Service Guide

ECL Comfort 296 / 310 controllers

Modbus networking guide

1.0 Contents

1.0 Contents... ... ..............................................................................................................................................................................................................................................1

2.0 Introduction ............................................................................................................................................................................................................................................. 2

3.0 Conclusion .... ............................................................................................................................................................................................................................................ 2

4.0 Modbus network definitions ............................................................................................................................................................................................................. 3

4.1 Multipoint serial bus infrastructure .......................................................................................................................................................................................3

5.0 ECL 296 / 310 Modbus network specification .............................................................................................................................................................................4

6.0 Installation class and surge / lightning protection ....................................................................................................................................................................5

7.0 Annexure A: Modbus network wiring guidelines ...................................................................................................................................................................... 6

7.1 Central heating station ................................................................................................................................................................................................................7

7.2 Repeater stations (individual houses with repeater) .......................................................................................................................................................8

7.3 Individual houses (without repeater) ....................................................................................................................................................................................9

8.0 Annexure B ............................................................................................................................................................................................................................................ 10

8.1 Selection of parts ........................................................................................................................................................................................................................10

8.2 Surge protector wiring..............................................................................................................................................................................................................11

8.3 “Modbus” to “mains” separation ...........................................................................................................................................................................................12

© Danfoss |2018.08

VI.LV.H3.02 | 1

Service guide ECL 296 / ECL 310 Modbus

2.0 Introduction

In smaller Modbus networks ligthning can be a challenge for the

connected devices like ECL Comfort 296 / ECL 310 controllers.

If not protected, Modbus interfaces are subject for being burned in

case of lightning.

This has resulted in the present service guide which includes

recommendations for new installations.

The document is prepared in compliance with www.modbus.org

This document is handling protection of the Modbus network.

Please be aware of the protection of the main site (230Vac) i.e. by

installing a Phoenix PLT-SEC-T3-230-FM.

3.0 Conclusion

1. Each nodes in the “Modbus network” (central heating station,

repeater station or individual house) are highly recommended

to have “surge protector”. It must be selected as per section 6

and installed as described in section 7.

2. A surge protection with a spark gab between Signal GND and

Protective Ground (PE) is required in the individual house installation.

3. Recommendation on Modbus reference common signal connection, shield connection, termination resistor connection may

be referred in section 5, 6, 7 and 8.

