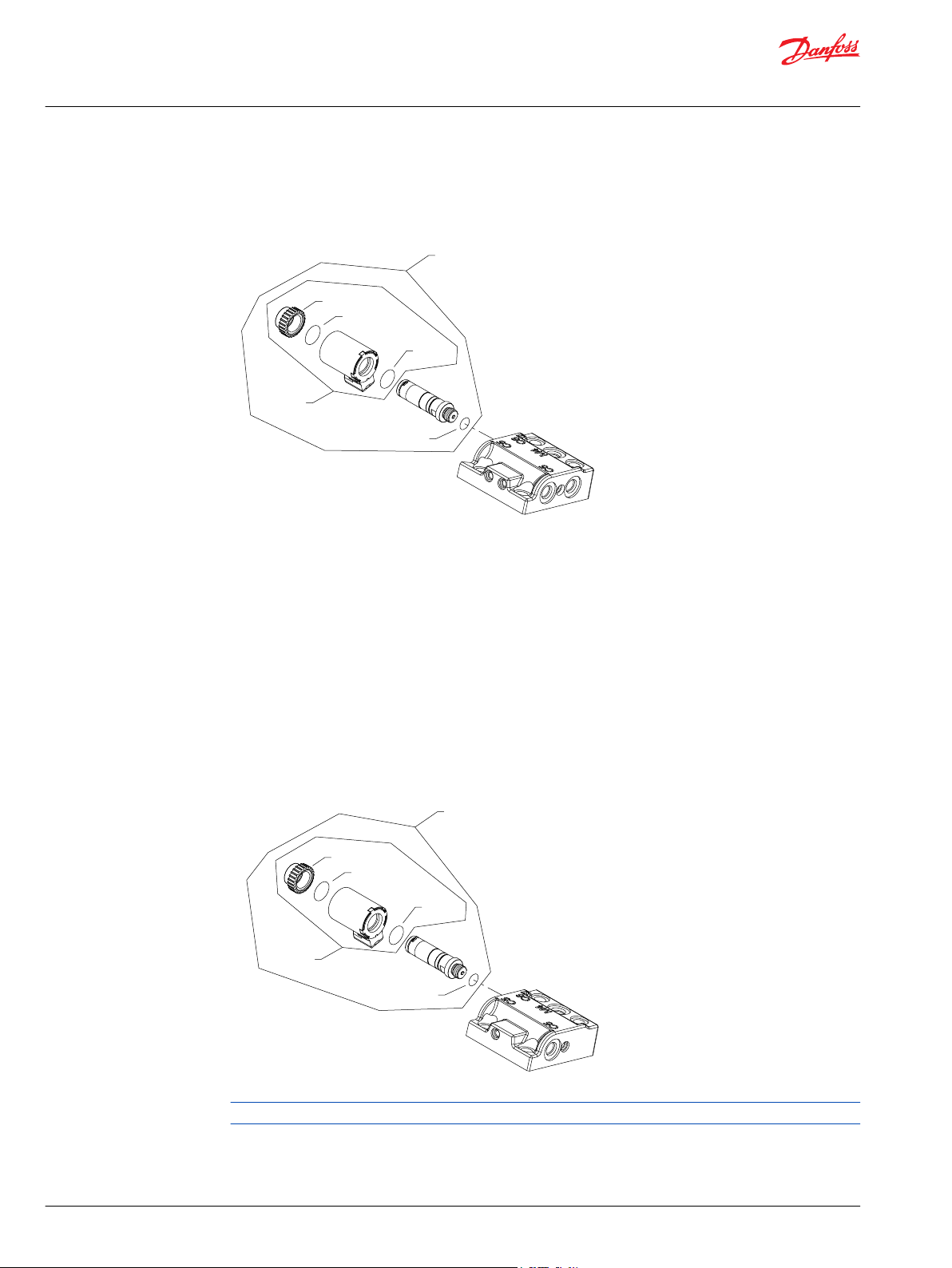

H1B control L1-LH

L1 and L2 configuration

LH configuration

Generic housings used to show part locations only.

* Included in overhaul seal kit Q210

16 | © Danfoss | December 2021 AX152986482121en-000611

Page 17

Parts Manual

H1B 250 Bent Axis Motor

Control

Electric proportional

Order code: L1

Item Date Begin Date End Part Number Part Name Qty. per

B0010 11-18 149053 Solenoid valve, proportional, 12 volt 1

B0020 11-18 11031746 Coil kit, 12 volt 1

B0025 11-18 11004735 O-ring 1

B0027 11-18 11004749 Coil nut 1

B0028 11-18 063172 O-ring 1

B0029 11-18 11037174 O-ring 1

B0035 11-18 11001952 O-ring 1

B0040 11-18 11014185 Plastic cap 1

B0050 11-18 716860 Screw, M5 x 12 3

Order code: L2

B0010 11-18 11002705 Solenoid valve, proportional, 24 volt 1

B0020 11-18 11031749 Coil kit, 24 volt 1

B0025 11-18 11004735 O-ring 1

B0027 11-18 11004749 Coil nut 1

B0028 11-18 063172 O-ring 1

B0029 11-18 11037174 O-ring 1

B0035 11-18 11001952 O-ring 1

B0040 11-18 11014185 Plastic cap 1

B0050 11-18 716860 Screw, M5 x 12 3

Model/Kit

Hydraulic proportional

Order code: LH

B0010 14-37 11146306 Actuator assembly 1

B0050 14-37 716860 Screw, M5 x 12 3

B0060 14-37 140644 Plug assembly 1

B0061 14-37 140644 Plug assembly 1

B0180 14-37 076042 (9003509-0012) Seal nut, M12 1

B0190 14-37 012575 (9004105-1170) O-ring 1

©

Danfoss | December 2021 AX152986482121en-000611 | 17

Page 18

*B0035

B0040

B0010

B0020

B0050

B0025

B0028

B0027

B0029

B0190

B0180

B0050

B0060

B0061

B0010

Parts Manual

H1B 250 Bent Axis Motor

Control

H1B control M1-MH

M1, M2 configuration

MH configuration

Generic housing used to show part location only.

* Included in overhaul seal kit Q210

18 | © Danfoss | December 2021 AX152986482121en-000611

Page 19

Parts Manual

H1B 250 Bent Axis Motor

Control

Order code: M1

Item Date Begin Date End Part Number Part Name Qty. per

B0010 11-18 149053 Solenoid valve, proportional, 12 volt 1

B0020 11-18 11031746 Coil kit, 12 volt 1

B0025 11-18 11004735 O-ring 1

B0027 11-18 11004749 Coil nut 1

B0028 11-18 063172 O-ring 1

B0029 11-18 11037174 O-ring 1

B0035 11-18 11001952 O-ring 1

B0040 11-18 11014185 Plastic cap 1

B0050 11-18 716860 Screw, M5 x 12 3

Order code: M2

B0010 11-18 11002705 Solenoid valve, proportional, 24 volt 1

B0020 11-18 11031749 Coil kit, 24 volt 1

B0025 11-18 11004735 O-ring 1

B0027 11-18 11004749 Coil nut 1

B0028 11-18 063172 O-ring 1

B0029 11-18 11037174 O-ring 1

B0035 11-18 11001952 O-ring 1

B0040 11-18 11014185 Plastic cap 1

B0050 11-18 716860 Screw, M5 x 12 3

Model/Kit

Order code: MH

B0010 14-23 11146306 Actuator assembly 1

B0050 14-23 716860 Screw, M5 x 12 3

B0060 14-23 140644 Plug assembly 1

B0061 14-23 140644 Plug assembly 1

B0180 14-23 076042 (9003509-0012) Seal nut, M12 1

B0190 14-23 012575 (9004105-1170) O-ring 1

Order code: N1, NA, NB

No parts

©

Danfoss | December 2021 AX152986482121en-000611 | 19

Page 20

*B0034

B0020

B0010

B0026

B0028

B0024

*B0034

C2000

B0010

B0026

B0028

B0024

Parts Manual

H1B 250 Bent Axis Motor

Control

H1B control P1-T2

P1 and P2 configuration

T1 and T2 configuration

Generic housings used to show part location only.

* Included in overhaul seal kit Q210

20 | © Danfoss | December 2021 AX152986482121en-000611

Page 21

Parts Manual

H1B 250 Bent Axis Motor

Control

Order code: P1

Item Date Begin Date End Part Number Part Name Qty. per

B0010 11-18 11013613 Solenoid valve, proportional, 12 volt 1

B0020 11-18 11031751 Coil kit, 12 volt 1

B0024 11-18 11031608 O-ring 1

B0026 11-18 11027046 Coil nut 1

B0028 11-18 063172 O-ring 1

B0034 11-18 085043 (9004201-3700) O-ring 1

Order code: P2

B0010 11-18 11013614 Solenoid valve, proportional, 24 volt 1

B0020 11-18 11031762 Coil kit, 24 volt 1

B0024 11-18 11031608 O-ring 1

B0026 11-18 11027046 Coil nut 1

B0028 11-18 063172 O-ring 1

B0034 11-18 085043 (9004201-3700) O-ring 1

Model/Kit

Order code: T1

B0010 11-18 11013615 Solenoid, on/off, 12 volt 1

B0024 11-18 11031608 O-ring 1

B0026 11-18 11027046 Coil nut 1

B0028 11-18 063172 O-ring 1

B0034 11-18 085043 (9004201-3700) O-ring 1

C2000 11-18 11031763 Coil kit, 12 volt 1

Order code: T2

B0010 11-18 11013616 Solenoid, on/off, 24 volt 1

B0024 11-18 11031608 O-ring 1

B0026 11-18 11027046 Coil nut 1

B0028 11-18 063172 O-ring 1

B0034 11-18 085043 (9004201-3700) O-ring 1

C2000 11-18 11031764 Coil kit, 24 volt 1

©

Danfoss | December 2021 AX152986482121en-000611 | 21

Page 22

B0060

B0320

B0330

QB300

B0300

Parts Manual

H1B 250 Bent Axis Motor

Control

H1B control TA, TH

TA configuration

TH configuration

Generic housings used to show part location only.

* Included in overhaul seal kit Q210

22 | © Danfoss | December 2021 AX152986482121en-000611

Page 23

Parts Manual

H1B 250 Bent Axis Motor

Control

Order code: TA

Item Date Begin Date Begin Part Number Part Name Qty. per

B0060 11-46 140644 Plug assembly 1

Order code: TH

B0300 15-27 11157844 PCOR override adapter assembly 1

B0320 15-27 11157843 Sensing spool 1

B0330 15-27 11164139 O-ring 1

QB300 15-27 085043 (9004201-3700) O-ring 1

Model/Kit

©

Danfoss | December 2021 AX152986482121en-000611 | 23

Page 24

*C0130

C0025

C0060

C0080

C0075

C0010

C0060

(removed 11-21)

