Page 1

Technical Paper

Flow and Dierence Pressure Optimize Guide

Introduction

Balancing a

heating system

Between 80 and 90 % of all buildings in Northern

Europe have heating systems with little or no

hydronic balancing.

The results are:

• Discomfort due to under- or overheating

• Discomfort due to noise problems

• High energy costs

The purpose of balancing a heating system is to

optimize the ow and get as good a heat consumption as possible.

To achieve this we have to make sure that the

right amount of water is distributed to the

radiators, as well as the pump pressure or setting

of the dierential pressure regulator is correct.

Balancing - installation - performance

1. Exact calculation of the heating output,

or

2. Estimation of the Heating output:

• Get drawings with room sizes in m2 of all ats.

If drawings are not available a laser range

nder can be used for measuring the areas.

• Select the heat loss.

• Calculate the ow.

• Determine preset values for each radiator

valve according to the calculated ow. Find

the selected preset in the Presetting table (see

next page).

• Decide together with the property owner or

caretaker limitations and the current room

temperature. Consider the need for thermostats with remote sensor.

• All radiator valves must be preset.

• Fill with water and bleed the system.

In 2-pipe heating systems a correct dimensioning

and adjustment of the valves is a prerequisition

for achieving optimal energy consumption and

high user comfort.

By spending a few minutes on studying this

paper you will be ready to use RA-DV Dynamic

Valve s™.

