Page 1

Data Sheet

Thermostatic operated water valve

Type FJVA

With built-in temperature sensor

Thermostatic operated water valves are used

for the innite, proportional regulation of ow

quantity, depending on the setting and the

sensor temperature.

The Danfoss range of thermostatic operated

water valves includes a series of industrial

products for both cooling and heating

regulation. The valves are self-acting, i.e. they

operate without the supply of auxiliary energy

such as electricity or compressed air.

Because the valves constantly match ow

quantity to demand they are especially suitable

for temperature regulation.

The required temperature is maintained

constant with no overconsumption of:

• Cooling water in cooling systems; hot water

or steam in heating systems

• Thus operating economy is always reasonable

Features:

• Self-acting thermostatic operated water

valve, which operates without auxiliary

energy

• Opens on rising temperature of cooling water

• Valve opening degree is not aected by

cooling water pressure dierential

• Hand regulation - unique option on the

market, which saves installation time

• Regulating range dened for the point at

which the valve begins to open

AI155286424361en-000401

Page 2

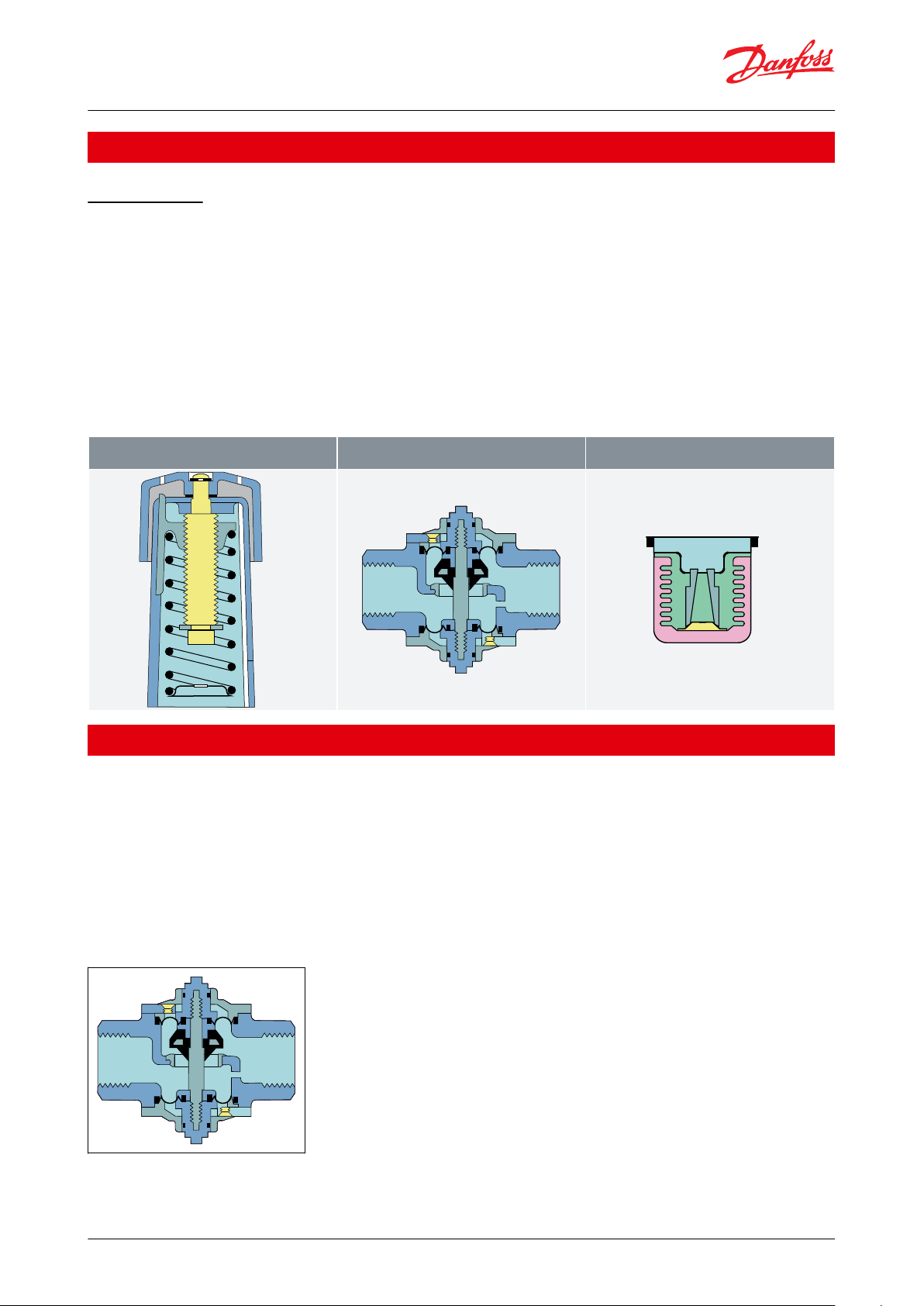

Setting section with knob,

reference spring and setting scale.

Valve body with orice,

closing cone and sealing elements.

Sensor in hermetically

sealed thermostatic element.

Danfoss

3N1101

Danfoss

3N1447

Danfoss

3N1446

Danfoss

3N1447

Thermostatic operated water valve, Type FJVA

Functions

How it works?

When the three elements are built together and the valve is installed, the function sequence is as follows:

1.

A temperature-dependent pressure - charge vapour pressure - builds up in the sensor.

2.

This pressure is transferred to the valve via the bellows and acts as an opening or closing force.

3.

The knob on the setting section and the spring exert a force that acts counter to the bellows.

4.

When balance is created between the two opposing forces, the valve spindle remains in its position.

5.

If the sensor temperature - or the setting - is changed, the point of balance becomes displaced and the valve

spindle moves until balance is re-established, or the valve is fully open or closed.

6.

On sensor temperature change the ow quantity change is approximately proportional.

7.

The illustrations show an FJVA cooling water valve, but the function principle applies to all types of thermostatic

valves.

Table 1: FJVA valves consist of three main elements

Applications

FJVA valves are for applications where, because of installation problems, etc., it is desirable to avoid using a capillary

tube. This applies mainly where regulation accuracy requirements are more moderate and where an integral bypass

can be accepted.

