Page 1

Installation, start-up

and operating instructions

Domestic Water Heater FLS-50

Always keep the operating manual near the

device.

Read the operating manual before commencing

work.

Notice! Before starting the device, make sure

that it is not damaged and that it is in perfect

working order.

DKDHR

VI.GE.T1.02 © Danfoss 12/2010

1

Page 2

Installation, start-up and operating instructions FLS-50

1 General ............................................................................................................................................... 4

1.1 Information about the operating manual ............................................................................................................4

1.2 Supporting documents ...............................................................................................................................................4

1.3 Explanations of the symbols .....................................................................................................................................4

1.4 Warranty and liability ...................................................................................................................................................5

1.5 Copyright ..........................................................................................................................................................................5

1.6 Spare parts .......................................................................................................................................................................6

1.7 Dismantling ......................................................................................................................................................................6

1.8 Disposal .............................................................................................................................................................................6

2 Safety.................................................................................................................................................. 7

2.1 General ..............................................................................................................................................................................7

2.2 Responsibility of the operator ..................................................................................................................................7

2.3 Intended use ...................................................................................................................................................................7

2.4 Possible misuse ..............................................................................................................................................................7

2.5 Occupational safety .....................................................................................................................................................8

2.6 Personal protective equipment ...............................................................................................................................8

2.7 Potential hazards involving the device .................................................................................................................8

2.8 Emergency stop switch ...............................................................................................................................................9

2.9 Operating personnel ....................................................................................................................................................9

2.10 What to do in case of danger or accidents.........................................................................................................9

2.11 Residual hazards/risk analysis .............................................................................................................................. 10

3 Technical data .................................................................................................................................. 11

3.1 Technical and main system data ............................................................................................................................11

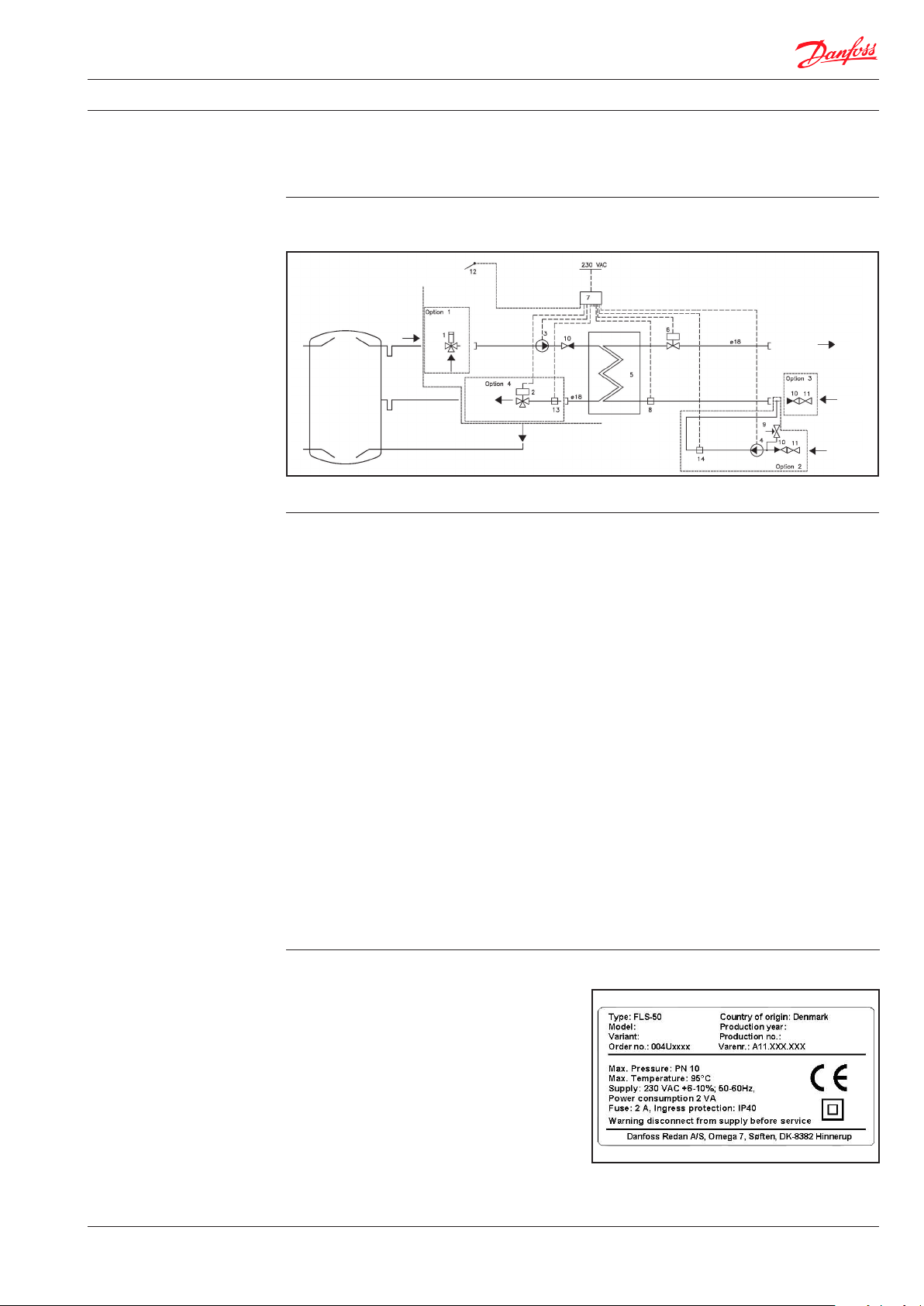

3.1.1 Circuit diagram ......................................................................................................................................................11

3.1.2. Bill of materials .....................................................................................................................................................11

3.1.3 Type plate .............................................................................................................................................................. 12

3.1.4 Pressure loss curve ............................................................................................................................................ 12

3.1.5 Capacity examples ............................................................................................................................................. 12

3.1.6 FLS-50 + options ................................................................................................................................................. 12

3.1.7. Dimensions and photo of components ..................................................................................................... 13

4 Function ........................................................................................................................................... 14

4.1 Function / General ...................................................................................................................................................... 14

5 Setup ................................................................................................................................................ 15

5.1 Assembly and installation/general ...................................................................................................................... 15

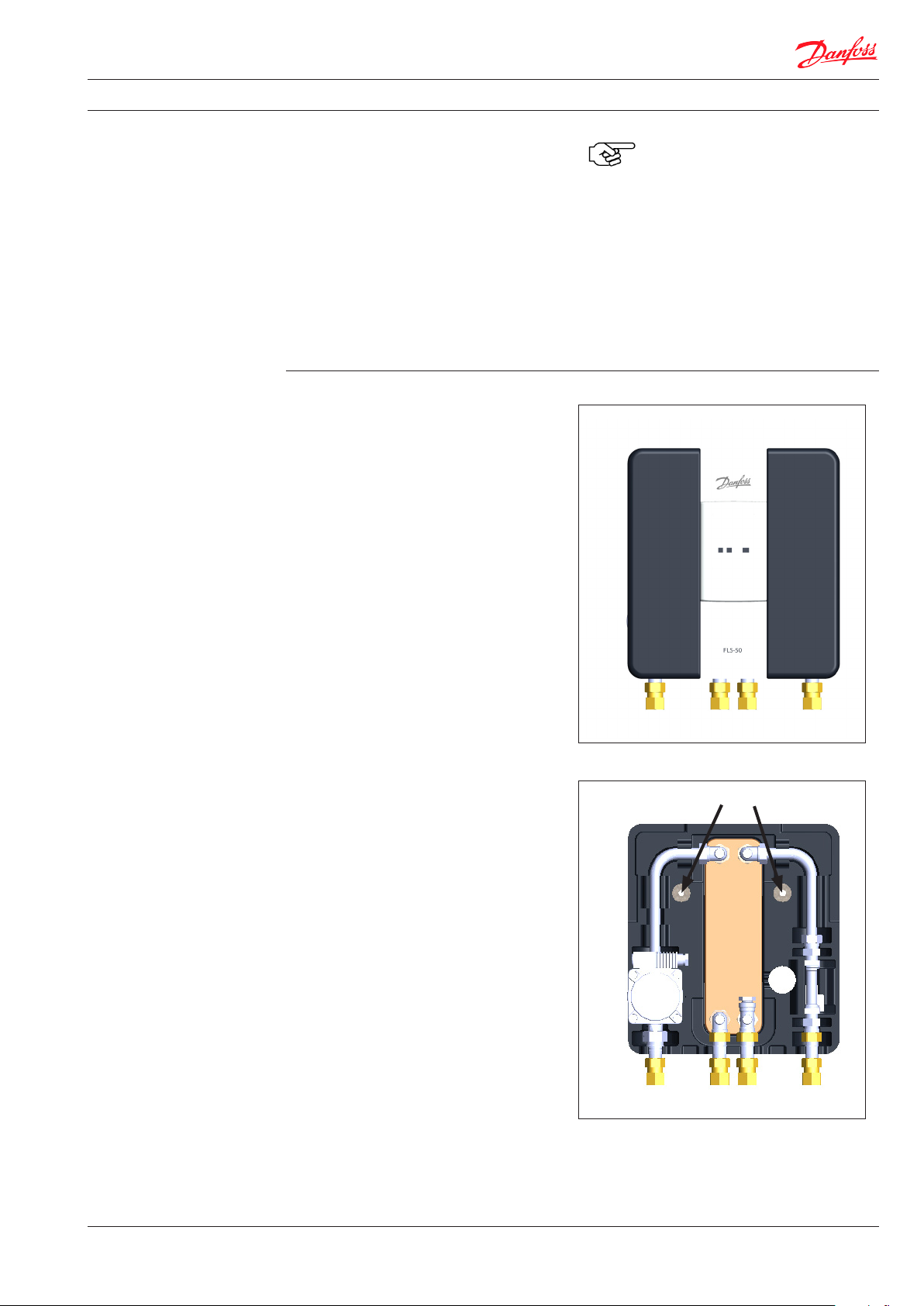

5.1.1 Figure FLS-50 ........................................................................................................................................................ 15

6 Transport, packing and storage .................................................................................................... 16

6.1 Transport pallets with a fork lift truck .................................................................................................................16

6.2 Transport inspection ................................................................................................................................................. 17

6.3 Packaging ...................................................................................................................................................................... 17

6.4 Storage ........................................................................................................................................................................... 17

7 Installation ....................................................................................................................................... 18

