Data sheet

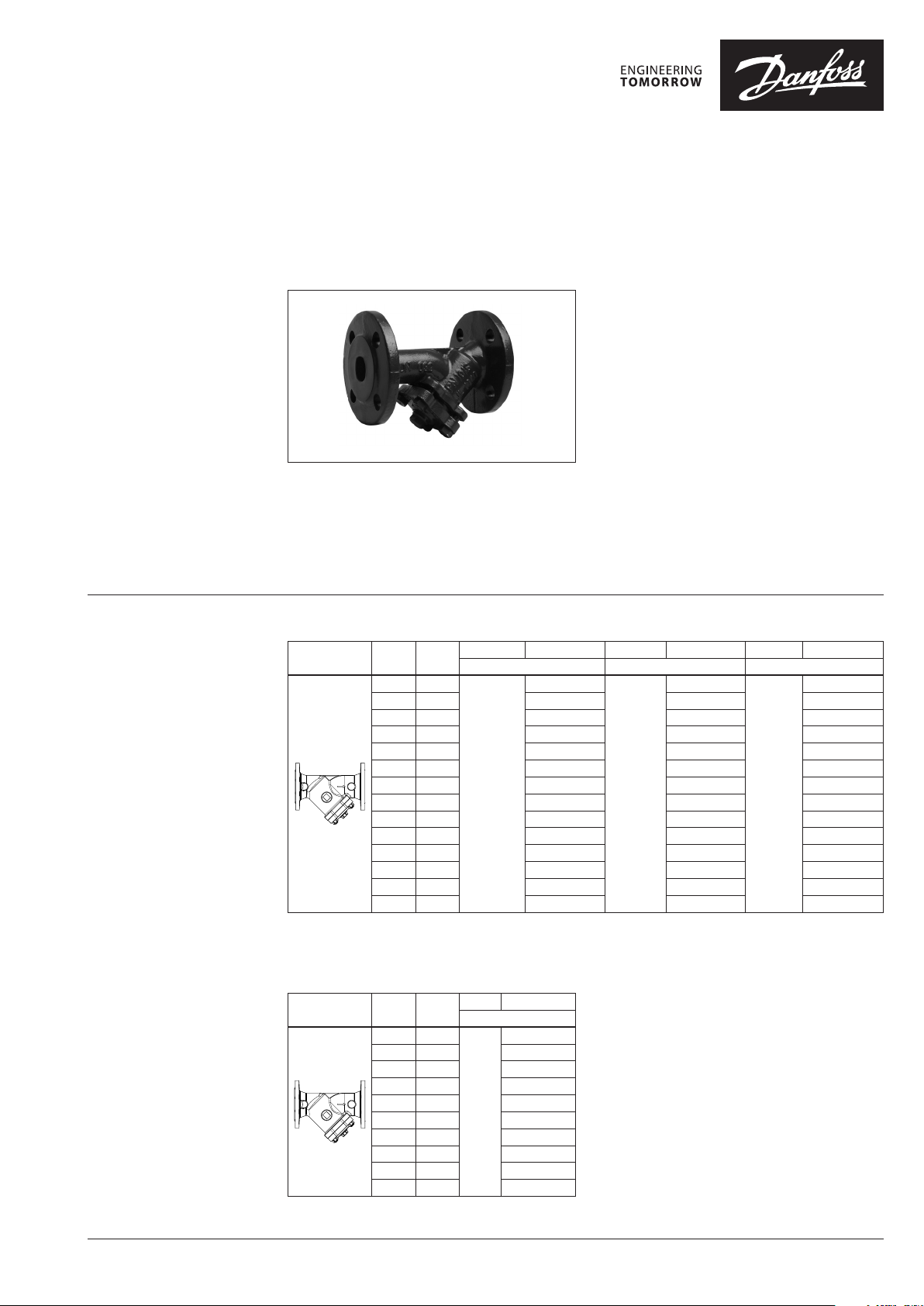

FVF strainer

Description

Ordering

Strainer is installed to protect sensitive

equipment like meters, pumps, control valves

against danger caused by foreign particles and in

wide range of other applications.

Furthermore, strainer is available with a plug,

magnetic insert or ball valve. Combination with

ball valve allowing a quick and efficient cleaning.

