Page 1

Technical Information

ATEX Certified

Bent Axis Variable Displacement Motors

H1B060/080/110/160/210/250

www.danfoss.com

Page 2

Technical Information

ATEX Certified Bent Axis Variable Displacement Motors – H1B 060/080/110/160/210/250

Revision history Table of revisions

Date Changed Rev

April 2022 Updated literature references 0102

June 2021 First edition 0101

2 | © Danfoss | April 2022 BC382476944585en-000102

Page 3

Technical Information

ATEX Certified Bent Axis Variable Displacement Motors – H1B 060/080/110/160/210/250

Contents

General Information

ATEX Introduction............................................................................................................................................................................4

Explosive atmosphere.....................................................................................................................................................................4

Explosion triangle....................................................................................................................................................................... 4

General zone classification...................................................................................................................................................... 4

Equipment category and zones.............................................................................................................................................5

Contents of marking.................................................................................................................................................................. 6

Marking of Danfoss Bent Axis motors..................................................................................................................................7

Production place and date of motors..................................................................................................................................8

Example ATEX label - H1B........................................................................................................................................................8

Maximum Surface Temperature

Viscosity and temperature for H1B motors.............................................................................................................................9

Master Model Code

H1B ATEX Displacement, Product Version, Port Configuration.................................................................................... 10

ATEX Certified Versions of H1B motors............................................................................................................................ 10

Control options...............................................................................................................................................................................11

PCOR and BPD options................................................................................................................................................................ 12

Threshold setting and orifice options.................................................................................................................................... 13

Endcap, flange and housing options......................................................................................................................................14

Shaft, sensor, and loop flushing shuttle system options.................................................................................................15

Loop flushing and special hardware options...................................................................................................................... 16

Minimum and maximum displacement options................................................................................................................17

PCOR pressure setting, paint and nametag options.........................................................................................................18

Technical Specifications

ATEX technical specifications....................................................................................................................................................19

Ambient temperature.................................................................................................................................................................. 19

Oil types / Operating fluids.........................................................................................................................................................19

Oil temperature.........................................................................................................................................................................19

Viscosity........................................................................................................................................................................................19

©

Danfoss | April 2022 BC382476944585en-000102 | 3

Page 4

Ignitable

substance (Gas)

Oxygen Source of ignition

(Spark or heat)

P301 800

Technical Information

ATEX Certified Bent Axis Variable Displacement Motors – H1B 060/080/110/160/210/250

General Information

ATEX Introduction

The ATEX Directive 2014/34/EU specifies the minimum safety requirements for equipment intended for

use in potentially explosive atmospheres in European Union member states. ATEX is derived from the

French term ATmosphères EXplosives.

Hydraulic motors are designed for mobile and stationary applications. Some motors are used in related

applications, where locations are classified as hazardous areas.

The equipment intended for use in hazardous areas are divided into two groups:

Group I: Equipment intended for use in underground parts of mines (mining equipment).

Group II: Equipment intended for use in other places than mines (non-mining equipment).

The Danfoss hydraulic motors, type H1B are intended for use in Group II applications.

