Page 1

Fact sheet

Q

AB-QM f low checker DN 40-250 and AB-QM 4.0 DN 15-20

Verifying the flow on AB-QM valves

Flow verif ication

in an installation

Fig. 1

To verify that an installation functions according

to the design specif ications checking only the

most critical valve in the installation is needed

(see f igure 1).

The AB-QM maintains a constant differential

pressure over the valve and any excess pressure

will automatically be throttled. If there is not

enough differential pressure the valve cannot

reach the set f low.

The valve that is furthest away from the pump or

the valve in the circuit with the highest resistance

has the lowest available differential pressure, so

if this critical valve has enough pressure it means

the other valves will also function properly.

Important:

To get a useful measurement the installation

should run on full load, so all actuators in

the installation should be opened fully. This

ensures that you are measuring under the most

unfavorable circumstances. The AB-QM’s will

have more differential pressure available when

the installation is working on partial load.

To get useful measurement the commisioning

zone should run on full load, so all actuators in

the installation should be opened fully. Please

check if coincidence factor was taken into

consideration.

Method of verif ication

AB-QM DN40-250

Method of measurement

AB-QM DN40-250

AB-QM 4.0 DN15-20

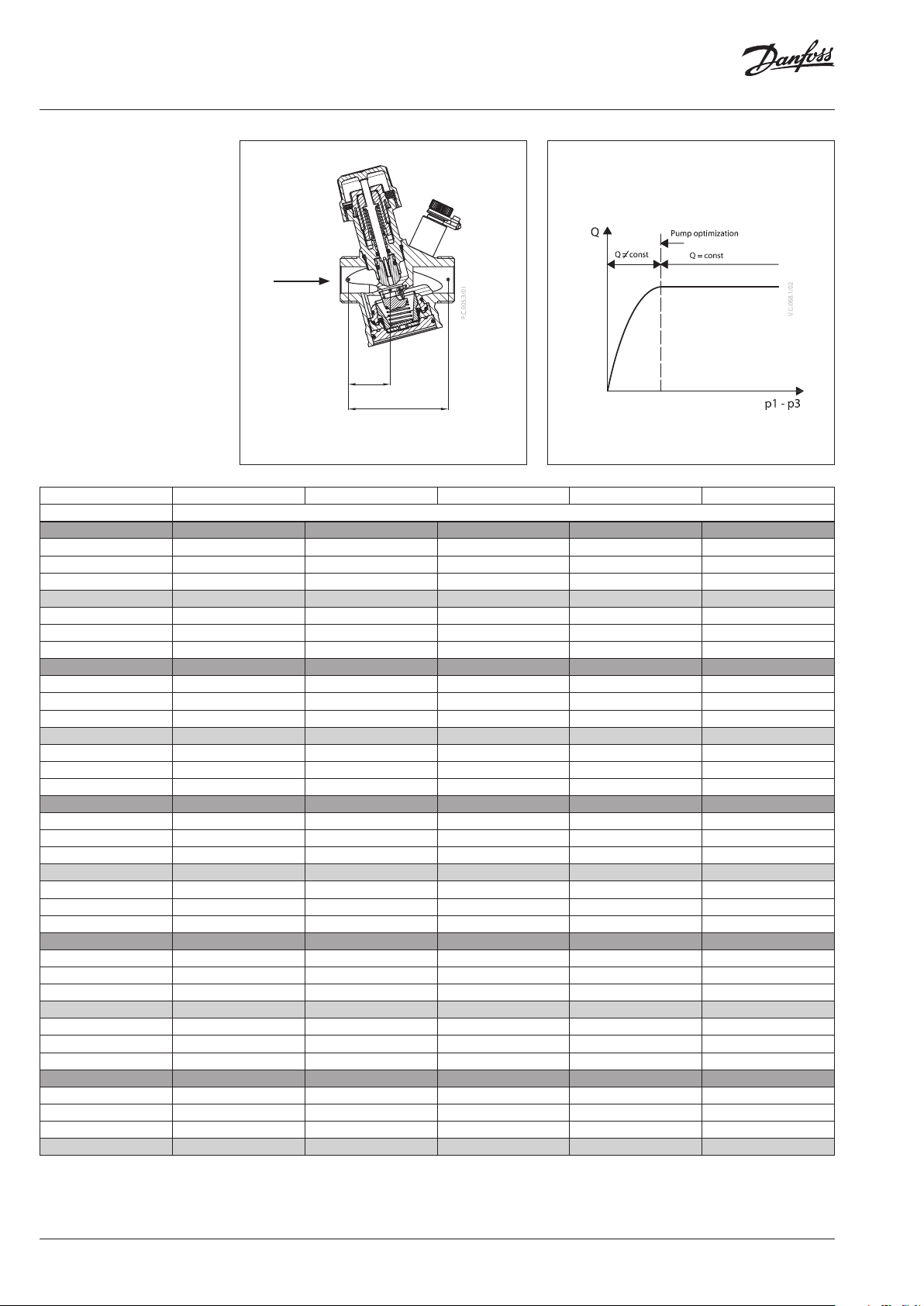

Measure the differential pressure across the

whole valve.

