Page 1

Installation Instructions

Finger Guards

®

VLT

Soft Starter MCD 200/MCD 500

1 Product Overview

These instructions provide information about installation of

nger guard kits. The instructions are targeted at users already

®

familiar with the VLT

Starters MCD 200/202. Read the instructions before installation

and ensure that instructions for safe installation are observed.

Additional resources

Further manuals and instructions are available for download at

vlt-drives.danfoss.com/Support/Technical-Documentation/.

Soft Starters MCD 500, or VLT® Compact

2 Items Supplied

The nger guard is available in dierent kits depending on

model and enclosure size. For a list of all available kit part

numbers, refer to chapter 4.5 Packing List.

3 Safety Instructions

Finger guards t over the soft starter power terminals to

increase IP rating and prevent accidental contact with live

terminals.

WARNING

ELECTRICAL SHOCK HAZARD

VLT® Soft Starters contain dangerous voltages when

connected to mains voltage.

Models MCD5-0360C ~ MCD5-1600C: The bus bar and heat

sink are live while the unit operates (starts, runs, or stops). If

the soft starter is installed without a main contactor, the bus

bar and heat sink are live whenever mains voltage is

connected. This is also the case when the soft starter is

ready or tripped.

Improper installation of the motor or the soft starter, and

installing or servicing with power connected, can cause

death, serious injury, or equipment failure.

To avoid death, serious injury, or equipment failure:

Only use qualied electricians for carrying out the

•

electrical installation.

Disconnect the soft starter from all power sources

•

before installation or service.

Fit

•

connected.

Treat the bus bar and heat sink as live whenever

•

the unit has mains voltage connected. Also take

this precaution when the soft starter is tripped or

waiting for a command.

Follow the guidelines in these instructions and local

•

electrical safety codes.

guards to all terminals, even if no cable is

nger

Danfoss A/S © 04/2016 All rights reserved. MI17A602

Page 2

Installation Instructions

Finger Guards

®

Soft Starter MCD 200/MCD 500

VLT

4 Installation

4.1 IP20 Protection for MCD 200, MCD5-0131B

~ MCD5-0215B, and MCD5-0245C

MCD 200 and MCD 500 (enclosure sizes G2 and G3C) models

use rubber

protection when used with cable of diameter 22 mm or

greater.

guards. Rubber

nger

guards provide IP20

nger

Installation

1. Place 3 nger guards side by side in 1 retaining

bracket. Align the assembly so that the screw holes

in the bracket match the screw holes in the soft

starter.

MCD 200 only: Remove the 2 top screws from the

casing around the power terminals.

MCD 500 G3C enclosure size models only: Fit the

nger guard base chassis to the MCD 500 enclosure

rst before installing rubber nger guards.

2. Feed each power cable through the narrow end of

each nger guard. Connect the cables to the

appropriate terminals on the soft starter.

3. If the cables do not t through the nger guards,

shorten the nger guards at the narrow end to make

a bigger opening.

4. Screw the retaining bracket to the soft starter.

MCD 200 only: Use the screws from step 1 to attach

the retaining bracket to the soft starter casing.

MCD 500 G3C enclosure size models only: Fit the

nger guard cover over the nger guard base chassis

to complete the arrangement.