7.1 Assembly preparations ................................................................................................................ 18

7.1.1 Electrical connection .......................................................................................................................................... 18

7.1.2 Assembly of FLS-50 ............................................................................................................................................ 21

7.1.2.1 Assembling the basic device ................................................................................................................... 22

7.1.2.2 Assembling Option 1 ................................................................................................................................. 23

7.1.2.3 Assembling Option 2 ................................................................................................................................. 23

7.1.2.4 Assembling Option 3 ................................................................................................................................. 25

7.1.2.5 Assembling Option 4 ................................................................................................................................. 26

2

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Page 3

Installation, start-up and operating instructions FLS-50

8 Start-up ............................................................................................................................................ 27

8.1 Controller ....................................................................................................................................................................... 27

8.2 Fault and shutdown................................................................................................................................................... 28

8.3 Restarting after a fault .............................................................................................................................................. 28

9 Operation .........................................................................................................................................28

9.1 Switching the device on ........................................................................................................................................... 28

9.2 Switching the device o ..........................................................................................................................................28

10 Maintenance ..................................................................................................................................29

10.1 Safety information ...................................................................................................................................................29

10.2 Maintenance work ................................................................................................................................................... 30

10.3 Measures after maintenance work ....................................................................................................................30

11 Faults .............................................................................................................................................. 31

11.1 Functional faults ........................................................................................................................................................ 31

11.2 Safety information ................................................................................................................................................... 32

11.3 What to do in case of faults................................................................................................................................... 32

12 Spare parts ..................................................................................................................................... 32

11.3 What to do in case of faults................................................................................................................................... 32

13 Appendix I ...................................................................................................................................... 33

13.1 Exchanger calculations ........................................................................................................................................... 34

13.2 Pressure loss curve, Primary pump .................................................................................................................... 39

13.3 Temperature sensor ................................................................................................................................................40

13.4 Temperature/ow meter .......................................................................................................................................44

13.5 Pressure loss curve, Circulation pump ............................................................................................................. 45

14 Appendix II ..................................................................................................................................... 46

14.1 Declaration of Conformity .................................................................................................................................... 47

DKDHR

VI.GE.T1.02 © Danfoss 12/2010

3

Page 4

Installation, start-up and operating instructions FLS-50

1 General 1.1 Information about the operating manual

This operating manual describes installation,

operation and maintenance of the system.

Compliance with the safety and handling

instructions is a requirement for working safely

and using the system properly.

Apart from this, the local accident prevention

regulations and general safety regulations

applicable where the system is used must also be

observed.

The operating manual is a part of the product

and should be kept accessible near where the

system is operated at all times for installation,

1.2 Supporting documents

If not stated otherwise, the individual system

components are purchased modules from other

manufacturers. All the components used in the

system have been subject to risk assessments by

their manufacturers. The component

manufacturers have declared that the design of

the components complies with applicable

European and national regulations.

The manufacturers' conformity declarations and

the operating, maintenance and repair

1.3 Explanations of the symbols

Important safety and technical information in

this operating manual is marked with warning

signs. The information must be observed to

prevent accidents, injury and damage to

property.

operation, maintenance and cleaning personnel.

The graphics in this manual, which are intended

to provide a better description of the facts, are

not necessarily to scale and may deviate slightly

from the actual system design.

Apart from this operating manual, the operating

instructions for the installed components should

also be observed. The information contained in

these – especially in relation to safety – must be

complied with.

instructions for the individual components are

inseparable elements of the system

documentation. All the instructions on safety,

assembly and installation, operation,

maintenance, dismantling and disposal of the

components contained in the manufacturers'

documentation must be followed by operating

personnel.

NOTICE!

This symbol indicates instructions which, if not

followed, may result in damage,

malfunctions and/or failure of the system.

WARNING!

This symbol indicates hazards that could aect

health or cause injuries, permanent bodily harm

or death.

Observe the instructions on occupational safety

closely and be especially careful in such cases.

WARNING!

Risk of injury from electrical current.

This symbol draws your attention to dangerous

situations involving electrical current. If the

safety instructions are not complied with, there

is a risk of serious injury or death. Work must be

carried out only by a qualied electrician.

NOTE!

This symbol highlights hints that should be

observed to ensure ecient, problem-free

operation of the system.

4

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Page 5

Installation, start-up and operating instructions FLS-50

1.4 Warranty and liability

All data and information in this operating

manual were compiled with consideration of

applicable regulations, the current technical/

engineering development status and our many

years of knowledge and experience.

The actual scope of delivery may dier from the

explanations and drawings shown here in case of

special designs, if additional options are ordered

or due to recent technical modications. If you

have any questions, please contact the

manufacturer.

1.5 Copyright

The operating manual should be treated as

condential. It is intended only for people

involved with the system. The operating manual

may not be handed over to a third person

without the written consent of the manufacturer.

If you have any questions, please contact the

manufacturer.

This operating manual should be read

carefully before any work is done to and

with the device, especially before it is used for the

rst time. The manufacturer accepts no liability for

damage or faults that result from non-compliance

with the operating manual .

We may make technical modications within the

scope of improving performance characteristics

and in the course of further development.

The warranty does not cover components, such

as tools, that are subject to normal wear when

the device is used as intended or consumables

such as grease, oil or cleaning agents.

In all other respects, the obligations agreed in

the delivery contract shall apply in addition to

the manufacturer's general terms and conditions

of business and terms and conditions of delivery

and the statutory regulations applicable at the

time the contract was concluded.

The information, texts, drawings, pictures

and other presentations are protected by

copyright and are subject to other industrial

property rights. Misuse of the above is indictable.

The content, including excerpts, may not be

copied in any way whatsoever, nor may it be

utilised or disclosed without the written consent

of the manufacturer. Compensation shall be due

in case of infringements of the above. We reserve

the right to assert further claims.

DKDHR

VI.GE.T1.02 © Danfoss 12/2010

5

Page 6

Installation, start-up and operating instructions FLS-50

1.6 Spare parts

Use only the manufacturer's original spare parts.

1.7 Dismantling

To dispose of the device separately, clean it and

dismantle it with consideration of applicable

occupational safety and environmental

protection regulations. See also: Hygiene.

WARNING! Risk of injury.

Stored residual energies, sharp-edged

components, sharp points and edges on

and in the device or on the required tools

may cause injury. Therefore, all work to dismantle

the device must be carried out only by qualied

personnel.

WARNING! Not drinking water!

Domestic water in system

parts that have not been used

for a long period may not

have drinking water quality. Please prevent use,

empty the system parts and dispose of the water .

Wrong or faulty spare parts may cause

damage, malfunctions or complete

failure of the system.

If unapproved spare parts are used,

this voids all warranty, service, compensation

and liability claims against the manufacturer, its

agents, dealers and representatives.

Before starting to dismantle the device:

– Switch the device o and make sure that it

cannot be switched on again.

– Physically isolate the complete power supply

from the device, discharge stored residual

energy properly.

– Remove operating and auxiliary materials and

residual processing materials in an

environmentally friendly manner.

1.8 Disposal

If no return or disposal agreement has been

made, when components have been properly

dismantled dispose of the materials as follows:

• Scrap residual metal materials.

• Have plastic elements recycled.

• Sort and dispose of the other components

according to their properties.

• Dispose of residual media properly. Observe the

statutory regulations when discharging additives

(glycol, etc.).

NOTICE!

Electric scrap, electronic components,

lubricants and other auxiliary materials

are subject to special waste treatment

and may be disposed of only by authorised

specialist companies.

Remove substances such as grease, oil,

preservatives and cleaning agents from the

device separately and in an environmentally

compatible manner. Use approved containers to

catch and keep the respective substances. Until

nal disposal, store containers, clearly marked

with information about the content, level and

date, in such a way that they cannot be misused.

6

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Page 7

Installation, start-up and operating instructions FLS-50

2 Safety

This section gives an overview

of all important safety aspects

for optimum protection of

personnel and for the safe and

fault-free operation of the

device.

The individual chapters also

contain specic safety

information, marked with

symbols, to prevent direct

hazards.

2.1 General

When it was developed and produced, the

device complied with all applicable,

acknowledged rules of technology and is

deemed to be safe to operate. However, the

device may harbour risks if it was installed by

unqualied personnel or is not used for its

intended purpose. Therefore, every person who

is to work on or with the device must have read

and understood the operating manual before

commencing work. The operator is advised to

have personnel conrm that they acknowledge

the operating manual.

Changes of any type, additions or conversions to

the device are not allowed.

2.2 Responsibility of the operator

• Always keep the operating manual near the

device and make sure that it is accessible at all

times for installation, operating, maintenance

and cleaning personnel.

• Operate the device only in a technically faultless

and safe condition.

• Keep safety features freely accessible at all

times and check them regularly.

Statements regarding occupational safety refer

to the regulations of the European Union

applicable at the time the device was

manufactured. The operator must ensure that

the listed occupational safety measures comply

with the current status of the regulations and

observe new regulations throughout the entire

service life of the device. Outside the European

Union the applicable occupational safety laws

and regional regulations and provisions must be

complied with.

Apart from the occupational safety information

in this operating manual, the general safety,

accident prevention and environmental

protection regulations applicable to the use of

NOTE!

Always coordinate any changes or

extensions with the manufacturer.

All safety, warning and operating instructions for

the device must be kept in a legible condition.

Damaged signs or stickers must be replaced

without delay.

Specied settings and adjustment ranges must

be complied with.

the device must be observed and complied with.

The operator and his authorised personnel are

responsible for fault-free operation of the device

and for clear denition of responsibilities

regarding installation, operation, maintenance

and cleaning of the device.

The information in the operating manual must

be followed completely and absolutely.

The operator must also ensure that

– in a risk assessment other risks arising due to

the particular working conditions at the place

where the device is installed are identied.

– all other work and safety information identied

in the workplace risk assessment is dened in

operating instructions.

– the German Ordinance on Industrial Safety and

Health (BetrSichV, Federal Law Gazette I 2002,

3777) applies.

DKDHR

2.3 Intended use

The operating safety of the device is guaranteed

only if it is used as intended in accordance with

the data in the operating manual.

Intended use also includes correct adherence to

the installation, operation, maintenance and

cleaning instructions.

2.4 Possible misuse

The device is installed inside a system and has no

separate control. With the installation the

operator must ensure that suitable safety

features are available so that the device can be

shut down in case of danger or faults.

