Page 1

MAKING MODERN LIVING POSSIBLE

20%

Save $280

H118L-E Heat pump Evaporator

For increased heat pump business

Innovative | Optimised | Low hold-up volume | High heat transfer | Compact | Rapid delivery

Per heat exchanger

On refrigerant because

of the H118L-E’s low

hold-up volume.

Reduction in refrigerant

Charge compared with a

traditional BPHE. This new

evaporator is the ideal solution

to help you meet the world’s

climate and energy aspirations.

www.danfoss.com

Page 2

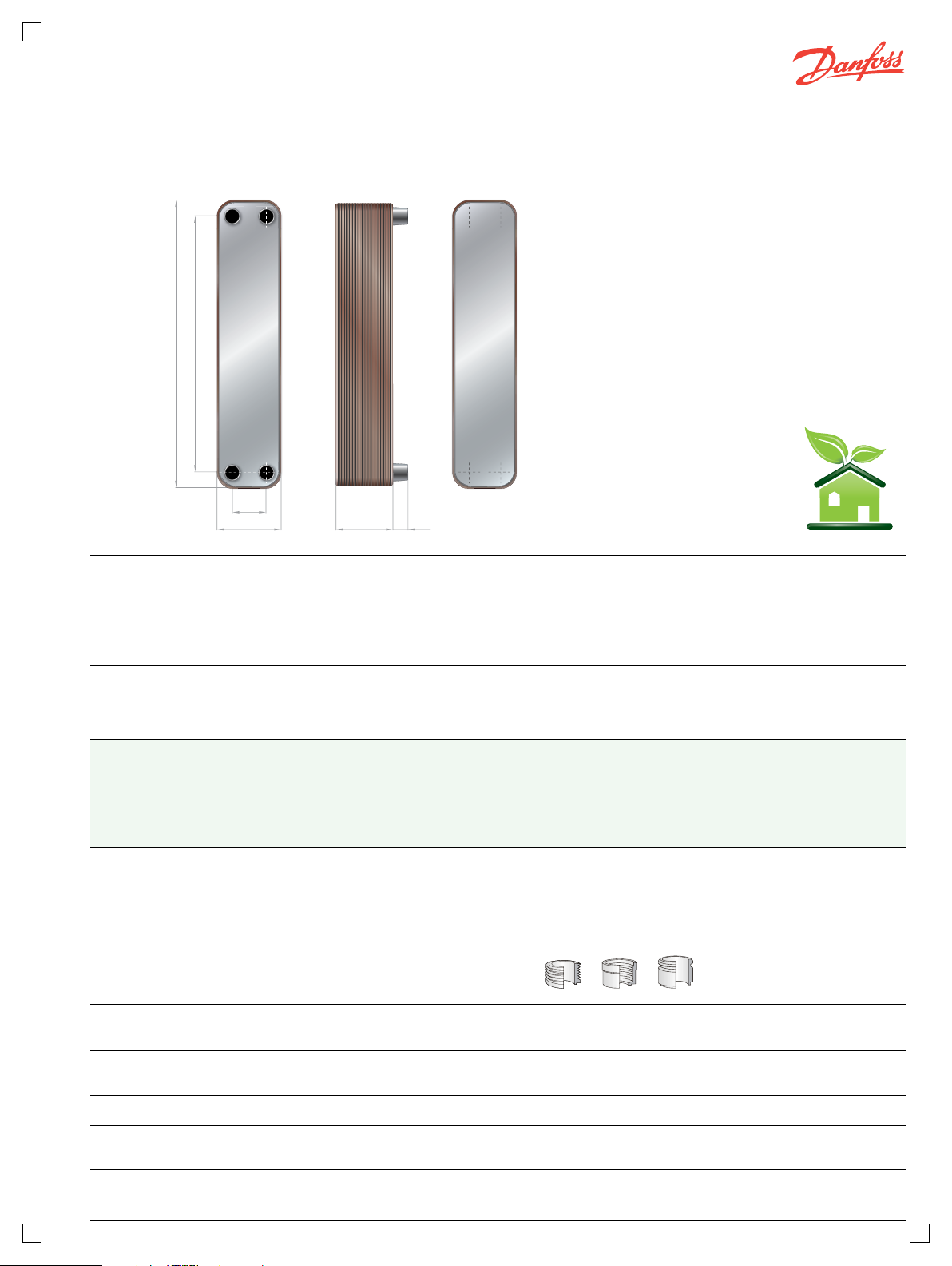

H118L- E

613/ 24.1”