Explosive atmosphere

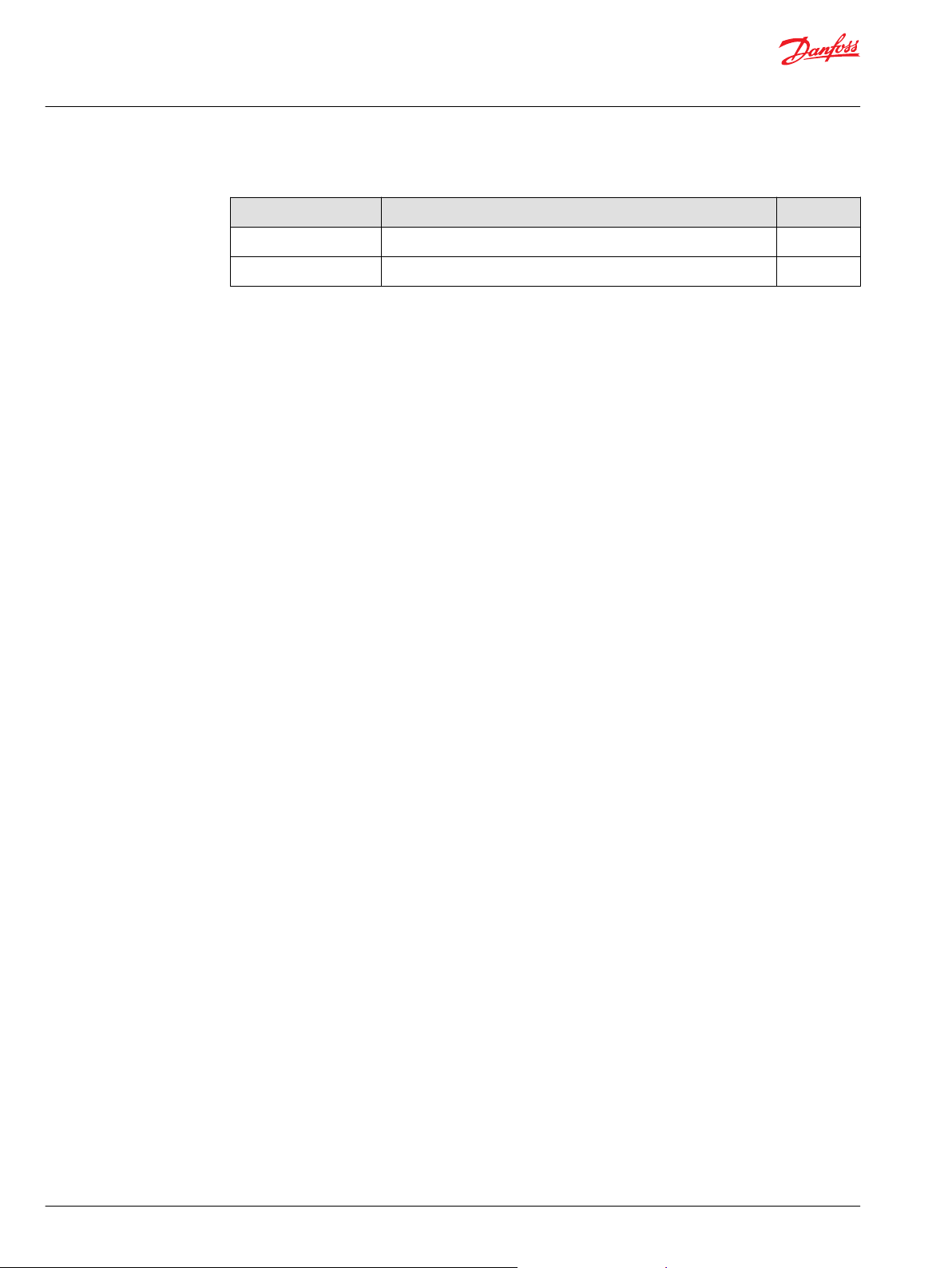

Explosion triangle

A “hazardous area” is defined as an area in which the atmosphere contains, or may contain in sufficient

quantities, flammable or explosive gases, dusts or vapours. In such an atmosphere a fire or explosion is

possible when three basic conditions are met. This is often referred to as the “hazardous area” or

“explosion” triangle.

An atmosphere with the potential to become an explosive atmosphere during operating conditions

and/or under the influence of the surroundings is defined as a potentially explosive atmosphere.

Products covered by directive 2014/34/EU are defined as intended for use in potentially explosive

atmospheres. Removing one of the elements eliminates all risk of explosion.

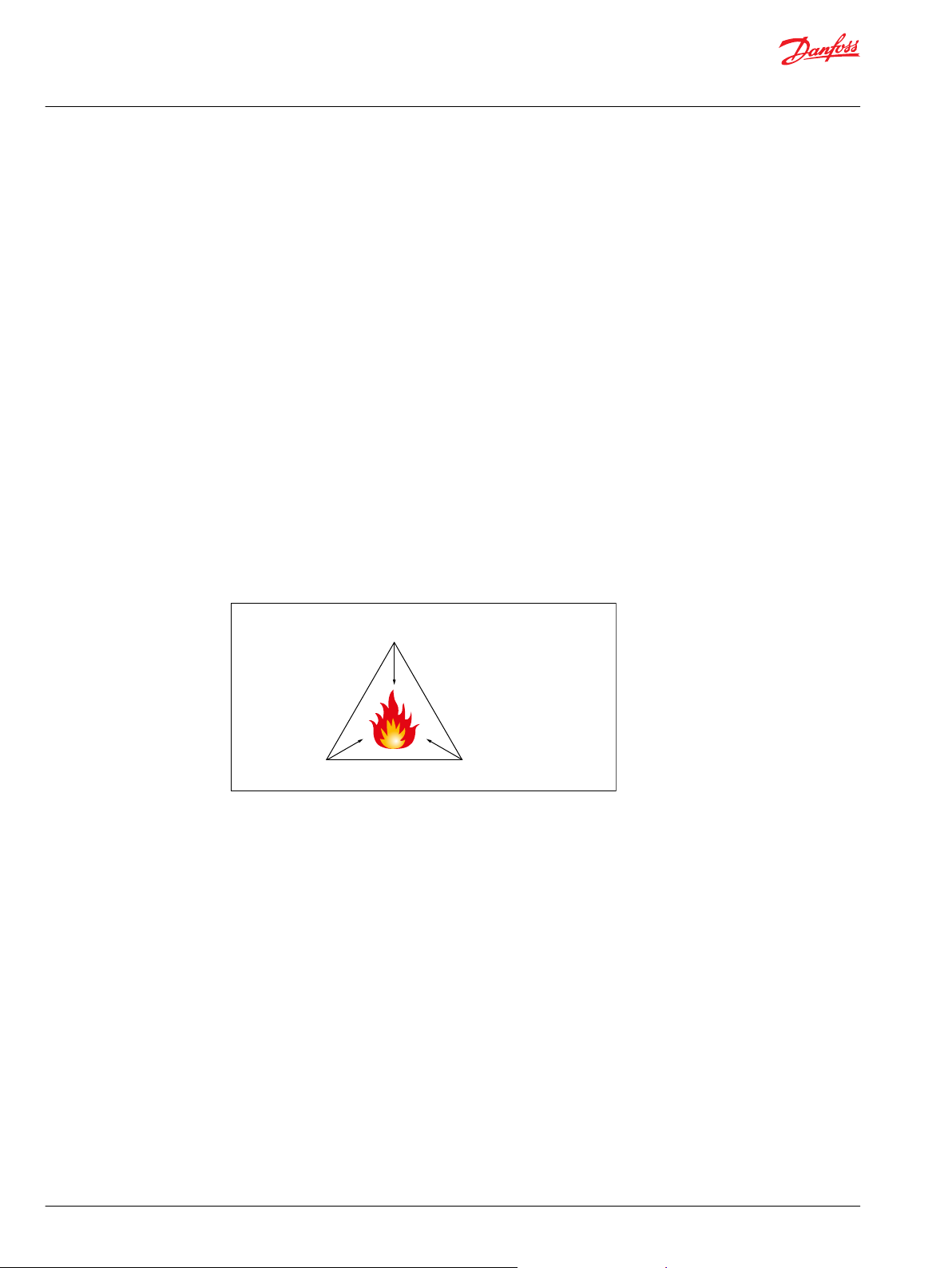

General zone classification

Directive 99/92/EC divides the Hazardous areas into zones and defines criteria by which products are

categorized within these zones; Zone 0 / 20 is the most restrictive and Zones 1 / 21 and 2 / 22 are less

restrictive. The following table describes the zones in an installation where there is a potential for

explosive atmospheres. The owner of the installation must analyze and assess the area in which the

explosive gas/dust mixture may occur, and if necessary must divide it into zones. This process of zoning

then allows the correct plant and equipment to be selected for use in the area.