VI.GE.T1.02 © Danfoss 12/2010

Any additional and/or other use of the device is not

allowed and shall be deemed to be an unintended

use. Claims of any kind against the manufacturer

and/or his agents due to damage caused by

unintended use of the device shall be excluded. The

operator and/or owner shall be solely liable for all

damage resulting from unintended use .

NOTE!

e.g. Emergency stop button, etc.

7

Page 8

Installation, start-up and operating instructions FLS-50

2.5 Occupational safety

If the instructions on occupational safety are

followed, this can prevent risks for persons and/

or the system.

Non-compliance with these instructions can

result in risks for persons and objects due to

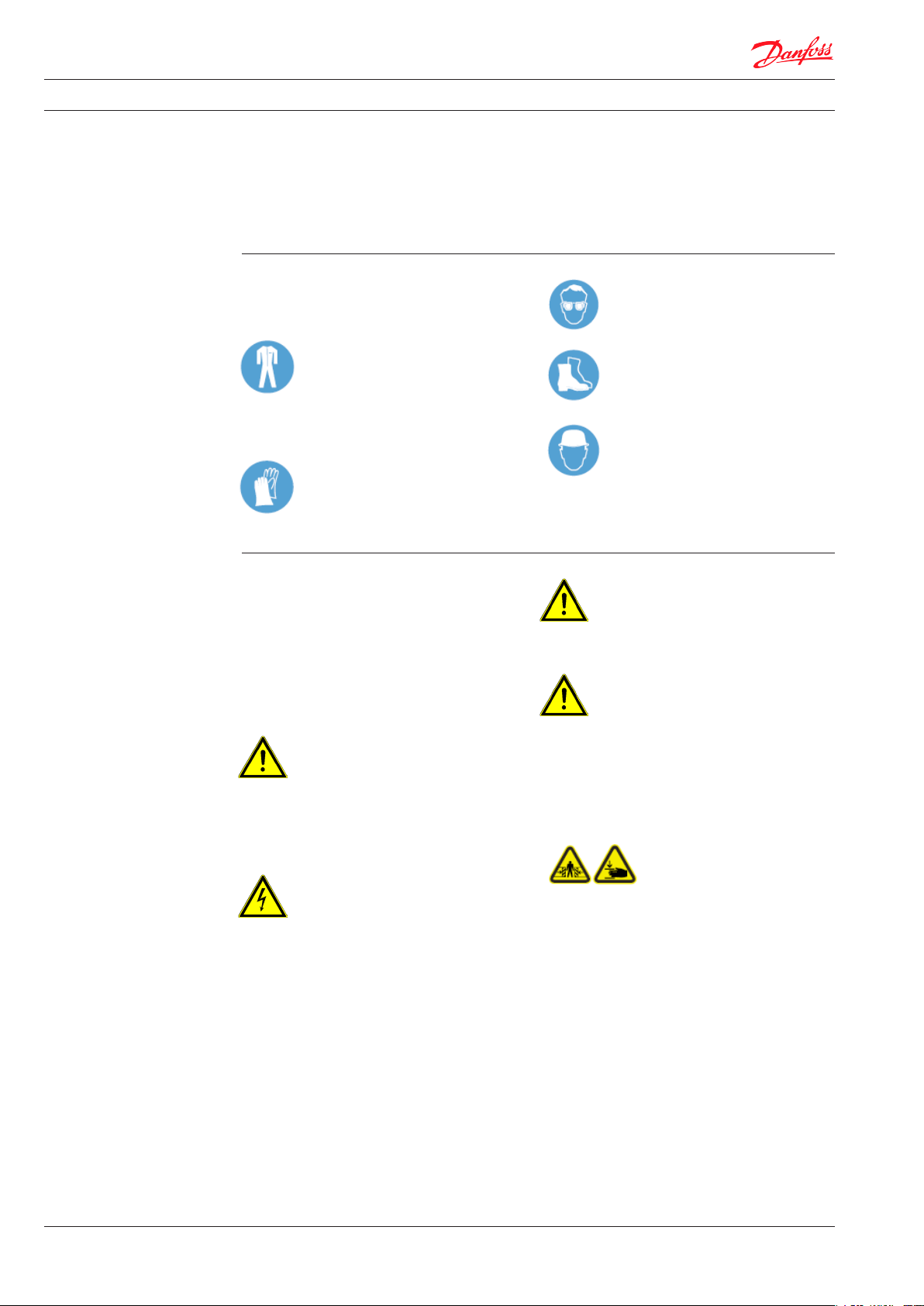

2.6 Personal protective equipment

When working on the device, the following must

be worn:

Industrial protective clothing

is tightly tting work clothing with low

tear resistance, close tting sleeves and

with no protruding parts. Its main

purpose is to protect the wearer when he or she

is reaching into moving parts.

Do not wear rings, chains or other jewellery.

Protective gloves

to protect the hands against friction,

abrasion, puncture wounds or more

serious injuries caused by hot surfaces.

2.7 Potential hazards involving the device

The device was subjected to a risk analysis. The

design and construction of the device based on

this analysis are state of the art.

However, there are residual hazards.

The device generates a strong spray of liquid

when the drainage or ventilation ttings are

opened.

The device works with a pressure of 10 bar.

WARNING! Risk of injury.

Risk of liquid spraying out under high

pressure. Wear personal protective

equipment when carrying out all work on the

device .

The device works with electrical voltages up to

230 V and currents up to 16 A.

WARNING! Risk of injury from electrical

current.

Electrical energies can cause very serious

injuries. There is a danger to life if the insulation or

individual components are damaged.

– Before carrying out any maintenance, cleaning

or repair work, switch o the main switch and

make sure that it cannot be switched on again.

– If work is being carried out on the electrical

system, isolate it from the power supply.

– Do not remove or disable any safety facilities

by altering them.

mechanical eects or failure of the system and

the entire workplace.

Non-compliance with the safety regulations

voids all claims for compensation.

Safety glasses

to protect the eyes against ying

parts and splashes of liquid.

Safety shoes

to protect the wearer against falling

parts and slipping on slippery oors.

Hard hat

to protect the wearer against falling

and ying parts and materials.

WARNING! Risk of injury.

Sharp-edged parts of the housing and

sharp corners can cause skin abrasions.

Wear protective gloves when working on the device.

WARNING! Risk of burning.

Hot surfaces can cause serious burns. Always

wear personal protective equipment when

carrying out all work on the device .

The device works at a maximum temperature of 95°C.

Components in the device may contain

automatic moving parts (motors, gears, etc.).

The devices can be very heavy.

WARNING! Crushing hazard.

When the device is being

transported, also if lifting

equipment is used, crushing can

occur due to the weight. The

device may contain components that move with

electricity (motors, gears) which could also cause

crushing if they are touched during operation.

Always isolate the device and wear protective

clothing when working on the device.

8

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Page 9

Installation, start-up and operating instructions FLS-50

2.8 Emergency stop switch

The device is installed inside a system and has no

separate control. The operator must ensure that

emergency stop switches in compliance with

applicable accident prevention regulations are

2.9 Operating personnel

The device may be operated and maintained

only by authorised, trained and instructed

personnel. These personnel must have been

instructed especially about potential risks.

An instructed person is deemed to be a person

who has been instructed about the work he or

she has been entrusted with and the potential

risks associated with improper behaviour and, if

necessary, who has been instructed about the

necessary safety features and safety measures.

Trained personnel are deemed to be persons

who, due to their professional training,

knowledge and experience and knowledge of

the relevant regulations, are able to assess the

work they have been entrusted with and

recognise potential risks.

If personnel do not have the required

knowledge, they must be trained.

The responsibilities for operation and

maintenance must be clearly dened and

adhered to so that there is no unclear

distribution of competency under the aspect of

safety.

installed. The operator must prove that he has

informed operating personnel about the

location and functions of the emergency stop

switches.

The device may be operated and maintained

only by persons who can be expected to carry

out their work reliably. The mode of working

must not have an adverse eect on the safety of

persons, the environment or the device. Persons

under the inuence of drugs, alcohol or

medication that slows their reactions may not

carry out any type of work on or with the device.

The choice of personnel must take account of

the national young persons employment laws

and any underlying job-specic regulations.

Operators must also ensure that no unauthorised

persons work on or with the device.

Unauthorised persons, such as visitors etc., may

not come into contact with the device. They

must remain at an appropriately safe distance

from the device.

Users must report changes on the device that

have an adverse eect on safety to the operator

immediately.

2.10 What to do in case of danger or accidents

In case of danger or an accident, switch the

device o immediately with an emergency stop

switch.

Safety features with an emergency stop function

should be activated only in emergency

situations.

Safety features may not be used to switch the

device o under normal conditions.

Always be prepared for accidents or re.

Have rst aid facilities (medical kit, eye rinse

bottles, etc.) and re extinguishers nearby.

Personnel must be condent in the use of and

know the locations of safety, accident reporting,

rst aid and rescue facilities. This ensures that

risks are averted and that the best possible

assistance is given in case of accidents.

DKDHR

VI.GE.T1.02 © Danfoss 12/2010

9

Page 10

Installation, start-up and operating instructions FLS-50

2.11 Residual hazards/risk analysis

Location of hazard Type of hazard Aim of protec tion Measure

Shut-o valves and ttings in

the station

Piping and components in

the station

Complete station Electric shock Safe contact with the station Protection against accidental

Complete station Splashing liquids and/or

Complete station Overheating of the station or

Crushing in case of manual

operation

Can burn the skin if touched Safe contact with open

steam under high pressure

heat transfer to the

connected house system in

excess of the permitted

temperature

Manual operation of the

shut-o valves and ttings

must be possible without

danger.

station

Controlled reduction of

excess pressure in the event

of a fault

Stop heating in case of a fault Safety features acc. to DIN

The design leaves sucient

space for ergonomic

operation.

Thermal insulation of piping

and components

Warning signs at the station

Warning information in the

operating manual

contact

Safety features acc. to DIN

4747 T1 (hot water) and/or

DIN EN 12828

4747 T1 (hot water) and/or

DIN EN 12828

During operation, the residual hazard can be

limited to the following alphabetical value

according to Suva risk assessment: B5/C4/D3/E2.

The residual hazard potential results from

non-compliance with the above operating

instructions. The assemblies were produced

according to the explicit specications of the

operator, who is responsible for compliance with

the specied parameters, selection and

qualication of the operating personnel.

The system is equipped with the following

warning sign, which points out the most

important residual hazards:

The system must be operated only by trained , qualied personnel after they have

studied the enclosed documentation in detail. Before the system is started for the rst

time, it must be lled and completely deaerated. Exceeding the permitted operating

pressure or the maximum permitted operating temperature according to the type plate

or any other use apart from the intended use are not allowed.