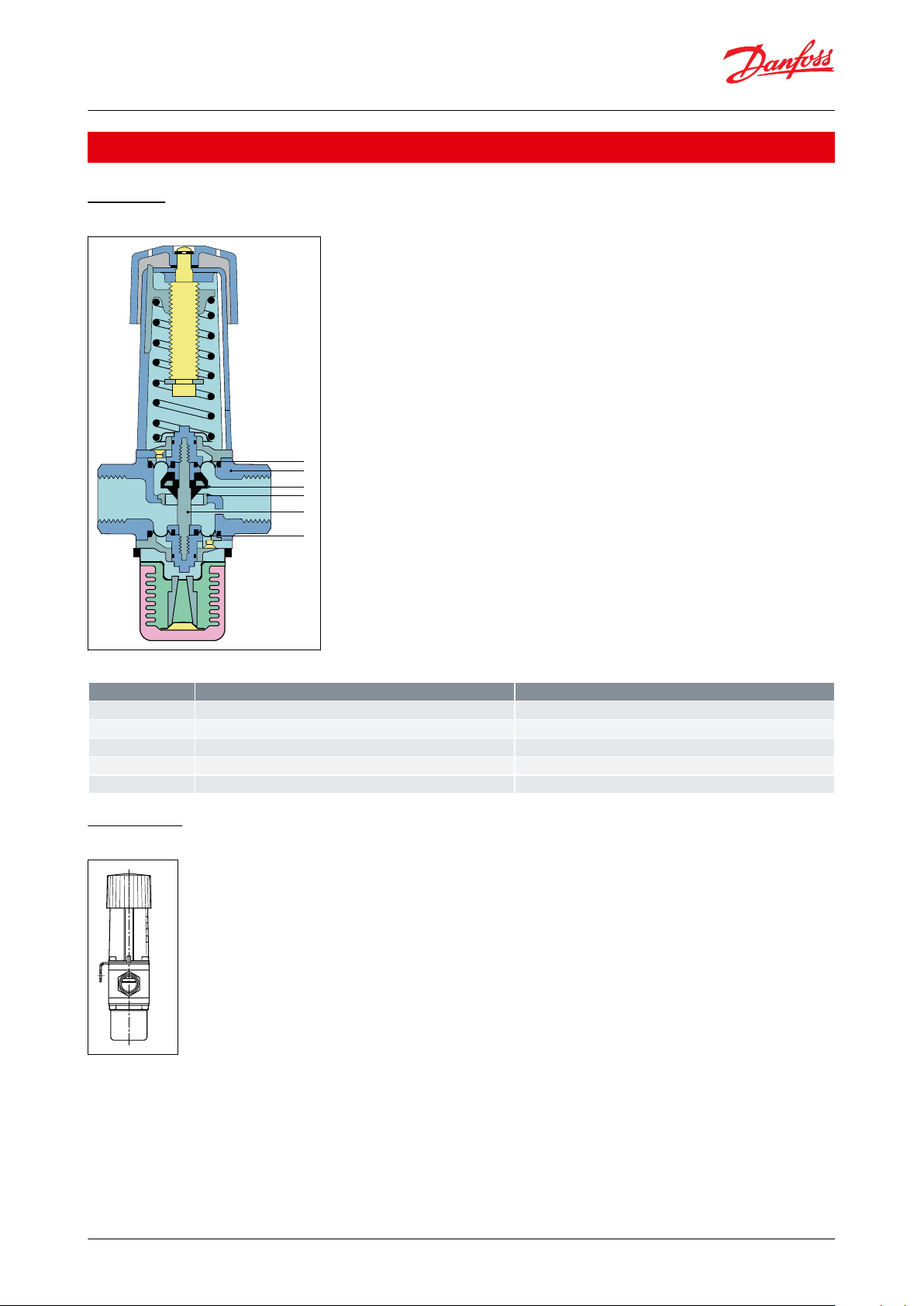

In FJVA the whole bellows element is used as the sensor. The valve reacts to the cooling water temperature and

therefore it must always be installed in the return line. Thus, indirect regulation is involved.

To ensure the medium temperature to inuence the thermostatic element, when the valve is closed, a by-pass in the

valve (see Figure 1: Valve body with by-pass) provides a constant minimal ow through the valve.

Figure 1: Valve body with by-pass

Valves of this type operate with signicantly longer time constants than AVTA valves where the sensor is located at

the point at which the temperature is to be regulated. FJVA is mainly used in systems where large and sudden load

changes do not occur.

© Danfoss | Climate Solutions | 2021.03 AI155286424361en-000401 | 2

Page 3

1

2

4

3

5

2

Danfoss

3N554

No.

Description

Material

1

Spindle

Brass2Diaphragms

Rubber - ethylene - propylene (EPDM)

3

Valve body and other metal parts

Forged brass

4

Valve cone

Nitrile rubber (NBR)

5

Valve seat

Stainless steel

Danfoss

3N554

Thermostatic operated water valve, Type FJVA

Product specication

Materials

Figure 2: Materials connected with FJVA

Table 2: Materials - parts in contact with the medium

Installation

Figure 3: FJVA installation

The valves can be installed in any position. An arrow on the valve body indicates the direction of ow. FJVA valves

are also marked so that the letters RA can be read straightforwardly. The installation of an FV lter ahead of the valve

is recommended.

