Page 1

Data Sheet

FHV-A/FHV-R

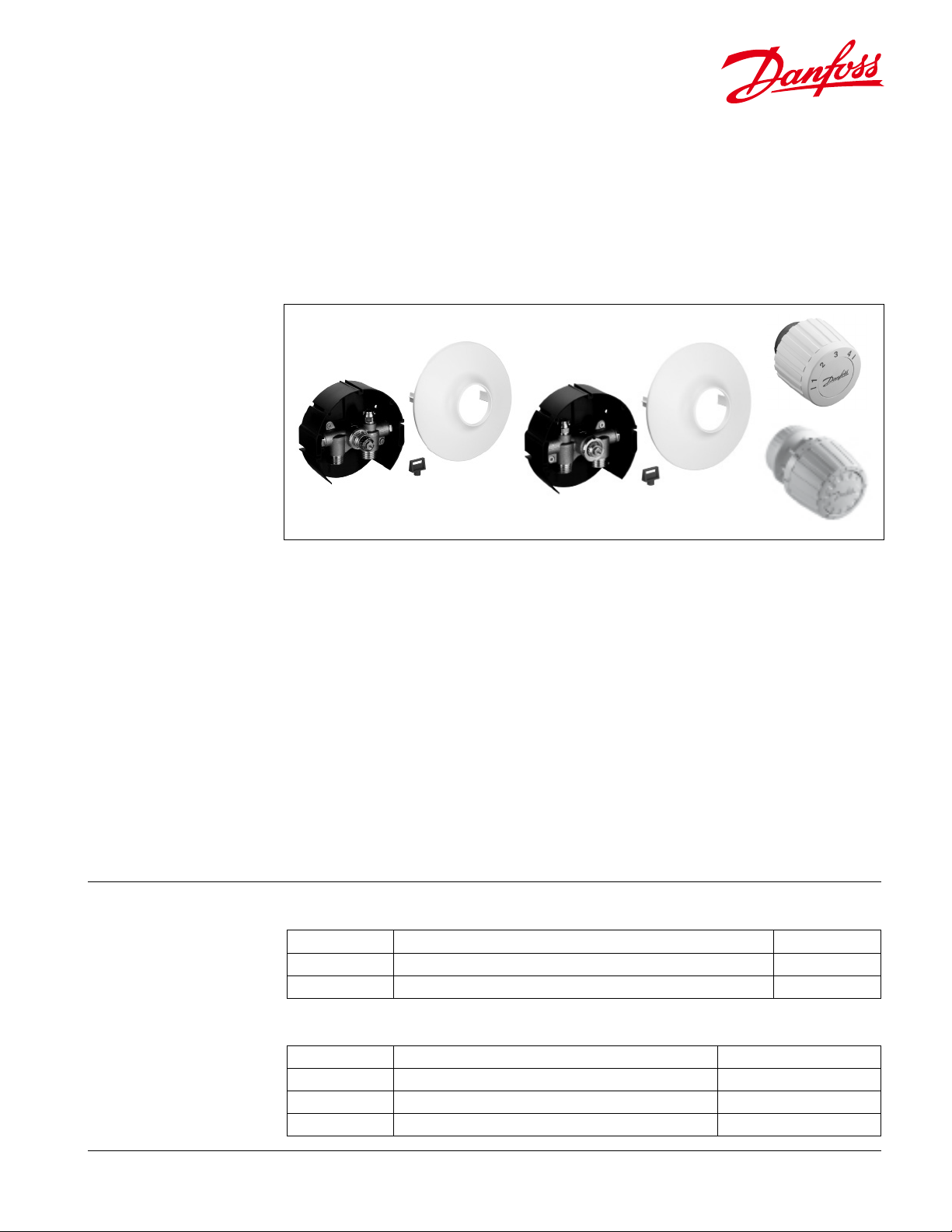

Application:

FHV-A FHV-R

Ordering

Information:

The oor-heating valve (FHV) provides an

economical method of incorporating a radiant

oor heating system into an existing hot water

or radiator system. FHV self-acting regulators

are well suited to handle underoor heating

temperature in single rooms, such as bathrooms,

entry ways or kitchens.

FHV control valves are exible to use, easily

installed and are available in two versions:

FHV-A control valves are ideally suited to control

individual underoor heated rooms. The FHV-A

is placed on the supply side of a oor heating

system, and is capable of providing hydraulic

balancing via the FHV-A’s integral pre-setting

feature. In controlling the room air temperature

a standard RA 2000 operator is tted to the

When ordering the FHV assembly order the valve body, appropriate operator, tail pieces and union nuts.

