Page 1

Danfoss District Heating

Page 1 of 9

Guideline of Water Quality for copper brazed Plate Heat Exchangers

0 Summary

Danfoss District Heating has prepared this guideline for the water quality of tap water and

district heating water used in plate heat exchangers of stainless steel (1.4404, X2CrNiMo17-12-2

acc. to EN 10088-2:2005 ~ AISI 316L) brazed with pure copper.

The water flowing in these brazed plate heat exchangers (PHEX) varies a lot from application to

application and corrosion can become a problem in some situations. This guideline is based on a

comprehensive literature survey and on our experiences from many years using copper brazed

stainless steel PHEX.

It is important to point out that this water specification is not a guarantee against corrosion, but

must be considered as a tool to avoid the most critical water applications. A summary of the

parameters and their recommended limits are listed in table 2 for water on the secondary side

(tap water, drinking water) and table 3 for primary water (heat supply, district heating water).

These limits are only valid for PHEX made of stainless steel 1.4404 brazed with pure copper.

1 Introduction

Danfoss District Heating has prepared this guideline for the water quality of tap water and

district heating water used in heat exchangers of stainless steel (1.4404, X2CrNiMo17-12-2 acc.

to EN 10088-2:2005 ~ AISI 316L) brazed with pure copper. Normally, tap water (drinking water)

flows in the secondary side and a heating media (e.g. district heating water) flows in the primary

side of the heat exchanger.

Surfaces in contact with water can be subject to two problems, scale formation and corrosion.

Gases and salts being dissolved in the water play the major role; besides that, component design

(e.g. design, materials used, fabrication processes) and operating conditions (e.g. temperature,

flow conditions, times of stagnation) influence the risk for scaling and/or corrosion.

Furthermore it must be kept in mind that the reaction rate of chemical reactions, e.g. the

corrosion rate, increases with increasing temperature. According to van’t Hoff’s rule, the increase

is in the order of factor 2 to 3, for every 10 °C of temperature increase.

Knowing the chemical water composition and the operating conditions of a heating system, the

risk for scaling and corrosion can be evaluated. Based on that, recommendations in order to

avoid scaling and/or corrosion problems in components can be given. This is the intention of

this water specification.

Page 2

Danfoss District Heating

Page 2 of 9

1.1 Scale formation

Raw water used for the production of drinking water (tap water) contains more or less high

amounts of dissolved gases and salts depending of the geological properties of the extraction

area. These differences cause a different composition also in the finally produced drinking water.

For the formation of scale, especially carbonate hardness (= content of hydrogen carbonate) and

total hardness, i.e. sum of calcium- and magnesium ions, are determinant; besides that, other

ions like e.g. sulphate can have an influence.

From the compounds mentioned above, lime scale (boiler scale, calcium carbonate, CaCO3) can

be formed under increasing temperatures and/or loss of carbon dioxide, e.g. by degassing).

Further temperature increase might lead to deposition of different salts, e.g. gypsum (CaSO4).

Other compounds being able to cause blocking of components are iron containing deposits like

„rust“, i.e. iron oxides and –hydroxides, or magnetite. These can be built in the PHEX itself, but

can also be flushed in from other parts of the entire system, being formed due to corrosion

processes elsewhere in the system.

1.2 Corrosion

Corrosion can be caused by different mechanisms resulting in many types of corrosion. Some of

these can take place in a PHEX during service. Most of the corrosion mechanisms are caused

chemically, whereas the chemical composition of the water influences the different materials

differently.

Besides of the factors mentioned above (material, operating conditions…), oxygen content plays

a major role in corrosion of metals. Furthermore, pH-value (acid concentration), acid capacity

(buffering capacity), salt content, are important parameters for corrosion to occur. Insofar,

knowledge of these is crucial for the evaluation of possible corrosion risks.

A detailed explanation of the different types of corrosion would go beyond the scope of this

report; however, an overview of the most typical corrosion types is given in the following table 1.