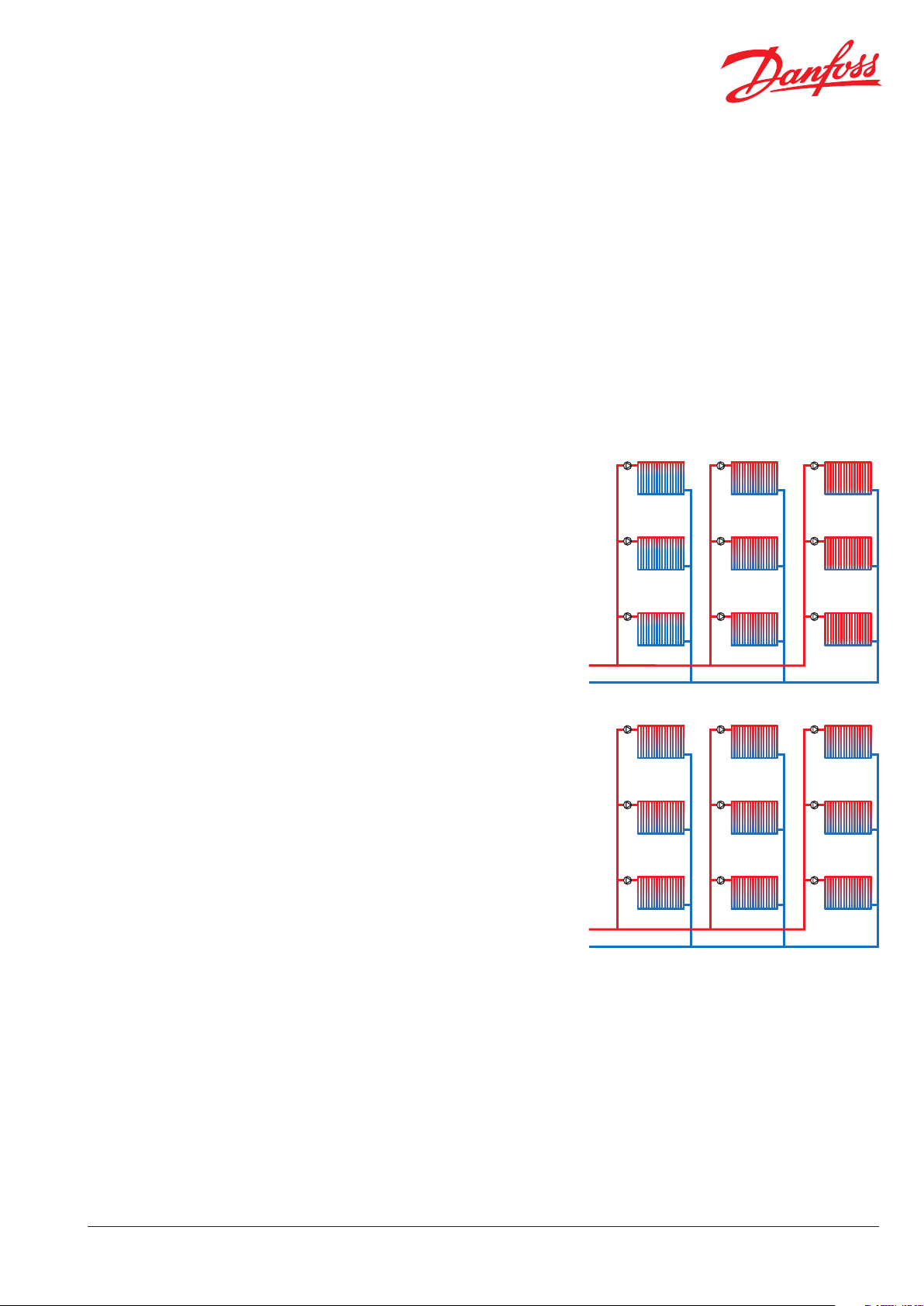

Fig. 1: Pressure and ow changes

Fig 2: Comfort with hydronic balancing

VFGWG102 © Danfoss 05/2014

1

Page 2

Technical Paper Flow and Dierence Pressure Optimize Guide

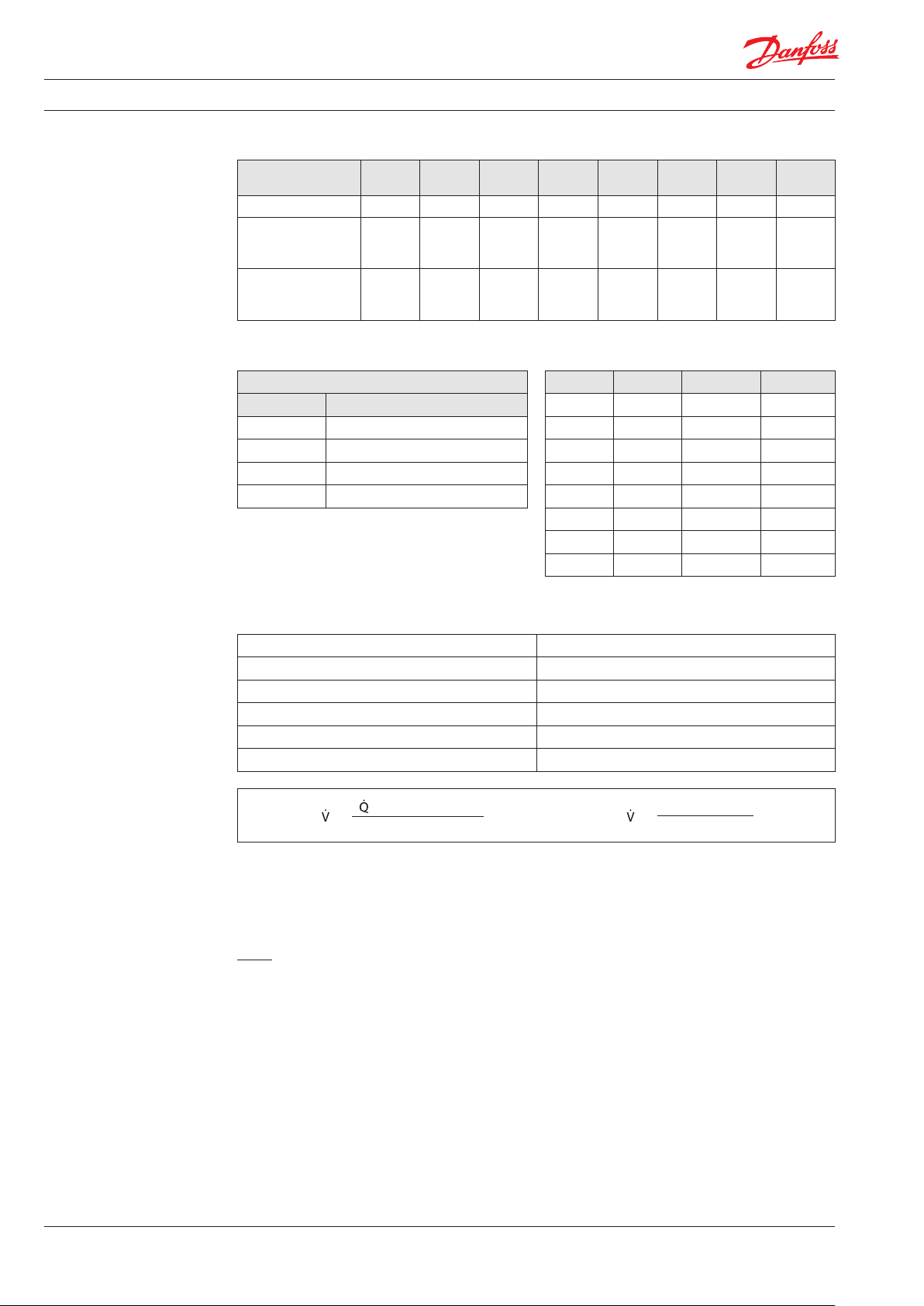

Tables

1. Heat loss (empirical values)

Yea r of

construction

Single family house 180 W/m2170 W/ m2150 W/m2115 W/m295 W/m275 W/m260 W/m240 W/m

Townhouse:

- at the end

- in the middle

Multi family house:

- up to 8 oors

- more than 8 oors

2. Dierence ow and return temperature

Typical values (K)

∆t (K) Heat source

10 -15 Heat pump

15-20 Low temperature boiler

20 -25 Condensing boiler

25-40 District energy, indirect

until

1958

160 W/m

140 W/m

130 W/m

120 W/m

2

150 W/m

2

130 W/m

2

120 W/m

2

110 W/m

1959-

1968

2

130 W/m

2

120 W/m

2

110 W/m

2

100 W/m

1969-

1973

2

110 W/m

2

100 W/m

2

75 W/m

2

70 W/m

1974 -

1977

2

2

2

2

1978 -

1983

90 W/m

85 W/m

65 W/m

60 W/m

2

2

2

2

1984-

1994

70 W/m

65 W/m

60 W/m

55 W/m

3. Presetting

RAW RA2000 living/TWA

15 20 25 1

20 25 30 2

30 30 35 3

40 40 45 4

50 50 60 5

2

2

2

2

1995-

2001

55 W/m

50 W/m

45 W/m

40 W/m

from

2002

2

35 W/m

2

30 W/m

2

33 W/m

2

33 W/m

Presetting

70 75 80 6

90 95 100 7

110 125 135 N

2

2

2

2

2

Example

Building type Multi family house

Year of construction 1984

Room size 40 m

2

Number of radiators in the room 1

Heat eect needed 55 W/m2 (according to table 1)

Dierence ow (ΔT) needed 20° C (according to table 2)

Formula:

(W/m2) x m2 x 0.86

=

∆t (K)

= ..... l/h

55 x 40 x 0.86

=

20

Presetting should be 7 (according to table 3, with RA2000).

Presetting of more radiators in the room

Two radiators in the room of same size should be

preset to:

94.6

= 4 7. 3 l /h = presetting 5 (with RA2000)

2

Are the radiators of dierent sizes, the presetting

should be calculated according to each radiator’s

area coverage.

Further calculation possibilities concerning the

radiator performance as well as the heat loss

oers the Danfoss Heating App and the DanBasicSoftware.

Note!

Corner rooms, rooms with ceiling towards the

outside and without heated oors, walls and

concrete deck directly on soil requires slightly more

eect from the radiator to provide the same comfort

as in other rooms (raise the presetting with 0.5

compared with a normal room).

= 94.6 l/h

2

VFGWG102 © Danfoss 05/2014

Page 3

Technical Paper Flow and Dierence Pressure Optimize Guide

Presetting

The presetting values of RA-DV valves can be

adjusted easily and accurately without the use of

tools (default setting = N).

Presetting can be selected in steps from 1 to 7:

• Remove protective cap / thermostatic sensor.

• Find reference mark (R).

• Turn setting ring until the aquired presetting

aligns with the reference mark.

Fig. 3: RA-DV reference mark

At setting N the valve is fully open. This setting

can be used as a ushing position, if the system

has to be ushed out because of dirt problems.

When the thermostatic sensor has been installed,

the presetting is protected against unintended

regulation.

For easy presetting a special presetting tool

(code no. 013G7830 ) is available.

Fig. 4: Presetting tool 013G7830

Pump Optimization

It is posilbe to save pump energy. Rule-of-tumb:

1/2 ow = 1/8 charging rate.

The operation is as follows:

• All RA-DV valves must be preset.

• Demount all the sensors.

• Change the current presetting of the valve at

the most unfavorable position to 2. Measure the

dierential pressure over this valve with

Danfoss ∆P tool and adjust the pressure of the

pump (g. 6).

• During the process the pressure for open and

closed valve positions are measured and the

dierence is displayed (g. 5). Lower the pump

pressure until it changes, then increase the

pressure until it does not change. Now the

desired ∆P is obtained (RA-DV ∆P min. = 0.1 bar).

• Reinstall the sensors.

• Set the heat curve on the controller (in the

heating room) at a reasonable value compared

to previous settings and in relation to dimensioning outdoor temperature = approx. 65° C

inlet temperature (according to the heat curve).

How to use the Danfoss ∆p tool

- see movie on YouTube.com

Fig. 5: Danfoss ∆p tool Fig. 6: Measure on the last radiator (valve).

VFGWG102 © Danfoss 05/2014

3

Page 4

Technical Paper Flow and Dierence Pressure Optimize Guide

Danfoss Installer App

Make balancing easy with the Danfoss Installer App!

Get it for free at App Store / Google Play or scan the QR code.

For more information on RA-DV valves, see special data sheet.

4

VFGWG102 © Danfoss 05/2014

Loading...

Loading...