Main data:

• DN 15-300

• PN 16/25

FVF strainer is designed for heating, district

heating and cooling systems.

• Temperature:

- Circulation water / water with glycol:

−10 … 150 °C (PN 16), −20 … 150 °C (PN 25)

Strainer removes and retains foreign particles like

welding beads, swarf, sand, etc. carried along by

heating / cooling medium.

• Connections:

- flange (strainer) DIN EN 1092-2

- thread (ball valve)

Flange1) strainer FVF

2)

DN

k

Picture

1)

Flanges acc. to EN 1092-2 (PN 16 and PN 25 respectively)

2)

For strainers wi th normal screens

3)

To prevent scalds during drai ning the draining ball valve must b e equipped with drain hose , that leads to drainage system

(mm)

100 201 065B7734 065B 7748 065B7778

125 350 065B7735 065B7749 065B7779

150 542 065B7736 065B7750 065B7780

200 870 065B7737 0 65B7751 065B7781

250 1.26 0 0 65B7738 065B7752 0 65B7782

300 1.735 065B7739 065B7 753 065B7783

VS

(m3/h)

15 5.3

20 9.5 065B7727 06 5B7741 065B7771

25 16. 5 065B7728 065 B7742 065B7772

32 20 065B7729 065 B7743 065B7773

40 33 065B7730 065B7 744 065B7774

50 54 065B 7731 06 5B7745 065B7775

65 95 065B7732 065B774 6 065B7776

80 140 065B7733 0 65B7 747 065B7777

T

max

PN 16 with draining ball valve PN 16 PN 25

150 oC

Code No. T

065B7726

3)

max

150 oC

Code No. T

06 5B774 0

max

150 oC

Code No.

065B7770

Flange1) strainer FVF, I-pack

2)

T

Picture

1)

flanges acc . to EN 1092-2 (PN 16)

2)

for strainer s with special screens

DN

(mm)

15 5.1

20 9.2 065B7755

25 15.1 065B7756

32 18.4 065B 7757

40 30.6 065B7762

50 49 065B7763

65 86.7 065B7764

80 133.6 065B7765

100 192. 8 065B7766

125 326.4 065B7767

k

VS

(m3/h)

Code No.

max

150 oC

PN 16

065B7754

© Danfoss | 2020.08 AI160486460376en-011201 | 1

Data sheet FVF strainer

Ordering (continuous)