5. Repeat steps 1–4 for the other set of terminals.

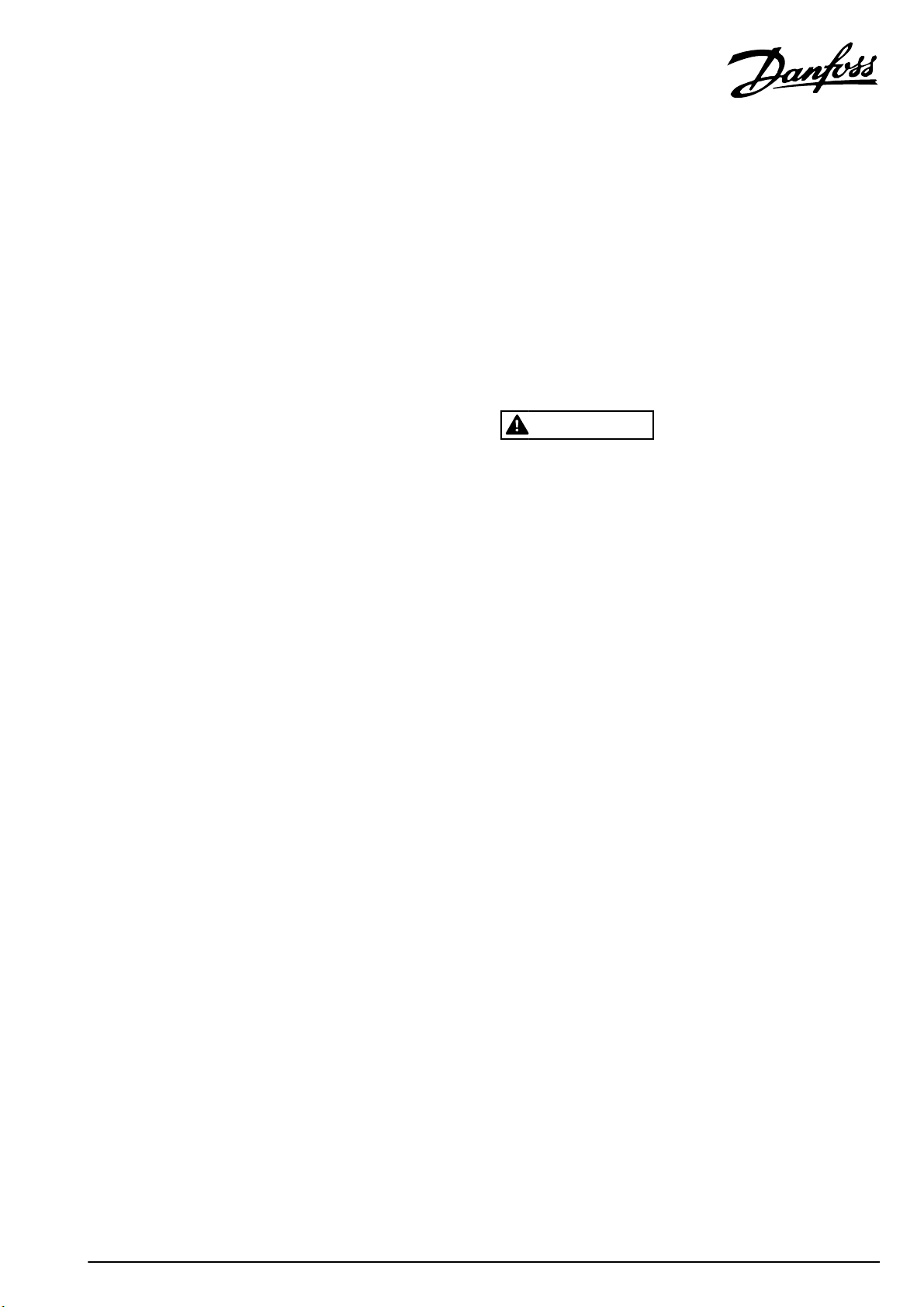

Illustration 4.2 Finger Guard Installation for MCD 500 G2 Enclosure

Size

1Screws

2 Retaining bracket

3 Finger guards

Table 4. 1 Leg en d to Illustration 4.1 and Illustration 4.2

1Screws

2 Retaining bracket

3 Finger guards

4 Finger guard base chassis

5Top cover

Illustration 4.1 Finger Guard Installation for MCD 200

2

Illustration 4.3 Finger Guard Installation for MCD 500 G3C

Enclosure Size

Danfoss A/S © 04/2016 All rights reserved. MI17A602

Page 3

Installation Instructions

Finger Guards

®

Soft Starter MCD 200/MCD 500

VLT

4.2 IP20 Protection for MCD5-0245B ~

MCD5-0961B

MCD 500 (enclosure sizes G3B and G4B) models use rubber

nger guards. Rubber nger guards provide IP20 protection

when used with cable of diameter 22 mm or greater.

Installation

1. MCD5-0245B ~ MCD5-0396B: Screw the nger guard

plate to the base of the soft starter.

MCD5-0469B ~ MCD5-0961B: Screw the nger guard

bracket to the enclosure of the soft starter.

2. Fit 1 polycarbonate retaining bracket over each nger

guard.

3. Feed each power cable through the narrow end of

each nger guard. Connect the cables to the

appropriate terminals on the soft starter.

4. If the cables do not t through the nger guards,

shorten the nger guards at the narrow end to make

a bigger opening.

5. Screw each retaining bracket to the nger guard

plate/bracket.

6. MCD-50469B ~ MCD5-0961B: Fit the nger guard

cover over the bracket to complete the arrangement.