Risk of burning from touching the surface or from the emissions of hot media (water/

steam). Avoid touching the assembly or wear suitable protective clothing.

Crushing hazard when operating the assemblies

Risk of electric shock before working on the electrical system, isolate it

All ange connections, screw joints and electrical clamp and screw connections must be

checked and tightened if necessary before the system is lled and put into operation.

Switch pumps on only when they are full (no dry running).

Before starting the system for the rst time, install it professionally (if not

completely assembled in the factory):

• Safety valve/drainage and steam piping according to DIN 4751 and/or DIN 1988

• Strainer in primary supply line/secondary return line

• Potential equalisation acc. to VDE 0100 Part 540 (earthing/earth wires/potential

equalisation)

10

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Page 11

Installation, start-up and operating instructions FLS-50

3 Technical data

3.1 Technical and main system data

You will nd the main system data on the type

3.1.1 Circuit diagram

Installe d in top buer

tank

Scope of del ivery

Buer tank

Top

Buer tank

Return

Buer tank

Middle

Buer tank B ottom

3.1.2. Bill of materials

1 Three-way mixer valve

2 Three-way valve On/O

3 Pump

4 Pump, circulation

5 Plate heat exchanger

6 Temperature/ow meter

7 Controller

8 Temperature sensor

9 Safety valve

10 Non-return valve

11 Shut-o valve

12 Temperature sensor

13 Temperature sensor

14 Temperature sensor

plate and in the documents in the appendixes

(cover sheet, circuit diagram, data sheet).

CW

¾“

Circ.

¾“

HW

¾“

DKDHR

Optional accessories

Option 1: Temperature control, inlet

Option 2: Circulation

Option 3: Shut-o valves/ball valves

Option 4: Stratication control

3.1.3 Type plate

The type plate is attached to the system.

The type plate contains the following data:

– Manufacturer

– Device no.

– Year of construction (year/calendar week)

– Type

– Power

– Dimensioning parameters

– Max. permissible operating temperature

– Max. permissible operating pressure

– Test pressure

VI.GE.T1.02 © Danfoss 12/2010

Example of type plate

11

Page 12

Installation, start-up and operating instructions FLS-50

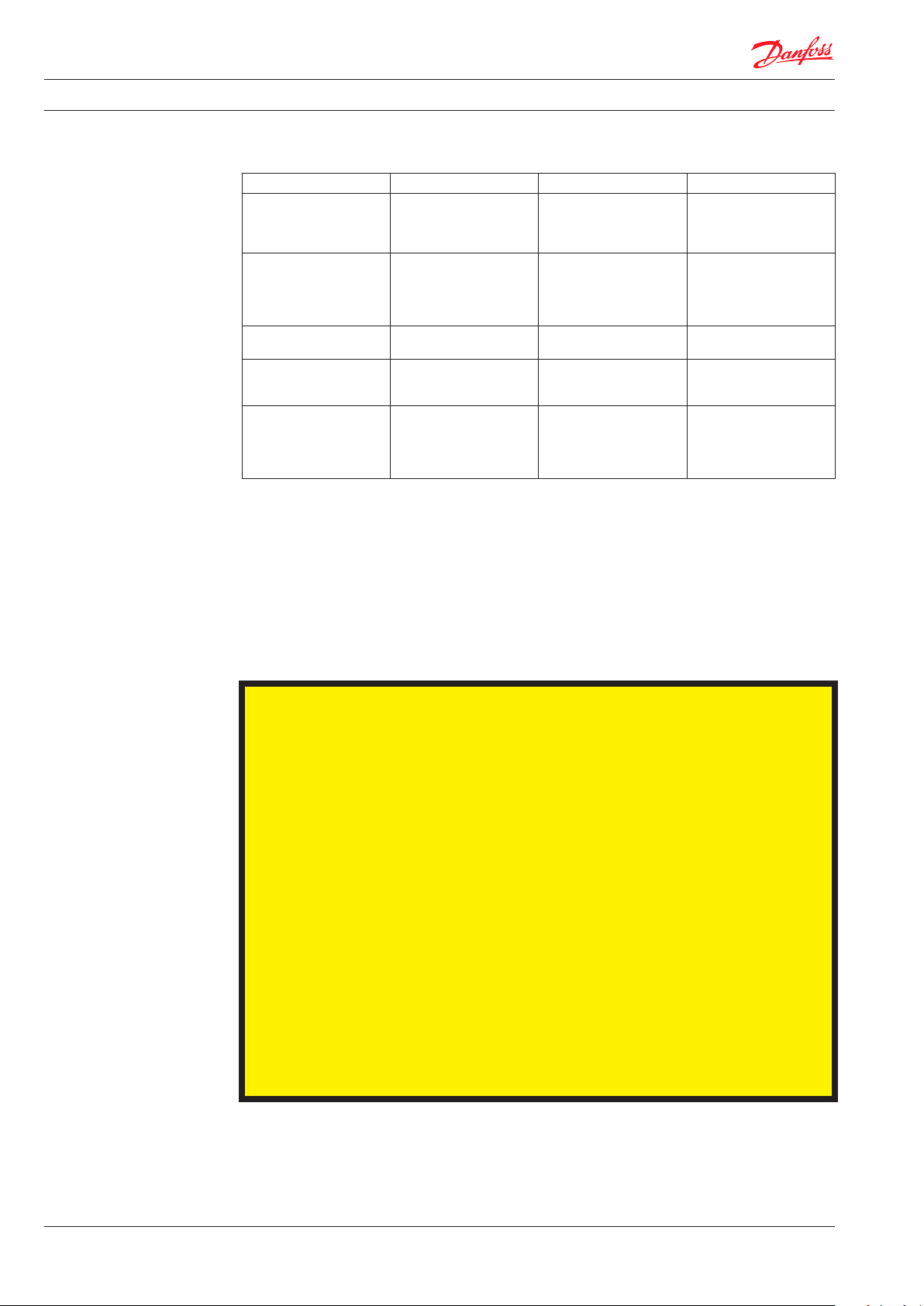

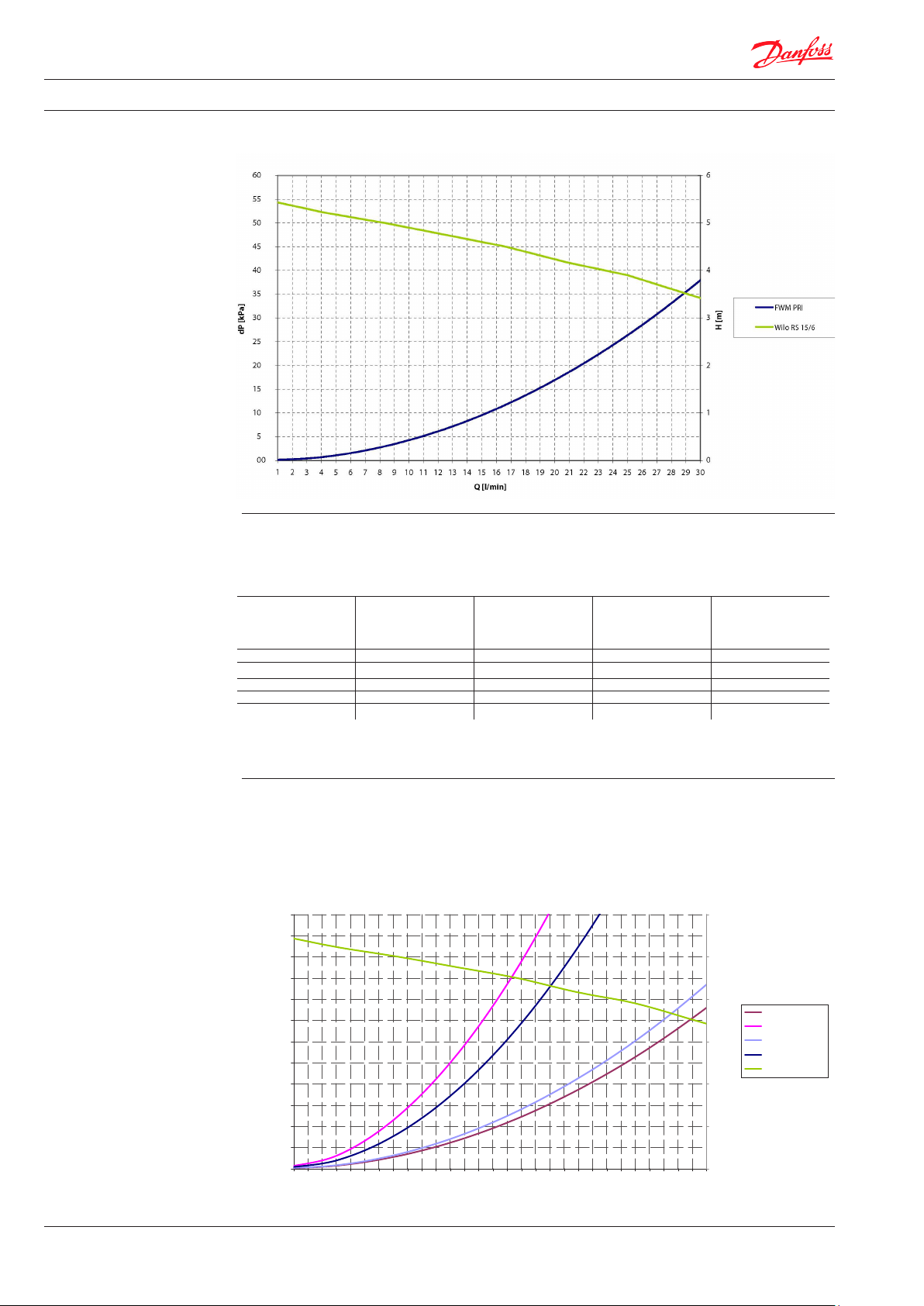

3.1.4 Pressure loss curve

3.1.5 Capacity examples

Capacity examples

HW

Temperature

°C

10/45 20 50 60/20 18

10/45 14 34 50/27 21

10/45 25 60 75/16 15

10/55 18 55 75/20 15

10/55 12 36 60/30 18

* Max. chloride compounds 150 mg/l

HW

Flow rate

l/min.

HW

Power

CW

Supply/Return

Primary

°C

Flow

Primary

l/min.