Page 3

Danfoss District Heating

Page 3 of 9

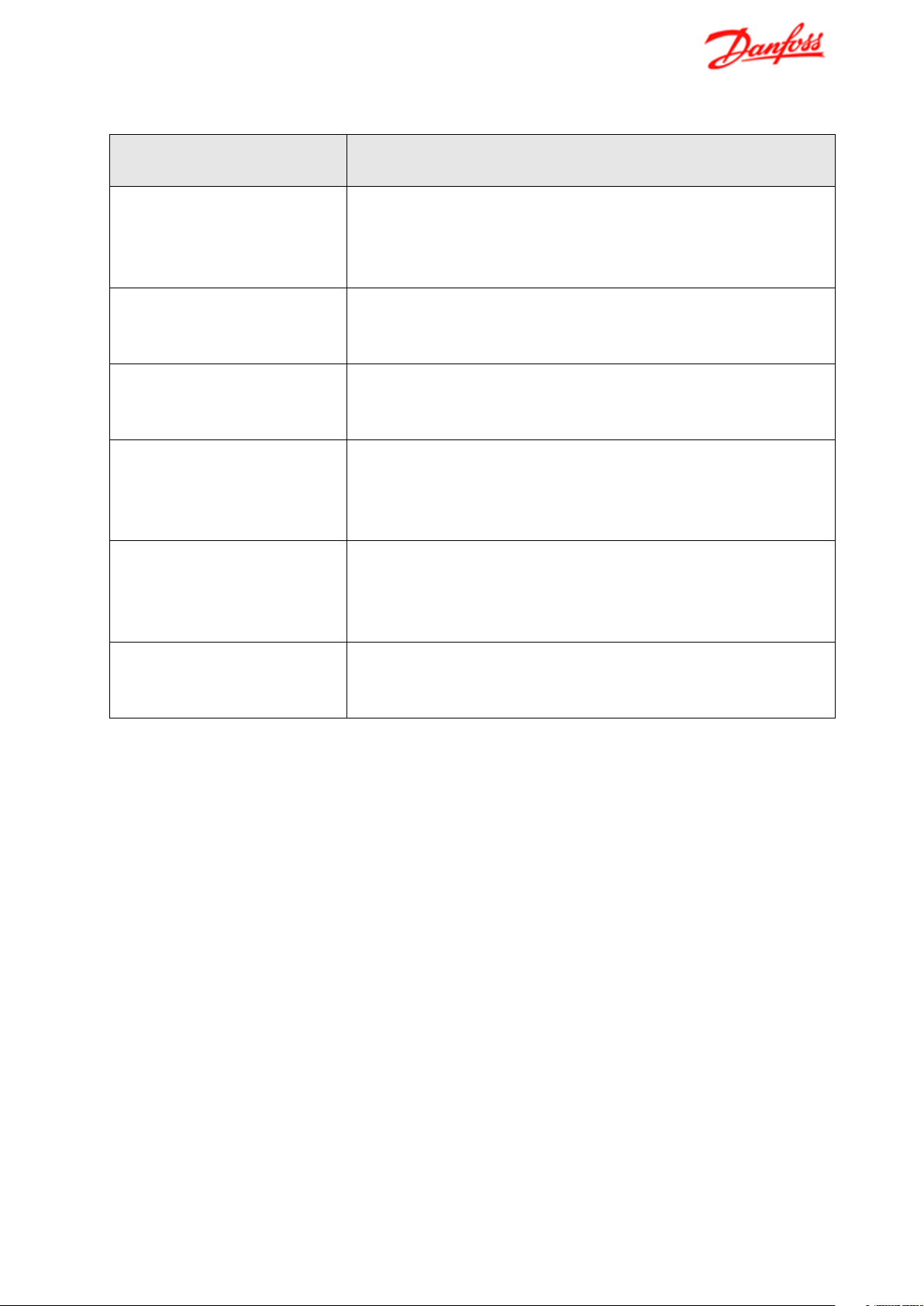

Table 1 Typical corrosion types in copper brazed stainless steel plate heat exchangers

Corrosion type

Description

General corrosion

If general corrosion takes place in a PHEX it is typical copper

possibly leaks in the heat exchanger.

Crevice corrosion

Normally the heat exchanger is free of crevices, but crevices

deposits as well as imperfect brazing joints.

Galvanic corrosion

Metallic contact between copper and stainless steel in water of

high electrical conductivity can initiate a corrosive attack of the

more electronegative metal, in this case copper.

Stress corrosion cracking

Stress corrosion cracking (SCC) can occur in stainless steel if

SCC; it will often take place at temperatures above 60 °C.