2 | © Danfoss| 2018.08

VI.LV.H3.02

Service guide ECL 296 / ECL 310 Modbus

4.0 Modbus network definitions

4.1 Multipoint serial bus infrastructure

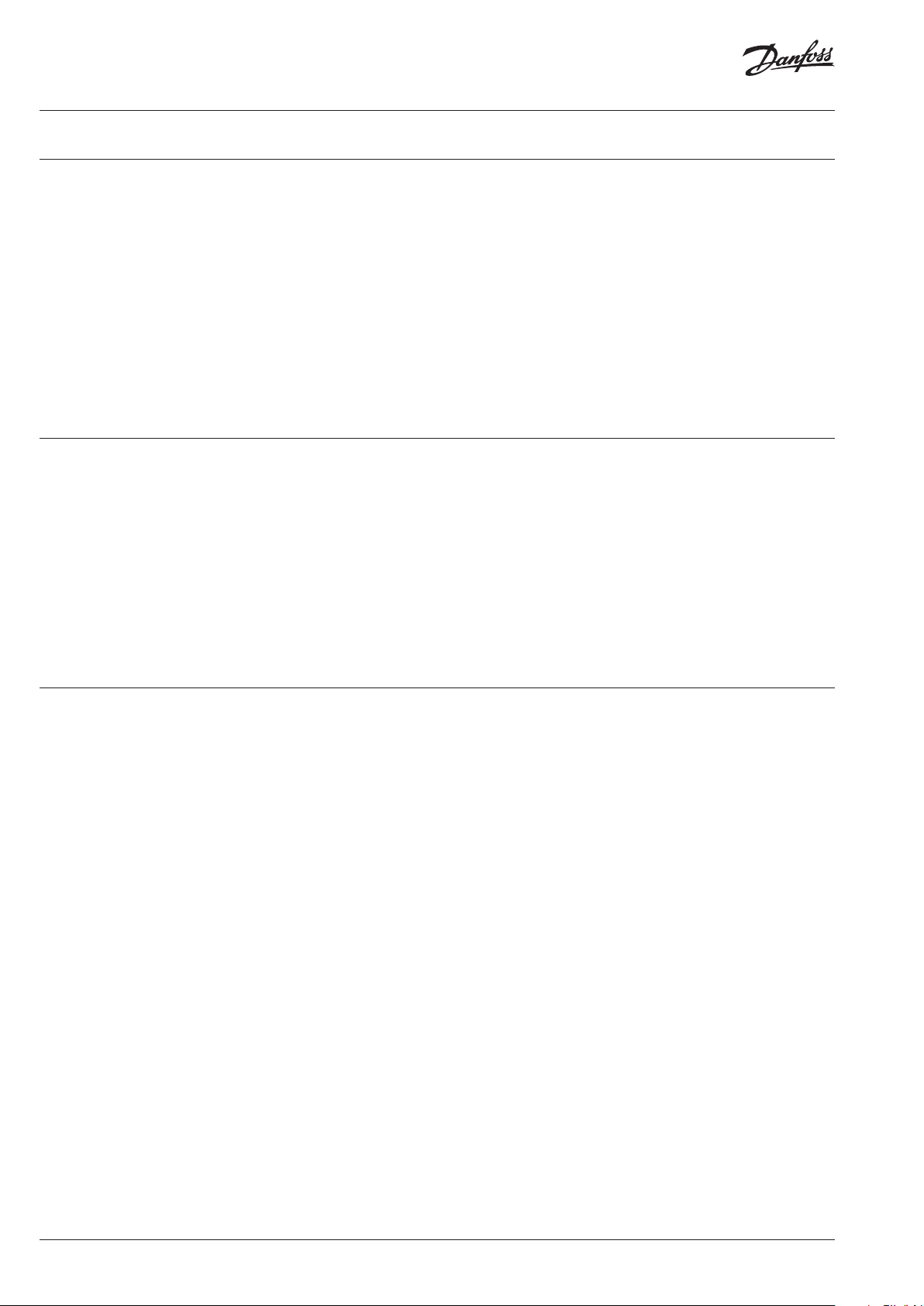

The below drawing gives a general overview of the serial bus

infrastructure in a Modbus multipoint serial line system.

1) = surge protector 2) = repeater

The following conventions are adopted in the figure above:

1. The interface with the trunk is named ITr (Trunk Interface)

2. The interface between the device (ECL 296 / 310) and the

Passive Tap ( surge protector) is named IDv (Derivation

Interface)

3. The interface between the device (ECL 296 / 310) and the

Active Tap (repeater) is named AUI (Attachment Unit Interface)

4. LT = line termination. Resistor: 120 ohm , 0,5 W up to 150 ohm,

0,5 W

A multipoint Modbus serial line bus is made of a principal cable

(the trunk) and possibly some derivation cables.

Line terminations are necessary at each extremity of the trunk

cable for impedance adaptation.

VI.LV.H3.02

© Danfoss | 2018.08 | 3

Service guide ECL 296 / ECL 310 Modbus

5.0 ECL 296 / 310 Modbus network specification

The ECL 296 / 310 Modbus physical layer interface is supported by

the half duplex RS485 interface (A, B, Signal Ground (S. Gnd.)).

1. Maximum trunk (ITr) length = 1200 meters for AWG24 (0,51mm

diameter) copper (less AWG= bigger diameter: is better).

Note: AWG= American wire gauge (AWG).

2. Maximum number of nodes in the network = 32 (including

master node, ECLs and repeater node).

Note: Each repeater node is capable of driving another 32

nodes (including repeater node) of 1200 meter.

I.e. 30 ECLs between two repeater stations (or) 31 ECLs in the

network connected to master node / repeater node. Refer the

figure below.

3. Maximum derivation cable length per node (per ECL) = 1,25

meters (calculated based on 40 m max. derivation cable length

for 32 nodes).

4. Line termination (to ensure the communication quality) = At

each extremity of the trunk cable (150 ohms (or) 120 ohms, 0,5

watts resistor at both ends.

Note: Repeaters are having internal termination resistors which

can be “switched on/ switched OFF” by the user.

a.