7. Repeat steps 1–6 for the other set of terminals.

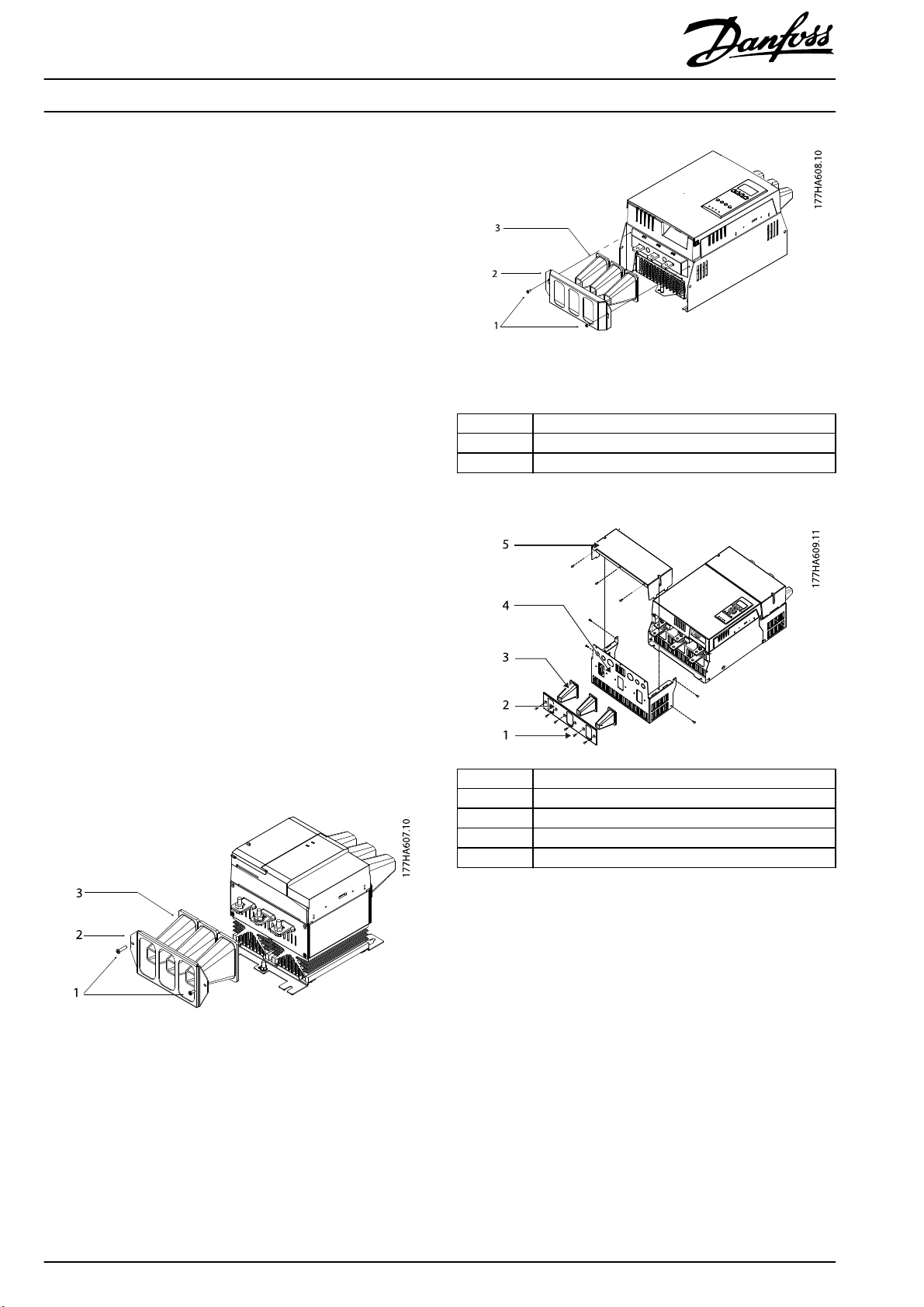

1Screws

2 Retaining bracket

3 Finger guards

4 Finger guard bracket

5Top cover

Illustration 4.5 Finger Guard Installation for MCD 500 G4B

Enclosure Size

4.3 IP20 Protection for MCD5-360C ~

MCD5-1600C

MCD 500 enclosure sizes G4C and G5C use nger guard

chassis enclosures to isolate live bus bars.

1Screws

2 Retaining bracket

3 Finger guards

4 Finger guard plate

Illustration 4.4 Finger Guard Installation for MCD 500 G3B

Enclosure Size

NOTICE

Each kit is only sucient for protection of either top or

bottom cable terminals. If both top and bottom cable

termination is used, 2 nger guard kits are required.