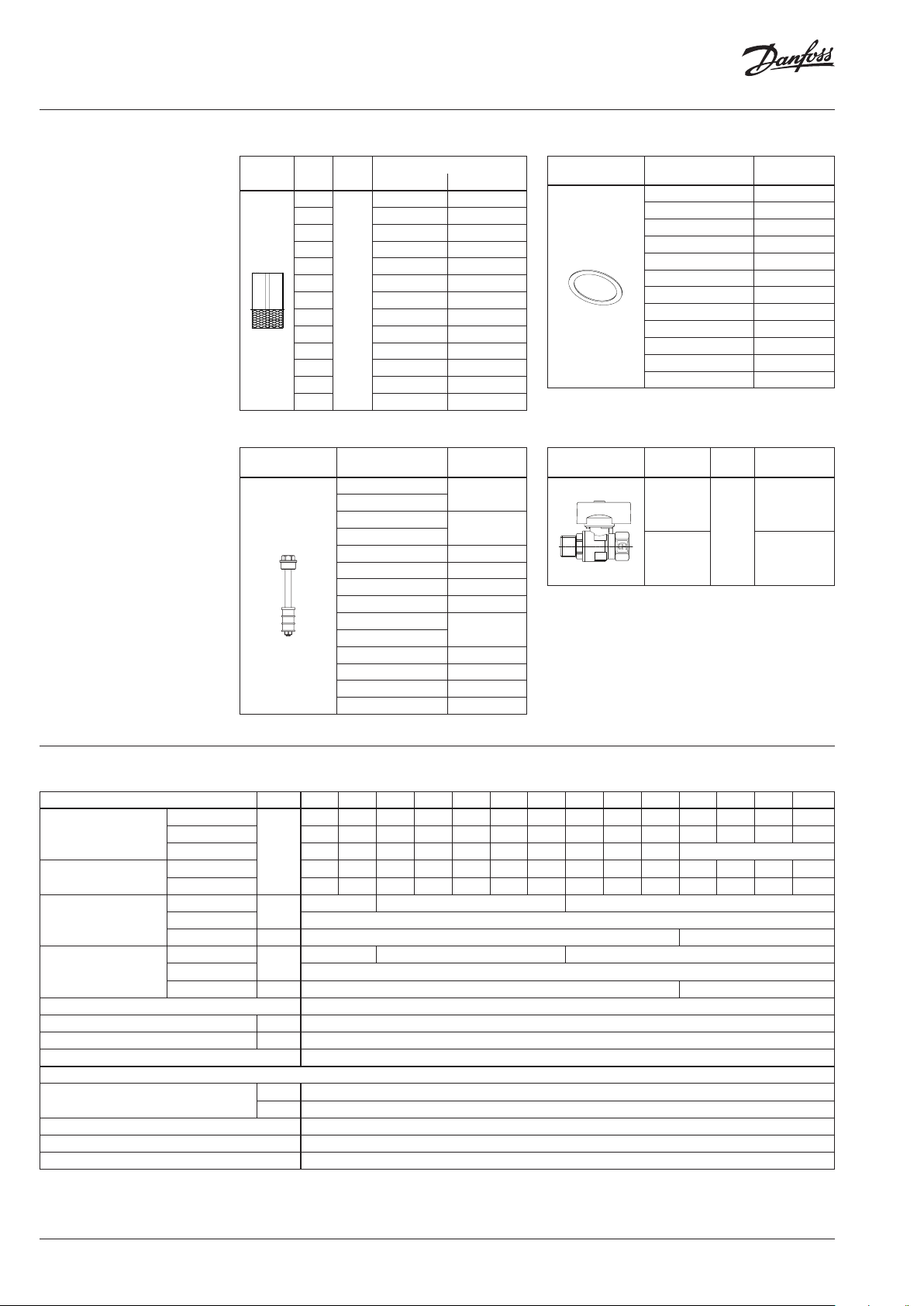

Spare parts FVF-Screen

Picture

DN

(mm)PN(bar)

15/20

25 0 65B7812 0 65B7826

32 065B7813 0 65B7827

40 065B7814 065B7828

50 065B7815 065B7829

65 065B7816 065B7830

16, 2 5

80 065B7817 065 B7831

100 065B7818 065B7832

125 065B7819 065B7833

150 065B7820 0 65B7834

200 065B7821 065B7835

250 065B7822 065B7836

300 065B7823 065B7837

Code No.

(normal) (fine)

065B7810 065B7824

Accessories FVF-M magnetic insert

Picture

DN

(mm)

15

20

25

32

40 065B7792

50 065B7793

65 065B7794

80 065B7795

100

125

150 065B7797

200 065B7798

250 065B7799

300 065B7800

Code No.

065B7790

065B 7791

065B7796

Spare parts FVF-Gasket

Picture

DN

(mm)

15/20 065B7886

25/32 065B7887

40 065B78 88

50 0 65B7889

65 0 65B7890

80 065B7891

100 065B7892

125 065B7893

150 065B7894

200 065B7895

250 065B7896

300 065B7897

Accessories FVF-B ball valve

Picture

DN

(mm)

10

(used for

FVF

DN 15 - 50)

15

(used for

FVF

DN 65 - 300)

T

(°C)

150

max

Code No.

Code No.

065B7802

065B7801

Technical data

Nominal diameter DN 15 20 25 32 40 50 65 80 100 125 15 0 200 250 300

normal screen

kVS value

fine screen 5.0 9.0 14. 8 18 30 48 85 131 189 320 494 818 1184 1631

special screen 5.1 9.2 15 .1 18.4 30.6 49 86.7 133.6 192 .8 326.4 -

kVS value

(with magnetic insert)

normal screen 4.8 8.6 14.9 18 29 49 86 127 183 316 489 809 117 2 1613

fine screen 4.5 8.1 13 .3 16 27 44 77 119 17 0 297 459 760 1101 1516

normal screen

Mesh size

fine screen 0.25

special screen 0.40 -

Number of meshes

normal screen

fine screen 625

n/cm

special screen 280 Flow medium Circulation water / glycolic water up to 50%

Nominal pressure PN 16 or 25

Medium temperature

Connection Flanges acc. to DIN EN 1092-2 (PN 16 and PN 25 respectively)