C0060

C0050

E00T2

E00T3

C0050

C0110

C0120

C0010

C0060

C0050

C0080

C0070

C0060

C0050

*C0130

E00T2

E00T3

C0110

C0120

C0090

*M223

*M224

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

H1B servo pressure AA, AD

AA configuration

AD configuration

* Included in overhaul seal kit Q210

24 | © Danfoss | December 2021 AX152986482121en-000611

Page 25

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

Order code: AA

Item Date Begin Date End Part Number Part Name Qty. per

C0010 11-18 11086113 Control housing, 2-position (SAE) 1

C0025 11-18 11000893 Shuttle valve assembly 1

C0050 11-18 140644 Plug assembly (SAE) 2

C0060 11-22 11040532 Plug assembly 2

C0060 11-18 11-21 11040532 Plug assembly 3

C0075 11-18 11016166 Spool 1

C0080 11-18 1160236 Spring (SAE) 1

C0110 11-18 737866 (9007314-1207) Screw, M12 x 30 2

C0120 11-18 283325 (9007314-1211) Screw, M12 x 50 2

C0130 11-18 11016168 Control seal 1

Order code: AD

C0010 12-14 11110070 Control housing, 2-position 1

C0050 12-14 140644 Plug assembly (SAE) 2

C0060 11-22

C0060 11-22 11040532 Plug assembly 2

C0070 12-14 11016228 Spool 1

C0080 12-14 11160236 Spring (SAE) 1

C0090 12-14 509360 Adjuster 1

C0110 12-14 737866 (9007314-1207) Screw, M12 x 30 2

C0120 12-14 283325 (9007314-1211) Screw, M12 x 50 2

C0130 12-14 11016168 Control seal 1

M223 12-14 085043 (9004201-3700) O-ring 1

M224 12-14 732479 O-ring 1

Model/Kit

©

Danfoss | December 2021 AX152986482121en-000611 | 25

Page 26

C0100

C0060

C0060

E00T2

C0060

E00T3

C0025

C0050

*C0130

C0110

C0010

C0100

C0060

C0060

E00T2

C0060

E00T3

C0025

C0050

*C0130

C0110

C0010

C0320

C0300

C0320

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

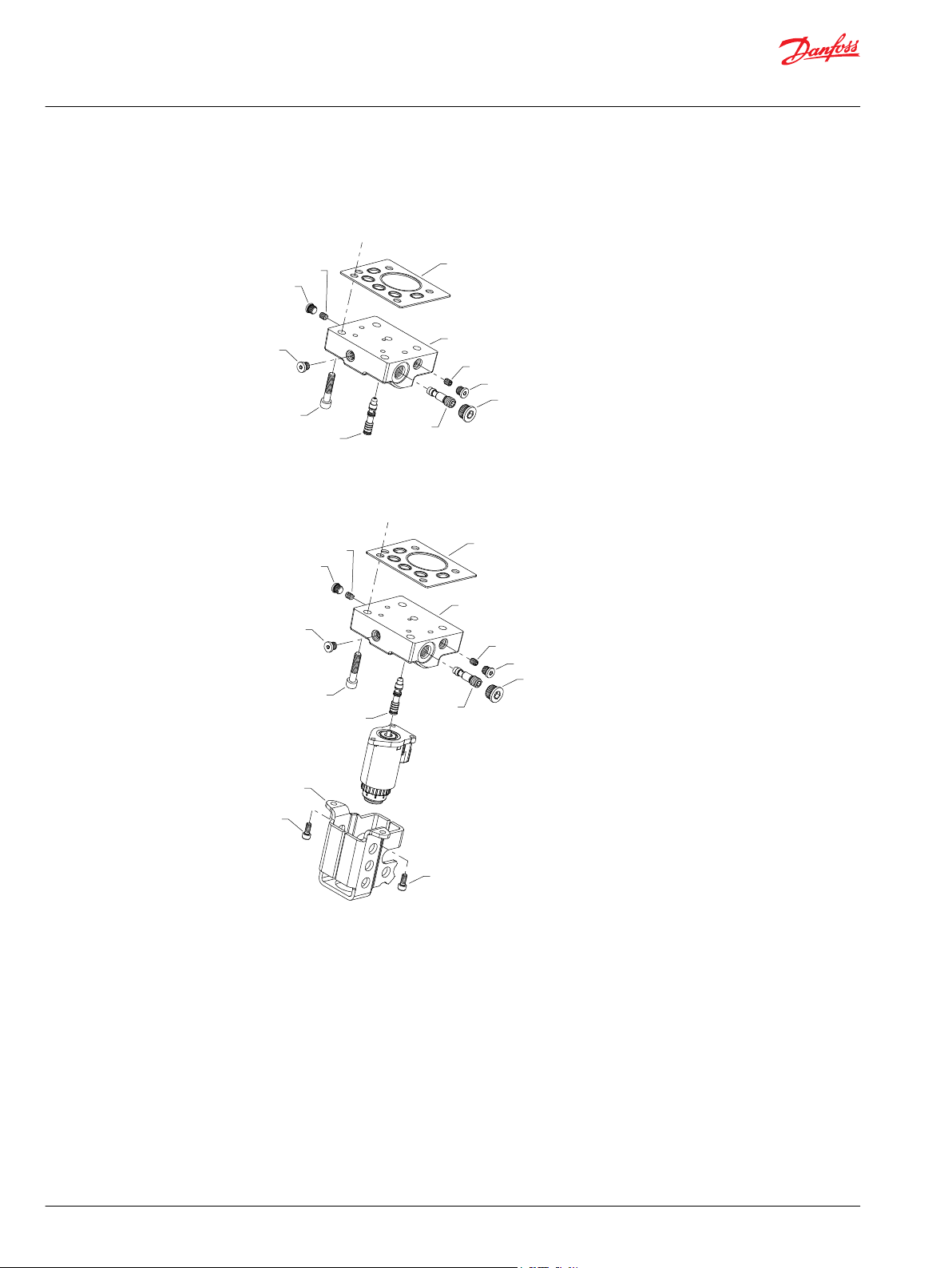

H1B servo pressure BA, BB

BA configuration

BB configuration

26 | © Danfoss | December 2021 AX152986482121en-000611

* Included in overhaul seal kit Q210

Page 27

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

Option BA and BB are available in SAE and metric. Please order accordingly.

Order code: BA

Item Date Begin Date End Part Number Part Name Qty. per

C0010 11-18 149057 Control housing, proportional (SAE) 1

C0010 15-45 11161819 Control housing, proportional (metric) 1

C0025 11-18 11000893 Shuttle valve assembly 1

C0050 11-18 140644 Plug assembly (SAE) 1

C0050 15-45 11178808 Plug assembly (metric) 1

C0060 11-18 11040532 Plug assembly 3

C0100 11-18 11146871 Spool (SAE) 1

C0100 15-45 11146871 Spool (metric) 1

C0110 11-18 710855 Screw, M8 x 35 4

C0130 11-18 149040 Control seal 1

Order code: BB

C0010 12-24 11116918 Control housing, proportional (SAE) 1

C0010 16-49 11169197 Control housing, proportional (metric) 1

C0025 12-24 11000893 Shuttle valve assembly 1

C0050 12-24 140644 Plug assembly (SAE) 1

C0050 16-49 11178808 Plug assembly (metric) 1

C0060 12-24 11040532 Plug assembly 3

C0100 12-24 11146871 Spool (SAE) 1

C0110 12-24 710855 Screw, M8 x 35 4

C0130 12-24 149040 Control seal 1

C0300 12-24 11086158 Protective cover 1

C0320 12-24 395822 Screw, M6 x 12mm 2

Model/Kit

©

Danfoss | December 2021 AX152986482121en-000611 | 27

Page 28

E00T2

E00T3

C0100

C0060

C0060

C0060

C0025

C0050

*C0130

C0110

C0010

C0320

C0300

C0320

C0010

C0060

C0050

C0080

C0070

C0060

C0050

*C0130

E00T2

E00T3

C0110

C0120

C0090

*M223

*M224

E00T3

E00T2

C0100

C0010

C0025

*C0130

C0060

C0050

C0060

C0060

C0110

(BC)

(BD)

(CA)

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

H1B servo pressure BC, BD, CA

Parts configuration

* Included in overhaul seal kit Q210

Option BC is only available in metric configuration. Option CA is available is both SAE and metric

configurations. Please order accordingly.

28 | © Danfoss | December 2021 AX152986482121en-000611

Page 29

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

Order code: BC

Item Date Begin Date End Part Number Part Name Qty. per

C0010 16-38 11169197 Control housing, proportional (metric) 1

C0025 16-38 11000893 Shuttle valve assembly 1

C0050 16-38 11178808 Plug assembly (metric) 1

C0060 16-38 11040532 Plug assembly 3

C0100 16-38 11146871 Spool (metric) 1

C0110 16-38 710855 Screw, M8 x 35 4

C0130 16-38 149040 Control seal 1

C0300 16-38 11086158 Protection cover 1

C0320 16-38 395822 Screw, M6 x 12 2

Order code: BD

C0010 12-14 11110071 Control housing, 2-position 1

C0050 12-14 140644 Plug assembly (SAE) 2

C0060 12-14 11040532 Plug assembly 2

C0070 12-14 11016228 Spool 1

C0080 12-14 11160236 Spring (SAE) 1

C0090 12-14 509360 Adjuster 1

C0110 12-14 737866 (9007314-1207) Screw, M12 x 30 2

C0120 12-14 283325 (9007314-1211) Screw, M12 x 50 2

C0130 12-14 11016168 Control seal 1

M223 12-14 085043 (9004201-3700) O-ring 1

M224 12-14 732479 O-ring 1

Model/Kit

Order code: CA

C0010 11-18 149057 Control housing, proportional (SAE) 1

C0010 11161819 Control housing, proportional (metric) 1

C0025 11-18 11000893 Shuttle valve assembly 1

C0050 11-18 140644 Plug assembly (SAE) 1

C0050 16-35 11178808 Plug assembly (metric) 1

C0060 11-18 11040532 Plug assembly 3

C0100 11-18 11146871 Spool (SAE) 1

C0100 16-35 11146871 Spool (metric) 1

C0110 11-18 710855 Screw, M8 x 35 4

C0130 11-18 149040 Control seal 1

©

Danfoss | December 2021 AX152986482121en-000611 | 29

Page 30

C0030

C0020

C0060

C0010

C0060

*B0034

C2000

C0040

B0026

B0028

B0024

C0060

C0050

*C0130

E00T2

E00T3

C0050

C0110

C0120

C0080

C0070

C0090

*M223

*M224

C0060

(removed 11-21)

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

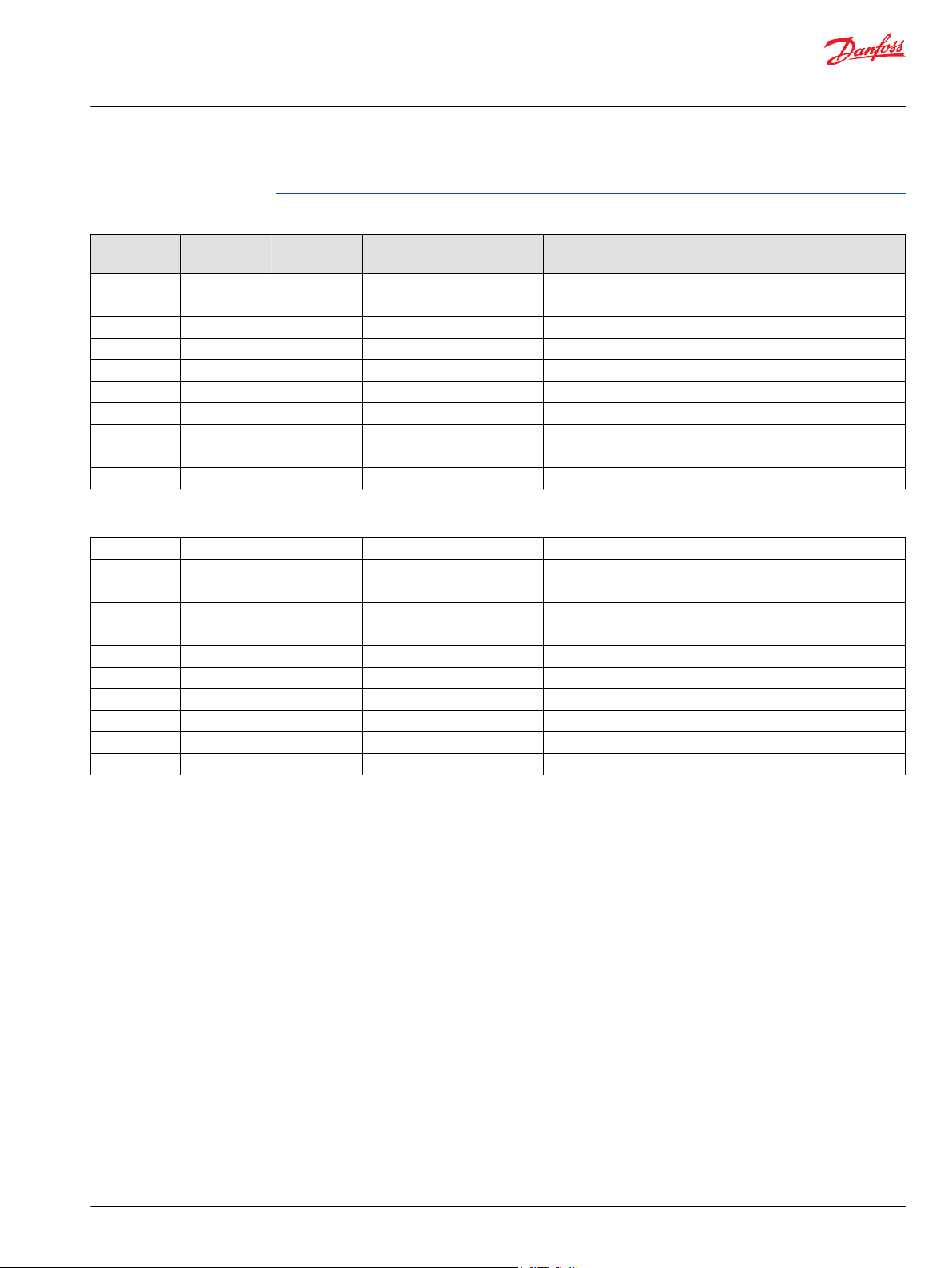

H1B servo pressure D1, D2

D1 and D2 configuration

* Included in overhaul seal kit Q210

30 | © Danfoss | December 2021 AX152986482121en-000611

Page 31

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

Order code: D1 and D2 common parts

Item Date Begin Date End Part Number Part Name Qty. per

B0024 11-18 11031608 O-ring 1

B0026 11-18 11027046 Coil nut 1

B0028 11-18 063172 O-ring 1

B0034 11-18 085043 (9004201-3700) O-ring 1

C0010 11-18 11086114 Control housing, PCOR 1

C0020 11-18 11016229 Spool 1

C0030 11-18 11160236 Spring 1

C0050 11-18 140644 Plug assembly (SAE) 2

C0060 11-22 11040532 Plug assembly 3

C0060 11-18 11-21 11040532 Plug assembly 4

C0070 11-18 11016228 Spool 1

C0080 11-18 11160236 Spring 1

C0090 11-18 509360 Adjuster 1

C0110 11-18 737866 (9007314-1207) Screw, M12 x 30 2

C0120 11-18 283325 (9007314-1211) Screw, M12 x 50 2

C0130 11-18 11016168 Control seal 1

M223 11-18 085043 (9004201-3700) O-ring 1

M224 11-18 732479 O-ring 1

Model/Kit

Order code: D1

C0040 11-18 11013615 Solenoid, on/off, 12 volt 1

C2000 11-18 11031763 Coil kit, 12 volt 1

Order code: D2

C0040 11-18 11013616 Solenoid, on/off, 24 volt 1

C2000 11-18 11031764 Coil kit, 24 volt 1

©

Danfoss | December 2021 AX152986482121en-000611 | 31

Page 32

C0025

C0010

C0060

C0060

(removed 11-21)

