Data Sheet

Adaptor

Type FSA

Easy and fast component replacement

With the are / solder adaptor, type FSA, are

connections can be easily and reliably changed

to solder connections.

The adaptor provides a method of joining that

preserves the advantages of are connections,

i.e. easy and fast component replacement. At

the same time, the are / solder adaptor also

provides the advantage of soldered joints, i.e. a

high degree of tightness that prevents leakage.

The adaptor contains no soft gaskets or O-rings

which age and loose their sealing properties.

Instead, it contains a copper seal which

protects the are collar against wear and

fatigue. This copper seal ensures a thightness

similar to that of soldered joints.

The copper seal must be changed each time

the adaptor is dismantled for servicing are

components.

Frost grooves in the nut mean that the

adaptors are suitable for wet environment,

where the temperature is below the water

freezing point. The nut cannot be loosened by

encapsulated ice formation.

Features

• The are / solder adaptor, type FSA, is for use

where servicing or some other factor makes a

“genuine” solder connection impractical.

• The adaptor can be used with advantage for

components with are connections on:

1.

Pressure controls

2.

Filter driers

3.

Sight glasses, etc.

AI151686417214en-000501

1

2

12Marking

Frost grooves

Size

Torque

1

⁄4 in. / 6 mm

20 Nm

3

⁄8 in. / 10 mm

30 Nm

1

⁄2 in. / 12 mm

60 Nm

5

⁄8 in. / 16 mm

100 Nm

3

⁄4 in. / 18 mm

200 Nm

Type

Designation

FSA

Flare/ solder adapter

3

Flare nut in eighth of an inch

2 =

1

⁄4 in. or 6 mm, 3 = 3⁄8 in. or 10 mm, 4 = 1⁄2 in. or 12 mm, 5 = 5⁄8 in. or 16 mm, 6 = 3⁄4 in.

6 m

Solder connection

2 =

1

⁄4 in., 3 = 3⁄8 in., 4 = 1⁄2 in., 6 = 3⁄4 in. 6m = 6 mm, 10m = 10 mm, 12m = 12 mm, 16m = 16 mm or 5⁄8 in., 18m = 18 mm

Type

Connection

L

[mm]

L

1

[mm]

Stamping

Weight

[kg]

Flare

[in.]

Solder

[ODF]

FSA 22

FSA 26m

1

⁄4

1

⁄4

1

⁄4

in.

6 mm3939

7

7INMM

0.05

0.05

FSA 32

FSA 36m

FSA 33

FSA 310m

3

⁄8

3

⁄8

3

⁄8

3

⁄8

1

⁄4

in.

6 mm

3

⁄8 in.

10 mm

50

50

50

50

7

7

8

9

IN

MM

IN

MM

0.09

0.09

0.09

0.09

FSA 44

FSA 412m

1

⁄2

1

⁄2

1

⁄2

in.

12 mm57571010INMM

0.11

0.11

FSA 516m

5

⁄8

5

⁄8

in. or 16 mm

5712MM

0.14

FSA 66

FSA 618m

3

⁄4

3

⁄4

3

⁄4

in

18 mm68681414INMM

0.28

0.28

Adaptor, type FSA

Product specication

Standards

DIN 8964, which stipulates a maximum leak rate for refrigeration plant of < 6.4 × 10-6 mbar l/s at a dierential

pressure of 10 bar He.

The Dutch refrigeration standard (9.12.94/IBP 07d 94007, part 2.2.8.2.): In variation to regulation 2.2.8.1 anged

joints, compression joints, quick-couplings, at or conical packing or trapped O-rings will be permitted, but only if

the packing or O-ring provide the seal and are replaced if the joint is disconnected and then remade.