The test plugs are placed in such a way that

differential pressure p1−p3 (Δp) over the valve is

measured (see f igure 2).

If the measured value is below 30 kPa then there

is not enough differential pressure available for

the AB-QM to function properly. If the measured

value is above 30 kPa then the AB-QM has

enough differential pressure available and the

f low is according to the setting (see f igure 3).

Measure the differential pressure across the

control valve.

The test plugs are placed in such a way that

p1−p2 is measured (see f igure 2).

Therefore the measured differential pressure

can be used to calculate the f low directly. It’s

necessary to use the table that was derived from

statistical measurements

Since the measurements across the measuring

points are inf luenced by the dynamic pressure,

turbulences, f low patterns, internal tolerances,

setting accuracy and accuracy of the measuring

Setting the f low

DN 40-100: 1 turn=10 %

DN 125-250: 1 turn=5.0 %

Note: for more infor mation about setting p rocedure please refer

to instructio ns

equipment we believe that the total accuracy of

the measurement is lower than performance of

the valve.

Therefore we recommend not to adjust the

setting when the results are within 10 % of the

expected f low.

Calculating the f low

ΔpCv = p1−p2

pkv

CvCv

For kvCv values see tables in figure 4 and 7

© Danfoss | 2022.01 AM322356127863en-000102 | 1

Page 2

Fact sheet AB-QM f low checker DN 40-250 and AB-QM 4.0 DN15-20

AB-QM 4.0 DN 15-20

Flow

direction

p1−p2

Δp=p1−p3

∆p

min

DN 15-20

Fig. 2

Presetting

s (%)

10 0 .0 411 0.145 0.2588 0.18 0 0.4152

12. 5 0.0531 0 .180 0.34 0.240 0.5346

15 0.0 659 0.215 0.4085 0.300 0.6472

17. 5 0.0779 0.250 0.4754 0.360 0.7515

20 0.0890 0.285 0 .5426 0.420 0. 8558

22.5 0.1000 0.320 0.6095 0.490 0.9602

25 0. 1111 0.355 0 .6767 0.560 1.0645

27. 5 0.1221 0.390 0.7502 0.630 1.168 8

30 0.13 32 0.425 0.8237 0.70 0 1. 2815

32.5 0 .1442 0.460 0.8969 0.770 1. 3951

35 0.1570 0.495 0.9705 0.840 1.5023

37. 5 0 .1686 0.530 1.0407 0 .910 1.59 81

40 0.1796 0. 574 1.1076 0.980 1. 6939

42.5 0.1907 0 .618 1.174 8 1.050 1.7896

45 0.2018 0.662 1.2416 1.120 1.8854

47. 5 0 .2129 0.706 1.3165 1.19 0 1.98 12

50 0.2245 0.750 1. 3887 1.260 2.0770

52.5 0.2360 0.798 1.4579 1. 330 2.1728

55 0.2476 0 .847 1. 5274 1.400 2.2247

57. 5 0. 2592 0.895 1.59 66 1.470 2.2582

60 0.2707 0.943 1.6 657 1. 540 2. 2916

62.5 0.2823 0.992 1.7 342 1. 610 2 .3251

65 0.2939 1.04 0 1.79 1.665 2.3587

67. 5 0.3054 1.08 8 1.846 1. 720 2.3972

70 0. 3172 1.135 1.902 1.775 2.4356

72.5 0.3293 1.183 1.958 1.8 29 2. 4741

75 0. 3414 1.230 2 .0139 1.884 2 .5126

77. 5 0. 3535 1.278 2.0835 1.939 2 .5619

80 0.3655 1.325 2 .1364 1.99 6 2.6122

82.5 0.3765 1.373 2 .1756 2.054 2.6626

85 0.3876 1.420 2.217 2 2. 111 2.7245

87. 5 0.3986 1. 455 2.2722 2 .169 2.7897

90 0.4097 1. 490 2.3343 2 .2 11 3.1346

92.5 0.4226 1. 525 2.398 2.249 3.4703

95 0.4367 1.560 2.4778 2.288 3.554 4

97. 5 0.4509 1. 595 2. 5298 2.326 3.6422

100 0.4650 1.6 30 2.6 2.365 3.7300

Fig. 4 The f low is according to set ting if the calculated f low is in the range of ±10 % of the set flow.

