Page 1

Data sheet

Filter solutions for

Danfoss high-pressure pumps and

energy recovery devices

hpp.danfoss.com

Page 2

Data sheet | Filter solutions for Danfoss high-pressure pumps

1. Introduction

1.1 Cartridge filters

Cartridge filters are widely used in industrial and

domestic applications for removal of suspended

solids in water. The variety of cartridges available

and the confusing methods of ratings, however,

make selection of cartridges difficult for consumers. It becomes important for users,

therefore, to understand cartridge filters, how

they work, and how manufacturers rate them.

1.2 Filtration

Filtration is a process of removing unwanted

solids from fluids by passing the fluid through a

form of sieving material that retains the solids,

but allows the fluid to pass through. Filtration

efficiency is, therefore, the percentage of solid

retention by the sieve. It is this “sieve” that we

refer to as the filter medium, or simply the filter.

A contaminant is generally referred to as the

material that is to be removed from the fluid, and

the clean fluid is called the

filtrate. In today’s market, manufacturers use

three types of ratings to evaluate filters: nominal

rating, absolute rating and beta ratio.

1.3 Nominal filter rating

A nominal filter rating is an arbitrary value

determined by the filter manufacturer, based

upon removal of some percentage of all particles

of a given size or larger.

- The rating is typical based on a weight percent

(etc. 60 -95%)

- The 5-40% that pass through are NOT defined

by the manufacturer (normally much larger

particles pass through).

- The rating is based on a weight analysis test.

- There is a high risk of channelling when a filter

medium has some oversized pores or a wide

pore-sized distribution.

- There is a high risk of bypass when

cartridge-to-housing seal is ineffective.

1.4 Absolute filter rating

The absolute rating or cut-off point of a filter

refers to the diameter of the largest hard

spherical particle, normally expressed in

micrometres (µm), which will pass through the

filter under specified test conditions.

- The filter is tested under a specific

international well known test method (modified OSU-F2 single-pass filter test system).

- The rating is based on a particle measuring

test.

- The filter is reproducible.

- Higher ∆P does not result in particle

unloading.

- The filter can withstand flow pulsations as well

as viscosity and temperature changes.

- There is no risk of channelling due to the high

quality of the filter media.

- Absolute filtration means that the fluid is

filtered both horizontally and vertically. In

comparison, an inferior nominal type of filter

will allow particles which are more than 10

µ in length to pass the filter, as it only filters

the fluid according to the diameter of the

particles.

- It is NOT possible to reproduce the filter.

- Particle unloading is rising when the ∆P across

the filter increases

2

AI317041322125en-000201 | 03.2021

Page 3

Data sheet | Filter solutions for Danfoss high-pressure pumps

2. Requirements

2.1 Filtration requirement

To achive warrenty and assure the service intervals stated from Danfoss, the PAH, PAHT, APP

pumps require water with no particles larger than

10 micron (10 µ). Thus a 10 µ absolute filter with a

Beta value > 5000 must be used.

- 10 µ means that particles of 10 µ or larger in

size will be caught by the filter.

β-value of filter Filter efficiency

2 50.00% 50,000

4 75.00% 25,000

10 90.00% 10,000

20 95.00% 5,000

40 97. 50 % 2,500

100 99.00% 1,000

200 99.50% 500

-

The Beta value > 5000 refers to the efficiency

of the filter. A filter with a Beta value of > 5000

catches 99.98% of the particles being 10 µ or

larger. This means if there are 100,000 particles

in the fluid (10 µ or larger), only 20 of them

would pass through that filter. Other types of

filters on the market have a Beta value > 10

(90% efficiency), and these filters would allow

10,000 of the 100,000 particles to pass through

the filter.

Number of particles downstream for each

100,000 particles upstream

500 99.80% 200

1,000 99.90% 100

2,000 99.95% 50

5,000 99.98% 20

10,000 99.99% 10

2.2 Filter types

Pleated polypropylene filter elements use the

very latest gradient density micro-fibre media

technology to provide a combination of excellent

absolute micron ratings, high flow rates, and high

dirt-holding capacity.

2.3 Features

- The absolute particle retention provides

excellent protection of the pump and the rest

of the system.

- Compatibility with a broad range of process

chemicals allows use in most applications.

- High flow rate and long service life ensure

minimum downtime of the system.

- High dirt-holding capacity.

- Filter element is easily exchanged.