C0060

C0050

*C0130

E00T2

E00T3

C0080

C0070

C0090

*M223

*M224

C0050

C0110

C0120

C0010

C0060

C0050

C0080

C0075

C0110

C0120

C0050

C0025

C0060

*C0130

E00T2

E00T3

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

H1B servo pressure DA, EA

DA configuration

EA configuration

* Included in overhaul seal kit Q210

32 | © Danfoss | December 2021 AX152986482121en-000611

Page 33

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

Order code: DA

Item Date Begin Date End Part Number Part Name Qty. per

C0010 11-18 11086115 Control housing, PCOR 1

C0025 11-18 11000893 Shuttle valve assembly 1

C0050 11-18 140644 Plug assembly (SAE) 2

C0060 11-22 11040532 Plug assembly 2

C0060 11-18 11-21 11040532 Plug assembly 3

C0070 11-18 11016228 Spool 1

C0080 11-18 11160236 Spring 1

C0090 11-18 509360 Adjuster 1

M223 11-18 085043 (9004201-3700) O-ring 1

M224 11-18 732479 O-ring 1

Order code: EA

C0010 11-22 11099281 Control housing, 2-position 1

C0025 11-22 11000893 Shuttle valve assembly 1

C0050 11-22 140644 Plug assembly 1

C0060 11-22 11040532 Plug assembly 2

C0075 11-22 11122114 Spool, 2-position 1

C0080 11-22 11160236 Spring 1

C0110 11-22 737866 (9007314-1207) Screw, M12 x 30 2

C0120 11-22 283325 (9007314-1211) Screw, M12 x 50 2

C0130 11-22 11016168 Control seal 1

Model/Kit

©

Danfoss | December 2021 AX152986482121en-000611 | 33

Page 34

C0060

E00T2

E00T3

C0010

C0060

C0080

C0070

*M223

*M224

C0050

C0110

C0120

C0030

C0020

C0050

*C0130

B0024

B0026

B0028

C2000

*B0034

C0040

C0090

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

H1B servo pressure G1, G2

G1 and G2 configuration

* Included in overhaul seal kit Q210

34 | © Danfoss | December 2021 AX152986482121en-000611

Page 35

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

Order code: G1 and G2 common parts

Item Date Begin Date End Part Number Part Name Qty. per

B0024 16-07 11031608 O-ring 1

B0026 16-07 11027046 Coil nut 1

B0028 16-07 063172 O-ring 1

B0034 16-07 085043 (9004201-3700) O-ring 1

C0010 16-07 11173253 Control housing, 2-position 1

C0020 16-07 11016229 Spool 1

C0030 16-07 11160236 Spring 1

C0050 16-07 140644 Plug assembly (SAE) 2

C0060 16-07 11040532 Plug assembly 3

C0070 16-07 11016228 Spool 1

C0080 16-07 11160236 Spring 1

C0090 16-07 509360 Adjuster 1

C0110 16-07 737866 (9007314-1207) Screw, M12 x 30 2

C0120 16-07 283325 (9007314-1211) Screw, M12 x 50 2

C0130 16-07 11016168 Control seal 1

M223 16-07 085043 (9004201-3700) O-ring 1

M224 16-07 732479 O-ring 1

Model/Kit

Order code: G1

C0040 16-07 11013615 Solenoid valve, 12v 1

C200 16-07 11031763 Coil kit, 12 volt 1

Order code: G2

C0040 16-07 11013616 Solenoid valve, 24v 1

C2000 16-07 11031764 Coil kit, 24 volt 1

©

Danfoss | December 2021 AX152986482121en-000611 | 35

Page 36

*C0130

C0060

E00T2

E00T3

C0050

C0010

C0060

C0050

C0025

C0110

C0120

C0080

C0070

C0090

*M223

*M224

*C0130

C0060

E00T2

E00T3

C0010

C0060

C0020

C1400

C1400

C0080

C0070

C0090

*M223

*M224

C0050

C0110

C0120

*C0130

C0060

E00T2

E00T3

C0010

C0060

C0080

C0070

C0090

*M223

*M224

C0050

C0110

C0120

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

H1B servo pressure HA-HD

HA configuration

HB and HD configuration

HC configuration

* Included in overhaul seal kit Q210

36 | © Danfoss | December 2021 AX152986482121en-000611

Page 37

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

Order code: Common parts

Item Date Begin Date End Part Number Part Name Qty. per

C0070 15-37 11016228 Spool 1

C0080 15-37 11160236 Spring 1

C0090 15-37 509360 Adjuster 1

C0110 15-37 737866 (9007314-1207) Screw, M12 x 30 2

C0120 15-37 283325 (9007314-1211) Screw, M12 x 50 2

C0130 15-37 11016168 Control seal 1

M223 15-37 085043 (9004201-3700) O-ring 1

M224 15-37 732479 O-ring 1

Order code: HA

C0010 15-37 11162117 Control housing, 2-position 1

C0025 15-37 11000893 Shuttle valve assembly 1

C0050 15-37 140644 Plug assembly 2

C0060 15-37 11040532 Plug assembly 2

Model/Kit

Order code: HB

C0010 15-37 11162118 Control housing, 2-position 1

C0020 15-37 11162120 Spool 1

C0050 15-37 140644 Plug assembly 1

C0060 15-37 11040532 Plug assembly 3

Order code: HC

C0010 15-37 11162119 Control housing, 2-position 1

C0050 15-37 140644 Plug assembly 1

C0060 15-37 11040532 Plug assembly 2

Order code: HD

C0010 20-48 11272360 Control housing, 2-position 1

C0020 20-48 11162120 Spool 1

C0050 20-48 140644 Plug assembly 1

C0060 20-48 11040532 Plug assembly 3

C1400 20-48 11151817 Limiter plug 2

©

Danfoss | December 2021 AX152986482121en-000611 | 37

Page 38

E00T3

E00T2

C0010

C0050

C0140

C0050C0050

C0025

C0080

C0060

C0150

C0060

*C0130

C0110

C0120

C0160

*QC160

C0060

C0050

C0140

C0080

C0060

C0150

C0060

C0010

C0025

C0060

C0050

*C0130

E00T3

C0110

C0120

C0160

QC160

E00T2

(HE)

(HF)

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

H1B servo pressure HE, HF

HE and HF configuration

* Included in overhaul seal kit Q210

Option HE is available in SAE and metric. Please order accordingly.

