Page 1

Installation and Instruction

PLRCA.PI.GK0.A1.02 / 520H3006

© Danfoss Saginomiya

A. Failure to read and follow all instruction carefully before installing or

operating this flow switch could cause personal injury and/or

property damage. Save these instructions for future use.

B. NOTE FOR SAFETY

Approved by Drawing NumberCatalog NumberNamedatedrawn by

1991

APR.

PADDLE TYPE FLOW SWITCH

FQS

1/2

A-QS-90003-A

Warning

Never remove the cover when power is applied. This can result in electric shock.

Connect wiring after turning off power. This can result in electric shock.

Do not sprinkle water over the microswitch. This can result in electric shock.

Do not connect a load exceeding the electric rating. This can result in bad contacts.

Do not turn screws other than the operating value setting screw.

Incorrect operations or water leakage can occur.

Install the switch so that the arrow indication and the fluid flow match.

The switch does not work if fluid flows in the opposite direction.

In addition, paddles can be damaged.

Use fluid that does not corrode the liquid contacting material. In addition, use

fluid in liquid form. Gas or liquid mixed with gas causes unstable operations.

Connect the switch to ground. Do not connect the grounding wire to a gas pipe,

water pipe, lightning rod or the grounding wire of a telephone line.

If the grounding is not appropriate, this can result in electric shock.

Use fluid with flow velocity of 2m/s or less. In addition, avoid strong pulsating

fluid and vibration. Paddle can be damaged.

C. DESCRIPTION

Type FQS Flow Switch with SPDT micro switch detects the fluid flow in pipe line.

The electric contact block is completely sealed from the fluid in the pipe line by a bellows.

When a flow rate increases,the actuating plate⑦ will move while the resistant force ordering.

4

3

2

1

Terminal

5

6

7

8

MARK

Screwed in depth

D. SPECIFICATIONS

・Structure Open

・Liquid contacting material Copper alloy

or stainless paddle(option)

・Maximum operating pressure 0.98 MPa

・Allowable fluid temperature 5 to 80 ℃

・Endurance operations 100,000 operations

・Mounting screw R1(MPT) or NPT(option)

・Ambient temperature -25 to +80 ℃

・Ambient humidity 80 %RH or less

(No freezing, no condensation)

・Contact structure Single-pole double-throw

・Electrical ratings Unit: A

Type name,

Standard

(G)

DC high load type

(D)

Voltage

125V AC

250V AC

30V DC

125V DC

125V DC

250V DC

Resistive

15

15

6

0.5

10

3

Lamp

loadload

1.5

1.25

1.5

0.5

1.5

1.5

Motor

load

5

3

5

0.05

5

2

Type name,

Small load type

(K)

FLOW

C

Flow rate increase

A: Normally open terminal

B: Normally closed terminal

BA

C: Common terminal

symbolsymbol

Voltage

24V DC

100V AC

Minimum

applicable load

0.01

0.01

Maximum

current load

0.1

0.1

Paddle 3

Paddle 1

Paddle 2

№

Parts Name

Label

Insulated Plate

Micro Switch

Adjusting Screw

Metal Fitting For

5

Flow Adjusting Screw

Flow Adjusting Screw

Actuating Plate

Adjusting Spring

Q'ty.

11

12

13

14

1

16

17

18

Page 2

Installation and Instruction

PLRCA.PI.GK0.A1.02 / 520H3006

© Danfoss Saginomiya

Approved by Drawing NumberCatalog NumberNamedatedrawn by

1991

APR.