If “repeaters” are used in the extremity of the trunk cable, then

switch on the repeater termination (striped block, represented

by 3):

b.

If “repeaters” are used to make a branch from one of the intermediate nodes, then do not switch on the “repeater termination”

(unstriped block connected to ITr cable).

1) = surge protector

2) = repeater

3) = line termination (LT)

c.

If the ECL is used in the extremity node of the trunk cable, connect

an external line termination (150 ohm / 120 ohm, 0,5 watts resistor).

4 | © Danfoss| 2018.08

VI.LV.H3.02

Service guide ECL 296 / ECL 310 Modbus

5. Grounding arrangements (to improve “general electrical safety”

and “communication quality”) - S. Gnd. must be connected directly to the protective ground (PE= Earth), at the master device

(ONE POINT ONLY).

6. Cables shield arrangements (to improve “general electrical

safety”) - One end of each cable’s shield must be connected to

protective ground (PE= Earth). Do not connect both ends of the

shield to PE as it forms an unwanted “group loop”.

6.0 Installation class and surge / lightning protection

“To secure the Modbus electronics (ECL 296 / 310, repeater…) from

surge / lightning in the network, “external protection devices” must

be selected based on the installation class of the network” and rightly

installed in “each site”.

Installation class 4 definitions:

Electrical environment where the interconnections are running as

outdoor cables along with power cables, and cables are used for

both electronic and electrical circuits.

“Surge protector requirements” for “installation class 4”, IEC 610004-5, (Modbus network with ECLs):

Parameter Surge protection requirement Recommended protection,

PT 3-PB-ST and PT 1X2+F-BE

Class 4 - surge voltage: network:

1,2µs / 50µs

Short circuit current (42 ohm impedance) Higher than 95,2A 10kA

Maximum continious voltage - core to

core (A, B and S. Gnd. in ECL)

Output voltage limitation at 1 kV/μs

(core-core) spike

Output voltage limitation at 1 kV/μs

(core-earth) spike

Output voltage limitation at 1 kV/μs

(core-core) static

Output voltage limitation at 1 kV/μs

(core-earth) static

As per the above details, “PT 3-PB-ST and PT 1X2+F-BE” from

Phoenix meet the requirements. Similar products from other suppliers can also be used.

4kV 10kV 1,2µs / 50µs

5kA 8µs / 20µs

> 3,5V and ≤ 7V 5,2Vdc

Less than 1KV ≤ 55V

≤ 700V. Note: “S. Gnd.” MUST NOT be

shorted with “PE (protective earth)” in

surge protector base part.

Much less than 1KV ≤ 15V

Much less than 1KV ≤ 30V

≤ 700V

Installation guide:

• Outer field cables (both IN and OUT field cable wires), ITr / AUI,

must be connected to the “unprotected side” of the “external

surge protection device)

• The cables (IDv - which are well separated from mains supply

wires) must be connected to the “protected side” of the “external surge protection device)

VI.LV.H3.02

© Danfoss | 2018.08 | 5

Service guide ECL 296 / ECL 310 Modbus

7.0 Annexure A: Modbus network wiring guidelines

Typical Modbus network consists of:

• Central heating station

• Surge protector

• RS485 repeater

• Modbus gateway

• Repeater stations (individual buildings with repeater)

• Surge protector

• RS485 repeater

• Individual houses (without repeater)

• Surge protector

Each nodes in the Modbus network (central heating station,

repeater or individual building) can have “surge protector”.