38 | © Danfoss | December 2021 AX152986482121en-000611

Page 39

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

Order code: HE and HF common parts

Item Date Begin Date End Part Number Part Name Qty. per

C0025 11-18 11000893 Shuttle valve assembly 1

C0060 11-18 11040532 Plug assembly 3

C0110 11-18 737866 (9007314-1207) Screw, M12 x 30 2

C0120 11-18 283325 (9007314-1211) Screw, M12 x 50 2

C0130 11-18 11016168 Control seal 1

C0150 11-18 11068172 Spool 1

C0160 11-18 511244 Plug assembly 1

QC160 11-18 039297 (9004201-1200) O-ring 1

Order code: HE

C0010 11-18 11086117 Control housing, 2-position (SAE) 1

C0010 11-18 11175039 Control housing, 2-position (metric) 1

C0050 11-18 140644 Plug assembly (SAE) 2

C0050 11-18 11178808 Plug assembly (metric) 2

C0080 11-18 11160236 Spring (SAE) 1

C0080 11-18 11160236 Spring (metric) 1

C0140 11-18 9005110-8700 (315325) Plug assembly (SAE) 1

C0140 11-18 9005110-8700 (315325) Plug assembly (metric) 1

Model/Kit

Order code: HF

C0010 11-18 11086118 Control housing, 2-position (SAE) 1

C0050 11-18 140644 Plug assembly (SAE) 2

C0080 11-18 11160236 Spring (SAE) 1

C0140 11-18 9005110-8700 (315325) Plug assembly (SAE) 1

©

Danfoss | December 2021 AX152986482121en-000611 | 39

Page 40

C0120

C0110

C0010

C0100

C0060

C0060

*B0034

C2000

C0040

B0026

B0028

B0024

C0050

C0060

C0030

C0020

C0050

*C0130

C0060

E00T2

C0060

E00T3

C0080

C0070

*M223

*M224

C0090

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

H1B servo pressure K1, K2

K1 and K2 configuration

* Included in overhaul seal kit Q210

40 | © Danfoss | December 2021 AX152986482121en-000611

Page 41

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

Order code: K1 and K2 common parts

Item Date Begin Date End Part Number Part Name Qty. per

B0024 11-18 11031608 O-ring 1

B0026 11-18 11027046 Coil nut 1

B0028 11-18 063172 O-ring 1

B0034 11-18 085043 O-ring 1

C0010 11-18 11026748 Control housing, proportional, PCOR 1

C0020 11-18 11026792 Spool 1

C0030 11-18 11160236 Spring 1

C0050 11-18 140644 Plug assembly SAE 2

C0060 11-18 11040532 Plug assembly 9

C0070 11-18 11026751 Spool 1

C0080 11-18 11160236 Spring 1

C0090 11-18 509360 Adjuster 1

C0100 11-18 11146871 Spool 1

C0110 11-18 710855 Screw, M8 x 35 2

C0120 11-18 746644 (9007314-0810) Screw, M8 x 45 2

C0130 11-18 149040 Control seal 1

M223 11-18 085043 (9004201-3700) O-ring 1

M224 11-18 732479 O-ring 1

Model/Kit

Order code: K1

C0040 11-18 11013615 Solenoid, on/off, 12 volt 1

C2000 11-18 11031763 Coil kit, 12 volt 1

Order code: K2

C0040 11-18 11013616 Solenoid, on/off, 24 volt 1

C2000 11-18 11031764 Coil kit, 24 volt 1

©

Danfoss | December 2021 AX152986482121en-000611 | 41

Page 42

E101 604E

C0110

C0100

C0060

C0060

*C0130

C0050

C0060

C0025

C0060

C0050

C0010

C0060

E00T2

C0060

E00T3

C0080

C0070

*M223

*M224

C0090

C0120

C0120

C0110

C0010

C0100

C0060

C0060

C0050

C0060

*C0130

C0060

E00T2

C0060

E00T3

C0080

C0070

*M223

*M224

C0090

C1400

C0020

C1400

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

H1B servo pressure KA, KH

KA configuration

KH configuration

* Included in overhaul seal kit Q210

42 | © Danfoss | December 2021 AX152986482121en-000611

Page 43

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

Order code: KA

Item Date Begin Part Number Part Name Qty. per

C0010 11-18 11026749 Control housing, proportional, PCOR 1

C0025 11-18 11000893 Shuttle valve assembly 1

C0050 11-18 140644 Plug assembly (SAE) 1

C0060 11-18 11040532 Plug assembly 8

C0070 11-18 11026751 Spool 1

C0080 11-18 11160236 Spring 1

C0090 11-18 509360 Adjuster 1

C100 11-18 11146871 Spool 1

C0110 11-18 710855 Screw, M8 x 35 2

C0120 11-18 746644 (9007314-0810) Screw, M8 x 45 2

C0130 11-18 149040 Control seal 1

M223 11-18 085043 (9004201-3700) O-ring 1

M224 11-18 732479 O-ring 1

Model/Kit

Order code: KH

C0010 15-48 11161283 Control housing, proportional, PCOR 1

C0020 15-48 11151818 Spool 1

C0050 15-48 140644 Plug assembly 1

C0060 15-48 11040532 Plug assembly 9

C0070 15-48 11026751 Spool 1

C0080 15-48 11160236 Spring 1

C0090 15-48 509360 Adjuster 1

C100 15-48 11146871 Spool 1

C0110 15-48 710855 Screw, M8 x 35 2

C0120 15-48 746644 (9007314-0810) Screw, M8 x 45 2

C0130 15-48 149040 Control seal 1

C1400 15-48 11151817 Limiter plug 2

M223 15-48 085043 (9004201-3700) O-ring 1

M224 15-48 732479 O-ring 1

©

Danfoss | December 2021 AX152986482121en-000611 | 43

Page 44

C0100

C0060

C0060

E00T3

C0060

E00T2

C0050

*C0130

C0110

C0010

*B0034

C2000

C0070

B0026

B0028

B0024

C0120

C0040

C0080

C0050

C0020

C0030

C0060

C0060

C0090

*M223

*M224

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

H1B servo pressure M1, M2

M1 and M2 configuration

* Included in overhaul seal kit Q210

44 | © Danfoss | December 2021 AX152986482121en-000611

Page 45

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

Order code: M1 and M2 common parts

Item Date Begin Date End Part Number Part Name Qty. per

B0024 11-18 11031608 O-ring 1

B0026 11-18 11027046 Coil nut 1

B0028 11-18 063172 O-ring 1

B0034 11-18 085043 (9004201-3700) O-ring 1

C0010 11-18 11028958 Control housing, proportional, PCOR 1

C0020 11-18 11026792 Spool 1

C0030 11-18 11160236 Spring 1

C0050 11-18 140644 Plug assembly (SAE) 2

C0060 11-18 11040532 Plug assembly 9

C0070 11-18 11028957 Spool 1

C0080 11-18 11160236 Spring 1

C0090 11-18 509360 Adjuster 1

C0100 11-18 11146871 Spool 1

C0110 11-18 710855 Screw, M8 x 35 2

C0120 11-18 746644 (9007314-0810) Screw, M8 x 45 2

C0130 11-18 149040 Control seal 1

M223 11-18 085043 (9004201-3700) O-ring 1

M224 11-18 732479 O-ring 1

Model/Kit

Order code: M1

C0040 11-18 11013615 Solenoid, on/off, 12 volt 1

C2000 11-18 11031763 Coil kit, 12 volt 1

Order code: M2

C0040 11-18 11013616 Solenoid, on/off, 24 volt 1

C2000 11-18 11031764 Coil kit, 24 volt 1

©

Danfoss | December 2021 AX152986482121en-000611 | 45

Page 46

C0100

C0060

C0060

E00T3

C0060