Intergranular corrosion

Stainless steel can experience intergranular corrosion due to

Liquid metal embrittlement

If the brazing process takes place at too high brazing

decrease the strength of the stainless steel plates.

that will corrode and not stainless steel. If the copper brazing

corrodes it will result in loss of mechanical strength and

can be formed under deposits from scaling and other kinds of

tensile stresses and a high amount of chloride are present. An

increase in temperature will furthermore increase the risk of

[12]

[14]

formation of chromium carbide in the grain boundaries during

improper heat treatment. Areas with decreased chromium

content will become sensible towards corrosion.

temperatures, copper can diffuse into stainless steel and

Page 4

Danfoss District Heating

Page 4 of 9

2 Water specifications

2.1 Secondary side – Tap water

Parameters of normal tap water determining the overall corrosion stability of a PHEX are:

Temperature, pH, carbonate hardness (alkalinity), total hardness as well as chloride, sulphate and

nitrate concentration; conductivity is often used as sum parameter for the total ion (salt) content.

Since copper in general has lower corrosion stability than stainless steel 1.4404 in tap water, these

water specifications are mainly determined by copper corrosion. In general, corrosion of stainless

steel only occurs in tap waters containing high chloride concentrations at high temperature.

A description of the most important water parameters and their specifications are stated in the

following.

• Temperature: In general, an increase in temperature will increase the corrosion rate of most

metals. For copper in heated water, the likelihood of pitting is higher at temperatures above 60°C.

Also the risk of stress corrosion cracking of stainless steel will increase at temperatures above

60°C, and pitting and crevice corrosion in stainless steel is also temperature dependent (see the

section about chloride).

[1, 2, 14]

• pH: General corrosion of copper mainly depends on pH and the risk of corrosion is lowest if pH

is kept above 7.5 and below 9.0.

[1, 10, 12]

However, one must expect a pH around 7 in normal tap

water, but it is recommendable to avoid water with a pH below 7. Water of district heating

systems will often be alkaline up to pH 10.

• Alkalinity: If the content of hydrogen carbonate (HCO

[4, 5, 6, 8]

-

) in the water is very low, i.e. below 60

3

mg/l, corrosion products of copper may dissolve and be released into the system. It is also

-

recommendable not to exceed a HCO

concentration of 300 mg/l.

3

• Conductivity: A high conductivity in the tap water means that the water has a high concentration

[1, 10, 12]

of ionic substances. In general, an increase in conductivity of tap water will increase the corrosion

rate of most metals. A maximum conductivity of 500 µS/cm is in general a desirable value.

[9, 12]

2+

, Mg2+] / [HCO

• Hardness: Copper is susceptible to corrosion in soft water; the [Ca

(calculated in molar amounts) must therefore be greater than 0.5.

• Chloride: Presence of chloride in the drinking water will increase the risk of localized corrosion

of stainless steel. The limit value will depend on temperature according to tables 2 and 3.

• Sulphate: High concentrations of sulphate will increase the risk of pitting in copper. A maximum

[13]

-

] ratio

3

[14, 15]

sulphate concentration of 100 mg/l is recommendable, but corrosion can also take place at lower

concentrations if the [HCO

-

] / [SO

3

2-

] (calculated in molar amounts) ratio is below 1.

4

[1, 10]

• Nitrate: Nitrate ions have an influence similar to that of sulphate, and a maximum nitrate

concentration of 100 mg/l is recommendable.

• Chlorine: In many tap water installations, addition of chlorine is added for bacteriological

reasons. Chlorine is highly oxidizing and lowers the corrosion resistance of stainless steel.

Investigations of the stainless steel supplier Outukumpu Oyj have proven that the concentration

of free active chlorine should be kept below 0.5 mg/l in order to avoid corrosion of stainless steel

1.4404.

[10, 13]

[15]