4 | © Danfoss | April 2022 BC382476944585en-000102

Page 5

Zone 0

Zone 0

Zone 2

Zone 1

F301 801

Degree of protection Protection

Category

Very high Two independent protection measures or safe if two errors occur

independently

Category 1

High

Safe in normal operation and in anticipated case of commonly

occurring errors

Category 2

Normal Safe in normal operation

Category 3

P301 802

Technical Information

ATEX Certified Bent Axis Variable Displacement Motors – H1B 060/080/110/160/210/250

General Information

Zones Presence of potentially explosive atmosphere Type of risk

Gas (G) Dust (D)

0 20 Present continuously or for long periods Permant

1 21 Likely to occur in normal operation occasionally Potential

2 22 Not likely to occur in normal operation but. If it does

occur, will persist for a short period of time

Minimal

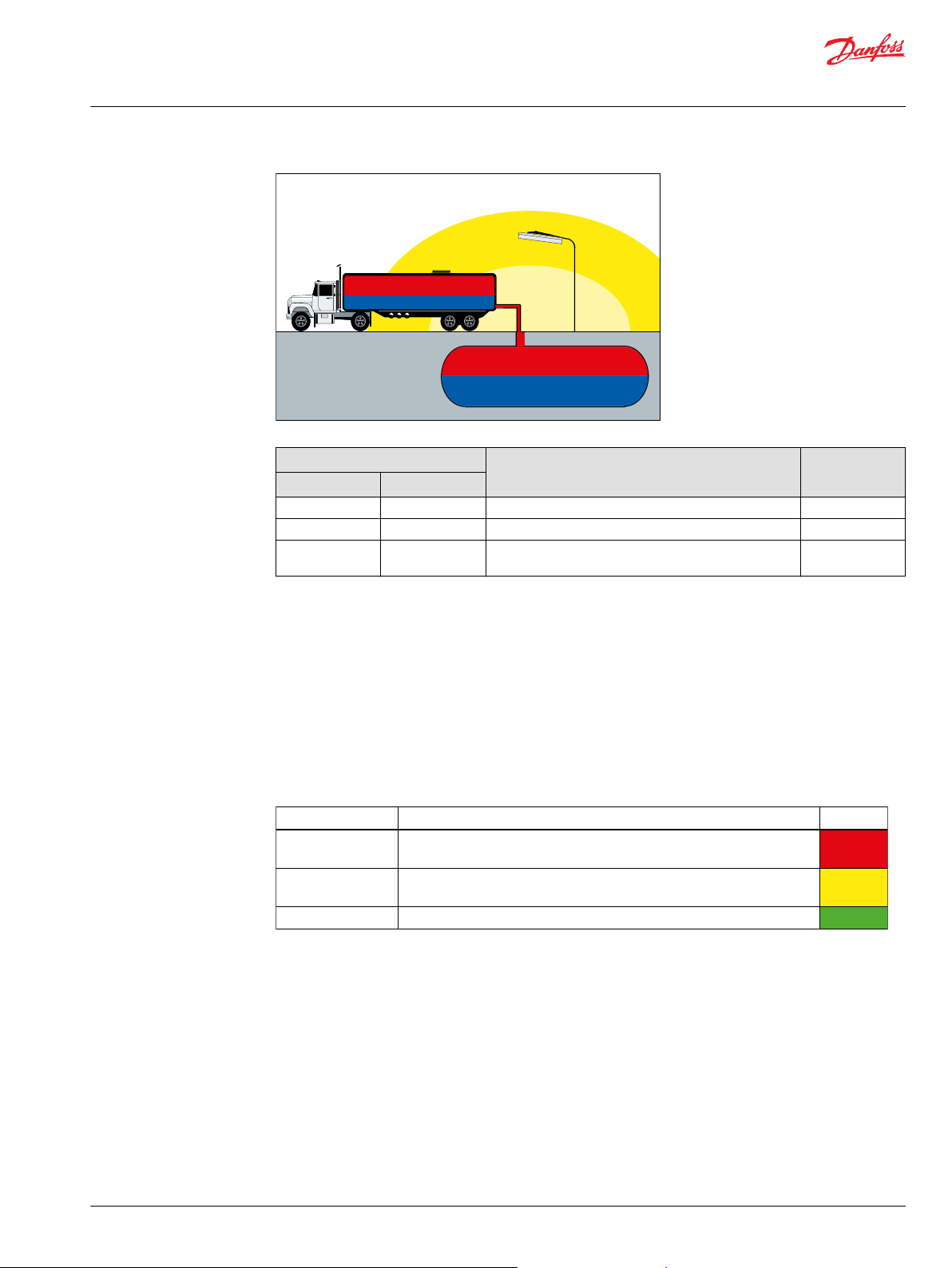

Equipment category and zones

Mechanical components with potential ignition sources e.g. components containing non-conductive

materials or layers or components with hot surface are covered by the ATEX-directive.

Non-mining equipment for potentially explosive atmosphere is classified as:

Equipment Group II – this group comprises three categories according to the level of safety provided:

•

Category 1

•

Category 2

•

Category 3

Category 1 equipment has the highest degree of protection – see the following below.

These products have to fulfil all requirements in the ATEX directive, and have to be marked with the

required “Ex” marking.

Equipment located in zone specified areas must fulfil the following requirements (see also the following

figure):

Category 3 – approved equipment can be installed in hazardous areas zone 2 / 22 and outside zone

•

categorized areas.