Technical data

Refrigerants: only approved for A1 and A2L refrigerants

Max. working pressure: PS/MWP = 46 bar

Leak rate: Max. 1 g / year

Table 1: Max. tightening torque

Type designation

Table 2: Type designation of FSA 36m

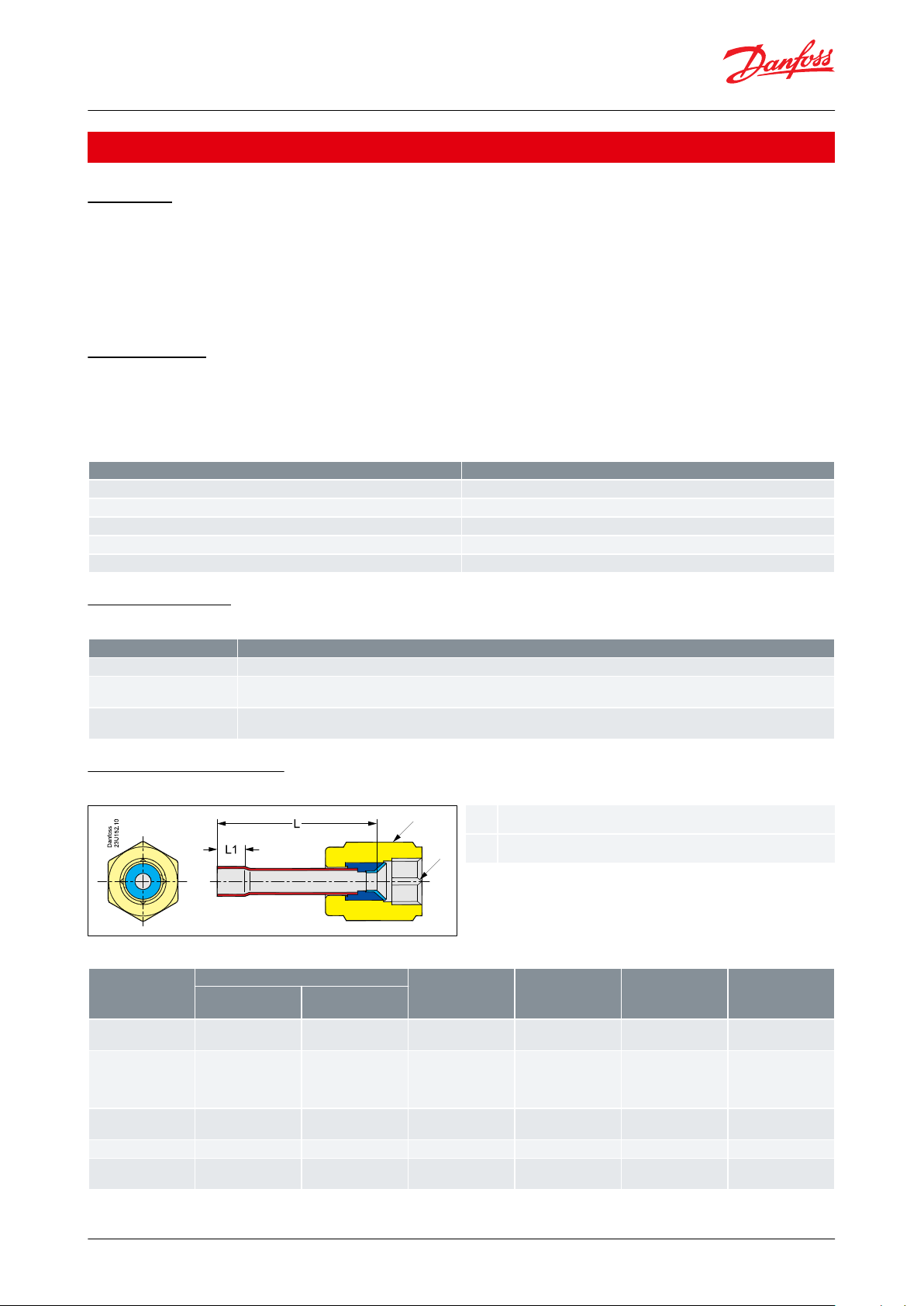

Dimensions and Weight

Figure 1: Type FSA

Table 3: Dimensions and weight of FSA

© Danfoss | Climate Solutions | 2021.03 AI151686417214en-000501 | 2

Type

Connections

Code no.

Flare

Solder

ininmm

Flare / solder adapter set: 2 pcs.

FSA 22

1

⁄4

¼-023U8002

FSA 33

3⁄83

⁄8

-

023U8004

FSA 44

1⁄21

⁄2

-

023U8006

FSA 516m

5⁄85

⁄8

-

023U8007

FSA 66

3⁄43

⁄4

-

023U8010

FSA 26m

1

⁄4

-6023U8001

FSA 310m

3

⁄8

-10023U8003

FSA 412m

1

⁄2

-12023U8005

FSA 516m

5

⁄8

-16023U8007

FSA 618m

3

⁄4

-18023U8009

Flare / solder adapter set, 1 pcs.

FSA 22

1

⁄4

¼-023U8012

FSA 32

3

⁄8

¼-023U8022

FSA 33

3⁄83

⁄8

-

023U8014

FSA 44

1⁄21

⁄2

-

023U8016

FSA 516m

5⁄85

⁄8

-

023U8017

FSA 66

3⁄43

⁄4

-

023U8020

FSA 26m

1

⁄4

-6023U8011

FSA 36m

3

⁄8

-6023U8021

FSA 310m

3

⁄8

-10023U8013

FSA 412m

1

⁄2

-12023U8015

FSA 516m

5

⁄8

-16023U8017

FSA 618m

3

⁄4

-18023U8019

Copper seal

Size

Qty.

Code no.

B2 - 4 spec.

1

⁄4

in / 6 mm

300

011L4025

B2 - 6

3

⁄8

in / 10 mm

300

011L4017

B2 - 8

1

⁄2

in / 12 mm

200

011L4018

B2 -10

5

⁄8

in / 16 mm

100

011L4019

B2 -12

3

⁄4

in / 18 mm

50

011L4020

Adaptor, type FSA

Ordering

Figure 2: Connections for

Flare/solder adapter

Table 4: Ordering of FSA

Figure 3: Copper seal

Table 5: Accessories

© Danfoss | Climate Solutions | 2021.03 AI151686417214en-000501 | 3

Document name

Document type

Document topic

Approval authority

067R1068

Manufacturers Declaration

PED

Danfoss

033F4006

Manufacturers Declaration

China RoHS

Danfoss

033F4011

Manufacturers Declaration

EU Rohs

Danfoss

Adaptor, type FSA

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 6: Certicates, declarations, and approvals

© Danfoss | Climate Solutions | 2021.03 AI151686417214en-000501 | 4

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.03 AI151686417214en-000501 | 5

Loading...

Loading...