Page 5

Danfoss District Heating

Page 5 of 9

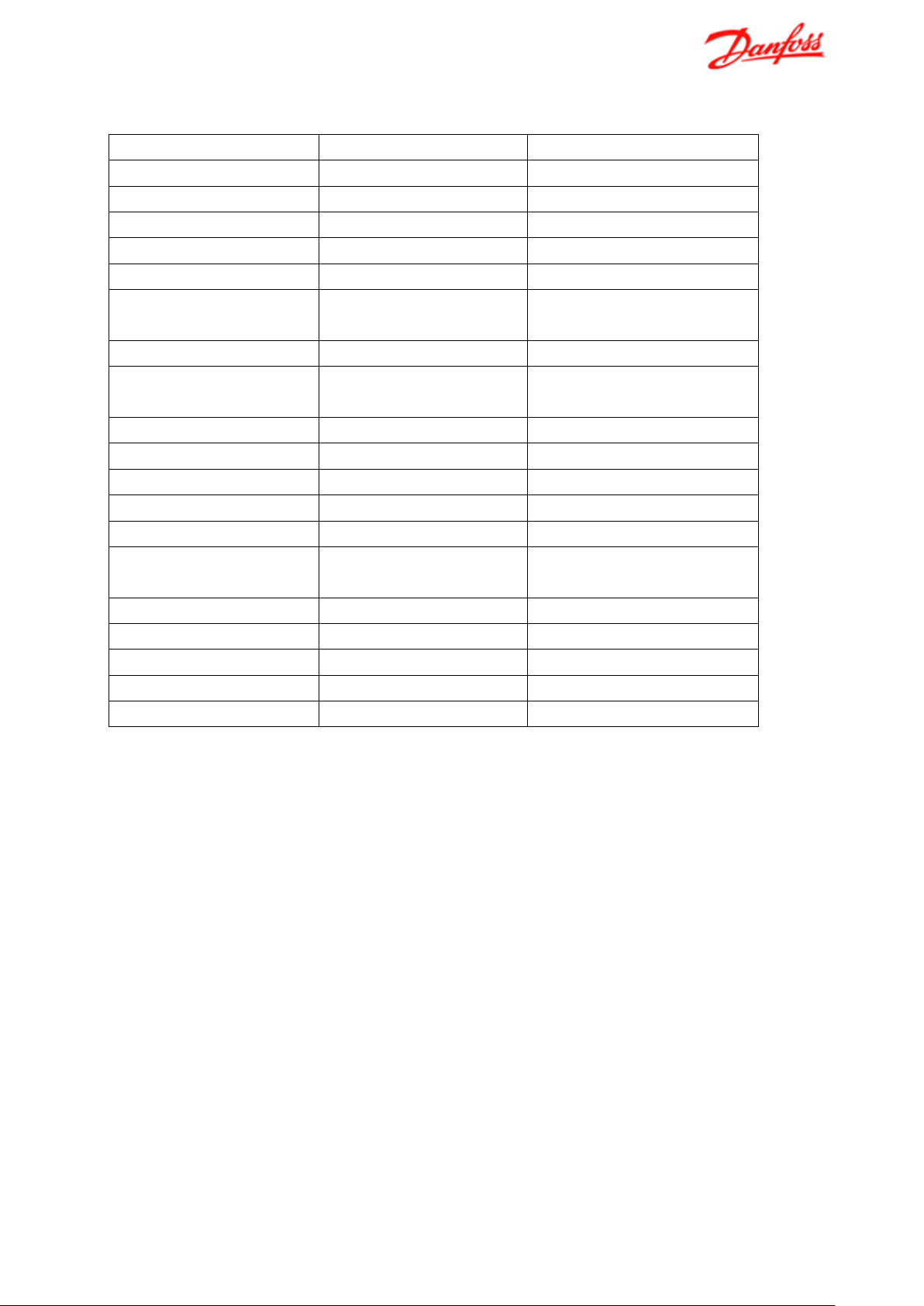

The following table shows summarized the specifications being recommended for copper brazed

Parameter

Remarks

Value

Appearance

clear

Smell

no smell

Content of impurities

free of sediments/particles

Oil and grease

< 1 mg/L

pH

between 7 and 10

El. conductivity

2500 μS/cm

Carbonate hardness *)

1 mmol/L < Ks

< 5 mmol/L **)

Total hardness ***)

[Ca2+, Mg2+]/[HCO

] > 0.5

Chloride

at T ≤ 20 °C

1000 mg/l

at T ≤ 50 °C

400 mg/L

at T ≤ 80 °C

200 mg/L

at T > 100 °C

100 mg/L

Sulphate

[SO

] < 100 mg/L and

[HCO

]/[ SO

] > 1.5

Nitrate

< 100 mg/L

Nitrite

not allowed

Ammonium

< 2.0 mg/L

Free chlorine

< 0.5 mg/L

Total iron

< 0.2 mg/L

Manganese

< 0.05 mg/L

plate heat exchangers of stainless steel for the secondary side, i.e. drinking water side.