Category 2 – approved equipment can be installed in hazardous areas zone 1 / 21, zone 2 / 22 and

•

outside zone categorized areas.

©

Danfoss | April 2022 BC382476944585en-000102 | 5

Category 1 – approved equipment can be installed in hazardous areas zone 0 / 20, zone 1 / 21, zone

•

2 / 22 and outside zone categorized areas.

Page 6

Zone 0Zone 1Zone 2

No requirementsts

Hazards area

Catagory

3

Catagory

2

Catagory

1

ATEX

Directive

Equipment

group II

P301 803

Ex

CE-marking Temperature class

Equipment group Gas Group

Equipment Category Protection type

Nature of atmosphere

Spe cifi c markin g Add itiona l m arki ng

CE II 2 G c II C T4

1

2

3

7

6

5

4

P301 805

Technical Information

ATEX Certified Bent Axis Variable Displacement Motors – H1B 060/080/110/160/210/250

General Information

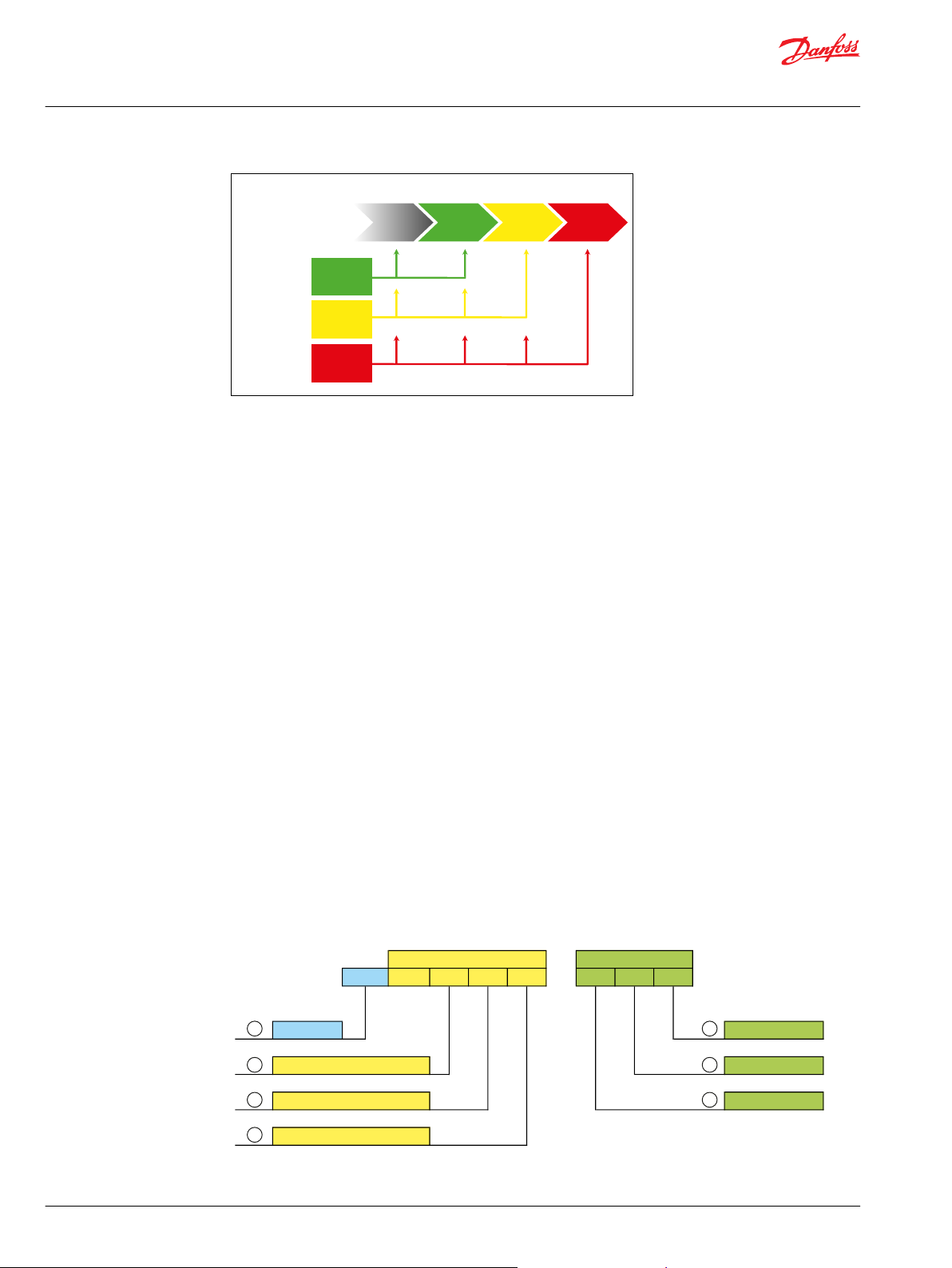

Contents of marking

The rules for the marking of systems, equipment and components are uniformly defined in the standards

relating to the general technical requirements – EN 13463-1 for mechanical equipment.

A priority for all Ex equipment and protective systems is that the marking should show the areas of their

designated use. Components covered within the scope of the ATEX directive have to be CE-marked, and

marked with the specific “Ex”-sign.

Principle

The marking must indicate the following:

•

The manufacturer who has put the item of equipment on the market

•

Manufacturer’s type identification

•

Year in which the equipment was manufactured

•

A serial number

And further the ignition protection marking

•

Symbol of the equipment group and category (M1 or M2 for group I mining equipment, or 1 or 2 or 3

for Group II non-mining equipment).

Additionally for Group II equipment only:

1. The letter “G” where explosive atmospheres caused by gases, vapours or mists are concerned;

and/or

2. The letter “D” where explosive atmospheres caused by dusts are concerned.

•

Type of ignition protection system.