3.1.6 FLS-50 + Options

When possible options are used the pressure loss ratio changes as shown in the curve below. The

TVM-H 25 mixing valve, among other elements, is recommended for primary-side installation with

service water values with dH > 20. This means a recommended ow temperature of 65°C can be set.

FLS‐50+Optioner

60,00

55,00

50,00

45,00

40,00

35,00

30,00

dP[kPa]

25,00

20,00

15,00

10,00

5,00

0,00

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

Q[l/min]

6

5

4

3

2

1

0

H[m]

FLS‐50PRI

FLS‐50+Optioner

FLS‐50+AMZ113

FLS‐50+TVM‐H25

WiloRS15/6

12

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Page 13

Installation, start-up and operating instructions FLS-50

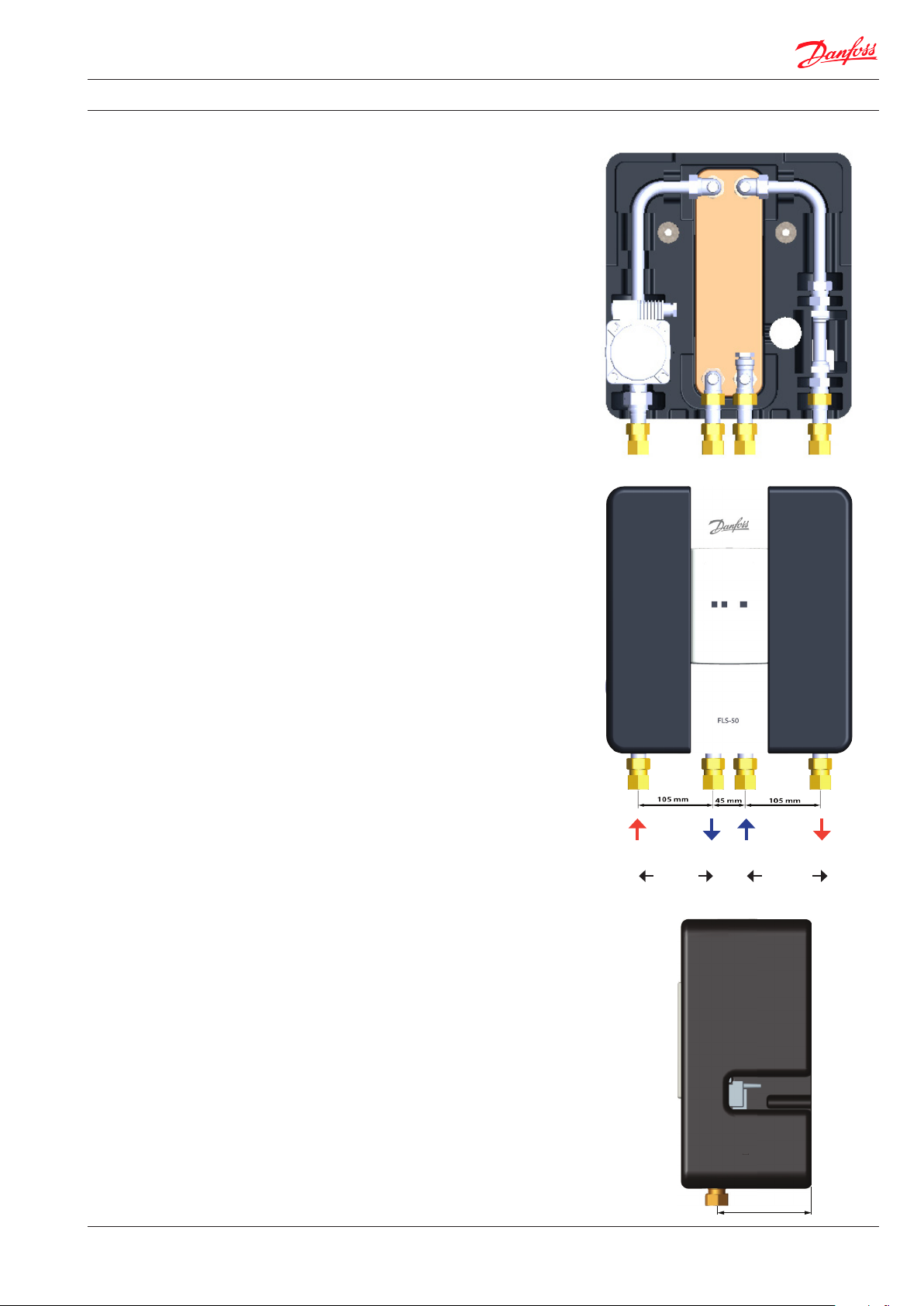

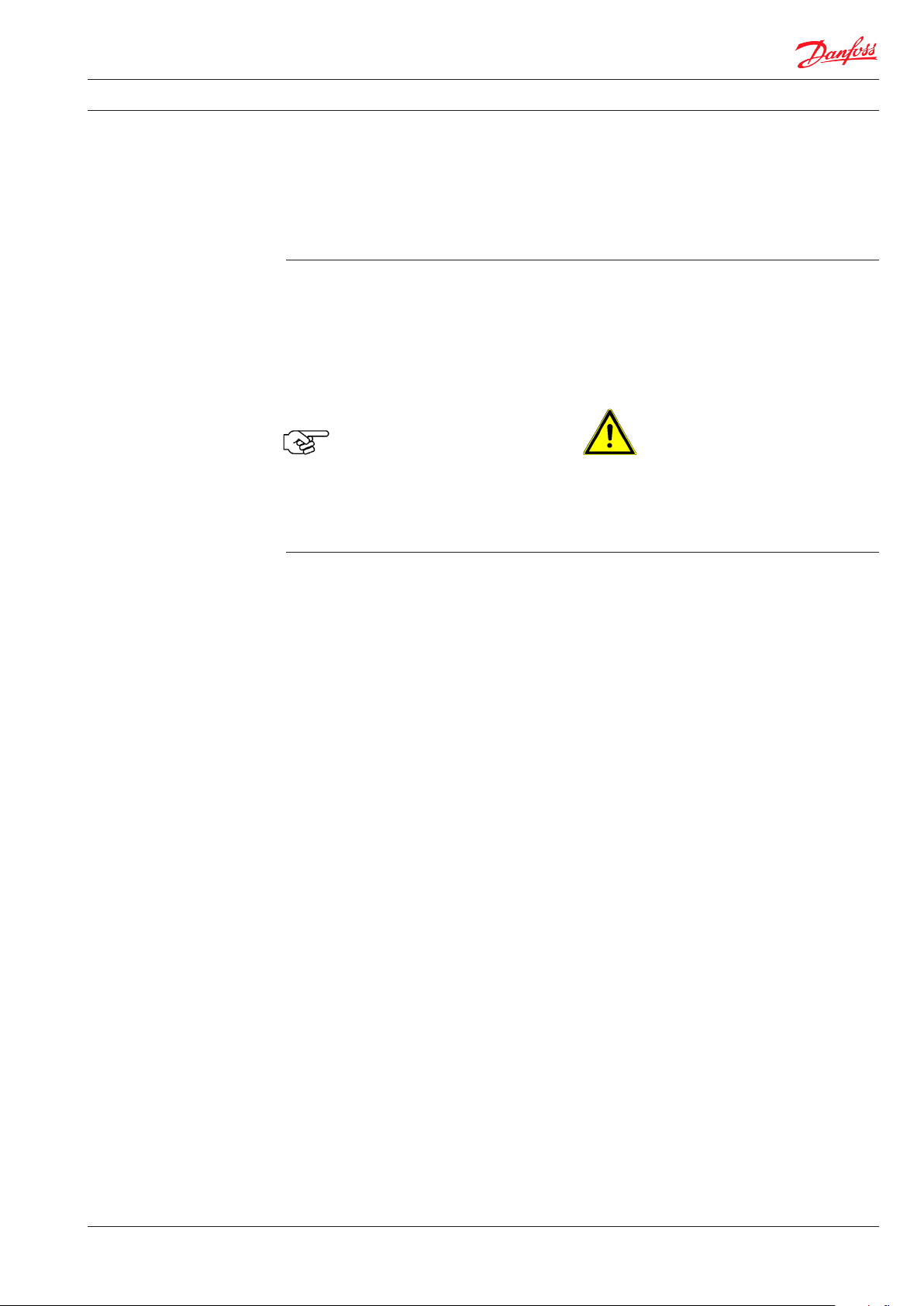

3.1.7 Dimensions and photo of

components

1 Three-way valve (option)

2 Three-way valve On/O (option)

3 Pump

4 Pump, circulation (option)

5 Plate heat exchanger

6 Temperature/ow meter

7 Controller

8 Temperature sensor

9 Safety valve (option)

10 Non-return valve

11 Shut-o valve (option)

10

5

3

6

8

Primary

Supply

Primary

Return

Primary Domestic

7

DHW DCW

hot water

DKDHR

VI.GE.T1.02 © Danfoss 12/2010

130 mm

13

Page 14

Installation, start-up and operating instructions FLS-50

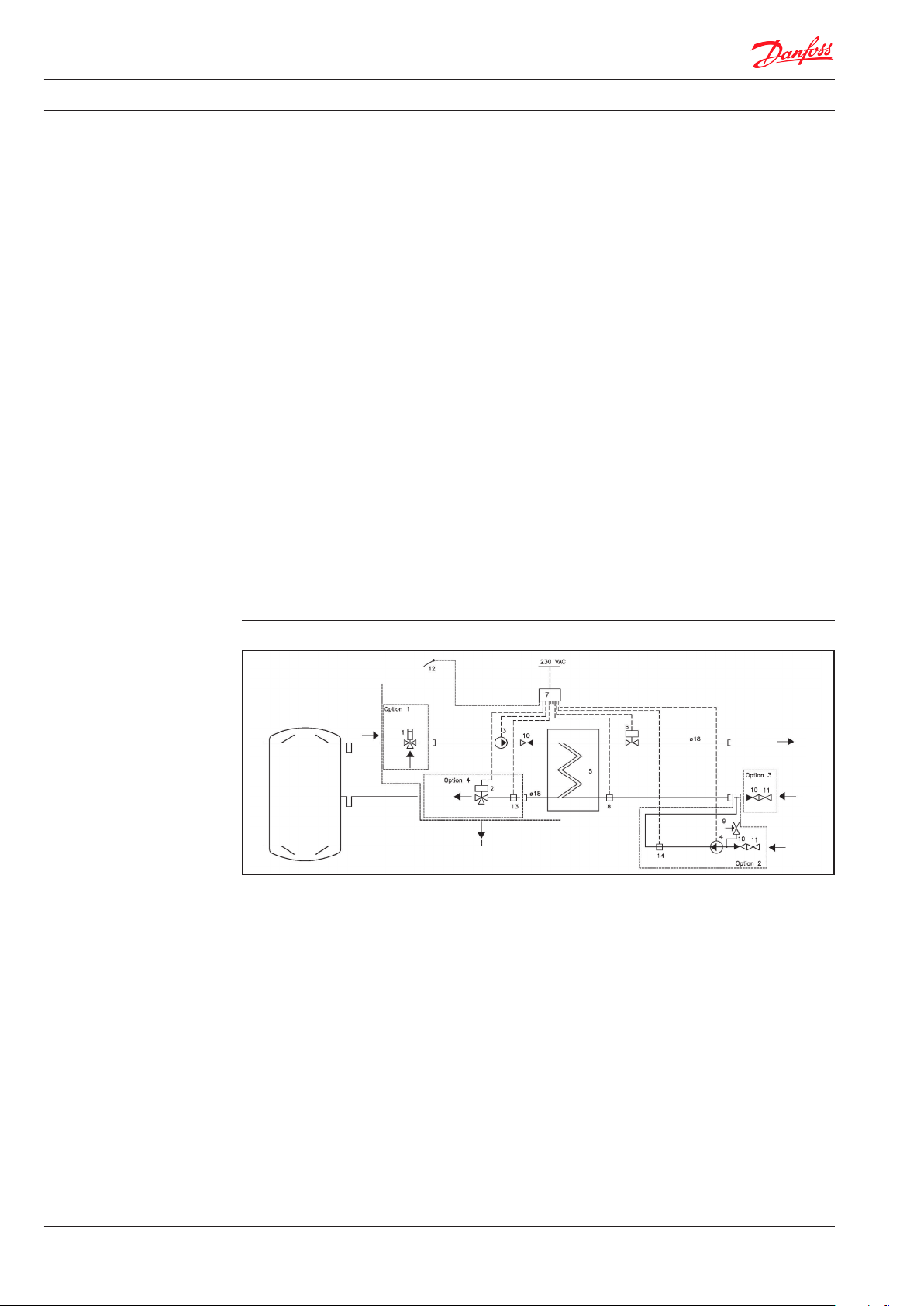

4 Function

4.1 Function / General

The FLS-50 is a domestic hot water heater for a

single household; the water is heated by an

instantaneous water heater

in combination with a buer tank. The hot water

supply and hot water feed to the buer tank can

generally be ensured with solar energy in

combination with other energy sources, such as

oil or gas boilers, district heating or heat pumps.

The instantaneous ow process oers good

protection against Legionella because the

amount of warm water in the heat exchanger is

kept to a minimum. The heat exchanger ensures

an adequate supply of domestic hot water at

supply temperatures from 50°C.

The FLS-50 ensures a constant hot water

temperature, even in case of peak ow and

uctuation supply temperatures, so that the

consuming devices are supplied with sucient

hot water in all operating conditions.

Primary circulation system

The primary side consists of a pump, a nonreturn valve and a temperature sensor.

Secondary circulation system

The secondary side consists of a ow/

temperature sensor on the hot water side and a

temperature sensor at the cold water inlet.

Control

The electronic controller in the FLS-50 ensures a

constant hot water temperature.

The controller receives signals from 3 sensors

that measure the supply temperature in the

primary side in the buer tank, the secondary

ow rate, the cold water inlet and the hot water

outlet. The electronic controller converts these

signals for innitely variable speed control of the

primary side pump that supplies the heat

exchanger with energy from the buer tank as

required.

Options

Options include a primary-side mixer valve, a

primary-side switching valve and sensor, an

installation kit for HW circulation, constant

maintenance of the circulation temperature by

power control of the pump and shut-o and

non-return valves at the CW inlet.

Construction

All pipes are stainless steel with threaded

connections. The entire mechanical construction

is xed in a prefabricated EPP insulated cabinet

by means of a click-in system and thus ensures

stability and easy replacement of spare parts.

The FLS-50 is to be installed vertically on the

buer tank or on a wall next to the buer tank.

Installe d in top buer

tank

Scope of del ivery

Buer tank

Top

Buer tank

Return

1 Three-way valve

2 Three-way valve On/O

3 Pump

4 Pump, circulation

5 Plate heat exchanger

6 Temperature/ow meter

7 Controller

8 Temperature sensor

9 Safety valve

10 Non-return valve

11 Shut-o valve

12 Temperature sensor

13 Temperature sensor

14 Temperature sensor

Buer tank

Middle

Buer tank B ottom

Optional accessories

Option 1: Temperature control, inlet

Option 2: Circulation

Option 3: Shut-o valves/ball valves

Option 4: Stratication control

Circ.

¾“

DHW

¾“

DCW

¾“

14

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Page 15

Installation, start-up and operating instructions FLS-50

5 Setup

5.1 Assembly and installation/general

Domestic water heater systems are usually

delivered completely piped and wired in a foam

insulated cabinet. All assemblies and

components are xed in the insulated cabinet by

means of a click-in system. System connections

are specied in the data sheet and in these

instructions.

Make sure that the wall has the necessary

load-bearing capacity for the system (including

the weight of the water!).

Examine the prepared connections carefully so

that they can be joined without any tension.

5.1.1 Figure FLS-50

NOTE!

Do not use a pipe wrench on screwed

joints. Use only a suitable spanner.

You will nd pictures of the device below.

DKDHR

VI.GE.T1.02 © Danfoss 12/2010

Assembly holes

15

Page 16

Installation, start-up and operating instructions FLS-50

6 Transport, packing and

storage

WARNING! Danger to life

When the system is being lifted, turned

and lowered there is a risk of serious

personal injury and material damage

from falling parts. Never stand beneath suspended

loads.

Always observe the following safety rules:

– Adapt transport to suit local conditions.

– Use only approved lifting equipment and