Table 2 Recommended water quality limits for water on secondary side of PHEX

4.3

-

3

2-

4

-

3

2-

4

*) = hydrogen carbonate content, temporary hardness, (carbonate) alkalinity

**) Ks

= acid capacity

4.3

***) = sum of calcium and magnesium ions

Page 6

Danfoss District Heating

Page 6 of 9

2.2 Primary side – District heating water

Water specifications for district heating water are given in several national guidelines being

evaluated for this specification

[4, 5, 6, 7, 8]

. All these guidelines deal with aspects of corrosion and

scale prevention in district heating systems.

The limits stated in the following table 3 are a reasonable compromise to avoid corrosion and

scaling on the primary side of the plate heat exchanger; they are widely identical with those for

tap water used on the secondary side.

The most important parameters influencing corrosion resistance of stainless steel in district

heating water are chloride, temperature and oxygen content. The acceptable chloride level will

depend on the maximum temperature which the PHEX is exposed to.

The most important parameters to limit the corrosion risk of copper is providing a virtually

oxygen free (below 0.1 mg/L) and alkaline environment (below pH 10) and keeping contents of

ammonia and sulphide below minimum limits (see table 3).

In district heating water, often softened or desalinated water conditioned to a pH around 9-9.5 is

used; oxygen content is either removed or chemically bonded. Special concerns should be made

about some of the chemicals which are used for pH-conditioning and/or as oxygen binders.

The use of ammonia for pH conditioning should be avoided due to the risk of copper (and brass)

corrosion. Instead, use sodium hydroxide (NaOH) or tri sodium phosphate (Na3PO4) to increase

the pH of the water.

Sodium sulphite (Na2SO3) has been widely used as an oxygen binder, but should be avoided in

systems containing copper and stainless steel. Due to the oxygen binding process, sulphite is

transformed to sulphate. Sulphate can be used by some bacteria which reduce sulphate to

sulphide, thus creating a corrosive environment towards copper and stainless steel. Instead,

organic oxygen binders such as tannins should be used.

Generally, increased concentrations of sulphide in the water could indicate bacterial

contamination in the district heating water system. Therefore it is recommended to keep a

minimum of sulphide in the water.

Other oxygen binders are sometimes added to the water. Some examples are C-vitamin and

Methyl-ethyl-ketoxim (MEKO). Biocides can also be added to the water in order to control the

formation of bacteria in the system. Tensides are sometime added to the water in order to reduce

friction in the system.

Page 7

Danfoss District Heating

Page 7 of 9

Table 3 Recommended water quality limits for district heating water on primary side

Parameter

Remarks

Value

Appearance

clear

Smell

no smell

Content of impurities

free of sediments/particles

Oil and grease

< 1 mg/l

pH at 25°C

7 to 10

Residual water hardness

[Ca2+, Mg2+]/[HCO

] > 0.5 ,

< 0.5 mmol/L (2.8 °dH)

Conductivity at 20°C

2500 µS/cm

Oxygen

<0.1 mg/L

(as low as possible)

Chloride

at T ≤ 20 °C

1000 mg/l

at T ≤ 50 °C

400 mg/L

at T ≤ 80 °C

200 mg/L

at T > 100 °C

100 mg/L

Sulphate

[SO

2-

] < 100 mg/L and

[HCO

]/[ SO

] > 1.5

Sulphite

e.g. use of oxygen binder

< 10 mg/L

Sulphide

< 0.02 mg/L

Nitrate

< 100 mg/l

Ammonium

< 2.0 mg/L

Total Org. Carbon TOC

< 30 mg/L

-

3

4

-

3

2-

4

2.3 Hardness, scaling and warranty

The ability to transfer heat in plate heat exchangers will be reduced by precipitation of contents

of the water (scaling) and deposition of impurities. Scaling is usually caused by the presence of

calcium and magnesium salts.

Total Hardness, is primarily the sum of calcium (Ca++) and magnesium (Mg++) ions in the water.

It is commonly expressed in milligram per litre (mg/L) or parts per million (ppm) of calcium

carbonate (CaCO3) or degrees hardness (°dH). A German °dH is equivalent to 17.8 ppm CaCO3.

Since 2004, water hardness is classified in the European Community acc. the EC-Regulation No

648/2004 on detergents

[16]

as shown in the following table.