•

Where appropriate, symbol of explosion group of the equipment.

•

For Group II equipment, the symbol indicating the temperature class or the maximum surface

temperature in °C, or both.

6 | © Danfoss | April 2022 BC382476944585en-000102

Page 7

Technical Information

ATEX Certified Bent Axis Variable Displacement Motors – H1B 060/080/110/160/210/250

General Information

Callout Description

1 CE marking

Specific marking

2 Equipment group I - Mining

II - Non-mining

3 Equipment category 1 (zone 0/20)

2 (zone 1/21)

3 (zone 2/22)

4 Nature of atmosphere G - Gas

D - Dust

Additional marking

5 Protection type fr - Protection by flow restricting enclosure

d - Protection by flameproof enclosure

c - Protection by constructional safety

b - Protection by control of ignition sources

p - Protection by pressurized enclosures

k - Protection by liquid immersion

6 Gas group IIA

IIB

IIC

Equipment without any explosion group maring can be used for

explosive atmosphere of explosive group IIA, IIB and IIC provided

the equipment is not marked for specific atmosphere.

7 Temperature class

T1 to T6

TX; where the maximum surface temperature depends not on

the equipment itself, but mainly on operating conditions (like

heated fluid) the relevant information shall be given in the

instruction for use in order to inform the user about this special

situation.

Marking of Danfoss Bent Axis motors

The Danfoss hydraulic motors are marked as equipment for Group II, category 2 for gas and dust

environment and with ignition protection constructional safety and liquid immersion.

Temperature class/Maximum surface temperature depends on the operating conditions (ambient and

fluid temperature).

ATEX marking

Marking For model code option

CE Ex II 3G Ex h IIA T3 Gc NNA (temperature class T3)

CE Ex II 3G Ex h IIA T4 Gc NNB (temperature class T4)

CE Ex II 3G Ex h IIA T5 Gc NNC (temperature class T5)

1

See Master Model Code and Maximum Surface Temperature for additional information.

1

For detailed information on selecting the appropriate T-codes, please see H1B ATEX User Manual,

BC382476021584.

©

Danfoss | April 2022 BC382476944585en-000102 | 7

Page 8

Made in Germany

Serial No.

N001623456

Model Code

Model No./Ident No.

H1B060-AT-E1ATNA

TBCNGN-NA05NN

035Z00NA

12345678

II 3G Ex h IIA T3 Gc

1

2

3

4

5

6

Technical Information

ATEX Certified Bent Axis Variable Displacement Motors – H1B 060/080/110/160/210/250

General Information

Production place and date of motors

The production location and date of the motors is shown at the first 5 digits of the serial no.

Example: Serial No: N191230941

Five first digits are N1912

N is the manufacturing location (N=Neumünster)

19 is the year (It stands for the last digit in the possible decade).

12 is the week

The last five digits are a consecutive number.

The ATEX certification of the units are done under the scope of:

"Directive 2014/34/EU of the European Parliament and of the Council of 26 February 2014 on the

harmonization of the laws of the Member States relating to equipment and protective systems intended for

use in potentially explosive atmospheres."

With following parameters:

•

Equipment group: II

•

Zone: 2 (gas)

•

Equipment Category: 3G

•

Temperature class: T5...T3

•

Explosion protection group: II A

The Conformity Assessment Procedure has to be executed according to Directive 2014/34/EU, annex VIII,

Modul A: Internal Production Control (see article 13, section 1 (c)).

The EU declaration of conformity has to be prepared and issued with regard to annex X of /1/. The

“Essential Health and Safety Requirements” defined by /1/, annex II, have to be considered.

Example ATEX label - H1B

Example of ATEX label: H1B motor produced in Germany

1. Manufacturer

2. Location of production

3. ATEX code

4. Material number

5. Model code, including unit and displacement

6. Production code

8 | © Danfoss | April 2022 BC382476944585en-000102

Page 9

W

W

Technical Information

ATEX Certified Bent Axis Variable Displacement Motors – H1B 060/080/110/160/210/250

Maximum Surface Temperature

Viscosity and temperature for H1B motors

Features Data

Intermittent

Viscosity

Temperature

1)

Intermittent = Short term t < 3 min per incident.

2)

Cold start = Short term t < 3 min; p ≥ 50 bar; n ≤ 1000 min-1(rpm); please contact Danfoss Power Solutions

especially when the temperature is below -25 °C [-13 °F].

Minimum 7 mm2/sec [49 SUS]

Recommended range 12 - 80 mm2 [66 - 371 SUS]

Maximum (cold start)

Minimum (cold start)

Maximum intermittent

Above maximum surface temperatures are without any deposited dust on the product. The possible

insulation effect of a dust layer on the surface has to be taken into account by the safety margin to the

minimum ignition temperature of the dust concerned. For up to 5 mm [1.97 in] layer thickness the safety

margin is 75°C [167°F]. For further information please see IEC 60079-14.

Warning

1)

2)

2)

1)

5 mm2/sec [42 SUS]

1600 mm2/sec [7416 SUS]

-40°C [-40°F]

115°C [239°F]

The above operating temperatures (ambient and oil) of the motors must be guaranteed by the end user.

Warning

It is compulsory to use oils whose inflammable degree is at least 50K above the maximum surface

temperature of the motors. See also Oil types / Operating fluids.