2.4 Applications

The Danfoss filters can be used in a wide range of

demanding applications such as:

- General water filtration

- RO/DI water filtration

- We recommend CIP cycles in the range of 3-10

PH

AI317041322125en-000201 | 03.2021

3

Page 4

Data sheet | Filter solutions for Danfoss high-pressure pumps

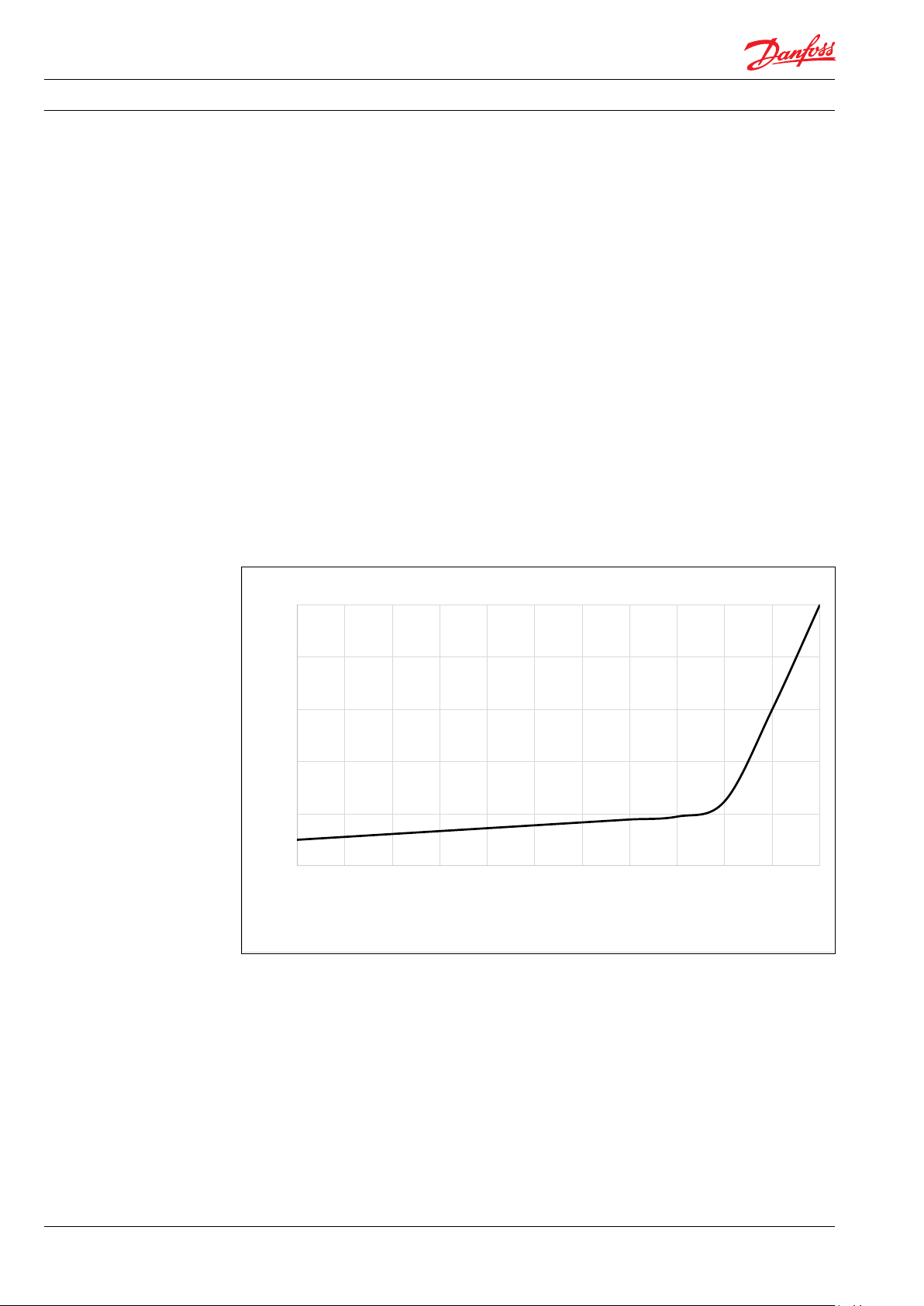

0

0,5

1

1,5

2

2,5

0 10 20 30 40 50 60 70 80 90 100 110

Pressure drop Bar

Time [%]

Typically filter life

Cartridge Pressure Drop

2.5 Right filter choice

There are 2 factors to consider in order to choose

the right filter:

a) The flow through the filter

b) Amount of dirt in the fluid (E.g. SDI).