PADDLE TYPE FLOW SWITCH

FQS

2/2

A-QS-90003-A

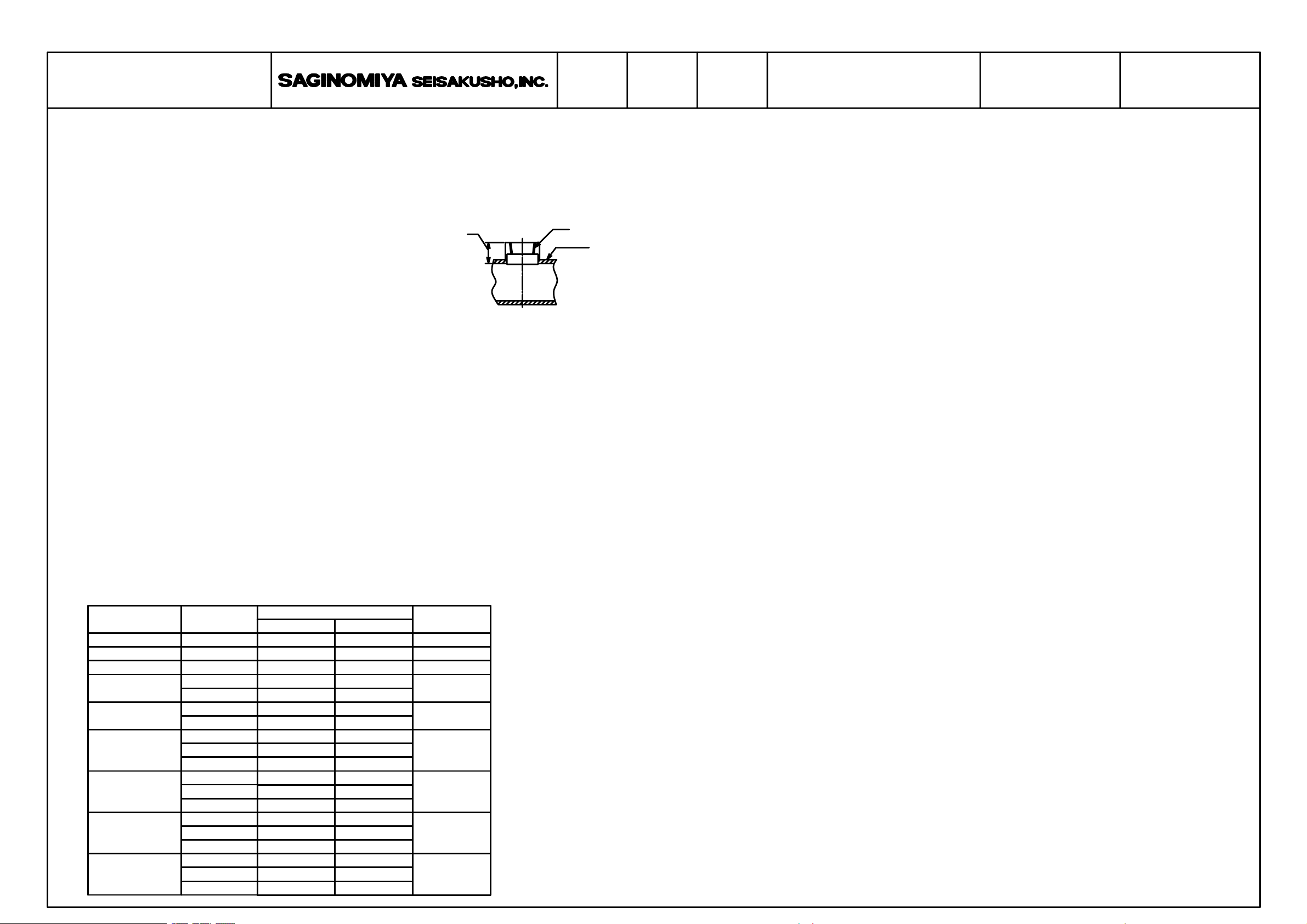

D.INSTALLATION METHOD

・Provide a straight pipe section of more than 5 times the piping diameter in front and

back of the flow switch. This is used to prevent hunting due to turbulent flow.

・Basically install the switch in horizontal piping with the cover facing upward but it

can be installed in vertical piping.

However,in the case of a vertical pipe installation, the operating value may change

about 20% compared to the horizontal pipe installation.

・For piping of the flow switch, use a commercially available

a

Rc1

Piping

Tee joint (conforming to JIS B 2301).