Installation

1. Fasten the nger guard base chassis to the main

enclosure of the soft starter using the screws

provided.

2. Drill power cable access holes into the gland plate

using the pilot holes provided. To prevent excessive

heating of the gland plate due to large eddy

currents, cut horizontal slits between the power cable

holes drilled into the gland plate.

3. Fit the gland plate to the nger guard base chassis

using the screws provided.

4. Run the power cables through the holes in the gland

plate and connect to the appropriate bus bar

terminals of the soft starter. To prevent fraying of

cables against the gland plate, t cable bushes or

glands (not supplied) appropriate for the size of

cable used.

5. Fit the nger guard cover over the nger guard base

chassis to complete the arrangement.

6. Repeat steps 1–5 for the other set of terminals.

MI17A602 Danfoss A/S © 04/2016 All rights reserved.

3

Page 4

Installation Instructions

Finger Guards

®

Soft Starter MCD 200/MCD 500

VLT

Illustration 4.6 Finger Guard Installation for MCD 500 G4C

Enclosure Size

4.4 Built-up Dimensions

Illustration 4.7 Finger Guard Installation for MCD 500 G5C

Enclosure Size

1Screws

2Gland plate

3 Finger guard base chassis

4 Finger guard cover

Table 4. 2 Leg en d to Illustration 4.6 and Illustration 4.7

A [mm (in)] 367 (14.4) 577 (22.7) 567 (22.3) 1161 (45.7) 878 (34.6) 853 (33.6) 1036 (40.8)

B [mm (in)] – – – 300 (11.8) 261 (10.3) 308 (12.1) 286 (11.3)

C [mm (in)]–––––1146 (45.1)1319 (51.9)

Illustration 4.8 Dimensions

4

ABCDEFG

MCD 200 MCD 500, G2 MCD 500, G3B MCD 500, G4B MCD 500, G3C MCD 500, G4C MCD 500, G5C

Danfoss A/S © 04/2016 All rights reserved. MI17A602

Page 5

Installation Instructions

Finger Guards

®

Soft Starter MCD 200/MCD 500

VLT

4.5 Packing List

175G9007 175G5662 175G5730 175G5731

MCD 200

1)

MCD 500 G2 enclosure size

6 nger guards (rubber) 6 nger guards (rubber) 9 nger guards (rubber) 12 nger guards (rubber)

2 retaining brackets 2 retaining brackets 9 retaining brackets 12 retaining brackets

1 installation instructions 4 M4x10 screws 2 nger guard plates 2 nger guard bracket

– 6 cable ties 18 M4x14 screws 2 nger guard cover

– 1 installation instructions 12 M4x12 screws 24 M4x16 screws

– – 1 installation instructions 12 M4x12 screws

– – – 1 installation instructions

Table 4.3 Packing List MCD 200, MCD 500 Enclosure Size G2, MCD 500 Enclosure Size G3B, and MCD 500 Enclosure Size G4B

175G5663 175G5664 175G5665

MCD 500 G3C enclosure size

2)

MCD 500 G4C enclosure size

3 nger guards (rubber) 1 nger guard grille 1 nger guard grille

1 nger guard cover 1 nger guard cover 1 nger guard cover

1 nger guard chassis 1 nger guard base chassis 1 nger guard chassis

1 clamp plate 2 nger guard side chassis 1 gland plate

11 M4x10 screws 1 gland plate 12 M4x10 screws

1 installation instructions 6 M4x10 screws 1 installation instructions

– 12 M4x16 screws –

–2 M4 nuts –

– 1 installation instructions –

1)

MCD 500 G3B enclosure size

1)

MCD 500 G4B enclosure size

2)

MCD 500 G5C enclosure size

1)

2)

Table 4.4 Packing List MCD 500 Enclosure Size G3C, MCD 500 Enclosure Size G4C, and MCD 500 Enclosure Size G5C

1) Only 1 kit required.

2) Each kit is only sucient for protection of either top or bottom cable terminals. If both top and bottom cable termination is used, 2 nger guard kits

are required.

MI17A602 Danfoss A/S © 04/2016 All rights reserved.

5

Page 6

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on

order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this material are property of the respective companies. Danfoss

and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss A/S

Ulsnaes 1

DK-6300 Graasten

vlt-drives.danfoss.com

MI17A602 04/2016

*MI17A602*

Loading...

Loading...