If the fluid is relatively clean (low SDI), the filter

choice can be based on the pump size as this will

indicate the flow through the filter.

If the fluid is relatively dirty with small particles, a

larger filter size should be chosen to increase the

dirt-holding capacity. For instance, for a flow of

60 l/min fluid containing many small particles a

filter for a flow up to 170 l/min should be chosen.

If the fluid is relatively dirty with larger particles,

a cheaper and less efficient pre-filter should be

placed in front of the main filter. This will ensure

a long life of the more expensive main filter, as

most of the larger dirt particles will be caught in

the cheaper pre-filter.

The prefilter may be of the type ”Nominal filter”.

4

AI317041322125en-000201 | 03.2021

Page 5

Data sheet | Filter solutions for Danfoss high-pressure pumps

3. Technical data

3.1 Absolute filters

The Danfoss filter product range includes different types of main filter elements, all fulfilling the

minimum requirement of 10 µ absolute with a Beta value > 5000.

One filter element end has an O-ring seal, and the other end has a closed cap, which has a different

design depending on the specific filter type.

Type 1, 2, 3, 4, 5 Type 6 Type 7

Single O-ring located Two O-rings located externally Two O-rings located externally

inside element, on element on element

other end flat closed other end with spear

Filter element Typ e 1 Typ e 2 Typ e 3

Element length

Filtration level

(Beta > 5000)

127 mm

(5”)

10 µ abs 10 µ abs 5 µ abs

254 mm

(10”)

508 mm

(20”)

Max flow (l/min) 15 30 60

3

Max flow (m

/h) 0.9 1.8 3.6

Max flow (gpm) 4 7.9 15.6

Element inner diameter

Element outer diameter

Effective surface

Max differential pressure

at 24 °C (75 °F)

Max operating

temperature

Materials

Element

End caps

Seals

27 mm

(1.06”)

70 mm

(2.75” )

2

0.28 m

(3 sq.ft.)

4 barg

(58 psig)

50 °C

(122 ° F)

Polypropylene Polypropylene Polypropylene

Polypropylene Polypropylene Polypropylene

Buna-N Buna-N Buna-N

27 mm

(1.06”)

70 mm

(2.75” )

0.55 m

(6 sq.ft.)

4 barg

(58 psig)

50 °C

(122 ° F)

27 mm

(1.06”)

70 mm

(2.75” )

2

1.1 m

(12 sq.ft.)

4 barg

(58 psig)

50 °C

(122 ° F)

2

Net weight

Max. differential pressure before

replacement of filter

0.21 kg

(0.46 lb)

2 barg

(29 psig)

0.27 kg

(0.6 lb)

2 barg

(29 psig)

0.47 kg

(1.0 lb)

2 barg

(29 psig)

Code number 180Z0037 180X5225 180Z0 019

AI3170 41322125en-000201 | 03.2021

5

Page 6

Data sheet | Filter solutions for Danfoss high-pressure pumps

Filter element Typ e 4 Type 5 Type 6 Ty pe 7

Element length

Filtration level

(Beta > 5000)

508 mm

(20”)

10 µ abs 10 µ abs 10 µ abs 10 µ abs

508 mm

(20”)

508 mm

(20”)

1020 mm

(40” )

Max flow (l/min) 60 170 170 1000

Max flow (m3/h) 3.6 10.2 10.2 60

Max flow (gpm) 15.6 44.9 44.9 264

Element inner diameter

Element outer diameter

Effective surface

Max differential pressure

at 24 °C (75 °F)

Max operating

temperature

Materials

Element

End caps

Seals

27 mm

(1.06”)

70 mm

(2.75” )

2

1.1 m

(12 sq.ft.)

4 barg

(58 psig)

50 °C

(122 ° F)

Polypropylene Polypropylene Polypropylene Polypropylene

Polypropylene Polypropylene Polypropylene Polypropylene

Buna-N Buna-N Buna-N Silicone

46 mm

(1.8”)

115 m m

(4.5” )

2.45 m

(26 sq.ft.)

3 barg

(43.5psig)

50 °C

(122 ° F)

46 mm

(1.8”)

102 mm

(4”)

2

1.8 m²

(19 sq. ft.)