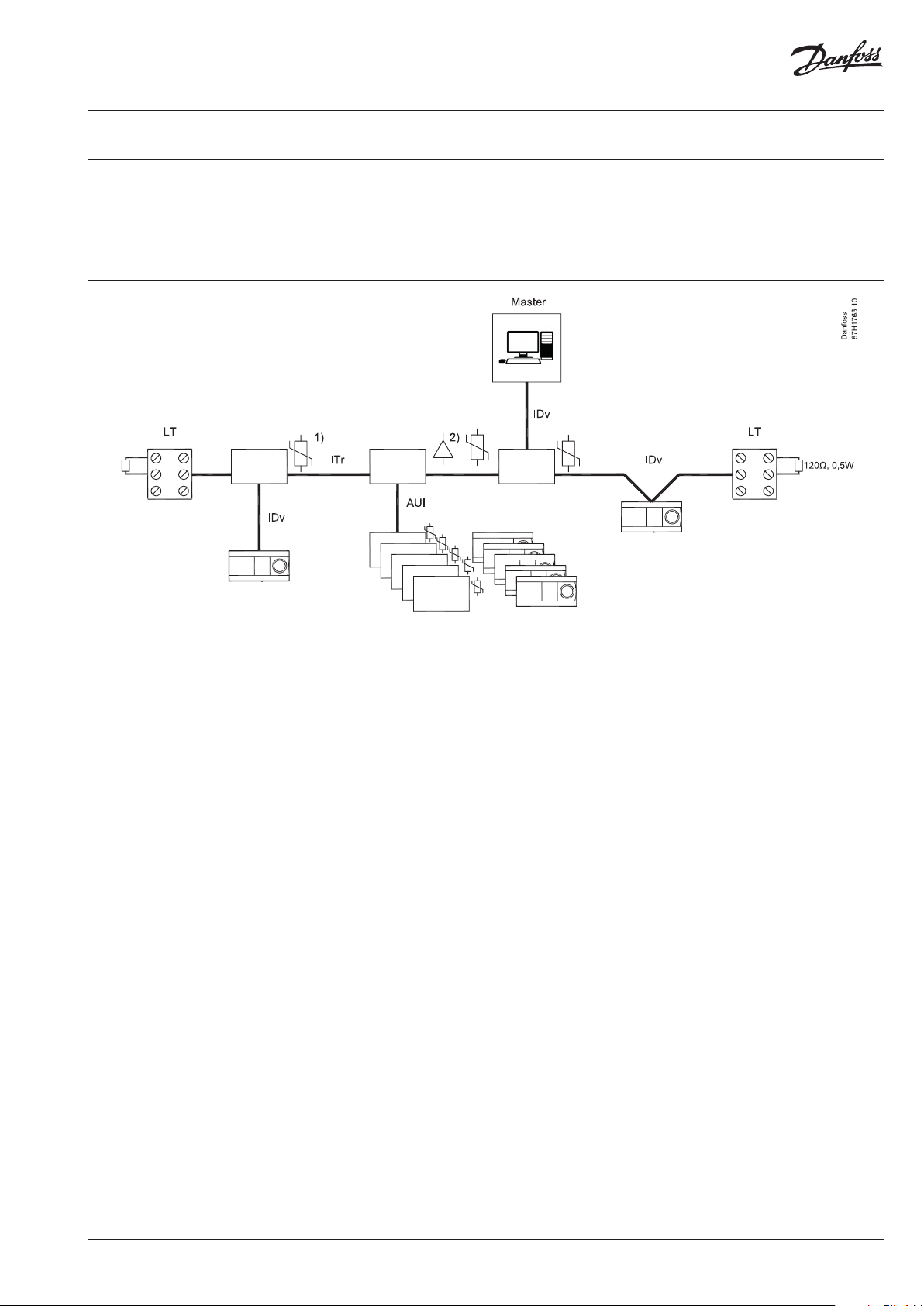

Top level logical drawing:

# 1 = central heating station (master)

# 2 = individual house W/O repeater

# 3 = repeater station (repeater+surge protection)

6 | © Danfoss| 2018.08

1) = surge protector

2) = repeater

VI.LV.H3.02

Service guide ECL 296 / ECL 310 Modbus

7.1 Central heating station

1) = surge protector 2) = repeater

Note:

a)

Repeater ports are galvanic isolated. Based on the central heating

station architecture, more than one network (like left wing, right

wing) is possible. Single point earthing on S.Gnd and shield cable

to be maintained (Refer section 5 point 5, 6).

Attention: Dot on the intersection lines (S.Gnd, PE) means that

those two signals are electrically shorted.

Surge suppressor connection should match as in section 8.2.

VI.LV.H3.02

© Danfoss | 2018.08 | 7

Service guide ECL 296 / ECL 310 Modbus

7.2 Repeater stations (individual houses with repeater)

1) = surge protector 2) = repeater

Note:

a)

Normally repeaters’ ports are galvanic isolated. Check the resistance between input common reference signal (S.Gnd1) and

output common reference signal (S.Gnd2) using multimeter.