E00T2

C0050

*C0130

C0110

C0010

C0070

C0110

C0080

C0050

C0060

C0060

C0025

C0090

*M223

*M224

C0060

C0100

C0060

C0060

E00T3

C0060

E00T2

C0050

*C0130

C0110

C0010

C0070

*B0034

B0020

B0026

B0028

B0024

C0040

C0080

C0050

C0020

C0030

C0060

C0060

C0320

C0300

C0320

C0120

C0320

C0310

C0320

C0090

*M223

*M224

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

H1B servo pressure MA, MF

MA configuration

MF configuration

* Included in overhaul seal kit Q210

46 | © Danfoss | December 2021 AX152986482121en-000611

Page 47

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

Order code: MA

Item Date Begin Date End Part Number Part Name Qty. per

C0010 11-18 11028959 Control housing, proportional, PCOR 1

C0025 11-18 11000893 Shuttle valve assembly 1

C0050 11-18 140644 Plug assembly (SAE) 2

C0060 11-18 11040532 Plug assembly 8

C0070 11-18 11028957 Spool 1

C0080 11-18 11160236 Spring 1

C0090 11-18 509360 Adjuster 1

C0100 11-18 11146871 Spool 1

C0110 11-18 710855 Screw, M8 x 35 2

C0120 11-18 746644 (9007314-0810) Screw, M8 x 45 2

C0130 11-18 149040 Control seal 1

M223 11-18 085043 (9004201-3700) O-ring 1

M224 11-18 732479 O-ring 1

Model/Kit

Order code: MF

B0020 12-05 11031763 Coil kit, 12 volt 1

B0024 12-05 11031608 O-ring 1

B0026 12-05 11027046 Coil nut 1

B0028 12-05 063172 O-ring 1

B0034 12-05 085043 (9004201-3700) O-ring 1

C0010 12-05 11123556 Control housing, proportional, PCOR 1

C0020 12-05 11101616 Spool 1

C0030 12-05 11160236 Spring 1

C0040 12-05 11013615 Solenoid, on/off, 12 volt 1

C0050 12-05 140644 Plug assembly 2

C0060 12-05 11040532 Plug assembly 9

C0070 12-05 11028957 Spool 1

C0080 12-05 11160263 Spring 1

C0090 12-05 509360 Adjuster 1

C0100 12-05 11146871 Spool 1

C0110 12-05 710855 Screw, M8 x 35 2

C0120 12-05 746644 (9007314-0810) Screw, M8 x 45 2

C0130 12-05 149040 Control seal 1

C0300 12-05 11086158 Protective cover 1

C0310 12-05 11086159 Protective cover 1

C0320 12-05 395822 Screw, M6 x 12mm 4

M223 12-05 085043 (9004201-3700) O-ring 1

M224 12-05 732479 O-ring 1

©

Danfoss | December 2021 AX152986482121en-000611 | 47

Page 48

C0100

C0060

E00T3

E00T2

*C0130

C0110

C0010

C0070

C0120

C0080

C0050

C0020

C0060

C0060

C1400

C1400

C0060

C0060

C0090

*M223

*M224

C0060

C0060

C0060

C0100

C0060

E00T3

C0060

E00T2

C0050

*C0130

C0110

C0010

C0060

*B0034

C2000

B0026

B0028

B0024

C0040

C0050

C0020

C0030

C0060

C0060

C0320

C0300

C0320

C0120

C0320

C0310

C0320

C0025

C0060

C0060

C0060

C0060

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

H1B servo pressure MH, MW

MH configuration

MW configuration

* Included in overhaul seal kit Q210

48 | © Danfoss | December 2021 AX152986482121en-000611

Page 49

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

Order code: MH

Item Date Begin Date End Part Number Part Name Qty. per

C0010 14-37 11151816 Control housing, proportional, PCOR 1

C0020 14-37 11151818 Spool 1

C0050 14-37 140644 Plug assembly 1

C0060 14-37 11040532 Plug assembly 9

C0070 14-37 11028957 Spool 1

C0080 14-37 11160236 Spring 1

C0090 14-37 509360 Adjuster 1

C0100 14-37 11146871 Spool 1

C0110 14-37 710855 Screw, M8 x 35 2

C0120 14-37 746644 (9007314-0810) Screw, M8 x 45 2

C0130 14-37 149040 Control seal 1

C1400 14-37 11151817 Limiter plug 2

M223 14-37 085043 (9004201-3700) O-ring 1

M224 14-37 732479 O-ring 1

Model/Kit

Order code: MW

B0024 12-05 11031608 O-ring 1

B0026 12-05 11027046 Coil nut 1

B0028 12-05 063172 O-ring 1

B0034 12-05 085043 (9004201-3700) O-ring 1

C0010 12-05 11101720 Control housing, proportional, PCOR 1

C0020 12-05 11101616 Spool 1

C0025 12-05 11000893 Shuttle valve assembly 1

C0030 12-05 11160236 Spring 1

C0040 12-05 11013615 Solenoid, on/off, 12 volt 1

C0050 12-05 140644 Plug assembly 2

C0060 12-05 11146871 Plug assembly 10

C0100 12-05 1146871 Spool 1

C0110 12-05 710855 Screw, M8 x 35 2

C0120 12-05 746644 (9007314-0810) Screw, M8 x 45 2

C0130 12-05 149040 Control seal 1

C0300 12-05 11086158 Protective cover 1

C0310 12-05 11086159 Protective cover 1

C0320 12-05 395822 Screw, M6 x 12 4

C2000 12-05 11031763 Coil kit, 12 volt 1

©

Danfoss | December 2021 AX152986482121en-000611 | 49

Page 50

C0010

*C0130

C0060

C0110

C0120

C0060

E00T2

E00T3

C0060

C0060

C0060

C0025

C0050

*C0130

C0110

C0010

C0170

*C0130

C0010

C0060

C0025

C0110

C0120

C0060

C0060

C0050

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

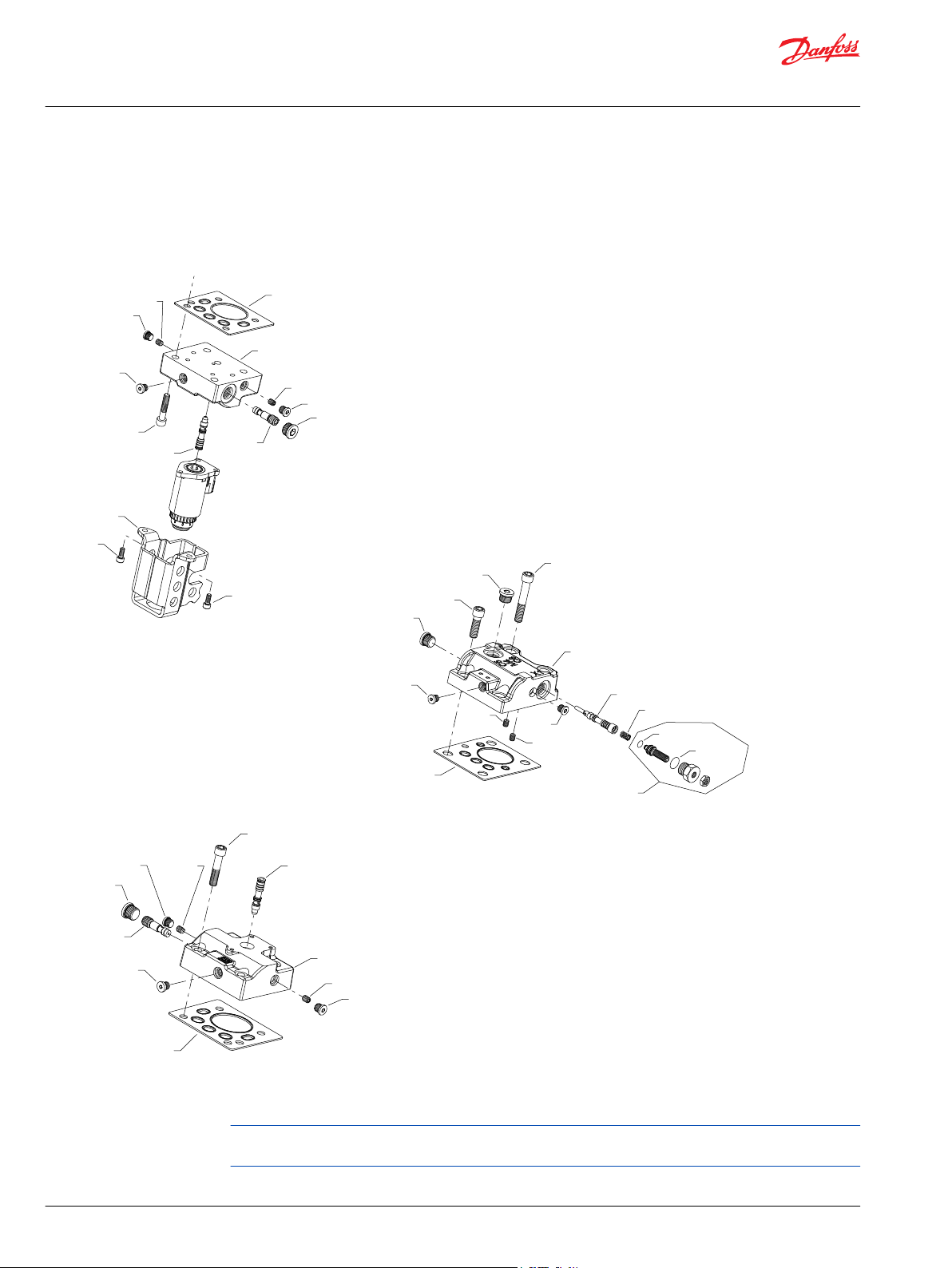

H1B servo pressure NP, NR, NT

NP configuration

NR configuration

NT configuration

50 | © Danfoss | December 2021 AX152986482121en-000611

* Included in overhaul seal kit Q210

Page 51

Parts Manual

H1B 250 Bent Axis Motor

Servo pressure supply

Order code: NP

Item Date Begin Date End Part Number Part Name Qty. per

C0010 11-18 11086116 Control housing, 2-position 1

C0050 11-18 140644 Plug assembly 1

C0060 11-18 11040532 Plug assembly 2

C0110 11-18 737866 (9007314-1207) Screw, M12 x 30 2

C0120 11-18 283325 (9007314-1211) Screw, M12 x 50 2

C0130 11-18 11016168 Control seal 1

Order code: NR

C0010 12-42 11123843 Control housing, proportional 1

C0025 12-42 11000893 Shuttle valve 1

C0050 12-42 140644 Plug assembly 1

C0060 12-42 11040532 Plug assembly 3

C0110 12-42 710855 Screw, M8 x 35 2

C0130 12-42 149040 Control seal 1

C0170 12-42 716860 Screw, M5 x 12 1

Model/Kit

Order code: NT

C0010 12-42 11123847 Control housing, 2-position 1

C0025 12-42 11000893 Shuttle valve 1

C0050 12-42 140644 Plug assembly 1

C0060 12-42 11040532 Plug assembly 3

C0110 12-42 737866 (9007314-1207) Screw, M12 x 30 2

C0120 12-42 283325 (9007314-1211) Screw, M12 x 50 2

C0130 12-42 11016168 Control seal 1

©

Danfoss | December 2021 AX152986482121en-000611 | 51

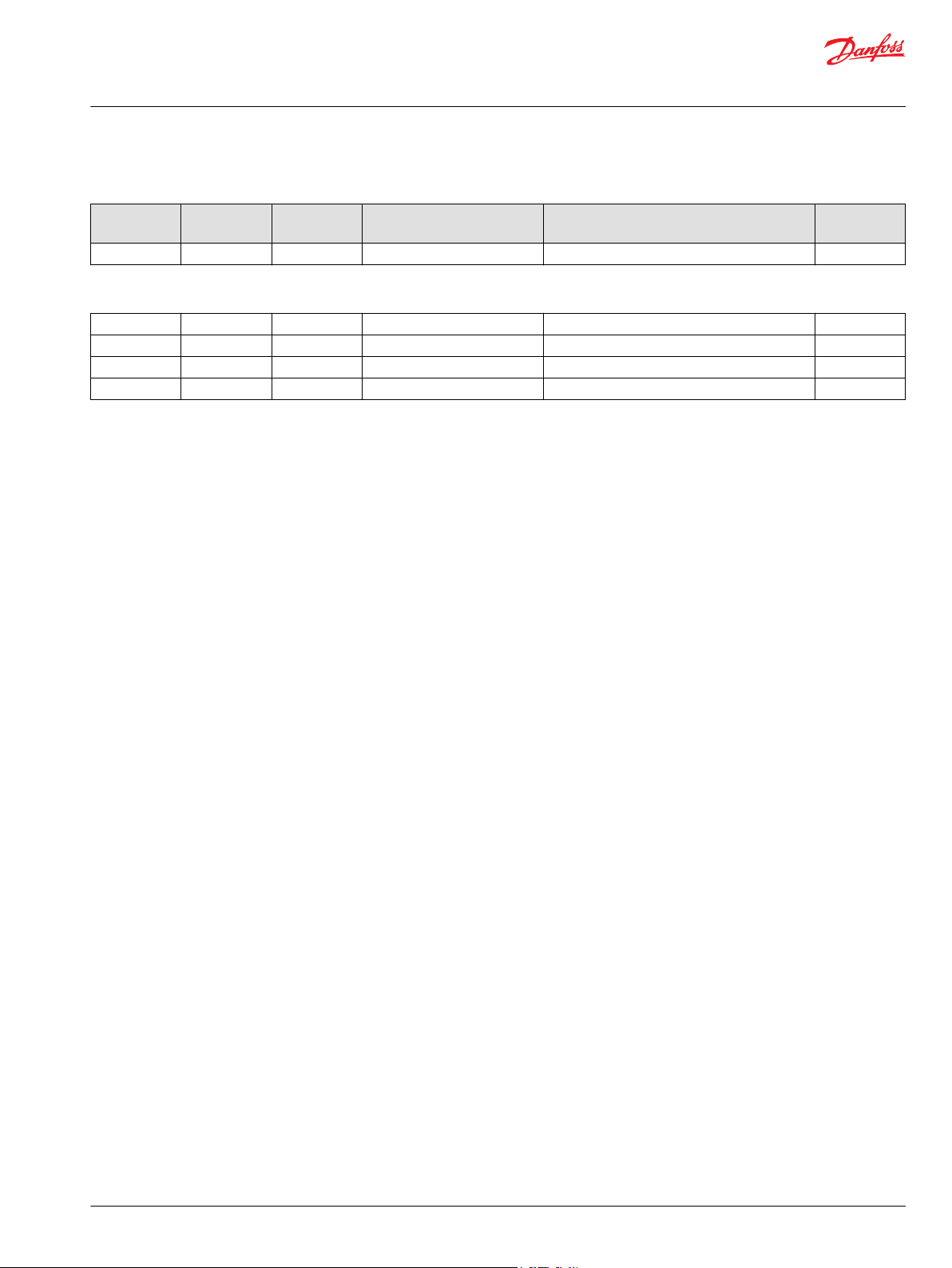

Page 52

E00T2

E00T3

Parts Manual

H1B 250 Bent Axis Motor

Orifice

H1B orifice A, B, C, D

A-D orifice plugs

See servo pressure supply drawing for orifice location.