lashing gear with adequate load-bearing

capacity.

– Fix the device only on suitable lashing points,

not on protruding machine parts or on rings of

built-on components. Make sure that the

lashing sits securely.

6.1 Transport pallets with a fork lift truck

Packages that are xed on pallets may be

transported by a fork lift truck under the

following conditions:

• The fork lift truck must be designed to carry the

weight of the transport units.

• The driver must be authorised to drive the fork

lift truck.

Lifting:

1. Drive the fork lift truck with the forks

between or beneath the cross pieces of the

pallet.

2. Drive the forks in so far that they protrude

from the other side of the pallet.

3. Make sure that the pallet cannot topple over if

the centre of gravity is not in the middle.

4. Lift the package and start transporting the

pallet.

WARNING! Danger to life

When the pallet is being lifted, turned

and lowered there is a risk of serious

personal injury and material damage

from falling parts. Never stand beneath suspended

loads.

– Ropes and straps must have safety hooks. Do

not use damaged ropes or straps with abraded

areas. Do not place ropes or straps on sharp

edges, do not knot or twist them. Pay attention

to the centre of gravity of the device when

lashing.

– Never lift, swivel or lower loads above people.

– Always take great care and attention when

moving the device.

Transporting with a fork lift truck

16

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Page 17

Installation, start-up and operating instructions FLS-50

6.2 Transport inspection

Check the delivery for completeness and transport

damage immediately on receipt.

In case of obvious transport damage, do not accept

the delivery or accept it only with provisions.

Record the extent of the damage on the transport

documents/forwarder's delivery note.

6.3 Packaging

The devices are delivered in dierent forms of

packaging.

Packaging may include materials that are added

to the packages as moisture or frost protection

(e.g. silica gel bags, anti-freeze, etc.).

If no other arrangement regarding returning the

packaging material has been made, it remains

with the customer.

NOTE!

The German Packaging Ordinance that

came into eect on 1 December 1991 states that

transport packaging may be returned to the

6.4 Storage

When the packages have been unloaded they

must be stored until they are to be installed with

consideration of the shipping marks.

Packaged machine parts and accessories must

not be unpacked.

The following regulations apply to storage:

– Store in a dry place. Relative humidity:

max. 60 %.

– Make sure that the packages are not stored

outdoors. It must also be ensured that the

oor of the storage room is dry while the parts

are being stored.

Initiate a complaint.

Complain about hidden defects as soon as they

become obvious, as claims for compensation can

be asserted only within the statutory period.

supplier. Our transport packaging may be returned

to your local Danfoss department

as long as we do not incur

any costs. We will not accept transport

packaging that is delivered and not prepaid.

NOTICE!

Packaging must be disposed of in an

environmentally compatible manner and

in agreement with the corresponding

disposal regulations. For this purpose DANFOSS has

signed an agreement with Interseroh AG and

packaging may be deposited at the company's

collection points.

– Protect the packages against direct sunlight.

Storage temperature 15 to 25 °C – store dust

free.

– Avoid mechanical vibration and damage.

– If parts are to be stored for a longer period,

longer than approx. 3 months, the conservation

measures should be checked. In case of

aggressive weather conditions, the

conservation may have to be renewed.

DKDHR

VI.GE.T1.02 © Danfoss 12/2010

17

Page 18

Installation, start-up and operating instructions FLS-50

7 Installation

WARNING! Risk of injury.

Improper installation and assembly can

cause serious injury and/or material

damage. Therefore, installation and

assembly work may be carried out only by qualied

personnel in compliance with the safety

regulations.

Pipe connections are generally:

- Heating connections as weld-on ends

- Flange connections acc. to DIN EN (pressure stages PN 6 … 40)

- Threaded connections acc. to DIN 2999 as female or male threads

- Threaded connections acc. to DIN 2993/ISO 228 as male threads

7.1 Assembly preparations

Before starting assembly, check that all

assemblies and individual parts are complete

and undamaged.

NOTICE!

Damaged components must not be

assembled.

Install only fully intact parts.

7.1.1 Electrical connection

Only a qualied electrician may carry out the

electrical installation of the station in compliance

with all applicable rules and regulations.

The FLS-50 is wired and tested in the factory.

Use only compliant connection parts to connect

the system to the household system. Check

compliance of the connection type, the pressure

stage and the dimension.

Please ensure the following before you begin with

the electrical connection:

• Read the relevant parts in the warning information section.

• The station should be connected to a

230 V AC power supply. The power connection must be carried out in accordance with

ocial regulations.

• The system must be wired and connected

to an external main switch so that it can be

switched o for maintenance, cleaning or repair work.