If a mounting bracket is used - see Spare parts and accessories - it must always be between valve body and setting

section (see illustration).

© Danfoss | Climate Solutions | 2021.03 AI155286424361en-000401 | 3

Page 4

Q [m3/h]

Danfoss

3N492

Thermostatic operated water valve, Type FJVA

Sizing

When sizing and selecting thermo. operated water valve, it is most important to ensure that the valve is able to give

the necessary quantity of cooling water at any time, irrespective of the load. Therefore, to select a suitable size of

valve, it is necessary to know the precise amount of cooling required. On the other hand, to avoid the risk of

unstable regulation (hunting), the valve should not be oversized. The type of charge must be selected on the basis

of the temperature to be maintained, and on an assessment of the characteristics of each type, as described in the

foregoing.

In general the aim should be to select the smallest valve capable of giving the required ow.

Valve size

The following data are used when selecting valve size:

• Required cooling water ow, Q [m3/h]

• Temperature rise in cooling water, ∆t [°C]

• Dierential pressure across valve, ∆p [bar]

With fully open valve the dierential pressure should be around 50% of the total pressure drop across the cooling

system.

The following diagrams are intended to make valve sizing easier:

• Figure 4: Heating or cooling with water

• Figure 5: Relation between water quantity and pressure drop across valve

• Figure 6: Nomogram showing the valve kv range

• Figure 7: Valve ow quantity in fully open position, as a function of pressure drop Δp.