519/20.4”

Q4 Q1

Q4 Q1

Q3 Q2

Q3 Q2

H1 H4

H1 H4

H2 H3

H2 H3

INTRODUCTION

KEY FEATURES

TECHNICAL DATA

n = NUMBER O F PLATES

STANDARD

MATERIALS

STANDARD

CONNECTIONS

98/3.9”

18 6/ 7.3”

15. 5+1.74 x n

0.61+0.07 x n 29/4 8/1.1”/1.9”

Evaporator optimised for R410A in high-eciency commercial ground source heat pumps with capacities between 20-120 kW

(68-409 kBTU/hr). The heat exchanger features innovative Micro Plate technology that improves heat transfer and reduces the amount

of material used.

To meet demands for higher COPs in heat pumps, the H118L-E is designed to work eciently with close temperature approaches,

while a low pressure drop on the brine side reduces the pump power and keeps the overall COP high.

The low hold-up volume reduces the refrigerant charge and offers valuable savings.

• Minimal hold-up volume: Less refrigerant charge

• Reduced pressure drop: For a more ecient heat pump

• Smaller footprint: Enabling more compact heat pumps

• Reduced CO

footprint: Environmentally friendly with high heat transfer and minimal refrigerant charge.

2

Min. working temperature: -196 °C (-320 °F)

Max. working temperature: 200 °C (390 °F)

Max. working pressure: 45 bar (650 psi)

Hold-up volume (l): Q1-Q2/ Q3-Q4: 0.151×n/2 / 0.151×(n-2)/2

(ft3): Q1-Q2/ Q3-Q4: 0.005×n/2 / 0.005×(n-2)/2

Weight: 7.94 kg+0.26 × n (17.53lb+0.57 × n)

Cover plates: AISI 304

Connections: AISI 304

Plates: AISI 316

Brazing filler: Pure copper

Other material combinations can be provided upon request. Please contact your Danfoss sales representative for more information.

Standard connections as per below are optimised for this product as condenser in heat pump system. For other connections, please contact

your Danfoss representative.

Q3 (Refrigerant inlet): soldering 5/8”, 7/8” or 1 1/8”

Q4 (Refrigerant outlet): soldering 1 3/8”, 1 5/8“ or 2 1/8”

Q1-Q2 (Brine side): External threaded 1 1/2”, 2” or Victaulic 2”

THIRD- PARTY

APPROVALS

ACCESSORIES

– STUD BOLTS

ACCESSIBILITY

CORRESPONDING

CONDENSERS

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reser ves the right to alter its products without notice. This also applies to

products already on order provided that su ch alterations can be made without conse quent changes being ne cessary in specific ations already agreed.

All trademarks in this material are the property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A /S. All rights reser ved.

520H623 6 DKQB.PD.300.M2.22

Europe: Pressure Equipment Directive (PED). America: Underwriters Laboratory Inc (UL). The third-party approvals stated are standard for all our

products. For details of other existing approvals or to discuss how we can meet your local needs, please contact your Danfoss representative.

Stud bolts on front and/or back plates for mounting suppor t are available upon request. Please contact your Danfoss sales

representative for more information.

We will help you set up a logistics solution that will meet your needs.

A corresponding Micro Plate heat exchanger for condenser duties (H118L-C) is also available, fully tested and ready for heat pump

applications.

produced by M almøresund, ww w.malmoresund.se, p hoto by Lars Owesson, w ww.owesson.s e, March 2012

Loading...

Loading...