3 barg

(43.5 psig)

50 °C

(122 ° F)

65 mm

(2.56”)

153 mm

(6”)

10 m²

(107.6 sq.ft.)

4 barg

(58 psig)

50 °C

(122 ° F)

1)

1)

1)

Net weight

Max. differential pressure before

replacement of filter

0.48 kg

(1.1 l b)

2 barg

(29 psig)

1.35 kg

(3.0 lb)

2 barg

(29 psig)

0.97 kg

(2.1 l b)

2 barg

(29 psig)

4.0 kg

(8.8 lb)

1.5 barg

(22 psig)

Code number 180Z0006 180Z0285 180Z0083 180Z0653

1

) Recommended max. flow if the fluid is relatively clean and pre-filtered with a hig quality

filter, rated less than 5 µ and efficiency of min.

95%. If fluid is not relatively clean a max. flow

of 36 m³/h is recommended.

3.2 Replacement of filter element

At max. differential pressure, the filter element has reached its dirt capacity.

6

AI3170 41322125en-000201 | 03.2021

Page 7

Data sheet | Filter solutions for Danfoss high-pressure pumps

3.3 Housings

Housing

5”

Blue

10”

Blue

20”

Blue

20”

Big blue

40”

Red

Max flow (l/min) 15 30 60 170 1000

3

Max flow (m

/h) 0.9 1.8 3.6 10.2 60

Max. flow (gpm) 4 7.9 15.6 44.9 264

Housing length

Housing diameter

Max pressure at

45 °C (113 °F)

Max operating

temperature

184 mm

(7.24” )

115 m m

(4.52”)

8.6 barg

125 (psig)

45 °C

(113 °F )

311 mm

(12.24” )

130 mm

(5 .11” )

8.6 barg

125 (psig)

45 °C

(113 °F )

568 mm

(22.36”)

130 mm

(5 .11” )

8.6 barg

125 (psig)

45 °C

(113 °F )

600 mm

(23.62”)

183 m m

(7.20 ”)

6.2 barg

(90 psig)

45 °C

(113 °F )

138 4 mm

(54.48”)

270 mm

(10.62”)

16 barg

(232 psig)

60 °C

(140 °F

Vent ¼” BSP

Inlet ½” BSP ¾” BSP ¾” BSP 1½” BSP

3” Vic. Cut

groove

Connections

Outlet ½” BSP ¾” BSP ¾” BSP 1½” BSP

Drain

3” Vic. Cut

groove

1” Vic. Cut

groove

Volume 37 l.

GRP (Glass

Housing Polypropylene Polypropylene Polypropylene Polypropylene

reinforced

polypropylene)

Materials

Accessories

recommended

Net weight

Caps

Reinforced

polypropylene

O-ring Buna-N Buna-N Buna-N Buna-N

Victaulic

fittings

0.7 kg

(1.54 lb)

Reinforced

polypropylene

Filter

spanner

(Code no.

180N0785)

1.4 kg

(3.1 lb)

Reinforced

polypropylene

Filter

spanner

(Code no.

180N0785)

2.1 kg

(4.6 lb)

Reinforced

polypropylene

Filter

spanner

(Code no.

180 N1438)

4.1 kg

(9 lb)

Polypropylene

Silicone

PTFE

Acetal

For vertical

mount: Legs

for housing

(180Z0652)

46 kg

(101 lb)

Code number 180Z0281 180X5224 180Z0213 180Z0082 180Z0651

AI3170 41322125en-000201 | 03.2021

7

Page 8

Data sheet | Filter solutions for Danfoss high-pressure pumps

3.4 Pre-filtration (nominal filters)

Danfoss offers two different pre-filtration solutions that can be used in addition to the main-

Polypropylene fibre melt blown design with poly

core (90% efficiency) provides optimum sediment

filtering capacity.

filters (and NOT instead of the main filters).

Typ e A Type B

Max flow (l/min) 30 85

Max flow (m³/h) 1.8 5.1

Max flow (gpm) 7.9 22.5

Filtration level

Element length

Element outer diameter

Element inner diameter

Max differential pressure

at 24 °C (75 °F)

Max operating

temperature

Element Polypropylene Polypropylene

3 µ Nominal

Graded density structure

508 mm

(20”)

64 mm

(2.5”)

26 mm

(1.02”)

3.4 barg

(50 psig)

50 °C

(122 ° F)

3 µ Nominal

Graded density structure

508 mm

(20”)

116 mm

(4.5” )

28 mm

(1.10”)

3.4 barg

(50 psig)

50 °C

(122 ° F)

Materials

Code number 180Z0396 180Z0081

Core Polypropylene Polypropylene

Seal None None

3.5 Right pre-filter choice

The 4.5” pre-filter (180Z0081) with a large

graded density structure is a better pre-filter

but more expensive.