Figure 4: Heating or cooling with water

Example:

Necessary cooling output 10 kW with ∆t = 10 °C

Required ow 0.85 m3/h

© Danfoss | Climate Solutions | 2021.03 AI155286424361en-000401 | 4

Page 5

Danfoss

3N554

Thermostatic operated water valve, Type FJVA

Figure 5: Relation between water quantity and pressure drop across valve

Example:

Flow 0.85 m3/h with a pressure drop of 1.5 bar.

The kv value becomes 0.7 m3/h.

Figure 6: Nomogram showing the valve kv range

Kv values are always given for water ow in [m3/h] with a pressure drop ∆p of 1 bar.

The valve should be selected so that the necessary kv value lies in the middle of the regulation range.

Example:

FJVA 15 are the most suitable for a kv value of 0.7.

© Danfoss | Climate Solutions | 2021.03 AI155286424361en-000401 | 5

Page 6

[bar]

A

B

[m3/h]

Danfoss

3N1444

ABPressure drop across valve

Capacity with fully open valve

Danfoss

3N1444

Type

H1H

2

L

L

1

abNet weight

FJVA 15

205

1337214

G 1/2270.9

FJVA 20

205

1339016

G 3/4321.0

FJVA 25

215

1389519

G 1411.1

Thermostatic operated water valve, Type FJVA

Figure 7: Valve ow quantity in fully open position, as a function of pressure drop Δp.

Dimensions and Weights

Figure 8: Dimensions and Weights

Table 3: Dimensions and Weights

© Danfoss | Climate Solutions | 2021.03 AI155286424361en-000401 | 6

Page 7

Danfoss

3N9005

Danfoss

3N9005

Type

kv value

Bypass

(1)

Connection

Code no.

FJVA 15

1.9

ø2.0

G 1/2

003N8210

FJVA 20

3.4

ø2.0

G 3/4

003N8244

FJVA 25

5.5

ø2.5

G 1

003N8245

Type

kv value

Bypass

(2)

Connection

Code no.

FJVA 15

1.9

ø2.0

G 1/2

003N8211

FJVA 15

1.9

ø1.5

G 1/2

003N8247

FJVA 20

3.4

ø2.0

G 3/4

003N8215

FJVA 25

5.5

ø2.5

G 1

003N8216

Temperature range [°C]

Code no.

0 – 30

003N0285

25 – 65

003N0084

Designation

Description

Code no.

Danfoss

3N9002

Mounting bracket

For FJVA

003N0388

Set of 3 nitrile (NBR) diaphragms sets for mineral oil

For

FJVA 10

FJVA 15

FJVA 20

FJVA 25

003N0448

Plastic hand knob

For FJVA

003N0520

Thermostatic operated water valve, Type FJVA

Ordering

Regulation range: 0 – 30 °C

Media temperature: -25 – 55 °C

Dierential pressure: 0 – 10 bar

Table 4: Ordering

(1)

(1)

Bypass k

Bypass k

v

v

ø2.0 mm: 0.11 m3/h

ø1.5 mm: 0.06 m3/h

ø2.5 mm: 0.16 m3/h

Regulation range: 25 – 65 °C

Media temperature: -25 – 90 °C

Dierential pressure: 0 – 10 bar

Table 5: Ordering

(2)

(2)

Bypass k

Bypass k

v

v

ø2.0 mm: 0.11 m3/h

ø1.5 mm: 0.06 m3/h

ø2.5 mm: 0.16 m3/h

Spare parts and accessories

Table 6: Service elements

Table 7: Accessories

© Danfoss | Climate Solutions | 2021.03 AI155286424361en-000401 | 7

Page 8

File name

Document type

Document topic

Approvals Authority

003N9613.AB

Manufacturers Declaration

PED/RoHS

Danfoss

003N9614.AA

Manufacturers Declaration

China RoHS

Danfoss

RU Д-DK.БЛ08.В.00191_18

EAC Declaration

EAC

EAC

UA.089.D.00188-17

UA Declaration

TYSK

TYSK

Thermostatic operated water valve, Type FJVA

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 8: Certicates, declarations, and approvals

© Danfoss | Climate Solutions | 2021.03 AI155286424361en-000401 | 8

Page 9

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.03 AI155286424361en-000401 | 9

Loading...

Loading...