18

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Page 19

Installation, start-up and operating instructions FLS-50

Electrical connection

Fresh water controller FWC3

Sensor side

max. 12V

Note

Extra low voltages max. 12VAC/DC

Connection in left terminal compartment

Terminal: Connection for:

S1 PT1000 cold water

(Optional, see below)

S2 PT1000 circulation

S3 PT1000 buer tank opt.

S4 Supply primary opt.

S5 VFS hot water

(yellow wire)

S6 VFS ow l/min

(white wire)

+ VFS +5V DC

(brown wire)

- Bridge sensor -

The PT1000 sensor can be poled

any way.

Power supply side

230VAC

Danger

Power supplies 230VAC 50-60Hz

Connection in right terminal compartment

Terminal: Connection for:

L Power supply outer cable L

N Power supply neutral

conductor N

R1 Fresh water pump L N

Fresh water pump N

R2 Circulation pump L

N Circulation pump N

The earth wire PE is connected to the PE

metal terminal block

Relay R1: Only for controlling the

speed of standard pumps, min.

Note

load 20VA

The sensor earth (S1-S4) and the VFS (green wire) are connected to the sensor terminal

block - .

Sensor1/Cold water: If no sensor is connected, a temperature of 10°C is assumed for the

cold water. See also 11.2 Sensor calibration on Page 22

Sensor mounting S3 contact sensor must be mounted on

the primary return before the switching

valve.

DKDHR

VI.GE.T1.02 © Danfoss 12/2010

19

Page 20

Installation, start-up and operating instructions FLS-50

Electrical connection

Fresh water controller FWC4

Sensor side

max. 12V

Note

Extra low voltages max. 12VAC/DC

connection in left terminal compartment.

Terminal: Connection for:

S1 PT1000 cold water

(Optional, see below)

S2 PT1000 circulation

S3 Primary, return (opt.)

S4 Primary, supply (opt.)

S5 not occupied

S6 0..10 V / PWM

+ not occupied

- Bridge sensor -

Power supply side

230VAC

Danger

Power supplies 230VAC 50-60Hz

Connection in right terminal compartment

Terminal: Connection for:

L Power supply outer cable L

N P o we r su pp ly n eu tra l

conductor N

R1 Fresh water pump L N

Fresh water pump N

R2 Circulation pump L

N Circulation pump N

R3 Valve, return L (opt.)

N Valve, return N (opt.)

The PT1000 sensor can be poled any way

The earth wire PE is connected to the PE

metal terminal block

Relay R1: Only for controlling the

speed of standard pum ps, min.

Note

load 20VA

The sensor earth (S1-S4) is connected to the sensor terminal block - .

The VFS sensor is inserted directly into the slot on the circuit board in the sensor terminal area

Sensor1/Cold water: If no sensor is connected, a temperature of 10°C is assumed for the

cold water. See also 11.2 Sensor calibration.

Sensor mounting S3 contact sensor must be mounted on the primary return before the switching valve.

S4 tank sensor is provided and must be mounted at the top in the buer tank.

AMZ 113 switching valve is provided and must be mounted in the primary return and

connected electrically to the Mate-n-lok.

20

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Page 21

Installation, start-up and operating instructions FLS-50

7.1.2 Assembly of FLS-50

The device may be installed and connected only

by authorised personnel. Installation must be in

compliance with the local standards and

regulations.

The FLS-50 must be equipped with features that

ensure that the device can be separated from all

energy sources.

When the device is being installed, attention

must be paid that the domestic water heater

remains accessible for assembly and

maintenance work.

All pipes and connections must be cleaned and

rinsed before installing the domestic water

heater

IMPORTANT! Tighten all screws and connections

since they may have become loose during

transport.

The water heater is intended for wall installation.

Fix the station to the wall with two bolts, screws,

expansion plugs or similar.

With systems with a safety valve, a connection

for drainage must be constructed in accordance

with local regulations.

Assembly holes

24

All pipe connections have

a thread ex factory

Earth:

H 375 x W 345 x D 250 mm

Connections:

1 Primary supply,

2 Primary return

3 DCW supply

4 DHW supply

Connection dimensions:

All connections: G¾ (IG)

Weight: Approx. 11 Kg

1 2 3 4

DKDHR

VI.GE.T1.02 © Danfoss 12/2010

21

Page 22

Installation, start-up and operating instructions FLS-50

7.1.2.1 Assembling the basic

device

The station is delivered in a foam insulated

cabinet - as a click-in system. The station is

installed in the bottom part of the insulated

cabinet.

Please note:

The buer tank temperature sensor is

delivered separately and has to be installed

on site and be connected to the controller.

3 m cable for the buer tank temperature

sensor is preinstalled in the controller

1) Install the temperature sensor (delivered

separately) at the top of the buer tank.

2) Install cable (preinstalled from controller)

from the station to the temperature sensor.

3) Connect the temperature sensor to the

cable.

4) Connect the power socket (Schuko) to

230 V AC.

22

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Page 23

Installation, start-up and operating instructions FLS-50

7.1.2.2 Assembling Option 1

Primary mixer valve

7.1.2.3 Assembling Option 2

Circulation

The TVM-H is an automatic three-way mixer

valve with inbuilt thermostat to maintain

and ensure a constant temperature.

For further information, see the

enclosed operating instructions

TVM-H / TVM-W.

A complete circulation kit is available as an

option for connecting a circulation system:

Gasket ¾" 24 x 17.5 x 3 mm (145.056) (1)

Circulation kit, complete (oem. 134.102) (2)

Gasket ¾" 24 x 17.5 x 3 mm (145.056) (1).

2

1

1

DKDHR

Installing the circulation kit:

• Dismantle the double socket joint

(in Point A).

VI.GE.T1.02 © Danfoss 12/2010

A

2

1

1

23

Page 24

Installation, start-up and operating instructions FLS-50

• Install the gasket and circulation kit in

Point A.

• Replace the double socket joint and the

gasket (in Point B).

Connect the temperature sensor to the

controller in terminal S2 and minus (÷).

A

2

B

24

Connect the pump to the controller in

terminal R2, neutral and to the earth.

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Page 25

Installation, start-up and operating instructions FLS-50

7.1.2.4 Assembling Option 3

Non-return valve and shut-o

valve

The non-return valve and the ball valve can

be installed directly on the station (see

Photo 1) (please note: dismantle the double

socket joint in Point A before installing the

non-return valve and the ball valve), or on

the circulation kit (see Photo 2).

Gasket ¾" 24 x 17 x 1 mm (171.040) (1)

Non-return valve (135.120) (2)

Gasket ¾" 24 x 17 x 1 mm (171.040) (1)

Ball valve ¾" M/N (131.055) (3)

A

1

2

1

3

Photo 1

Photo 2

DKDHR

VI.GE.T1.02 © Danfoss 12/2010

25

Page 26

Installation, start-up and operating instructions FLS-50

7.1.2.5 Assembling Option 4

In this version the station is built

with the Sorel FWC 4 Controller.

Cables for the switching valve

and the sensors have to be wired

on site.

The AMZ 113 is a three-way switching valve

for optimum zone control.

For further information, see the

enclosed operating instructions

AMZ 113.

Connect the controller in terminal S3 and

minus (÷).

Datablad ON/OFF Zoneventiler

Anvendelse

Anlægseksempler

2-vejs type AMZ 112

3-vejs type AMZ 113

2-vejs zoneventil AMZ 112 anvendes i

centralvarme- og fjernvarmeanlæg til ON/

OFF regulering af enkelte eller flere varme/

køleflader.

Begge motorer kan styres af et SPST kontaktsæt med sluttefunktion eller en SPDT

skiftekontakt. Motorerne er desuden forsynet med endestopkontakt til signal eller til start af

pumpe, blæser eller kedel ved helt åben ventil. Der er mulighed for manuel betjening.

Ventiler leveres med indvendigt gevind i str. DN 15, 20 og 25.

RA 2000 RA 2000

Zonestyring af radiatoranlæg

Styring af fastbrændsel i forbindelse med kedel Prioritetsstyring af varmtvandsbeholder

VD.HC.N1.01 © Danfoss 11/03 1

3-vejs zoneventil AMZ 113 er en skifteventil,

der anvendes til fordeling af vandstrømme i

f.eks kedelanlæg i forbindelse med

fastbrændselskedel e ller til pri oritetsstyring.

TP7000 M/A

AMZ 112

Zonestyring af varmeblæsere

VVS-automatik 9.10.00

AMZ 112

RA 2000

26

Connect the three-way valve to the

controller in terminal R3, neutral L

and to the earth.

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Page 27

Installation, start-up and operating instructions FLS-50

8 Start-up The following measures must be carried out:

– The rst time the device is used (see appendix,

Start-up log)

– When the device is restarted after complex

maintenance work has been carried out

– When the device is restarted after having

been relocated

– When the device is restarted after a fault has

been rectied.

– When the device is restarted after it has not

been used for a long period

– Check the water quality. Max. 150 mg/l

Before start-up check that all safety regulations

have been observed.

Fill the household system with domestic water.

To prevent damage, make sure that when the

system is being lled the pressure does not

exceed the permitted operating pressure.

8.1 Controller

The electronic controller is set in the factory.

Connect the controller to the power supply.

Select the language, set the date and time and

the controller is

ready for operation.

NOTE!

Pay attention to the measures required to

maintain domestic water quality. Important

information can be found in the technical rules (see

overview of regulations in the Appendix).

By agreement, the device is installed and started

up for the rst time by the manufacturer's

employees, authorised partner companies or the

specialist installation company.

Customers must not start the device for the rst

time on their own.

In any case, the completed start-up log (see

appendix) is a requirement for the device

warranty.

Before the rst start-up, the installation company

should rinse the secondary side adequately.

Check that all connections are sealed and joined

properly.

Fill the system to the required static height.

SPECIAL WARNING!

If a circulation kit is connected, you must

select menu item 5.4 "Circulation On" to switch on

the circulation pump.

Changes to the settings can be made according

to the controller manufacturer's instructions,

which are enclosed with the station.

DKDHR

VI.GE.T1.02 © Danfoss 12/2010

27

Page 28

Installation, start-up and operating instructions FLS-50

9 Operation

The system is operated in

automatic mode. During

operation no personnel are

needed near the system.

8.2 Fault and shutdown

WARNING! Risk of injury from electrical

current.

Leaking water can make the entire

system live, which can endanger life.

Before starting work, isolate the system and make

sure that it cannot be switched on again.

WARNING! Risk of burning.