©

Danfoss | April 2022 BC382476944585en-000102 | 9

Page 10

A B C D E F G H J K L M N P

H1 B

A

Q R

Z

A

N N N

Technical Information

ATEX Certified Bent Axis Variable Displacement Motors – H1B 060/080/110/160/210/250

Master Model Code

H1B ATEX Displacement, Product Version, Port Configuration

Displacement

Code Displacement

060

080

110

160

210

250

A – Product version

A

60 cm³ [3.66 in³]

80 cm³ [4.88 in³]

110 cm³ [6.71 in³]

160 cm³ [9.76 in³]

210 cm³ [12.81 in³]

250 cm³ [15.25 in³]

Revision code

Z – Port configuration

A

Inch, Customer O-ring port sealing according to ISO 11926-1

ATEX Certified Versions of H1B motors

Example:

All ATEX certified H1B motors are equipped with mechanical / hydraulic controls only.

10 | © Danfoss | April 2022 BC382476944585en-000102

Page 11

A B C D E F G H J K L M N P

H1 B

A

Q R

Z

A

N N N

Technical Information

ATEX Certified Bent Axis Variable Displacement Motors – H1B 060/080/110/160/210/250

Master Model Code

H1B control options

B – hydraulic controls

Code Control type PCOR Note

DH

LH

MH

KH

HE

HF

TH

TA

Hydraulic Proportional

Hydraulic 2-position

PCOR

—

—

—

—

External pressure control supply

Default (w/o control pressure) = Maximum

External pressure control supply

Default (w/o control pressure) = Minimum

External pressure control supply

Default (w/o control pressure) = Maximum

External pressure control supply

Default (w/o control pressure) = Minimum

Default (high pressure below PCOR pressure)

©

Danfoss | April 2022 BC382476944585en-000102 | 11

Page 12

A B C D E F G H J K L M N P

H1 B

A

Q R

Z

A

N N N

Technical Information

ATEX Certified Bent Axis Variable Displacement Motors – H1B 060/080/110/160/210/250

Master Model Code

H1B PCOR and BPD options

C – PCOR and BPD

Code PCOR

BA

CA

DA

KA

MA

HA

HB

HE

HF

MH

KH

1

means option is available

1

BPD Details Use with control:

— — — LH

— — — MH

— — TH

— — KH

— — DH

—

Hydraulic

— — HE

— — HF

Hydraulic

Hydraulic

Internal servo pressure supply

De-energized BPD = PCOR active, port not defined

without pilot pressure difference on XA or XB

TH

TH

DH

KH

12 | © Danfoss | April 2022 BC382476944585en-000102

Page 13

A B C D E F G H J K L M N P

H1 B

A

Q R

Z

A

N

N

N

Technical Information

ATEX Certified Bent Axis Variable Displacement Motors – H1B 060/080/110/160/210/250

Master Model Code

H1B threshold setting, orifice options

D – Threshold setting (Hydraulic adjustment)

Code Pressure Code Pressure

A

B

C

D

E

F

G

H

I

J

K

L

N

2 bar [29 psi] M 14 bar [203 psi]

3 bar [43.5 psi] O 15 bar [217.6 psi]

4 bar [58 psi] P 16 bar [232.1 psi]

5 bar [72.5 psi] Q 17 bar [246.6 psi]

6 bar [87 psi] R 18 bar [261 psi]

7 bar [101.5 psi] S 19 bar [275.6 psi]

8 bar [116 psi] T 20 bar [290 psi]

9 bar [130.5 psi] U 22 bar [319 psi]

10 bar [145 psi] V 24 bar [348 psi]

11 bar [159.5 psi] W 26 bar [377.1 psi]

12 bar [174 psi] X 28 bar [406.1 psi]

13 bar [188.5 psi] Y 30 bar [435 psi]

Non applicable All options (except N) to be used for DH, LH, MH, KH

controls.

E – Orifices (M4 and M5)

Code Diameter

A

B

C

Ø1.2 mm [0.047 in]

Ø0.8 mm [0.031 in]

Ø0.6 mm [0.024 in]

©

Danfoss | April 2022 BC382476944585en-000102 | 13

Page 14

A B C D E F G H J K L M N P

H1 B

A

Q R

Z

A

N

N

N

Technical Information

ATEX Certified Bent Axis Variable Displacement Motors – H1B 060/080/110/160/210/250