Valve bodies include wall box, cover and valve

Code No. Description Cv*

003L1001 FHV-A pre-settable valve body 0.05-0.92

003L1000 FHV-R retur temperature limiting valve 1.03

*Cv is the eater ow rat e through the fully o pen valve at a pressu re drop of 1 psi. To determi ne the pressure drop t hrough the valve at o ther ow rates use th e formula: ∆P = (Q/Cv)2, where Q = water o w in GPM

FHV-A valve.

FHV-R valves are designed for systems using

oor heating in conjunction with radiators. The

valve is place on the return side of the radiant

oor system. The valve’s operator, FJVR, senses

the return uid temperature of the system and

regulates the valve appropriately. When the

FHV-R is used for a radiant heating system,

the maximum oor heated area should not be

greater than 110 sq. ft.

Note: The ow temperature must not be

permitted to exceed the maximum supplied

water temperature as recommended by the oor

heating supplier. This can be accomplished via

use of Danfoss’ 3-way (MR) or 2-way (FTC with RA

2000 or RAVV with VMT) thermostatic valve and

a circulator in the oor heating loop.

Operators

Code No. Description Temperature Range

013G 8250 RA 2000 operator for, FHV-A 45° - 86°F (7° - 30°C)

003L10 40 FJVR operator for, FHV-R 50° - 122°F (10° - 50°C)

003L10 70 FJVR operator for, FHV-R 50° - 176°F (10 ° - 80°C)

VDUIE222 © Danfoss 10/17

1

Page 2

Data Sheet FHV-A / FHV-B Floor Heating Valve

Ordering

Information:

(Cont.):

Spare Parts

and Accessories:

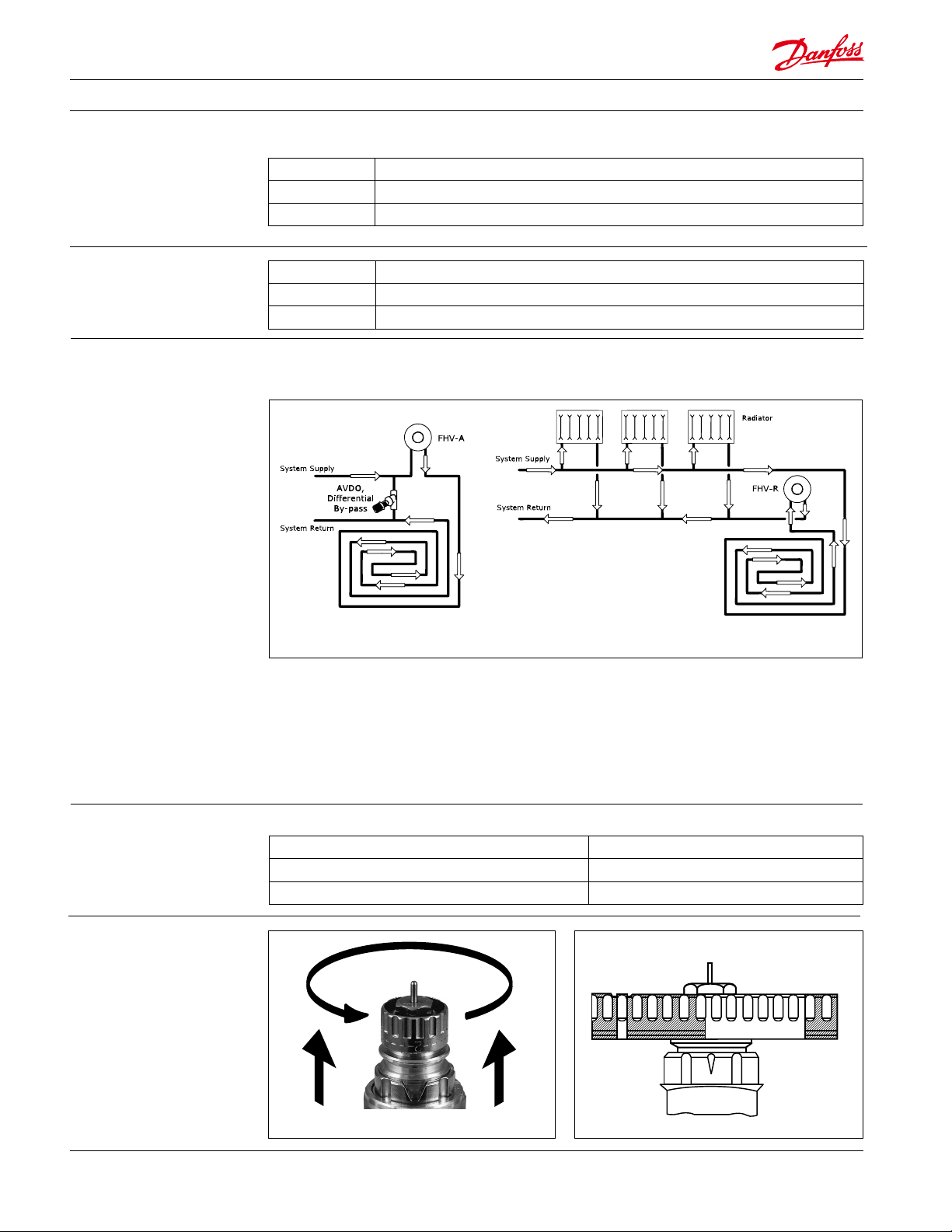

System layout:

Tail pieces and union nuts require two of each

013U0496 1/2” Union Nut

013U8608 1/2” Solder Female Tailpiece

013U0496 1/2” Male Threaded Tailpiece

Code No. Description

013G 0290 Packing gland for FHV-A

013U 0070 Packing gland for FHV-R

In laying a radiant oor heating system with the FHV valve, it is recommended to utilize the double

parallel spiral pattern otherwise known as the counter ow tube layout.

Technical

Specication:

Pre-setting:

Installed on the supply side Installed on the return side

The water supply temperature for the system

should be properly monitored to ensure the

surface temperature is appropriate for the

nished oor material.

The installation of either valves should be on a closed loop system

Maximum Flow Temperature 194 °F (90°C)

Maximum Operating Pressure 87 psi (6 bar)

Maximum Dierential Pressure (water) 8.7 psi (0.6 bar)

The maximum square footage allowed for the

FHV-R application is 110 sq. ft. Since the FHV-R

valve monitors the uid temperature and not

the air, it will not completely close. The adjusted

set temperature for the operator should be

appropriate for the nished oor material.

N

1 2 3 4 5 6 7

2

VDUIE222 © Danfoss 10/17

Page 3

Data Sheet FHV-A / FHV-B Floor Heating Valve

Design and

Function:

The incorporated pre-settable option on the

FHV-A valve body has an easy setting adjustment

ring with clearly engraved setting markers scaled

from 1-7 and N. Setting the appropriate valve is

quick and precise, without the need for a special

tool. The preset selections are in 0.5 increments

between 1 and 7, with N being in a full ow

position. (Refer to Capacity charts for ow rates)

To set the valve:

1. Remove the protective cap or sensor element

2. Lift setting ring

3. Rotate ring to the desired ow setting, and

align position with indicator located on the

collar of the valve

4. Allow setting ring to drop down into position

FHV-A

1. Pressure pin 2. Gland seal

3. O-ring seal 4. Return spring

5. Valve cone 6. Valve body

7. Connection

Materials in contact with water

Setting cylinder PPS

Spindle Ms, resistant against de-zincication

O-ring EPDM

Valve cone NBR

Pressure spring, valve spring Chrome-plated steel

Valve body, other metal parts Ms 58

FHV-R

1. Pressure pin 2. Gland seal

3. Valve cone 4. Valve body

5. Connection

VDUIE222 © Danfoss 10/17

3

Page 4

Data Sheet FHV-A / FHV-B Floor Heating Valve

Dimensions:

Dimensions for FHV-A and FHV-R

A B C D E F

2.30” 1.22” 2.00” ∅ 5.60” ∅ 6.40” 5.60”

Capacity Diagrams:

Capacity with RA 2000 operator at R-band between 0.5k and 2k.

4

VDUIE222 © Danfoss 10/17

Page 5

Data Sheet FHV-A / FHV-B Floor Heating Valve

Capacity Diagrams

(Cont.):

Capacity with FJVR operator.

Danfoss can accept no responsibility for possible errors in printed materials and reserves the right to alter its products without notice. All trademarks

in this material are property of the respective companies. Danfoss and Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss

Toronto, ON / Baltimore, MD

Tel: 1-888-DANFOSS (326-3677) option 3

Fax: 416-352-5981

www.heating.danfoss.us

VDUIE222 © Danfoss 10/17

5

Loading...

Loading...