Page 8

Danfoss District Heating

Page 8 of 9

Table 4 Classification of water hardness acc. to EC-Regulation No. 648/2004 on detergents

Range of hardness

Calcium carbonate

[mmol/L] 1)

Calcium carbonate

[mg/L] 2)

°dH 2)

soft Less than 1.5 Less than 150 Less than 8,4 °dH

medium 1.5 to 2.5 150 to 250 8,4 to 14 °dH

hard More than 2.5 More than 250 More than 14 °dH

1

) Acc. to the Système international d’unités from 1971, sum of earth alkali is given in mmol/L.

2

) Statement of values in mg/L and “degree of German Hardness °dH” is only informative.

Heating of water with high hardness causes precipitation of lime scale (CaCO3). This will appear

as a layer on the plate surface. Heating above 55°C may cause extensive precipitation of lime scale.

This will reduce the ability to transfer heat in plate heat exchangers.

It is therefore important to select Danfoss heat exchangers in sizes which secure that flow speed

is as high as possible. This will help to reduce scaling.

Content of impurities can also be deposited as a layer on the plate surface.

Impurities and lime scaling can be removed by flushing the heat exchanger with different types

of chemicals, depending on the composition of the deposit. Danfoss recommends using suppliers

with a proven technology and experience in cleaning heat exchangers.

Flushing can remove the depositions and increase the ability to transfer heat, but it can also cause

reduction of the life of the heat exchanger.

Danfoss District Heating cannot take over the warranty responsibility for heat exchangers:

• With reduced capacity caused by lime precipitation and scaling

• Leaking externally or internally after flushing to remove precipitation and scaling.

• Leaking externally or internally caused by water induced corrosion if the recommendations

for the water quality in this guideline are not fulfilled.

Page 9

Danfoss District Heating

Page 9 of 9

3 References

[1] EN 12502-2:2004. Protection of metallic materials against corrosion – Guidance on the

assessment of corrosion likelihood in water distribution and storage systems – Part 2:

Influencing factors for copper and copper alloys

[2] EN 12502-4:2004. Protection of metallic materials against corrosion – Guidance on the

assessment of corrosion likelihood in water distribution and storage systems – Part 4:

Influencing factors for stainless steels

[3] EN 14868:08-2005 Protection of metallic materials against corrosion – Guidance on the

assessment of corrosion likelihood in closed water circulation systems.

[4] VDI 2035-2:08-2009 Prevention of damage in water heating installations, Part 2: Water-

side corrosion.

[5] AGFW-Arbeitsblatt FW 510:06-2011 Requirements for circulation water in industrial and

district heating systems and recommendations for their operation.

[6] ÖNORM H 5195-1:12-2010 Heat medium for technical building equipment, Part 1:

Prevention of damage by corrosion and scale formation in closed warm-water-heating

systems.

[7] SWKI BT 102-01:04-2012, Richtlinie “Wasserbeschaffenheit für Gebäudetechnik-Anlagen“

Ed.: Schweizerischer Verein von Gebäudetechnik-lngenieuren, www.swki.ch

[8] DFF-guideline “Vandbehandling og korrosionsforebyggelse i fjernvarmesystemer”. DFF

Danske Fjernvarmeværkers Forening, 1999.

[9] Mattsson, E., 1988. Counteraction of pitting in copper water pipes by bicarbonate dosing.

Werkstoffe und Korrosion 39,499-503

[10] Mattsson, E., 1990. Tappvattensystem av kopparmaterial. Korrosionsinstitutet, ISBN 91-

7332-558-9.

[11] Anonymus, 2004. Fachthema Gelötete Plattenwärmeüberträger. Euroheat & Power 33, 3,

96-104

[12] Nilsson, K., Klint, D., Johansson, M., 2007. Corrosion aspects of compact heat exchangers

consisting of stainless steel plates brazed with copper filler metal in water applications”,

14th Nordic Corrosion Congress, , Copenhagen, Denmark.

[13] Pajonk, G., undated. “Korrosionsschäden an gelöteten Plattenwärmetauschern”,

Materialprüfungsamt Nordrhein-Westfalen, Dortmund. http://www.vau-thermotech.de/

mediapool/40/409506/data/Korrosionsschaeden_an_geloeteten_Plattenwaermetauschern.pdf

[14] Outukumpu Corrosion Handbook for Stainless Steels”, Tenth edition, 2009

[15] Mameng, S., Pettersson, R., 2011. “Localised corrosion of stainless steels depending on

chlorine dosage in chlorinated water”. Outukumpu acom 03-2011.

[16] Regulation (EC) No 648/2004 of the European parliament and of the council of 31 March

2004 on detergents

Loading...

Loading...