Master Model Code

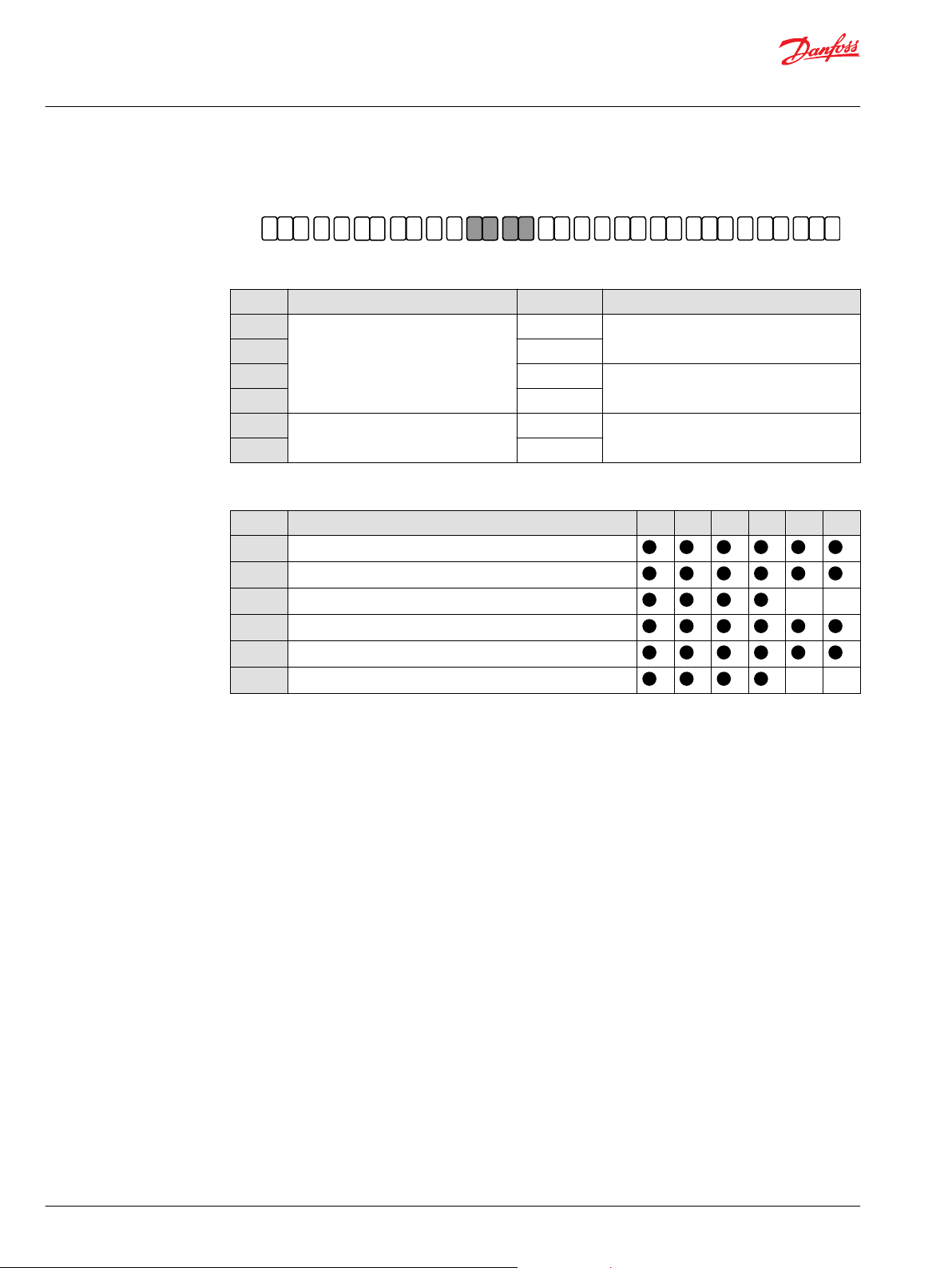

H1B endcap, flange and housing options

F – End-cap (ISO 6162, type 1)

Code Description Port type Compatible controls

PA

PB

RA

RB

TA

TB

Endcap for proportional controls

Endcap for 2-position and PCOR controls

G – Flange and housing

Code Description 060 080 110 160 210 250

VN

DN

CN

VS

DS

CS

SAE flange motor housing (ISO 3019/1), no speed sensor port

DIN flange motor housing (ISO 3019/2), no speed sensor port

Cartridge flange motor housing, no speed sensor port – –

SAE flange motor housing (ISO 3019/1), with speed sensor port

DIN flange motor housing (ISO 3019/2), with speed sensor port

Cartridge flange motor housing, with speed sensor port – –

axial port

side port

axial port

side port

axial port

side port

Use with controls: LH and DH

Use with controls: MH and KH

Use with controls: TA, TH, HE and HF

14 | © Danfoss | April 2022 BC382476944585en-000102

Page 15

A B C D E F G H J K L M N P

H1 B

A

Q R

Z

A

N N N

Technical Information

ATEX Certified Bent Axis Variable Displacement Motors – H1B 060/080/110/160/210/250

Master Model Code

H1B shaft, sensor, loop flushing shuttle system options

H – Shaft options according to speed ring

Code Speed ring Description 060 080 110 160 210 250

AN

AS

BN

BS

CN

CS

DN

DS

EN

ES

FN

FS

GN

GS

HN

HS

JN

JS

KN

KS

LN

LS

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

14 teeth 12/24 pitch

ANSI 92.1 1970 class 5

21 teeth 16/32 pitch

ANSI 92.1 1970 class 5

23 teeth 16/32 pitch

ANSI 92.1 1970 class 5

27 teeth 16/32 pitch

ANSI 92.1 1970 class 5

13 teeth 8/16 pitch

ANSI 92.1 1970 class 5

15 teeth 8/16 pitch

ANSI 92.1 1970 class 5

W30x2x30x14x9g

DIN 5480

W35x2x30x16x9g

DIN 5480

W40x2x30x18x9g

DIN 5480

W45x2x30x21x9g

DIN 5480

W50x2x30x24x9g

DIN 5480

– – – – –

– –

– – – –

– – –

– – – – –

– – – –

– – – –

– – –

– – – –

– – – –

– – – –

J – Sensor

N

P

No speed sensor

Speed sensor ready (plugged)

K – Loop flushing shuttle system

Code Description 060 080 110 160 210 250

A

B

N

©

Danfoss | April 2022 BC382476944585en-000102 | 15

Standard 6.5 bar [94 psi] shift pressure

12.5 bar [181 psi] shift pressure – –

No loop flushing function

Page 16

A B C D E F G H J K L M N P

H1 B

A

Q R

Z

A

N

N

N

Technical Information

ATEX Certified Bent Axis Variable Displacement Motors – H1B 060/080/110/160/210/250

Master Model Code

H1B loop flushing, special hardware options

L – Loop flushing relief valve (non-adjustable)

Code Flow 060 080 110 160 210 250

05

10

15

20

30

40

50

NN

*

Only in conjunction with loop flushing shuttle system B

5 l/min [1.321 US gal/min], 16 bar [232 psi] cracking pressure – – – –

10 l/min [2.642 US gal/min], 16 bar [232 psi] cracking pressure – – –

15 l/min [3.963 US gal/min], 16 bar [232 psi] cracking pressure – – – – –

20 l/min [5.283 US gal/min], 16 bar [232 psi] cracking pressure – – –

30 l/min [7.925 US gal/min], 16 bar [232 psi] cracking pressure – – –

*

40 l/min [10.567 US gal/min], 16 bar [232 psi] cracking pressure – – –

*

50 l/min [13.209 US gal/min], 16 bar [232 psi] cracking pressure – – –

No loop flushing function

M – Special hardware feature

NN Standard hardware for 2-pos. controls

NP

*

Motors build before March 2018 will have the NN in the Model code and will be updated automatically