In case of leaks on the primary side, water

at temperatures up to 95°C can escape.

Risk of burning.

8.3 Restarting after a fault

After a fault, the system is restarted

by the specialist company.

9.1 Switching the device on

To switch the device on, pay attention to the

requirements described in Section 8 " Start-up".

9.2 Switching the device o

The device is switched o at the main switch of

the electronic controller.

The heating pump is connected to the

power supply.

Immediately switch o the main switch or

remove the plug.

Close the shut-o tting.

It is important that you have a specialist

company rectify the fault.

The system can be switched on at the main

switch of the electronic controller and then it

operates automatically.

28

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Page 29

Installation, start-up and operating instructions FLS-50

10 Maintenance

10.1 Safety information

The appendix contains an overview of the most

WARNING!

Work on the device may be carried out

only by qualied, specially trained

personnel.

The following personal protection equipment must

always be worn close to the device:

– Close tting clothing (no loose sleeves,

rings, etc.)

– Safety glasses to protect the eyes against

ying parts and liquids

– Safety shoes to protect the wearer against

falling parts and slipping on slippery oors.

WARNING! Risk of injury from electrical

current.

Only qualied electricians may work on

electrical systems observing

the applicable safety regulations.

Before starting work, switch of the power supply

and make sure that it cannot be switched on again.

Maintenance schedule (recommendations)

Interval Maintenance work Comments

Check all connections tighten if necessary and/or replace gaskets

Check all parameters for set/target values and

permissibility

General visual check of all components for

damage

Check the functions of the safet y valve see also DIN 1988

Every 12 months

Check the functions of electric and elec tronic

components, switches, etc.

Clean lters and strainers see also DIN 1988

Check the electric safety features Temperature monitor and/or limiter

Check all components for function and

operability

Check outer condition Colouring (rust), thermal insulation

important technical regulations. For maintenance

of the system you will nd information especially

in DIN 1988, VDI 2895 and VDI 6023.

We recommend that you arrange for a local

installation company to service the system

regularly.

Section 10.2 contains the most important

measures for specic components and

assemblies.

The appendix also contains the corresponding

maintenance and operating instructions for

individual components that should be observed.

In case any are exceeded: Restore the proper

parameters

in case of obvious damage, check the

functions and replace if necessary

Manual switching on and o and opening and

closing of motor drive systems

e.g. open and close shut-o ttings

DKDHR

SPECIAL WARNING!

After maintenance work has been carried

out, all EPDM gaskets should be replaced.

VI.GE.T1.02 © Danfoss 12/2010

29

Page 30

Installation, start-up and operating instructions FLS-50

10.2 Maintenance work

The main jobs that should be carried out within

the scope of maintenance are described below.

Additional information can be found in the

manufacturers' instructions in the appendix.

This list is not complete. In any case, it is

important that the statutory and other relevant

technical regulations and requirements based on

local conditions are observed (e.g. TABs, power

company regulations, etc.)

Fittings:

Generally, the ttings used are maintenance free.

Within the scope of maintenance work the

functions should be checked in terms of

moveability of hand wheels and levers by

opening and closing them.

This prevents dirt and calcium residues settling

on balls, valve discs and valve seats. In Appendix

I you will nd the manufacturers' instructions for

the most common components.

Heat exchanger:

After long operation, because of the relatively

high temperatures the plates or tubes of heat

exchangers are especially subject to calcication.

Within the scope of the above maintenance work

these should be cleaned if there is a reduction in

power. Brazed plate heat exchangers can be

rinsed. In case of more serious deposits, weak

inhibited acid solutions (e.g. 5% formic, acetic or

phosphoric acid) may be used.

The drawing shows this arrangement:

Rinsing/cleaning brazed plate heat exchangers

Tank:

Appendix 1 (No. 3) contains information about this.

10.3 Measures after maintenance work

After maintenance work and before switching

the device on again, remember:

– Check that all screwed connections are tight.

– Check that all safety features, covers, tank lids

that were removed have been replaced

properly.

– Make sure that all tools, materials and other

equipment that were used have been

removed from the working area.

Tubes:

The tubes used are made from high-quality

stainless steel. If they are contaminated, they can

be treated like the tank.

– Clean the working area and remove any

spilled materials, such as liquids, processing

material.

– Make sure that all safety features on the

device and the system work properly.

30

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Page 31

Installation, start-up and operating instructions FLS-50

11 Faults

Faults in electrical systems or

in mechanical or hydraulic

components may be repaired

only by specially trained and

qualied personnel.

In case of faults that cannot be

rectied with the following

measures, notify the

manufacturer or an authorised

service partner.

11.1 Functional faults

Fault Possible cause Rectifying the fault Comment

Domestic hot water

temperature too

low

Water hygien e at

risk!

Domestic hot water

temperature too

high

Risk of sc alding.

Domestic hot water

temperature

uctuates or is not

constant

Risk of sc alding.

Medium leaking

Risk of sc alding.

No power - Switch on the main switch - Check

No water supply

- no cold water pressure

Incorrec t controller setting(s) Correct settings Controller instructions

Closed shut-o tting(s) Open tting

Defective sensor Replace sensor

Supply pump defective or not

switched on

Circulation pump defective or

not switched on

Defective VFS valve Clean/ensure smooth operation or

System wrongly dimensioned - Check dimensioning

System unable to provide

sucient water

Heat exchanger furred up Replace heat exchanger

Cavitation on the pump Increase primary system pressure Pump makes noises

- No

power supply

- Electric drive open

Incorrec t controller setting(s) Correct settings Controller instructions

Defective sensor Replace sensor

Defective VFS valve Clean/replace valve

Incorrec t controller setting(s) Correct settings

Pump defec tive Replace pump

Leaking connections (ange/

screw joints)

Leaking ttings (housing/screw

joints)

- Leaks from brazed

heat exchangers

- Contamination/calcication

Pressure surges

the inlet lines

- Check fuses/circuit breaker

Operating conditions - Pressure Volume

Switch on/replace

Switch on/replace

replace

- Extend/enlarge system

- Check dimensioning

- Extend/enlarge system

- Take system out of op eration

- Ensure power supply

- Manual emergency operation

- Controller gain

- Reset time

- Valve travel time

Switch system o

- Check operating parameters for

permissibility

(see type plate)

- Check connection, tighten

if necessary, replace gaskets

- Check that t tings are installed

correctly - Tighten stung (gasket)

sleeves or replace component

Replace device See manufacturer's

Water supplier

Contact our exper t advisors

Controller instructions

See manufacturer's

instructions or contact

customer service

instructions or contact

customer service

DKDHR

VI.GE.T1.02 © Danfoss 12/2010

31

Page 32

Installation, start-up and operating instructions FLS-50

11.2 Safety information

WARNING!

If faults are not rectied properly, this can

lead to serious injury and/or

material damage Therefore, faults may be

rectied only by trained and

authorised personnel.

12 Spare parts

11.3 What to do in case of faults

In all cases:

1. In case of faults that represent a direct danger

for people, property and/or operating safety,

immediately stop the system with the

emergency stop function.

2. In case of faults that do not cause such

dangers, switch the system o using the

system controls, also interrupt the power

supply to the system and make sure that it

cannot be switched on again.

Use only the manufacturer's original spare parts.

NOTICE!

Wrong or faulty spare parts and

components from third-party

manufacturers can cause serious

damage, incorrect functions or complete failure of

the device.

If unapproved spare parts are used, this voids all

warranty, service, compensation and liability

claims against the manufacturer, its agents,

dealers and representatives.

When ordering spare parts, you must provide:

– Device type

– Serial/Production No.

– Part No. /Article Number (see bill of materials

circuit diagram)

3. Immediately notify the person responsible

about the fault.

4. Have the type and scope of the fault identied

by authorised, qualied personnel, determine

the cause of the fault and have it rectied.

– Quantity

– Name

– Required form of delivery (post, freight, sea,

air, express)

– Shipping address

– If necessary, a sketch or photo with comments

Orders for spare parts without the above

information cannot be handled. If no information

about the type of shipping is provided, the parts

will be delivered according to the supplier's

preference.

Appendix I also contains a list of the most

important suppliers of bought-in components,

where spare parts can also be requested after

the end of the warranty period . In these cases,

also notify the manufacturer about the installed

parts in detail, so that equal replacements can be

oered.

32

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Page 33

Installation, start-up and operating instructions FLS-50

13 Appendix I

DKDHR

VI.GE.T1.02 © Danfoss 12/2010

33

Page 34

Installation, start-up and operating instructions FLS-50

13.1 Heat exchanger calculations

34

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Page 35

Installation, start-up and operating instructions FLS-50

DKDHR

VI.GE.T1.02 © Danfoss 12/2010

35

Page 36

Installation, start-up and operating instructions FLS-50

36

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Page 37

Installation, start-up and operating instructions FLS-50

DKDHR

VI.GE.T1.02 © Danfoss 12/2010

37

Page 38

Installation, start-up and operating instructions FLS-50

38

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Page 39

Installation, start-up and operating instructions FLS-50

13.2 Pressure loss curvePrimary pump

DKDHR

VI.GE.T1.02 © Danfoss 12/2010

39

Page 40

Installation, start-up and operating instructions FLS-50

13.3 Temperature sensor

40

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Page 41

Installation, start-up and operating instructions FLS-50

DKDHR

VI.GE.T1.02 © Danfoss 12/2010

41

Page 42

Installation, start-up and operating instructions FLS-50

42

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Page 43

Installation, start-up and operating instructions FLS-50

DKDHR

VI.GE.T1.02 © Danfoss 12/2010

43

Page 44

Installation, start-up and operating instructions FLS-50

13.4 Temperature/ow meter

44

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Page 45

Installation, start-up and operating instructions FLS-50

13.5 Pressure loss curve

- circulation pump

DKDHR

VI.GE.T1.02 © Danfoss 12/2010

45

Page 46

Installation, start-up and operating instructions FLS-50

14 Appendix II

46

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Page 47

Installation, start-up and operating instructions FLS-50

14.1 Declaration of Conformity

DKDHR

VI.GE.T1.02 © Danfoss 12/2010

47

Page 48

Installation, start-up and operating instructions FLS-50

48

Danfoss A/S

District Energi Division

Omega 7, Søften

DK-8382 Hinnerup

Telephone: +45 87 43 89 43

Fax: +45 87 43 89 44

heating@danfoss.com

www.dh.danfoss.com

VI.GE.T1.02 © Danfoss 12/2010

DKDHR

Loading...

Loading...