If the flow demand is very low, a less expensive

pre-filter (180Z0396) is a good alternative.

3.6 Replacement of filter element

At a differential pressure of 1.5 barg (22 psig)

filter element has reached its dirt capacity.

Typ e A

3.7 Cross reference tabel

Housing

Element

180Z0213

(20” blue housing)

180Z0082

(20” big blue housing)

180Z0396 180Z0081

X

X

Typ e B

NOTE

Pre-filter elements and filter housings are

ordered separately.

8

AI3170 41322125en-000201 | 03.2021

Page 9

Data sheet | Filter solutions for Danfoss high-pressure pumps

4. Dimensions

F

10”

/64")

E

20”

Blue

56 mm

(2 1/5”)

133 mm

(5 1/4")

58 mm

(2 1/4”)

ø5,7

15

/64")

(

568 mm

(22 3/8")

A

D

C

B

5”

Blue

A

B

C

D

E

39 mm

1

/2")

(1

120 mm

3

/4")

(4

32 mm

1

/4")

(1

ø4,2

11

/64")

(

184 mm

1

/4")

(7

Blue

56 mm

(2 1/5")

133 mm

(5 1/4")

58 mm

(2 1/4")

ø5,7

15

(

311 mm

(12 ¼")

F ½" BSP ¾" BSP ¾" BSP 1½" BSP

20”

Big blue

77 mm

(3")

185 m m

(7 ¼")

77 mm

(3")

ø7, 7

5

/16")

(

600 mm

(23 5/8")

Code number 180Z0281 180X5224 180Z0213 180Z0082

AI3170 41322125en-000201 | 03.2021

9

Page 10

Data sheet | Filter solutions for Danfoss high-pressure pumps

4.1 Vertical mount

4.2 Horizontal mount

10

AI3170 41322125en-000201 | 03.2021

Page 11

Data sheet | Filter solutions for Danfoss high-pressure pumps

5. Accessories

6. Cross reference table

7. Pressure drop total

Element + housing

Filter spanner

Code no. 180N1488 180N0785 18 0N0785 18 0N1438

Element

Housing

180Z0281

(5” blue housing)

180X5224

(10” blue housing)

180Z0213

(20” blue housing)

180Z0082

(20” big blue housing)

180Z0651

(40” red housing)

Element /

Housing

180Z0037 (Type 1)

180Z0281

(5” blue housing)

180X5225 (Type 2)

180X5224

(10” blue housing)

180Z0019 (Type 3)

180Z0213

(20” blue housing)

180Z0006 (Type 4)

180Z0213

(20” blue housing)

180Z0285 (Type 5)

180Z0082

(20” big blue housing)

180Z0653 (Type 7)

180Z0651

(40” red housing”

5”

Blue

180Z0037

(Type 1)

Flow

180X5225

(Typ e 2)

X

15 l/m in 30 l/min 60 l/min 150 l/m in 666 l/min 1000 l/min

0.250 barg

(3.6 psig)

0.105 barg

(1.5 psig)

X

0.190 barg

(2.8 psig)

0.125 barg

(1.8 psig)

0.125 barg

(1.8 psig)

10”

Blue

180Z0 019

(Typ e 3)

X X

180Z0006

(Typ e 4)

0.340 barg

(4.9 psig)

0.340 barg

(4.9 psig)

0.130 barg

(1.9 psig)

20”

Blue

180Z0285

(Typ e 5)

X

0.390 barg

(5.7 psig)

180Z0083

(Typ e 6)

0.128 barg

(1.8 psig)

20”

Big blue

180Z0653

(Typ e 7)

0.230 barg

(3.6 psig)

X

AI3170 41322125en-000201 | 03.2021

11

Page 12

Danfoss A/S

Hogh Pressure Pumps

Nordborgvej 81

DK-6430 Nordborg

Denmark

© Danfoss | DCS (im) | 2021.03

AI317041322125en-000201 | 12

Loading...

Loading...