52 | © Danfoss | December 2021 AX152986482121en-000611

Page 53

Parts Manual

H1B 250 Bent Axis Motor

Orifice

Order code: A

Item Date Begin Date End Part Number Part Name Qty. per

E00T2 11-18 516598 Orifice plug, 1.2 mm 1

E00T3 11-18 516598 Orifice plug, 1.2 mm 1

Order code: B

E00T2 11-18 578542 Orifice plug, 0.8 mm 1

E00T3 11-18 578542 Orifice plug, 0.8 mm 1

Order code: C

E00T2 11-18 511825 Orifice plug, 0.6 mm 1

E00T3 11-18 511825 Orifice plug, 0.6 mm 1

Order code: D

E00T2 11-18 679316 Orifice plug, 0.5 mm 1

E00T3 11-18 679316 Orifice plug, 0.5 mm 1

Model/Kit

Order code: N

No parts

©

Danfoss | December 2021 AX152986482121en-000611 | 53

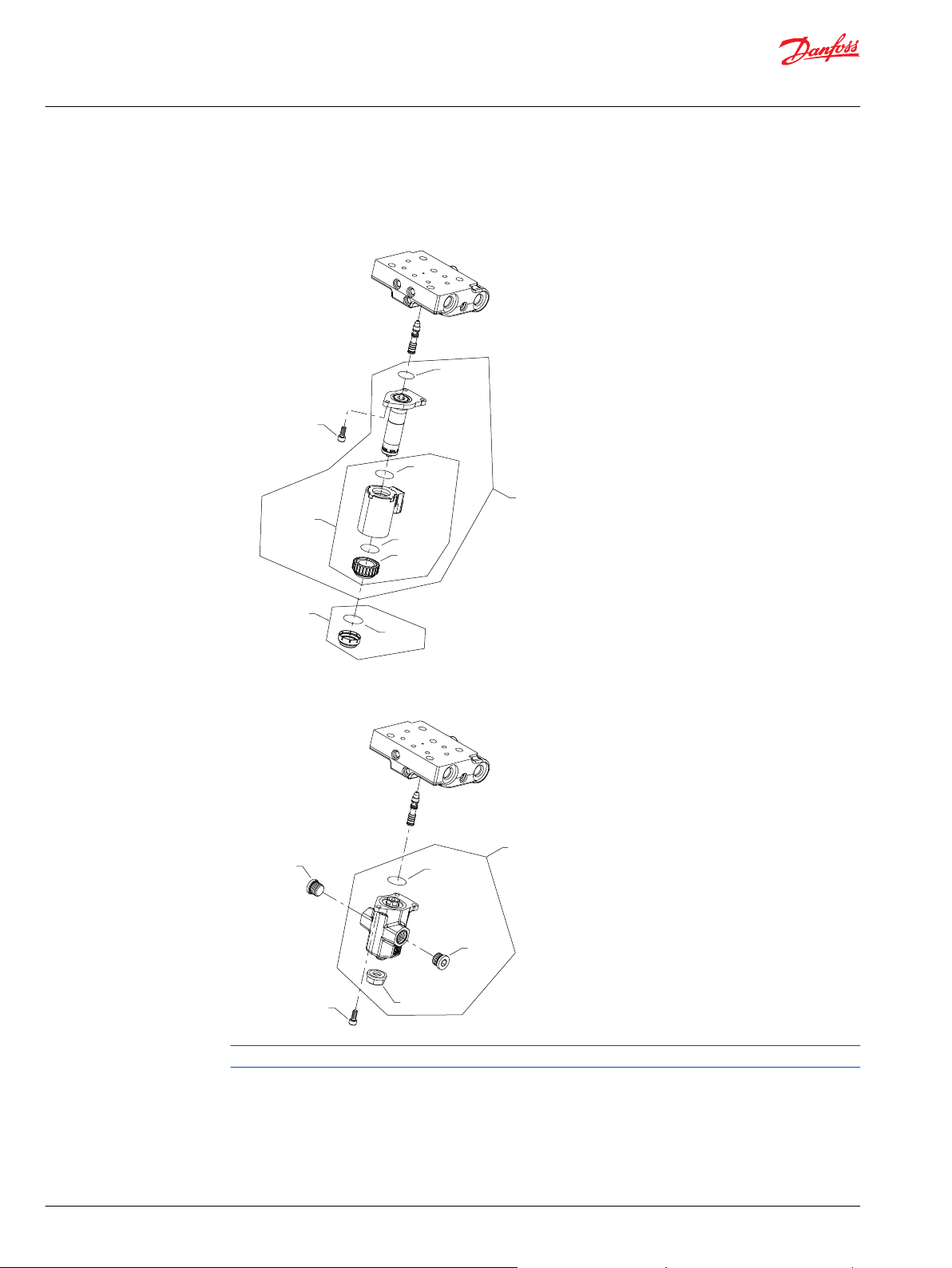

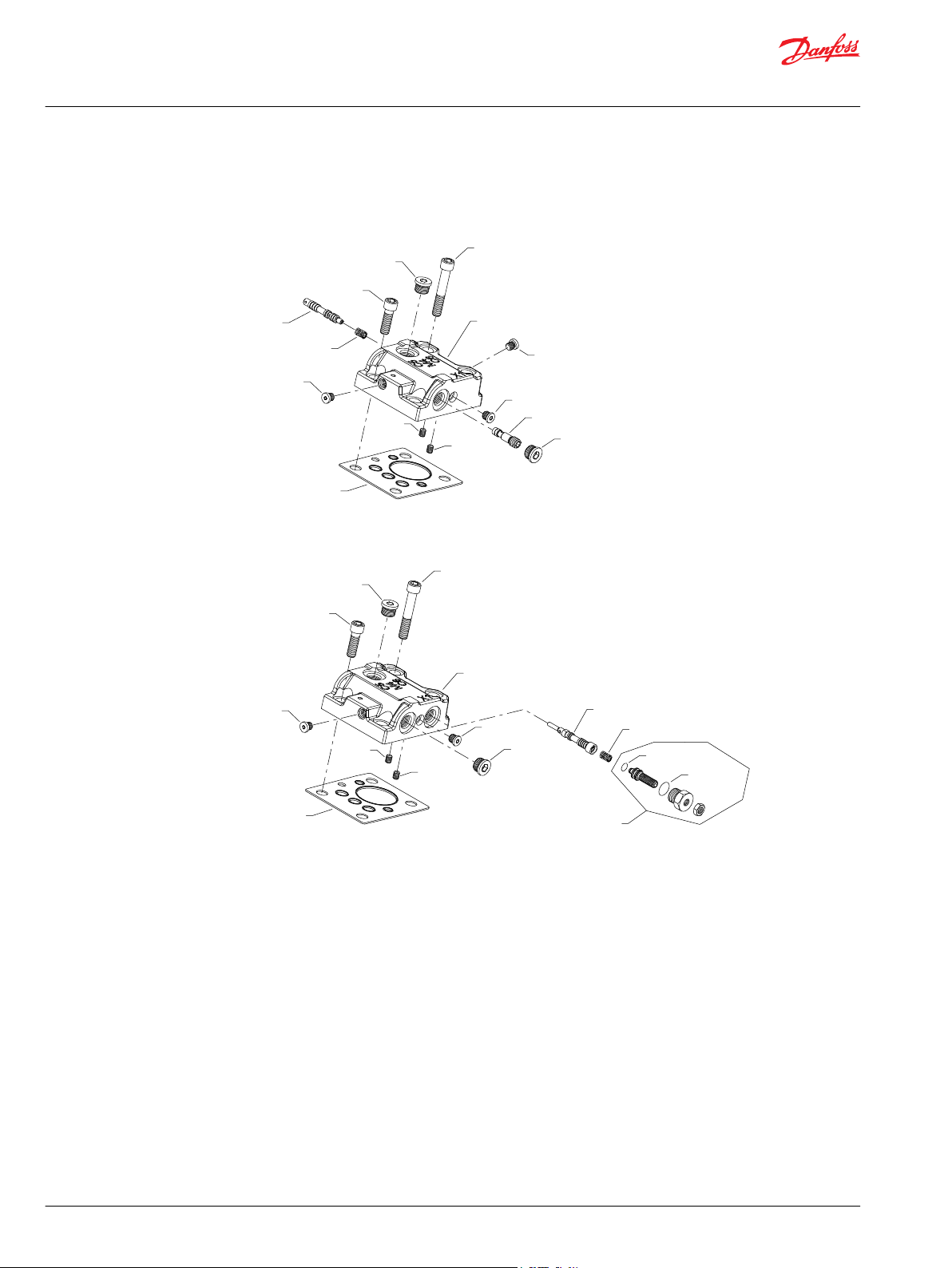

Page 54

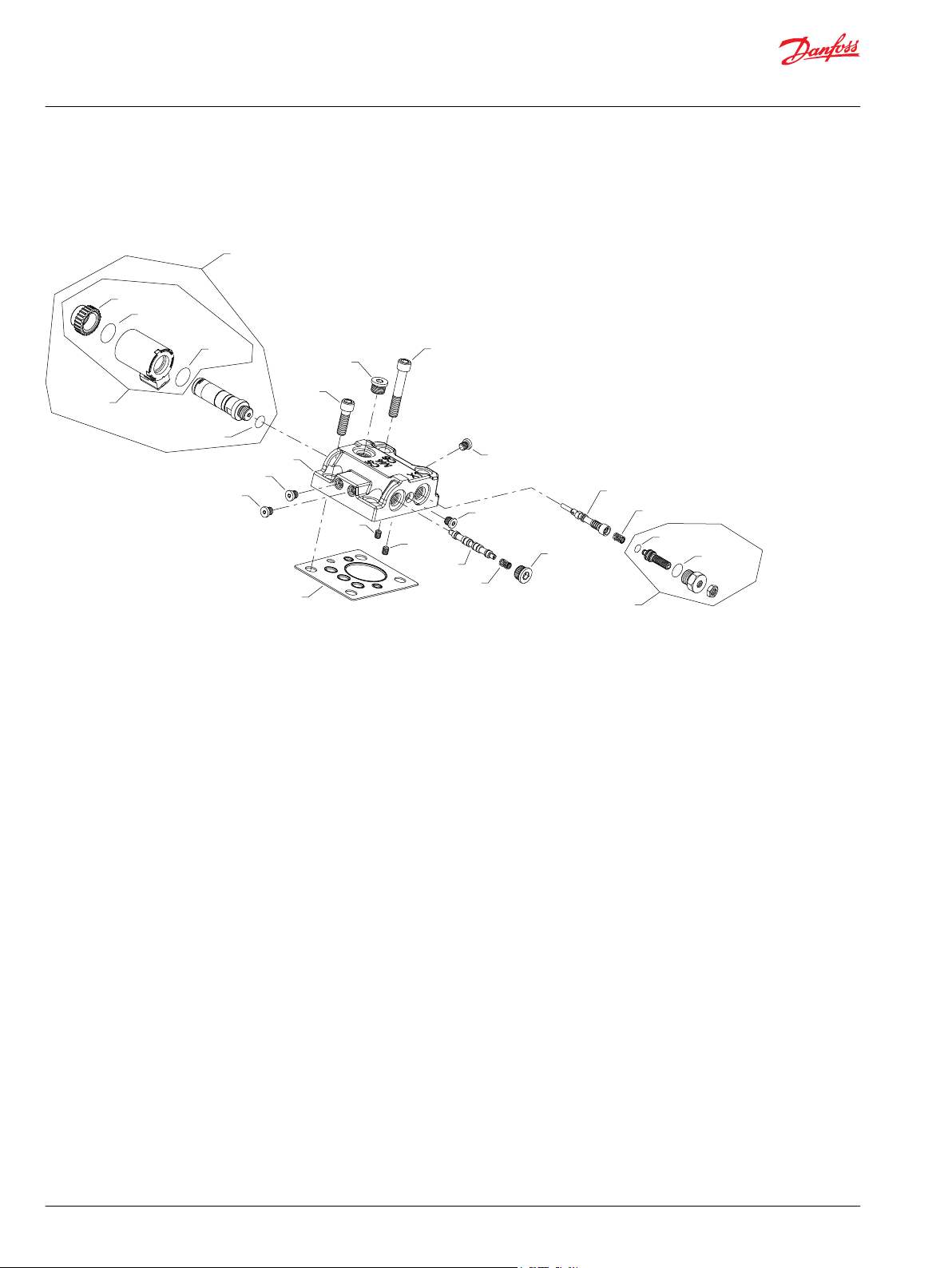

QF080

F0100

F0160

F0010

F0020

F0070

F0040

F0030

F0090

F0050

F0120

F0100

F0160

F0060

Parts Manual

H1B 250 Bent Axis Motor

End cap

H1B 250cc end cap PA

Parts configuration

* Included in overhaul seal kit Q210

This option is available in SAE and metric configurations. Please order accordingly.

54 | © Danfoss | December 2021 AX152986482121en-000611

Page 55

Parts Manual

H1B 250 Bent Axis Motor

End cap

Order code: PA

Item Date Begin Date End Part Number Part Name Qty. per

F0010 13-23 11090018 End cap, axial ports (SAE) 1

F0010 13-23 11172638 End cap, axial ports (metric) 1

F0020 13-23 11093066 Servo piston 1

F0030 13-23 11090825 Spring guide 1

F0040 13-23 11160235 Spring 1

F0050 13-23 11093068 Setting lug 1

F0060 13-23 11008915 Setting lug pin 1

F0070 13-23 042465 Set screw, M10 x 10 1

F0090 13-23 11014186 Button head screw 1

F0100 13-23 140644 Plug assembly (SAE) 2

F0100 13-23 11178808 Plug assembly (metric) 2

F0120 13-23 703900 Screw, M16 x 70 8

F0160 13-23 140644 Plug assembly (SAE) 2

F0160 13-23 11178808 Plug assembly (metric) 2

QF080 13-23 18-16 11086155 Valve segment assembly (SB-2018-028 on page

99)

Model/Kit

1

©

Danfoss | December 2021 AX152986482121en-000611 | 55

Page 56

F0150

F0150

QF080

F0100

F0010

F0020

F0070

F0040

F0030

F0090

F0050

F0120

F0100

F0060

Parts Manual

H1B 250 Bent Axis Motor

End cap

H1B 250cc end cap PB

Parts configuration

* Included in overhaul seal kit Q210

56 | © Danfoss | December 2021 AX152986482121en-000611

Page 57

Parts Manual

H1B 250 Bent Axis Motor

End cap

Order code: PB

Item Date Begin Date End Part Number Part Name Qty. per

F0010 13-23 11090017 End cap, side ports 1

F0020 13-23 11093066 Servo piston 1

F0040 13-23 11160235 Spring 1

F0050 13-23 11093068 Setting lug 1

F0100 13-23 140644 Plug assembly 2

F0120 13-23 703900 Screw, M16 x 70 8

F0150 13-23 664524 (9005110-9000) Plug assembly 2

QF080 13-23 18-16 11086155 Valve segment assembly (SB-2018-028 on page

99)

Model/Kit

1

©

Danfoss | December 2021 AX152986482121en-000611 | 57

Page 58

F0100

F0160

F0010

F0020

F0070

F0040

F0030

F0090

F0050

F0120

F0100

F0160

F0060

F0170

Parts Manual

H1B 250 Bent Axis Motor

End cap

H1B 250cc end cap PF

Parts configuration

* Included in overhaul seal kit Q210

This option is available in SAE and metric configurations. Please order accordingly.

58 | © Danfoss | December 2021 AX152986482121en-000611

Page 59

Parts Manual

H1B 250 Bent Axis Motor

End cap

Order code: PF

Item Date Begin Date End Part Number Part Name Qty. per

F0010 13-23 11161881 End cap, axial ports (SAE) 1

F0010 13-23 11184331 End cap, axial ports (metric) 1

F0020 13-23 11093066 Servo piston 1

F0040 13-23 11160235 Spring (SAE) 1

F0040 13-23 11160235 Spring (metric) 1

F0050 13-23 11093068 Setting lug 1

F0100 13-23 140644 Plug assembly (SAE) 2

F0100 13-23 11178808 Plug assembly (metric) 2

F0120 13-23 703900 Screw, M16 x 70 8

F0160 13-23 140644 Plug assembly (SAE) 2

F0160 13-23 140644 Plug assembly (metric) 2

F0170 13-23 11124768 Edge filter 2

QF080 13-23 18-16 11086155 Valve segment assembly (SB-2018-028 on page

99)

Model/Kit

1

©

Danfoss | December 2021 AX152986482121en-000611 | 59

Page 60

QF080

F0090

F0050

F0010

F0120

F0020

F0070

F0040

F0030

F0160

F0100

F0160

F0100

F0060

Parts Manual

H1B 250 Bent Axis Motor

End cap

H1B 250cc end cap RA

Parts configuration

* Included in overhaul seal kit Q210

This option is available in SAE and metric configurations. Please order accordingly.

60 | © Danfoss | December 2021 AX152986482121en-000611

Page 61

Parts Manual

H1B 250 Bent Axis Motor

End cap

Order code: RA

Item Date Begin Date End Part Number Part Name Qty. per

F0010 13-23 11090018 End cap, axial ports (SAE) 1

F0010 16-35 11172638 End cap, axial ports (metric) 1

F0020 13-23 11093066 Servo piston 1

F0040 16-35 11160235 Spring 1

F0050 13-23 11093068 Setting lug 1

F0100 13-23 140644 Plug assembly (SAE) 2

F0100 16-35 11178808 Plug assembly (metric) 2

F0120 13-23 703900 Screw, M16 x 70 8

F0160 13-23 140644 Plug assembly (SAE) 2

F0160 16-35 11178808 Plug assembly (metric) 2

QF080 13-23 18-16 11086155 Valve segment (SB-2018-028 on page 99) 1

Model/Kit

©

Danfoss | December 2021 AX152986482121en-000611 | 61

Page 62

QF080

F0090

F0050

F0010

F0120

F0020

F0070

F0040

F0030

F0100

F0150

F0150

F0100

F0060

Parts Manual

H1B 250 Bent Axis Motor

End cap

H1B 250cc end cap RB

Parts configuration

* Included in overhaul seal kit Q210

62 | © Danfoss | December 2021 AX152986482121en-000611

Page 63

Parts Manual

H1B 250 Bent Axis Motor

End cap

Order code: RB

Item Date Begin Date End Part Number Part Name Qty. per

F0010 13-23 11090017 End cap, side ports 1

F0020 13-23 11093066 Servo piston 1

F0040 13-23 11160235 Spring 1

F0050 13-23 11093068 Setting lug 1

F0100 13-23 140644 Plug assembly 2

F0120 13-23 703900 Screw, M16 x 70 8

F0150 13-23 664524 (9005110-9000) Plug assembly 2

QF080 13-23 18-16 11086155 Valve segment (SB-2018-028 on page 99) 1

Model/Kit

©

Danfoss | December 2021 AX152986482121en-000611 | 63

Page 64

QF080

F0090

F0050

F0010

F0120

F0020

F0070

F0040

F0030

F0060

F0160

F0100

F0100

F0160

Parts Manual

H1B 250 Bent Axis Motor

End cap

H1B 250cc end cap RE

Parts configuration

* Included in overhaul seal kit Q210

64 | © Danfoss | December 2021 AX152986482121en-000611

Page 65

Parts Manual

H1B 250 Bent Axis Motor

End cap

Order code: RE

Item Date Begin Date End Part Number Part Name Qty. per

F0010 13-23 11106050 End cap, axial ports 1

F0020 13-23 11093066 Servo piston 1

F0040 13-23 11160235 Spring 1

F0050 13-23 11093068 Setting lug 1

F0100 13-23 140644 Plug assembly 2

F0120 13-23 703900 Screw, M16 x 70 8

F0160 13-23 140644 Plug assembly 2

QF080 13-23 18-16 11086155 Valve segment (SB-2018-028 on page 99) 1

Model/Kit

©

Danfoss | December 2021 AX152986482121en-000611 | 65

Page 66

F0090

QF080

F0010

*P0044

*P0043

F0020

F0120

F0160

F0160

F0100

Parts Manual

H1B 250 Bent Axis Motor

End cap

H1B 250cc end cap TA

Parts configuration

* Included in overhaul seal kit Q210

This option is available in SAE and metric configurations. Please order accordingly.