Only if signals are having >1 Mohm, then connect the output side

S. Gnd. to PE.

b)

Internal termination of repeaters can be switched ON if the connection matches with section 5 point 4.a

c)

Internal termination of repeaters is switched OFF if the connection matches with section 5 point 4.b

Input cable (coming from central heating station) shield MUST be

floating and output cable shield is connected to earth.

This is to maintain single point earthing in each network, on S.Gnd

and shield cable (Refer section 5 point 5, 6).

8 | © Danfoss| 2018.08

1) = surge protector

2) = repeater

3) = line termination (LT)

VI.LV.H3.02

Service guide ECL 296 / ECL 310 Modbus

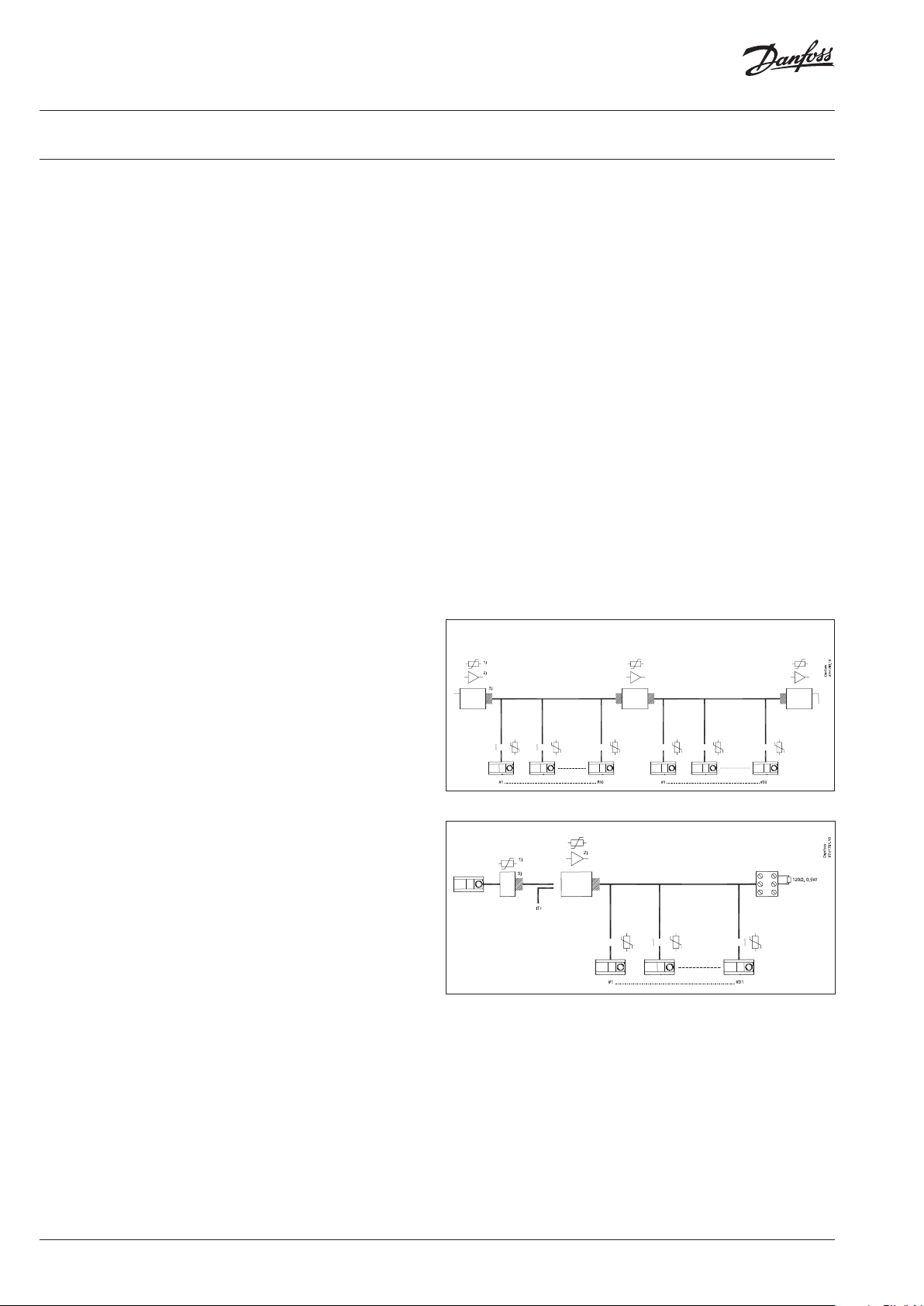

7.3 Individual houses (without repeater)

1) = surge protector

As there is no repeater used in this node, there is no galvanic isolated port created. S.Gnd is not connected to earth (PE).