Materials

Body (strainer)

PN 16 Grey cast iron EN-GJL-250 (GG-25)

PN 25 Ductile iron EN- GJS-400 -18-LT (GGG 40.3)

Body (ball valve) Dezincing free brass CuZn36Pb2As

Screen Stainless steel, mat. No 1.4301

Gasket Graphite

1)

Danfoss uses env ironmentally friendl y paint that is resistant to a temperature o f 150 oC.

5.3 9.5 16.5 20 33 54 95 140 201 350 542 870 1260 17 35

m3/h

mm

o

C −10 ... 150 (PN 16), −20 ... 150 (PN 25)

0.54 0.87 1.18

150 64 25

2

1)

2 | AI160486460376en-011201 © Danfoss | 2020.08

Data sheet FVF strainer

Pressure temperature

diagram

PN

❶

25

20

❷

15

❶ EN-GJS- 400-18-LT (GGG 40.3) PN 25

➋ EN-GJL-250 (GG 25) PN 16

Note: Danfoss uses environment

friendly paint which may crack at

temperatures above 150 °C.

Flow diagram

10

0 120 140 160 180 200 220 240 260 280 300 320 340 350

Maximum allowed operating pressure as a function of medium temperature (according to EN 1092-2).

o

C

Installation positions

Standard screen Fine screen

The medium flow direction must correspond to

an arrow on the strainer body.

Strainers are to be installed in horizontal position

with mesh bonet directed downwards. Vertical

position is also allowed (be aware - when

medium flows upwards strainer retains all

foreign particles but is not able to collect them).

Sufficient space to pull out the mesh for

replacement and cleaning must be ensured.

AI160486460376en-011201 | 3© Danfoss | 2020.08

Danfos

produc

Al

Danfoss A/S

Heating Segment • heating

Data sheet FVF strainer

Design

1. Body

2. Cover

3. Screen

4. Gasket

5. Screw

6. Nut

7. Plug screw

8. Magnet

9. Washer

10. Handle

11. Ball

12. Stem

A

With magnetic insert

A

With ball v alve

Dimensions

H

L H

DN

15 130 75 95 14 65 95 14 65 2.2

20 15 0 75 105 14 75 105 14 75 3.3

25 160 90 115 14 85 115 14 85 3.8

32 18 0 90 140 19 100 140 19 100 5.0

40 200 110 150 19 110 150 19 110 6.5

50 230 120 165 19 125 165 19 125 8.5

65 290 140 185 19 145 185 19 14 5 12. 0

80 310 16 5 20 0 19 16 0 200 19 16 0 16.6

100 350 220 220 19 180 235 23 190 25.0

125 400 260 250 19 210 270 28 220 39.0

150 480 300 285 23 240 300 28 250 61. 0

200 600 360 340 23 295 360 28 310 109

250 730 470 405 28 355 425 31 370 16 2

300 850 560 460 28 410 485 31 430 280

L

DN

PN 16 PN 25

ØD Ød dk ØD d dk

mm

Ød

ØD

dk

Weight

(kg)

s can accept no responsibility for possible errors in catalogues, brochures and o ther printed material. Danfoss reserves the right to alter its products w ithout notice. This also applies to

ts already on order provided that such alterations can be m ade without subsequential changes being necessary in specications already agreed.

l trademarks in this material are p roperty of the respective companies. Danfoss and al l Danfoss logotypes are trademarks of Danfoss A/S. All rights reser ved.

Ball valve

For strainers

DN

10 15 - 50 52 43 36 10

15 65 - 30 0 69 50 52 17. 3

DN

L L1 H D

mm

.danfoss.com • +45 7488 2222 • E-Mail: heating@danfoss.com

L1

H

DN

D

L

© Danfoss | DHS-SRMT/SI | 2020.084 | AI160486460376en-011201

Loading...

Loading...