66 | © Danfoss | December 2021 AX152986482121en-000611

Page 67

Parts Manual

H1B 250 Bent Axis Motor

End cap

Order code: TA

Item Date Begin Date End Part Number Part Name Qty. per

F0010 13-23 11115846 End cap, axial ports (SAE) 1

F0010 16-06 11175038 End cap, axial ports (metric) 1

F0020 13-23 11140319 Servo piston assembly 1

F0090 13-23 11014186 Button head screw 1

F0100 13-23 140644 Plug assembly (SAE) 1

F0100 16-06 11178808 Plug assembly (metric) 1

F0120 13-23 703900 Screw, M16 x 70 8

F0160 13-23 140644 Plug assembly (SAE) 2

F0160 16-06 11178808 Plug assembly (metric) 2

P0043 13-23 11063016 O-ring 1

P0044 13-23 11063013 Piston ring 1

QF080 13-23 18-16 11086155 Valve segment assembly (SB-2018-028 on page

99)

Model/Kit

1

©

Danfoss | December 2021 AX152986482121en-000611 | 67

Page 68

F0090

QF080

F0010

*P0044

*P0043

F0020

F0120

F0150

F0150

F0100

Parts Manual

H1B 250 Bent Axis Motor

End cap

H1B 250cc end cap TB

Parts configuration

* Included in overhaul seal kit Q210

68 | © Danfoss | December 2021 AX152986482121en-000611

Page 69

Parts Manual

H1B 250 Bent Axis Motor

End cap

Order code: TB

Item Date Begin Date End Part Number Part Name Qty. per

F0010 13-23 11115847 End cap, side ports 1

F0020 13-23 11140319 Servo piston assembly 1

F0090 13-23 11014186 Button head screw 1

F0100 13-23 140644 Plug assembly 1

F0120 13-23 703900 Screw, M16 x 70 8

F0150 13-23 664524 (9005110-9000) Plug assembly 2

P0043 13-23 11063016 O-ring 1

P0044 13-23 11063013 Piston ring 1

QF080 13-23 18-16 11116072 Valve segment assembly (SB-2018-028 on page

99)

Model/Kit

1

©

Danfoss | December 2021 AX152986482121en-000611 | 69

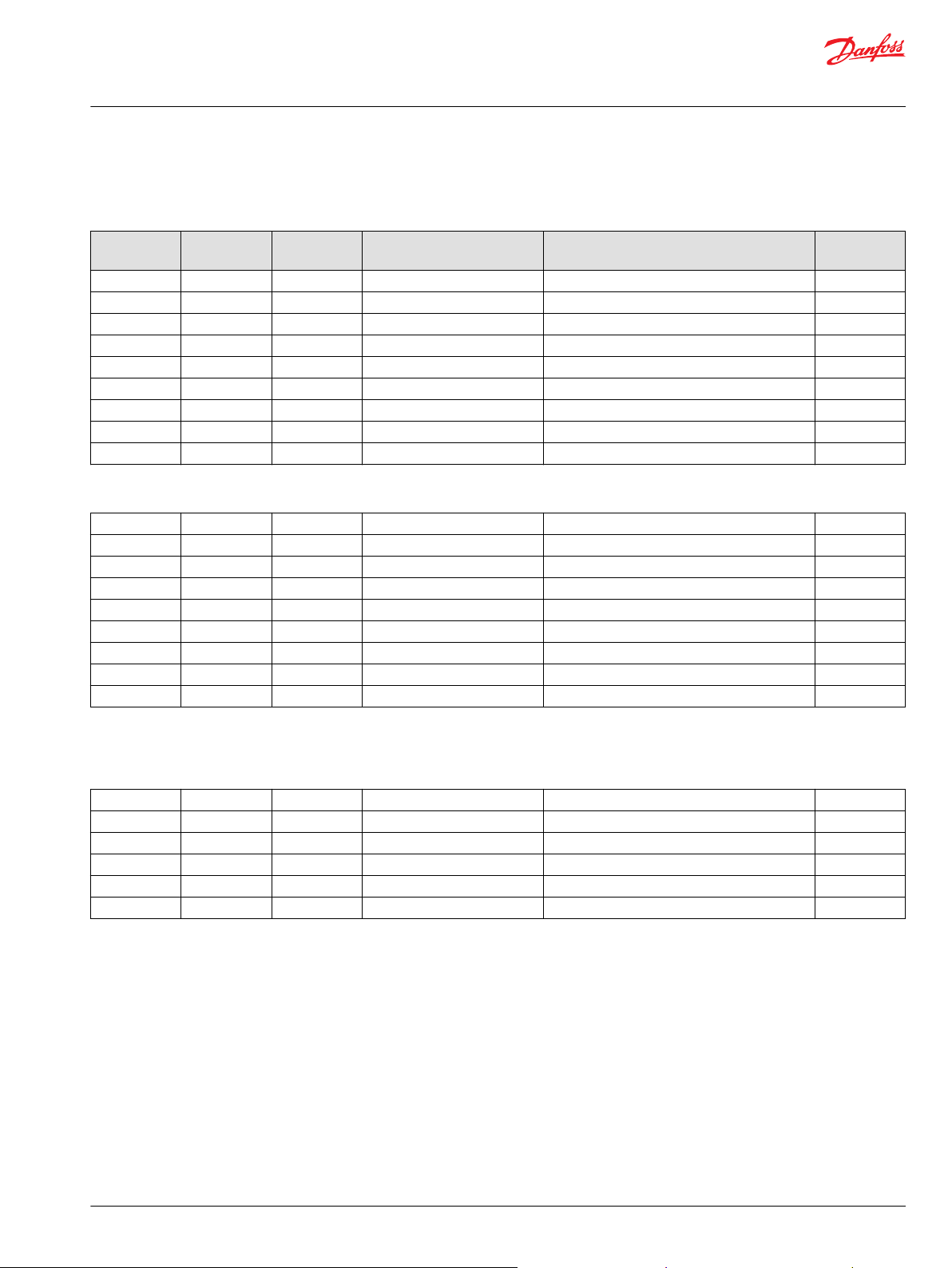

Page 70

G0040

G0040

G0010

G0050

*QG050

*G0020

G0030

G0060

G0061

*G0070

G0060

G0040

*G0070

G0040

G0061

G0050

*QG050

G0010

*G0020

G0030

(DN)

(DS)

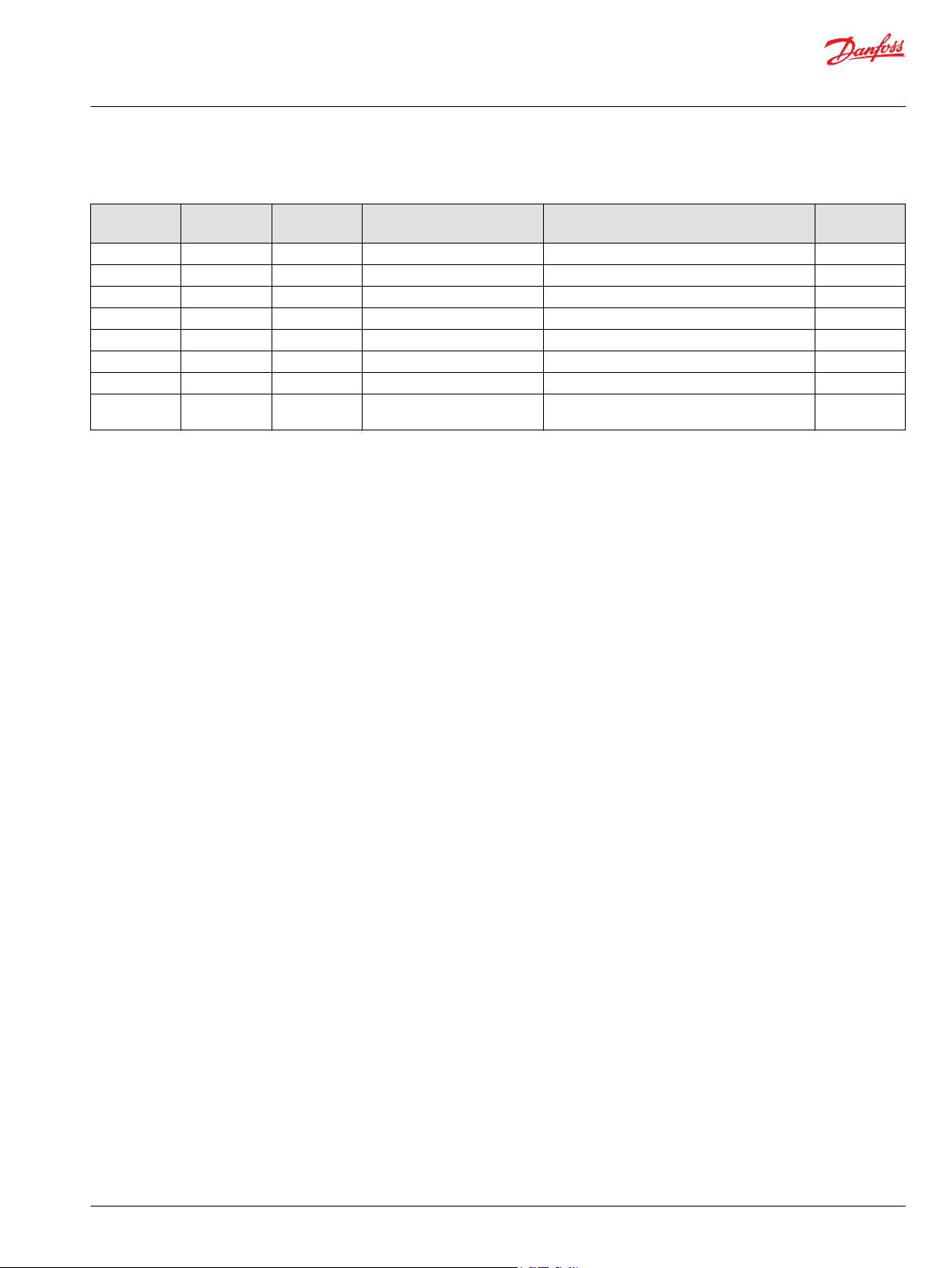

Parts Manual

H1B 250 Bent Axis Motor

Flange/housing

H1B 250cc flange/housing DN, DS

Parts configuration

* Included in overhaul seal kit Q210.

70 | © Danfoss | December 2021 AX152986482121en-000611

Page 71

Parts Manual

H1B 250 Bent Axis Motor

Flange/housing

Common parts

Item Date Begin Date End Part Number Part Name Qty. per

G0010 16-23 11180520 Housing, SAE with speed sensor port 1

G0020 16-23 519022 Lip seal 1

G0030 16-23 392423 Retaining ring 1

G0040 16-23 11007677 Pin 2

G0050 16-23 11063948 Shaft location plug assembly 1

G0060 16-23 320002 (9005110-9200) Plug assembly (SAE) 1

G0061 16-23 320002 (9005110-9200) Plug assembly (SAE) 1

G0070 16-23 11090824 Gasket 1

Order code: DN

J0010 16-23 11013290 PPU plug assembly 1

J0020 16-23 395822 (9007315-0603) Screw, M6 x 12 1

J0041 16-23 018499 (9004100-0160) O-ring 1

QG050 16-23 001123 (9004201-2500) O-ring 1

Model/Kit

Order code: DS

QG050 16-23 001123 (9004201-2500) O-ring 1

©

Danfoss | December 2021 AX152986482121en-000611 | 71

Page 72

G0040

G0040

G0010

G0050

*QG050

*G0020

G0030

*J0041

J0041

J0020

G0061

G0060

*G0070

G0040

G0040

G0010

G0050

*QG050

*G0020

G0030

*J0041

G0060

G0061

*G0070

J0010

J0020

(VC)

(VN)

Parts Manual

H1B 250 Bent Axis Motor

Flange/housing

H1B 250cc flange/housing VC, VN

Parts configuration

* Included in overhaul seal kit Q210

Option VN is available in SAE and metric configurations. Please order accordingly.