Input cable (coming from central heating station) shield MUST be floating and output cable shield is connected to earth. Or the input and

output shield continuity is maintained and it is not connected to earth (As shown above).

This is to maintain single point earthing in each network, on common reference signal (S.Gnd) and shield cable (Refer section 5 point 5,

6).

VI.LV.H3.02

© Danfoss | 2018.08 | 9

Service guide ECL 296 / ECL 310 Modbus

8.0 Annexure B

8.1 Selection of parts

There are many prebuilt connection options available on the market

on “surge protector base parts”, which may lead to the unwanted

ground looping and hence low quality / loss of communication (section 5 point 5).

These parts look alike in part numbering system and in component

outlook. So care must be taken to select the right parts. Refer the

below for example:

Possibilities for grounding the base element:

• PT 1x2-BE - S.Gnd. (pin 9/10) is shorted to PE (protective earth)

(3/4)

• PT 1x2+F-BE - spark gap between signal ground (pin 9/10) to

PE (protective earth) (3/4)

PT 1x2-BE

PT 1X2 +F-BE

Attention:

S.Gnd. must be connected to earth ONLY ONE POINT (section 5 point 5).

So use “PT 1X2 +F-BE”

10 | © Danfoss| 2018.08

VI.LV.H3.02

Service guide ECL 296 / ECL 310 Modbus

8.2 Surge protector wiring

The correct wiring is equally important to get the best “surge protection in the network level.

The “gas discharge tubes” (between pin 7, 11 to 9 in the juxtaposed

example) is capable of handling higher surge current, but this device

is slow responding.

The “transils” (between pin 8 to 12 and 10) are capable of handling

low surge current, but very fast responding.

These two sets of components (gas discharge tubes and transils) are

separated by a resistor which forces the surge to be first suppressed

by the gas discharge tube and the residue will be suppressed by

the transils.

PT 3-PB-ST and PT 1X2+F-BE logical drawing:

3-wire, PROFIBUS (up to 12 MHz)

Total width 17.7 mm

Refer the juxtaposed drawing for example.

• Odd numbered connection of PT 1X2+F-BE meant for outer filed

cables (both IN and OUT cable wires of field cable)

• Even numbered connection of PT 1X2+F-BE meant for repeater/

ECLs wires (both IN and OUT cable wires of ECLs / repeaters)

VI.LV.H3.02

© Danfoss | 2018.08 | 11

Service guide ECL 296 / ECL 310 Modbus

8.3 “Modbus” to “mains” separation

The surge / lightning protected Modbus cables “must be separated from

mains / switched mains signal” even for a short run. Other signals in

ECL 296 / 310 (M Bus, sensor signals, RS485 signals), which are meant

for indoor wiring, “must be separated from mains / switched mains

signal” even for a short run. Modbus signals may be taken along with

MBus, sensor signal and other RS485 signals.

Recommended:

1) = surge protector

1. Even for a short distance well separated (≥ 7mm) from mains

signal.

12 | © Danfoss| 2018.08

VI.LV.H3.02

Service guide ECL 296 / ECL 310 Modbus

VI.LV.H3.02

© Danfoss | 2018.08 | 13

Service guide ECL 296 / ECL 310 Modbus

14 | © Danfoss| 2018.08

VI.LV.H3.02

Service guide ECL 296 / ECL 310 Modbus

VI.LV.H3.02

© Danfoss | 2018.08 | 15

Service guide ECL 296 / ECL 310 Modbus

16 | © Danfoss | DHS-SMT/DK | 2018.08

*087H9289*

*VILVH302*

VI.LV.H3.02

Loading...

Loading...