DN 15 LF DN 15 NF DN 15 HF DN 20 NF DN 20 HF

kv

Cv

Fig. 3

(m3/h)

2 | AM322356127863en-000102 © Danfoss | 2022.01

Page 3

Fact sheet AB-QM f low checker DN 40-250 and AB-QM 4.0 DN15-20

AB-QM DN 40-100

Δp=p1−p3

p1−p2

Flow

direction

∆p

min

DN 40-100

Fig. 4

Presetting DN 40 DN 50 / DN 50H F DN 65 / DN 65HF DN 80 / DN 80HF DN 100 / DN 100HF

s (%) kvCv (m3/h)

20.0 3.40 4.60 4. 20 15. 50 19. 50

22.5 4.08 5.55 5.48 17.1 9 21.94

25.0 4.80 6. 50 6.75 18.88 24.38

27. 5 5.43 7. 45 8.03 20.56 26. 81

30.0 6.10 8.40 9.30 22.25 29.25

32.5 6 .78 9.35 10.58 23.94 31.69

35.0 7. 50 10. 30 11. 85 25.63 34.13

37. 5 8.13 11. 25 13 .13 2 7.31 36.56

40.0 8.80 12.2 0 14 .40 29.00 39.00

42.5 9.48 13.15 15.68 30.69 41.4 4

45.0 10.20 14 .10 16.95 32.38 43.88

47. 5 10. 83 15.05 18.23 34.06 46.31

50.0 11. 50 16.00 19. 50 35.75 48.75

52.5 12.18 16 .95 20.78 37. 44 51.19

55.0 12 .90 17.90 22.05 3 9.13 53.63

57. 5 13 .53 18 .85 23.33 40.81 56.06

60.0 14 .20 19.80 24.60 42. 50 58.50

62.5 14. 88 20.75 25.88 4 4.19 60.94

65.0 15. 55 21.70 27.15 45.88 63.38

67. 5 16.26 22.65 28.43 47. 56 65. 81

70.0 16.90 23.60 29.70 49.2 5 68.25

72.5 17. 58 24.55 30.98 50.94 71.81

75.0 18.25 25.50 32.25 52.63 75.38

77. 5 18 .93 26.45 33.53 54.31 78 .94

80.0 19.6 0 27. 40 34.80 56.00 82.50

82.5 20.28 28.35 36.08 57. 69 86.06

85.0 20.95 29.30 3 7.35 59. 38 89. 63

87. 5 21. 63 30.25 38.63 61. 06 9 3.19

90.0 22.30 31. 20 39.90 62.75 96.75

92.5 22.98 32.15 41.18 64.44 100 .31

95.0 23.65 33.10 42.45 66 .13 103. 88

97. 5 24. 33 34.05 43.73 6 7.81 107. 44

100.0 25.00 35.00 45.00 69.50 111. 00

Fig. 5 The f low is according to set ting if the calculated f low is in the range of ±10 % of the set flow.

Fig. 5

AM322356127863en-000102 | 3© Danfoss | 2022.01

Page 4

Fact sheet AB-QM f low checker DN 40-250 and AB-QM 4.0 DN15-20

AB-QM DN 125-250

Flow

direction

Fig. 6 Fig. 7

Presetting DN 125 / DN 125HF DN 150 / DN 150HF DN 200 / DN 200H F DN 250 / DN 250 HF

s (%) kvCv (m3/h)

20.0 40 53 57 86

22.5 45 60 66 99

25.0 49 67 75 112

27. 5 53 74 85 125

30.0 57 81 94 13 8

32.5 61 88 10 4 150

35.0 65 95 113 163

37. 5 69 101 122 176

40.0 73 108 132 189

42.5 77 115 141 202

45.0 82 12 2 151 215

47. 5 86 12 9 160 227

50.0 90 13 6 17 0 240

52.5 94 143 179 253

55.0 98 15 0 188 266

57. 5 102 157 198 279

60.0 106 163 207 292

62.5 110 170 217 304

65.0 114 17 7 226 317

67. 5 119 184 235 330

70.0 123 191 245 343

72.5 127 198 254 356

75.0 131 205 264 369

77. 5 135 212 273 381

80.0 139 219 283 394

82.5 143 225 292 407

85.0 147 232 301 420

87. 5 152 239 311 433

90.0 156 246 320 446

92.5 160 253 330 458

95.0 164 260 339 471

97. 5 168 267 348 484

100.0 172 274 358 497

102. 5 176 281 367 510

105.0 180 287 377 523

107.5 184 294 386 535

110 .0 189 3 01 396 548

Fig. 7 The f low is according to set ting if the calculated f low is in the range of ±10 % of the set flow.

Δp=p1−p3

p1−p2

DN 125-250

∆p

min

© Danfoss | DCS-SGDPT/SI | 2022.014 | AM322356127863en-000102

Loading...

Loading...