72 | © Danfoss | December 2021 AX152986482121en-000611

Page 73

Parts Manual

H1B 250 Bent Axis Motor

Flange/housing

Order code: VC

Item Date Begin Date End Part Number Part Name Qty. per

G0010 13-23 11095943 Housing, SAE with speed sensor port 1

G0030 13-23 11070170 Retaining ring 1

G0040 13-23 11007677 Pin 2

G0050 13-23 11063948 Shaft locating plug assembly 1

G0060 13-23 320002 (9005110-9200) Plug assembly 1

G0061 13-23 320002 (9005110-9200) Plug assembly 1

G0070 13-23 11090824 Gasket 1

G0120 13-23 11070158 O-ring 1

G2000 13-23 11095938 Shaft seal carrier assembly 1

QG050 13-23 001123 (9004201-2500) O-ring 1

Order code: VN

G0010 13-23 11089959 Housing, SAE flange with speed sensor port (SAE) 1

G0010 16-07 11172637 Housing, SAE flange with speed sensor port

(metric)

G0020 13-23 519022 Lip seal 1

G0030 13-23 392423 Retaining ring 1

G0040 13-23 11007677 Pin 2

G0050 13-23 11063948 Shaft locating plug assembly 1

G0060 13-23 320002 (9005110-9200) Plug assembly (SAE) 1

G0060 16-07 11164204 Plug assembly (metric 1

G0061 13-23 320002 (9005110-9200) Plug assembly (SAE) 1

G0061 16-07 11164204 Plug assembly (metric) 1

G0070 13-23 11090824 Gasket 1

J0010 13-23 11013290 PPU plug assembly 1

J0020 13-23 395822 (9007315-0603) Screw, M6 x 12 1

J0041 13-23 11013397 O-ring 1

QG050 13-23 001123 (9004201-2500) O-ring 1

Model/Kit

1

©

Danfoss | December 2021 AX152986482121en-000611 | 73

Page 74

*G0070

G0040

G0040

G0010

G0050

*QG050

*G0020

G0030

G0060

G0061

G0040

G0040

G0010

G0050

*QG050

*G0020

G0120

L514

G0200

G0030

G0060

*G0070

G0061

(VS)

(VT)

Parts Manual

H1B 250 Bent Axis Motor

Flange/housing

H1B 250cc flange/housing VS, VT

Parts configuration

* Included in overhaul seal kit Q210

Option VS is available in SAE and metric configurations. Please order accordingly.

74 | © Danfoss | December 2021 AX152986482121en-000611

Page 75

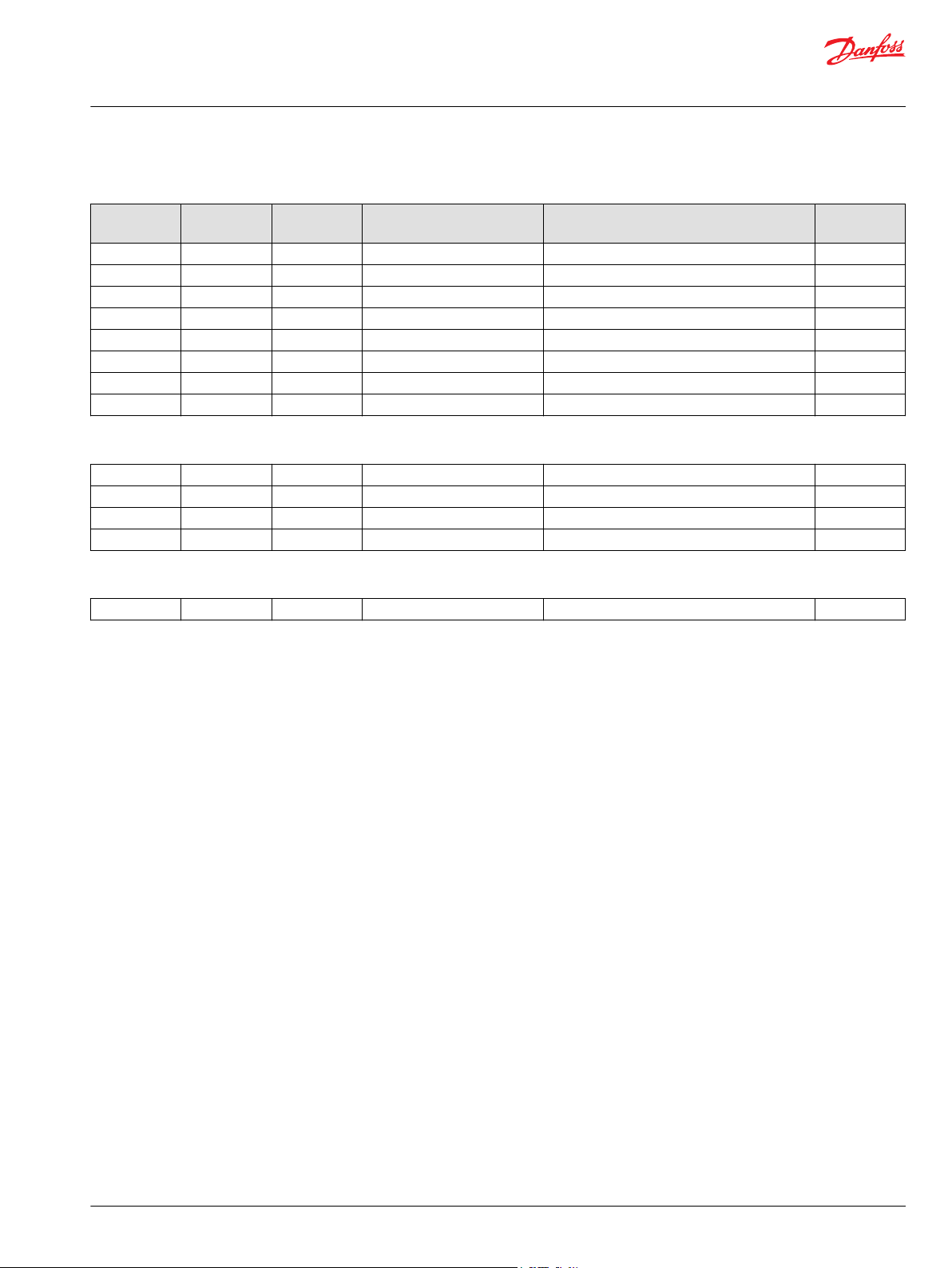

Parts Manual

H1B 250 Bent Axis Motor

Flange/housing

Order code: VS

Item Date Begin Date End Part Number Part Name Qty. per

G0010 13-23 11089959 Housing, SAE flange with speed sensor port (SAE) 1

G0010 15-45 11172637 Housing, SAE flange with speed sensor port

(metric)

G0020 13-23 519022 Lip seal 1

G0030 13-23 392423 Retaining ring 1

G0040 13-23 11007677 Pin 2

G0050 13-23 11063948 Shaft locating plug assembly 1

G0060 13-23 320002 (9005110-9200) Plug assembly (SAE) 1

G0060 15-45 11164204 Plug assembly (metric) 1

G0061 13-23 320002 (9005110-9200) Plug assembly (SAE) 1

G0061 15-45 11164204 Plug assembly (metric) 1

G0070 13-23 11090824 Gasket 1

QG050 13-23 001123 (9004201-2500) O-ring 1

Model/Kit

1

Order code: VT

G0010 14-27 11095943 Housing, SAE flange with speed sensor port 1

G0020 14-27 519022 Lip seal 1

G0030 14-27 11070170 Retaining ring 1

G0040 14-27 11007677 Pin 2

G0050 14-27 11063948 Shaft locating plug assembly 1

G0060 14-27 320002 (9005110-9200) Plug assembly 1

G0061 14-27 320002 (9005110-9200) Plug assembly 1

G0070 14-27 11090824 Gasket 1

G0120 14-27 11070158 O-ring 1

G0200 14-27 11152435 Seal carrier assembly 1

L514 14-27 521664 Lip seal 1

QG050 14-27 001123 (9004201-2500) O-ring 1

©

Danfoss | December 2021 AX152986482121en-000611 | 75

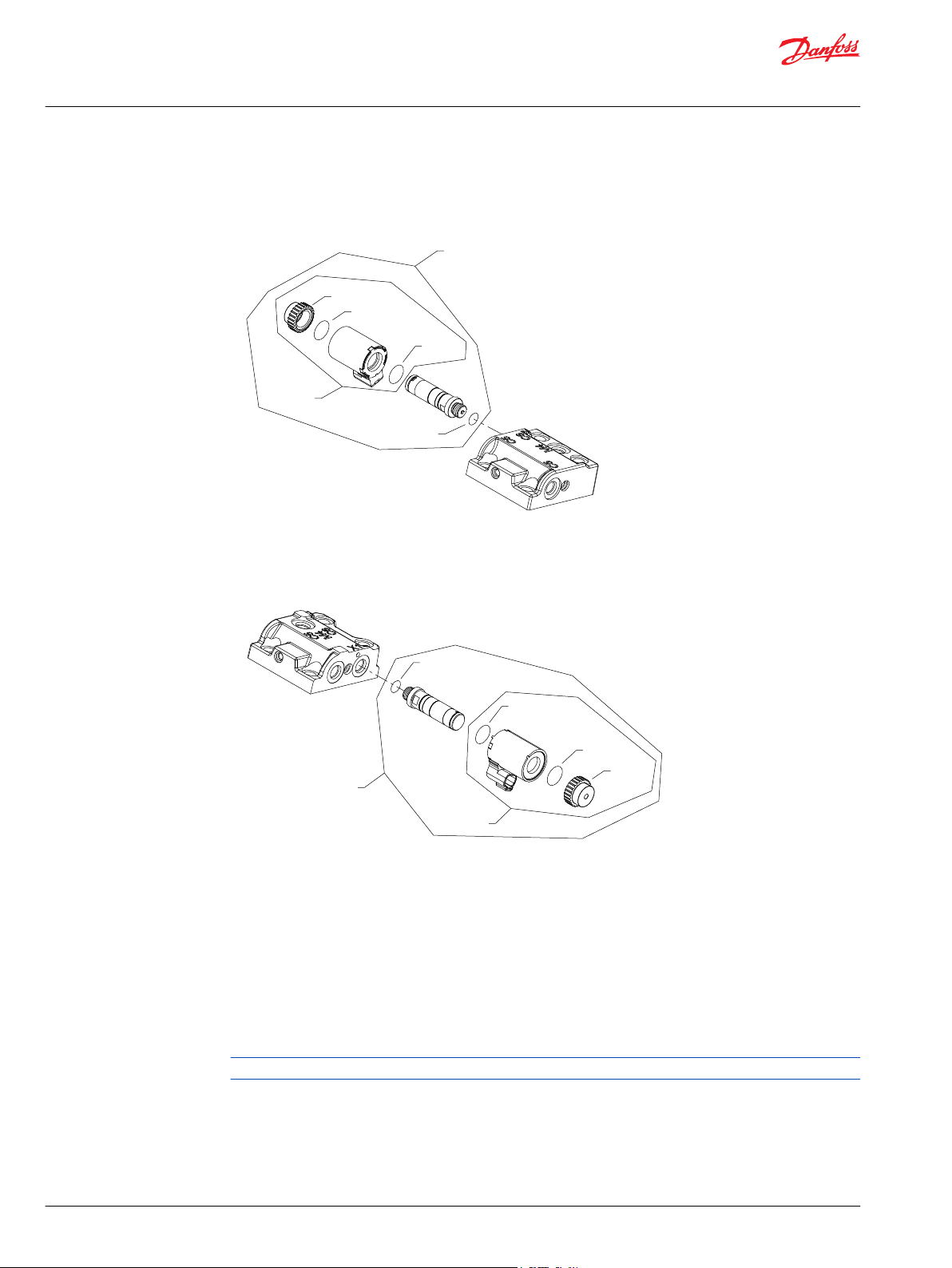

Page 76

QH300

QH030

H0180

QH300

QH030

(DS, FS, LS, PS)

(DN, FN, LN)

Parts Manual

H1B 250 Bent Axis Motor

Shaft

H1B 250cc shaft DN-PS

Parts configuration

76 | © Danfoss | December 2021 AX152986482121en-000611

Page 77

Parts Manual

H1B 250 Bent Axis Motor

Shaft

Order code: DN

Item Date Begin Date End Part Number Part Name Qty. per

QH030 13-23 11100639 Piston ring kit 1

QH300 13-23 11094973 Shaft assembly, 27 tooth, 16/32 pitch 1

Order code: DS

H180 13-23 11086231 Speed ring 1

QH030 13-23 11100639 Piston ring kit 1

QH300 13-23 11094970 Shaft assembly, 27 tooth, 16/32 pitch, speed ring 1

Order code: FN

QH030 13-23 11100639 Piston ring kit 1

QH300 13-23 11086222 Shaft assembly, 15 tooth 1

Order code: FS

H180 13-23 11086231 Speed ring 1

QH030 13-23 11100639 Piston ring kit 1

QH300 13-23 11086198 Shaft assembly, 15 tooth, speed ring 1

Model/Kit

Order code: LS

H0180 17-33 11086231 Speed ring 1

QH030 17-33 11100639 Piston ring kit 1

QH300 17033 11198219 Shaft assembly, 24 tooth 1

Order code: LN

QH030 18-26 11100639 Piston ring kit 1

QH300 18-26 11221814 Shaft assembly 1

Order code: PS

H180 13-23 11086231 Speed ring 1

QH030 13-23 11100639 Piston ring kit 1

QH300 13-23 11096985 Shaft assembly, 27 tooth, 16/32 pitch, speed ring 1

©

Danfoss | December 2021 AX152986482121en-000611 | 77

Page 78

J0010

*J0041

J0020

*J0041

J0010

J0020

J0010

*J0041

J0020

J0300

(P)

(B, C, S)

(D)

Parts Manual

H1B 250 Bent Axis Motor

Speed sensor

H1B 250cc speed sensor