If the available Tee joint cannot be installed, adjust the

dimension “a” in the diagram on the right to that of the

Tee joint of JIS.

・When installing the flow switch to piping, the depth of the

flow switch screwed in shall be 12±1.2mm.

・For wiring,follow the instructions written on the insulation plate of the microswitch.

E.OPERATING VALUE SETTING

・When the operating value is not specified, the flow switch is shipped with the

operating value set around the minimum flow rate.

・When you turn the flow adjusting screw ⑥ clockwise, the operating point goes up.

When you turn it counterclockwise, the operating point goes down.

But if you turn the screw counterclockwise too much, the operation becomes unstable

and if you turn it further, the setting screw breaks off.

・If you have changed the setting value, make sure to operate the paddles and check

the operation of the microswitch.

・Never remove the metal fitting ⑤ because this is used to prevent the flow adjusting

screw⑥ from loosening.

・The adjusting screw ④ is exclusively used by our service personnel.

Do not use this screw for adjustment.

・When setting the operating value, refer to either decreasing flow setting value or

increasing flow setting value.

F.OPERATION ADJUSTMENT RANGE TABLE

Piping

25A (1B)

32A(1/B)

40A(1/B)

50A (2B)

65A(2/B)

80A (3B)

100A (4B)

100A (4B)

125A (5B)

150A (6B)

1

4

1

2

1

2

combination

1

1

1

1+2

1

1+2

1

1+2+3

1+2

1

1+2+3

1+2

1

1+2+3

1+2

1

1+2+3

1+2

1

Adjustment range

1266

1781

MIN

18

43

63

50

151

105

356

100

226

481

200

386

821

350

595

530

837

Unit: L/min

MAX

45

100

135

150

220

355

360

225

480

510

385

820

870

594

1265

1342

836

1780

1890

flow velocityPaddle

of 2m/s

72

120

163

264

432

612

1044

1613

2268

・This table is based on the operating point for decreasing flow.

Decreasing flow setting value means the flow switch operates when the flow rate decreases.

Increasing flow setting value means the flow switch operates when the flow rate increases.

・Differential value (difference between the decreasing flow operating value and the

increasing flow operating value) is not determined specifically. The guideline value

is as follows:

Less than 50L/min: About 10L/min

From 50L/min to less than 100L/min: About 15L/min

100L/min or more: About 20% of the setting value

・This table is based on the condition when the depth screwed in is kept within 12±1.2mm.

Tee joint of JIS.

・Paddle size is in the following order: 1<2<3

flow switch screwed in shall be 12±1.2mm.

・When the setting value is not specified, the attached paddle 1 can be used for 40A

or less, 1+2 for 65A or less and 1+2+3 for 80A or more.

・When more than two paddles is attached, you can change the flow rate adjustment range

by removing the paddles one by one in order of the longer paddle first.

・To install the paddles, install the paddle 1 first then stack the paddle 2 and then

the paddle 3.

G.OPERATION CHECK

Install and calibrate the Product correctly and then check its operation to confirm

correct function of the whole system when using.

H.LIMIT ON APPLICATION

The product is not designed nor manufactured for an use in such equipment or system

that is intended to be used under such circumstances that may affect human life.

For application requiring extreme high reliability, please contact the Company first.

I.SCOPE OF WARRANTY

Unless otherwise agreed by the parties, warranty period of the Product shall be one

year after date of delivery to Buyer.

In case of failure attributable to the Company within such period, the Product shall

be repaired or replaced without charge, provided that any one of followings are out

of the warranty :

① Improper handling or application by user.

② Modification or repair by other than the Company.

③AnyfailuretobecausedbyactsofGod,fire,stormorthelike,war,riot

or the like and other causes beyond the control of the Company.

Warranty described in this paragraph means the warranty for the Product itself and

does not include warranty for any consequential damage arising out of or occasioned

by a defect or failure of the Product.

A FEB.12.2004 REVISION K.Suzuki

Loading...

Loading...