Standard hardware for proportional controls

*

16 | © Danfoss | April 2022 BC382476944585en-000102

Page 17

A B C D E F G H J K L M N P

H1 B

A

Q R

Z

A

N

N

N

Technical Information

ATEX Certified Bent Axis Variable Displacement Motors – H1B 060/080/110/160/210/250

Master Model Code

H1B minimum and maximum displacement options

N – Minimum displacement

Code Description Compatible frame

000 or 012 to 040 cm3/rev minimum displacement setting 60cc

000 or 016 to 054 cm3/rev minimum displacement setting 80cc

XXX

MB0 Plug (replaces minimum displacement limiter screw for 0° motors) All

P – Maximum displacement (non adjustable)

Code Displacement Use with controls: 060 080 110 160 210 250

N

A

B

C

E

Z

Q

R

S

T

U

V

000 or 022 to 074 cm3/rev minimum displacement setting 110cc

000 or 032 to 108 cm3/rev minimum displacement setting 160cc

000 or 042 to 142 cm3/rev minimum displacement setting 210cc

000 or 050 to 169 cm3/rev minimum displacement setting 250cc

100 % max. LH, MH, KH and DH

95 % max.

90 % max. – – –

85 % max. – – –

75 % max. – – –

100 % max.

95 % max. displacement

90 % max.

85 % max.

80 % max.

75 % max. –

65 % max.

LH and DH

TH and TA

TH and TA

TH and TA

TH and TA

– – – – –

size

– – –

©

Danfoss | April 2022 BC382476944585en-000102 | 17

Page 18

A B C D E F G H J K L M N P

H1 B

A

Q R

Z

A

N

N

N

Technical Information

ATEX Certified Bent Axis Variable Displacement Motors – H1B 060/080/110/160/210/250

Master Model Code

H1B PCOR pressure, paint and nametag options

Q – PCOR pressure setting

Code Pressure setting Code Pressure setting

00

16

17

18

19

20

21

22

For all controls without PCOR function 23 230 bar [3336 psi]

160 bar [2321 psi] 24 240 bar [3481 psi] – Standard setting

170 bar [2466 psi] 25 250 bar [3626 psi]

180 bar [2611 psi] 26 260 bar [3771 psi]

190 bar [2756 psi] 27 270 bar [3916 psi]

200 bar [2901 psi] 28 280 bar [4061 psi]

210 bar [3046 psi] 29 290 bar [4206 psi]

220 bar [3191 psi] 30 300 bar [4351 psi]

R – Paint and nametag

NNA

NNB

NNC

Factory setting (black paint, ATEX T3 tag, format A w/o filter)

Factory setting (black paint, ATEX T4 tag, format A w/o filter)

Factory setting (black paint, ATEX T5 tag, format A w/o filter)

18 | © Danfoss | April 2022 BC382476944585en-000102

Page 19

W

Technical Information

ATEX Certified Bent Axis Variable Displacement Motors – H1B 060/080/110/160/210/250

Technical Specifications

ATEX technical specifications

The technical specifications in this chapter are supplemental for ATEX systems only. For comprehensive

technical specifications, including maximum pressure rating, maximum flow, etc. please refer to the

standard H1B Technical Information document.

Danfoss does not claim responsibility for the use of the motors in operating conditions not allowed

according to the information shown in this document and the standard H1B Technical Information

document.

Painting or coating can be an electric insulator if a thickness greater than 200 um is applied. The

thickness of the paining of original DPS paint is less than 200 um.

Ambient temperature

Maximum ambient temperature depends on the requested ATEX class needed.

In general the ambient temperature should lie between -40° C [-40° F] and +70° C [158 °F] to ensure that

the shaft seal retains its sealing capacity.

Oil types / Operating fluids

In a hydraulic system the most important task of the oil is to transfer energy. At the same time the oil

must lubricate moving parts in hydraulic components, protect them from corrosion, and transport dirt

particles and heat out of the system. To ensure that hydraulic components operate without problems

and have long operating life it is therefore vital to select the correct oil type with the necessary additives.

Ratings and performance data are based on operating with hydraulic fluids containing oxidation, rust

and foam inhibitors. These fluids must possess good thermal and hydrolytic stability to prevent wear,

erosion and corrosion of motors components.

Warning

It is compulsory to use oils whose inflammable degree is at least 50K above the maximum surface

temperature of the pump. Maximum surface temperature for Group IIG and IID can be found under

Viscosity and temperature for H1B motors on page 9.

Oil temperature

Maximum oil temperature depends on the requested ATEX class needed (in this case T3)..

Under normal operating conditions it is recommended to keep the temperature in the range of 60 °C

[140 °F] to 85 °C [185 °F].

Viscosity

Maintain fluid viscosity within the recommended range for maximum efficiency and bearing life.

Minimum viscosity should only occur during brief occasions of maximum ambient temperature and

severe duty cycle operation. Maximum viscosity should only occur at cold start. Limit speeds until the

system warms up.

Fluid viscosity limits

Conditions mm2/s (cSt) SUS

Minimum 5 42

Continuous 7 49

Maximum 1600 7416

We recommend the use of an oil type having a viscosity of 12 - 80mm2/s [66 - 371 SUS] at the actual

operating temperature.

©

Danfoss | April 2022 BC382476944585en-000102 | 19

Page 20

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 2080 6201

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Cartridge valves

•

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Gear motors

•

Gear pumps

•

Hydraulic integrated

•

circuits (HICs)

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | April 2022 BC382476944585en-000102

Loading...

Loading...